Patents

Literature

162results about How to "Reduce rinse time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

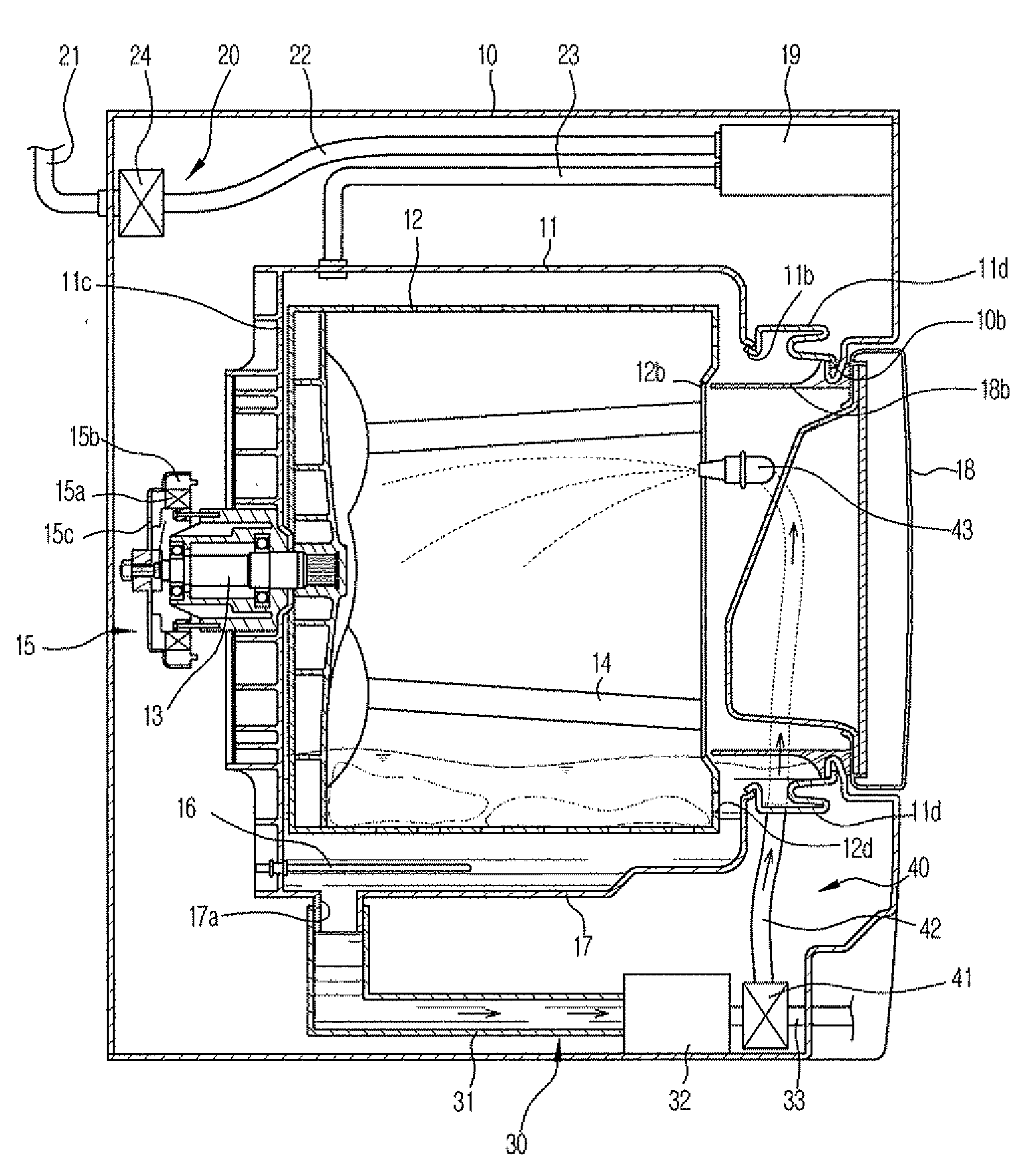

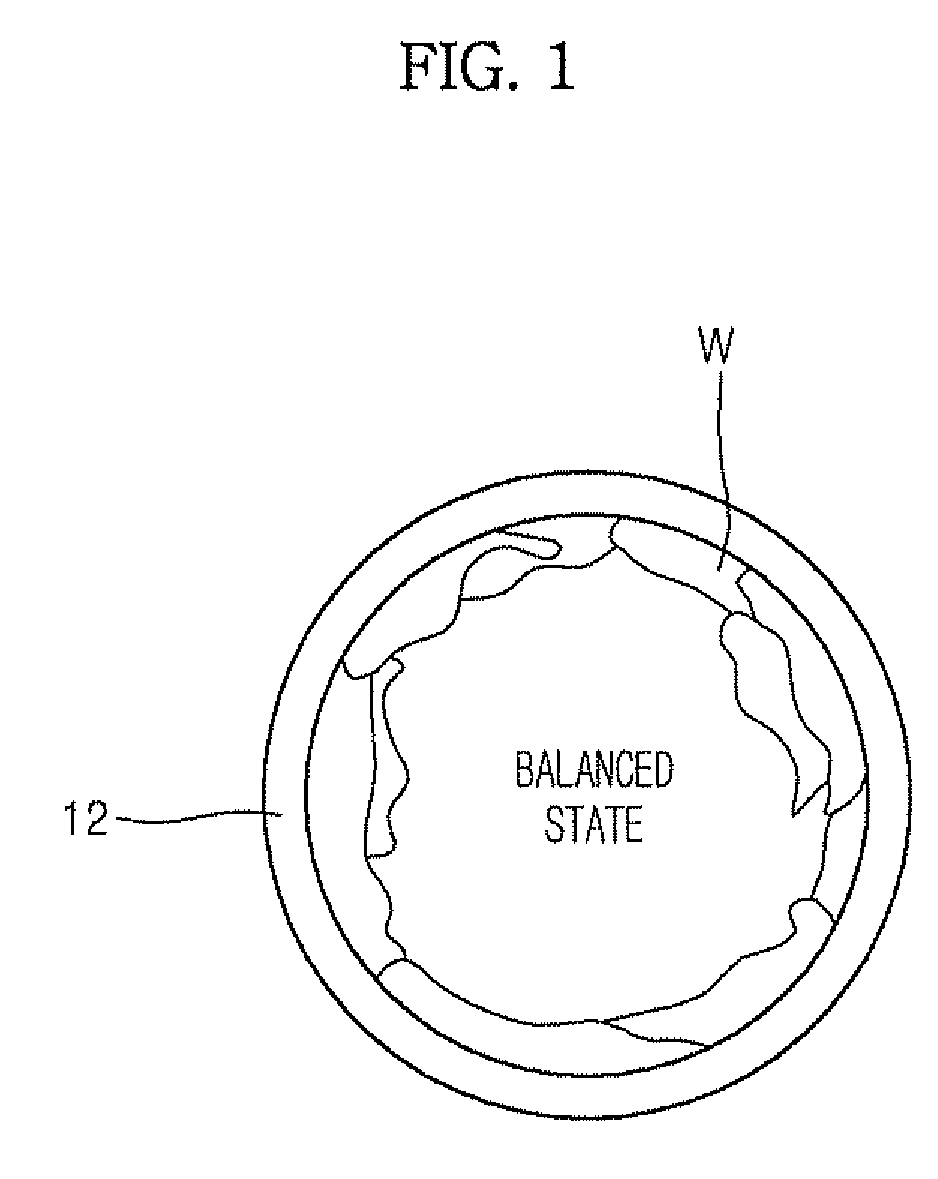

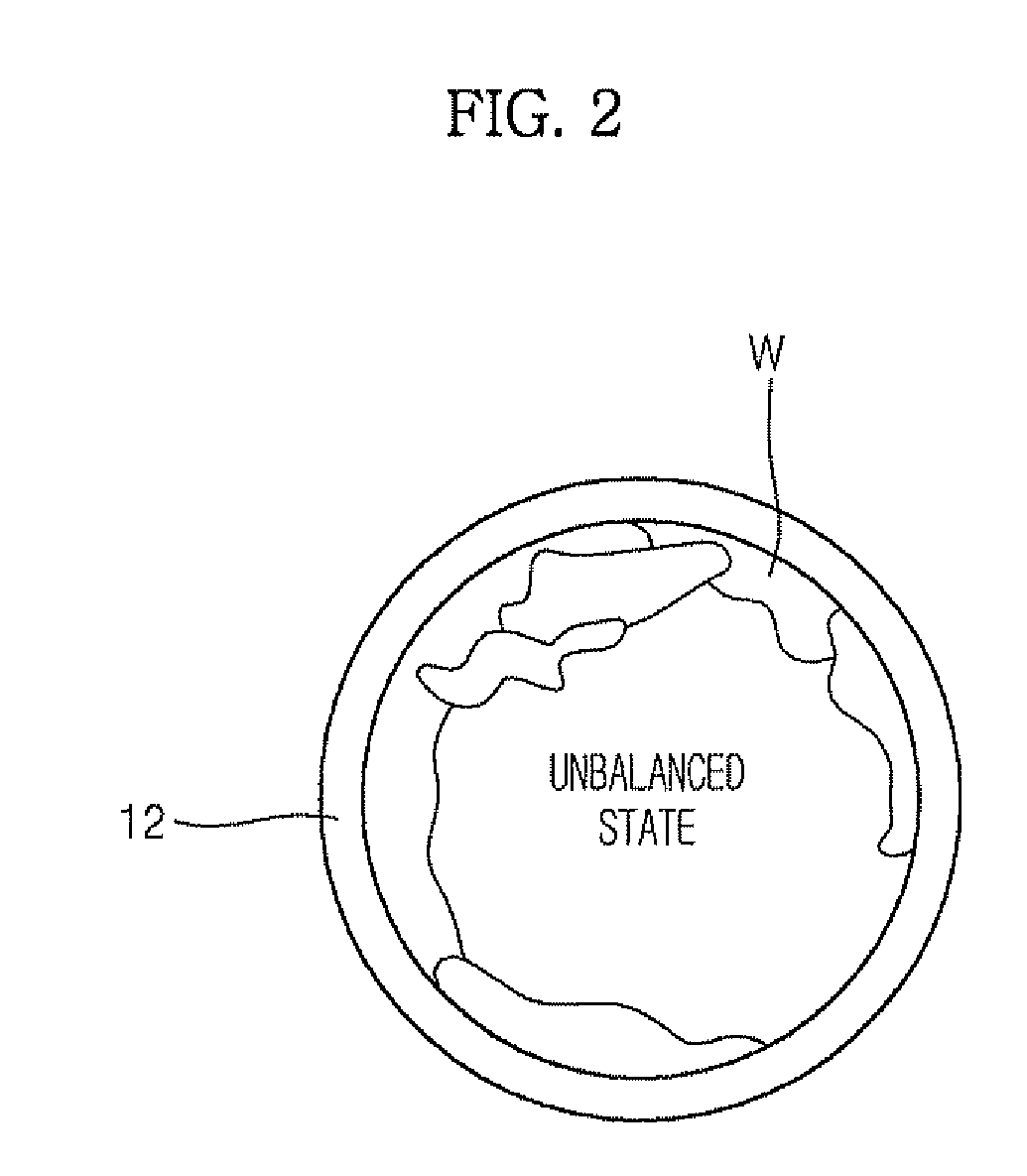

Washing machine and rinsing control method thereof

InactiveUS20090183319A1Improve rinsing efficiencyReduce rinse timeOther washing machinesControl devices for washing apparatusMechanical engineeringEngineering

Disclosed herein are a washing machine that performs a rinsing operation while rotating a drum at a predetermined RPM without stopping the drum after spin-drying and a rinsing control method thereof The washing machine includes a drum to receive laundry and a motor to rotate the drum. The rinsing control method includes rotating the drum to perform spin-drying and decelerating the drum to a predetermined velocity to perform rinsing. Consequently, it is possible to improve rinsing efficiency even using a small amount of water. Also, it is possible to uniformly distribute the laundry in the drum without eccentricity, although a laundry untangling process for spin-drying is performed only once during the rinsing, which is performed several times, thereby reducing the total rinsing time.

Owner:SAMSUNG ELECTRONICS CO LTD

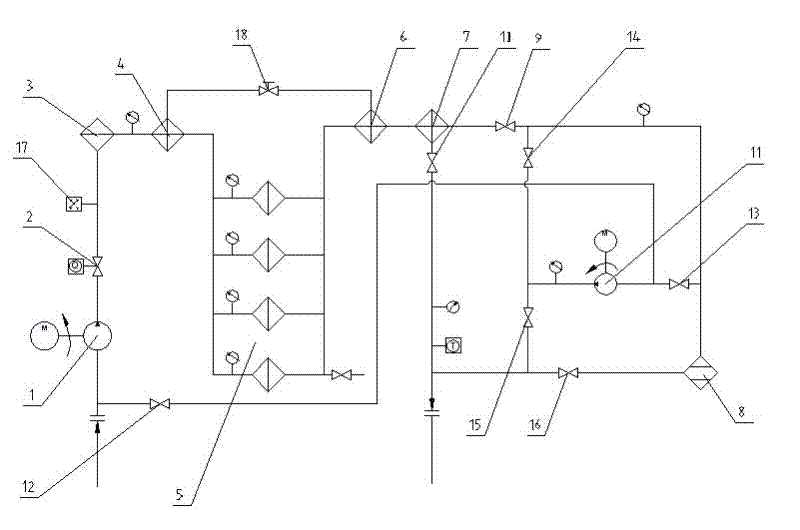

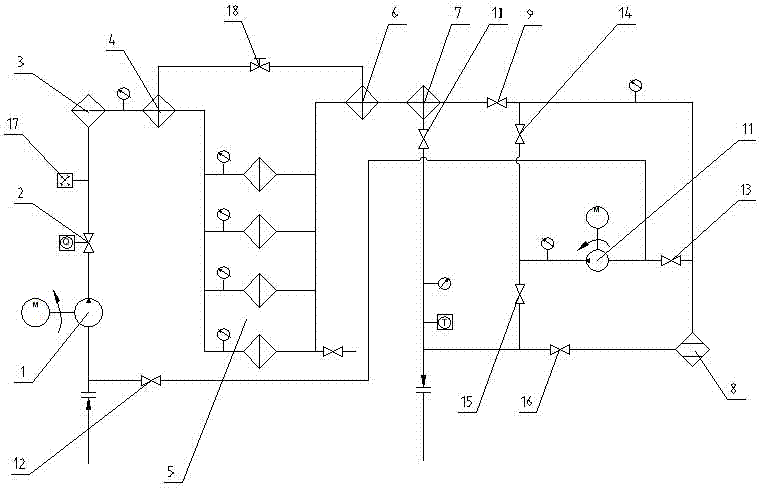

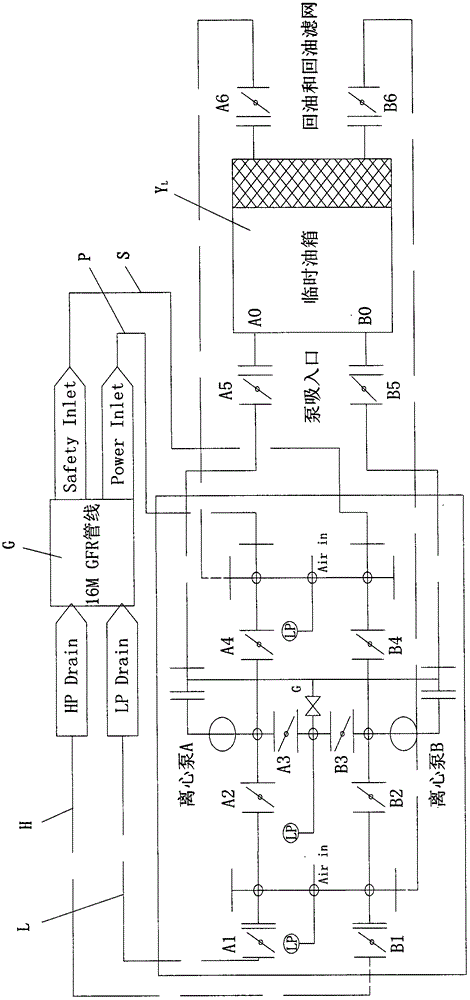

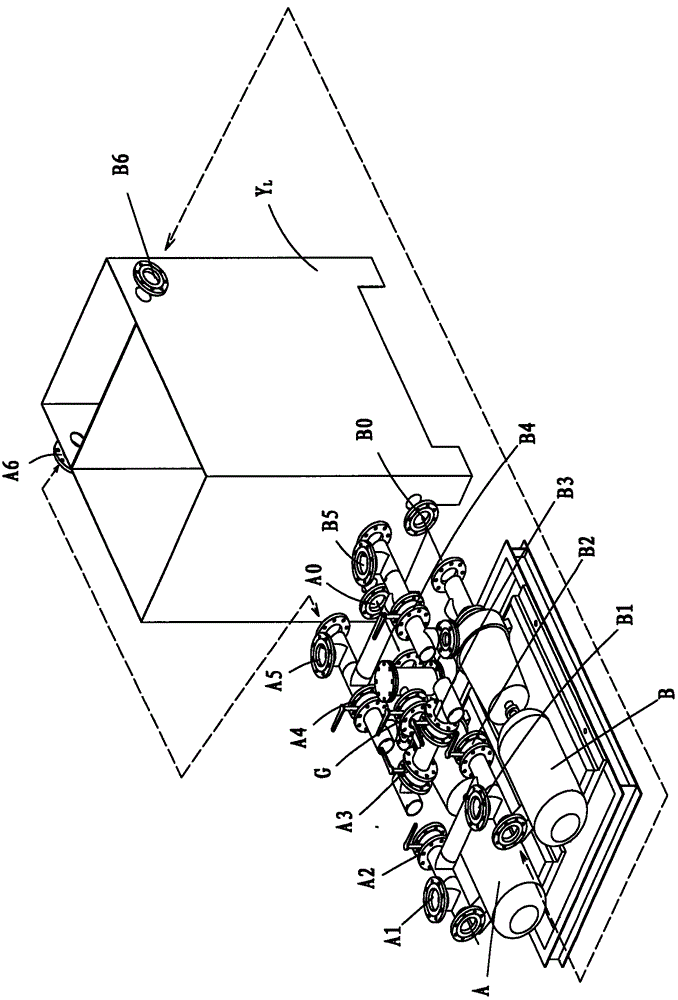

High-flow flushing device

InactiveCN102389886AReduce rinse timeGuaranteed flushing qualityHollow article cleaningFlushing timeTurbine

The invention relates to a high-flow flushing device which comprises a main oil pipeline and an auxiliary oil pipeline, wherein the main oil pipeline is provided with a main oil pump; the auxiliary oil pipeline is provided with an auxiliary oil pump; the main oil pipeline and the auxiliary oil pipeline are linked with each other; various filters, heaters and other protecting devices and valves are serially connected to the main oil pipeline; a plurality of pipelines with valves are linked with the auxiliary oil pipeline; and the valves are controlled to open and close, thereby achieving various flushing and filtering purposes. The high-flow flushing device has the beneficial effects that the high-flow flushing device can be used for shortening the flushing time for the steam turbine oil, ensuring the flushing quality of a steam turbine oil system, controlling and promoting the cleanness of turbine oil, and improving a working condition of a project for flushing and purifying the steam turbine oil.

Owner:ZHENJIANG KENENG ELECTRIC POWER EQUIP

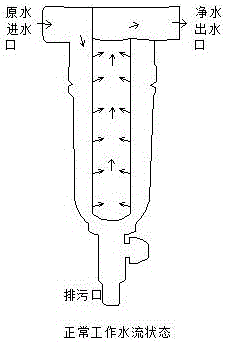

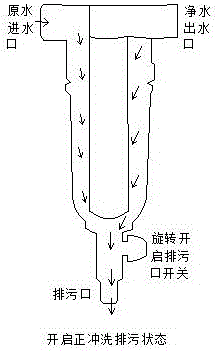

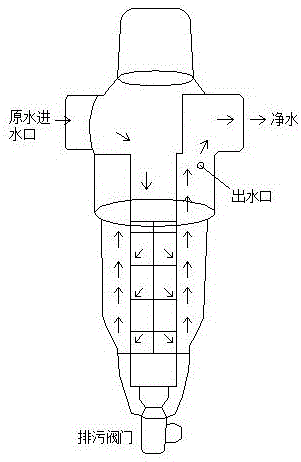

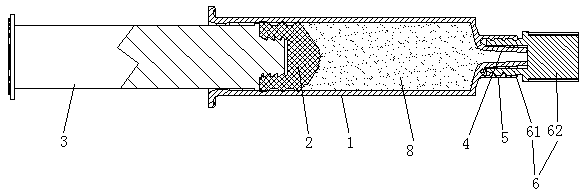

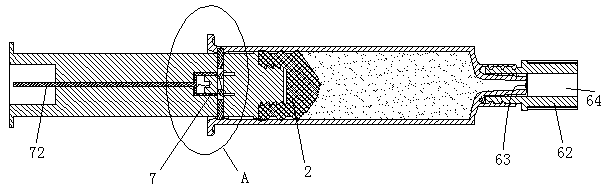

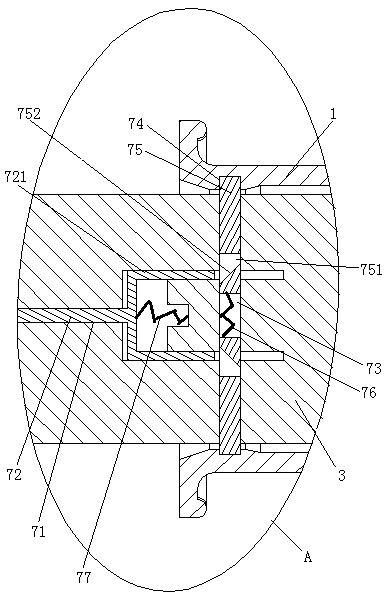

Backwash type front water filter

ActiveCN106267964AReasonable directionEasy to cleanStationary filtering element filtersWater filterWater flow

The invention discloses a backwash type front water filter, and belongs to the field of life articles. The backwash type front water filter comprises a cover body and a cylinder body, wherein the cover body is provided with a water inlet and a water outlet, and the cylinder body is connected with the cover body. A filtering cavity is defined in the cylinder body. A filter screen is arranged in the cylinder body and divides the filtering cavity into an inner filtering cavity body and an outer filtering cavity body. The water inlet is communicated with the inner filtering cavity body, and the water outlet is communicated with the outer filtering cavity body. A drain outlet is formed in the bottom of the cylinder body and provided with a drain valve. The drain outlet is communicated with the inner filtering cavity body. A piston plug capable of moving up and down and a partition block for stopping the communication of the water inlet and the water outlet are arranged on the cover body. A circulation channel for making the water outlet end communicated with the water inlet end is arranged on the partition block. By moving the piston plug up and down to block the circulation channel and the inner filtering cavity body respectively, the inflow water flow direction of the water inlet is controlled, the two wash modes of forward wash and backwash can be achieved, and the cleaning efficiency of the filter screen is improved.

