Patents

Literature

388 results about "Filter strip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filter strips, also referred to as buffer strips, are small, edge-of-field tracts of vegetated land that are used to reduce the contamination of surface water. They are primarily used in agriculture to control non-point source pollution, however, they may also be used to reduce sediment in storm water runoff from construction sites. There are several types of filter strips including vegetative filter strips, forested riparian buffers, and wind buffers. In agriculture, they are highly effective in reducing the concentration of nitrogen (N) and phosphorus (P) in runoff into surface water and are also effective in reducing sediment erosion and removing pesticides. This helps to prevent eutrophication and associated fishkills and loss of biodiversity. The use of filter strips is very common in developed countries and is required by law in some areas. The implementation and maintenance of filter strips is inexpensive and their use has been shown to be cost effective.

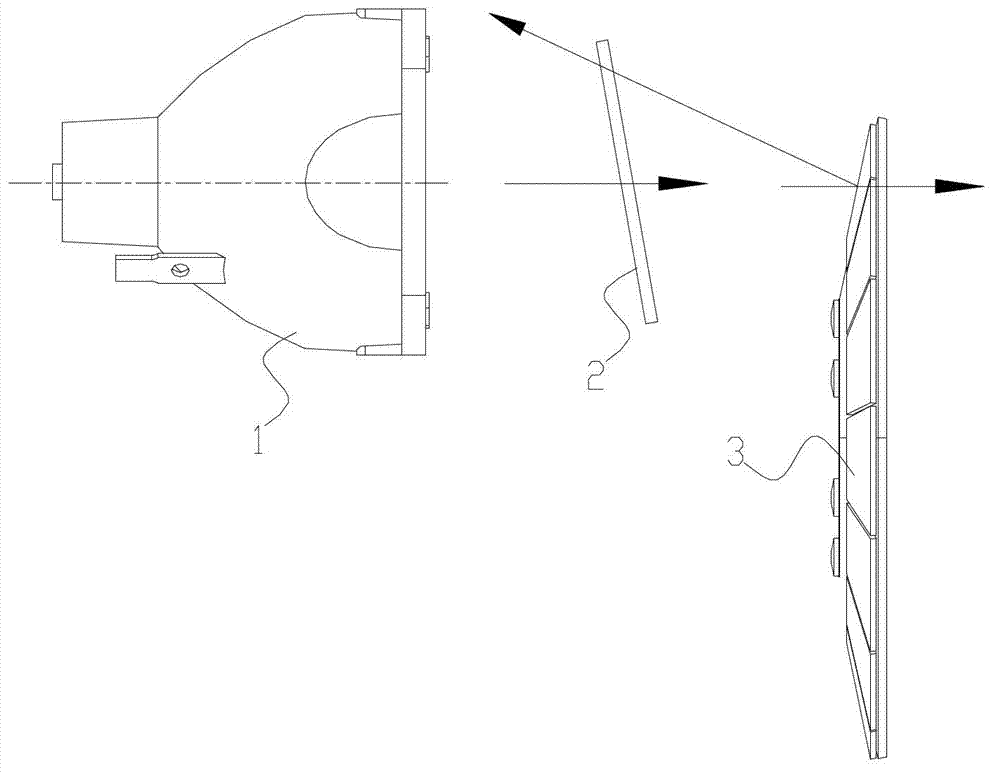

Laminated glass windscreen intended to be used at the same time as a HUD system reflector