Owner:江苏纯润环保科技有限公司

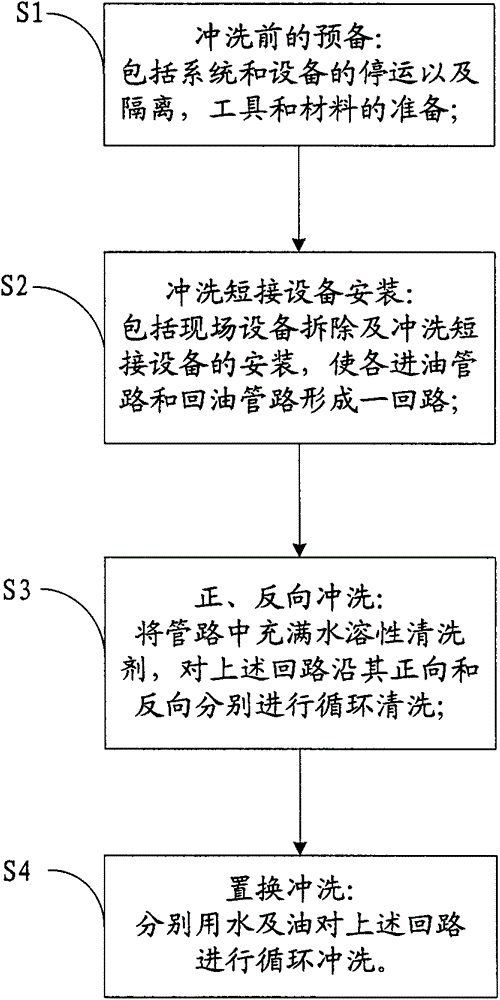

Method for washing oil adjusting system of steam turbine at nuclear power station

ActiveCN104415951AEasy temperature controlLess corrosiveHollow article cleaningNuclear powerWater soluble

The invention provides a method for washing an oil adjusting system of a steam turbine at a nuclear power station. The method comprises the following steps: preparation before washing: stopping and isolating the system and device, preparing the tools and materials; installation of washing short circuit device: disassembling the on-site device and installing the washing short circuit device, forming a loop by each oil changing line and oil return line; forward and backward washing: filling the lines with water soluble cleaning agent, respectively performing the circular washing to the loop along the forward direction and the backward direction; replacement washing: performing the circular washing to the loop by using the water and oil respectively. Because the external mass-flow washing short circuit device is used, and each oil charging line and the oil return line of the oil adjusting system of the steam turbine are connected totally to form one loop, the washing effect is obvious specifically, and the washing time is reduced greatly. Otherwise, the water circulation and oil replacement are respectively used for circularly washing the loop after washing, the replacement process is simplified, the cost is saved, and the operation efficiency of the steam turbine set is further improved.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

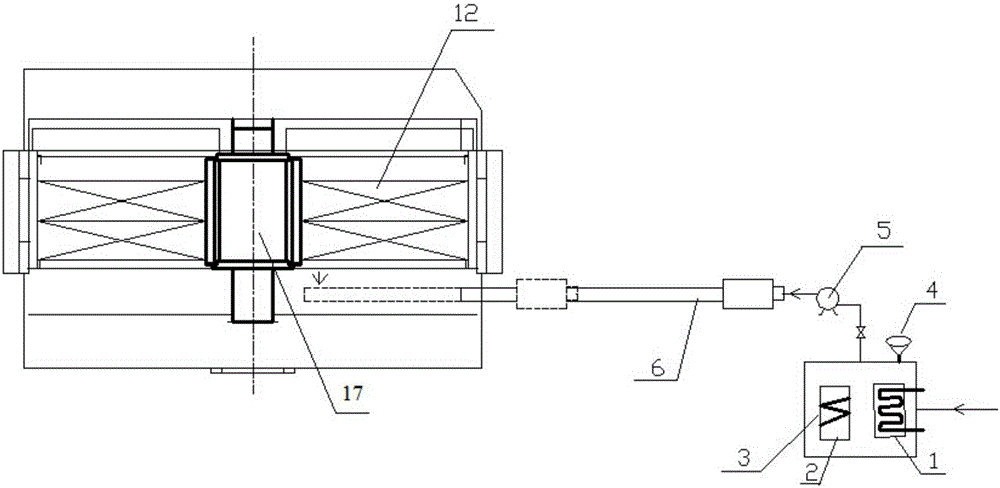

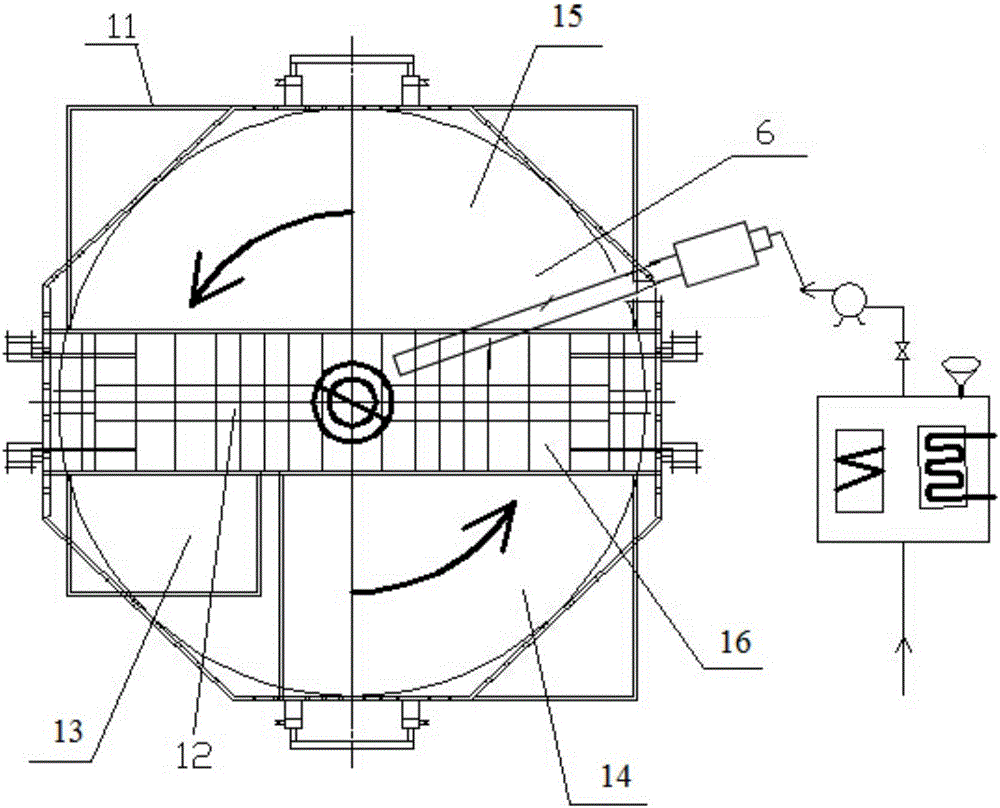

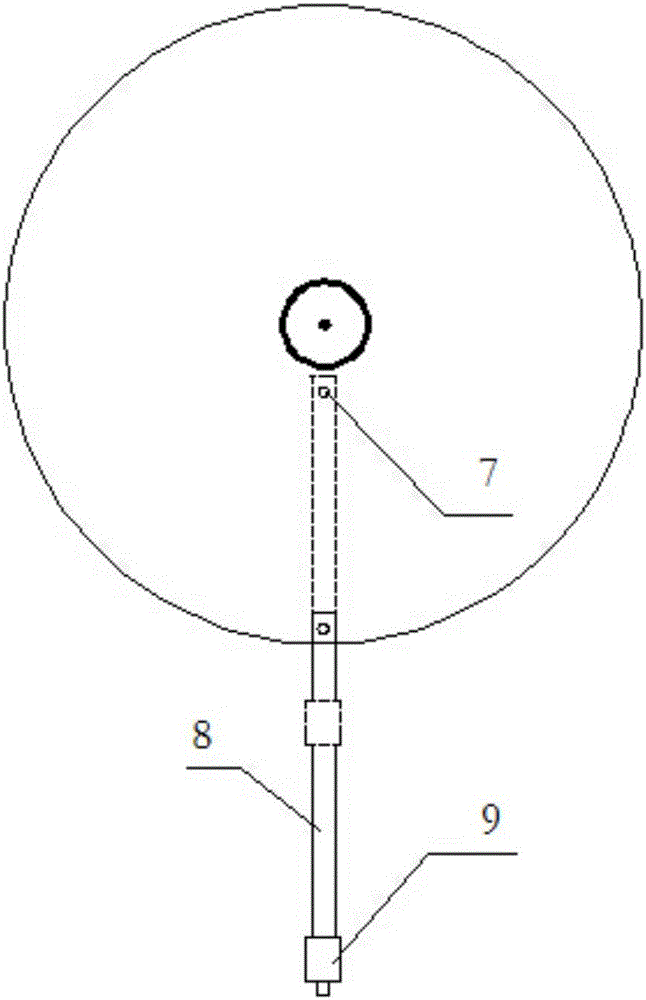

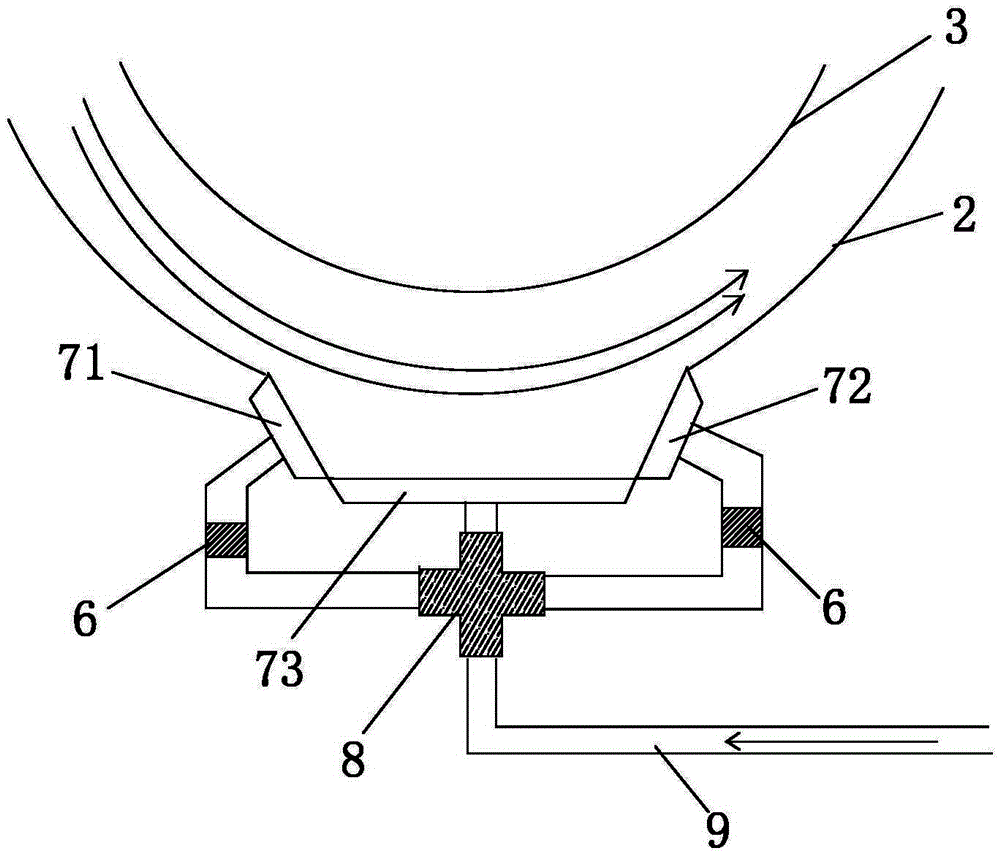

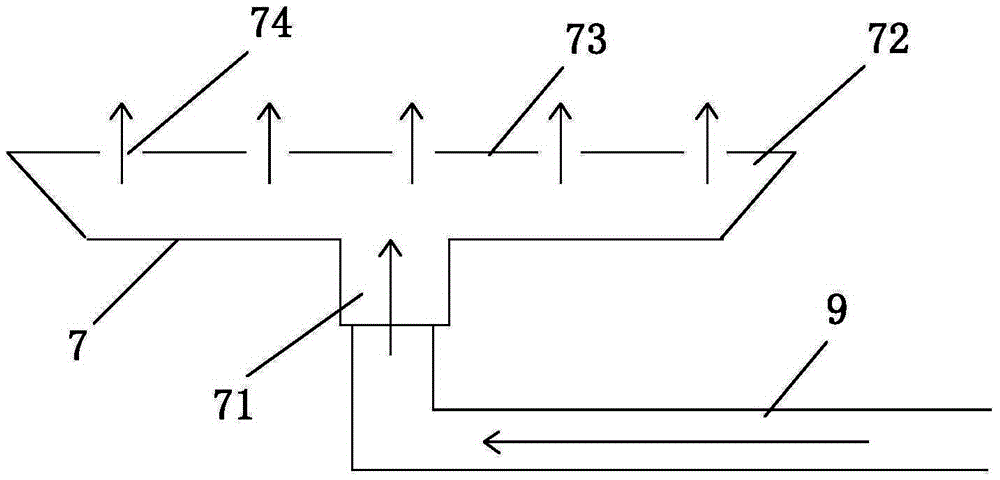

High-pressure-head low-flow non-isolated online cleaning device for rotary air preheater

InactiveCN105758253AReduce uneven expansionLower smoke temperatureFlush cleaningSolid removalAir preheaterElectricity

The invention provides a high-pressure-head low-flow non-isolated online cleaning device for a rotary air preheater.The device comprises a steam heating device, an electric heating device, a water tank, an agentia adding device, a high-pressure water pump and a soot blower, wherein the water tank, the agentia adding device, the high-pressure water pump and the soot blower are sequentially connected, and the steam heating device and the electric heating device are both arranged in the water tank.The device is simple in structure, convenient to implement, small in influence on unit operation, and capable of efficiently cleaning a heat exchanging element of the rotary air preheater under the online non-isolated condition.

Owner:GUODIAN SCI & TECH RES INST +1

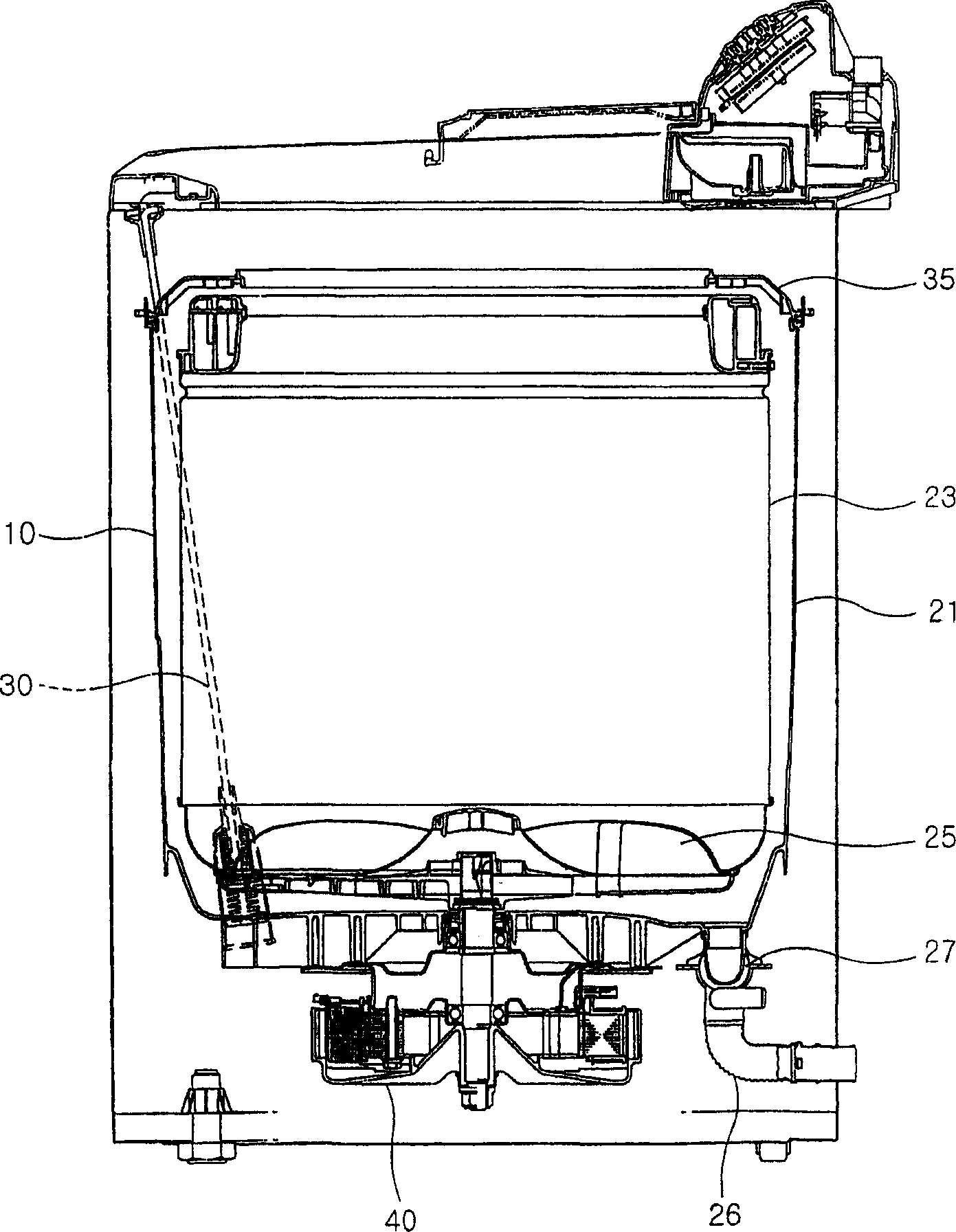

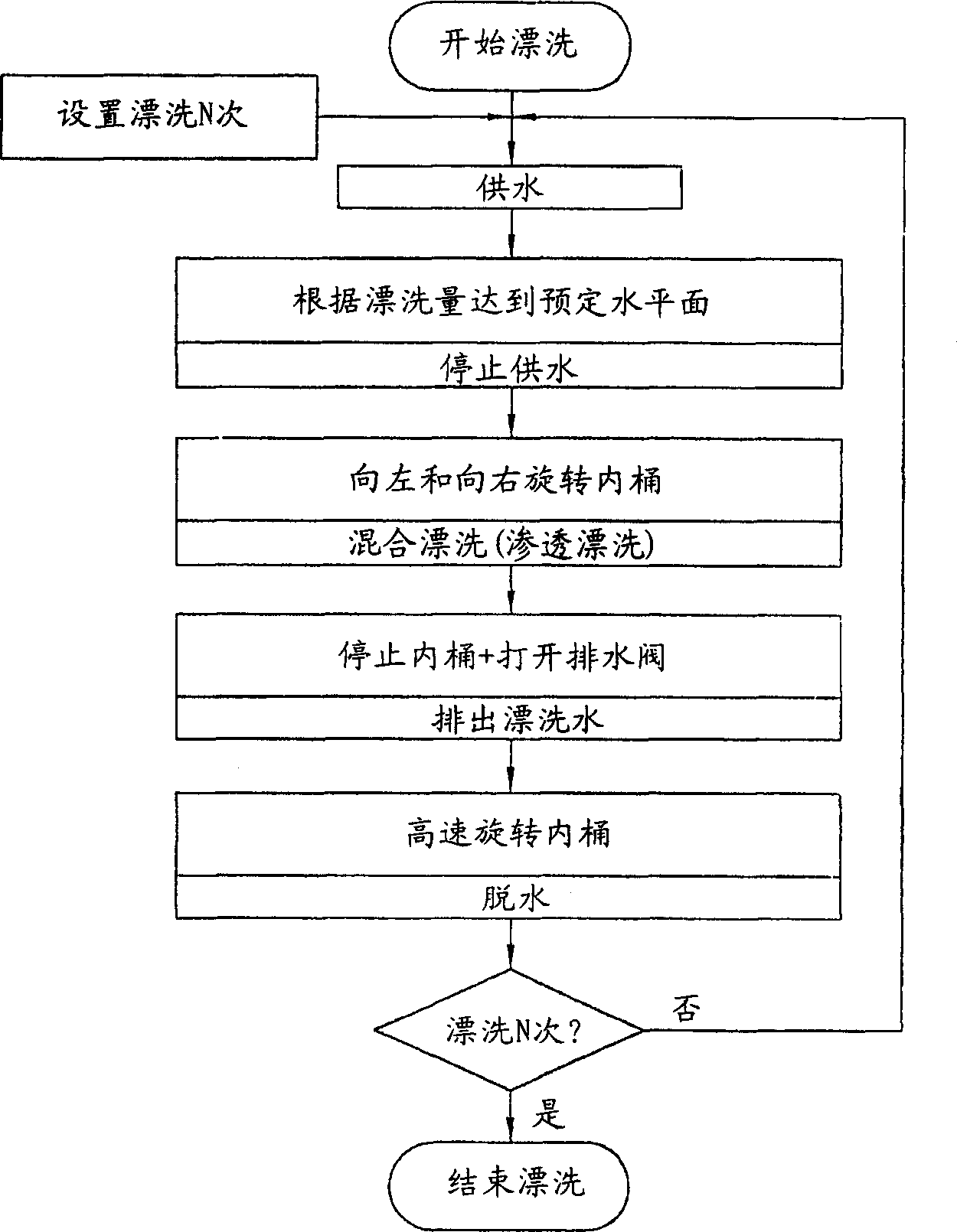

Rinse control method for washing machine

InactiveCN1503863AReduce wasteReduce rinse timeOther washing machinesControl devices for washing apparatusLow speedRinse water

A rinse control method for a washing machine including the steps of rinsing water supplying and infiltrating for supplying rinsing water rotating an inner tub at relatively low speed so that the rinsing water can be infiltrated into washing materials and rinsing water permeating and exhausting for draining the rinsing water rotating the inner tub at relatively high speed so that the rinsing water can be exhausted to the outside passing through the washing materials enable a swift rinsing operation with a smaller amount of rinsing water.

Owner:LG ELECTRONICS INC

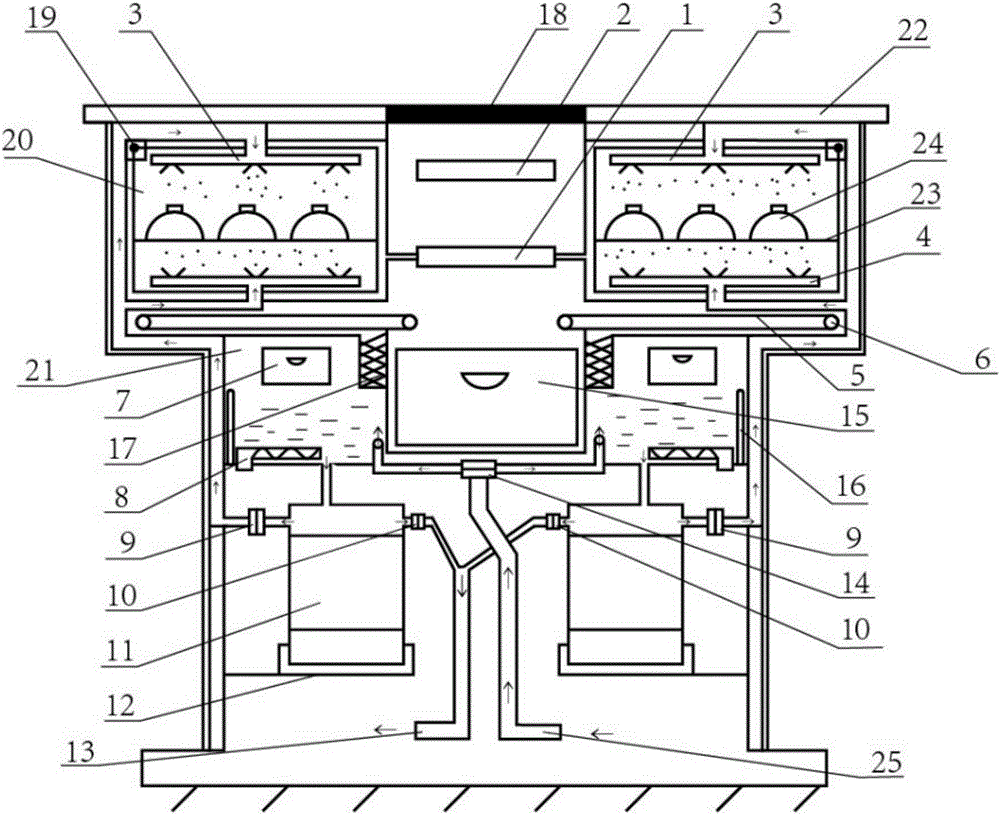

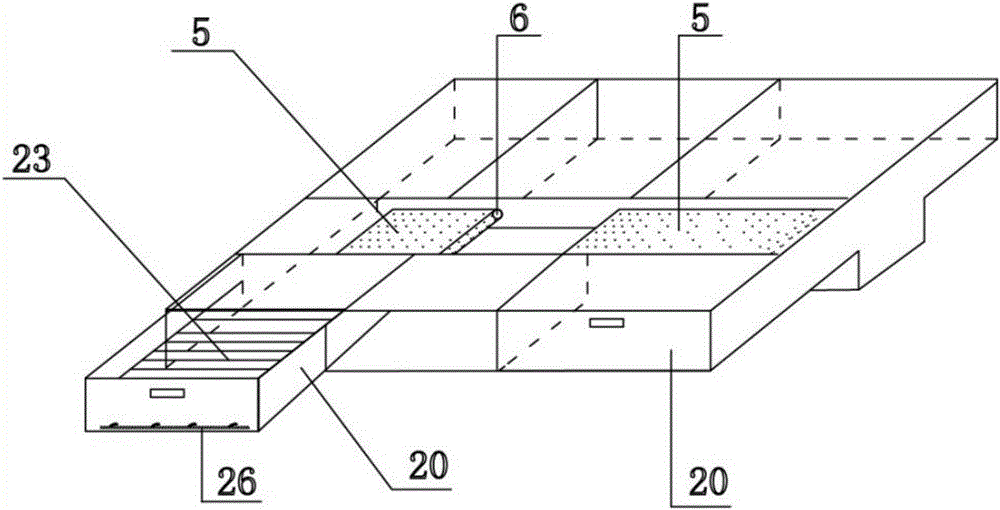

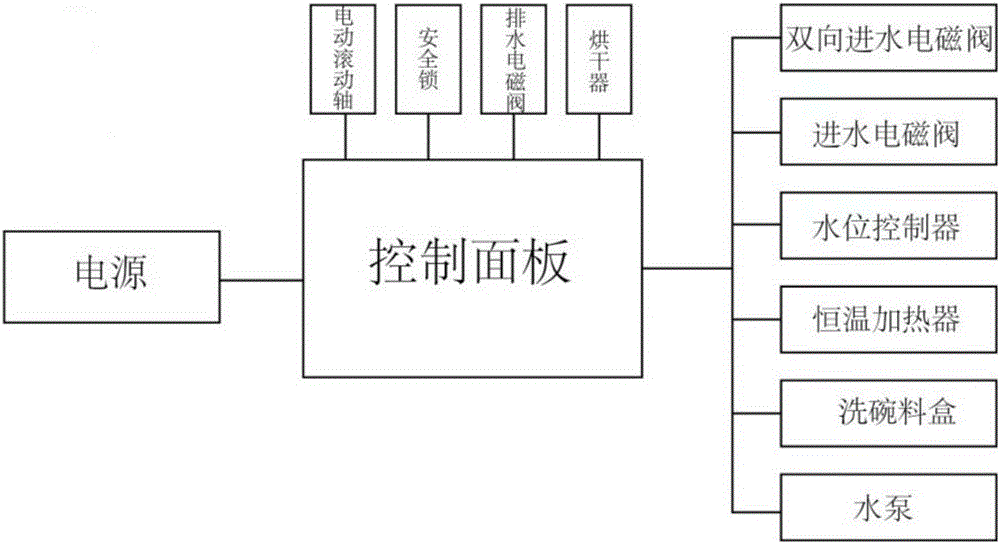

Fully-automatic multifunctional dining table with dish washing function

InactiveCN105286296APromote excretionSolve the problem of unclean flushing in dead cornersMachine detailsTableware washing/rinsing machinesGratingWater level

The invention discloses an improved fully-automatic multifunctional dining table with a dish washing function. The dining table comprises a table top and a hollow base and is characterized in that a drier, a control panel and a dish washing drawer are arranged under the table top, an upper water spray arm, a lower water spray arm, a grating and a residue flush pipe are arranged in the drawer, a filter strip is arranged behind and below the dish washing drawer, one end of the filter strip is located above the residue flush pipe and corresponds to the residue flush pipe, and the dish washing drawer is communicated with the drier; a water container is arranged in the hollow base, a constant-temperature heater, a water level controller, a dish washing material box and a filter mesh bag are arranged in the water container, and the lower portion of the water container is communicated with a water pump through a pipeline. The dining table is mainly used in various families.