Owner:SAINT GOBAIN VITRAGE SA

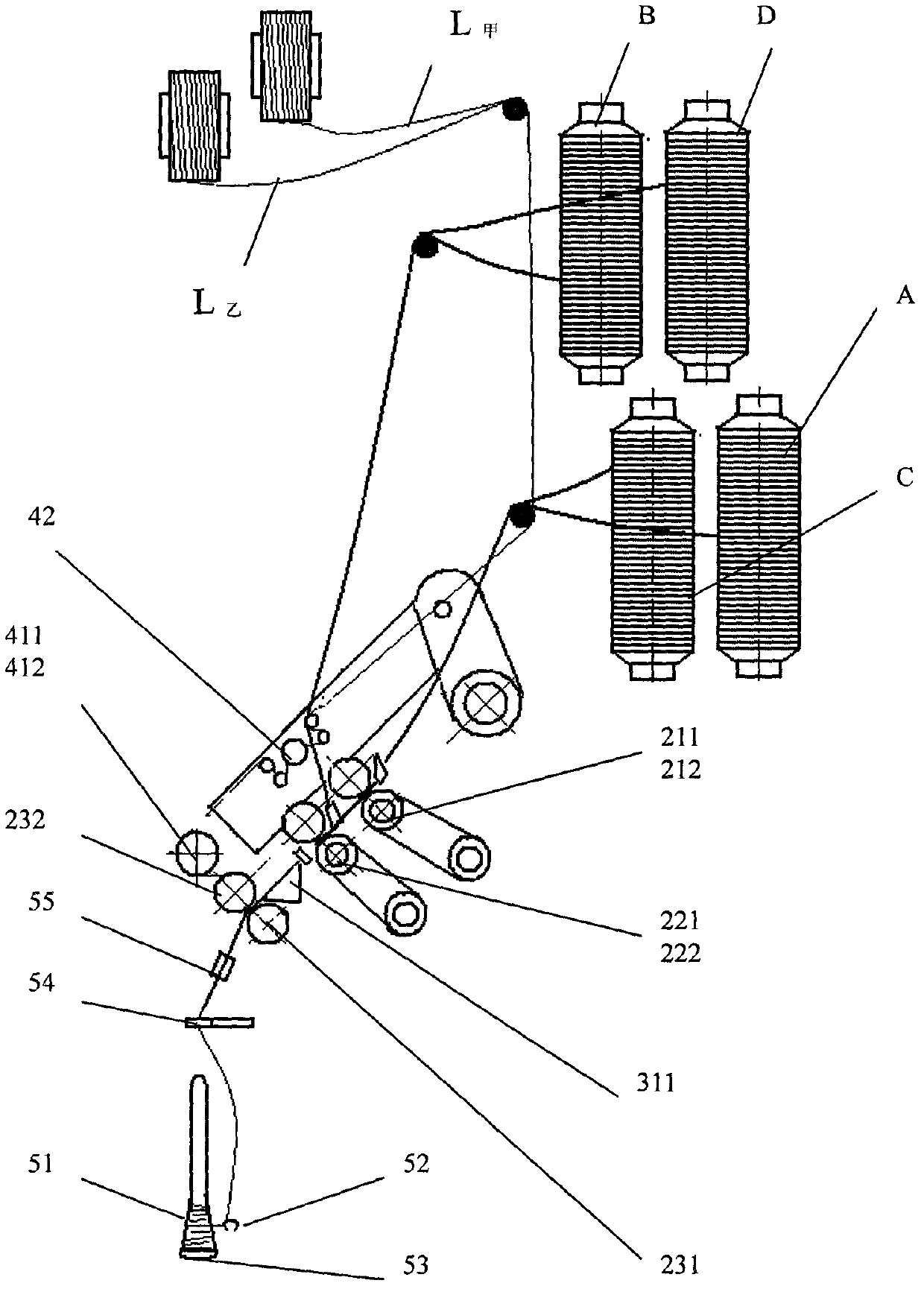

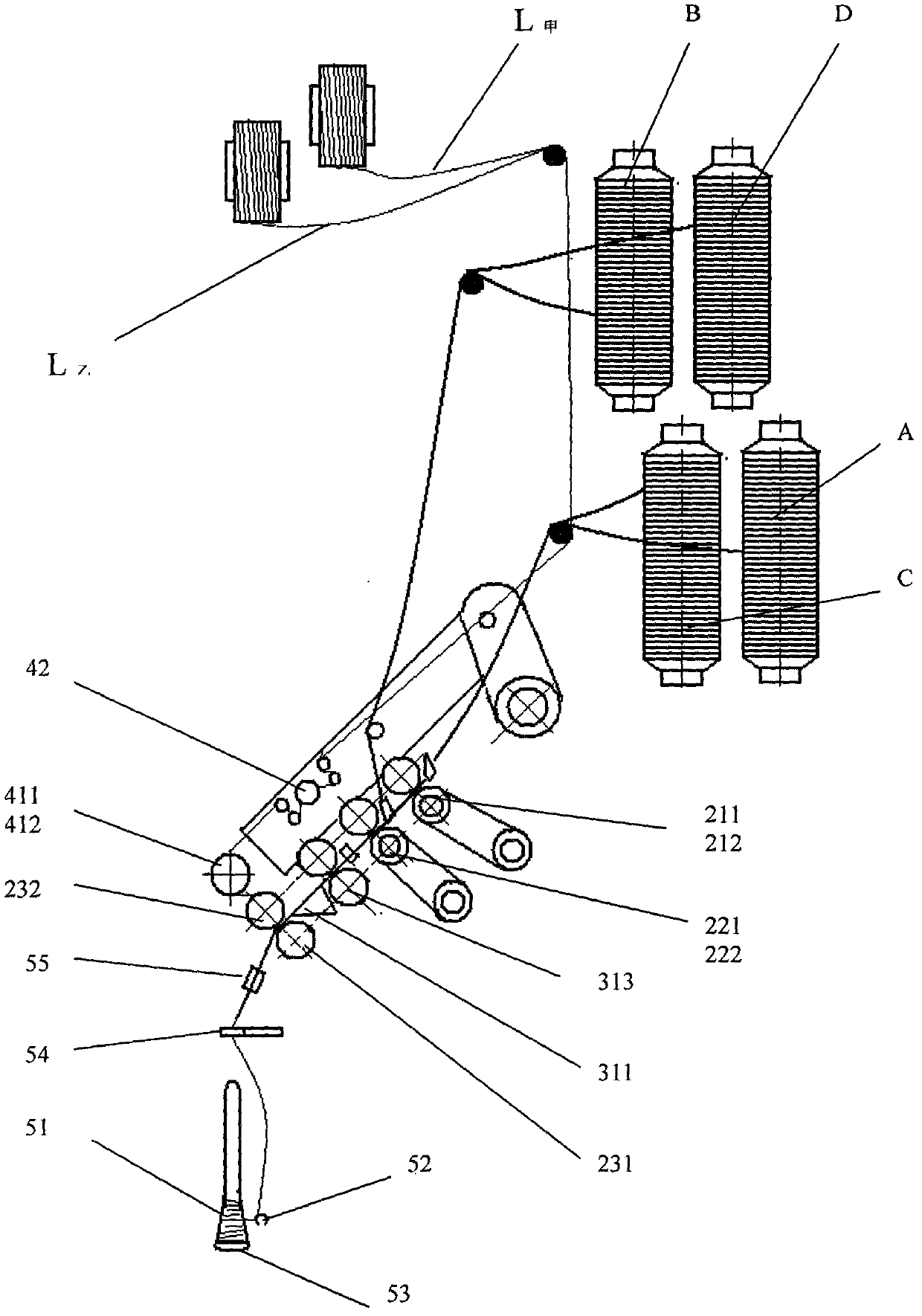

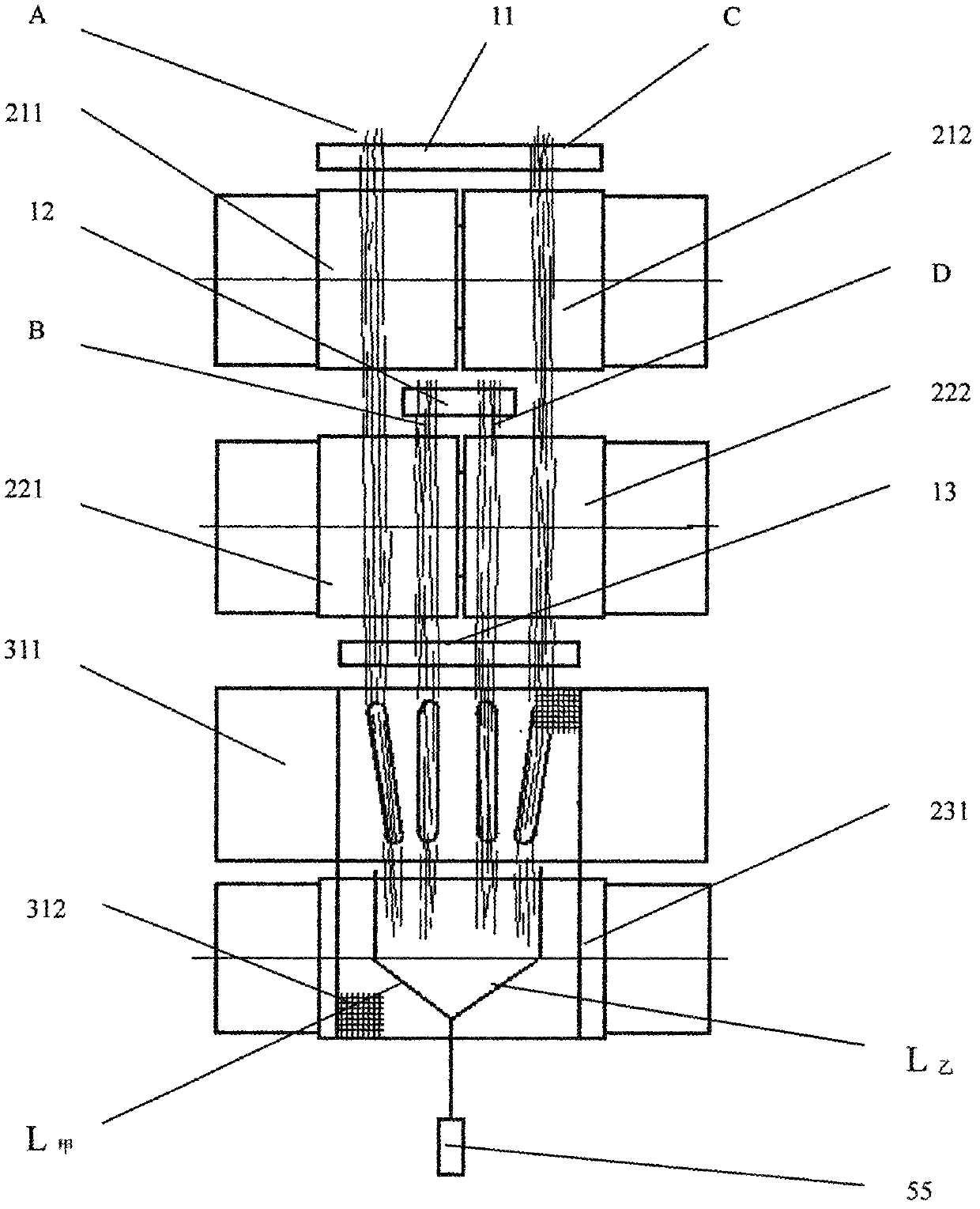

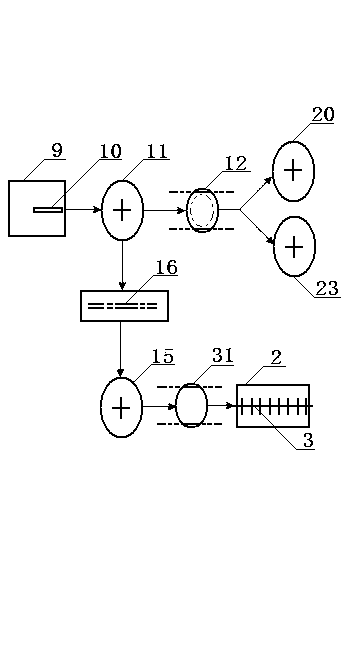

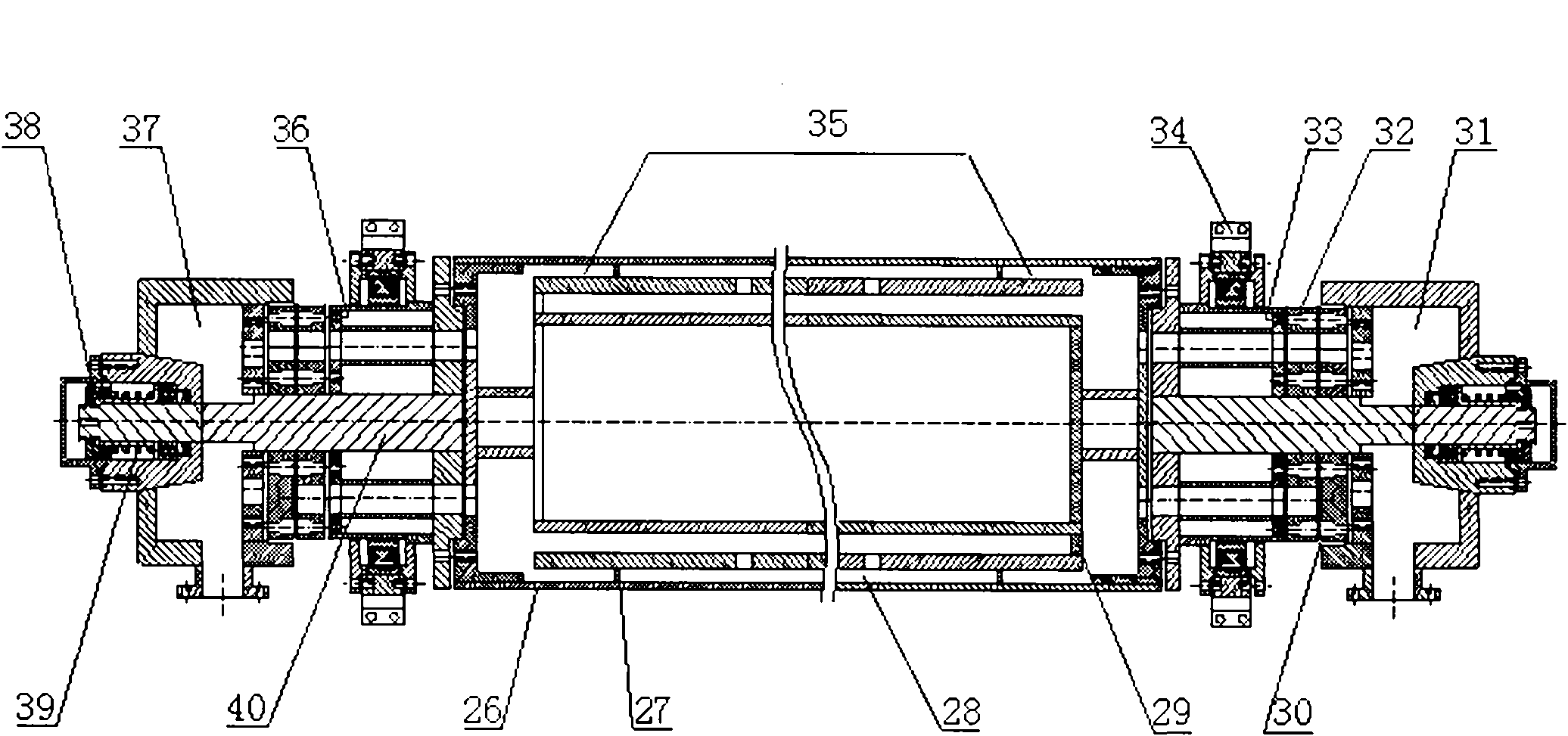

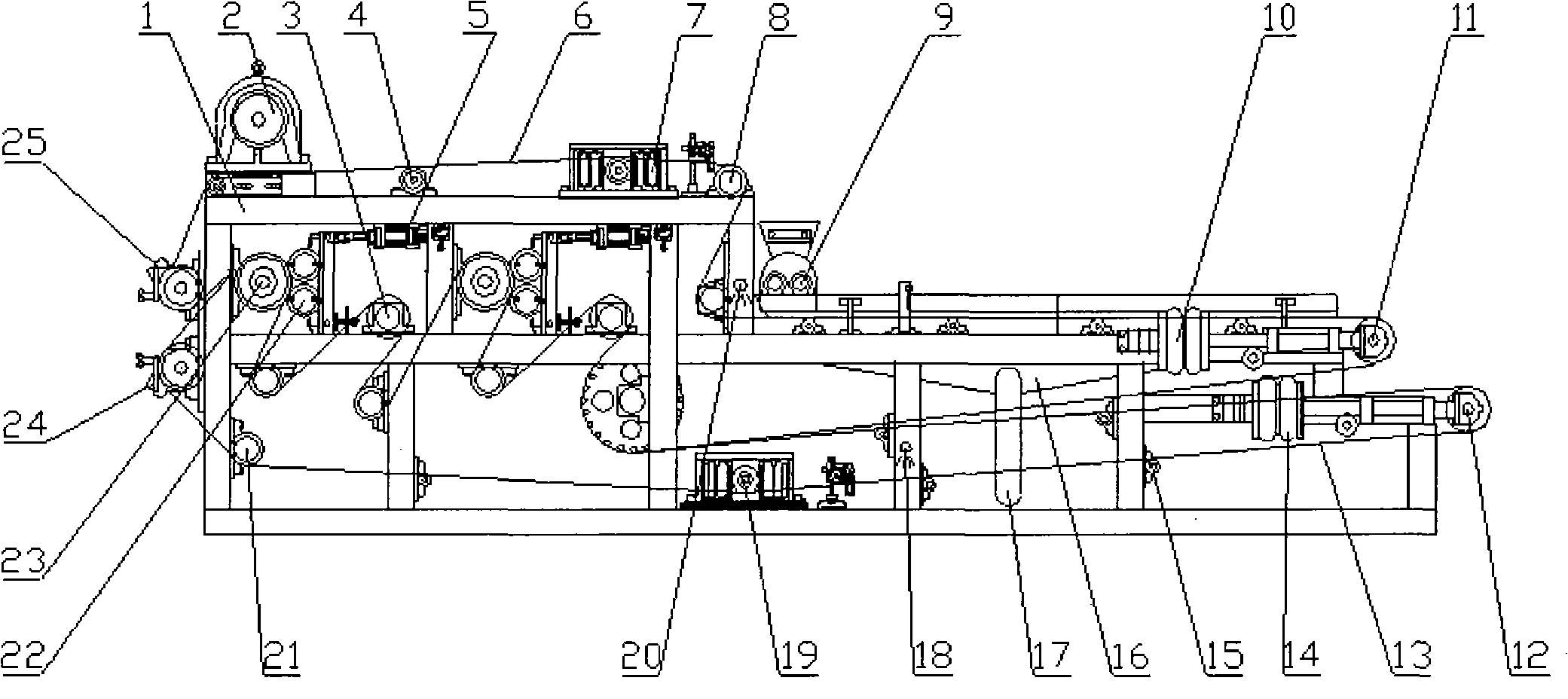

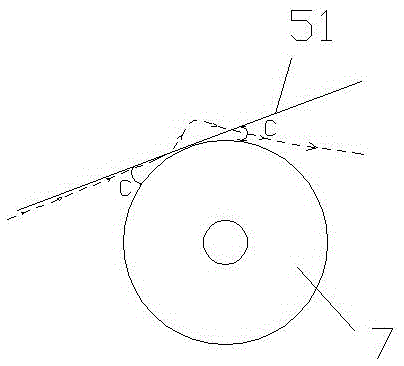

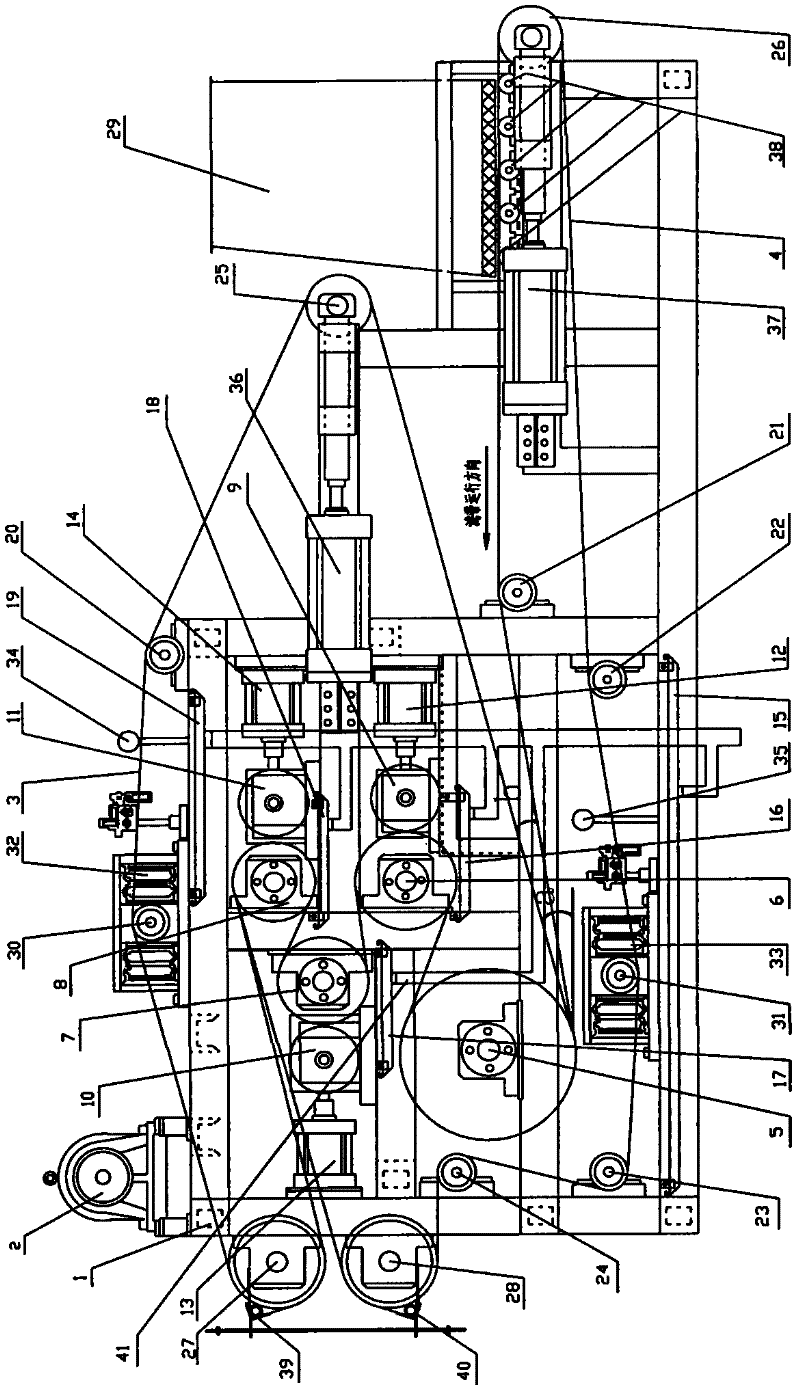

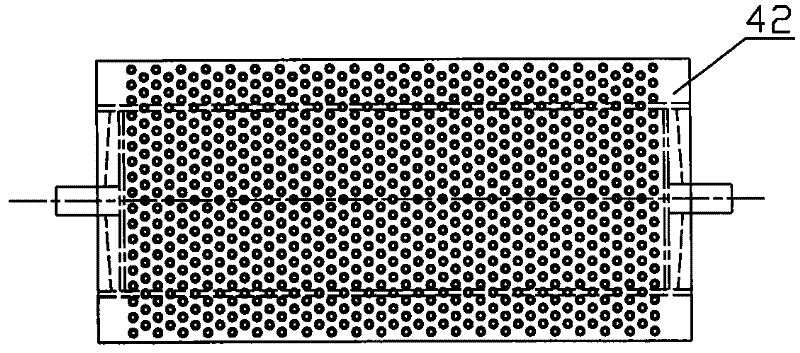

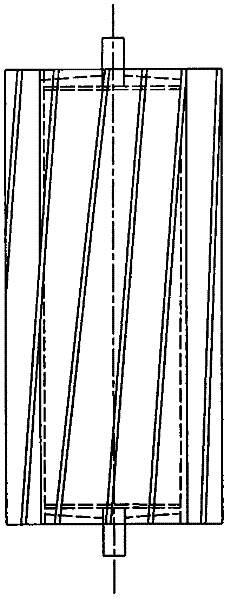

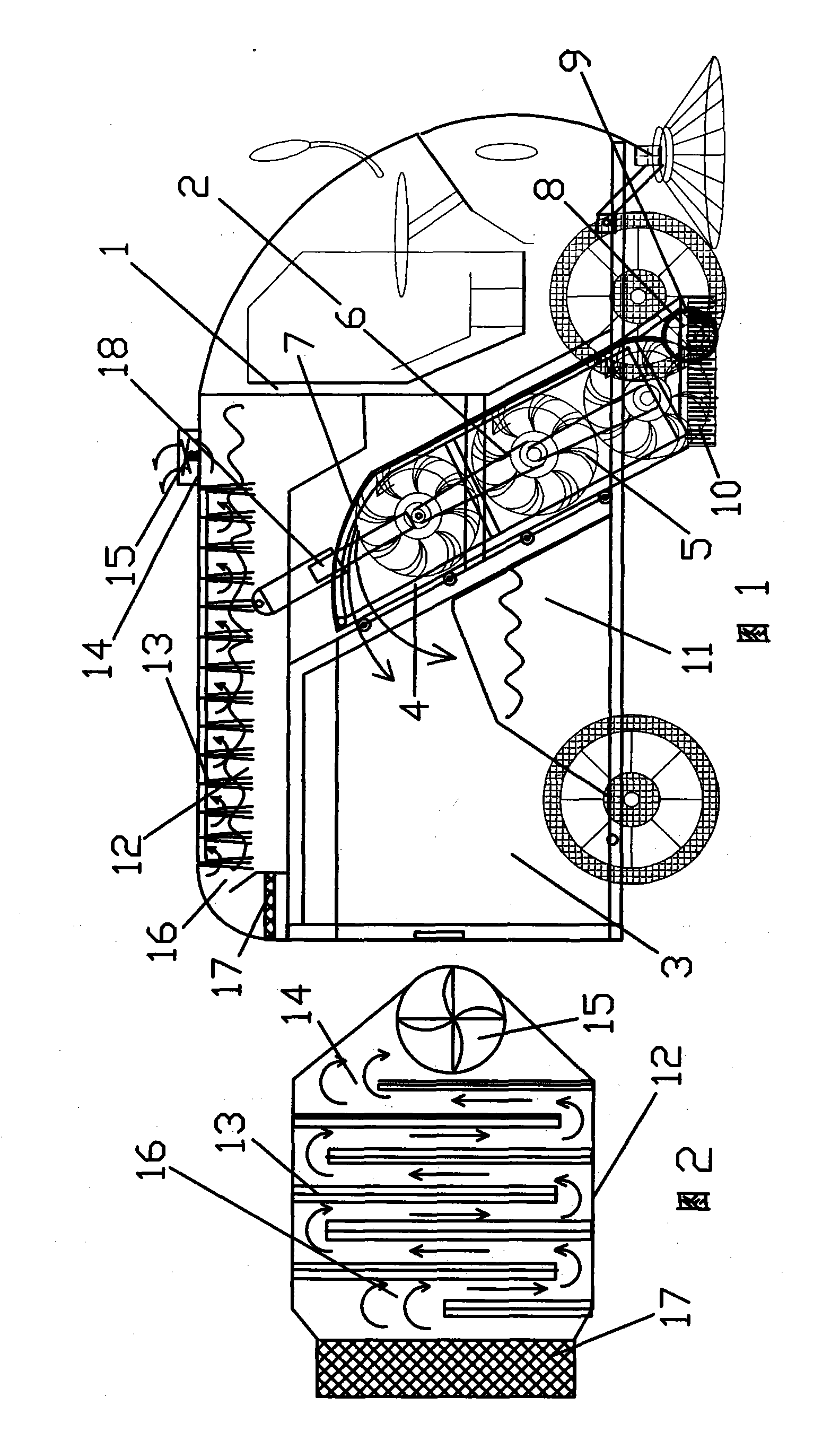

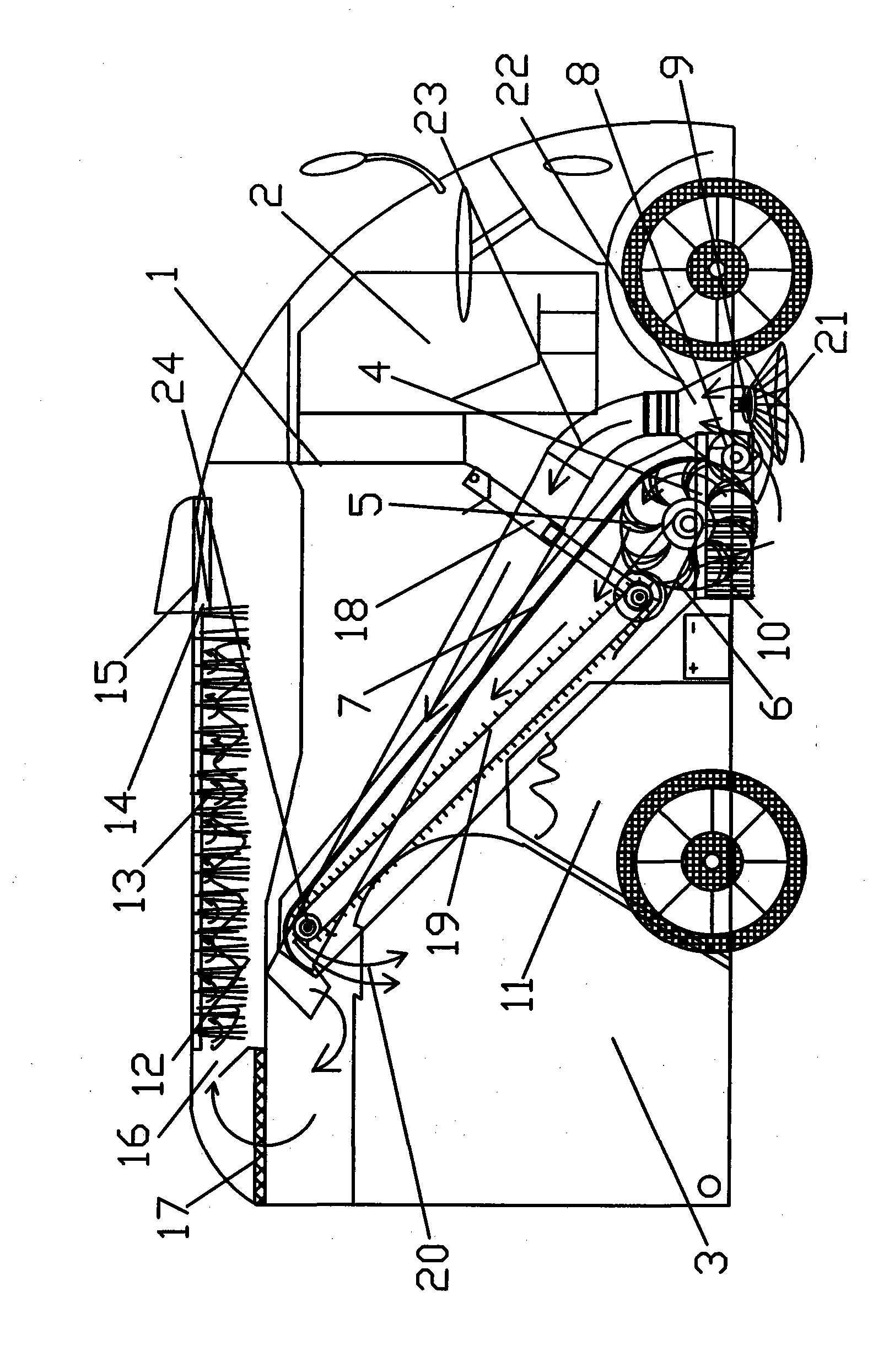

Multi-color embedding type section colorful spinning method, and device and product thereof

ActiveCN103276485ARealize segmented feedingRealize independent feedingDrafting machinesYarnEngineeringAbnormal shaped

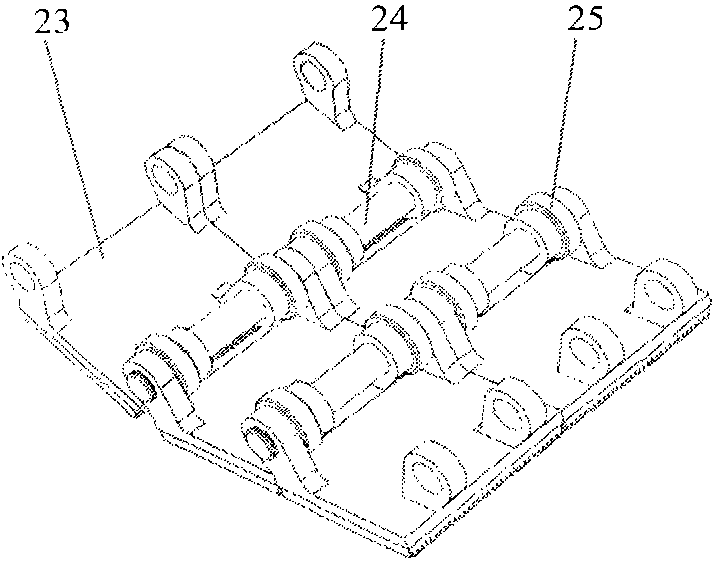

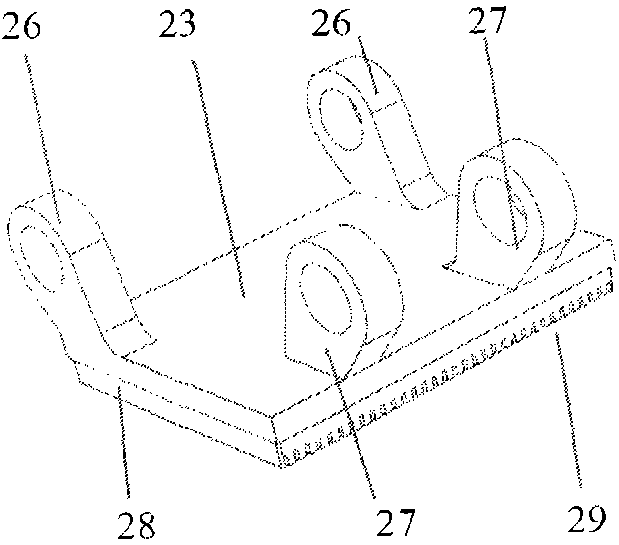

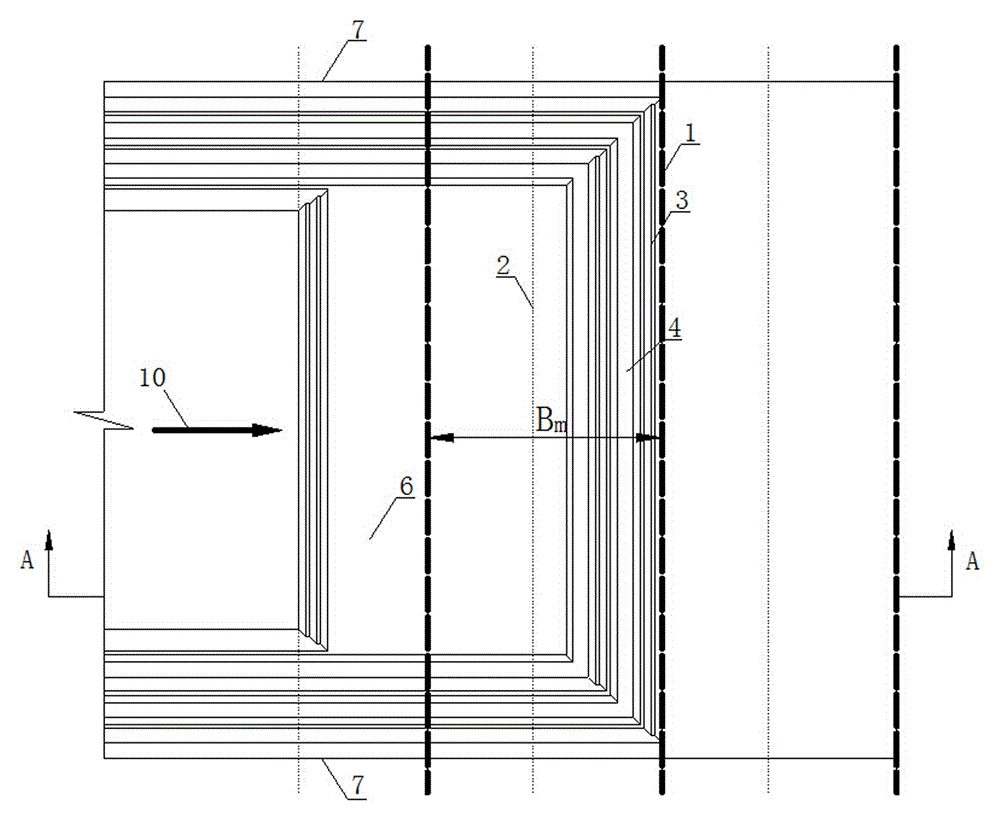

The invention provides a multi-color embedding type section colorful spinning method, and a device and a product thereof. Four feeding rollers which are driven by servo motors in an independent mode are utilized to form a drawing area with a front roller, a negative pressure special-shaped pipe, a grid ring and a grid ring transmission roller in the drawing area constitute a negative pressure holding and sliding moving mechanism of roving, the feeding rollers are controlled through a computer program controller, and interval feeding and drawing of four roving filters are achieved. By means of twisting of two filament yarns and self rotation in a twisting process, various filter strips which are output in a sectioned mode are twisted into co-mingled yarns, and multi-color embedding type section colorful spinning is achieved.

Owner:海安市春华线业有限公司

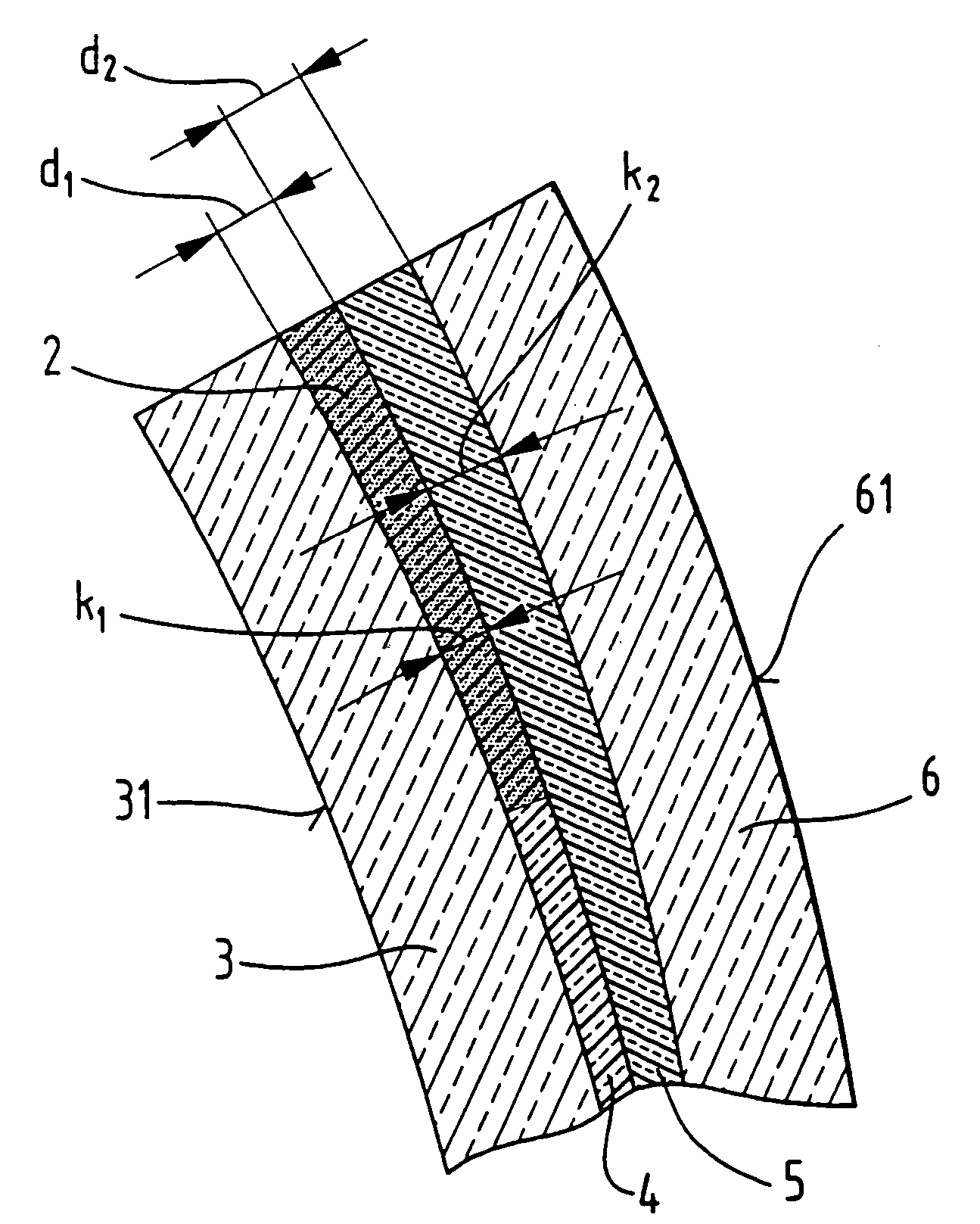

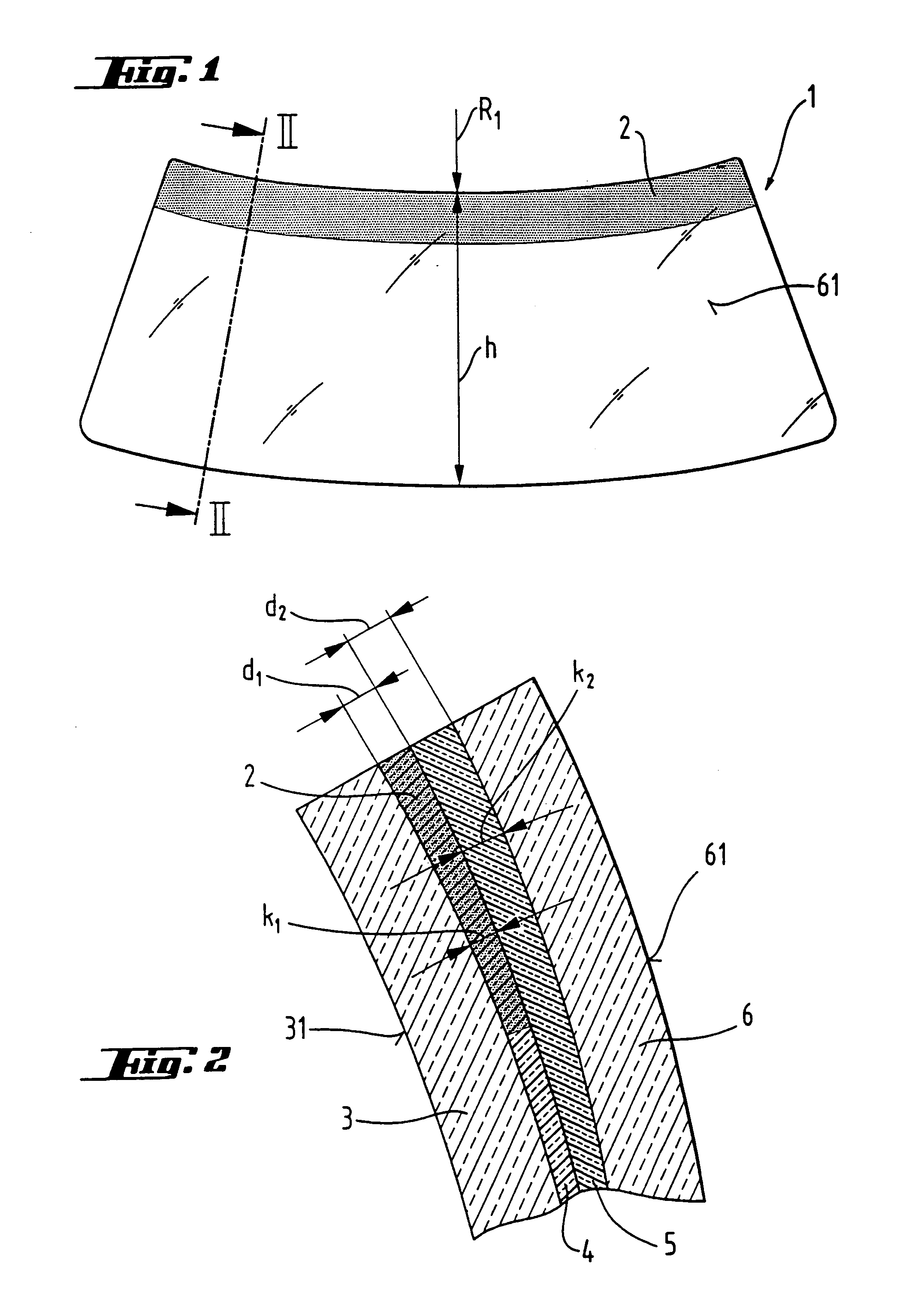

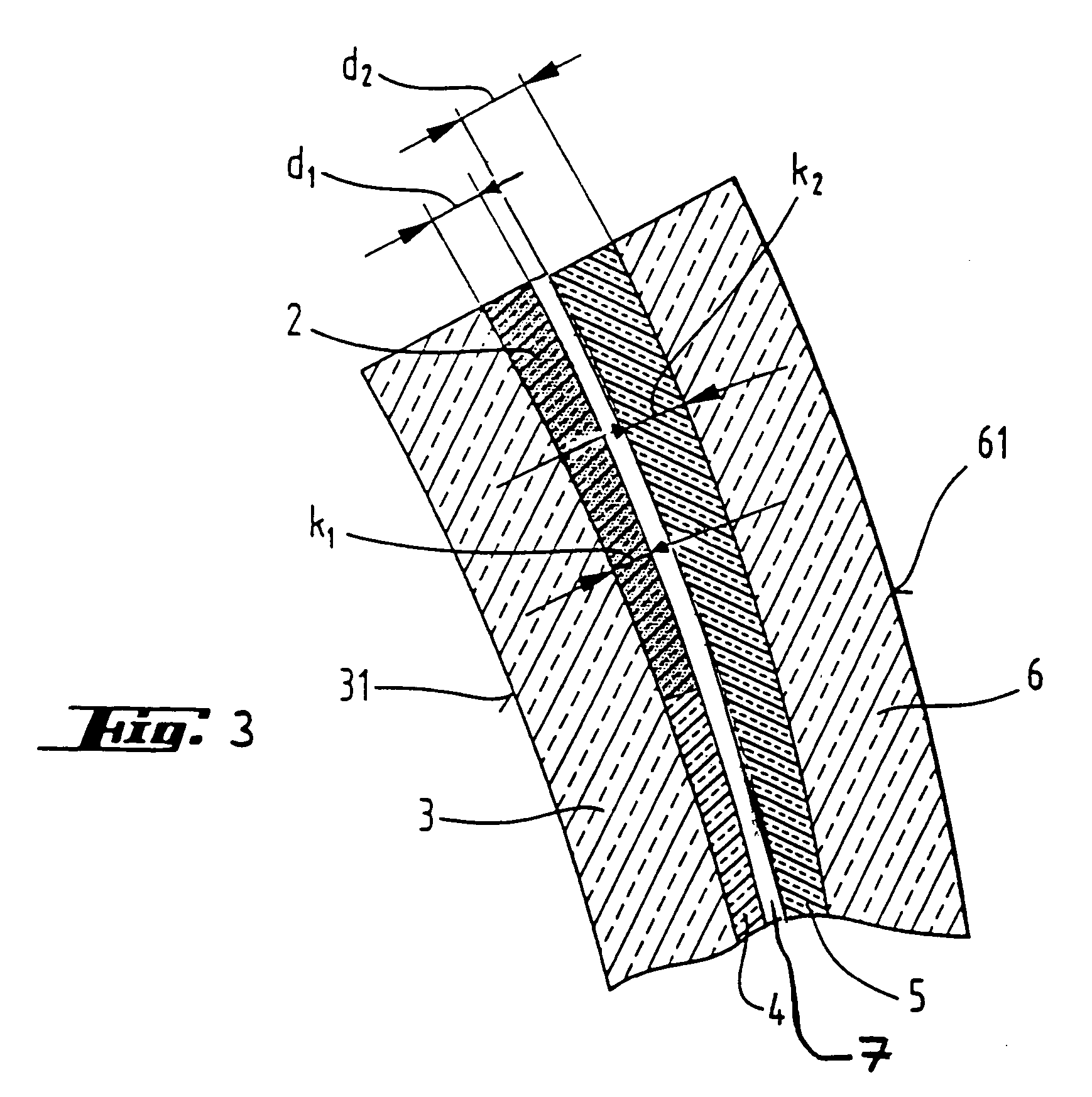

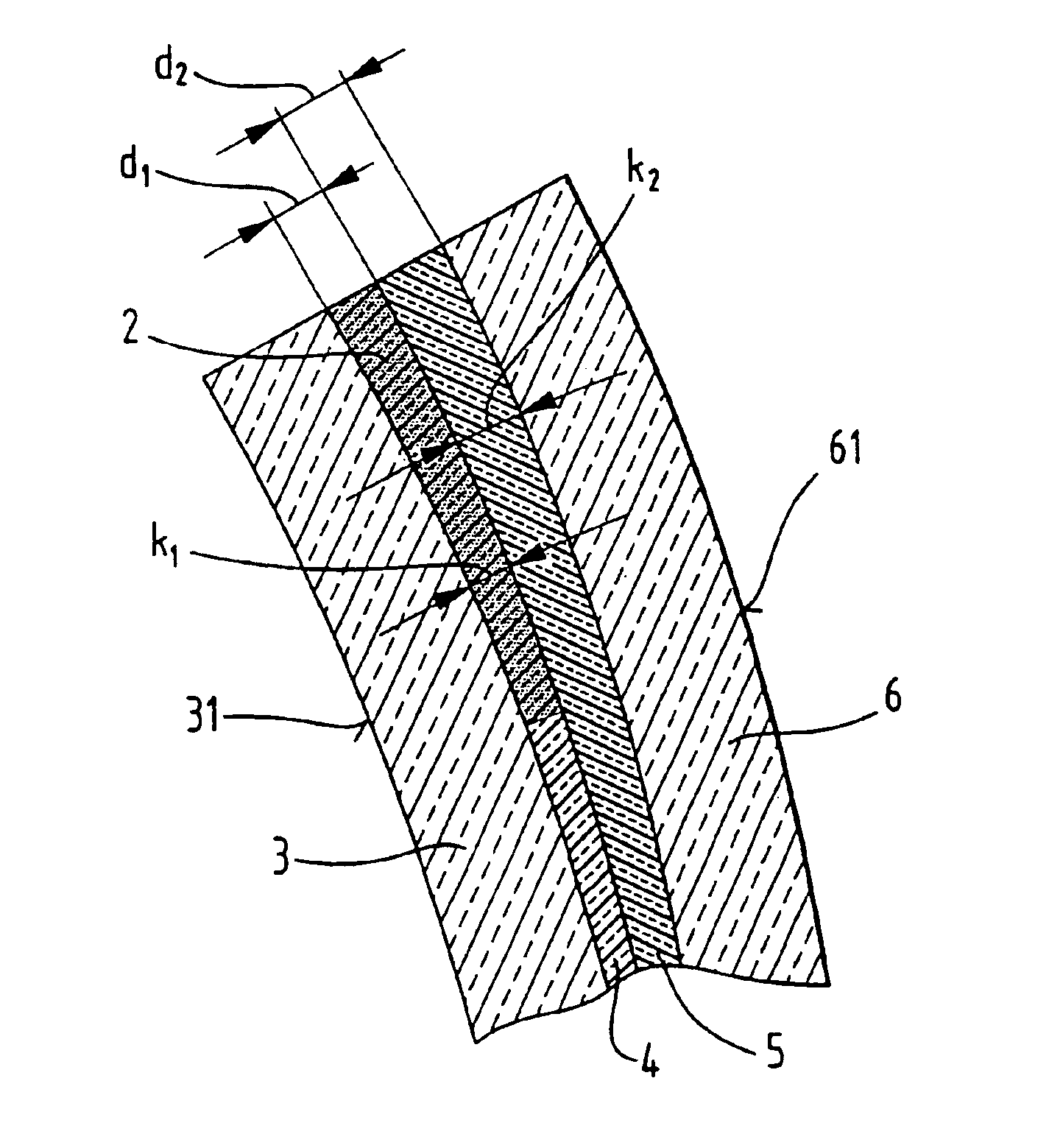

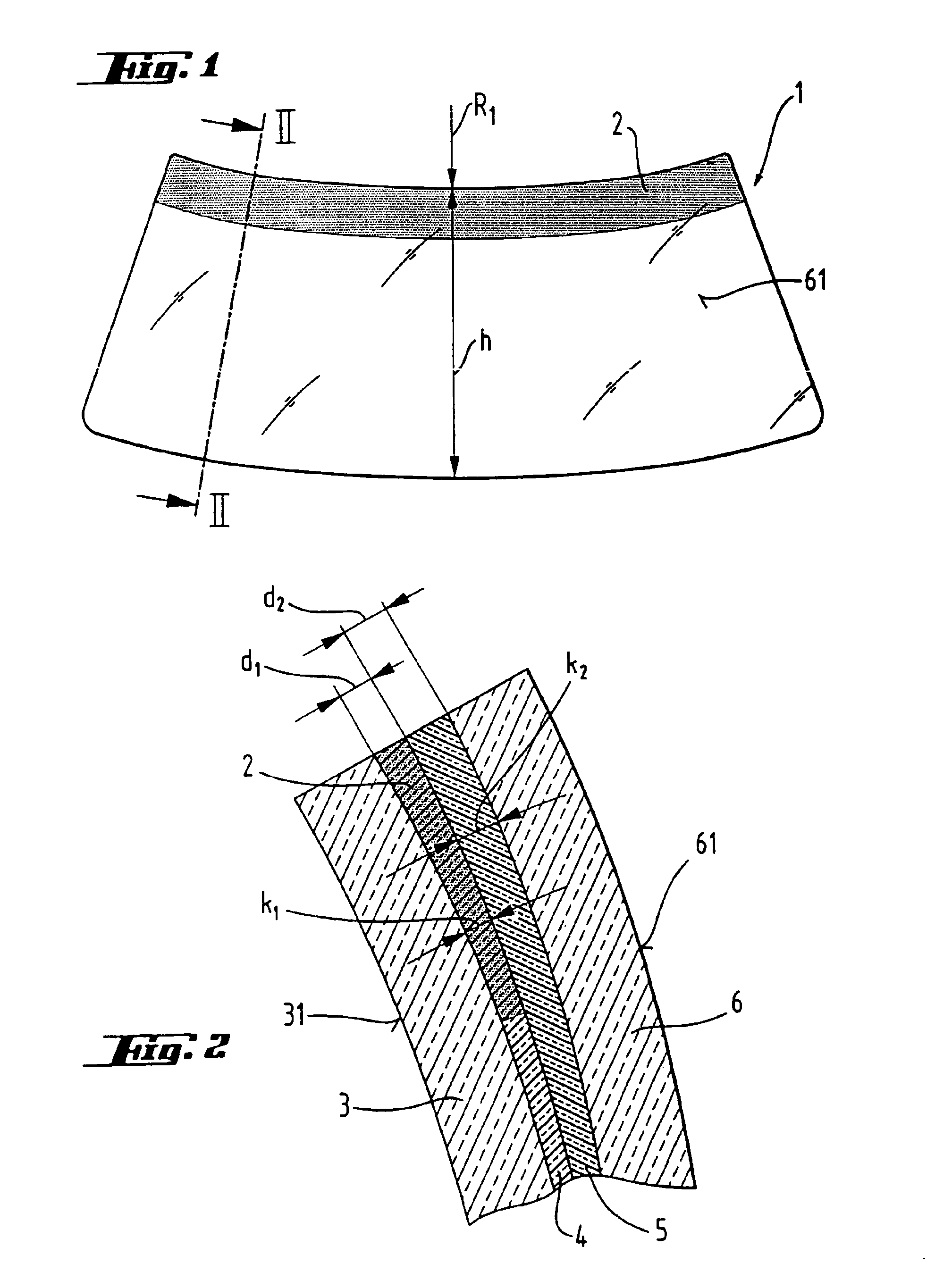

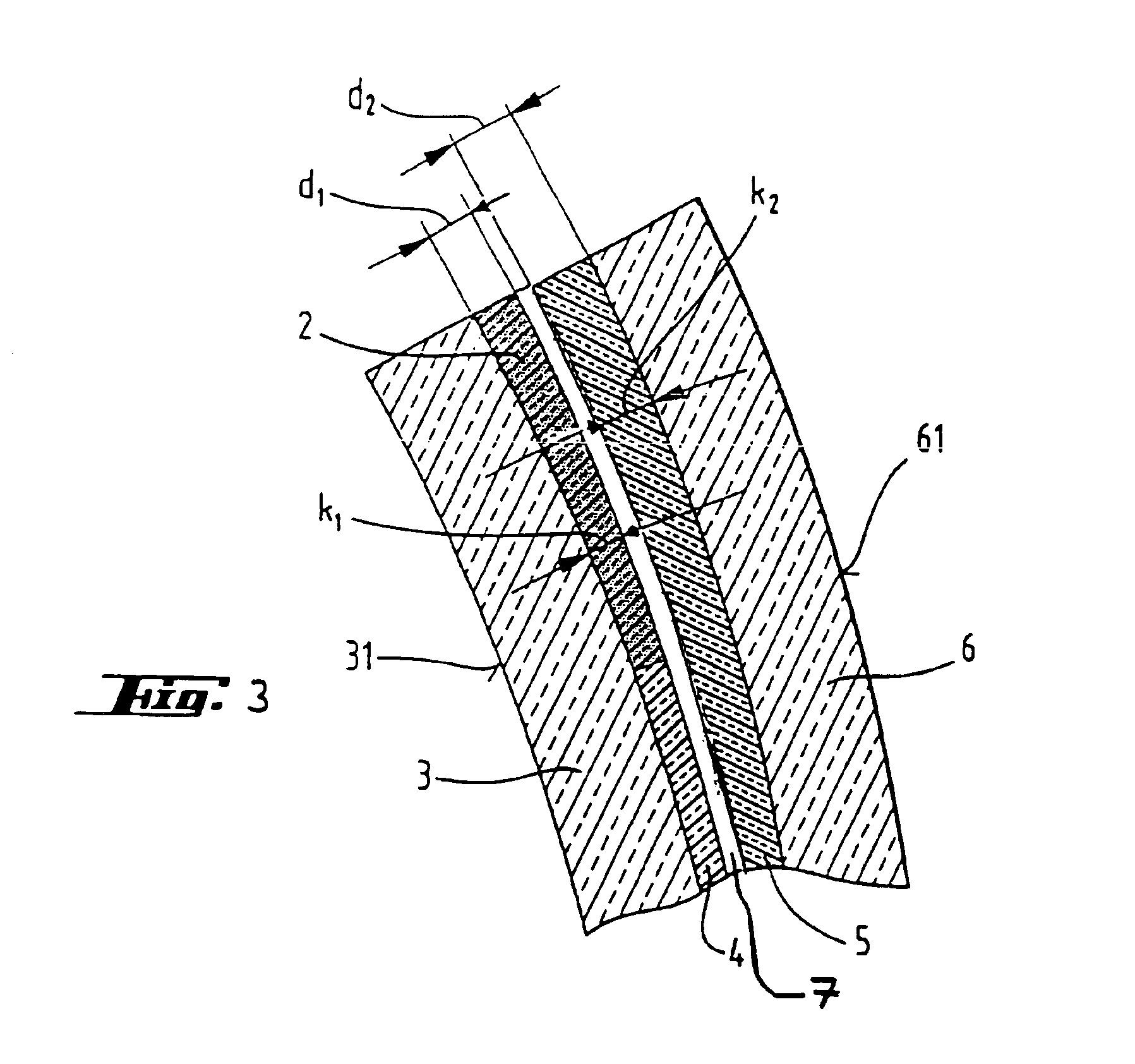

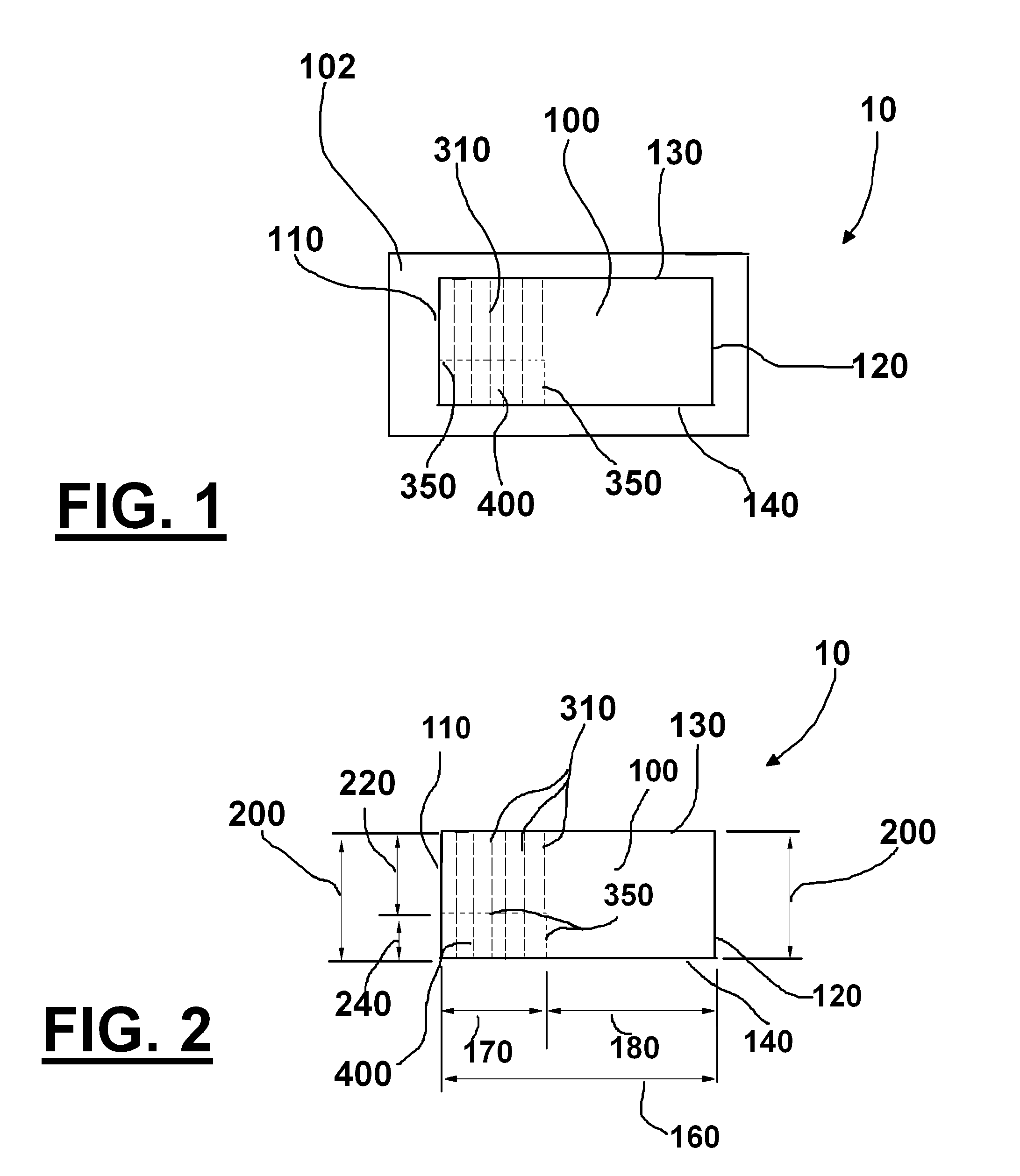

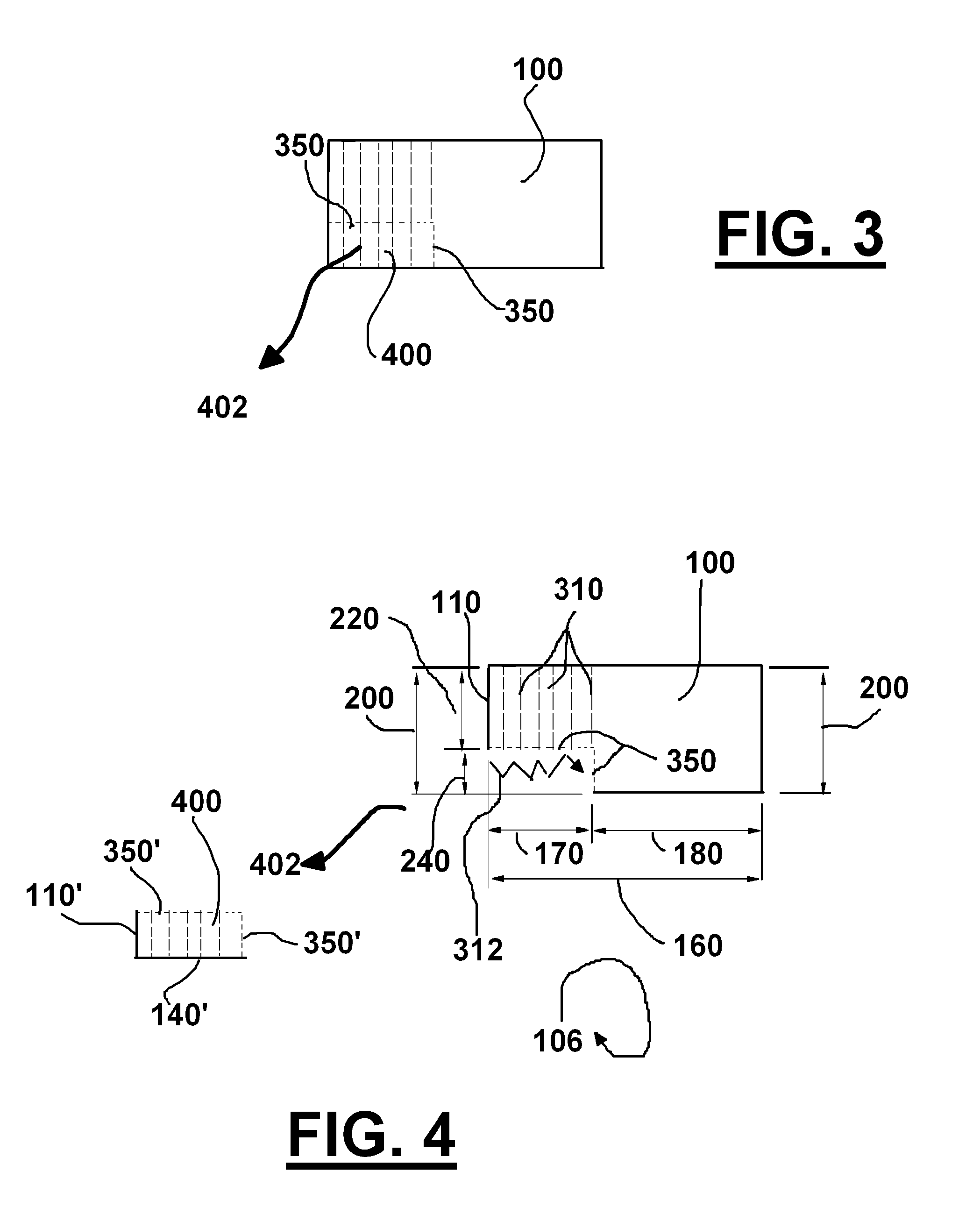

Laminated glass windscreen intended to be used at the same time as a HUD system reflector

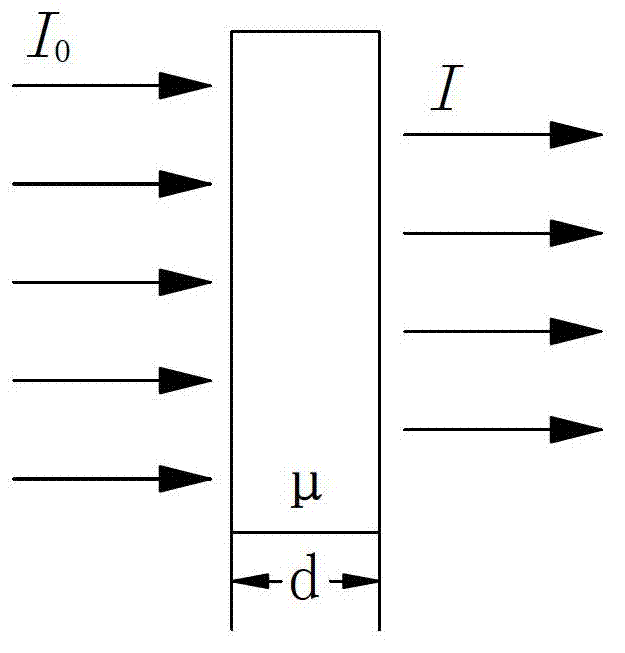

A laminated safety glass windscreen, which can also be used as a reflector in a HUD system, comprises at least first and second panes and a thermoplastic intermediate layer which joins these panes together. The cross-section of the intermediate layer is in the shape of a wedge, decreasing in thickness from top to bottom. The thermoplastic intermediate layer may be composed of two sheets, one of which is provided with a colored filtering strip and has a wedged cross-section conditioned by the appearance of this filtering strip. The other sheet has a wedged cross-section such that the two sheets together have the prescribed convergence angle for using the windscreen as a reflector.

Owner:SAINT-GOBAIN GLASS FRANCE

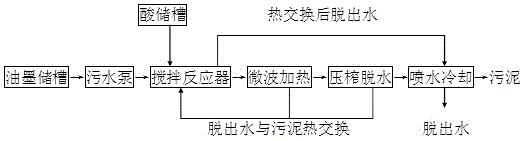

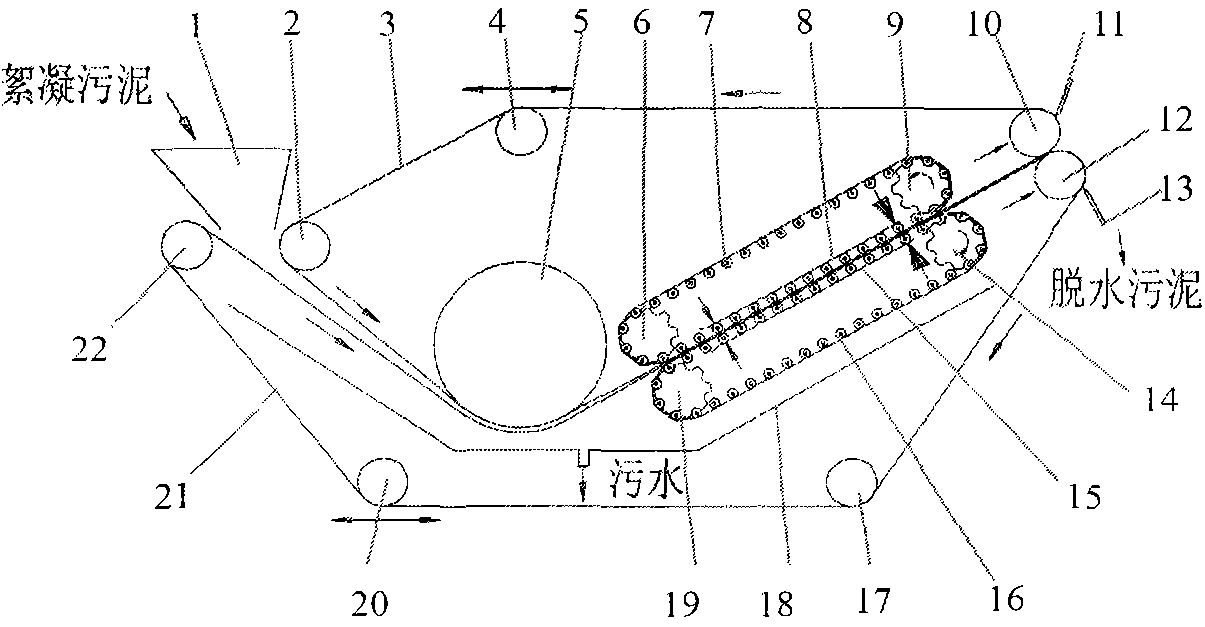

Method for treating high-concentration water-based ink waste liquid and dehydrating sludge in high-concentration water-based ink waste liquid

ActiveCN105084576AImprove dehydration efficiencyFast dehydrationSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentHigh concentrationWater based

The invention discloses a method for treating high-concentration water-based ink waste liquid and dehydrating sludge in the high-concentration water-based ink waste liquid. The method is characterized by comprising the following steps: collecting the water-based ink waste liquid, pumping the collected water-based ink waste liquid into a reactor, then adding inorganic acid into the waste liquid, carrying out stirring and adjusting the pH value of the waste liquid until the waste liquid is acidic; allowing the sludge to enter and be located on a dehydration filter belt, heating the sludge with microwaves, carrying out squeezing and dehydration, and spraying water on the dehydrated sludge to rapidly cool the surface of the dehydrated sludge; and taking the sludge off the filter belt and discharging dehydration water into a subsequent waste water treating system. With the method provided by the invention, integrated removal of pollutants in the ink waste liquid and dehydration of the sludge is realized; the removal rate of the pollutants reaches more than 90%; a decolorization ratio is up to more than 99%; and the treated sludge has a water content of lower than 40%.