Owner:毛丹

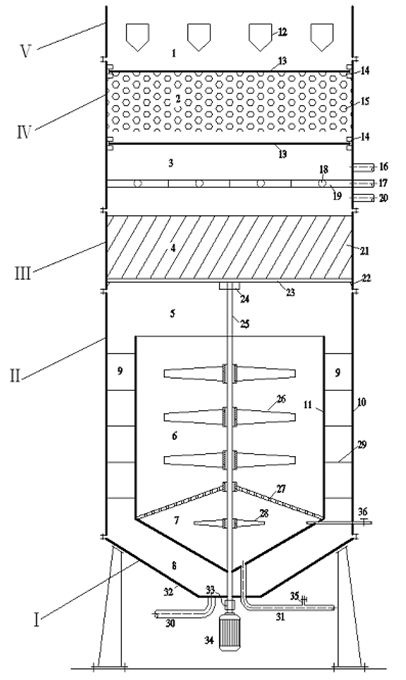

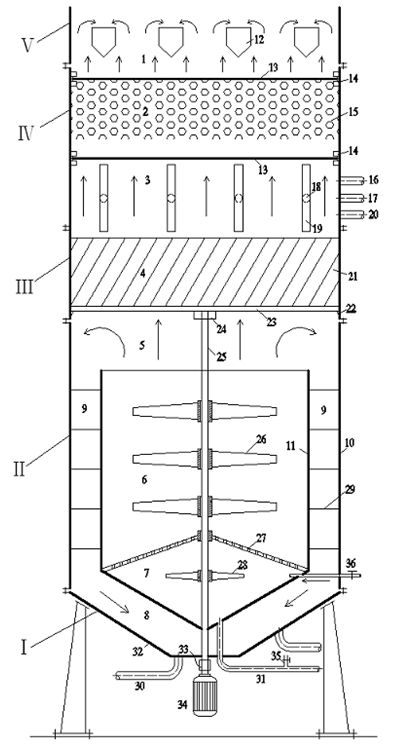

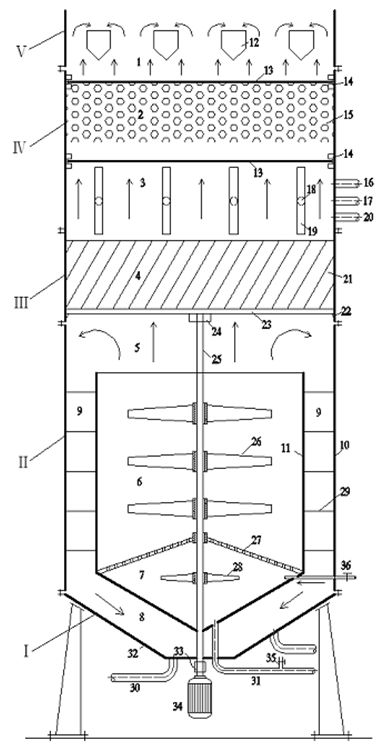

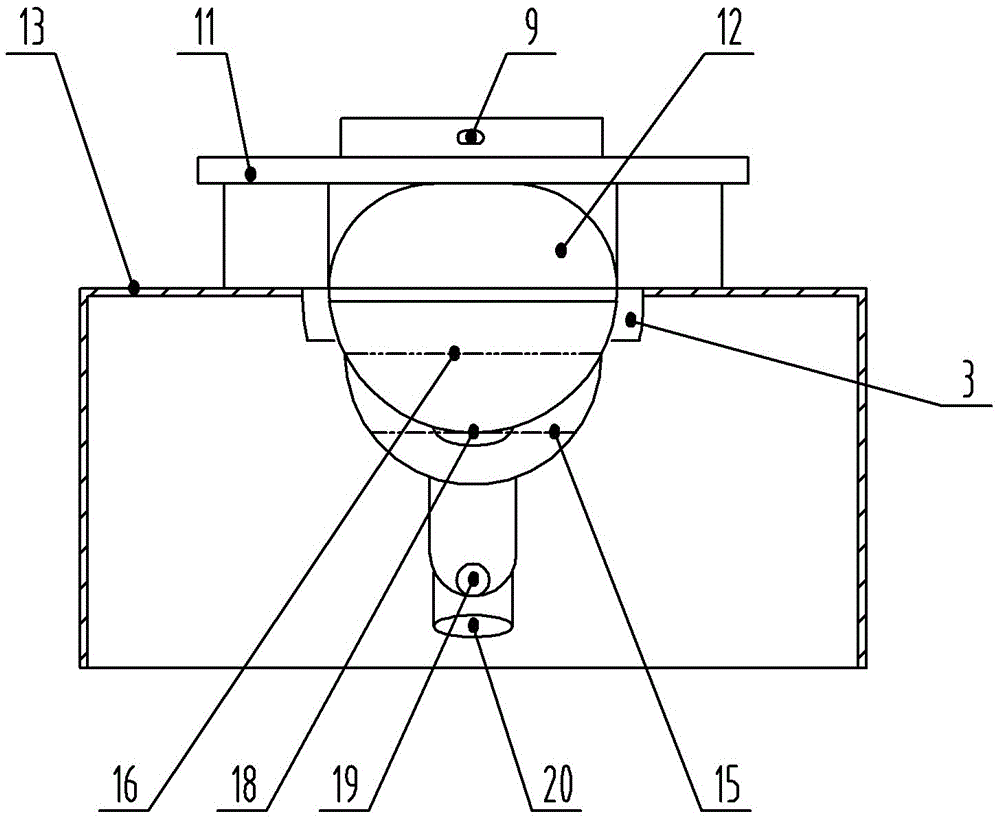

Intensive integrated water purification equipment

InactiveCN102120655ASmall footprintImprove land utilizationMultistage water/sewage treatmentFlocculationSludge

The invention discloses intensive integrated water purification equipment. The equipment is separated into five sections according to difference of water purification units, and the five sections are connected through flanges; and the equipment is provided with a mud collecting area, a primary flocculation area, an inner-cylinder clustering flocculation area / and an outer-cylinder sludge concentration area, a sludge separation area, an inclined tube sedimentation area, a backwashing gas distribution area, a filtration area, and a clear water area from bottom to top. The equipment is provided with devices such as an agitator blade used for particles to form agglomerated floc, a rotary gas distribution plate used for gas-water backwashing of a filter material, small-space spiral sloping panels used for concentrating sludge and the like; and the whole equipment is simple in structure, water purification functional units are compactly connected, the flat plane utilization rate is high, and the equipment is convenient to operate, can maximize the water purification function, and has important practical significance for medium and small water supply systems.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

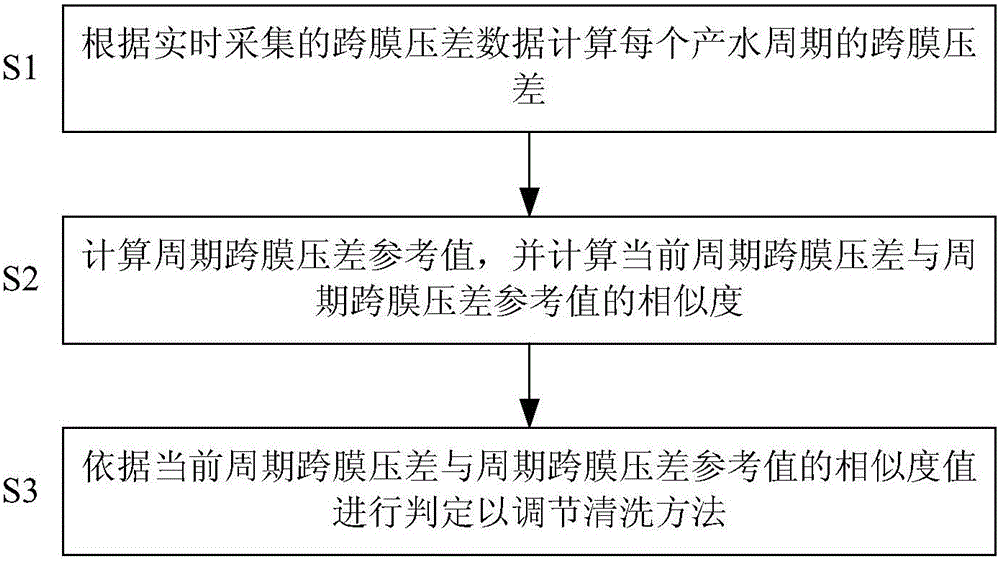

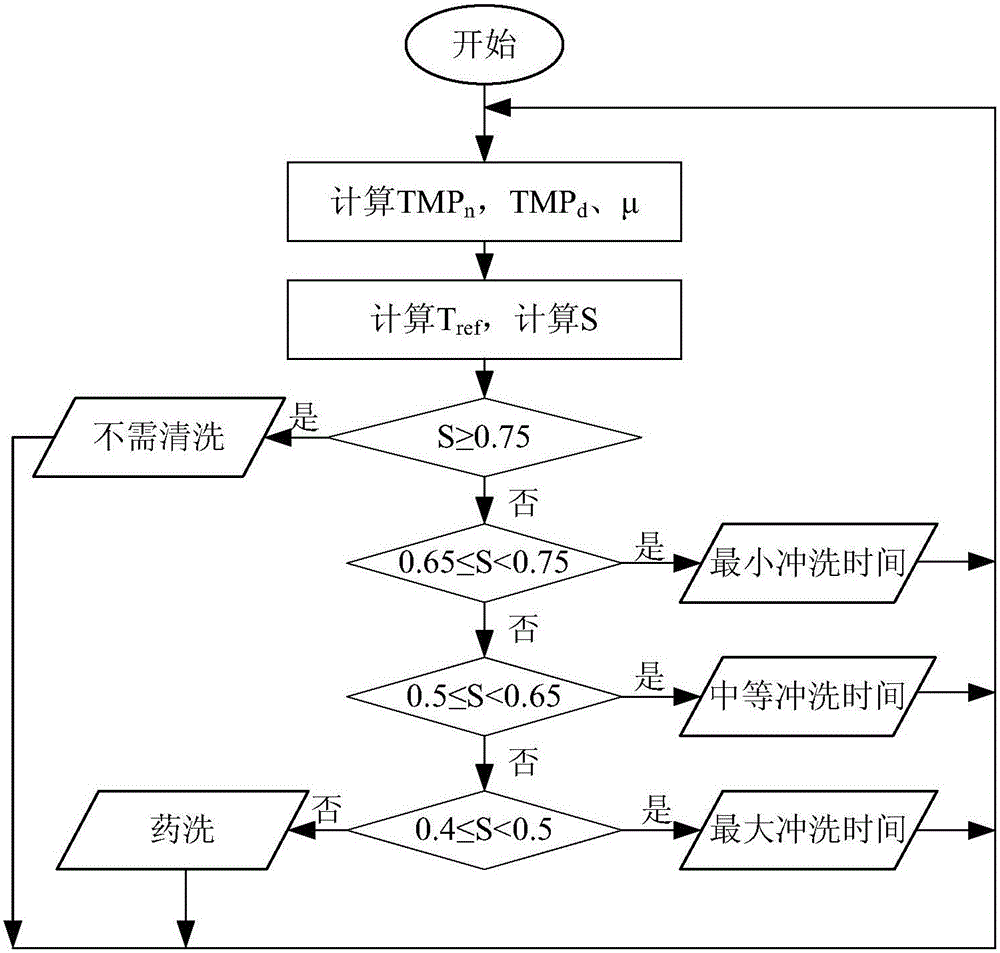

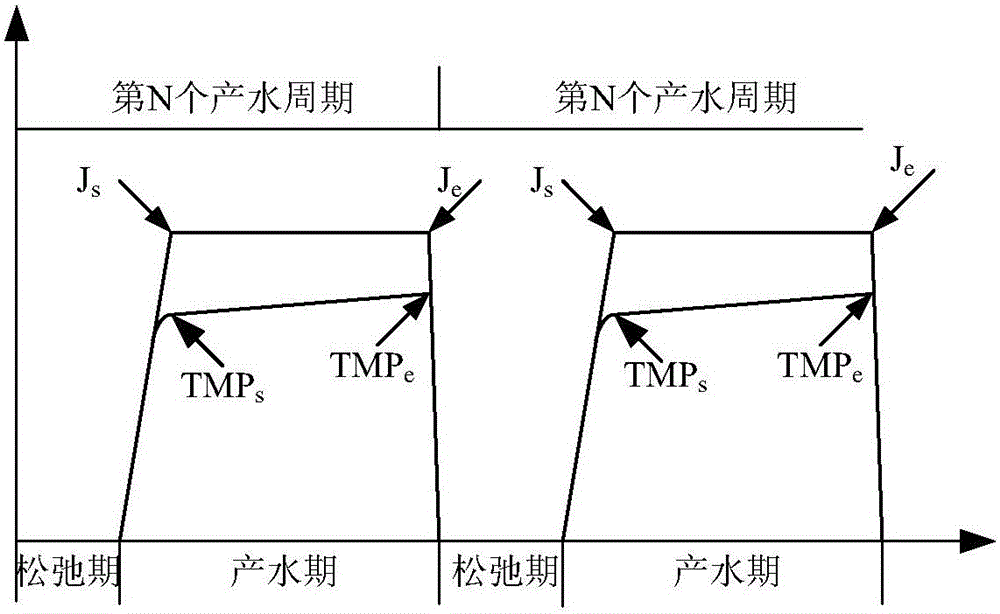

Optimized membrane bioreactor (MBR) back washing method

ActiveCN105084520AOptimize rinse timeImprove cleaning methodsSemi-permeable membranesSustainable biological treatmentMembrane bioreactorTransmembrane pressure

The invention discloses an optimized membrane bioreactor (MBR) back washing method. An MBR is operated at constant flux. The method comprises the following steps: I. computing the transmembrane pressure (TMP) of membrane modules of the MBR in a certain period of time; II. computing the similarity S in the certain period of time: specifically, firstly determining the reference value Tref of the TMP and then computing the similarity S by utilizing the TMP according to a formula in the specification; III. comparing the value of S with a preset threshold, washing the membrane modules by an online cleaning mode at different cleaning time if the value of S is not less than the preset threshold, and washing the membrane modules by an online chemical cleaning or offline cleaning mode if the value of S is less than the preset threshold. According to the actual situation of membrane pollution, through low-strength more timely cleaning, pollution of the MBR membrane is eliminated at the initial stage of formation, thus preventing synergistic deterioration effects caused because membrane pollution is not timely recovered, saving energy and time and prolonging the service lives of the membrane modules.

Owner:BEIJING JINKONG DATA TECH

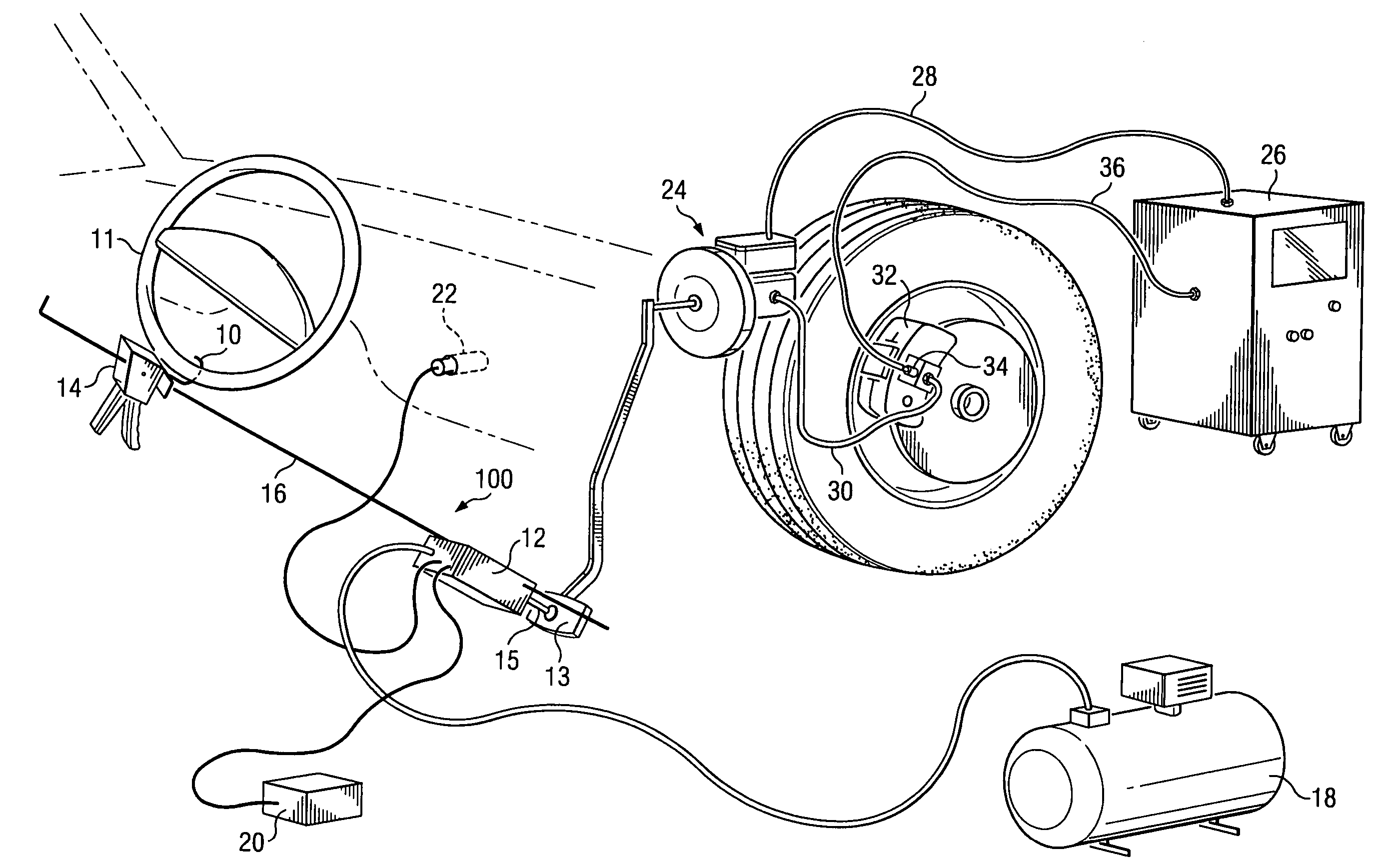

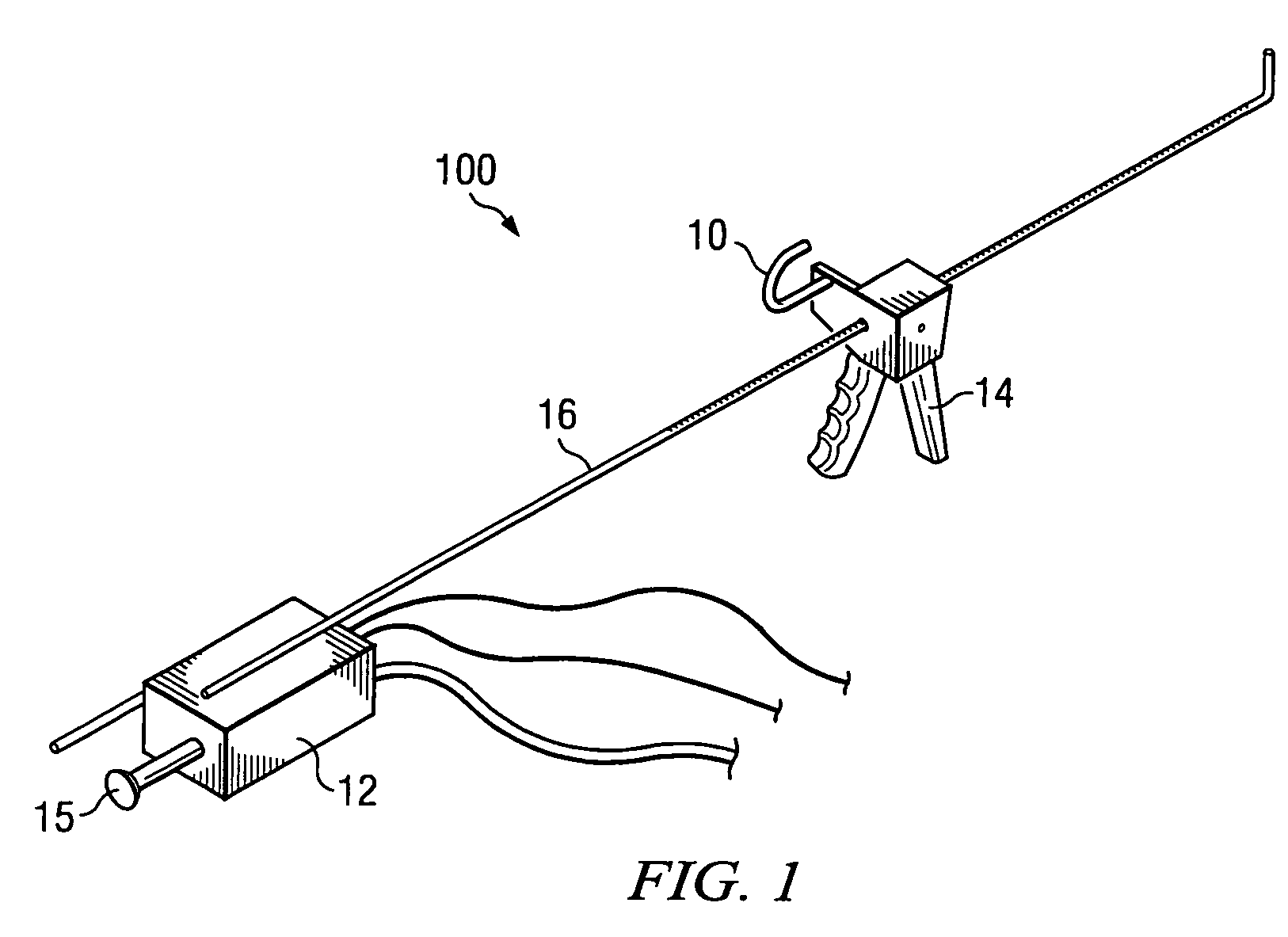

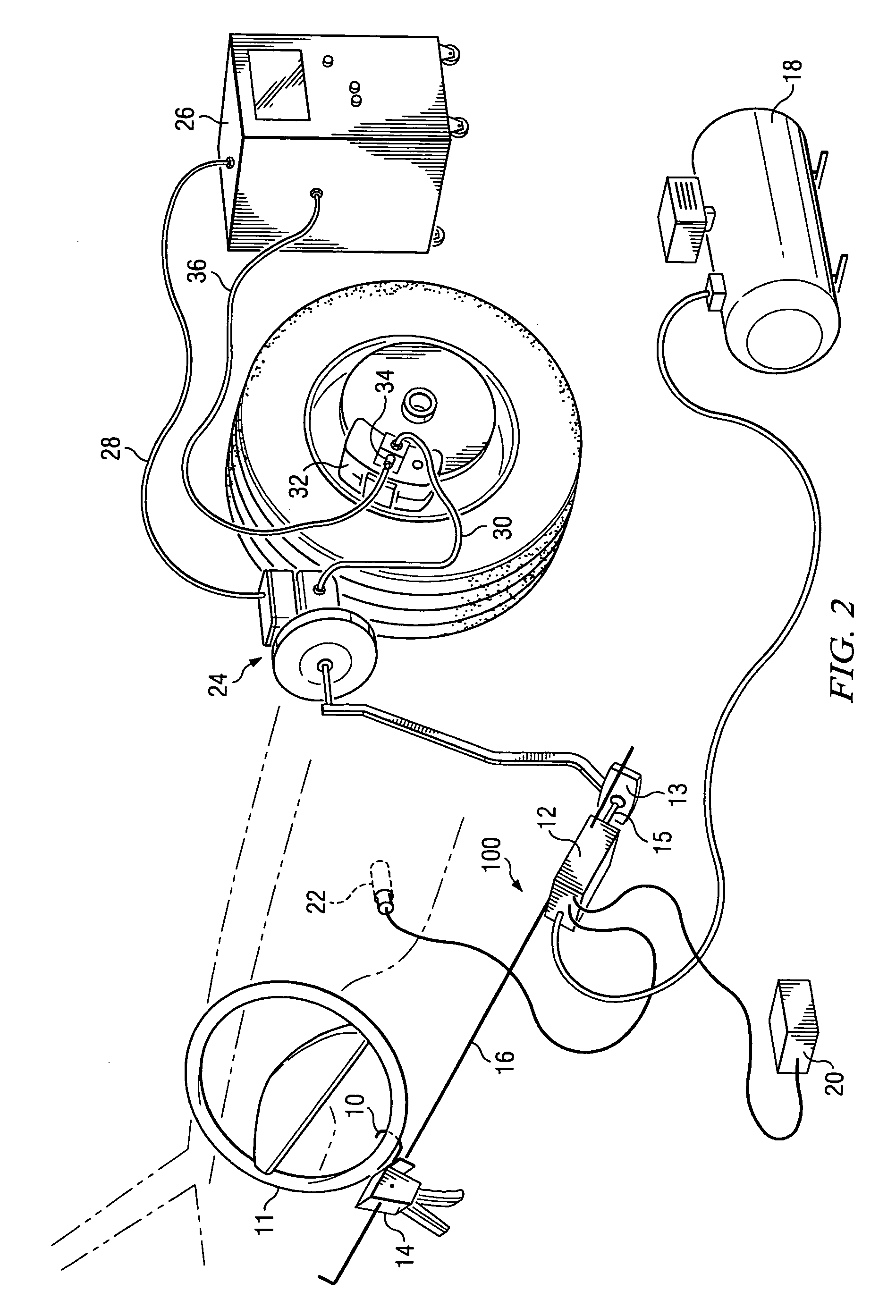

Brake flush accelerator

ActiveUS7152636B2Avoid pollutionReduce rinse timeControlling membersCrankshaftsMaster cylinderAir compressor

A Brake Flush Accelerator (BFA) selectively depresses a brake pedal while the master cylinder reservoir is under pressure from a brake flush machine, forcing fluid through the system at a very rapid rate. The BFA also provides a thorough flush as internal hydraulic pressure from the master cylinder can be used to exert force to remove contaminates from the brake system. The BFA exposes the low / no pressure area of the master cylinder to fluid flow from the pressurized master cylinder. When the brake pedal is depressed, a port in the master cylinder is opened which exposes the low / no pressure area of the master cylinder to fluid flow from the pressurized master cylinder reservoir. The BFA receives its pneumatic power from an air compressor or is easily adapted to a car tire. The BFA can be powered directly from the brake flush machine or attached to a vehicle's battery.

Owner:PHOENIX SYST

Method for directly treating air cooling drum boiler unit water supply

ActiveCN1945115AReduce depositionAdd lessSteam boilersSteam boilers componentsFlow-accelerated corrosionCorrosion

The present invention relates to boiler feed water treating technology, and is especially water treating method for directly air cooled steam drum boiler. Under the reductive condition, the condensed water from the condensing water tank is added with ammonia before entering the boiler directly under the condition of closing the oxygen discharging door of deaerator and the water hydrogen conductivity is controlled below 0.2microS / cm. In case of poor water quality, the oxygen discharging door is opened to convert into reductive mode. The present invention alters the traditional concept that dissolved oxygen will result in corrosion, and has double compact oxide film formed on surface of metal to inhibit the flow corrosion in thermal system, fine treatment of condensed water for long running time, no use of carcinogenic hydrazine and lowered ammonia adding amount for environment protection and health, and raised equipment utilization.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

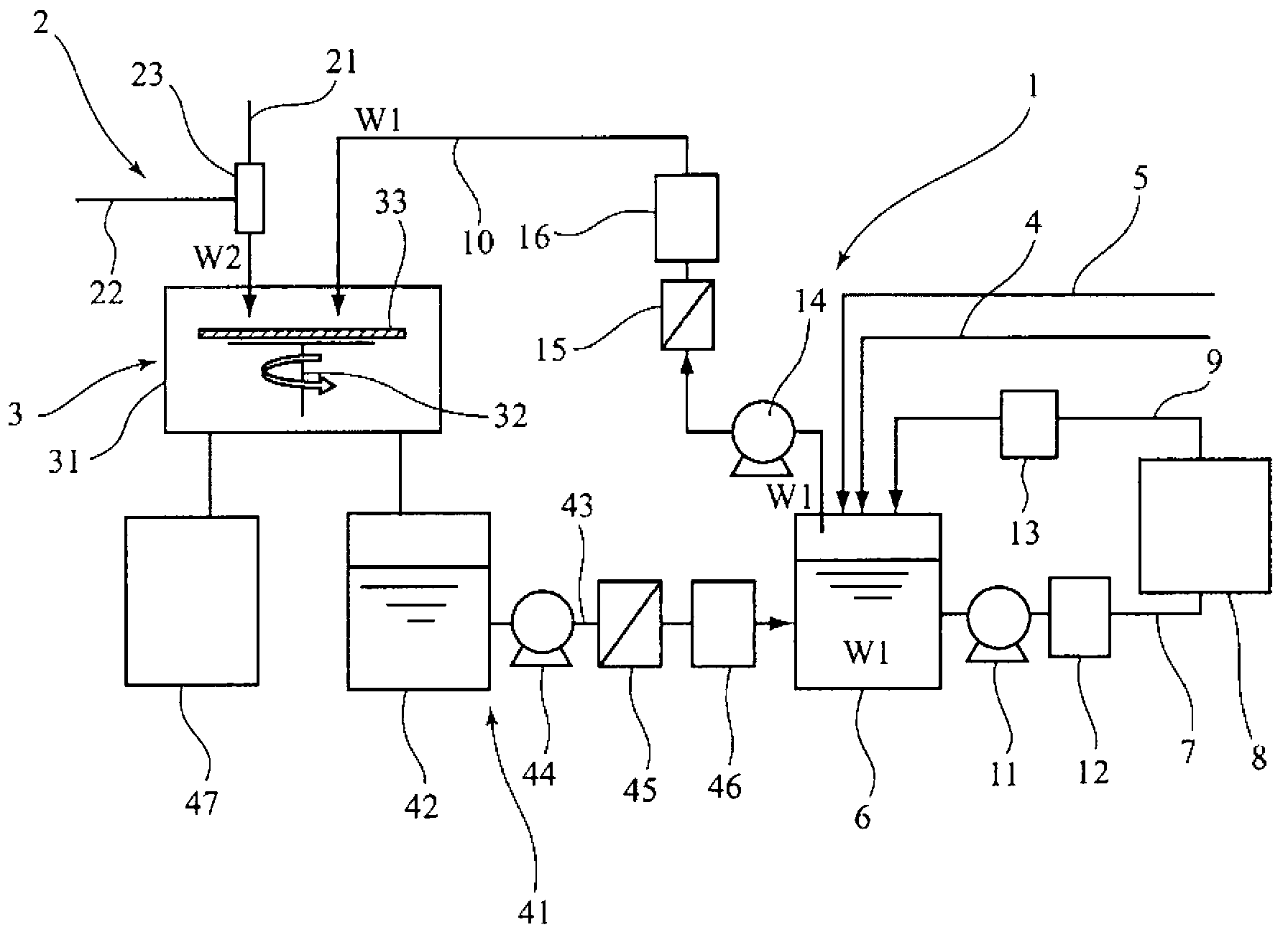

Method and system for cleaning electronic material

InactiveCN102844845AEasy to cleanReduce rinse timeSemiconductor/solid-state device manufacturingPhotosensitive material processingHybrid typeChemical storage

An electronic material cleaning system includes a chemical cleaning means, a wet cleaning means and a single-wafer cleaning apparatus. The chemical cleaning means comprises a functional chemical storage tank and an electrolytic reaction apparatus connected to the functional chemical storage tank via a concentrated sulfuric acid electrolysis line. The functional chemical storage tank can supply a functional chemical to the single-wafer cleaning apparatus via a functional chemical supply line. The wet cleaning means comprises a pure water supply line, a nitrogen gas supply line connected to a nitrogen gas source and an internal mixing type two-fluid nozzle connected respectively to the pure water supply line and the nitrogen gas supply line. Droplets generated from a nitrogen gas and ultrapure water can be sprayed from the tip of the two-fluid nozzle.

Owner:KURITA WATER INDUSTRIES LTD

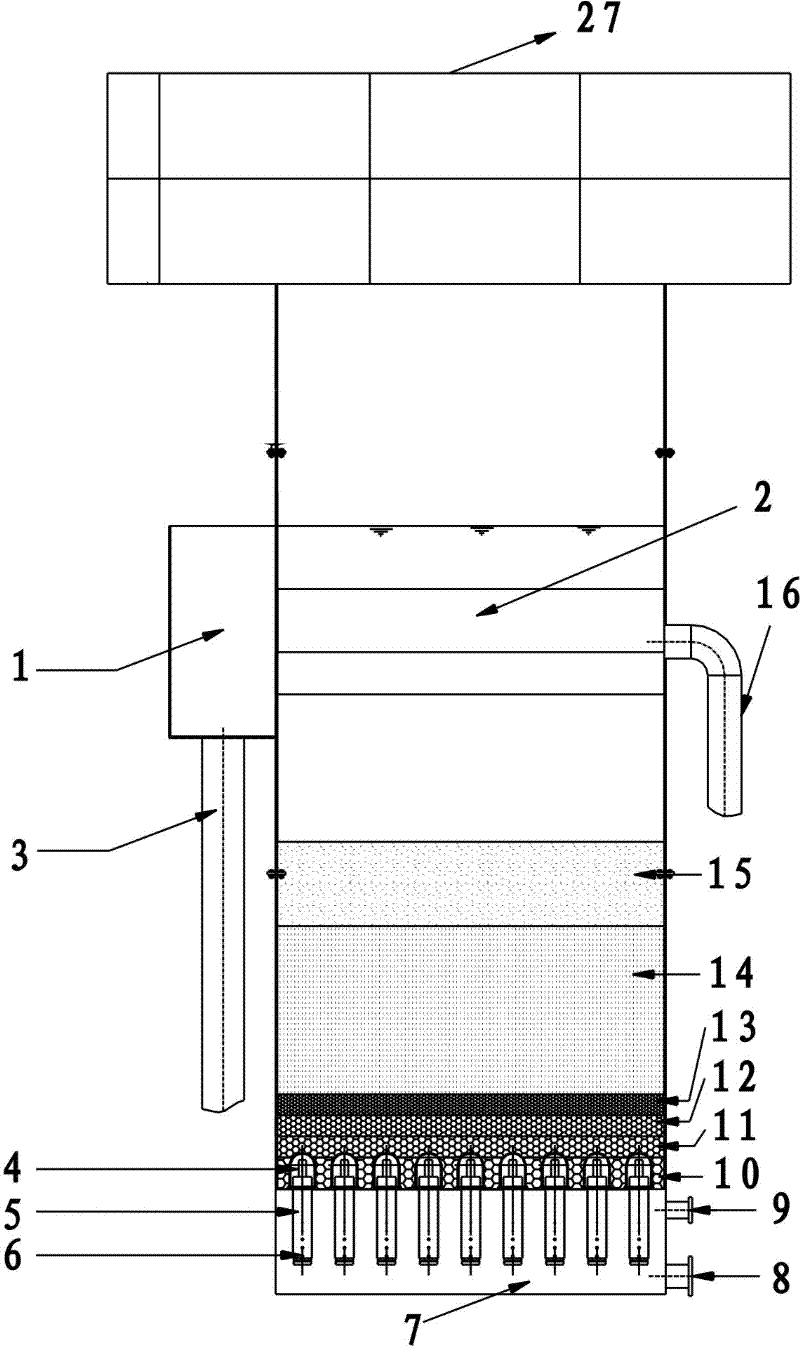

Air-water backwash filter and air-water backwash method

InactiveCN102407037AEasy to installMeet engineering needsLoose filtering material filtersGravity filtersThree stageFilter material

The invention relates to an air-water backwash filter and an air-water backwash method. The air-water backwash filter is characterized by comprising an air-water collection and distribution horizontal pipe and an air-water collection and distribution vertical pipe which are arranged at the bottom of the filter and used for filtering collected water and backwashing distributed water; and the air-water collection and distribution horizontal pipe and the air-water collection and distribution are arranged in a matched corresponding mode. The filter also comprises a rectangular water tank, an inlet pipe, a filtering material layer and a supporting layer, and a water collecting sump, wherein the rectangular water tank is used for evenly distributing unfiltered water and discharging backwash water; the inlet pipe is used for evenly distributing the unfiltered water in the rectangular water tank during filtering; the filtering material layer and the supporting layer are arranged at the lower end of the filter; the water collecting sump corresponds to the air-water collection and distribution vertical pipe and is provided with an outlet pipe and a backwash intake tube; the air-water collection and distribution vertical pipe is provided with inlet holes; the side face of the filter is provided with a drainage channel; and a drain pipe is connected below the drainage channel. The backwash process is divided into three stages as follows: stage one: air backwash; stage two: air-water backwash; and stage three: water backwash. The air-water backwash filter uses the air-water collection and distribution pipes to substitute a traditional filter head and filter plate, has the advantage of simplicity and rapidness in installation, is applicable to simultaneous construction without increase of additional large-scale equipment, is free from weather conditions, and can be rapidly installed to meet project demands especially for waterworks with a short construction period.

Owner:CHENGDU BISHUIQILI MUNICIPAL ENG

Blowing type roller washing machine and clothes-washing method thereof

ActiveCN105316909ADissolve fastEasy to dissolveOther washing machinesTextiles and paperStopped workEngineering

The invention discloses a blowing type roller washing machine and a clothes-washing method thereof. The washing machine comprises an inner barrel, an outer barrel, air chambers blowing air into the outer barrel to generate bubbles and an air pump. A gas heating device is arranged on an access for conveying air to the air chambers, and during washing, the air chambers are controlled to blow hot air into the outer barrel to act on water to generate hot bubbles. The number of the air chambers is at least two, the air chambers comprise a first air chamber and a second air chamber, and the blowing direction of the first air chamber and the blowing direction of the second air chamber are correspondingly consistent with the forward rotation direction and the reverse rotation direction of the inner barrel respectively. The air chambers further comprises a third air chamber, the third air chamber is arranged at the bottommost end of the outer barrel to be axially distributed, the blowing direction is upwards, and the first air chamber and the second air chamber are located on the two sides of the third air chamber respectively. When the washing machine is used for washing, the air pump and the gas heating device work, the air chambers blow the hot bubbles into the outer barrel; during the rinsing, the gas heating device stops working, the air pump works, and natural wind is formed in air chambers. According to the blowing type roller washing machine, the clothes washing ratio is improved, electric energy consumption is reduced, and the clothes-washing time is saved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

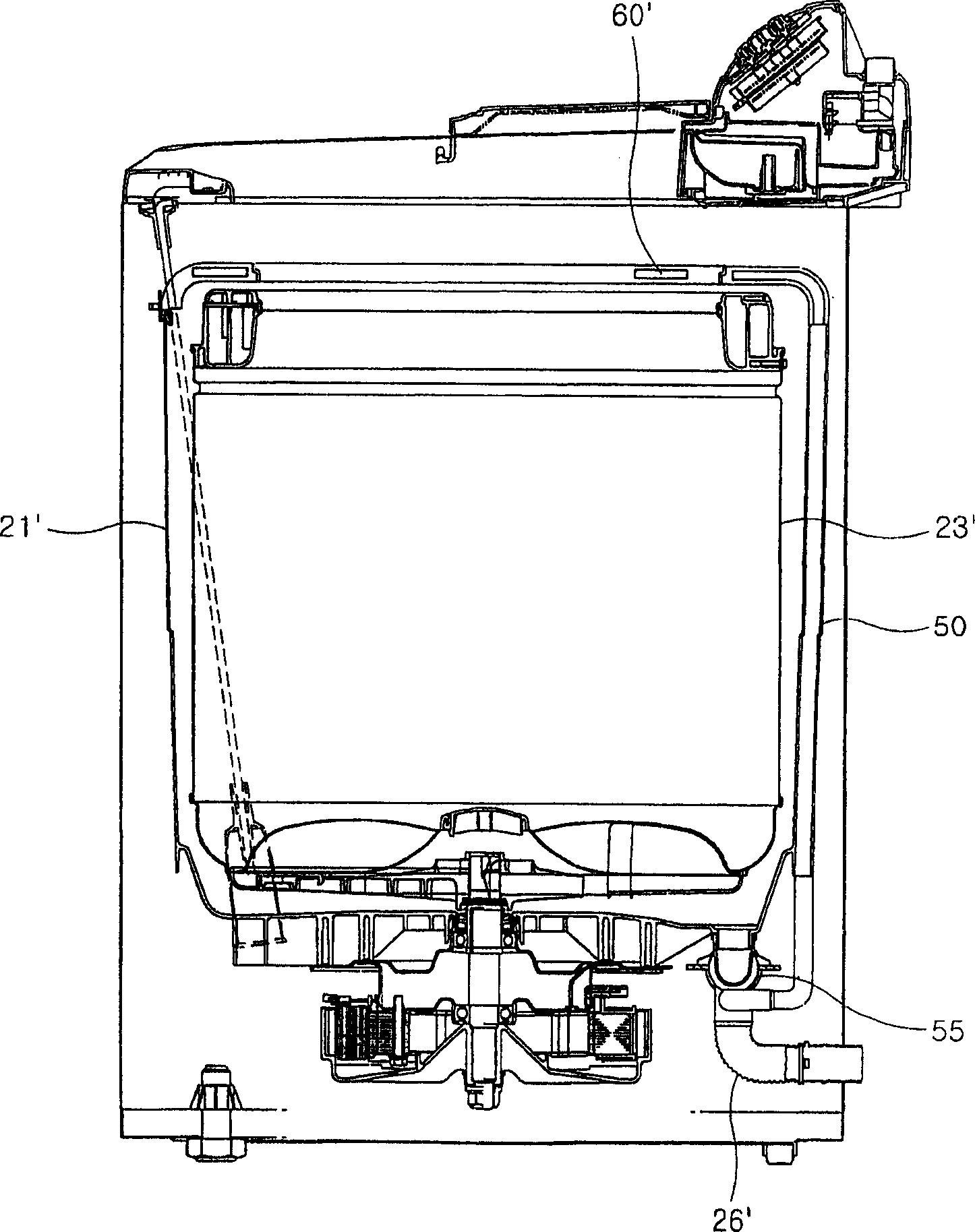

Air-blowing-type roller washing machine and clothes-washing method thereof

ActiveCN105220399AExtension of timeShorten washing timeOther washing machinesControl devices for washing apparatusCheck valveEngineering

The invention discloses an air-blowing-type roller washing machine and a clothes-washing method thereof. The washing machine comprises an internal cylinder, an external cylinder, at least two air chambers used for externally blowing air and an air pump. All the air chambers are independent. The air-blowing direction of at least one air-blowing chamber is the same as the forward-rotating direction of the internal cylinder. The air-blowing direction of at least another air-blowing chamber is the same as the backward-rotating direction of the internal cylinder. During washing, an air chamber in the air-outlet direction same as the rotation direction of the internal cylinder is controlled to blow air into the external cylinder in order to generate bubbles. All the air chambers are communicated with the same air pump by means of an air-flow distributor. Check valves are arranged among the air-flow distributor and all the air chambers. An air-heating device is arranged between the air-flow distributor and the air pump. During washing / rinsing operation of the washing machine, the internal cylinder rotates forward and an air chamber in the air-blowing direction same as the forward-rotating direction of the internal cylinder is controlled to blow air. The internal cylinder rotates backward and an air chamber in the air-blowing direction same as the backward-rotating direction of the internal cylinder is controlled to blow air. During washing, hot air is blown by air chambers and natural air is blown by air chambers. The air-blowing-type roller washing machine has a simple structure and helps to save clothes-washing time and increase clothes-washing efficiency.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Method for preparing soft tissue decellular matrix through supercritical fluid technology

InactiveCN107164298AIncrease the diffusion coefficientMass transfer speedBiological preparation purgeMuscle tissueBlood Vessel Tissue

The present invention discloses a preparation method of a soft tissue decellular matrix, and relates to the technical field of clinical medicine, biomedical medicine and regenerative medicine. According to the present invention, the natural soft tissue decellular matrix is prepared by using a supercritical fluid technology, wherein the natural soft tissue comprises small intestine tissue, blood vessel tissue, muscle tissue, heart tissue, valve tissue, lung tissue, spleen tissue, kidney tissue, liver tissue, stomach tissue, gallbladder tissue, fat tissue, cartilage tissue, trachea tissue, esophagus tissue, bladder tissue, ureter tissue, oviduct tissue, or uterus tissue. According to the present invention, with the preparation method, the damage on the soft tissue matrix component is low, and the obtained soft tissue decellular matrix has advantages of low immunogenicity and good biocompatibility.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

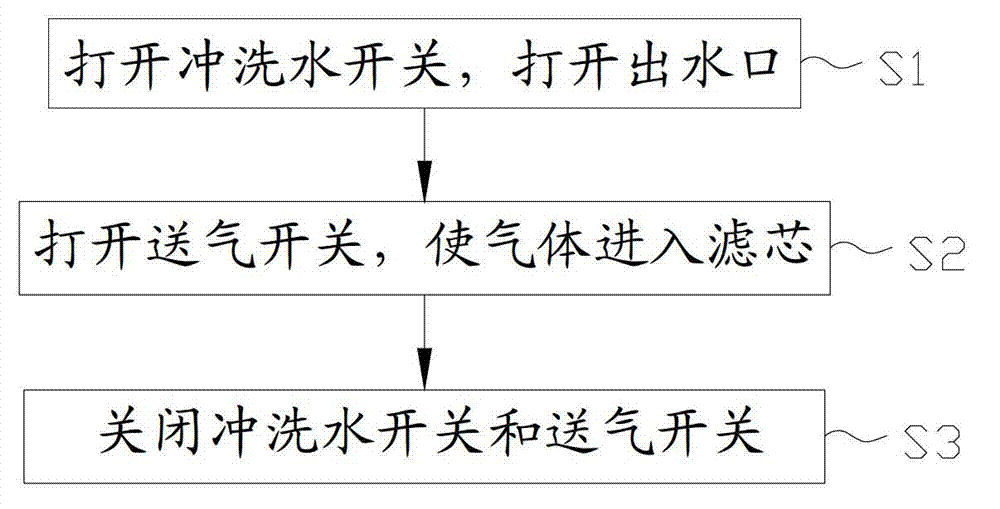

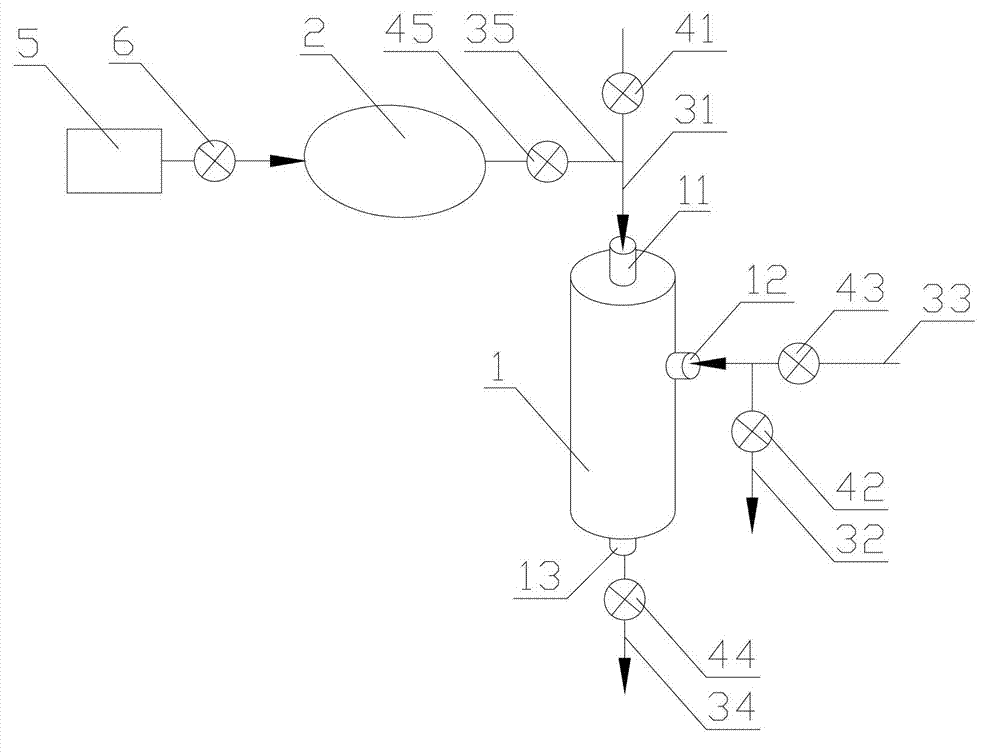

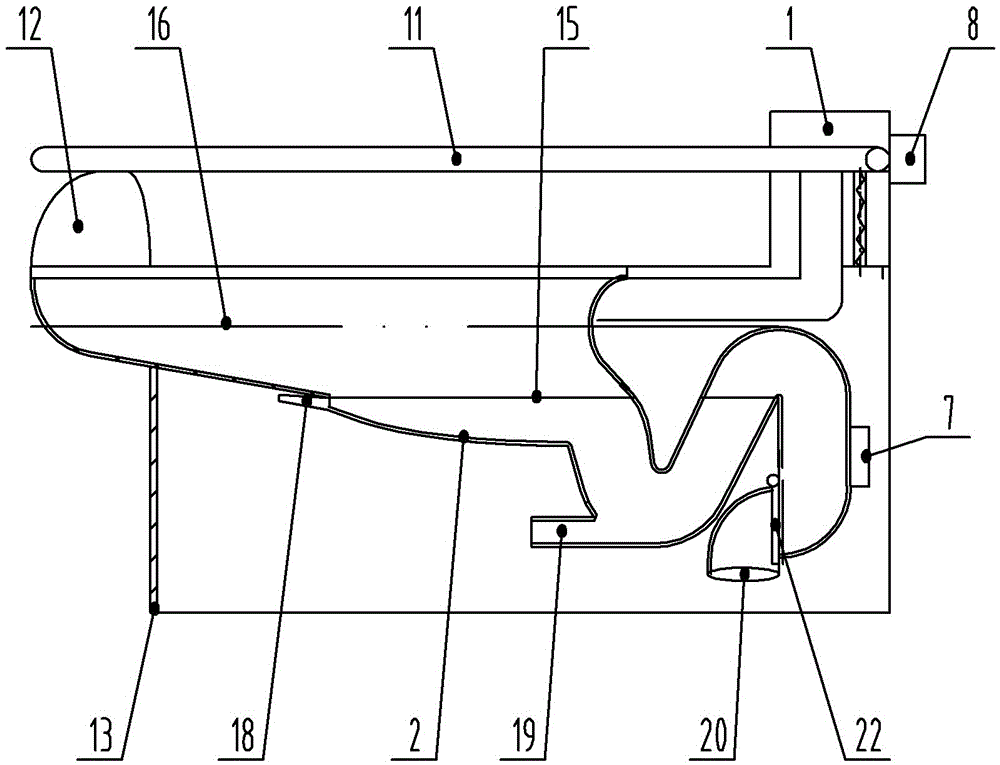

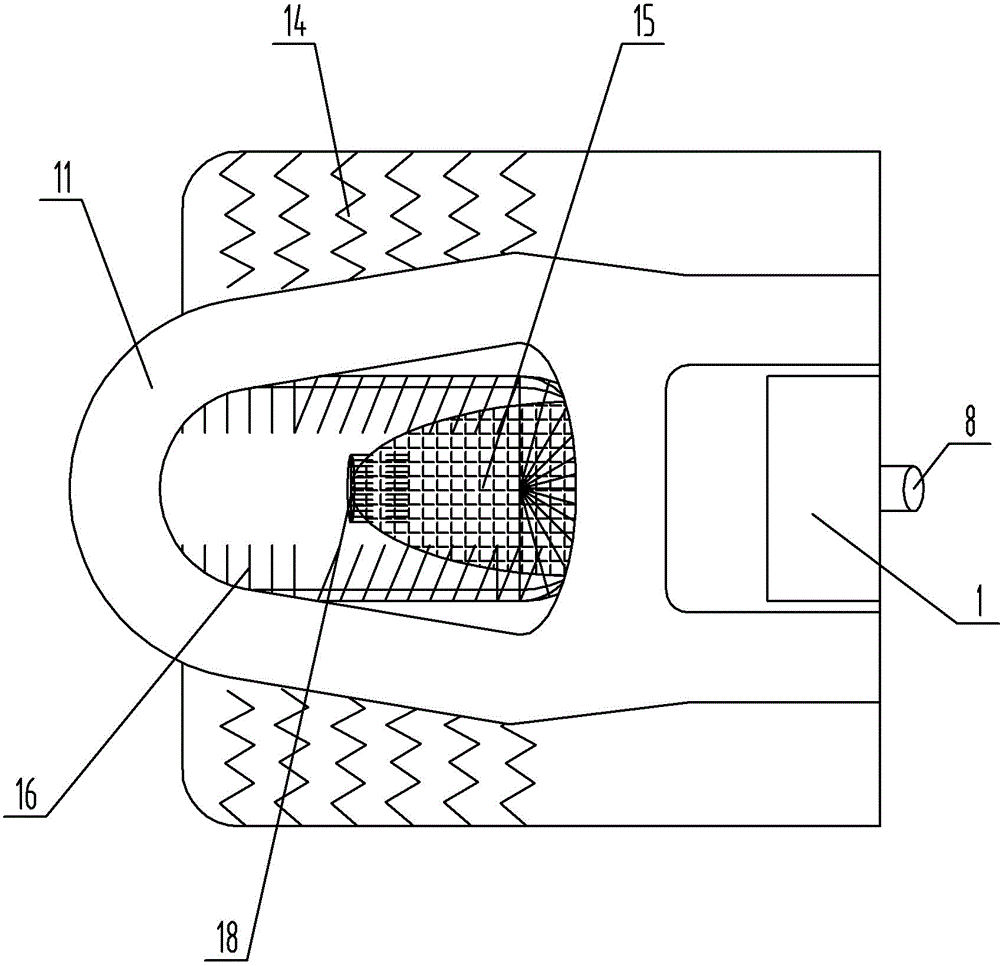

Internal-pressure type ultrafiltration membrane flusher and flushing method

InactiveCN103084069AReduce cloggingIncrease water fluxSemi-permeable membranesFlushing timeInternal pressure

The invention discloses an internal-pressure type ultrafiltration membrane flushing method and a flusher. The flusher provided by the invention comprises a flushing water pipe and a flushing water switch, a sewage discharge pipe and a sewage discharge switch, and further comprises an air storage tank and an air supply pipe, as well as an air supply switch arranged on the air supply pipe, wherein the air supply pipe is connected to the water inlet of a filter element. Under the action of pressure, the air in the air storage tank passes through the filter element and gaseous-liquid two phase flows are formed in the filter element; and the acting manner and the acting intensity of the single water phase with the attachments inside the membrane filaments are changed; therefore, flushing of the filter element can be finished well. Compared with the traditional flushing way, the flusher is capable of completing back flushing of the filter element better and more thoroughly; therefore, the water flux of the filter element after flushing is improved, stoppage of the ultrafiltration membrane is retarded, the service lives of the ultrafiltration membrane and the filter element are prolonged, the total water flux of the filter element is improved, and simultaneously, the flushing time is saved and the back flushing water is saved.