Owner:QINGDAO UNIV

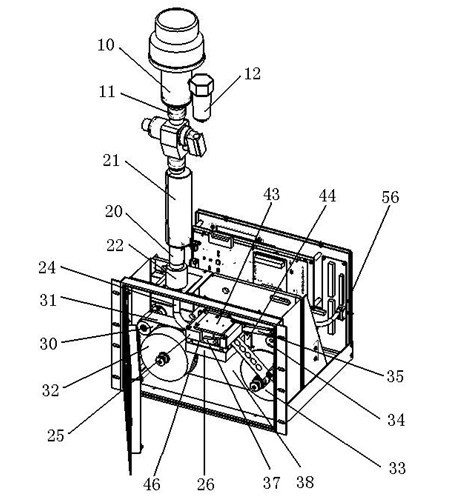

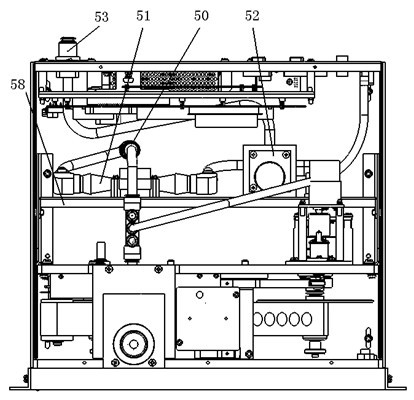

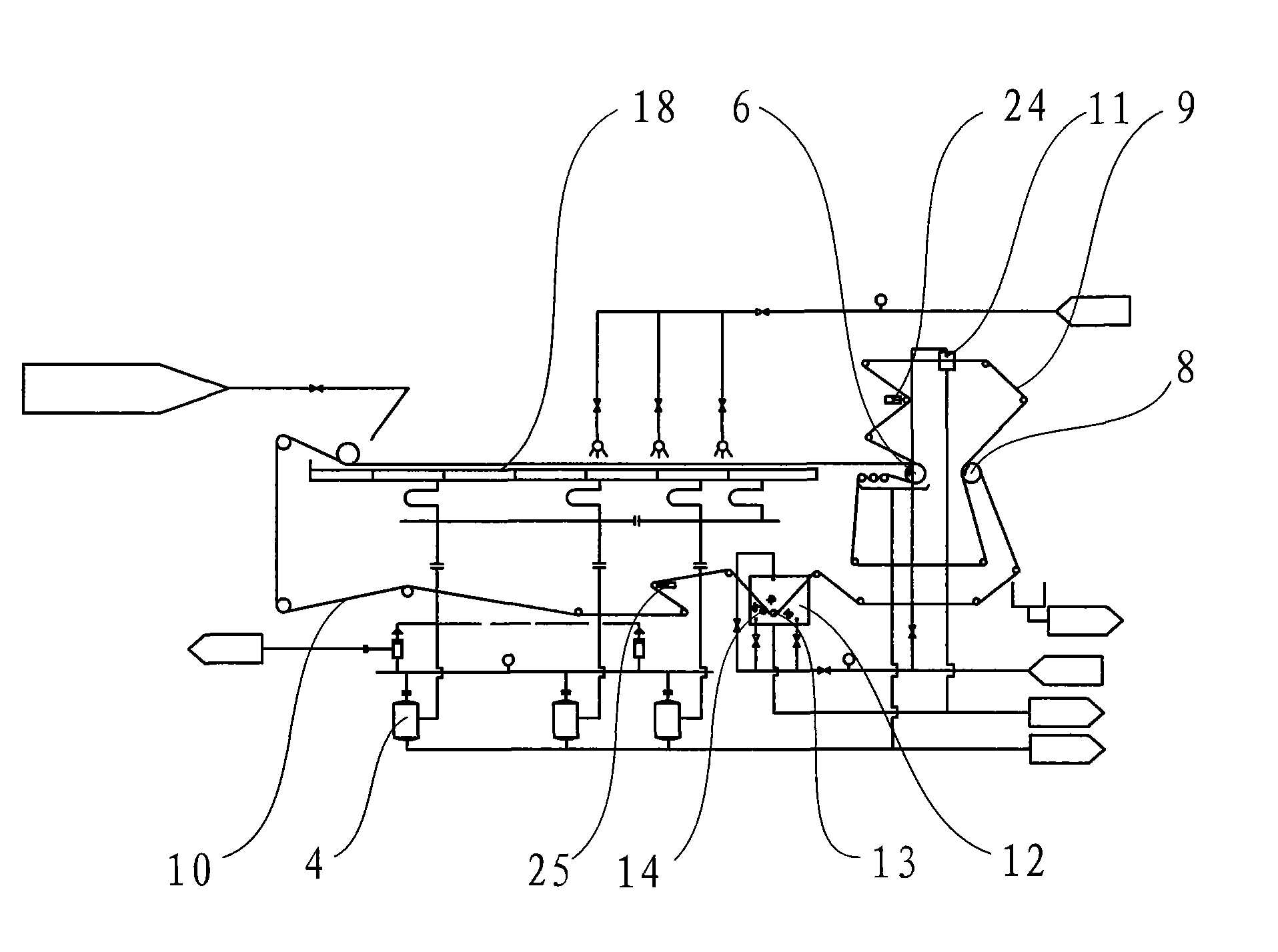

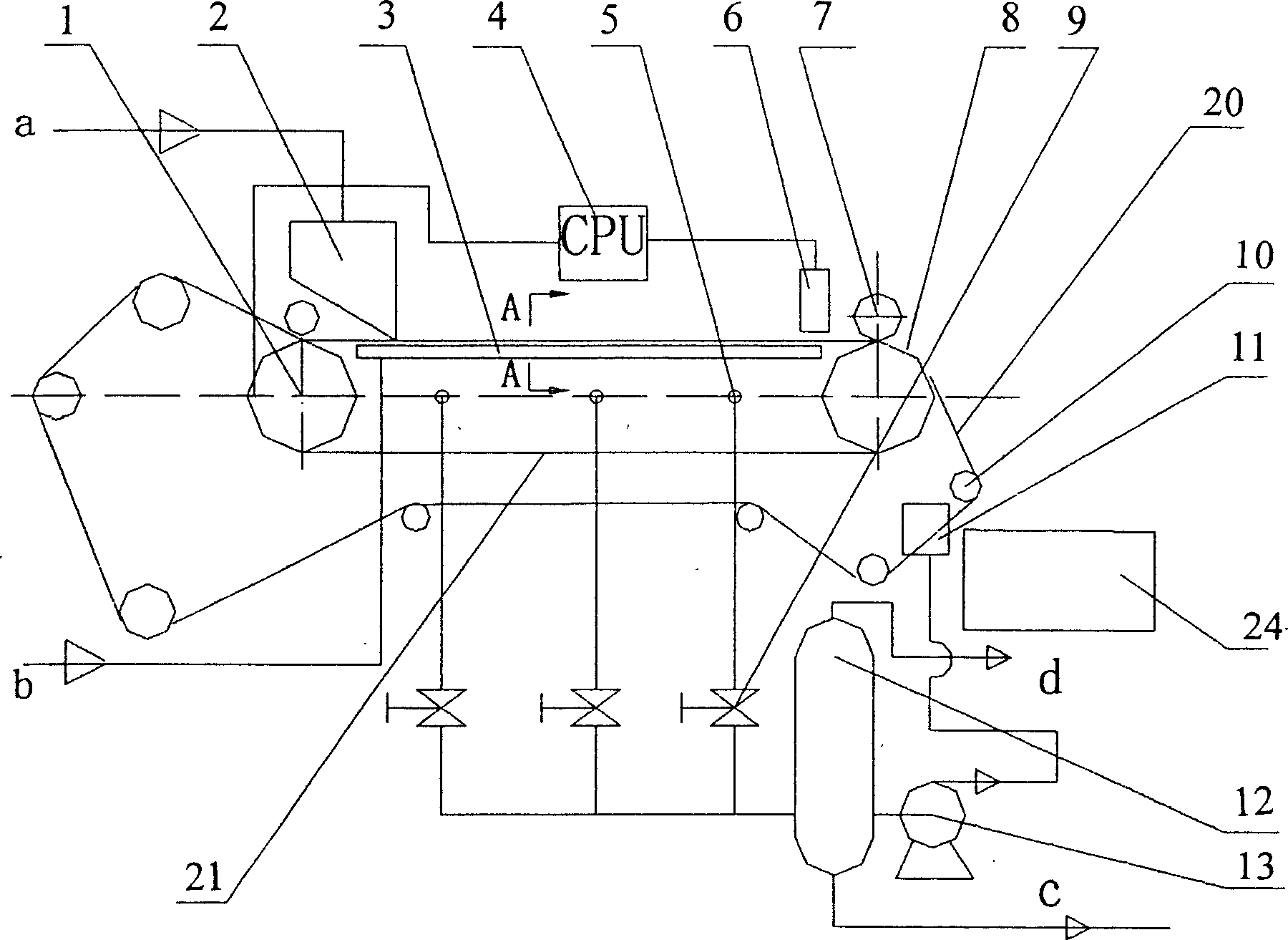

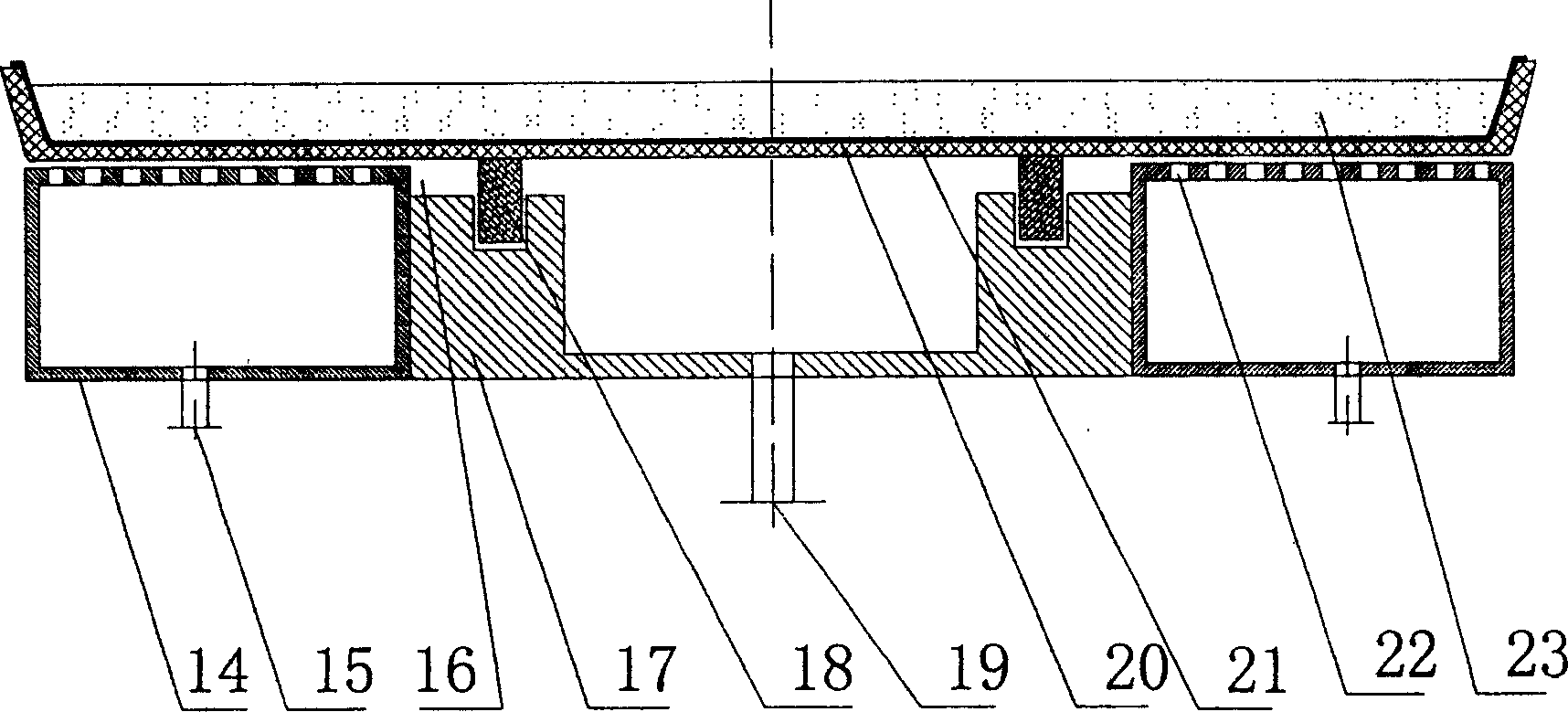

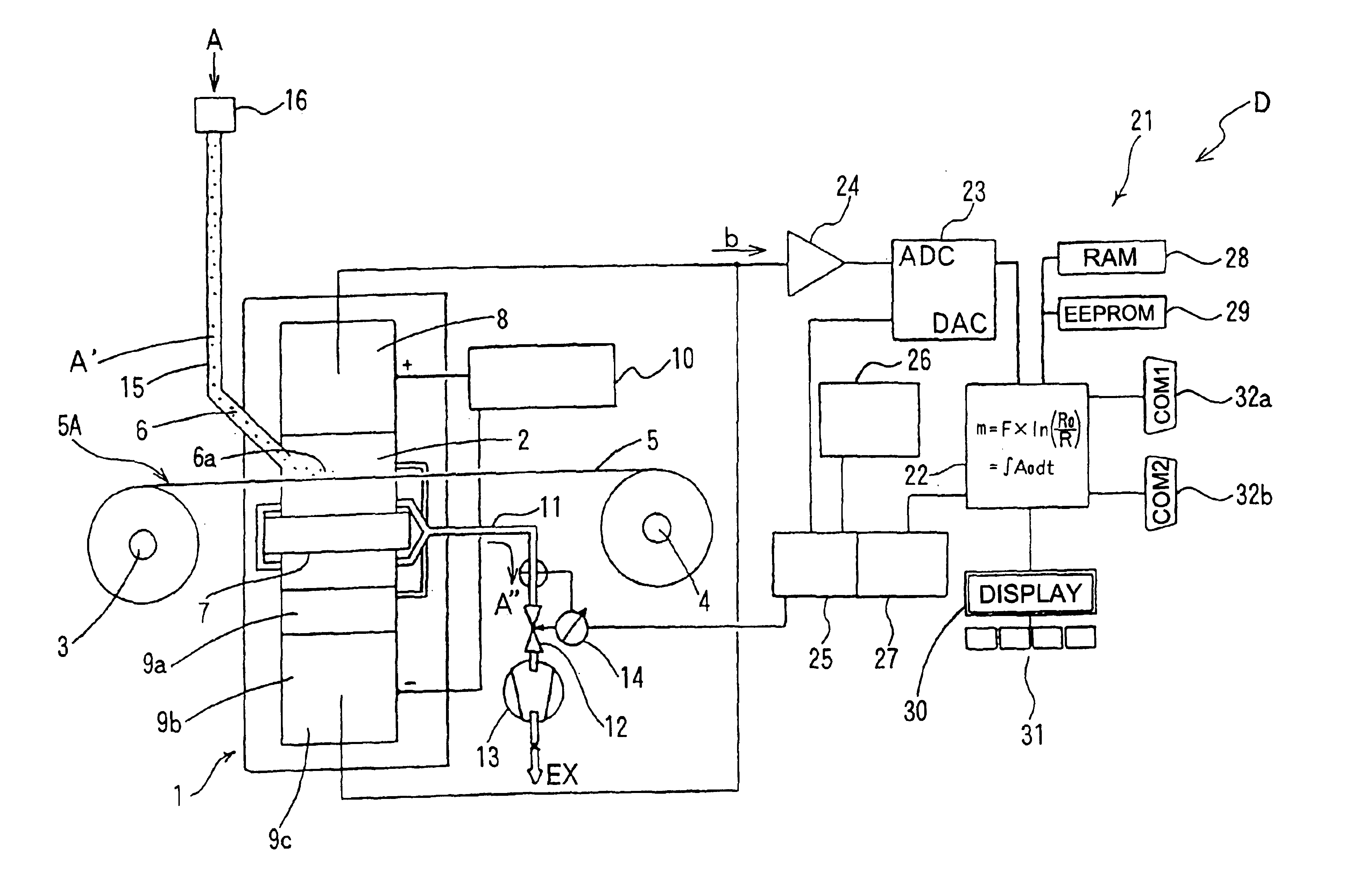

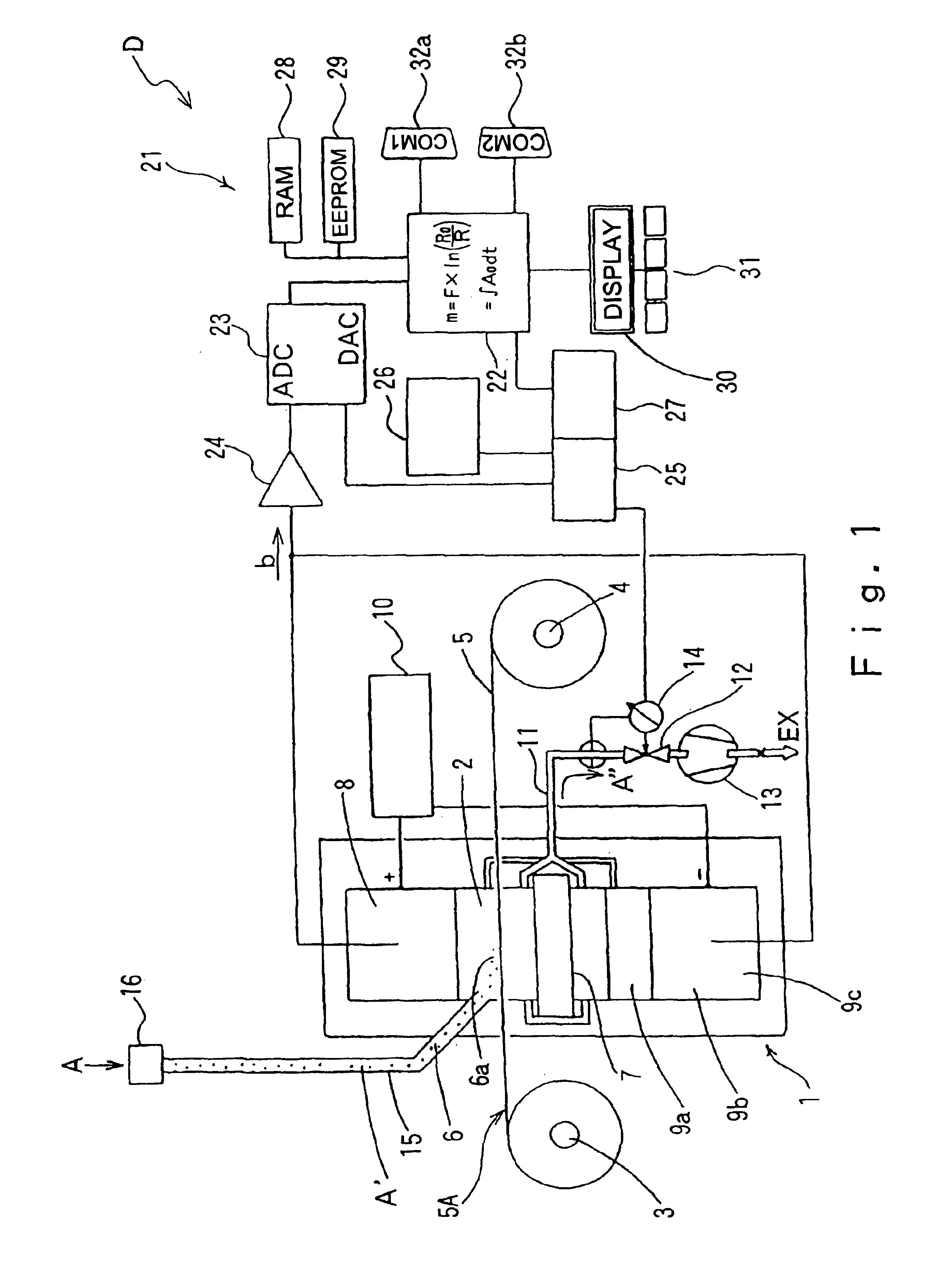

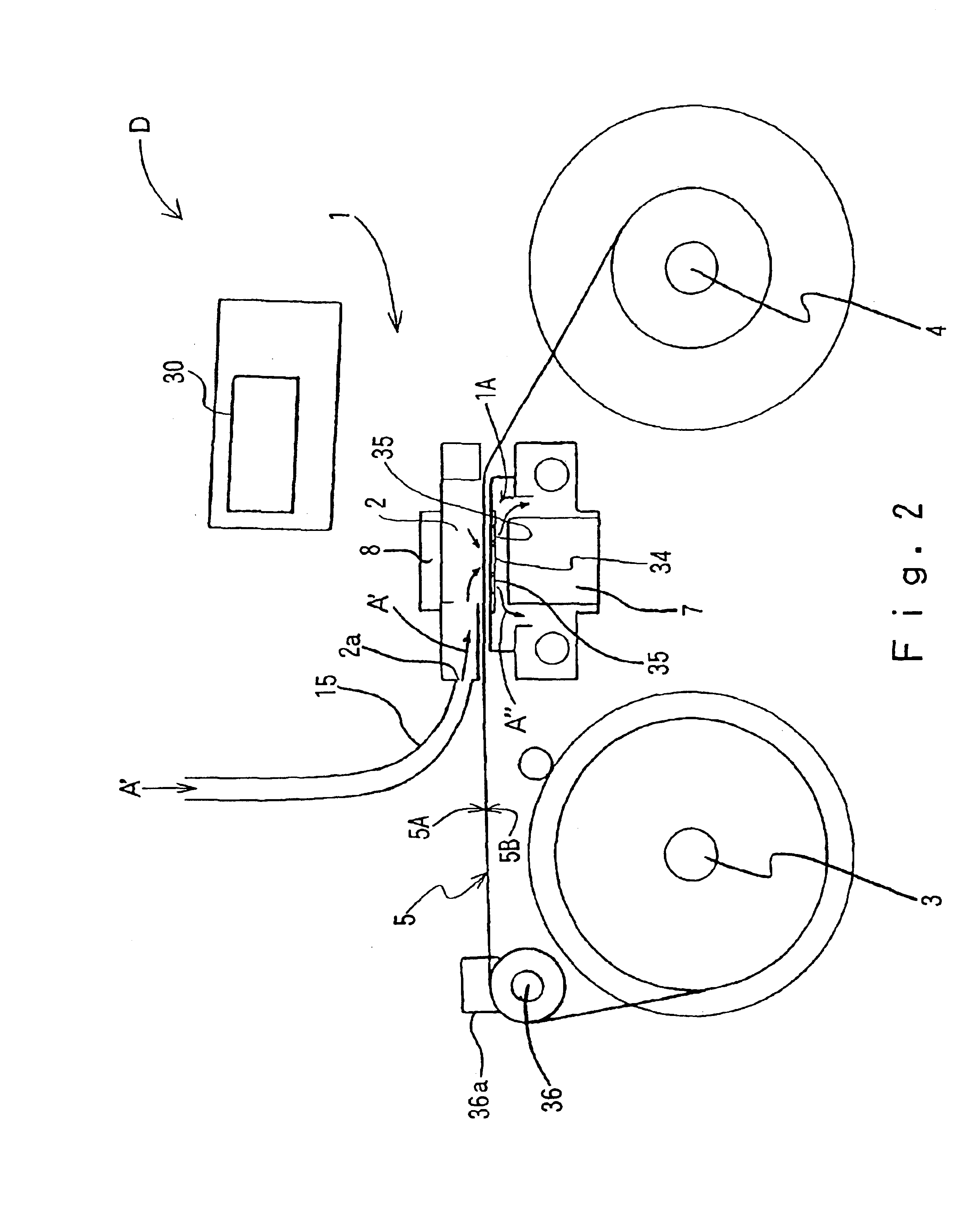

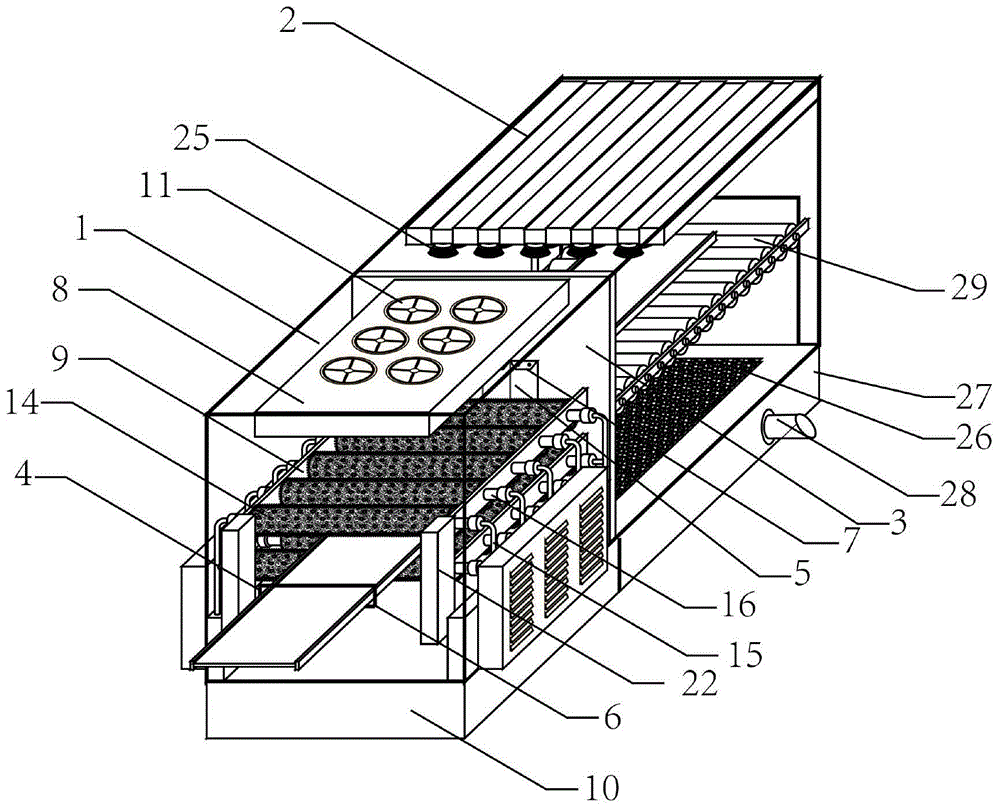

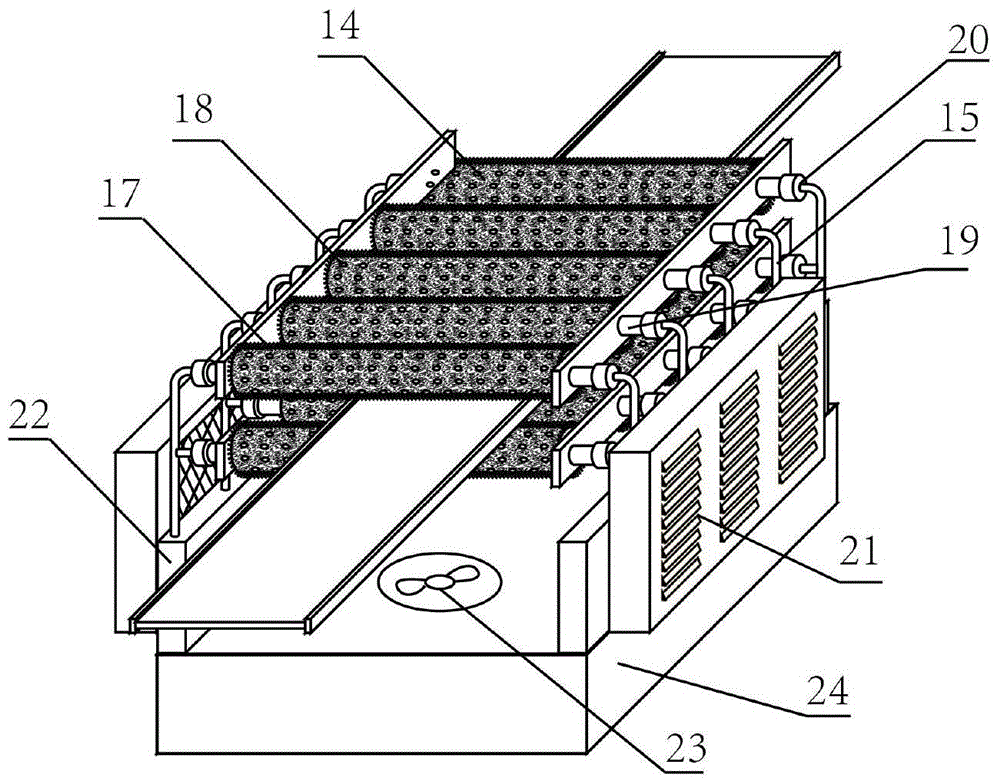

Automatic particle monitor

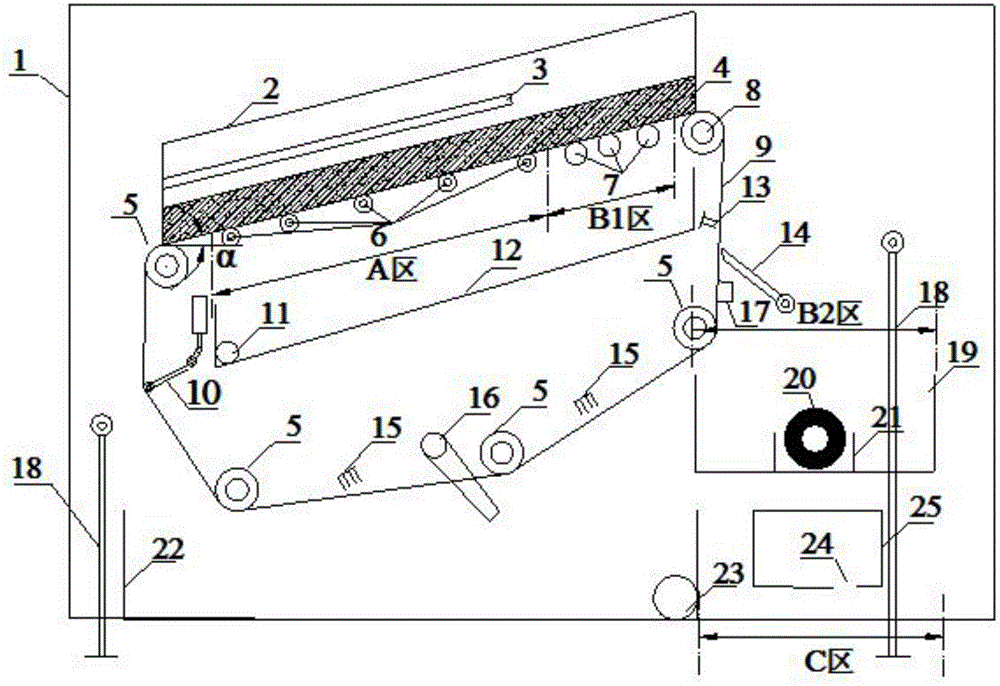

InactiveCN102608009AAccurate measurementContinuous measurementParticle suspension analysisGlass fiberAtmospheric air

An automatic particle monitor belongs to the technical field of atmosphere monitoring equipment and is used for monitoring the concentration of particles in atmosphere. The technical scheme includes that the automatic particle monitor consists of a dust sample separating portion, a dust sample collecting portion, a paper tape conveying portion, a dust sample detecting portion and a constant-flow portion, a cutter component of the dust sample separating portion is in direct-insertion type hard connection with a sampling tube of the dust sample collecting portion, a pipeline adapter connected to the lower end of the sampling tube is hermetically connected with a shell, the dust sample detecting portion is embedded in the dust sample collecting portion, a glass fiber filter tape of the paper tape conveying portion penetrates between a direct-proportion counter of the dust sample detecting portion and a radioactive source, a plurality of sensors and an adjusting valve of the constant-flow portion are connected onto a pipeline at the rear of an air outlet tube of the dust sample collecting portion, and the adjusting valve is connected with an external pump. The automatic particle monitor has the advantages that the automatic particle monitor is simple in structure, long in operating cycle and convenient in maintenance, monitors data fast and accurately, realizes real-time transmission and control with a center control station, does not need reagent, is pollution-free, and the like.

Owner:HEBEI SAILHERO ENVIRONMENTAL PROTECTION HIGH TECH

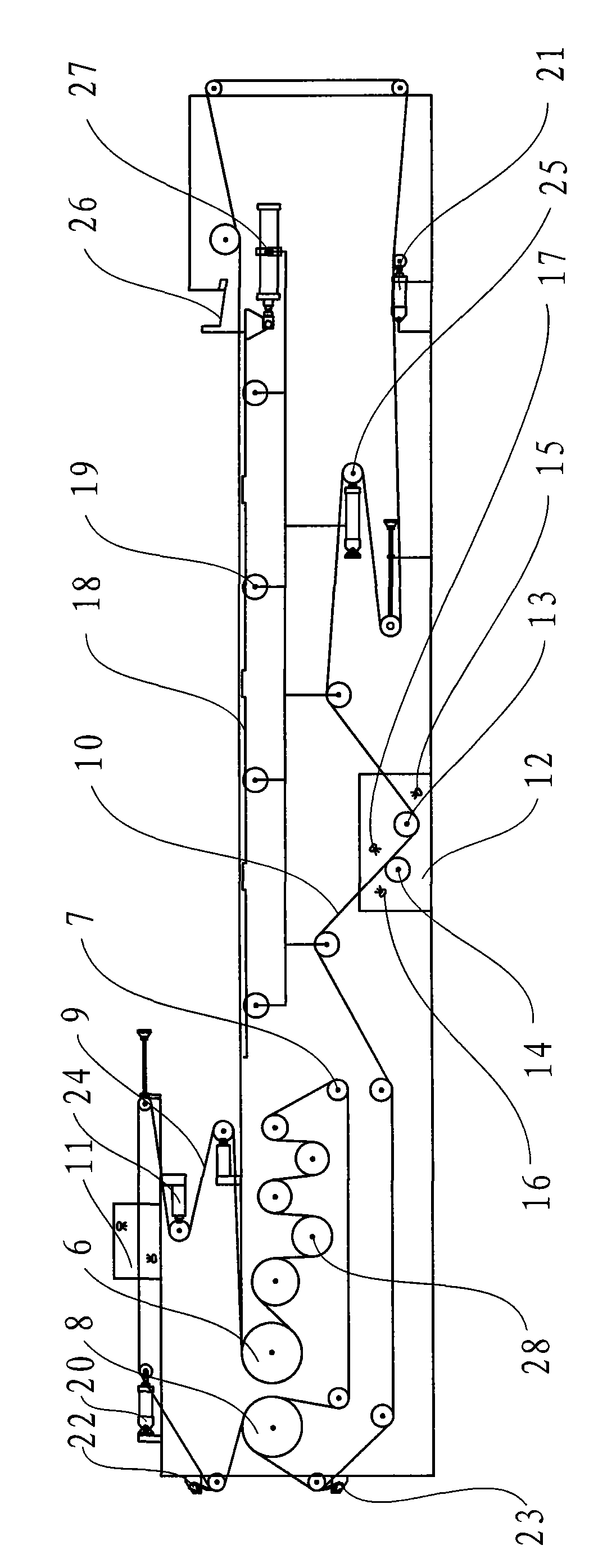

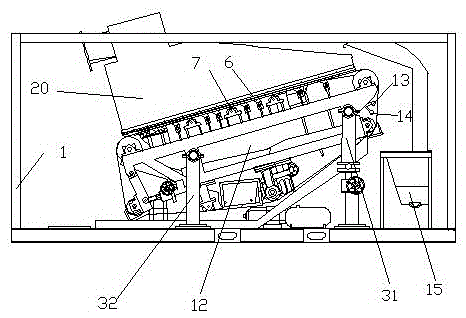

High-efficiency energy-saving belt filter press

InactiveCN103007614ANot easy to runSolve slipperyChemical industryMoving filtering element filtersChemical industrySlag

The invention discloses a high-efficiency energy-saving belt filter press which comprises a frame, a filter press belt, a hopper and a motor, and is characterized in that a material equalizing regulation device is arranged at a discharging end of the frame; the filter press belt is a double-layer filter cloth belt; a four-stage press filtering mechanism is arranged on the discharged filter press belt at intervals; a vacuum suction filtration disc for vacuumizing by utilizing a vacuum pump is arranged below the filter press belt behind a mesh cage roller; a tail gas cleaning mesh-cleaning roller and a filter press belt gas ejector pipe are respectively arranged on the mesh cage roller and on a belt return part of the filter press belt. The machine is uniform in feeding, long in service life, stable in performance, good in dewatering effect and high in yield, and the filter belt is difficult to block; the slag adhered to the mesh cage roller and the filter press belt is subjected to air injection cleaning by utilizing the vacuum pump tail gas, and water and electric energy are saved; and the machine is suitable for squeezing and dewatering manioc waste, cassava residues, bean dregs and distillers grains and water-containing raw materials in the industries such as municipal sludge, chemical industry, oil refining, papermaking and sugar refining.

Owner:陆汉克

Vacuum belt press filter

InactiveCN101612805AEasy to cleanRealize automatic continuous operationCleaning using liquidsPressesFiltrationPulp and paper industry

The invention relates to a vacuum belt press filter, comprising a rack, a vacuum filtration assembly, a press assembly and a filtration belt assembly, wherein the filtration belt assembly comprises an upper filtration belt, a lower filtration belt, and a cleaning device A and a cleaning device B which are used for respectively cleaning the upper filtration belt and the lower filtration belt; the cleaning device B comprises a front guide roller and a rear guide roller on the motion direction of the lower filtration belt, the front guide roller is arranged on the upper face the lower filtration belt, closely contacts the lower filtration belt and enables the lower filtration belt to form a V shape, the rear guide roller is arranged on the lower face of the lower filtration belt and is provided with a plurality of pinpricks, the size of each pinprick is matched with the size of a filtration pore of the filtration belt, and the rear guide roller contacts with the lower filtration belt by the pinpricks; and the cleaning device B is provided with a plurality of spray heads, and the spray heads are distributed on the upper face and the lower face of the lower filtration belt. The vacuum belt press filter of the invention has the advantage of favorable cleaning effect of the filtration belts, and belongs to the technical field of press machines.

Owner:HUZHOU HEHONG MACHINERY

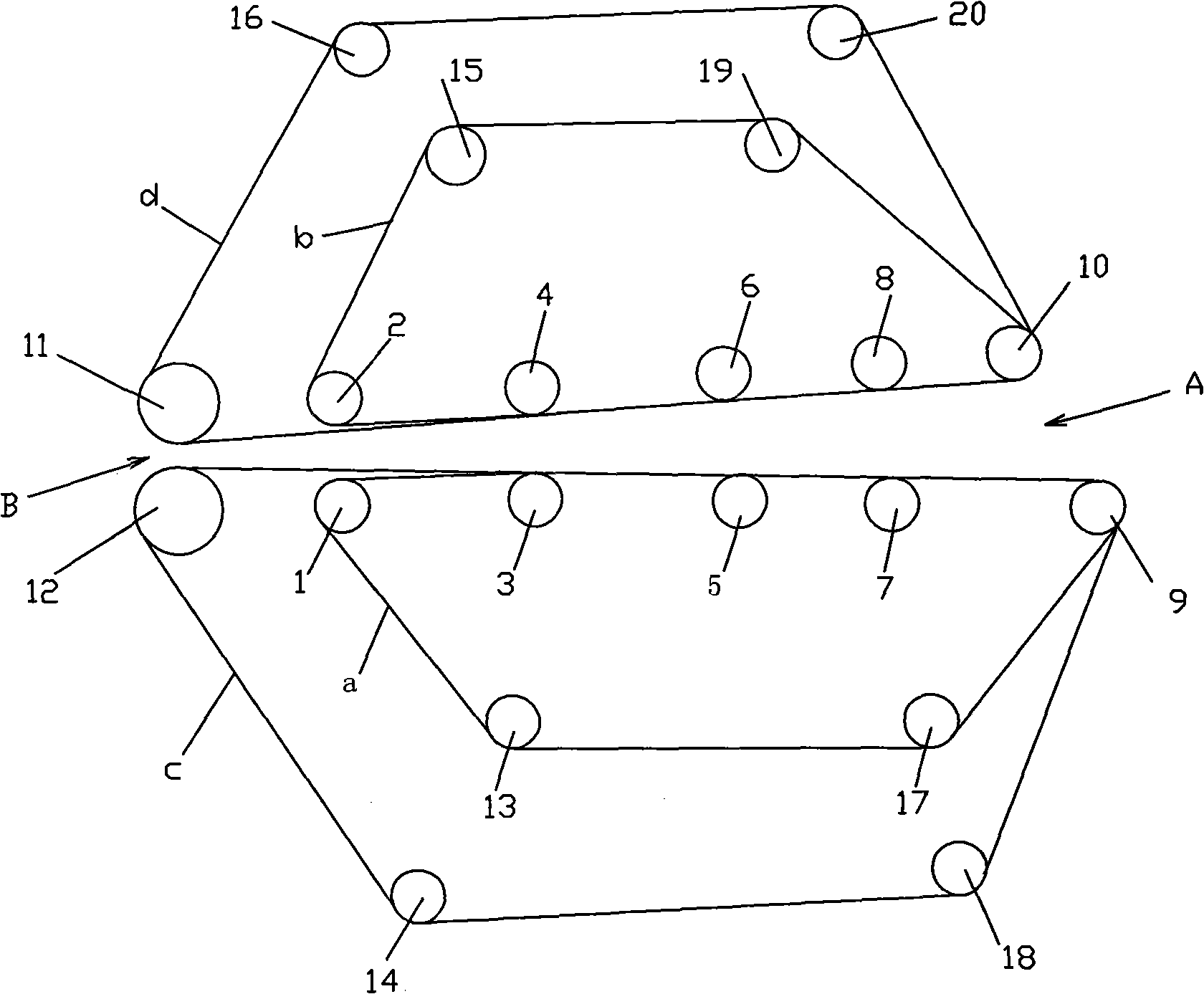

Triangular belt type filter press

InactiveCN101279163AReasonable structureDesign sciencePressesMoving filtering element filtersCounter pressureEngineering

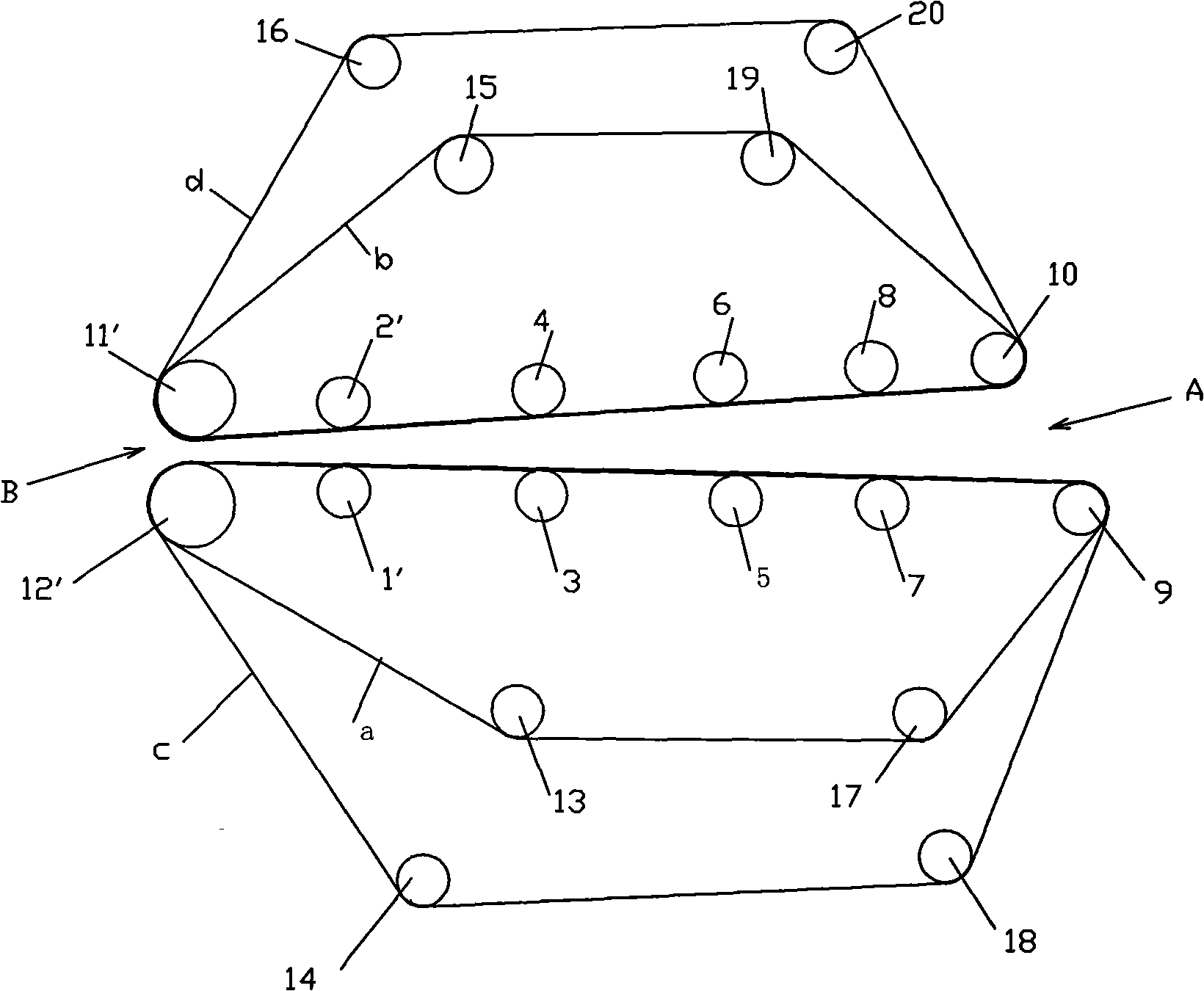

The invention discloses a wedge-shaped draper-type press filter which consists essentially of a chassis, a pressing area, a driving device, a feeding device, a scrapper assembly, a deviation-rectifying device, a rinsing device and a water receiving device. The structure of the wedge-shaped draper-type press filter is characterized in that the pressing area is a wedge-shaped pressing area with an included angle more than zero degree but less than 15 degrees between an upper filter strip and a lower filter strip; the wedge-shaped pressing area is divided into an upper press area and a lower press area; respective tension band and filter strip of the upper press area and the lower press area are stacked and wrapped outside respective press roll in parallel; the tension band is stuck to the press roll and the filter strip is firmly stuck outside the tension band; the press rolls of two press areas are arranged in a counter pressure way. The draper-type press filter of the invention adopts a single wedge-shaped press area, changes press dehydration technique of the prior art that adopts a plurality of press rolls to enwind and operate in snaking way, realizes that the press roll operates press dehydration in a counter pressure and liner way, greatly reduces the abrasion of the filter strips caused by tension, effectively prolongs the service life of the filter strips and can reduce operation energy consumption of the press filter.

Owner:ZHEJIANG HUAZHANG TECH

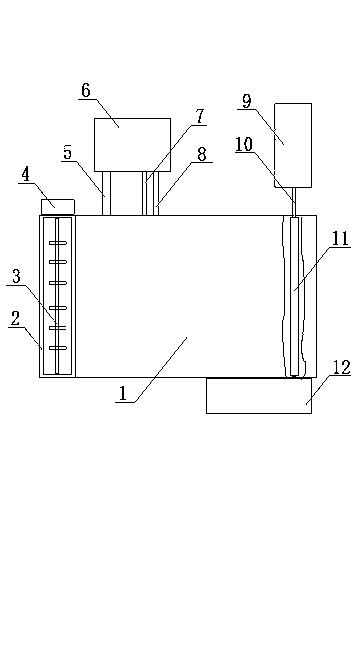

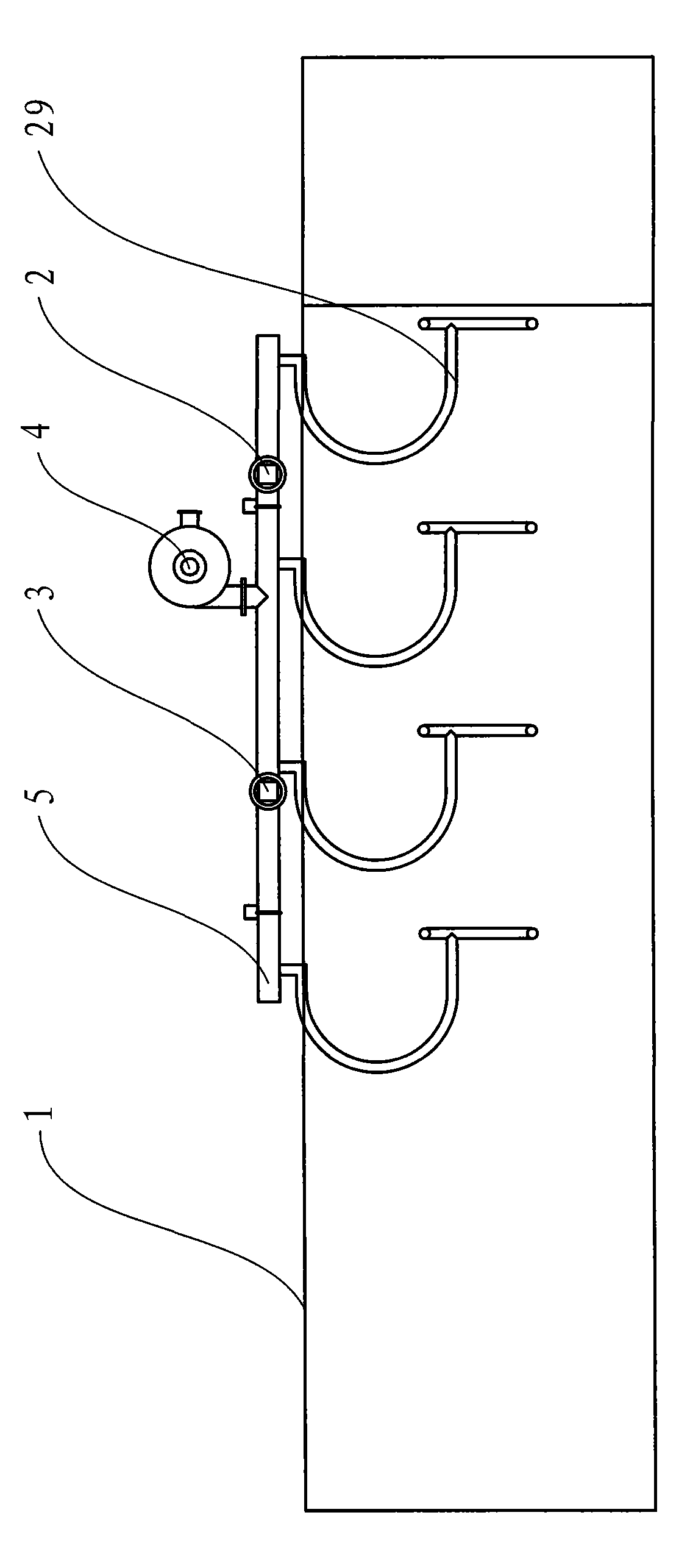

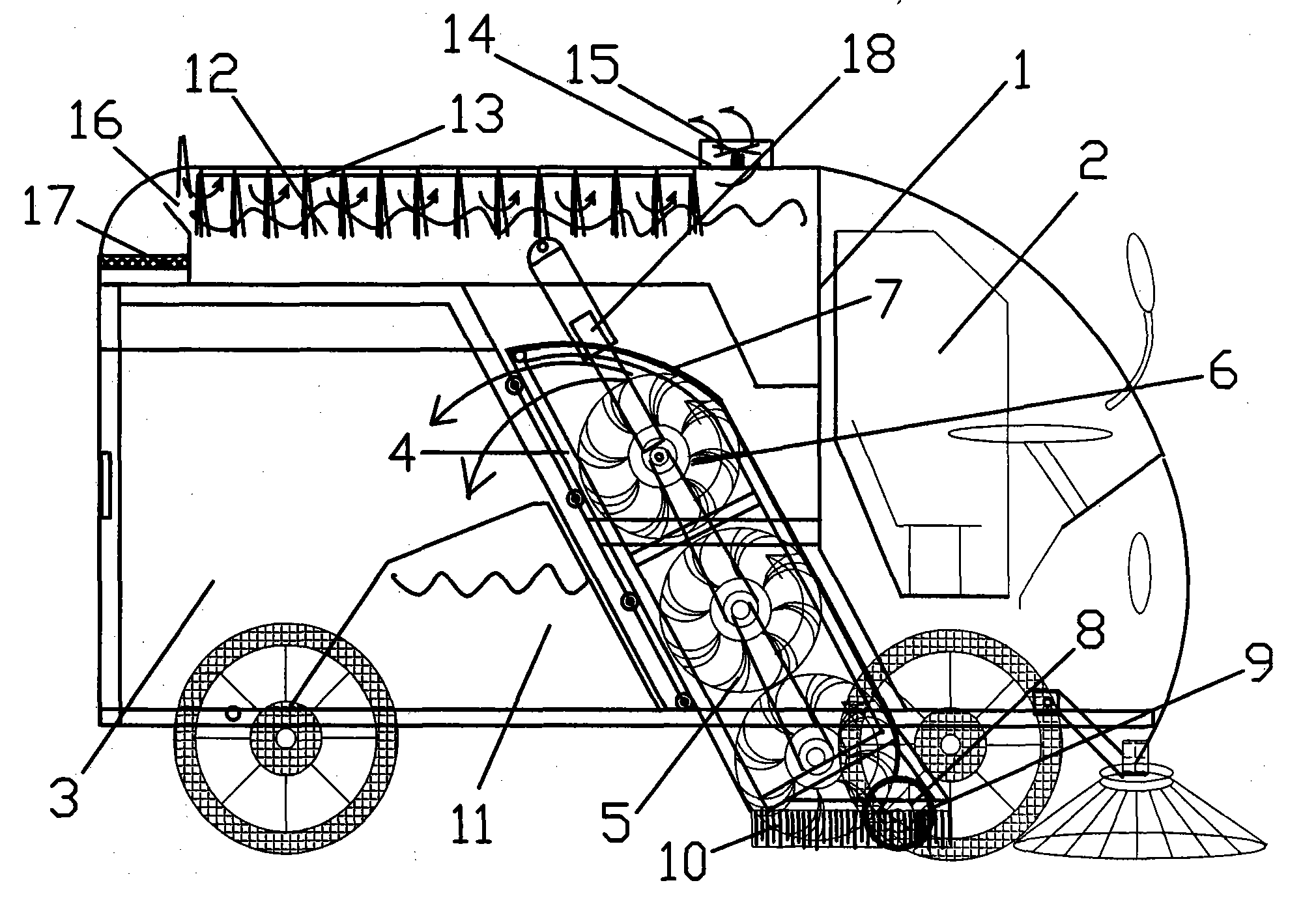

Self-cleaning dust filter

InactiveCN101543704ARealize automatic collectionImprove efficiencyHuman health protectionDispersed particle filtrationFiberFiltration

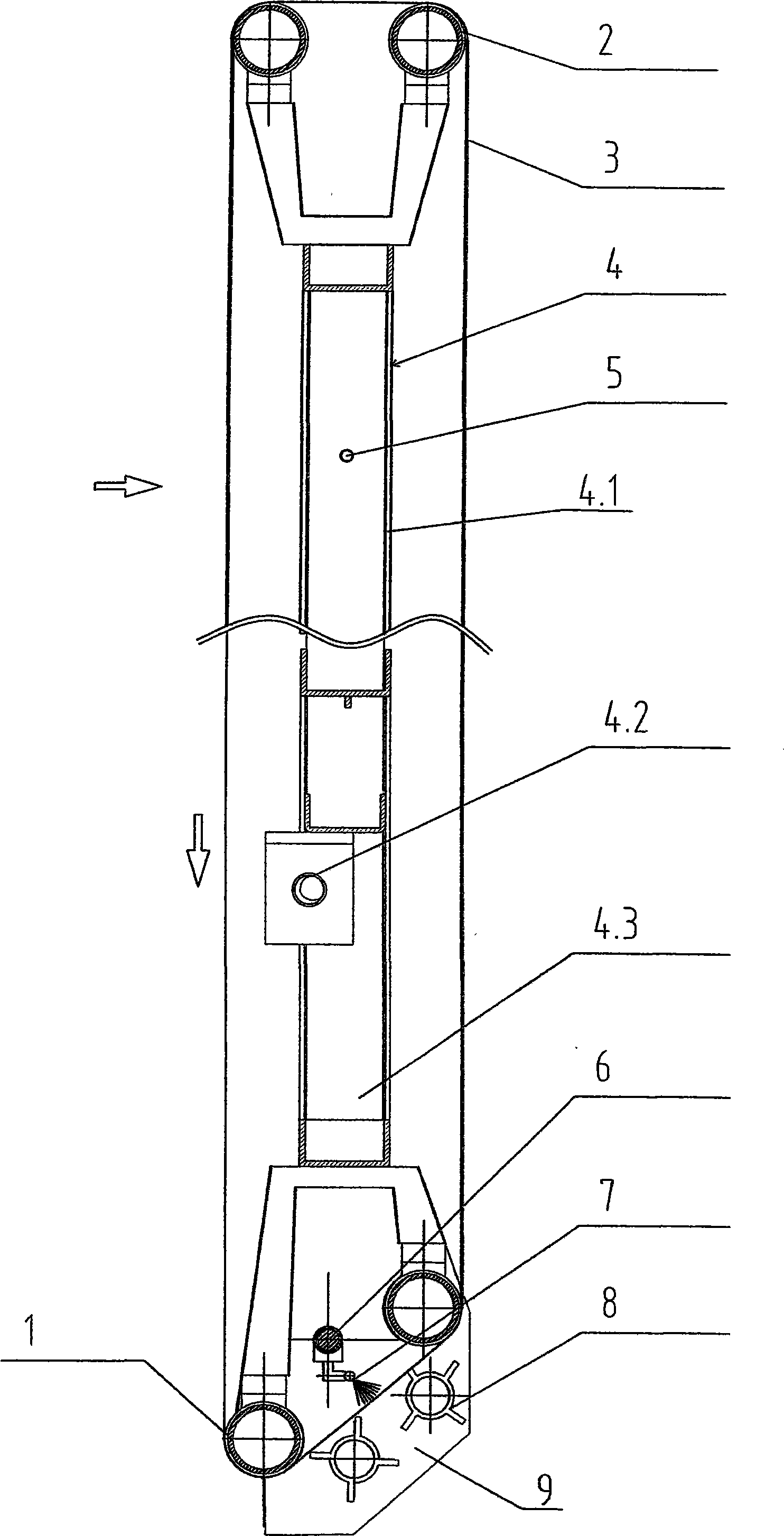

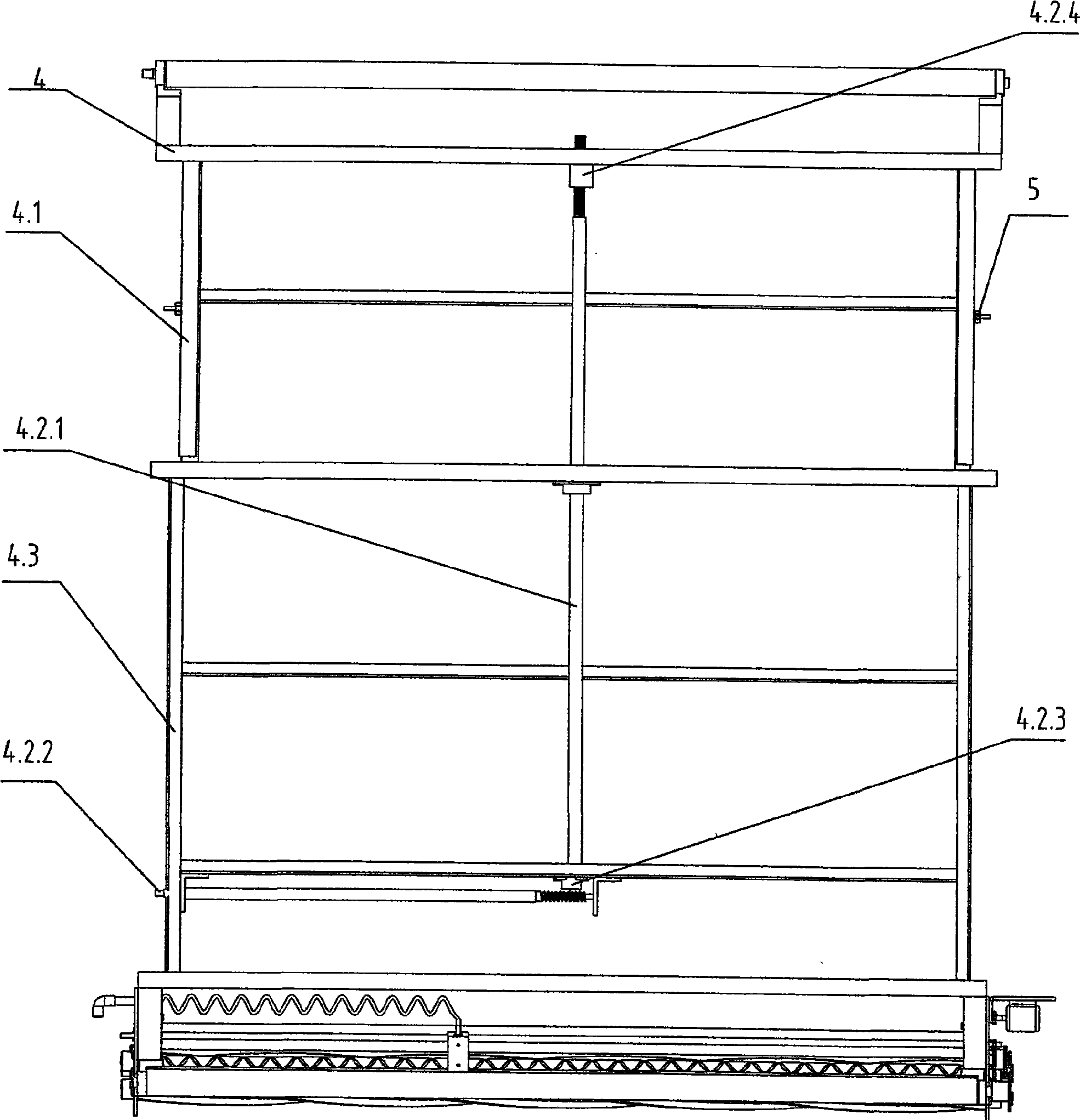

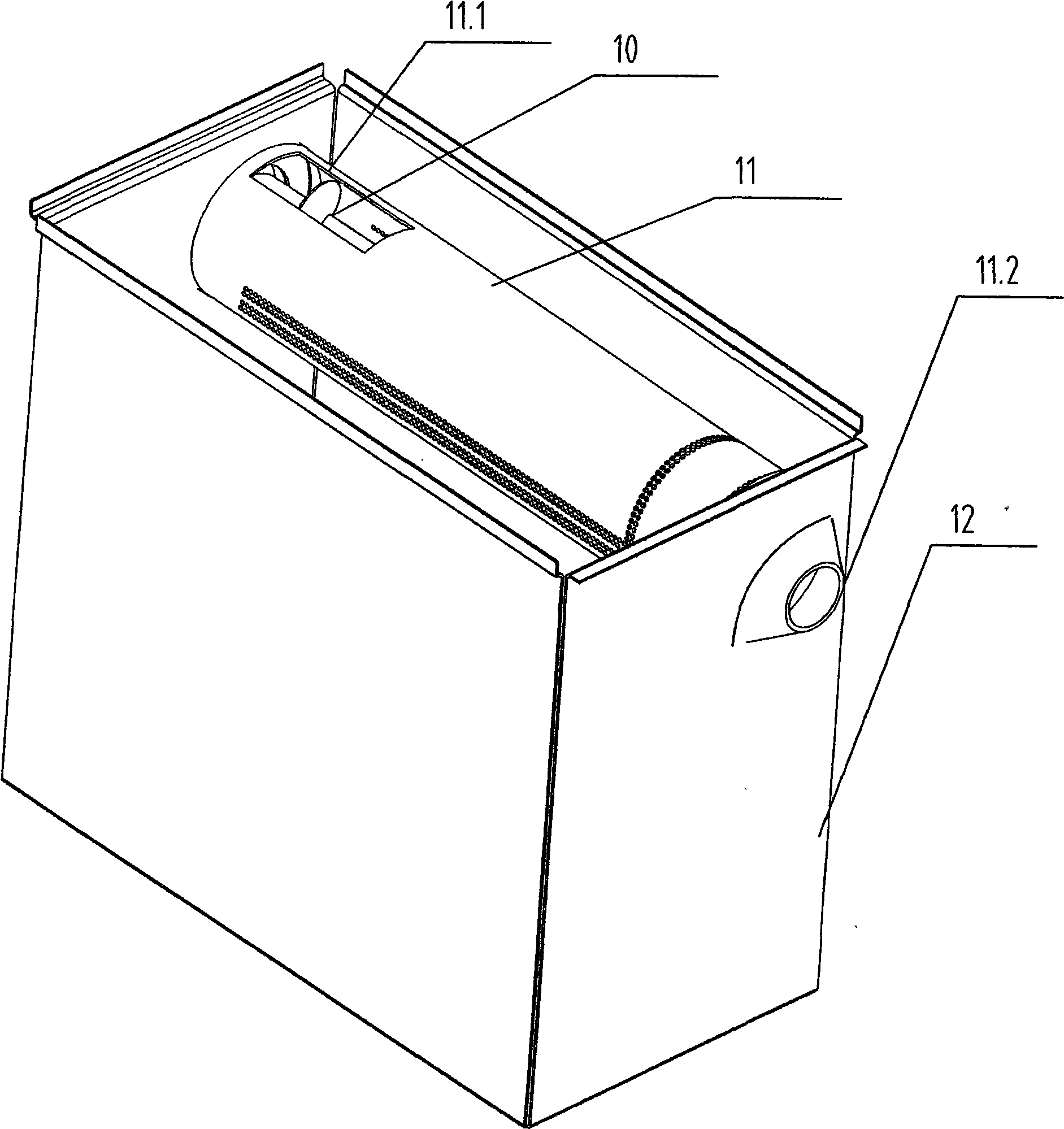

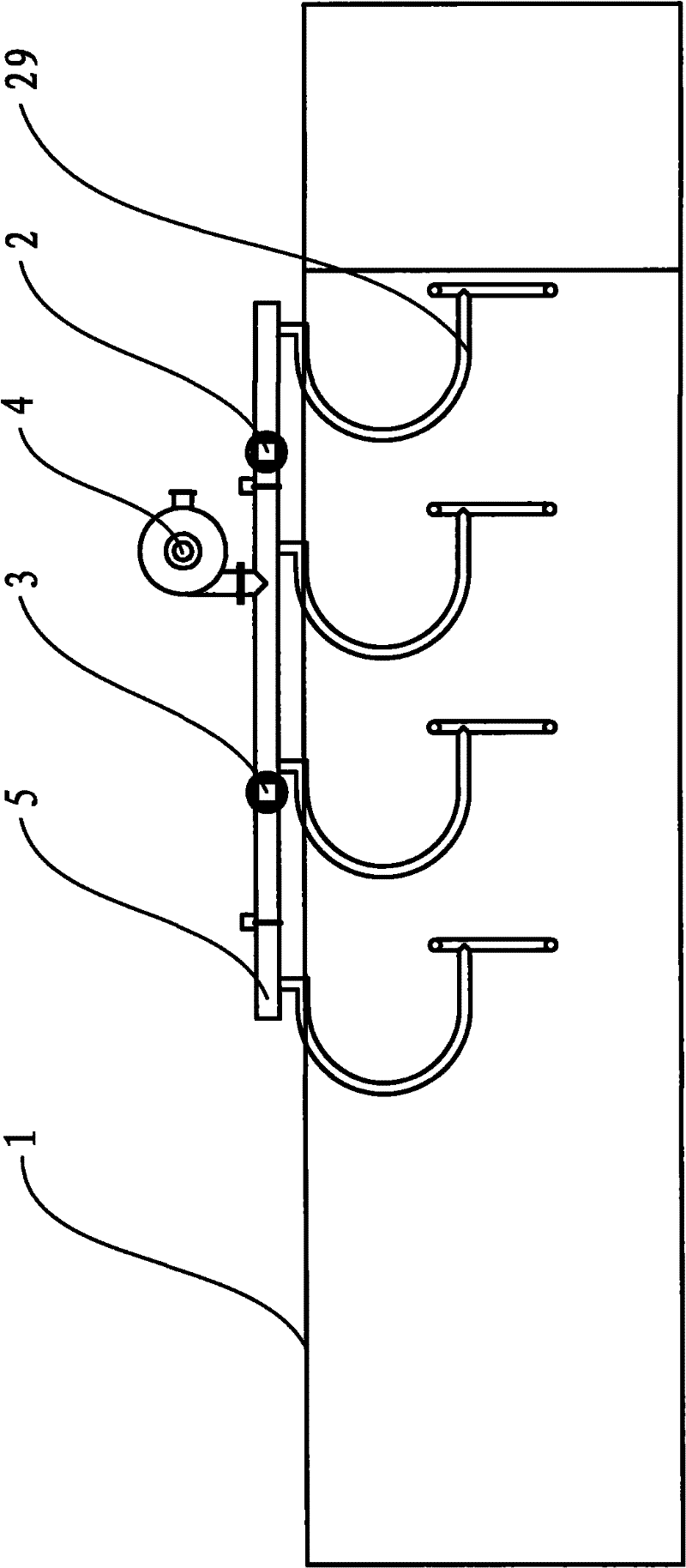

The invention relates to a self-cleaning dust filter suitable for air purification in production environments of industries, such as textile, grain processing, and the like. The self-cleaning dust filter comprises a dust filter main body and a water stain separation device, wherein the dust filter main body comprises a main body frame (4), a water tank (9), a driving rubber roller (1), a driven roller (2), a conveyer filter belt (3), a reciprocating screw rod (6), a high-pressure water pistol (7) and brush rollers (8); the driving rubber roller (1) is arranged at the lower part of the main body frame (4), and the driven roller (2) is arranged at the top of the main body frame (4); the conveyer filter belt (3) is sleeved on the driving rubber roller (1) and the driven roller (2), and the reciprocating screw rod (6) is arranged at the lower part of the main body frame (4) along the length direction of the driving rubber roller (1); the two brush rollers (8) are arranged in the water tank (9) along the length direction of the driving rubber roller (1), and the water stain separation device comprises a water reservoir (12), a mesh cylinder (11) and a screw (10). The self-cleaning dust filter is suitable for the dust filtration of viscous fibers.

Owner:JIANGSU JINGYA ENVIRONMENT TECH

Vacuum belt type filter and dehydration machine

InactiveCN1843559AReduce frictionSmall power configurationMoving filtering element filtersFriction reductionLow demand

The invention discloses a vacuum belt filter dewaterer. Wherein, the filter belt is adhered on the rubber belt of ripple groove that driven by the drive motor as the rubber belt to step for the same direction; the rubber belt ripple groove is connected to the vacuum room; the rubber belt is supported by two lubricative support blocks and sealed by water, while said two support blocks and rubber belt form the vacuum room; the rubber belt outside the vacuum room is aerial via the compressed air when in working to reduce the friction resistance; the filter cake is compressed and dewatered at the front of outlet to attain drier filter cake and reduce the energy for following drying; the filter screen can execute filtration after regeneration. The invention has the advantages that: it uses vacuum filtration, with large filter drive power; the filter cake is mechanically compressed with lower moisture percentage; it can automatically detect the thickness of filter cake, via which to control the speed of filter belt to confirm the uniformity of filter cake; it has lower demand for the solid content of filter liquid; and it can realize continuous operation with high automatic degree and better economic benefit.