Owner:SHENZHEN CHENGDELAI IND CO LTD

Full-automatic water-saving buttocks-splash-proof squatting and sitting dual-purpose toilet WC pan

ActiveCN104088347AAvoid Splashing ButtAutomatic control of water consumptionWater closetsFlushing devicesButtocksWater saving

The invention particularly relates to a full-automatic water-saving buttocks-splash-proof squatting and sitting dual-purpose toilet WC pan which comprises a water tank, a urinal, a flushing pipeline and a blowdown pipeline. The rear of the water tank is directly communicated with a running water pipe, the urinal is a squat toilet urinal, the flushing pipeline comprises a flushing water ring, a flushing water pipe and a spraying water pipe, and the blowdown pipeline comprises an S-shaped blowdown pipe. The urinal is provided with a cushion, a casing is arranged around the urinal, two side portions of the casing serve as pedals, the front end of the cushion is supported on a front baffle of the urinal, the rear end of the cushion is hinged to the casing at the rear of the urinal through a rotating shaft, a bottom wall of the urinal is inclined from front to rear downwards, a blowdown opening is arranged at the rear end of the urinal to be communicated with the S-shaped blowdown pipe, the flushing water ring surrounds the urinal, flushing water holes are evenly formed in the upper portion of the flushing water ring, and the flushing water pipe and the spraying water pipe are led out of the water tank, the other end of the flushing water pipe is communicated with the flushing water ring, the other end of the spraying water pipe is respectively communicated with a first spraying port and a second spraying port, a check valve is arranged at the position of a blowdown outlet of the S-shaped blowdown pipe, and an infrared sensor control switch is installed between the flushing water pipe and the spraying water pipe. The full-automatic water-saving buttocks-splash-proof squatting and sitting dual-purpose toilet WC pan is wide in applied range, integrates squatting and sitting, conforms to the Chinese's use characteristics, performs flushing automatically, is excellent in performance, saves water, performs flushing cleanly and cannot blocked easily.

Owner:邹国龙

Apparatus used for determining sediments in crude oil and fuel oil

The invention discloses an apparatus used for determining sediments in crude oil and fuel oil. The apparatus is mainly composed of a heating apparatus and an extracting apparatus. The extracting apparatus comprises an extracting flask, a condensing coil pipe, an extracting liner, and a liner support. The condensing coil pipe is fixed on the cap of the extracting flask. The two ends of the coil pipe penetrate through the cap, and the rest part of the coil pipe is positioned in the extracting flask. The liner support is suspended in the extracting flask. The extracting liner is arranged in the liner support. The extracting apparatus also comprises a flow guiding apparatus. The flow guiding apparatus comprises a round flow guiding plate with a diameter slightly smaller than the caliber of the extracting liner, and a connecting piece used for connecting the flow guiding plate and the condensing coil pipe. According to the invention, the flow guiding apparatus composed of the flow guiding plate and the connecting piece is added to the apparatus, such that a washing method with up-to-bottom washing is realized. In prior arts, 20 to 24 hours are required for determining a sample. With the apparatus provided by the invention, only 3 to 5 hours are needed. Therefore, determining efficiency is greatly improved, and the accuracy and high precision of determining results can be ensured.

Owner:钦州海关综合技术服务中心

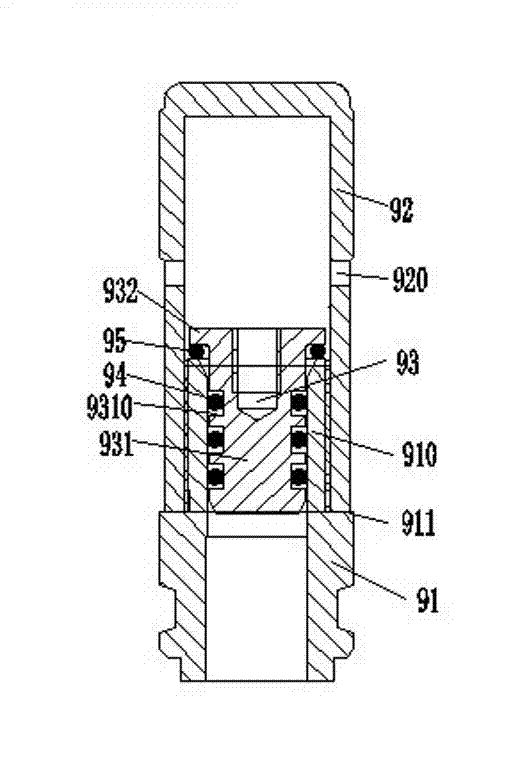

Pre-filling type catheter flusher and pre-filling type catheter flusher assembling and outputting method

ActiveCN109647808AReduce rinse timeReduce financial burdenHollow article cleaningCatheterPistonSyringe

The invention relates to a pre-filling type catheter flusher. The pre-filling type catheter flusher comprises an outer sleeve, a piston and a core rod, wherein the piston is sealed and movably connected in the outer sleeve, and the core rod is connected to the piston and extends from one end of the piston. A liquid outlet nozzle is arranged at the other end of the outer sleeve, a liquid outlet nozzle is detachably connected with a cap for sealing the liquid outlet nozzle, a normal saline storage cavity is formed between the outer sleeve, the piston and the liquid outlet nozzle, and normal saline is stored in the normal saline storage cavity. According to the pre-filling type catheter flusher, the problems of long consumed time and large waste due to the fact that an existing injector performs the current extraction of normal saline for flushing are solved.

Owner:JIMIN HEALTH MANAGEMENT CO LTD

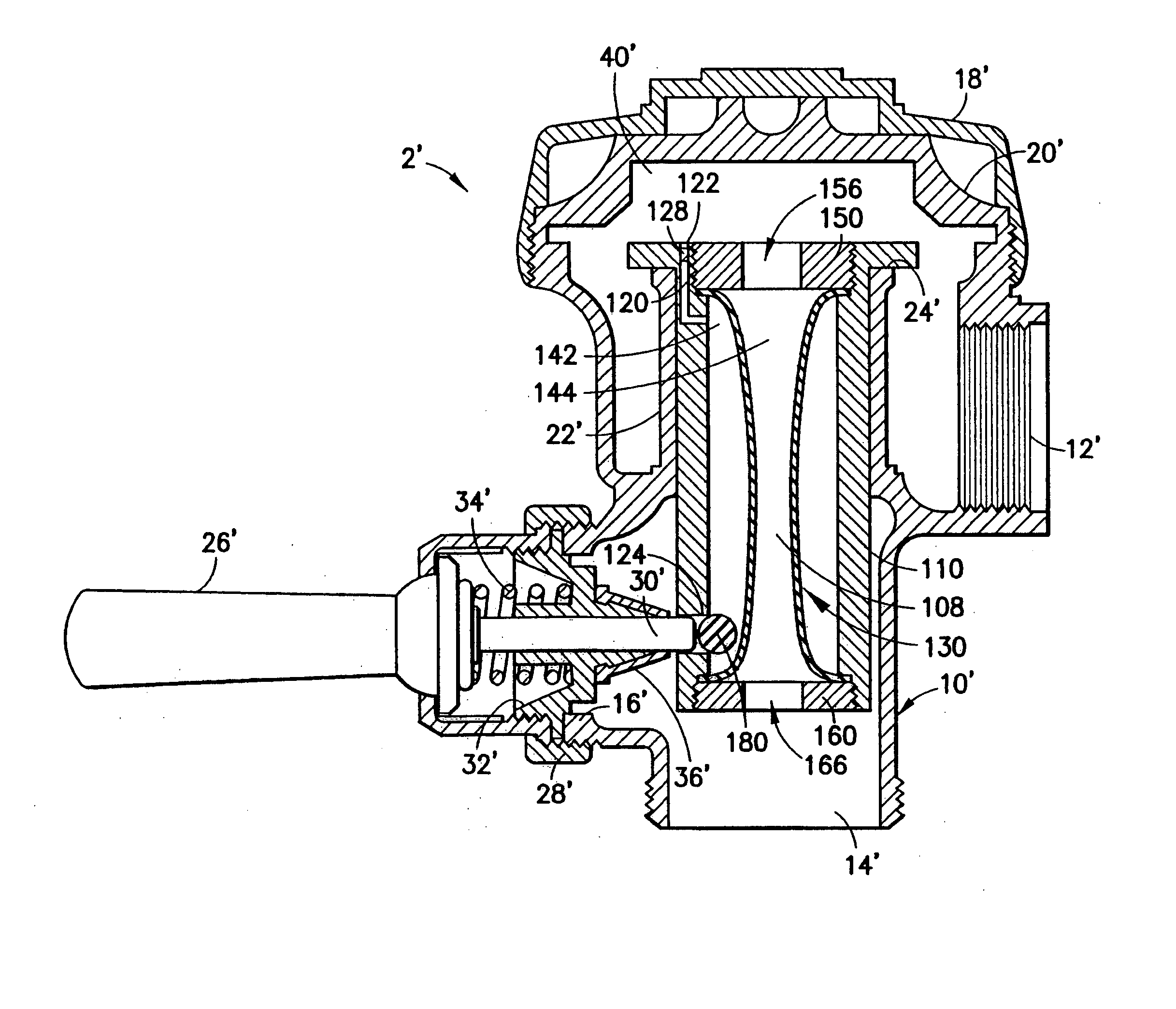

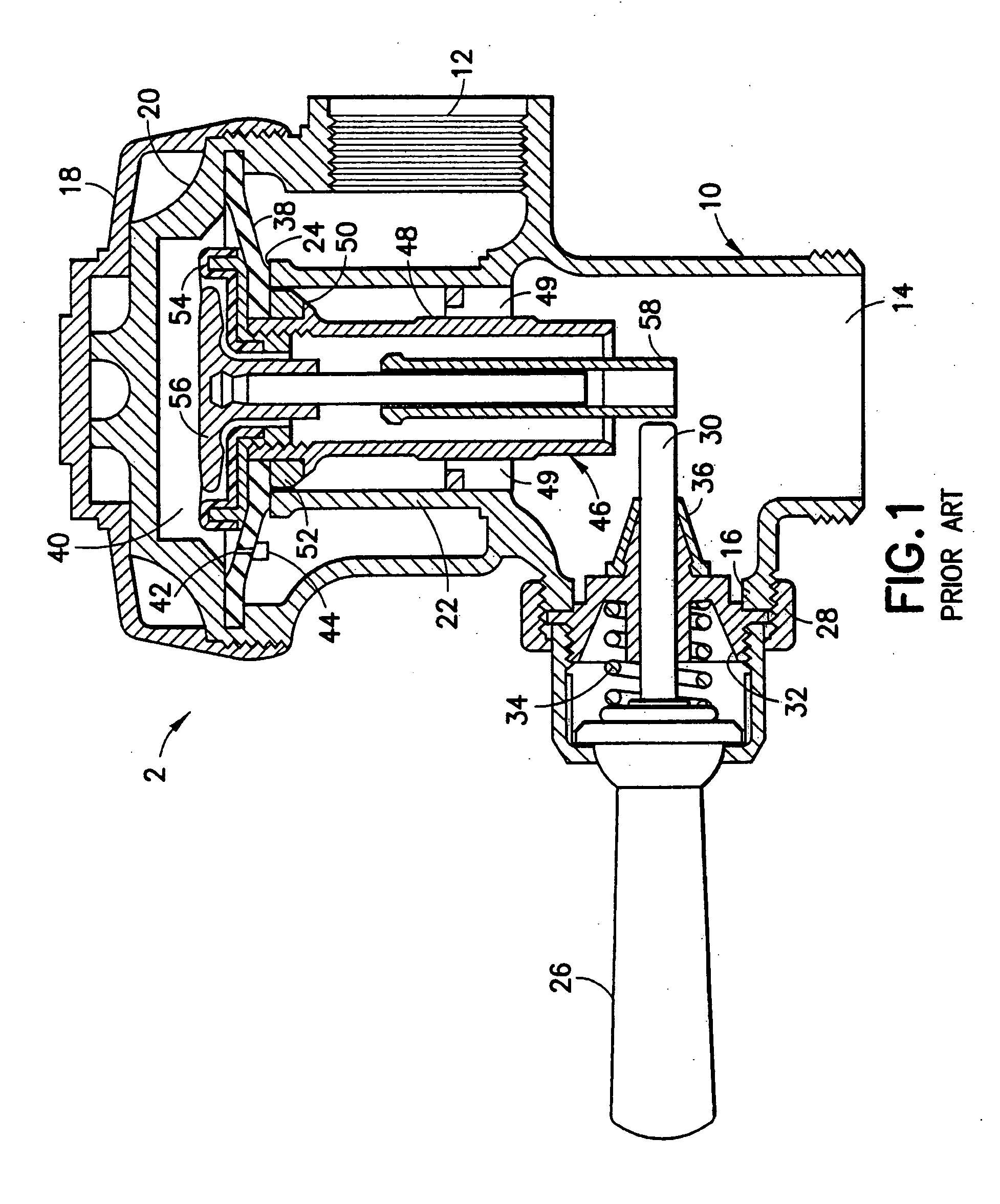

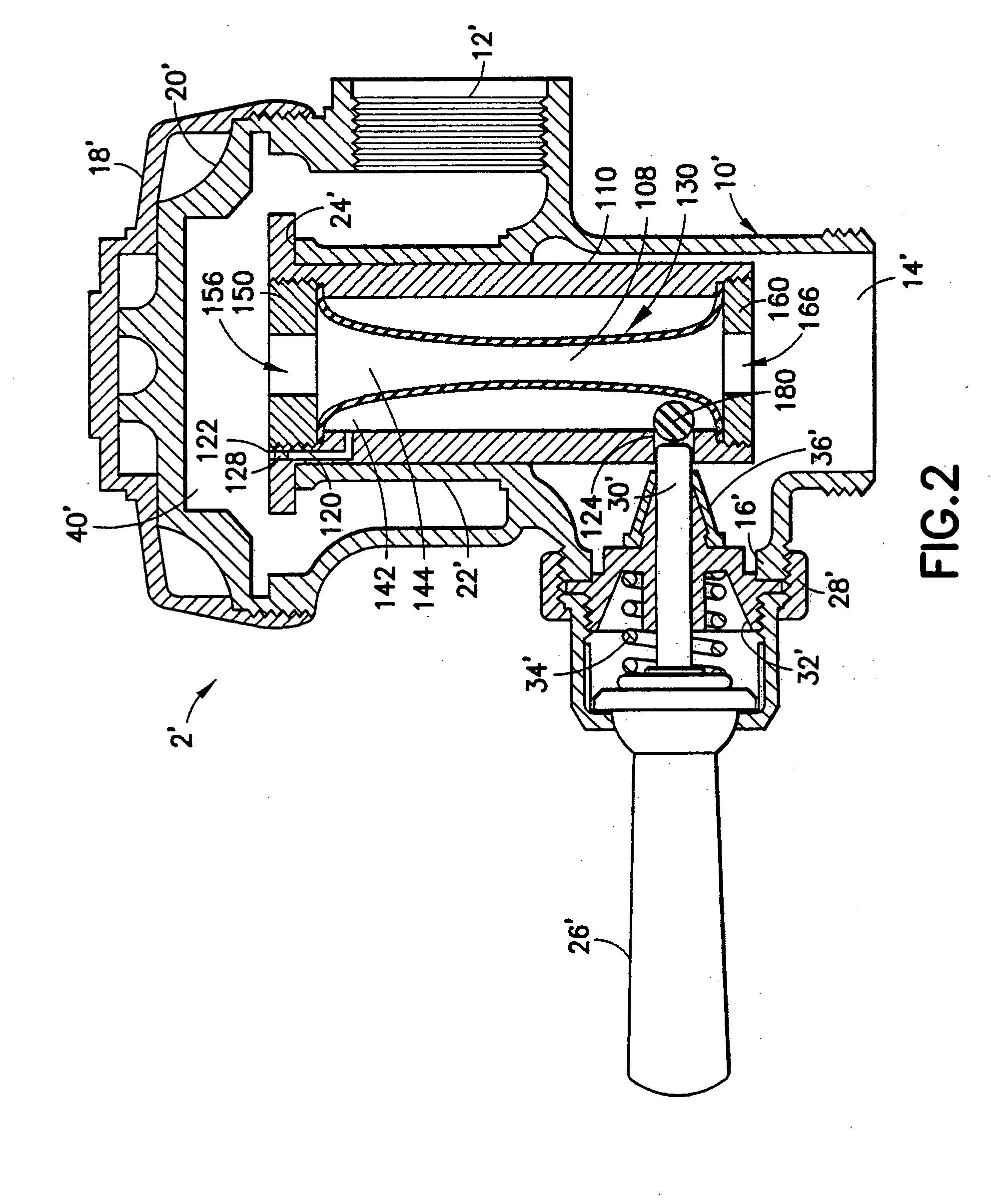

Pinch valve element for plumbing fixture flush valve

ActiveUS20050067590A1Reduce failure rateImproved cost efficiencyDiaphragm valvesOperating means/releasing devices for valvesPinch valveDiaphragm valve

The present invention discloses a pinch valve for replacing a diaphragm valve in a plumbing fixture. The plumbing fixture includes an inlet chamber defining a fluid inlet and in fluid communication with an inside chamber defining a fluid outlet. The pinch valve includes a cartridge member with a fluid inlet opening, a fluid outlet opening and a cartridge chamber defined by a cartridge chamber wall and in fluid communication with the fluid inlet opening and the fluid outlet opening. A flexible sealing member is positioned at least partially within the cartridge chamber and includes a wall with an inner surface defining an inner chamber and an outer surface defining an outer chamber between the outer surface of the flexible sealing member wall and the cartridge chamber wall. The inlet chamber of the plumbing fixture is in fluid communication with the inner chamber and the outer chamber.