Owner:ZHEJIANG UNIV

Vacuum belt press filter

ActiveCN101884857AEasy to dehydrateReduce moistureMoving filtering element filtersTherapeutic effectPulp and paper industry

The invention discloses a vacuum belt press filter, which comprises a frame, a driving device, a feeder, filter belts, a roller, a filter belt tension device, a filter belt cleaning device and a discharger. The driving device is arranged on the frame and drives the roller to rotate and upper and lower filter belts to run. The roller comprises a guide roller, a carrier roller, a constant pressure pressing roller and a vacuum roller. The vacuum belt press filter is characterized in that: the constant pressure pressing roller and / or the vacuum roller performs press filtering on wet materials in a singly mounted or oppositely mounted mode; the vacuum roller is at least provided with two or more vacuum cavities in the same vacuum chamber, and the vacuum cavities are distributed corresponding to the thickness of filter cakes of press-filtering materials, and are distributed from the higher part to the lower part and from the middle part to two sides in turn; during operation, higher and lower vacuum cavities form different vacuum degrees so as to guarantee that all the materials can be penetrated by vacuum negative pressure; and the water which is extruded out of the material surface and adhered on the filter belts is rapidly pumped into a vacuum pressing roller under the action of the mechanical extrusion of the pressing roller. Therefore, the great reduction of the water of press-filtering materials is realized, and the higher comprehensive treatment effect is achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

Particulate matter concentration measuring apparatus

InactiveUS6964190B2Accurate measurementHigh sensitivityComponent separationElectric discharge tubesCycloneProduct gas

Owner:HORIBA LTD

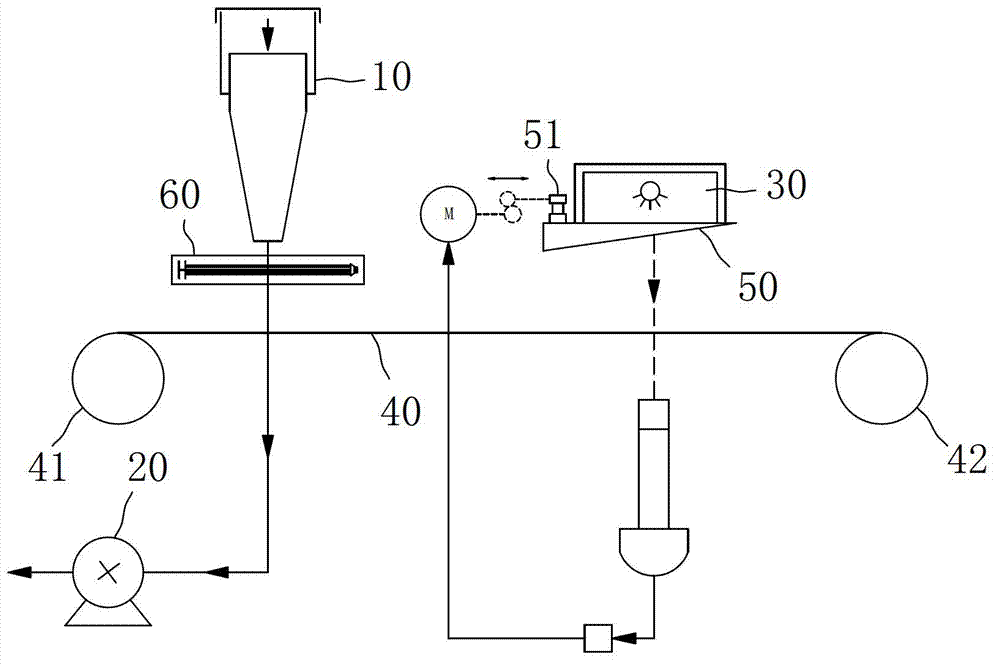

Rapid carbon separation device for sewage treatment

ActiveCN105477923AReduce processing costsReduce construction costsMembrane filtersMoving filtering element filtersFiltrationSewage

The invention relates to the technical field of water treatment and aims at providing a rapid carbon separation device for sewage treatment. The device comprises a filtration band which can load sewage at a minimum, a surge suction device is arranged below the filtration band, after the sewage is filtered through the filtration band, obtained clean water is collected below the filtration band, and impurities filtered out of the sewage are located on the filtration band and collected in a centralized mode. By means of application of the device to sewage treatment, the traditional sewage treatment process can be subverted thoroughly, construction cost of sewage treatment plants is greatly saved, and meanwhile sewage treatment cost is remarkably lowered.

Owner:WEIHAI FENGTAI NEW MATERIAL SCI & TECH

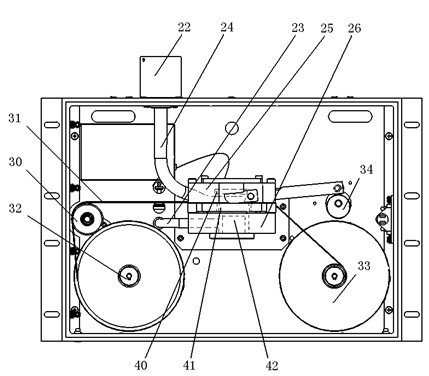

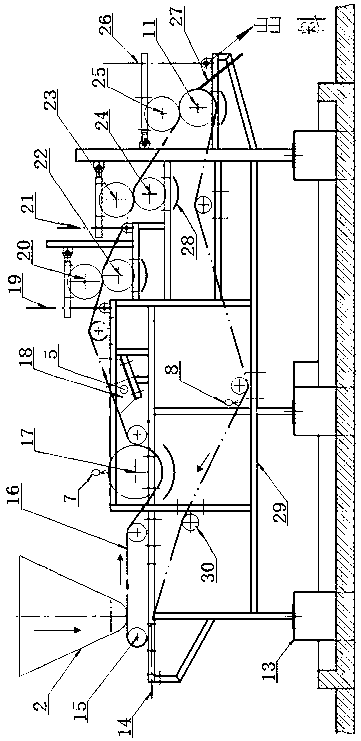

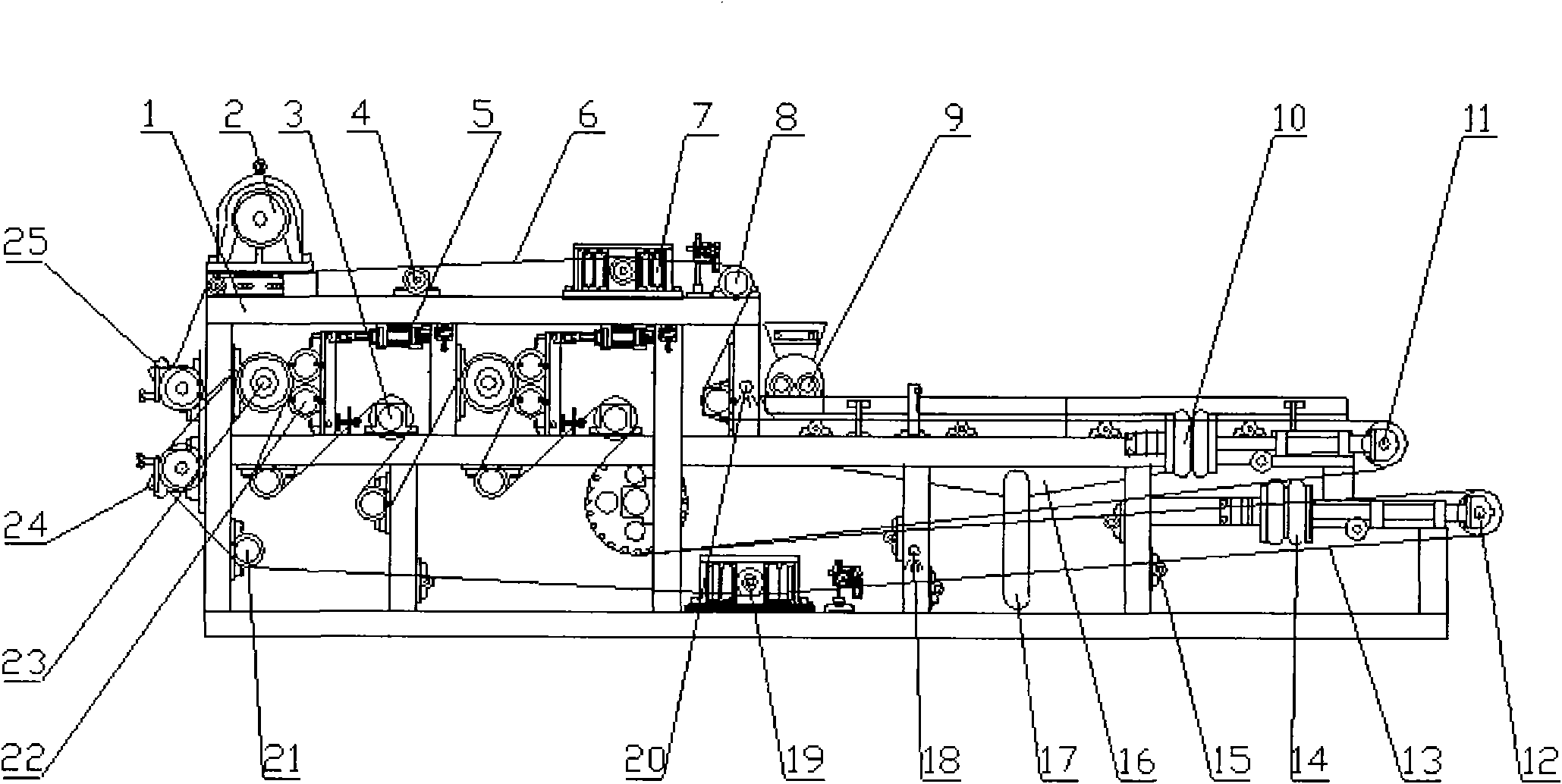

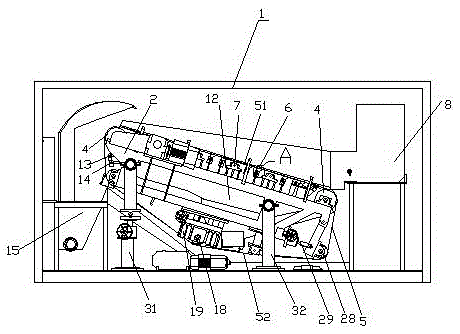

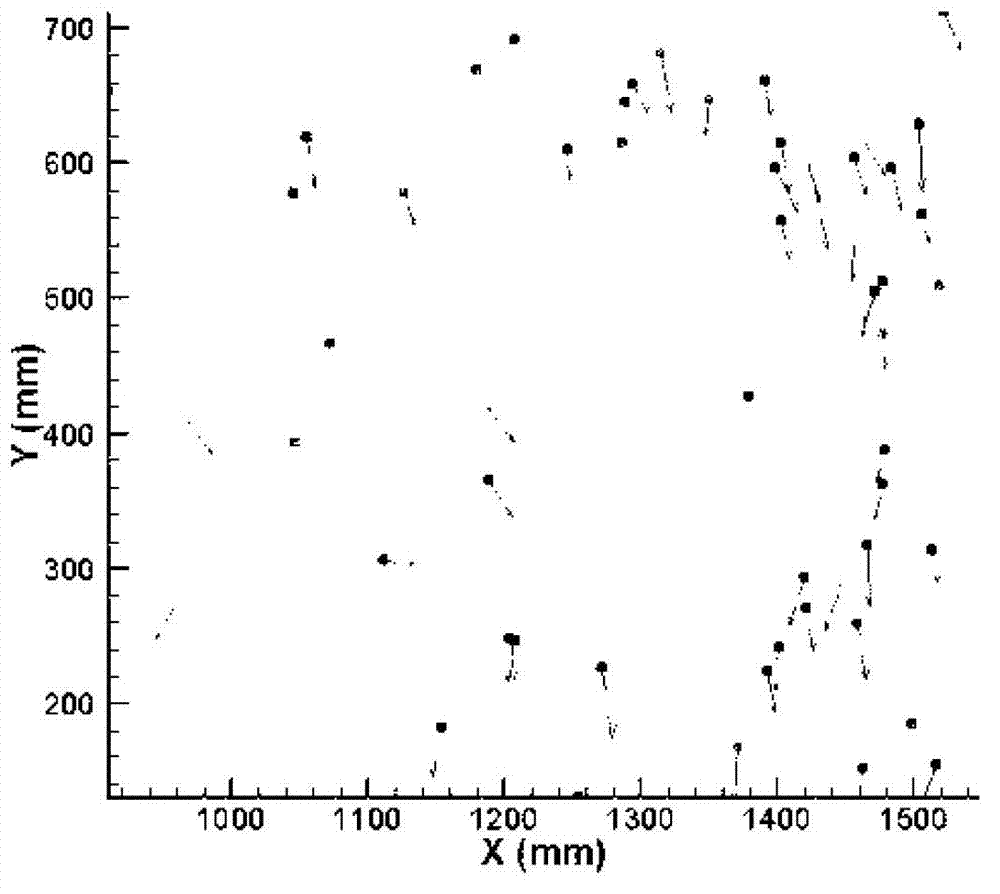

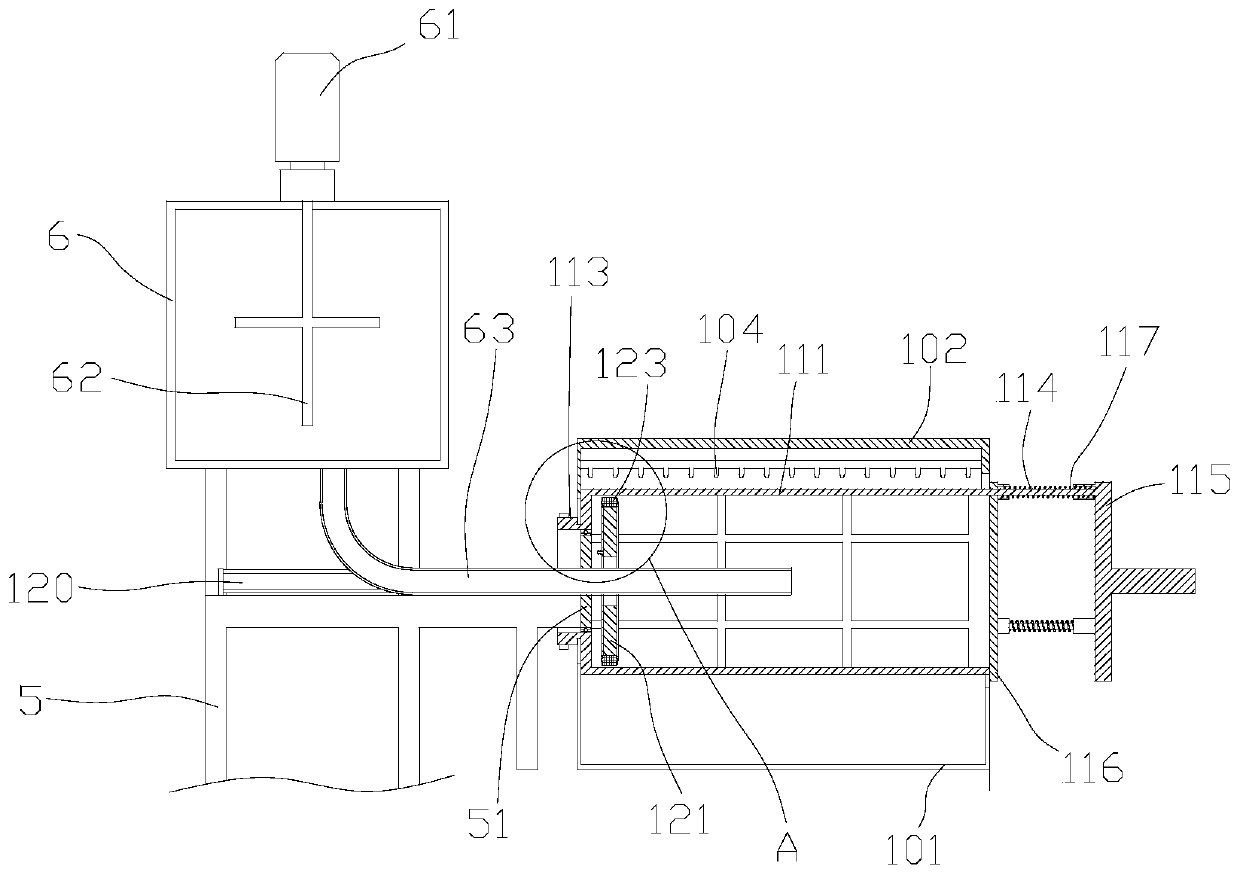

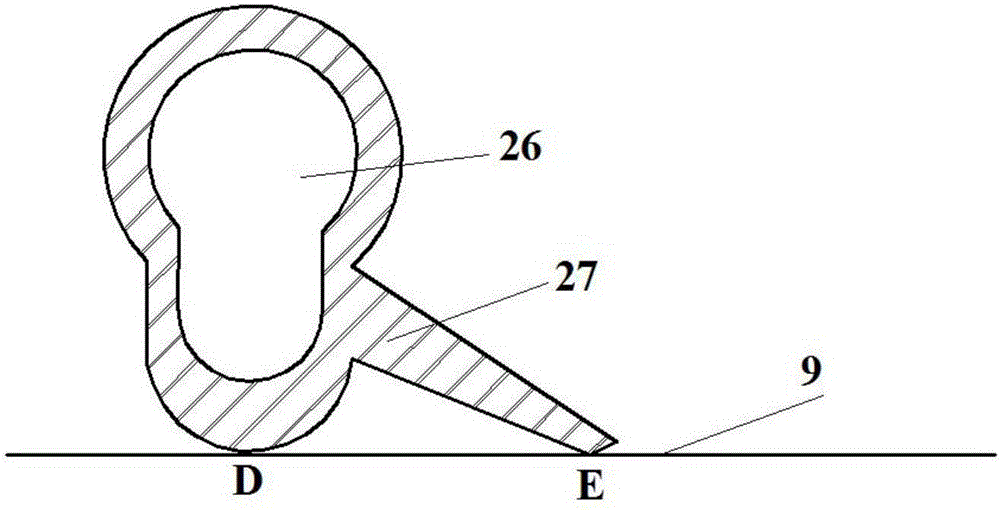

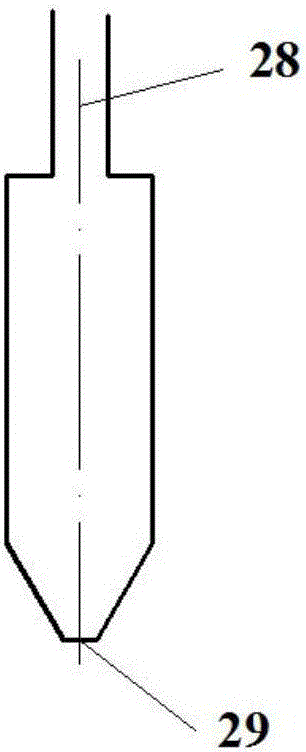

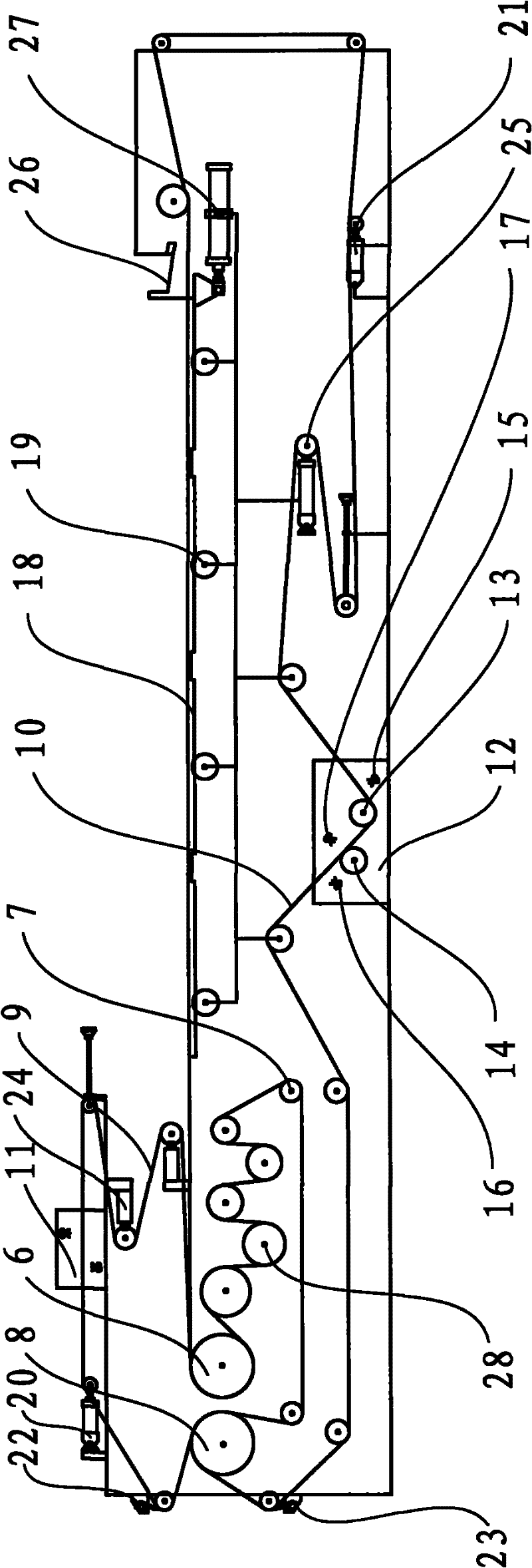

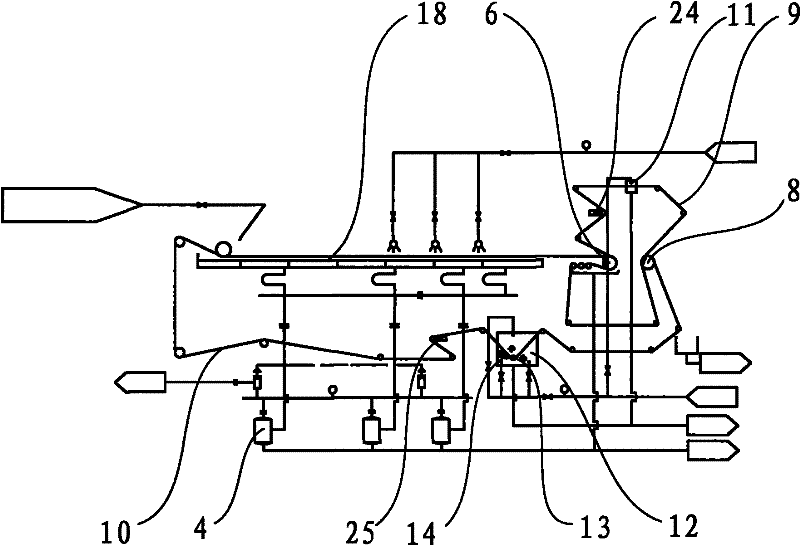

Method for measuring concentration of particulate matter, and device adopting method

ActiveCN103245601AEasy to calculateGuaranteed calculation accuracyParticle suspension analysisAir volumePower unit

The invention belongs to the technical field of concentration measurement of atmospheric particulates, and particularly relates to a method for measuring the concentration of a particulate matter by a PIV (Particle Image Velocimetry) method, and a device adopting the method. The method comprises the following steps of: acquiring the size, shape and volume of each particle and calculating the mass of all types of particles; calculating the total sampled air volume according to the known flow and measurement time; and calculating the concentration of a particulate matter (PM) to be measured. Not only the method is convenient and quick in measuring and calculating, but also the calculating precision can be effectively ensured. The device comprises a particulate matter sampling mechanism, a filter strip conveying mechanism, a beta-ray radiation mechanism and a beta-ray receiving and measuring mechanism; the device further comprises a damping control component and a power unit, wherein the damping control component is close to the radiation outlet end of a beta-ray radiation source; and a PIV unit is also included. The device has the advantages of safety and reliability in use, simple and practical structure, correspondingly and remarkably improved occupied area and maintenance efficiency, and high measuring accuracy.

Owner:合肥福瞳光电科技有限公司

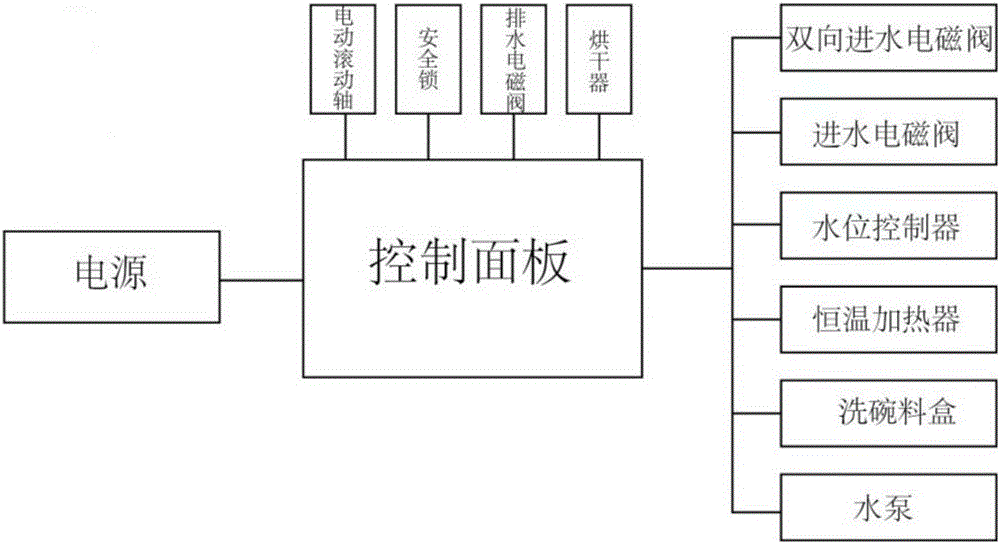

Fully-automatic multifunctional dining table with dish washing function

InactiveCN105286296APromote excretionSolve the problem of unclean flushing in dead cornersMachine detailsTableware washing/rinsing machinesGratingWater level

The invention discloses an improved fully-automatic multifunctional dining table with a dish washing function. The dining table comprises a table top and a hollow base and is characterized in that a drier, a control panel and a dish washing drawer are arranged under the table top, an upper water spray arm, a lower water spray arm, a grating and a residue flush pipe are arranged in the drawer, a filter strip is arranged behind and below the dish washing drawer, one end of the filter strip is located above the residue flush pipe and corresponds to the residue flush pipe, and the dish washing drawer is communicated with the drier; a water container is arranged in the hollow base, a constant-temperature heater, a water level controller, a dish washing material box and a filter mesh bag are arranged in the water container, and the lower portion of the water container is communicated with a water pump through a pipeline. The dining table is mainly used in various families.

Owner:毛丹

Novel high-performance belt pressure filter

ActiveCN102600656AImprove dehydration efficiencyAchieve separationMoving filtering element filtersEngineeringFilter press

The invention relates to a novel high-performance belt pressure filter, wherein a main pressure roller is orderly and spirally arranged from low to high in a vertical direction of a plane in a pressure filter area, horizontal position on the top of the previous roller ot two adjacent main pressure roller is higher or equal to the horizontal position at bottom of the next roller; a lower filter belt is overlaied with an upper filter belt to clamp the pressure filter materials so as to make the materials enter the pressure filter area from the main pressure roller at the lowest position; each main pressure roller of the upper filter belt and the lower filter belt in the pressure filter area is wrapped from lower part and leaves from upper part. Because of reasonable arrangement of the pressure rollers, the water produced by extruding the materials during pressure filter process automatically falls into a water catcher below a roller barrel so as to prevent the water reflowing into the extruded or to-be-extruded materials and to greatly increase the dehydration efficiency of the belt pressure filter.