Owner:SDB IP HLDG

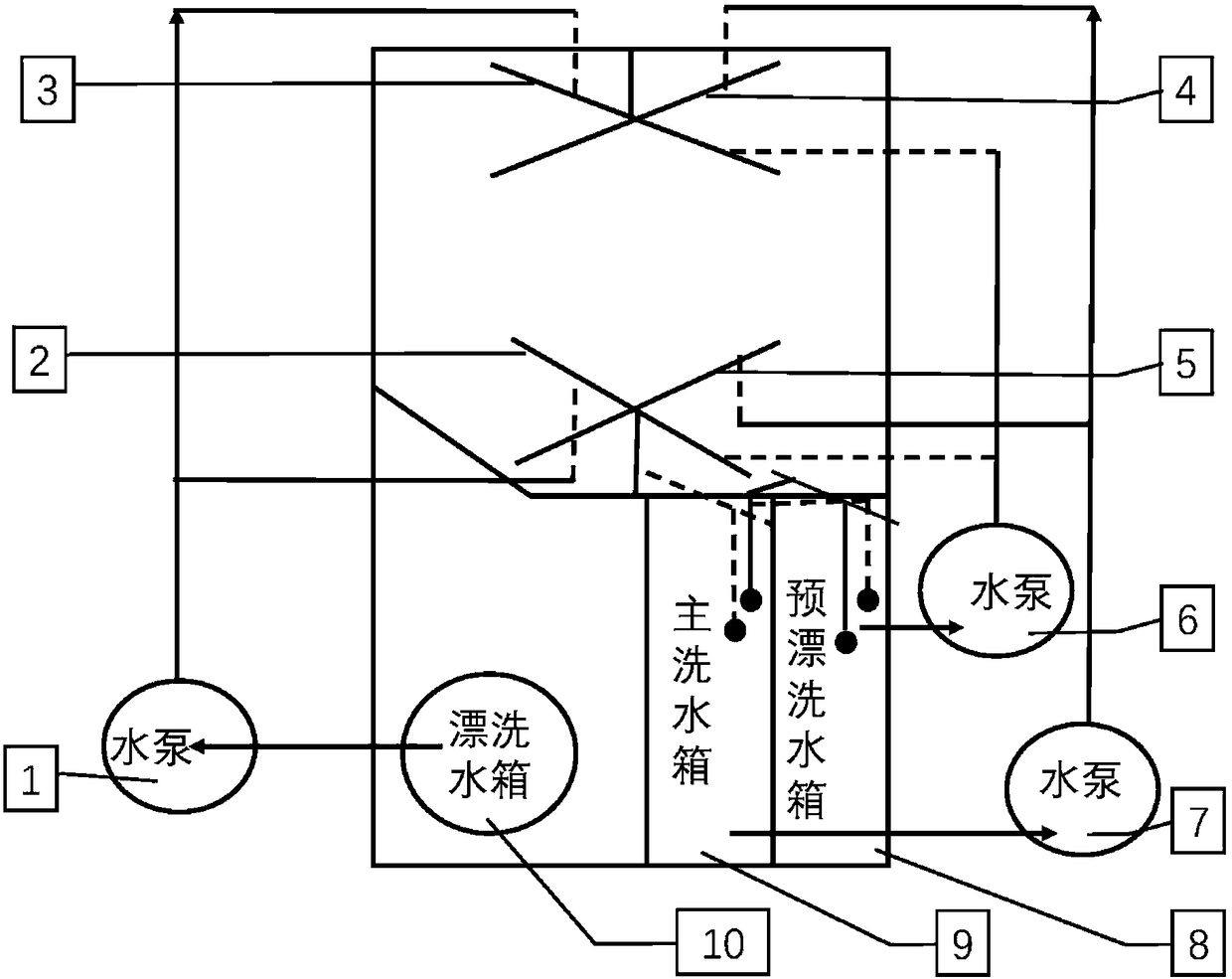

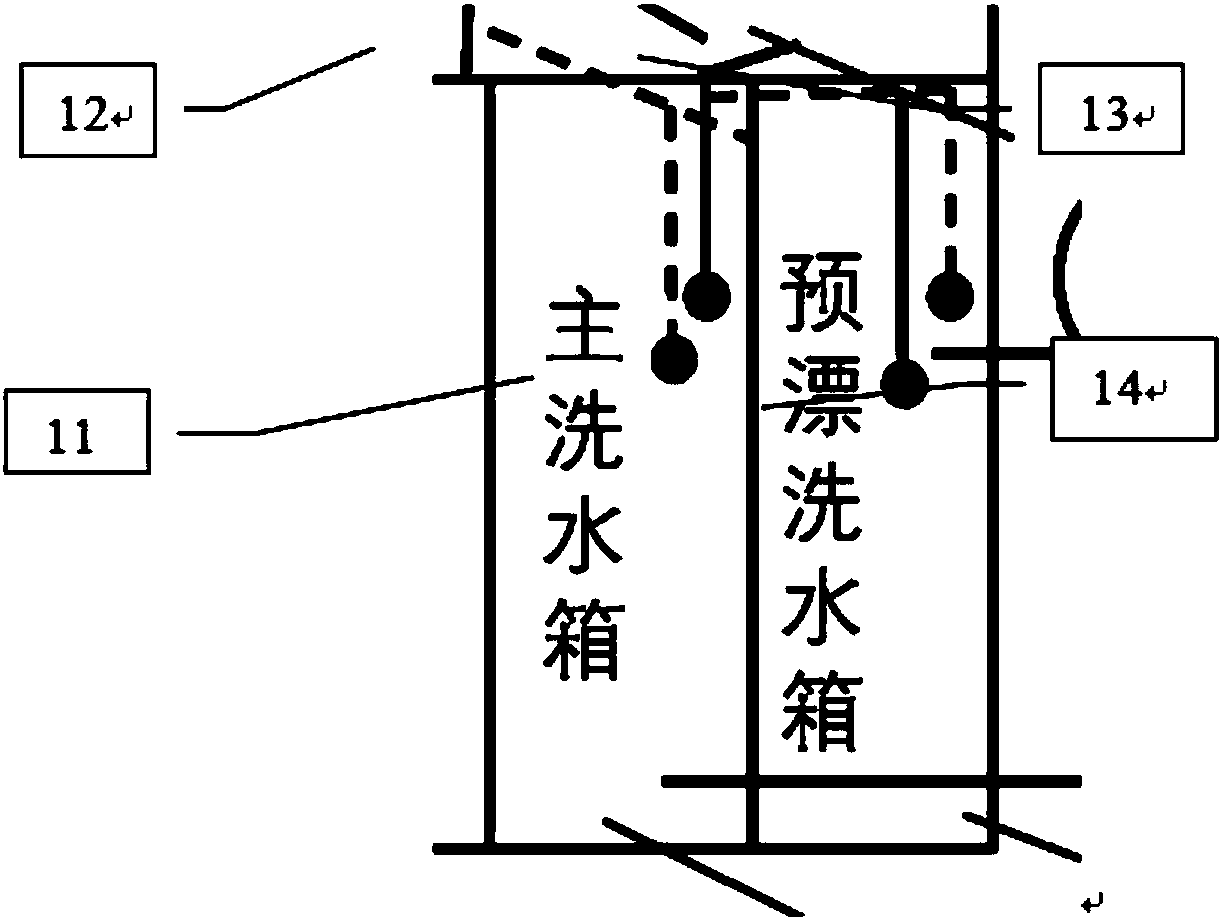

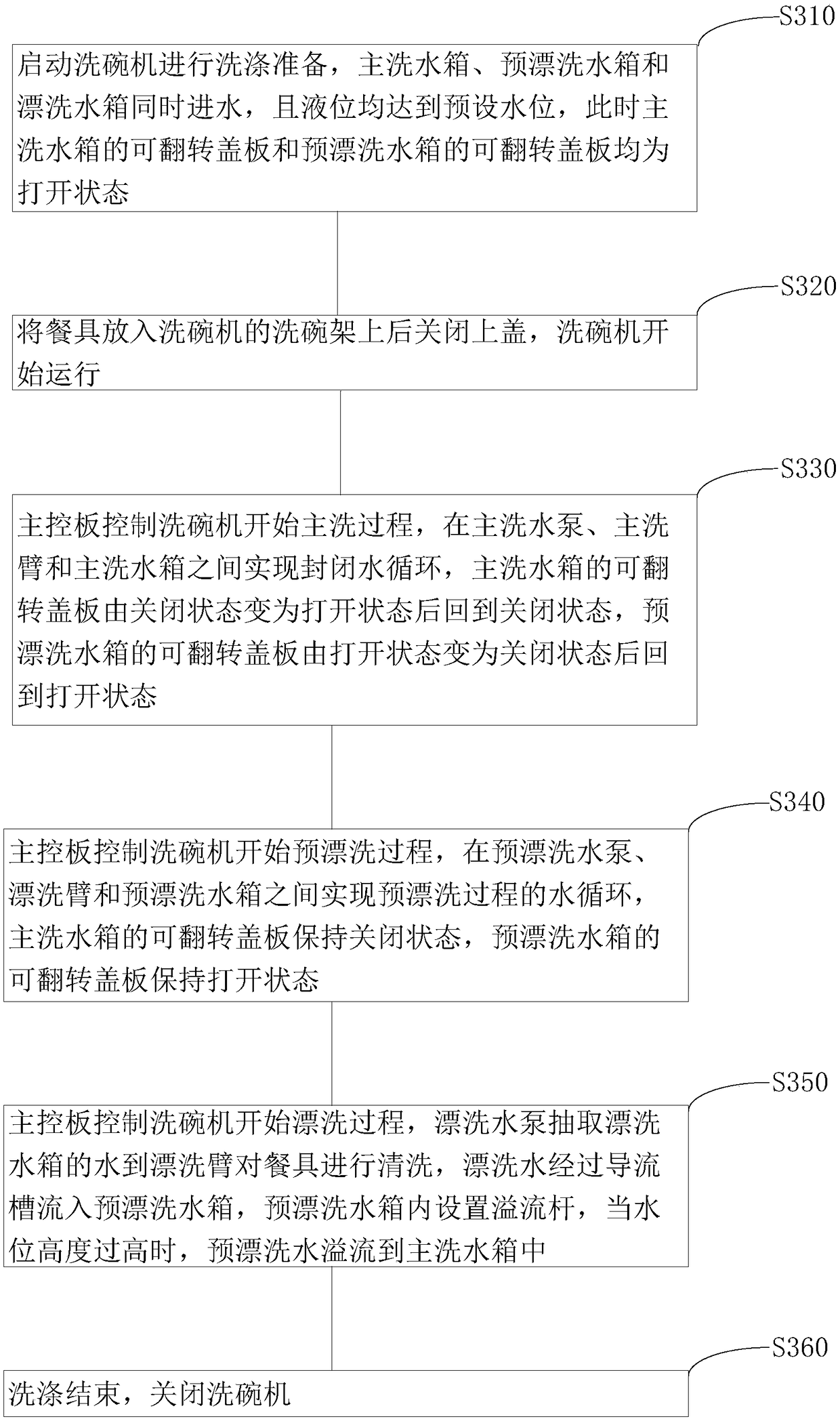

Rinsing water recycling device and method for commercial coverable dishwasher

PendingCN108185948AReduce rinse timeReduce water consumptionTableware washing/rinsing machine detailsWashing processesRinse waterWater flow

An embodiment of the invention provides a rinsing water recycling device and method for a commercial coverable dishwasher. The device comprises a main control board, a main washing water pump, a rinsing water pump, a pre-rinsing water pump, a main washing arm, a rinsing arm, a main washing water tank, a pre-rinsing water tank and a rinsing water tank; the main control board controls the main washing water pump to draw water; the water in the main washing water tank is drawn to the main washing arm to perform main washing spraying for dinnerware, the main washing water reflows to the main washing water tank; the main control board controls the pre-rinsing water pump to draw water, the water sprayed in last rinsing and stored in the pre-rinsing water tank is drawn to the rinsing arm, the water for last rinsing is recycled to perform pre-rinsing and spraying on dinnerware, and the pre-rinsing water reflows into the pre-rinsing water tank; the main control board controls the rinsing waterpump to draw water so that the water in the rinsing water tank is drawn to the rinsing arm to perform rinsing spraying on the dinnerware, and the rinsing water reflows into the pre-rinsing water tankfor storage. The rinsing water recycling device and method for the commercial coverable dishwasher have the advantages that the mechanical structure is simple, the design is reasonable, rinsing time is shortened, and water consumption and electricity consumption are reduced.

Owner:北京红岸水滴科技发展有限公司

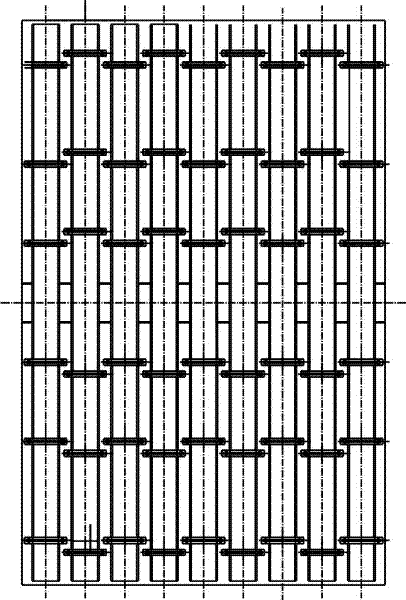

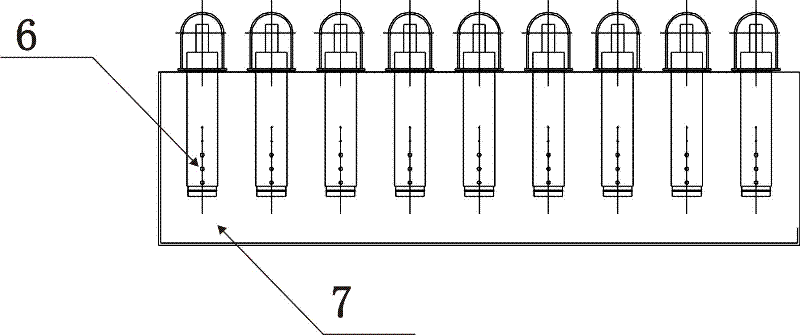

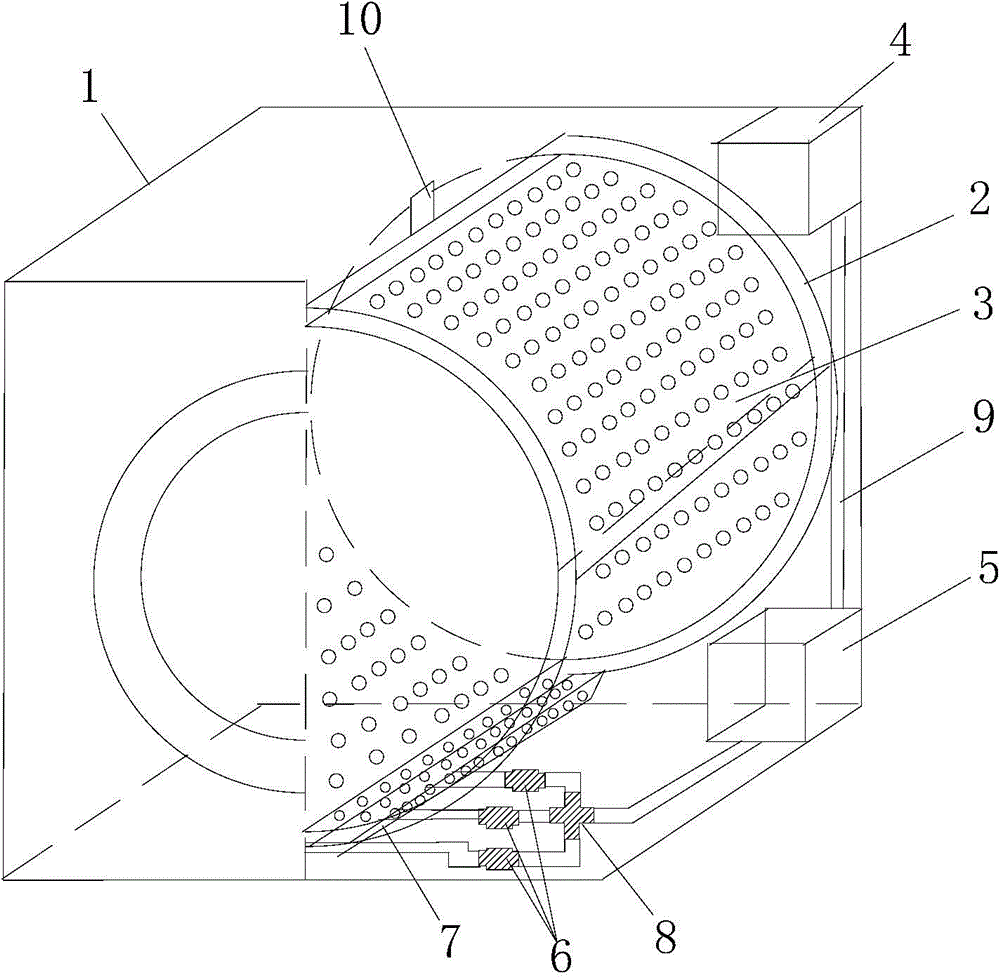

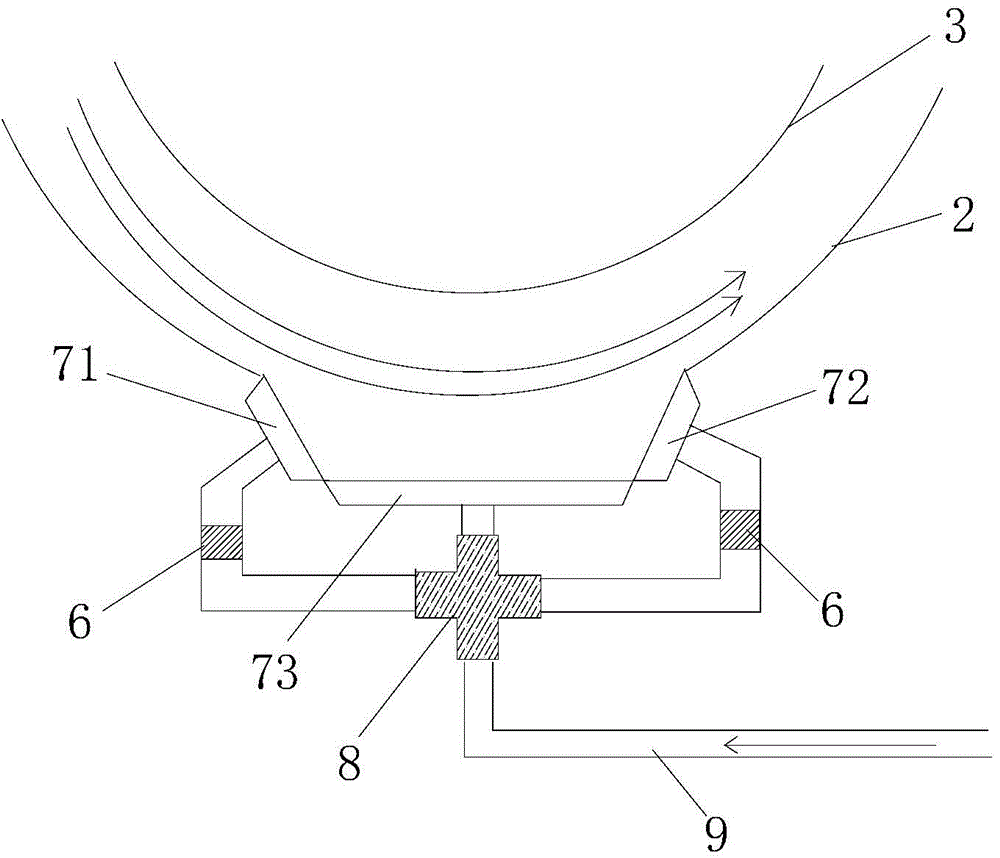

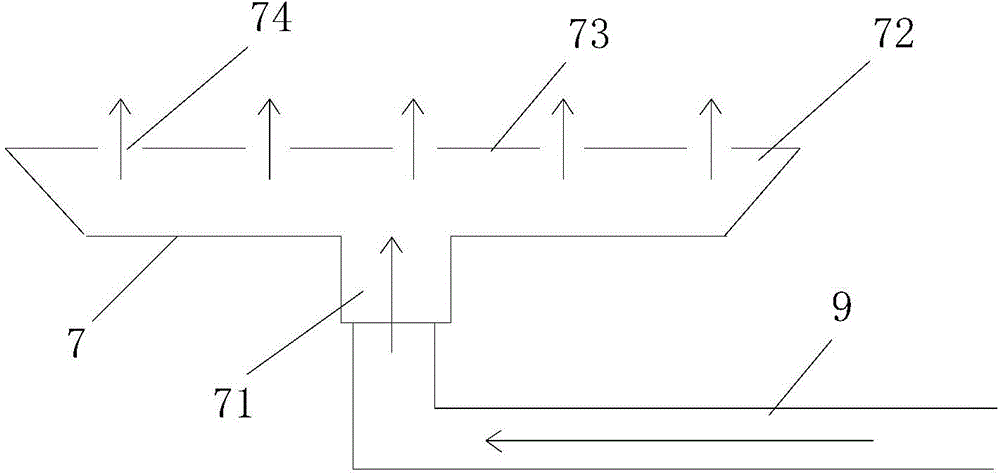

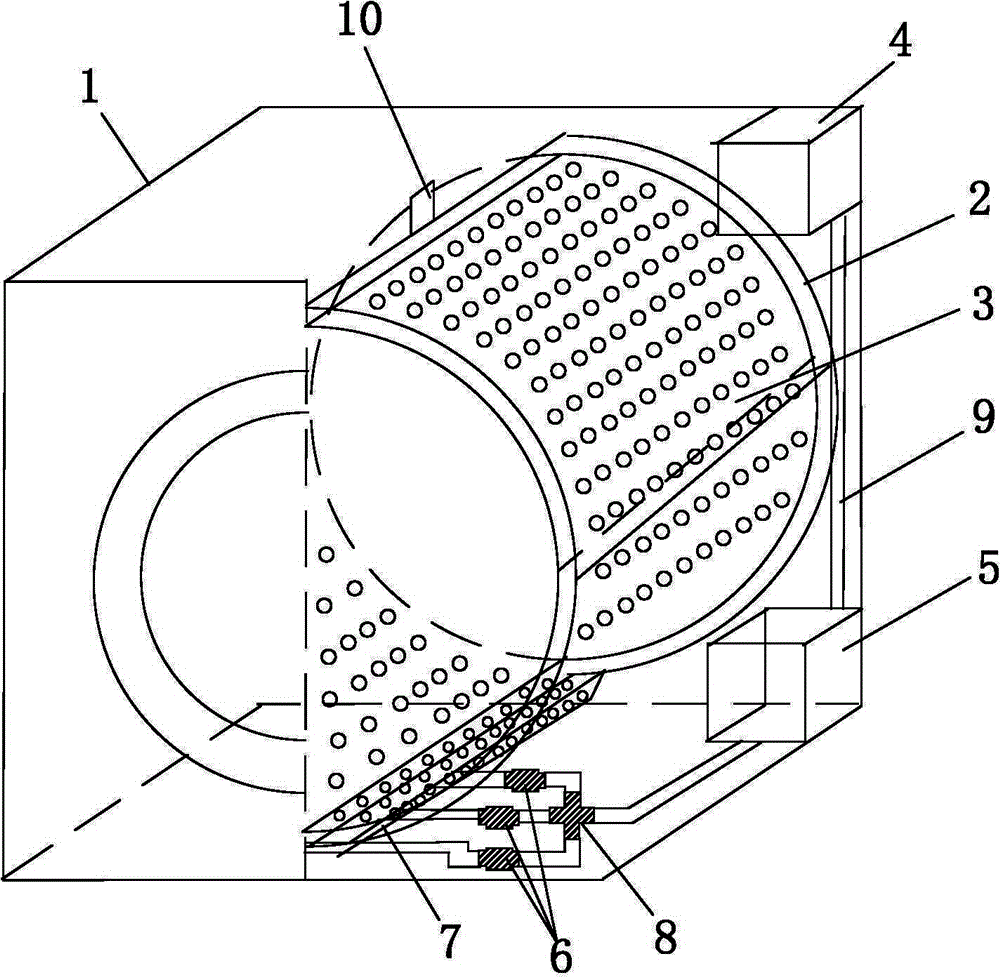

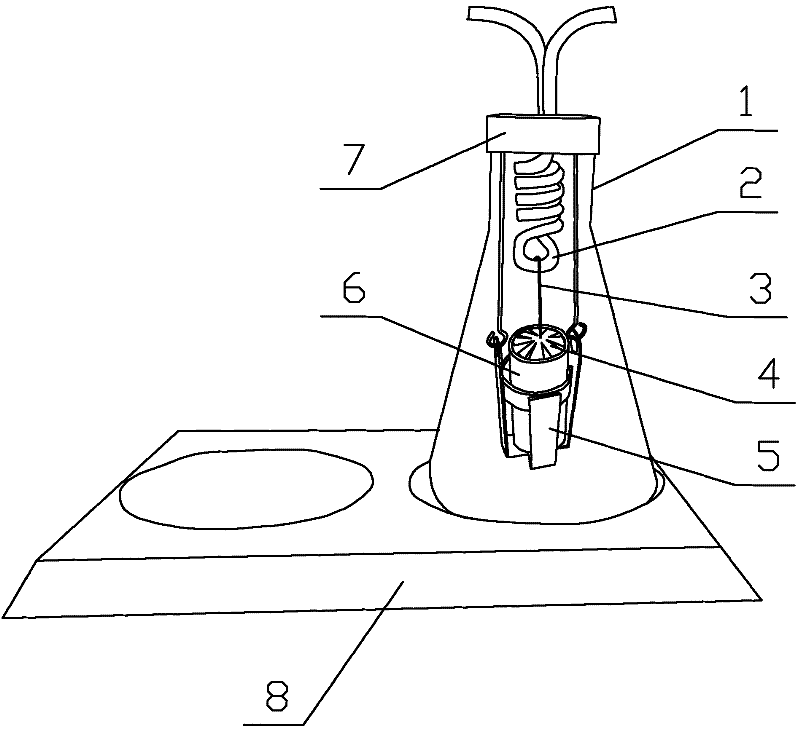

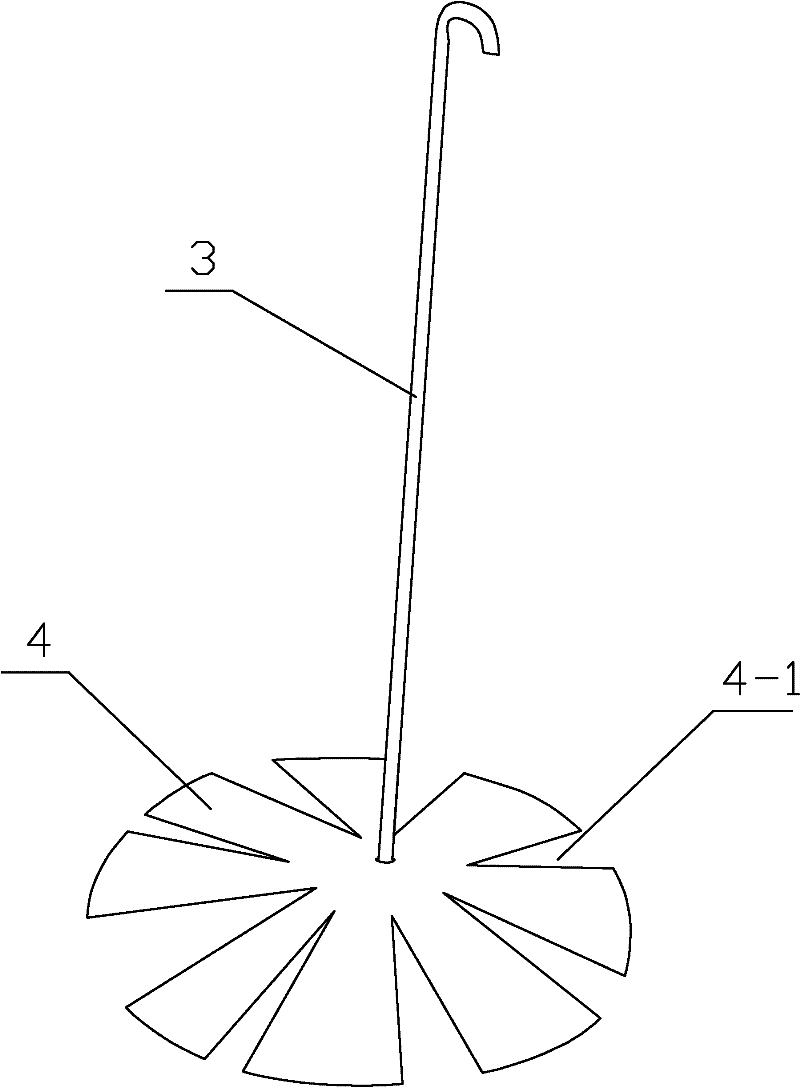

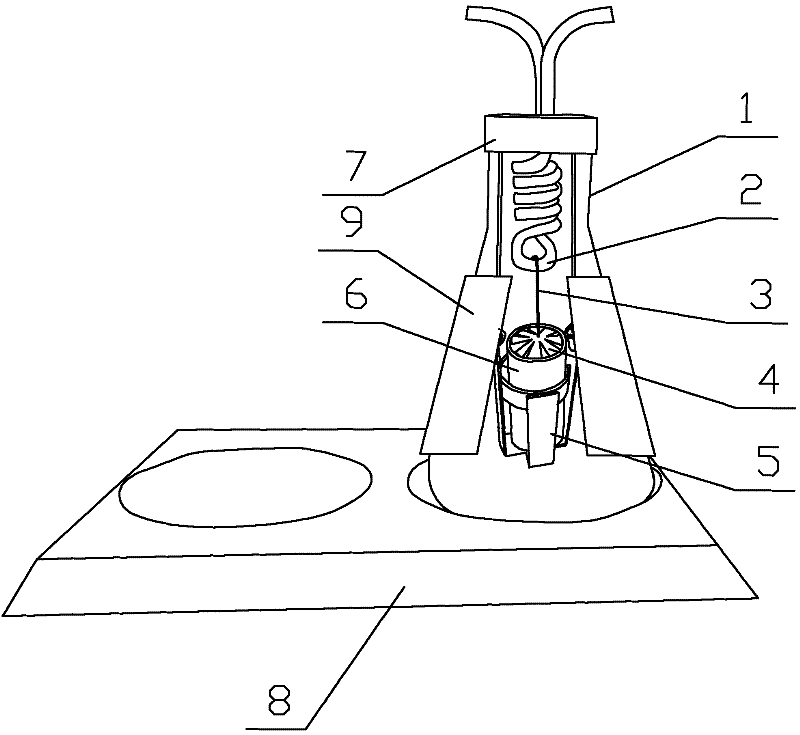

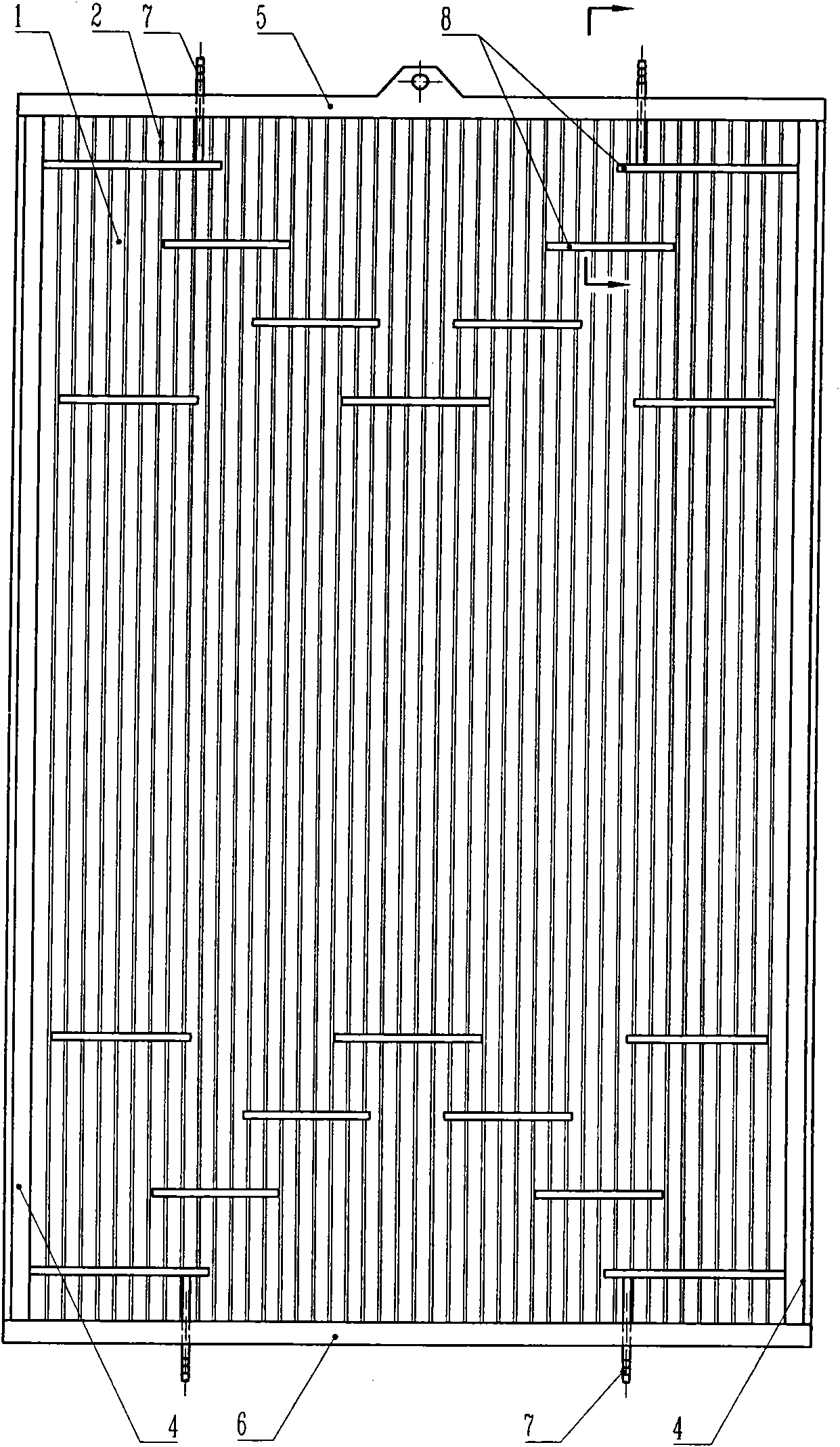

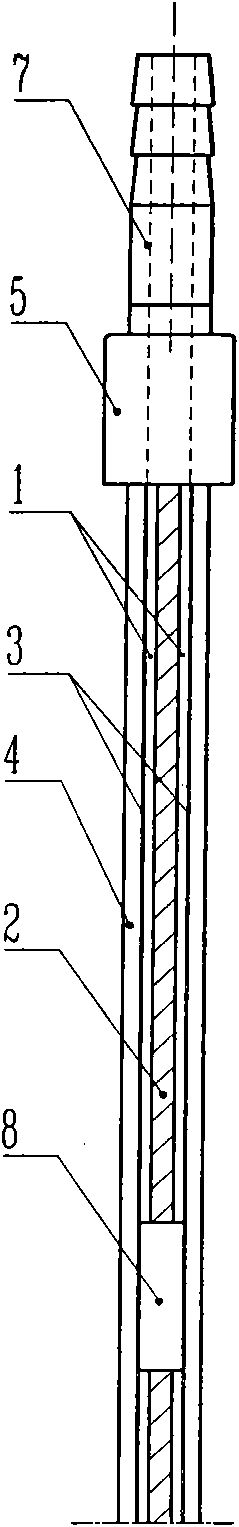

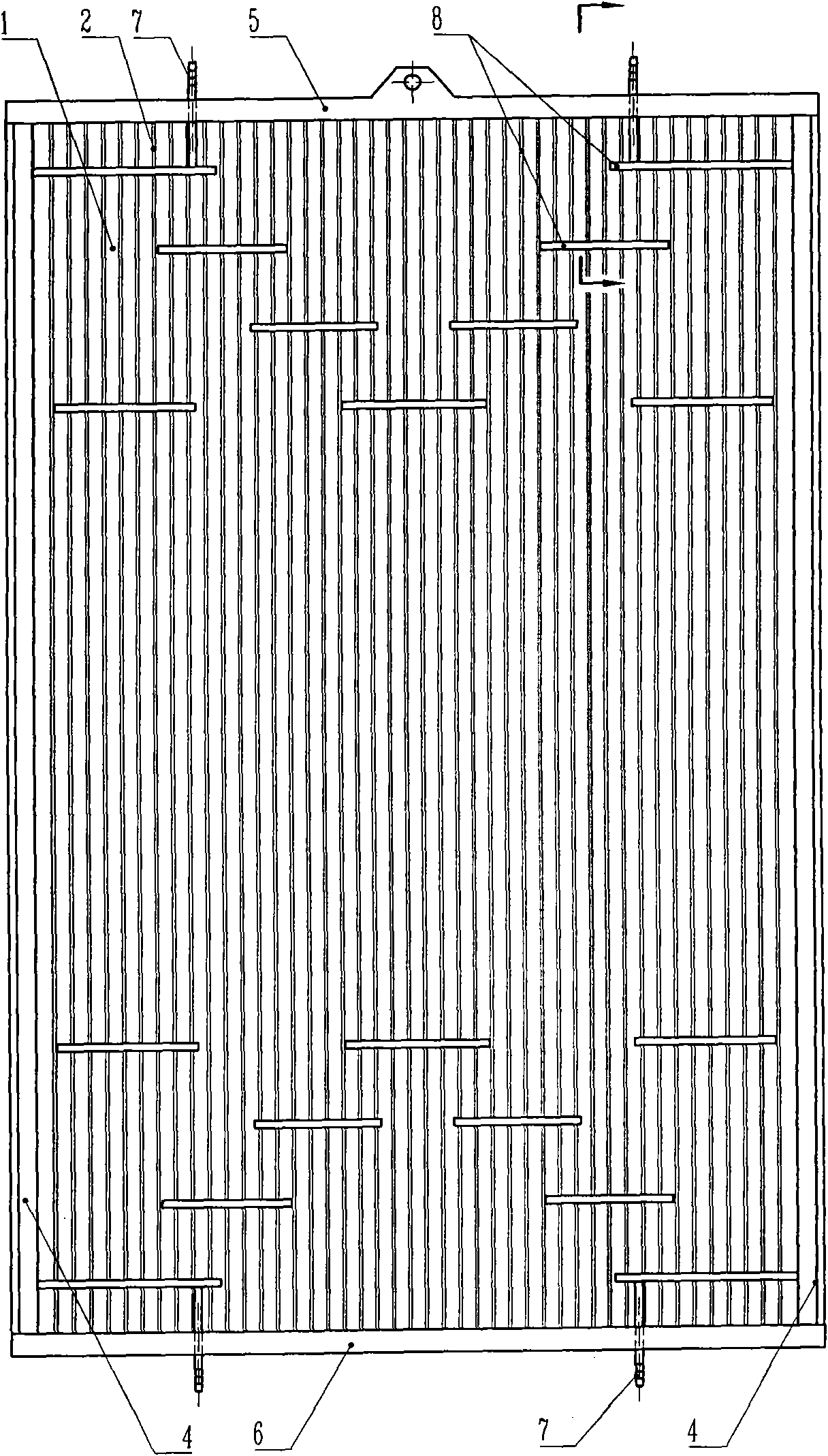

Novel submerged flat membrane element

ActiveCN101857302AEasy to backwashBackwashing is easySustainable biological treatmentBiological water/sewage treatmentBiochemical engineeringSewage treatment

The invention relates to a novel submerged flat membrane element, which comprises a middle support plate (2), wherein the two plate surfaces of the same plate are provided with a plurality of vertical guide channels (1); and the membranes (3) are arranged on the two surfaces of the middle support plate (2). The novel submerged flat membrane element is characterized in that: side compression bars (4) are arranged on the left and right sides of the middle support plate (2), and an upper end part (5) and a lower end part (6) are arranged on the upper and lower ends of the middle support plate (2) respectively; the upper end part (5) and the lower end part (6) are provided with two suction pipes (7) respectively; a plurality of water gathering channels (8) are formed on the middle support plate (2); and the membranes (3) are covered the outside of the water gathering channels (7). In the invention, four suction pipes adopted are favorable for the backwash of the membranes when the membranes are used for a period of time; the novel submerged flat membrane element has the characteristics of easy water outflow, large effective processing area, large flow and the like, improves the effective efficiency of aeration, reduces washing time and saves energy; the membranes can reach 2.5 meters at most; and the occupied area is smaller on the premise of identical sewage treatment amount.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

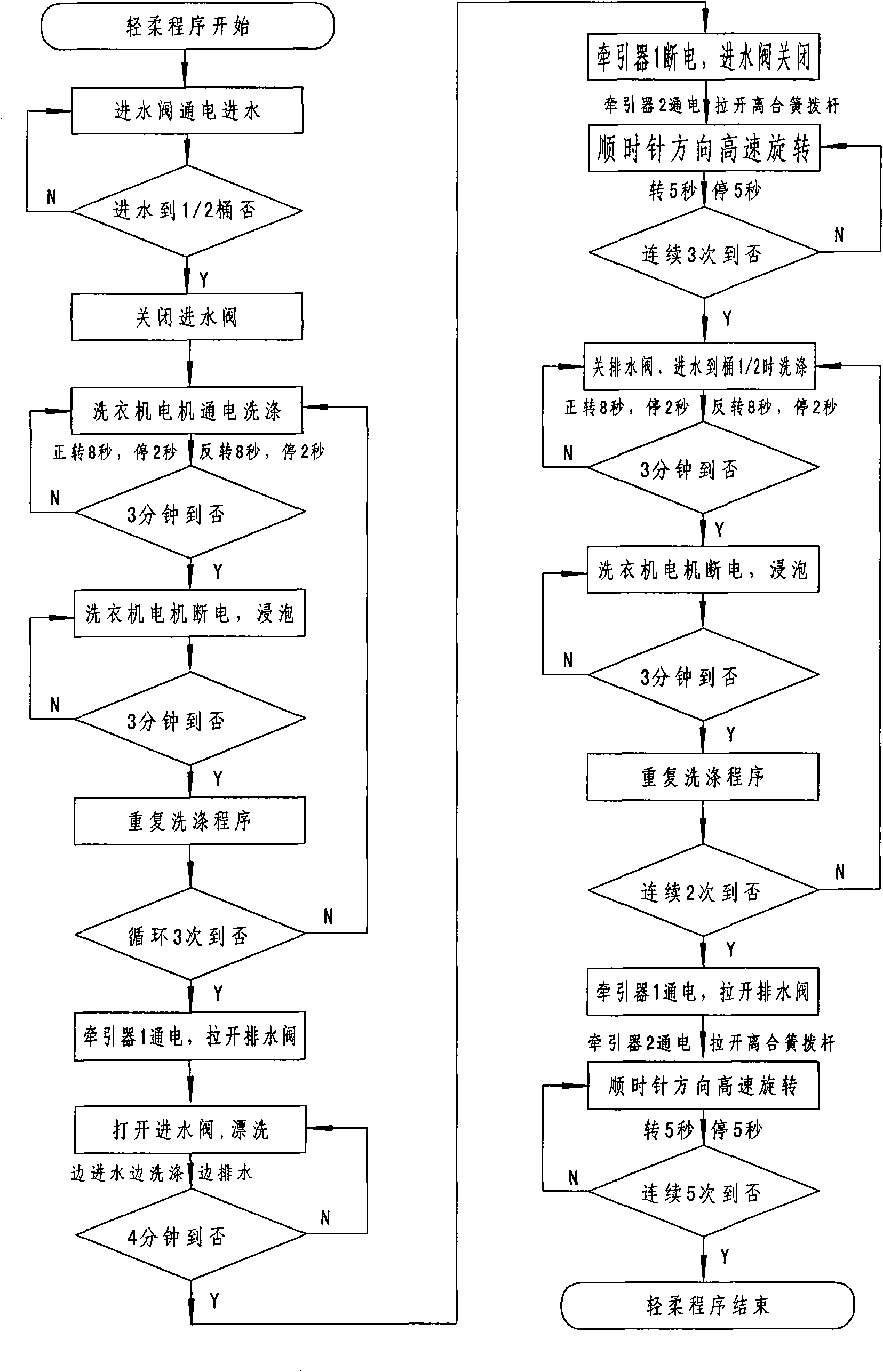

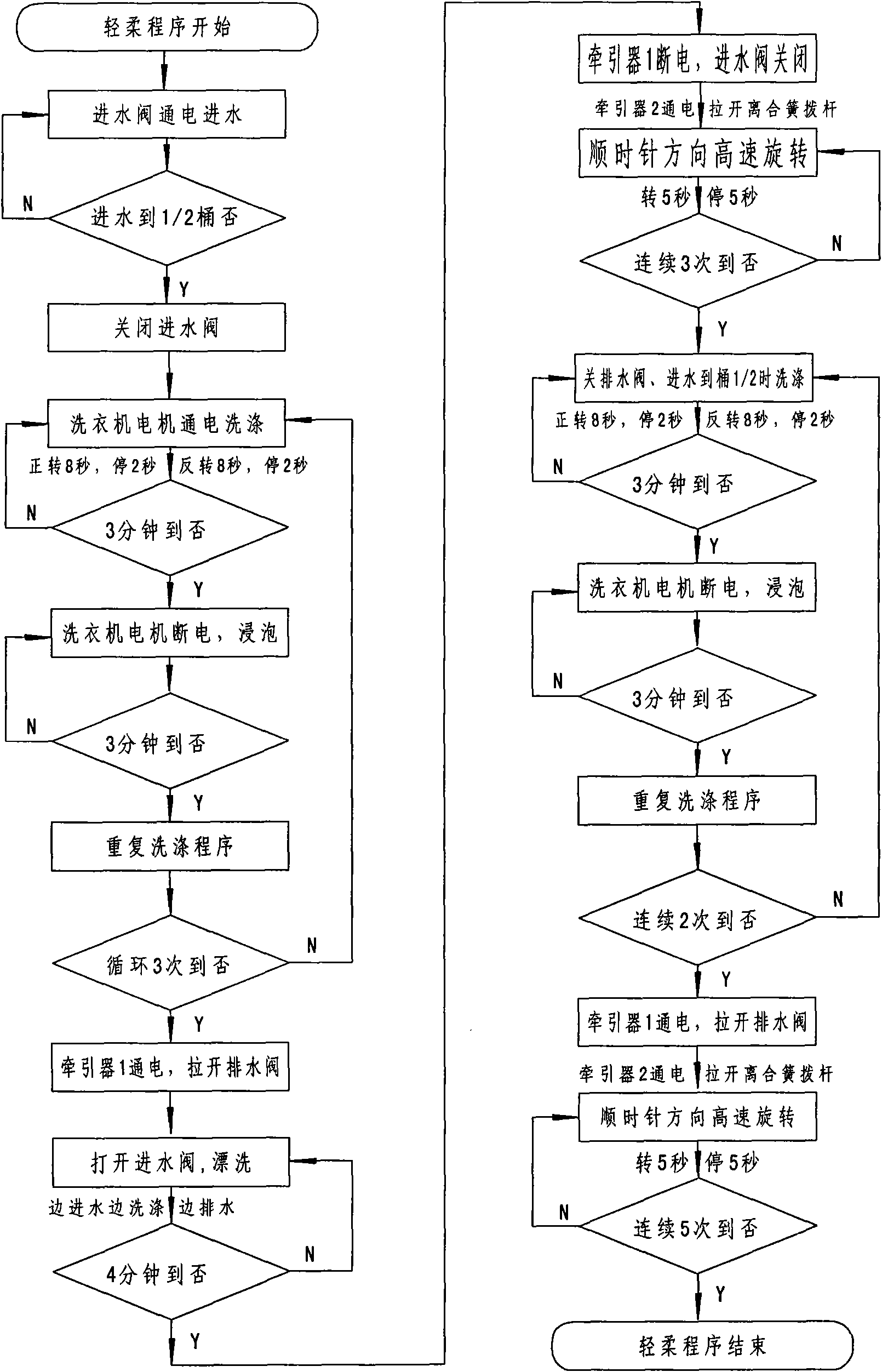

Soft cleaning program control method for washing machine

InactiveCN101935935AWash fully and gentlySoak wellOther washing machinesControl devices for washing apparatusWater resourcesInlet valve

The invention discloses a soft cleaning program control method for a washing machine, and relates to the technical field of circuit control of the washing machine. The method comprises a water feeding program, a washing program, a rinsing program and a dehydration program, and is characterized by comprising the following steps of: turning on a water inlet valve power supply; and electrifying a motor of the washing machine to start washing work when fed water reaches a set water level. Because a washing and soaking program method is adopted, clothes are excellently softened and soaked and dirt are easily removed, and the washing machine is effectively utilized, so electric energy is saved and service life of the washing machine is greatly prolonged; when the washing of the washing machine is ended, water feeding, washing and water discharging are simultaneously performed after the washing water is discharged; and thus the dirt washed off the clothes can be immediately discharged out of the washing machine without polluting the clothes again, the clothes can be easily rinsed, and the rinsing time and the water resource are saved.

Owner:ANHUI JULONG TRANSMISSION TECH

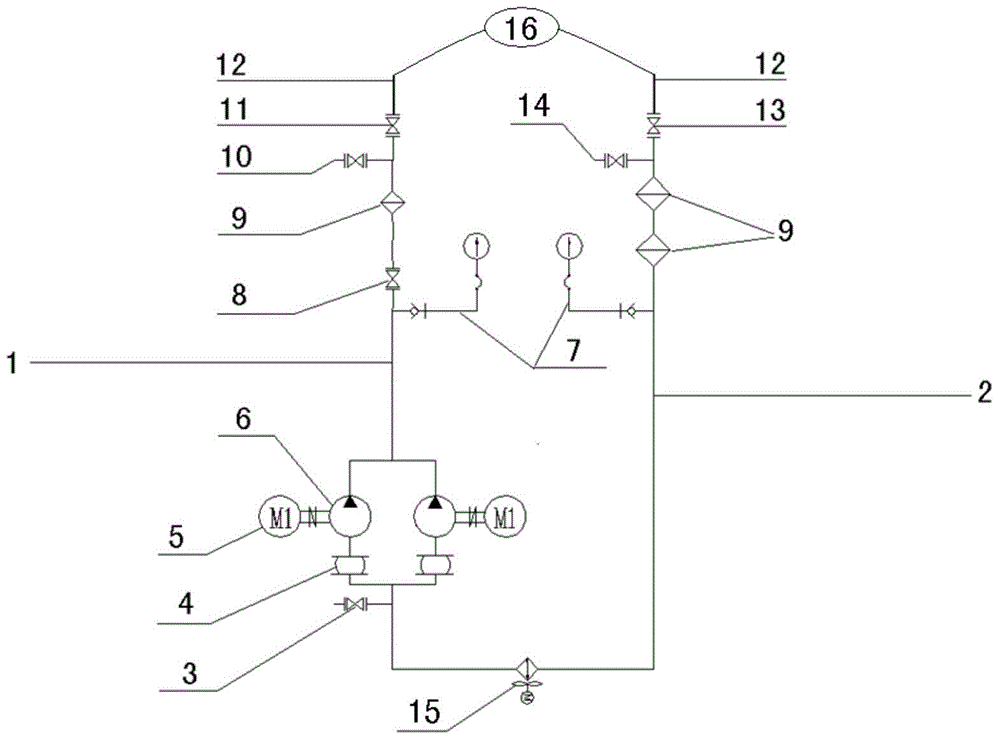

Closed type recycle washing device for pipeline of hydraulic system

InactiveCN104907294AReduce dosageRealize full circulationHollow article cleaningEngineeringHydraulic pressure

The invention discloses a closed type recycle washing device for a pipeline of a hydraulic system. The closed type recycle washing device comprises an oil washing pipe (1), an oil return pipe (2), a to-be-washed system (16), motors (5) and oil pumps (6); the oil washing pipe (1) is provided with the oil pumps (6) which is driven by the motors (5), the output ends of the oil pumps (6) are sequentially connected with pressure gages (7), a ball valve (8), filters (9), a ball valve (10) and a ball valve (11); the ball valve (11) is connected with one end of the to-be-washed system (16) through oil-resistant rubber hoses (12); the oil return pipe (2) sequentially passes through a ball valve (13), a ball valve (14), the filters (9), the pressure gages (7), an air cooler (15) and a ball valve (3) to be communicated with the input ends of the oil pumps (6); the ball valve (3) and the ball valve (10) are arranged on the side face of the oil washing pipe (1), and the ball valve (14) is arranged on the side face of the oil return pipe (2). The closed type recycle washing device has the advantages that the oil capacity used for washing is saved, the oil washing time is saved, the oil washing efficiency is improved, the on-site arrangement and conveying are convenient, the structure is simple, and the cost is saved.