Owner:GUANGXI LIYUANBAO SCI & TECH

Preparation process of honeycomb catalyst for coal-fired flue gas denitration in thermal power plant as well as product and application of preparation process

InactiveCN109046320AHigh strengthHigh compressive strengthGas treatmentHeterogenous catalyst chemical elementsSolventChemistry

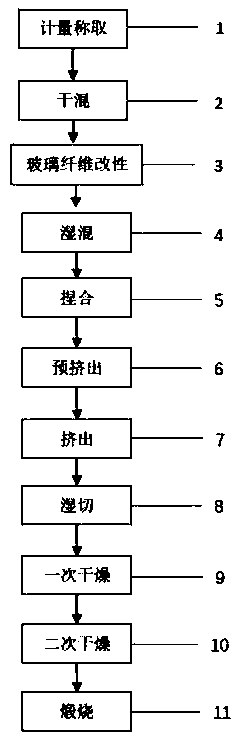

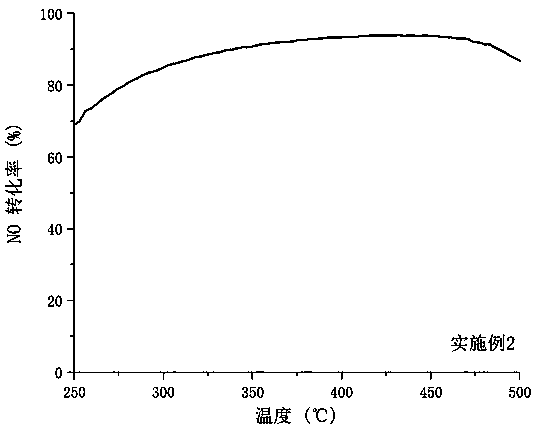

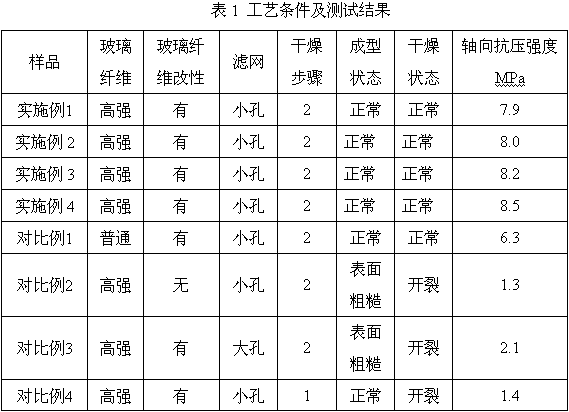

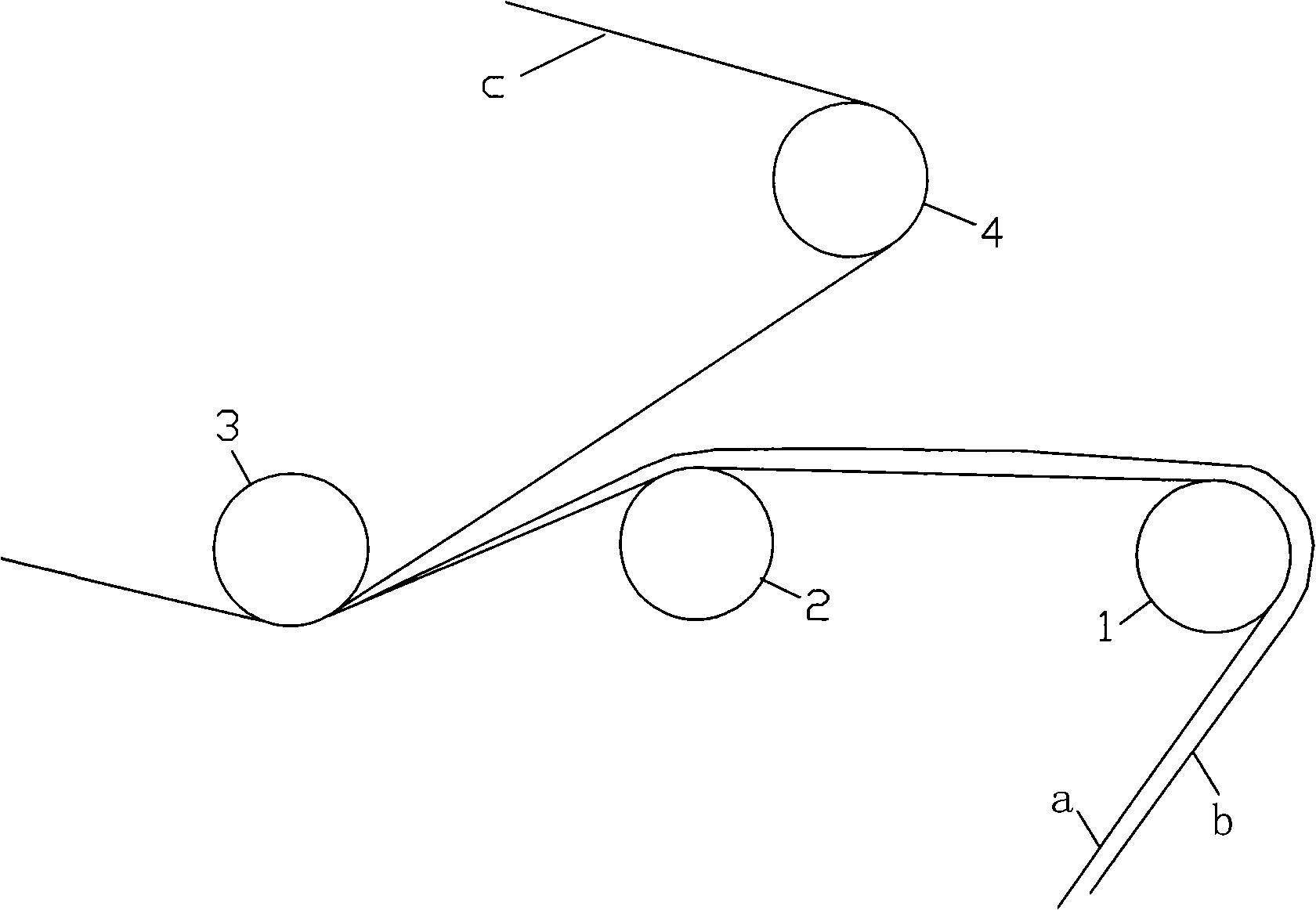

The invention discloses a preparation process of a honeycomb catalyst for coal-fired flue gas denitration in a thermal power plant as well as the product and application of the preparation process. According to the preparation process, TiO2, WO3, a catalytic addictive and V2O5 are taken as effective components, glass fibers, an organic binding agent, an inorganic binding agent, a pore-forming agent, a neutralizer and a solvent are added, and the honeycomb catalyst is prepared by mixing, kneading, carrying out extrusion molding, drying and firing. According to the preparation process, a wet green body is obtaining by adding the binding agents for modifying the glass fibers, adding the specific catalytic addictive, sequentially adding the other additives, adding a filter screen with a specific specification for filtering strips, carrying out extrusion molding and evenly mixing; the wet green body is treated by a drying process for twice, so that the large-size wet green body is enabled to be uniformly dried and does not easily crack; finally, the honeycomb catalyst is obtained by calcining. The honeycomb catalyst is high in compression strength, and the catalytic denitration rate ofthe honeycomb catalyst is greater than 80%.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Band press filter with mud fixing belt

ActiveCN101279162AAvoid material runningGuaranteed continuous operationMoving filtering element filtersBand-pass filterEngineering

The invention discloses a solid-liquid separation device, in particular to a draper-type press filter with a mud fixing draper. The draper-type press filter with the mud fixing draper consists essentially of a chassis, a driving device, a feeding device, a pressing and filtering area and an auxiliary device. The pressing and filtering area comprises a press roll and filtering strips and is arranged on the chassis; the driving device is connected with the press roll; the filter strips are wrapped outside the press roll; the feeding device faces a feeding inlet of the pressing and filtering area and the auxiliary device is positioned at the corresponding position of the filter strips. The structure of the solid-liquid separation device is characterized in that: the solid-liquid separation device also comprises the mud fixing draper which is folded between an upper filter strip and a lower filter strip and wrapped outside the press roll together with the lower filter strip. The solid-liquid separation device effectively overcomes the defects of material escaping and unsmooth feeding of the draper-type press filter existing in the prior art, guarantees the normal operation of the press filter and greatly promotes the dehydration output of the draper-type press filter.

Owner:ZHEJIANG HUAZHANG TECH

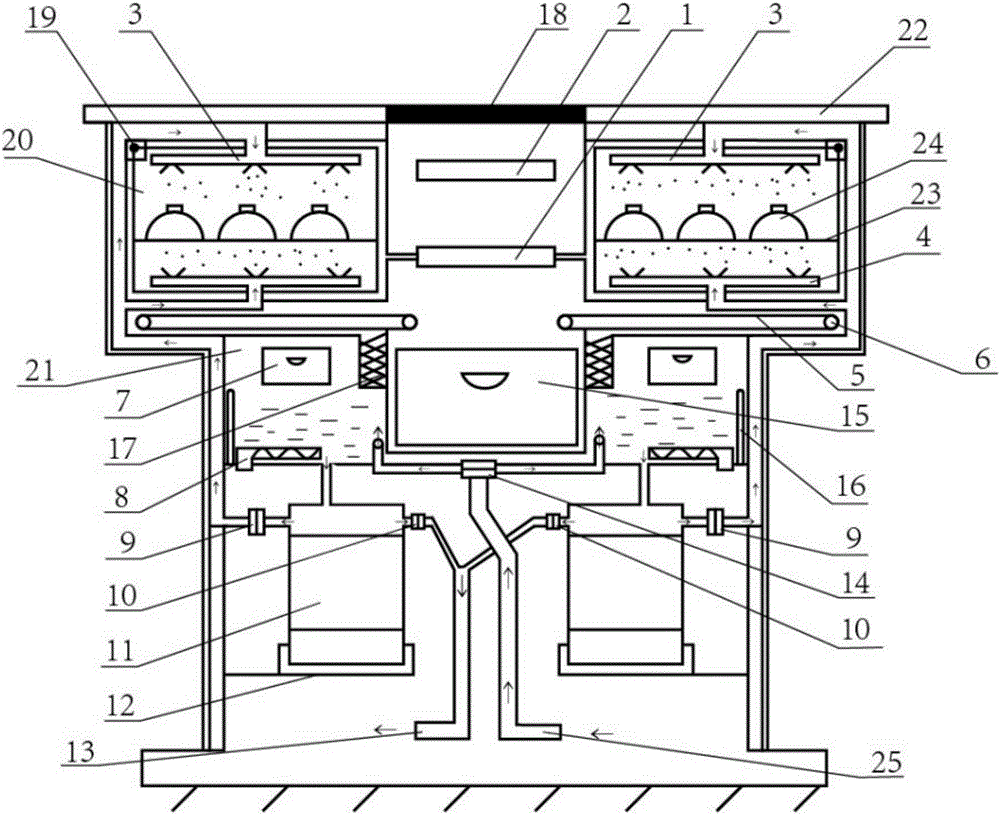

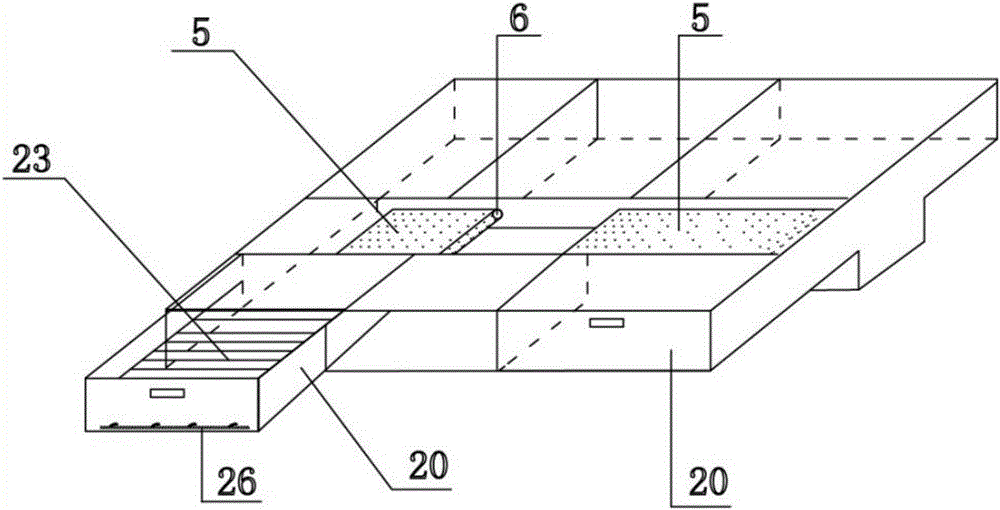

Culturing farm dung treatment system

InactiveCN110746076AAvoid breedingConvenient for subsequent transportation and storageSludge treatment by de-watering/drying/thickeningWaste water treatment from animal husbandryWater treatment systemAgricultural engineering

The invention discloses a culturing farm dung treatment system. The system mainly comprises a drum spin-drying device, a filter pressing device, a drying device and a controller, the left side of thedrum spin-drying device is connected with a stirring box, the filter pressing device is arranged below the drum spin-drying device, the drying device is arranged on the ground at the left side of thedrum spin-drying device; an elevator is arranged between the filter pressing device and the drying device, the drum spin-drying device comprises a rotatable support frame and a filter screen cloth, the filter pressing device comprises two filter belts and a plurality of rotating rollers, a plurality of drying plates are arranged in the drying device, excrement is laid and collected through a material distribution mechanism, a material storage bin is arranged on the ground below the drying plates, an air draft pipeline is arranged in the upper portion of a drying chamber, and the air draft pipeline is connected with an air draft fan and then extends into a deodorization pool. Solid-liquid separation of dung can be achieved, and the drying device can dry solid dung to obtain dry dung and process odor in the airing process.

Owner:李佳丽

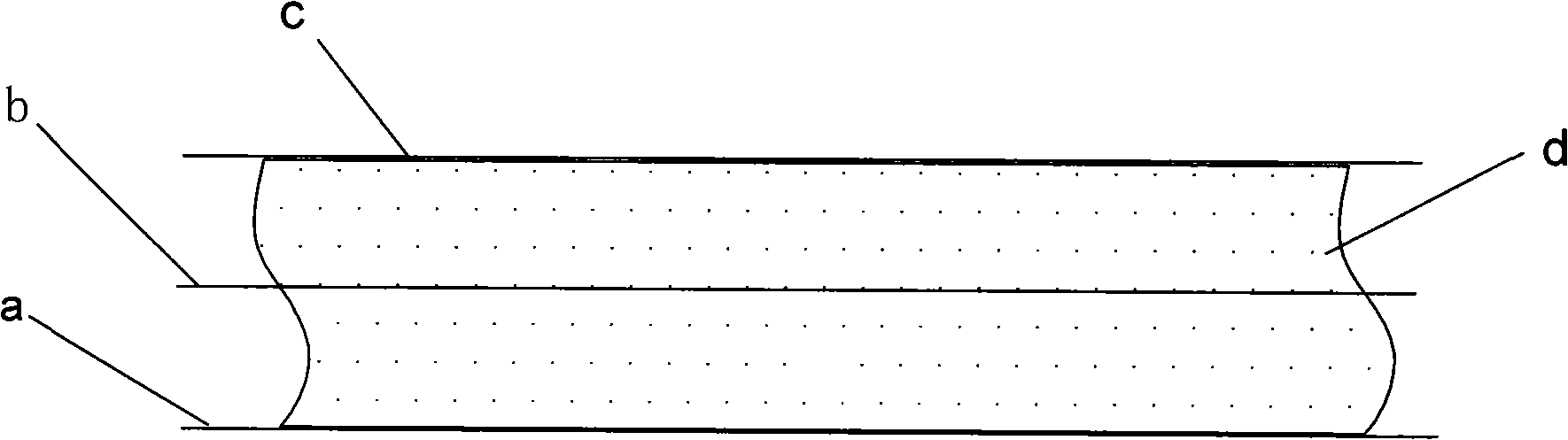

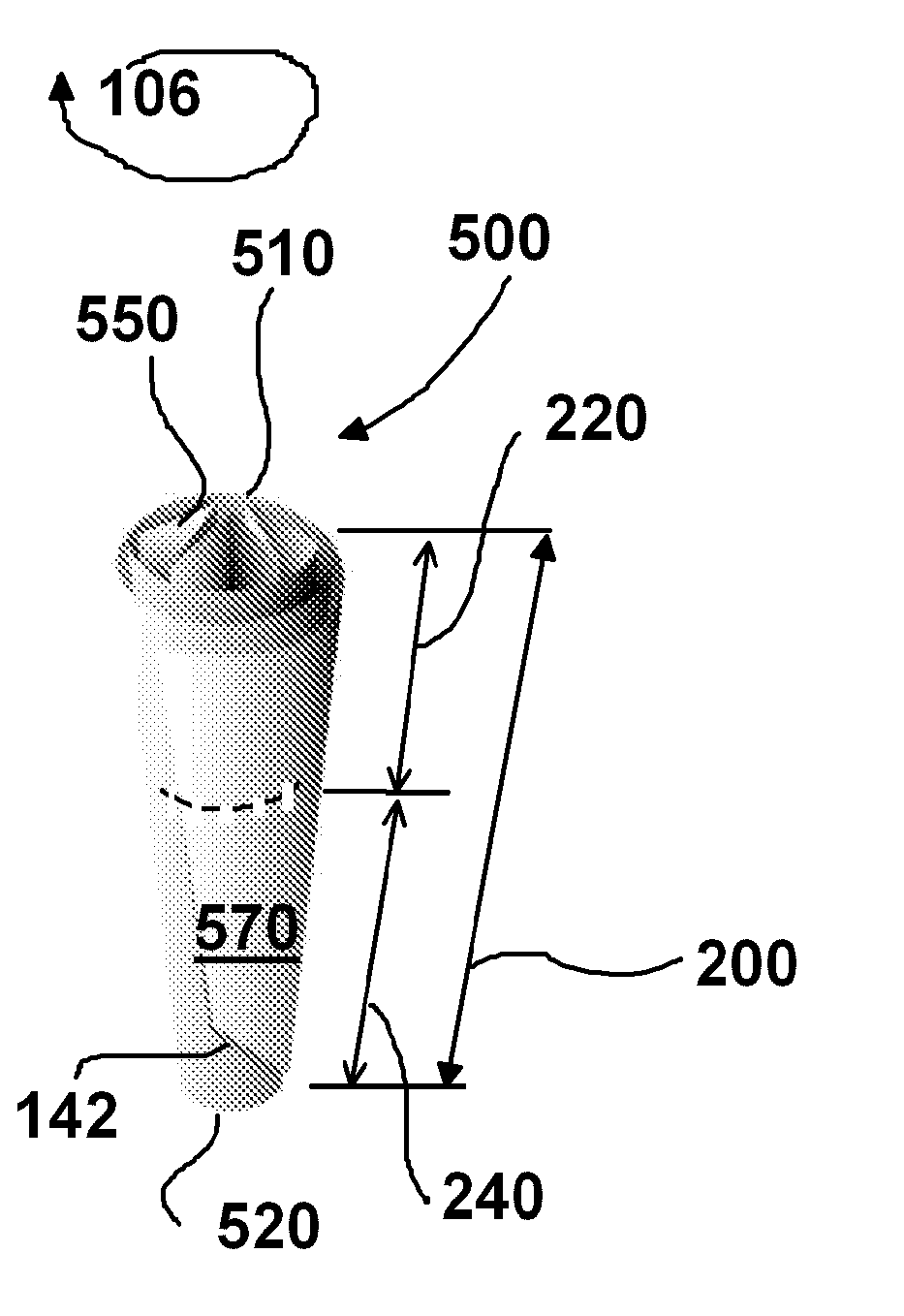

Filter tip, tubes, and cones

A filter strip is provided for rolling sheets to construct custom cigars and / or cigarettes. The filter strip may be made of a deformable material which can be positioned on one end of the rolling sheet. The filter strip can be folded in a zig zag or spiral filter section with open section located longitudinally below to form a filter tip. The filter tip can assist the user in rolling by hand a substantially cylindrical or conical cigar or cigarette. The filter tip prevents tobacco filler material from being drawn through the cigar or cigarette and into a user's mouth, and permits the entire amount of tobacco filler to be consumed / smoked without risking burned hands and / or lips.

Owner:SINCLAIR DANIEL JR

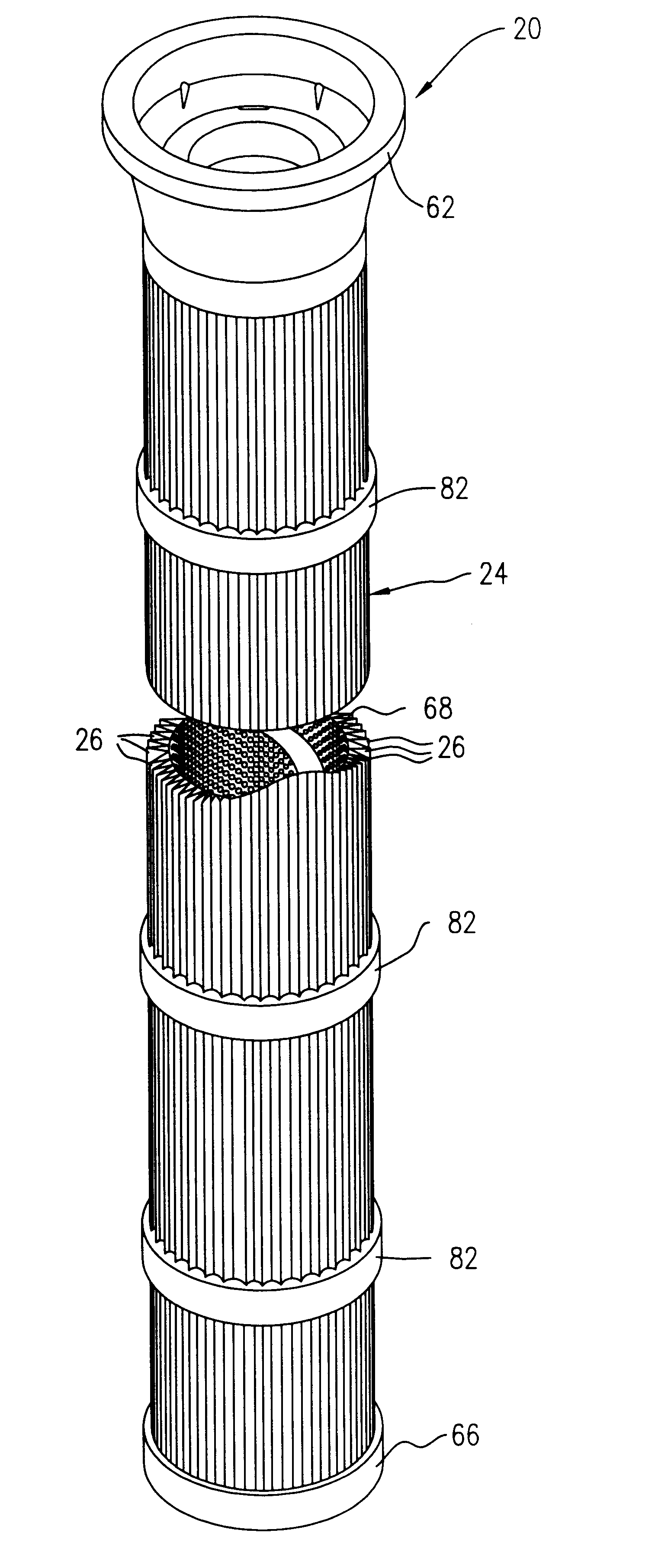

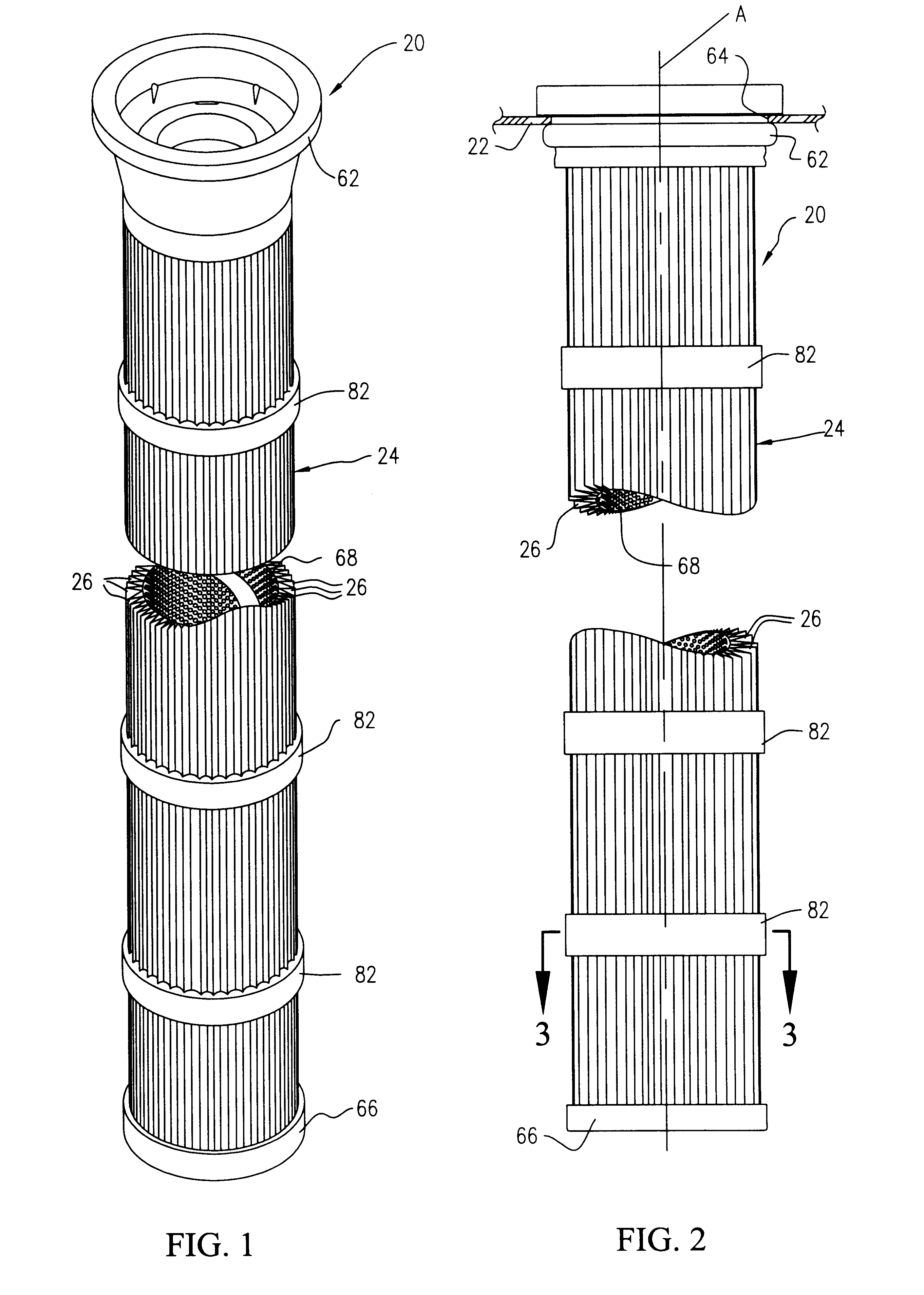

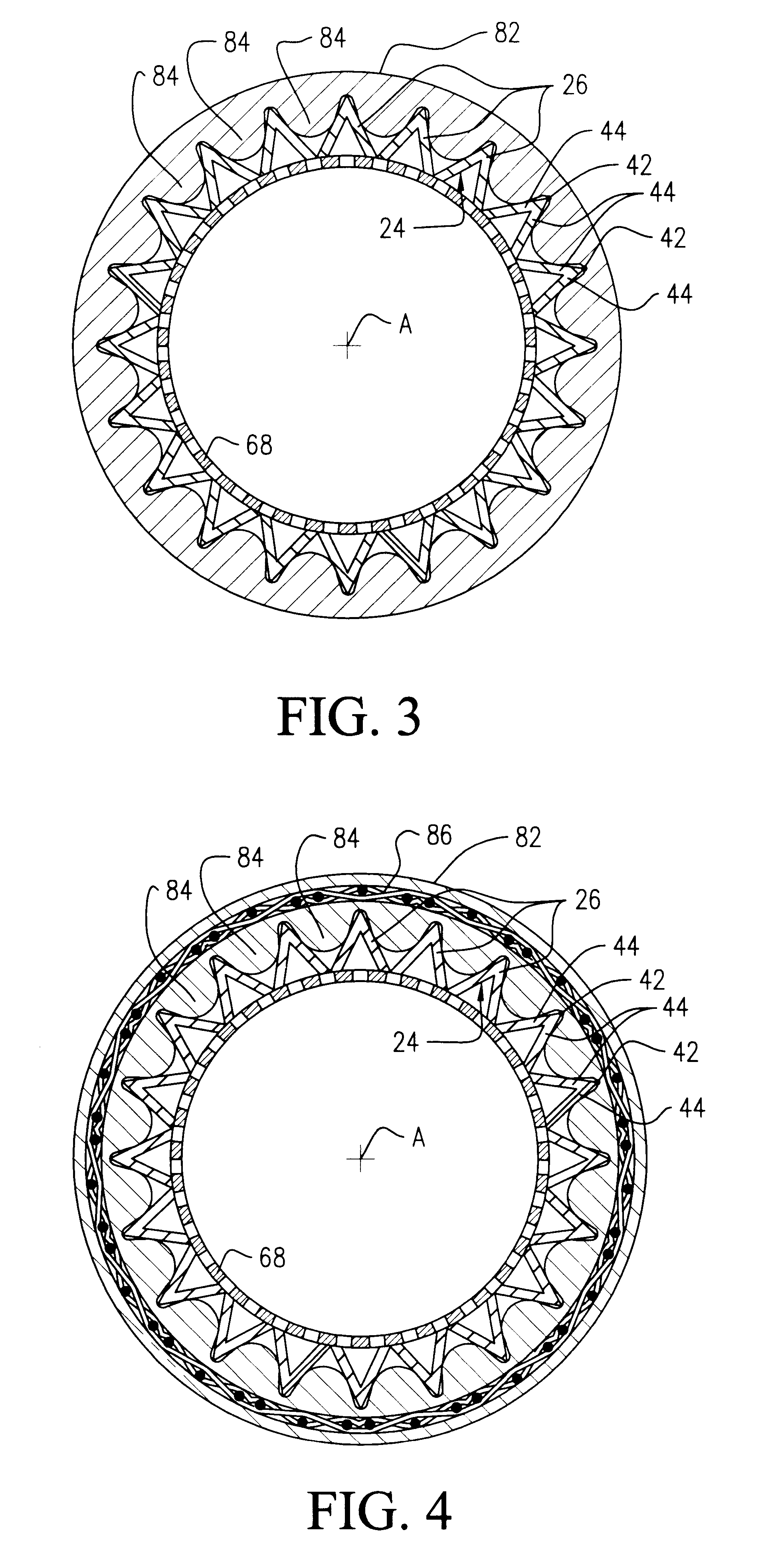

Filter cartridge with strap and method

A filter cartridge (20) for removing particulates from a particulate laden fluid stream moving one direction through the filter cartridge. The filter cartridge (20) is periodically subject to cleaning fluid moving in an opposite direction to the fluid stream. The filter cartridge (20) comprises filtration media (24) formed into a tubular configuration and having a plurality of circumferentially spaced apart pleats (26). A retention device (82) to limit radial movement of the filtration media (24) when subjected to the periodical cleaning fluid and to maintain the pleats (26) in the filtration media circumferentially spaced apart.A method of making a filter cartridge (20) for removing particulates from a fluid stream moving one direction through the filter cartridge and that is periodically subject to cleaning fluid moving in an opposite direction to the fluid stream. The method comprises the steps of providing filtration media (24) formed into a generally tubular configuration and having a plurality of circumferentially spaced apart pleats (26). A retention device (82) is applied to limit radial movement of the filtration media (24) in the opposite direction when subjected to the periodic cleaning fluid and to maintain the pleats (26) in the filtration media circumferentially spaced apart.

Owner:BHA ALTAIR

Cleaning device for filter belt of sludge electroosmosis dewatering machine

ActiveCN104958956AEfficient removalImprove cleaning efficiencySludge treatment by de-watering/drying/thickeningFilter regenerationElectricityTemperature control

The invention aims to provide a cleaning device for a filter belt of a sludge electroosmosis dewatering machine. The cleaning device comprises a dry washing device and a wet washing device, wherein a partition plate is arranged between the dry washing device and the wet washing device; a temperature control device, a scrubbing device and a dust collection device are arranged in a box body; the scrubbing device comprises a plurality of rolling brushes and a gas guide pipe; the rolling brushes comprise rotating rollers and a plurality of bristles; the rotating rollers adopt hollow structures, and a plurality of air outlet holes are formed in the rotating rollers; a plurality of spraying heads are arranged on the inner side of an upper cover in the box body of the wet washing device; a sewage collection tank is arranged at the lower part of a lower cover of the box body. The cleaning device has the beneficial effects that the dry washing device and the wet washing device are combined, so that most of solid particles fall off from the filter belt through the dry washing device by the combination of the high-pressure air and the rolling brushes and then enter the wet washing device; the spraying brushes are used for scrubbing off the sludge retained on the filter belt; by the step-by-step cleaning mode, the sludge on the filter belt can be effectively removed; the cleaning efficiency is high, water is saved, and the cleaning cost is reduced.