Owner:TIANJIN 20 CONSTR

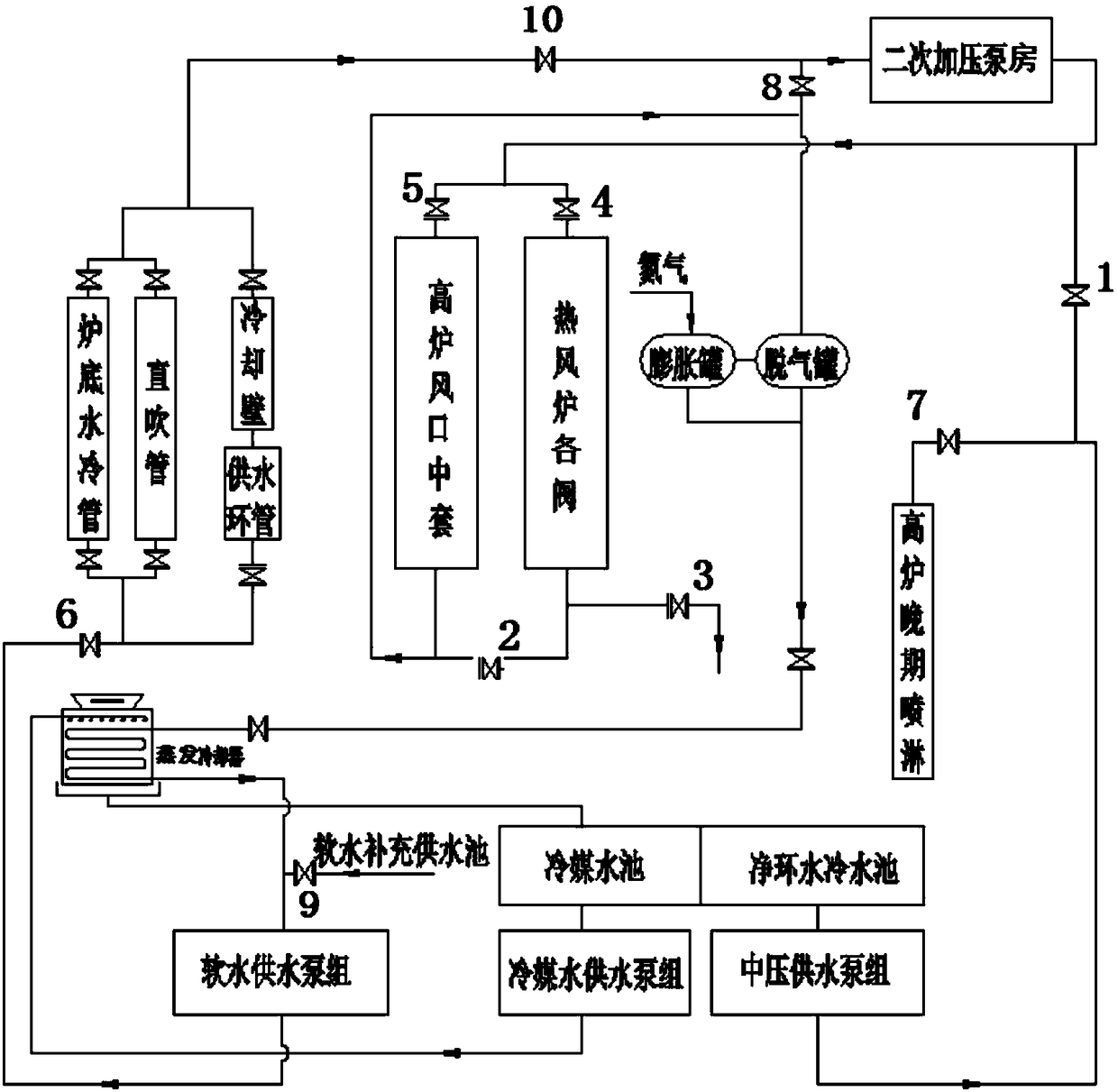

Air heating furnace cooling water supply system and control method

ActiveCN108193009ACooling does not affectIncrease usageBlast furnace detailsCooling devicesEngineeringBlast furnace

The invention discloses an air heating furnace cooling water supply system and a control method, and belongs to the field of ferrous metallurgy. The air heating furnace cooling water supply system comprises multiple air heating furnace valves, an intermediate pressure water supply pump set and a secondary booster pump chamber. A switching valve I and a connecting pipe are arranged on a soft waterpipeline output from the secondary booster pump chamber. Communicated soft water pipeline branches enter the air heating furnace valves and a blast-furnace tuyere medium sleeve. A three-way pipe is arranged on soft water pipelines output from the air heating furnace valves, soft water sequentially flows through a water inlet pipe and a water outlet pipe of the three-way pipe, a branch pipe is connected with a drainage pipe of the three-way pipe, and a switching valve III is arranged on the drainage pipe. A switching valve II is arranged on the soft water pipeline connected with the water outlet pipe. According to the air heating furnace cooling water supply system and the control method, the air heating furnace valves and cooling water of blast furnace equipment can be connected together and can operate independently, it is guaranteed that a blast furnace can carry out cooling wall piping when the air heating furnace valves are cooled, washing water can be fast provided during blast furnace cooling wall washing, and even cooling of the air heating furnace valves is not influenced during blast furnace staying maintenance.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Fully-automatic fish fresh preparation device and method

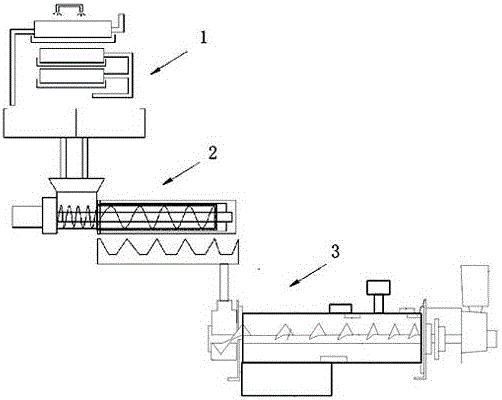

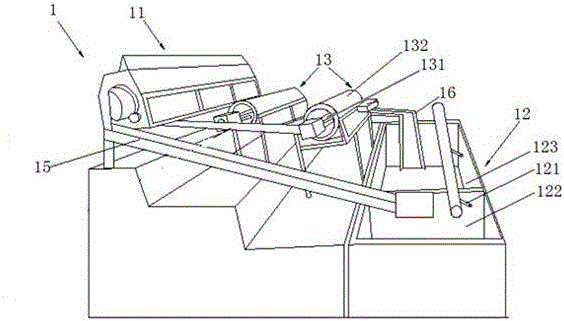

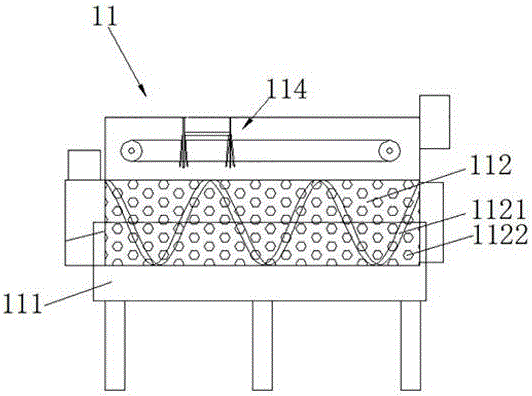

The invention relates to a fully-automatic fish fresh preparation device and method. The preparation device comprises a rinsing device, a fine filtering device and a dewatering device which are communicated with one another in sequence; the rinsing device comprises a rotary screen, a rinsing tank and a filtering roller; a spray head is arranged above the rinsing tank; the rinsing tank comprises a first rinsing tank and a second rinsing tank; the rotary screen conveys fish flesh to the first rinsing tank through an oblique slideway; the filtering roller conveys the fish flesh to the second rinsing tank through an L-shaped slideway; the rotary screen comprises a water tank, a hollow rotating drum is arranged in the water tank, a spiral convex channel is formed in the inner wall of the rotating drum, and water outlets are densely formed in the surface of the rotating drum; the bottom of the water tank is communicated with the filtering roller through a water pipe; a water spray device is arranged above the rotary screen; the filtering roller comprises a rotating shaft and a roller body wrapped with filter cloth.

Owner:ZHOUSHAN TENGXIN FOOD CO LTD

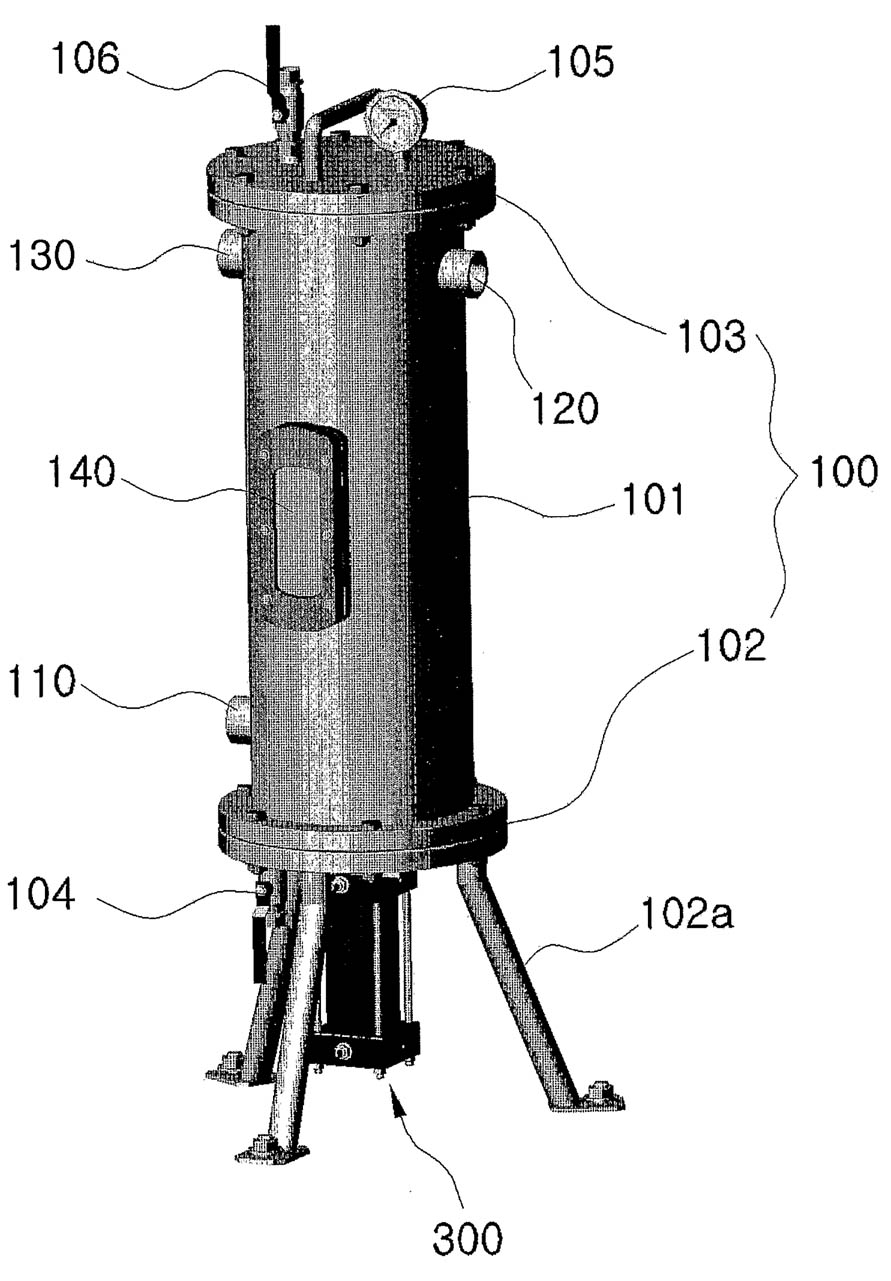

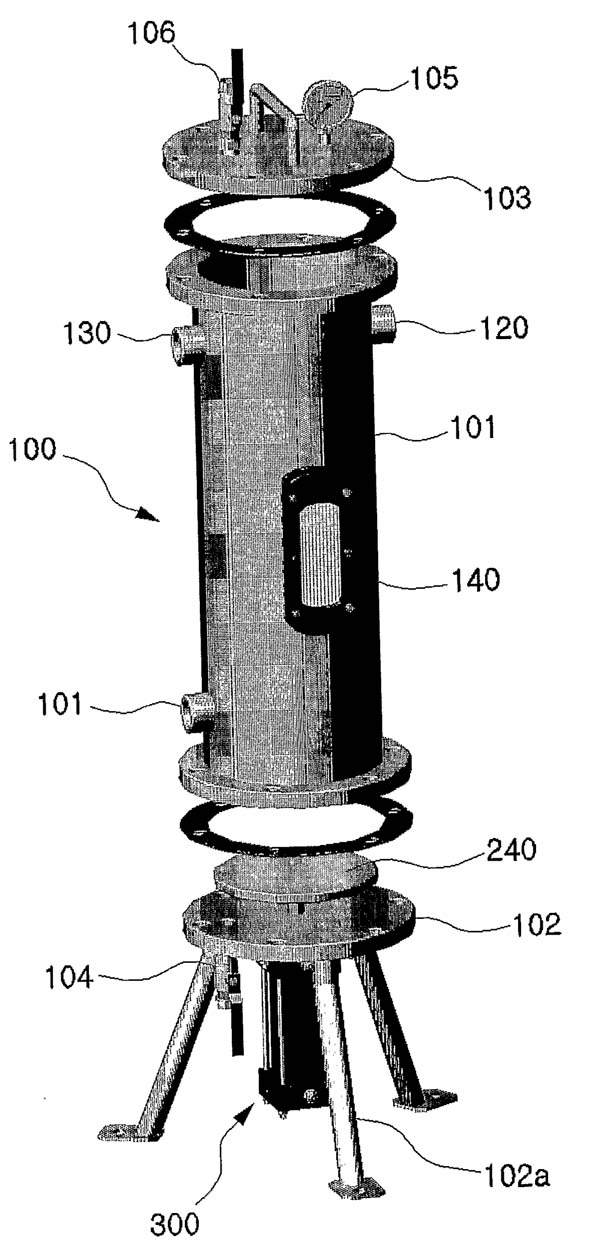

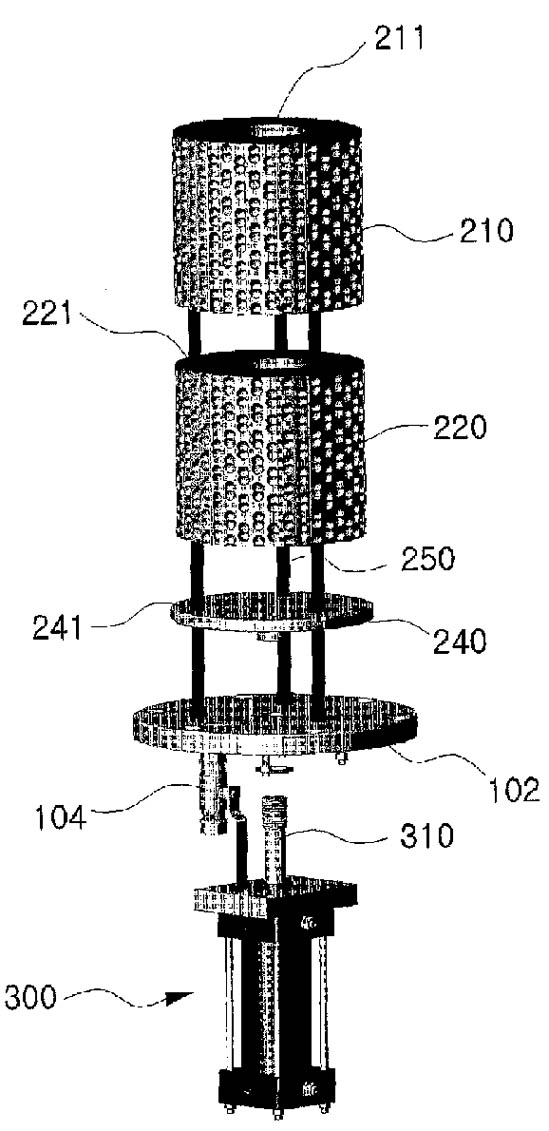

Filtration device having variable filter

InactiveCN101959570AAvoid distortionEasy to manufactureMembrane filtersStationary filtering element filtersFiltrationStructural engineering

Disclosed is a filtration device having a variable filter according to the present invention including a cylindrical housing 100; a plurality of cylindrical filters 210 and 220 which are serially disposed in the housing 100; an upper supporting plate 230 for supporting an upper side of the uppermost filter 210; a compressing plate 240 for supporting a lower side of the lowermost filter 220; a supporting rod 250 which is fixed to the upper supporting plate 230 and an lower end of the housing 100 and installed to pass through the filters 210 and 220; and a compressing means 300 which lifts up or down the compressing plate 240 so as to control pores of the filters 210 and 220 when filtering raw water.

Owner:郑守焕

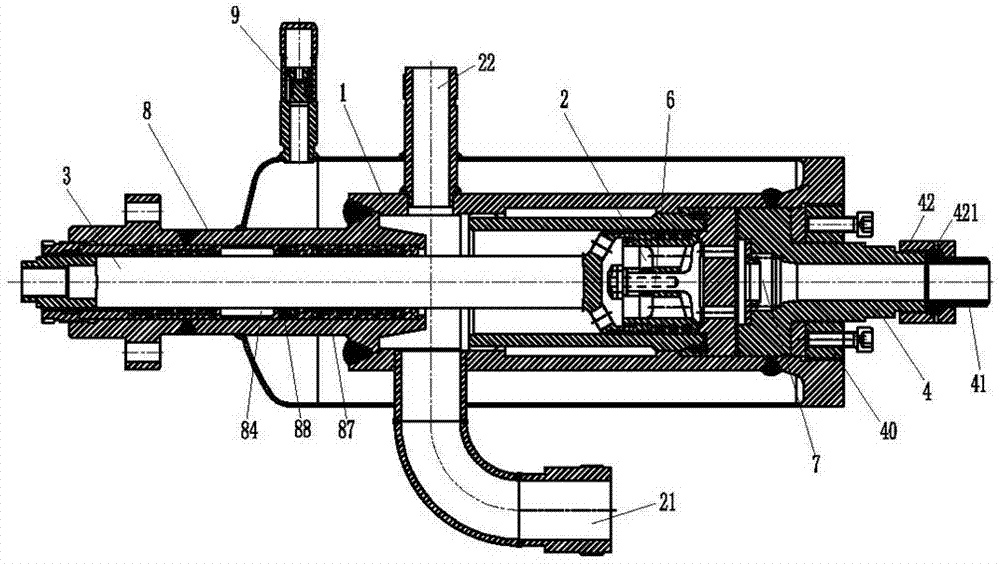

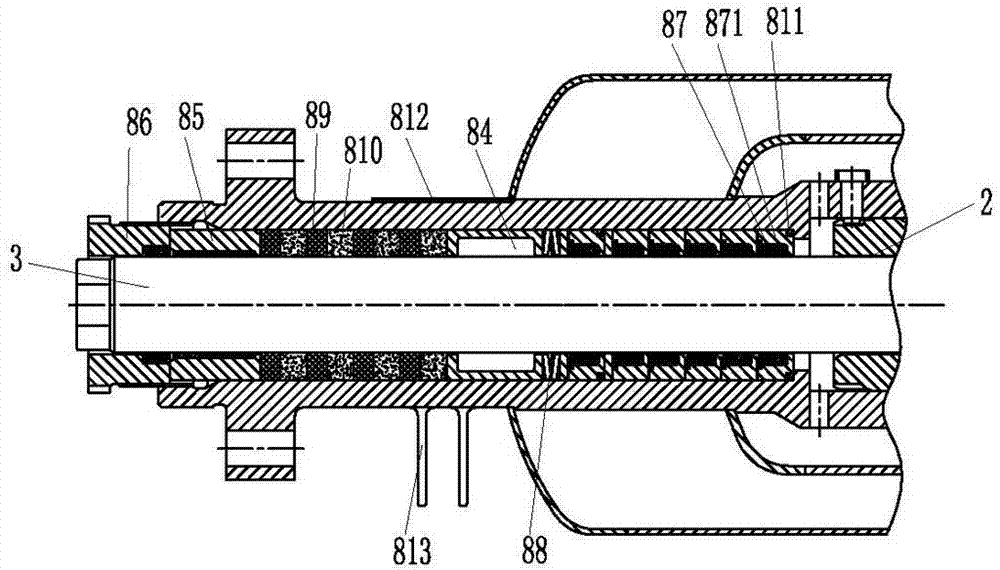

High purity ammonia low temperature reciprocating pump

ActiveCN103485995AGuaranteed purityReduce pollutionPositive displacement pump componentsPumpsEngineeringMechanical engineering

The invention relates to low temperature reciprocating pumps, in particular to a low temperature reciprocating pump for producing electronic grade high purity ammonia required in the industries of electronics, chemistry, metallurgy, steel and the like and conveying non-pollution high purity ammonia required in scientific research. The reciprocating pump comprises a bump body, an inner cylinder is arranged in the pump body, the inner cylinder is communicated with an inlet and an air return port, a liquid input valve is arranged at one end of the inner cylinder, the other end of the inner cylinder is provided with a liquid output valve corresponding to the liquid input valve, a piston rod is further arranged on one side, close to the liquid input valve, of the pump body, the inner wall, enclosing the piston rod, of the pump body is provided with a seal assembly, a liquid output flange is on the pump body and located on one side of the liquid output valve, the liquid output flange is connected with a liquid output connection pipe, the connecting position of the liquid output connection pipe and the liquid flange and is fixedly connected through a cap nut, a vacuum protection valve is further arranged on a casing of the pump body close to one side of the inner cylinder, and the requirement for conveying and pressurizing the electronic grade high purity ammonia is met.

Owner:HUZHOU SANJING CRYOGENIC EQUIP

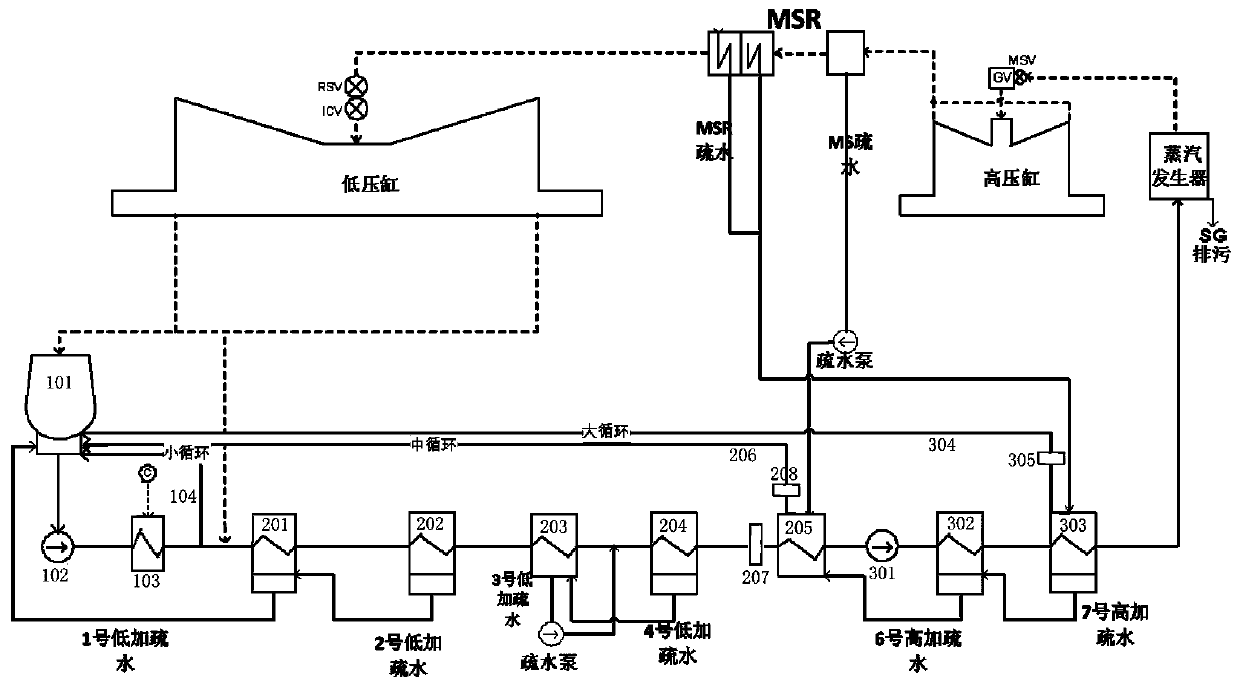

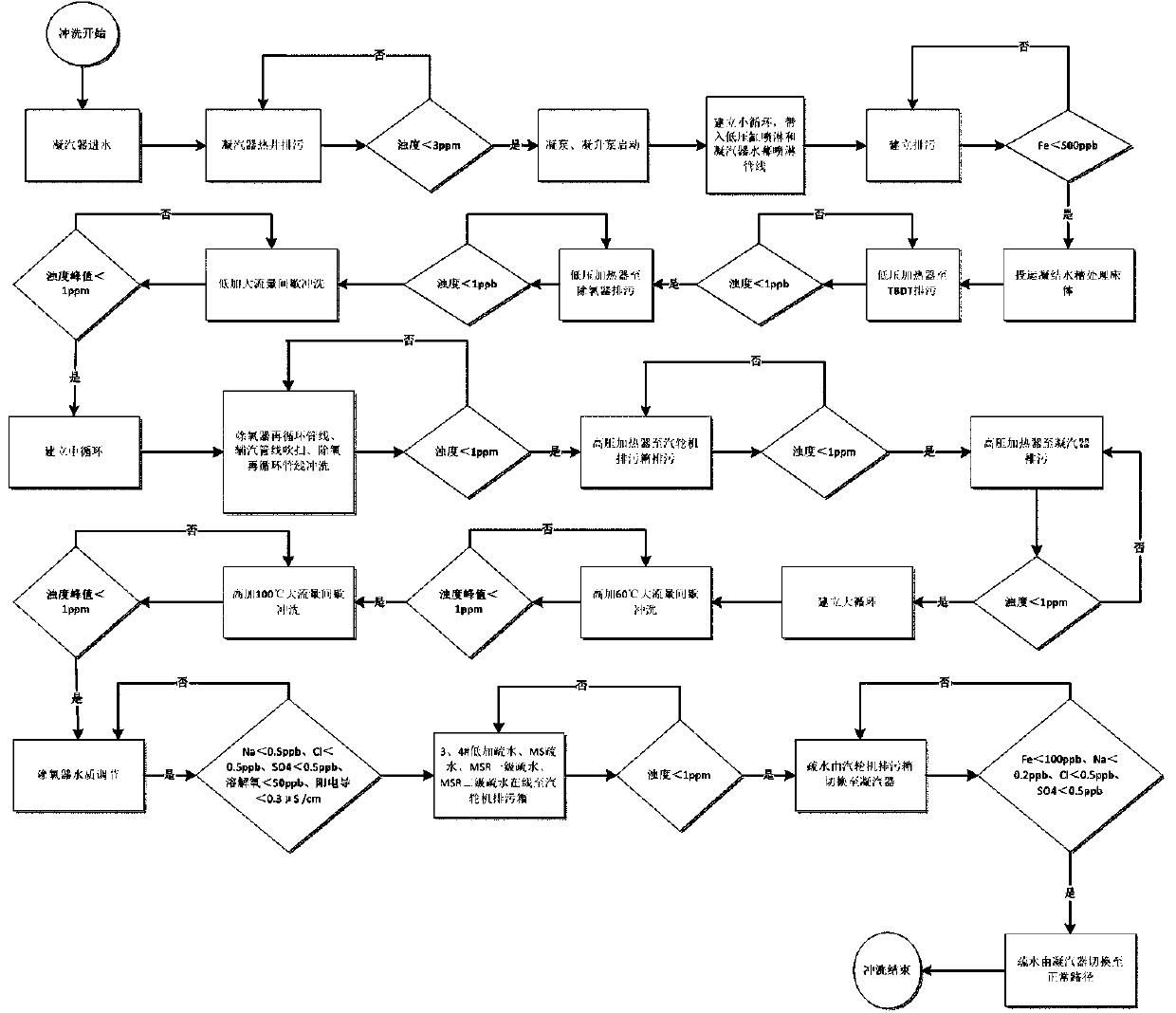

Nuclear power plant start secondary circuit flushing method

InactiveCN111550764AReduce consumptionReduce discharge pressureLiquid degasificationNuclear energy generationNuclear plantRinse water

A nuclear power plant start secondary circuit flushing method comprises the steps of small cycle flushing, medium cycle flushing and large cycle flushing started in sequence. After the small cycle flushing is completed, a condensate polishing system for purifying circulating water is put into operation, and the medium cycle flushing and the large cycle flushing are established, wherein the requirement after the small cycle flushing is that the concentration of Fe is less than 500 ppb; the requirement after the medium cycle flushing is that the turbidity is less than 1 ppm; and the requirementafter the large cycle flushing is that the peak turbidity value is less than 1 ppm. According to the flushing method, a flushing path is standardized, flushing indicators at each stage are clarified,and the process is strictly controlled to achieve the effect of refinement treatment; after the small cycle is established, a polishing bed body can be put into operation, flushing water is purified through polishing, and in a subsequent path flushing process, the flushing water consumption is effectively reduced, and the flushing efficiency is improved.

Owner:SANMEN NUCLEAR POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com