Owner:JIANGSU WANBAO MACHINERY

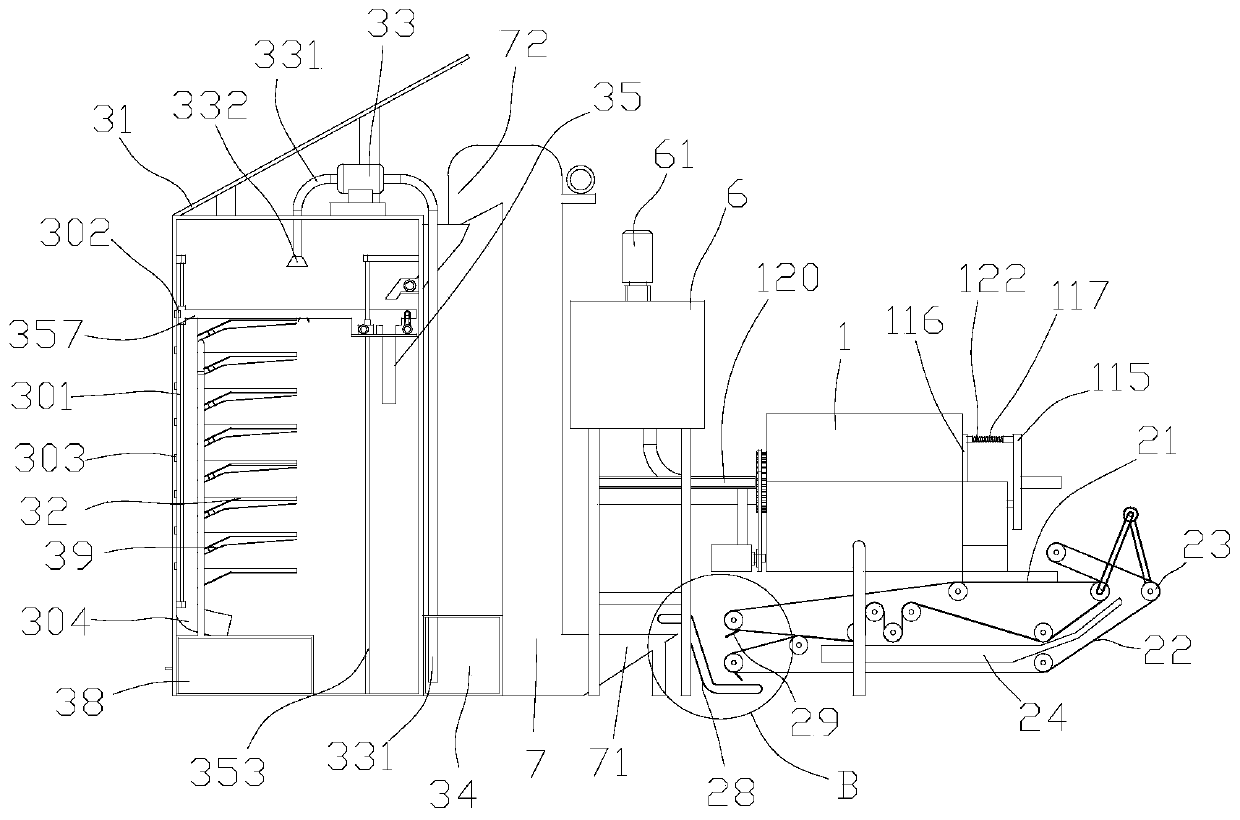

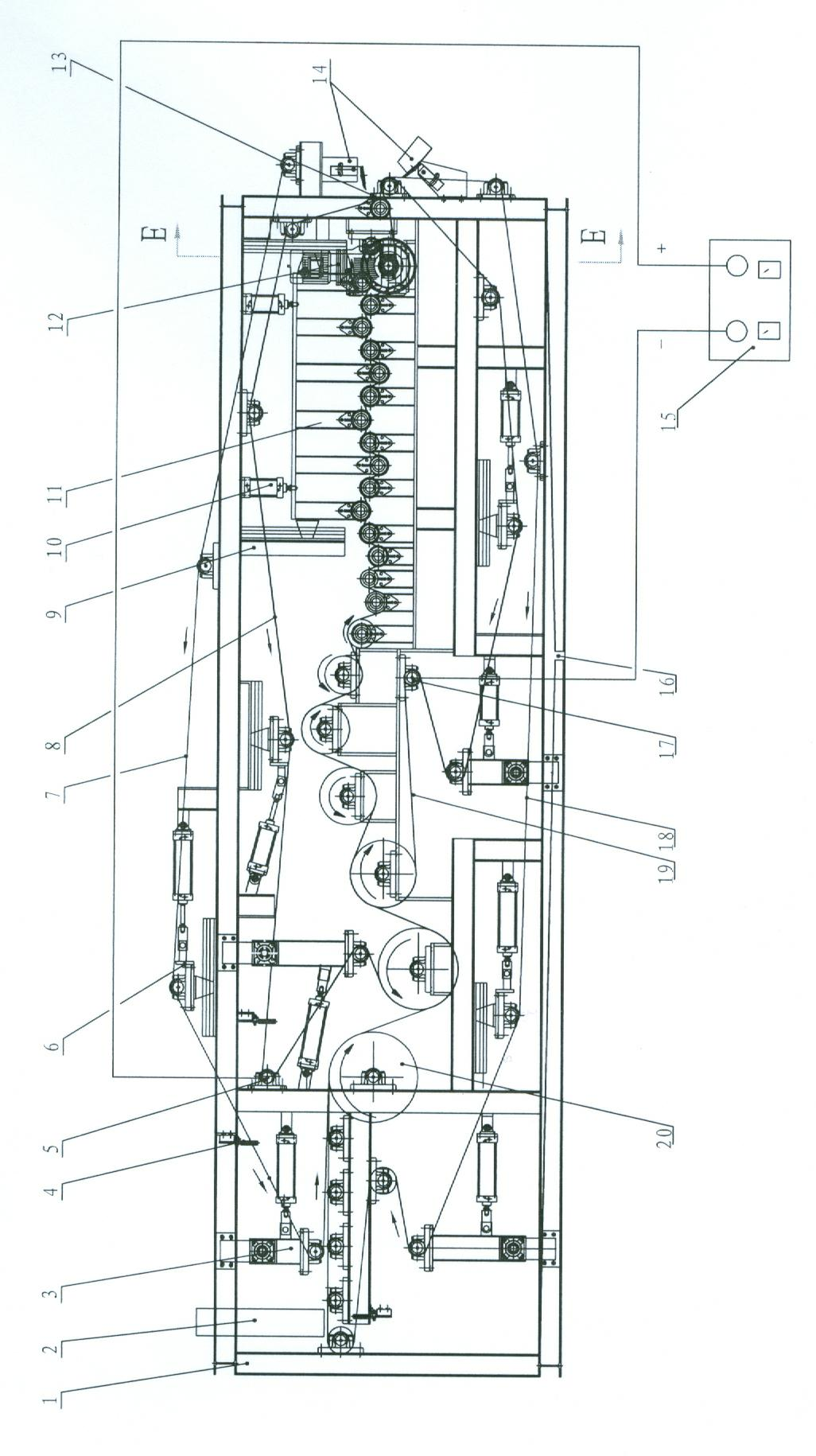

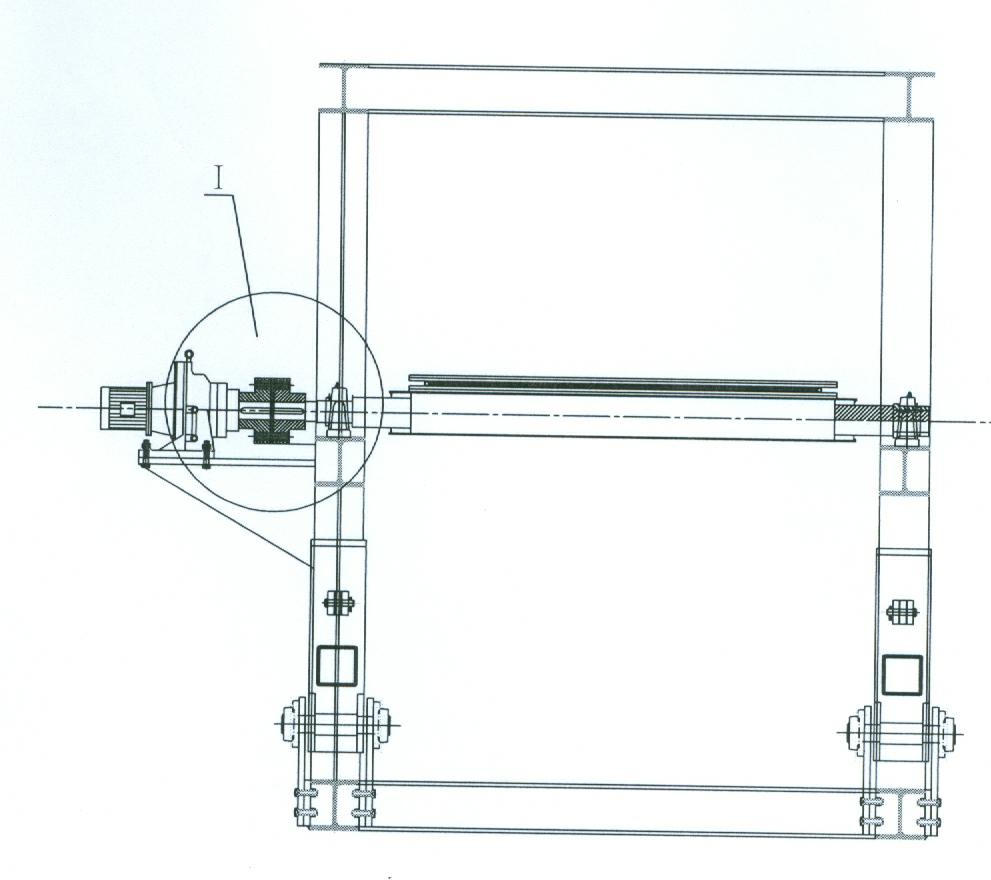

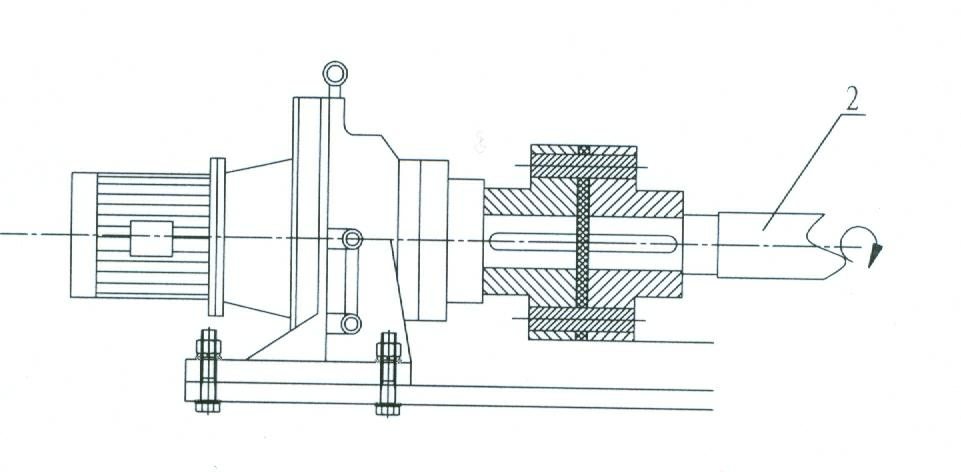

Electrolytic filtering/squeezing integrated sludge dewatering machine

ActiveCN102115302AIncrease productivitySmall footprintSludge treatment by de-watering/drying/thickeningSludge cakeInterstitial water

The invention discloses an electrolytic filtering / squeezing integrated sludge dewatering machine which comprises a primary squeezing and filtering region, an electrolytic filtering region, an electrolytic squeezing region and an external direct current power source, wherein the primary squeezing and filtering region, the electrolytic filtering region and the electrolytic squeezing region are sequentially arranged with one anther by taking a frame as a carrier. The sludge fallen from a hopper is primarily squeezed and filtered to remove the free water contained in the sludge. A driven upper filter strip and a driven lower filter strip are respectively and externally leaned against an upper squeezing strip and a lower squeezing strip connected the two poles of a direct current power source, so that the sludge clamped between the upper squeezing strip and the lower squeezing strip is electrolyzed, and the interstitial water and the cellular water in the sludge flow to the negative pole when the electric charge flows, i.e. the electrophoresis. The incompletely-dried sludge is carried into the electrolytic squeezing region and is forced under the condition that the sludge is stilled electrolyzed to accelerate the dewatering. By sequentially reducing the diameters of a plurality of the roll shafts and by adopting an installation technology measure that the adjoining roll shafts are installed in a misplaced way up and down, the machine can dewater by sequentially forcing, so that the dryness of a sludge cake is improved. The machine is particularly suitable for treating the biochemical active sludge precipitated by the urban domestic sewage or the industrial sewage.

Owner:江苏百新环境工程有限公司

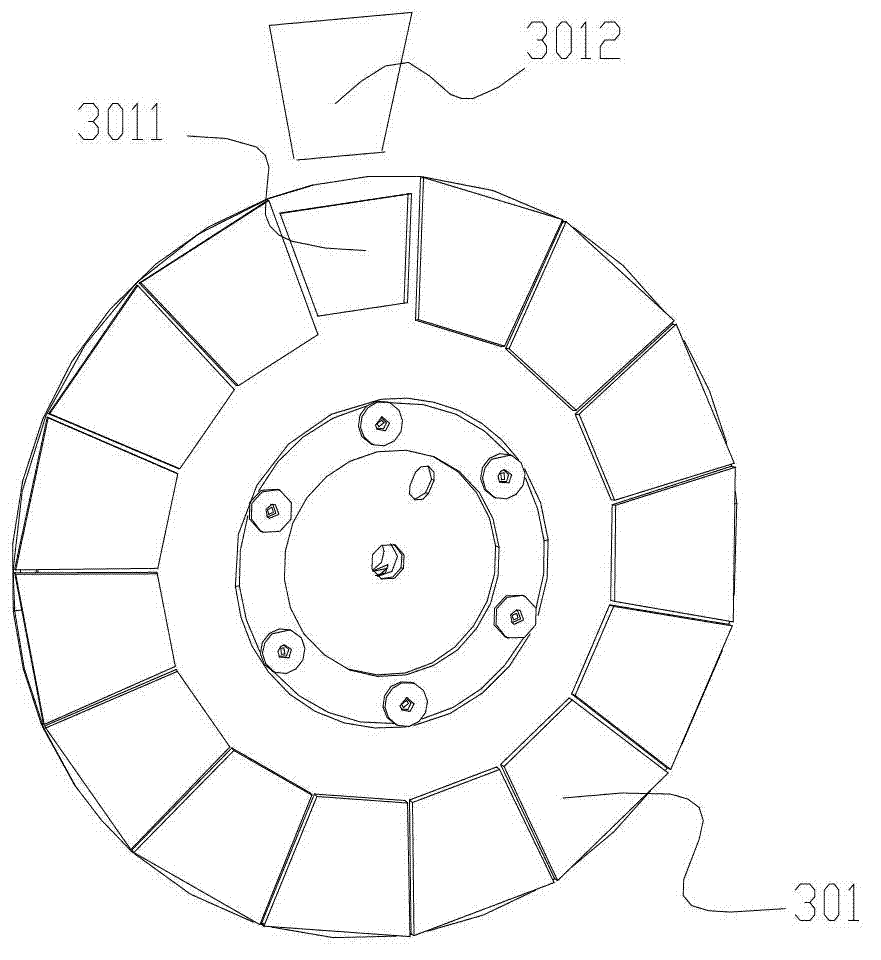

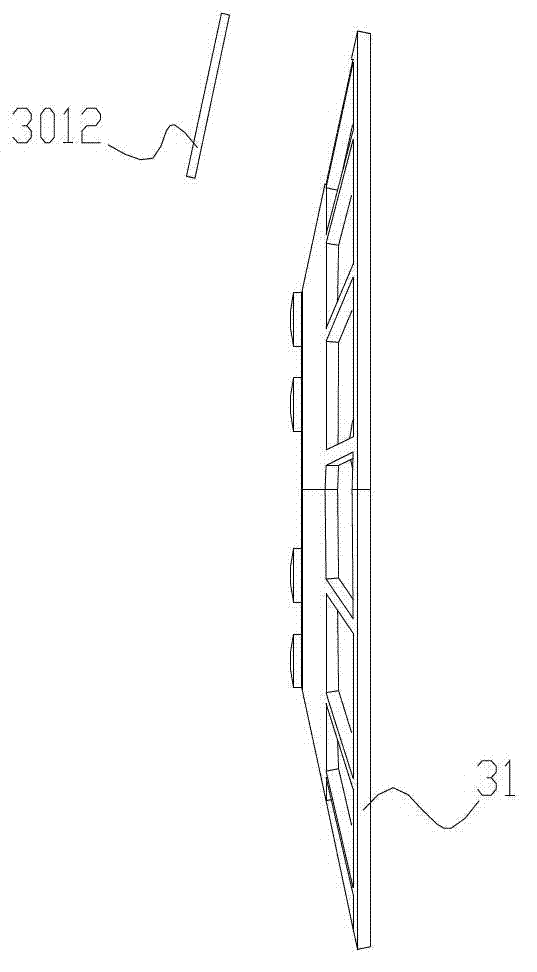

Stage lighting color filter device

ActiveCN102767792AExtended service lifeReduce the temperatureLighting heating/cooling arrangementsSpectral modifiersStage lightingEngineering

The invention discloses a stage lighting color filter device which comprises a color filter wheel and a lamp body. The color filter wheel is located in front of the lamp body, a color filter strip is arranged around the center of the color filter wheel, one end of the color filter strip close to the center of the color filter wheel serves as an inner end of the color filter strip, the inner end of the color filter strip is protruded towards one side of the lamp body, so that the color filter strip has an angle of inclination relative to the front end face of the lamp body, and the lamp body is opposite to the color filter strip. The stage lighting color filter device can lower temperature of a central zone of the lamp body and prolongs service life of the lamp body.

Owner:PR LIGHTING

Chain plate caterpillar filter press

InactiveCN103752058AIncreased pressure intensityIncrease solid contentFiltration separationSludgeEngineering

The invention discloses a filter press employing chain plate caterpillars for pressure application. The rolling compaction of a pair of rollers over filter belts is replaced by the flat pressing of two chain plate caterpillars over the filter belts on the basis of preserving an original wedge-shaped prepressing section and a cambered belt pressing section of a belt filter press, and continuous, increasing and high-intensity pressure can be provided for a material clamped between the two filter belts to continuously, thinly and rapidly dehydrate flocculated sludge under high pressure to obtain high-solid content dehydrated sludge.

Owner:汇川盛业技术(北京)有限公司

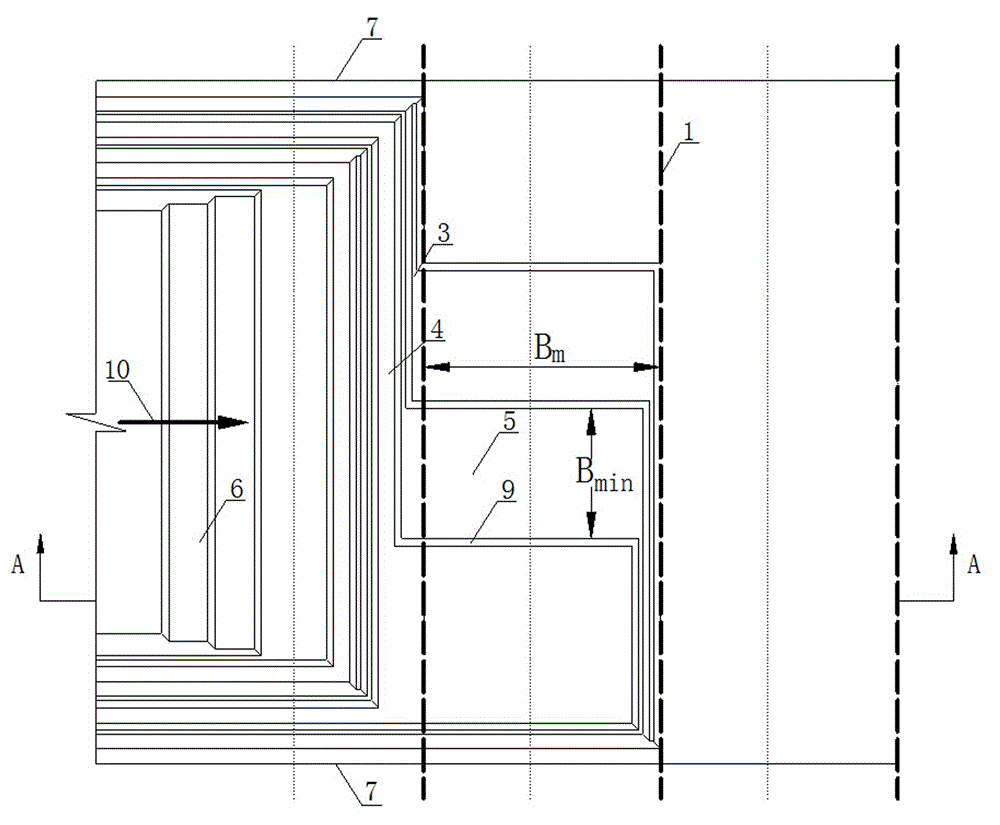

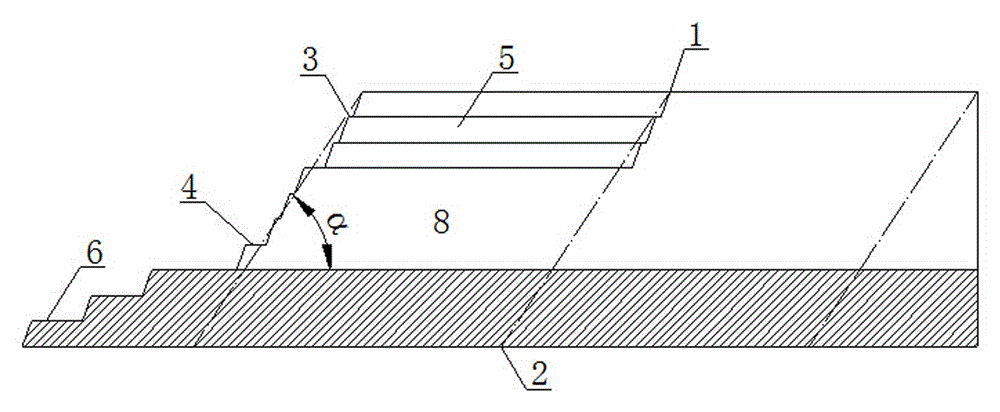

Mining method of open-pit mine

ActiveCN105114081AReduce widthReduced stripping peaksUnderground miningSurface miningEconomic benefitsSlope angle

The invention relates to a mining method of an open-pit mine. The mining method includes that a mine body in a final boundary range is divided into a plurality of strips along an advancing direction of a stope working slope, and mining is performed strip by strip; only a safety platform and a sweeping platform are arranged in an advancing direction of a vertical working slope; only two strips are operated constantly in the process of advancing of the working slope, mining operation is performed in a former strip, and stripping operation is performed in a later strip; after mining and digging of the former strip of the mine body are completed, stripping work of the later strip is finished just then, stripping equipment turns to a next strip for stripping, and so on. By the mining method, slope angle of the working slope is increased, stripping peak at the early stage of mine production is reduced effectively, equipment waste caused by changing of production stripping-mining ratio is avoided, the production stripping-mining ratio is balanced, stability of mine production is guaranteed, and good economic benefit is realized.

Owner:CINF ENG CO LTD

Method for machining deep hole of long-cylinder part

InactiveCN104625152ASimplification-oriented approachGuarantee quality and efficiencyBoring/drilling machinesLongest DiameterMachining process

The invention relates to the field of machining, in particular to a method for machining a deep hole of a long-cylinder part. The method comprises the following steps that the locating datum of the part is machined, wherein two coaxial outer circles are machined at the positions, close to the two ends, of the part, and are adopted as a locating datum plane; a lead hole is machined, wherein the lead hole must be machined before hole boring of the part to guarantee the rigidity of the part and prevent cutter back-off and cutter vibration of a cutter bit in the machining process; the size of the lead hole is equal to that of the bored aperture, and the boring cutter bit is located in the lead hole through a wood guide block. According to the method, the deep hole of the long diameter in the barrel part is effectively machined, the machining quality and machining efficiency of the inner hole are guaranteed well, the wood guide block is adopted in the machining process, and the complex guide method of adopting an abrasion-resisting filter strip is simplified, so that machining is more convenient and economical, and the machining efficiency can be improved.

Owner:李连江

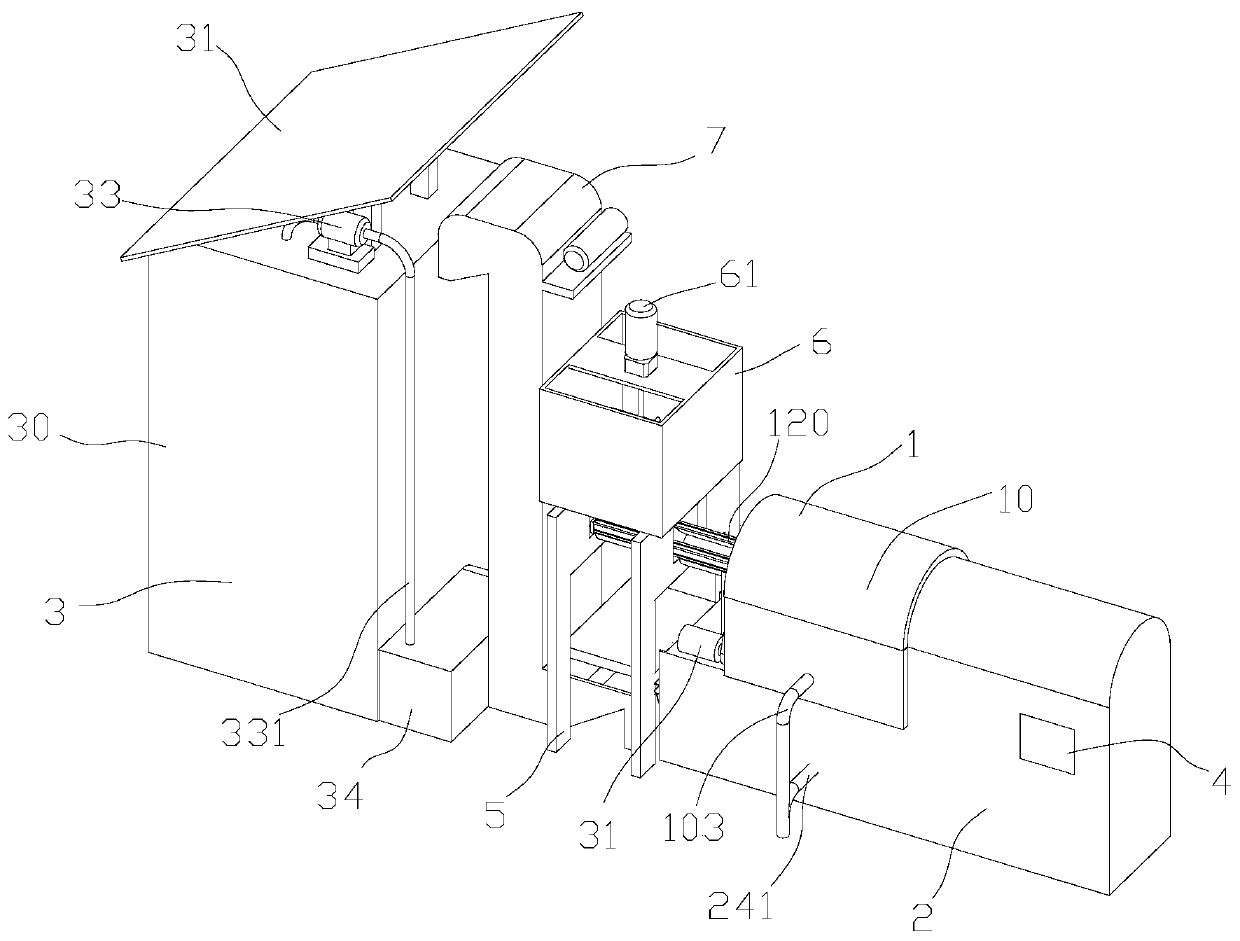

Integrated device for separating, concentrating, dehydrating and drying liquid impurities

ActiveCN106237692AAchieve separationReduce energy consumptionDrying gas arrangementsMoving filtering element filtersSmall footprintEnergy consumption

The invention discloses an integrated device for separating, concentrating, dehydrating and drying liquid impurities. The integrated device comprises a liquid impurity separating mechanism, a liquid impurity concentrating mechanism, a liquid impurity dehydrating mechanism and a liquid impurity drying mechanism, wherein the liquid impurity separating mechanism filters mixed liquid to separate the impurities in the liquid; the liquid impurity concentrating mechanism is arranged under a first filter belt at the bottom of a liquid channel; the liquid impurity concentrating mechanism primarily dehydrates the impurities filtered and stopped on the first filter belt so as to concentrate the impurities; the liquid impurity dehydrating mechanism collects the impurities which are filtered and stopped by the first filter belt and are concentrated, and performs squeezing dewatering on the impurities; the liquid impurity dehydrating mechanism is communicated with the liquid impurity drying mechanism; the liquid impurity drying mechanism dries the impurities which are dehydrated by the liquid impurity dehydrating mechanism and discharges the dried impurities. The device can separate, concentrate, dehydrate and dry the impurities in the liquid in sequence, and is low in energy consumption, small in occupied space and wide in field of application.

Owner:尚川(北京)水务有限公司 +1

Improved ground-planing-transmission type environmental-protection street cleaning vehicle

InactiveCN102174801ASimple structureReduce manufacturing costRoad cleaningWater storageThrough transmission

The invention provides an improved ground-planing-transmission type environmental-protection street cleaning vehicle comprising a vehicle body, wherein a cab is assembled at one side of the vehicle body, and a dustbin is assembled at the other side of the vehicle body. The street cleaning vehicle is characterized in that: (1) a plurality of retrograde-rotation sweeping rolling brushes are upwards arrayed and assembled between the cab and the dustbin and are mutually connected through transmission belts or transmission chains, and under the action of the output power of a direct-current motor, the plurality of retrograde-rotation sweeping rolling brushes can rotate reversely and act mutually at the same time so as to transmit swept wastes into the dustbin; and (2) a water storage and dust filtering device is assembled above the vehicle body, a plurality of dust-filtering strip brushes are arrayed and assembled in the water storage and dust filtering device in a staggered way so as to fulfill the functions of lengthening an air output channel and purifying dust in the air, and a suction ventilating fan is assembled in an air outlet of the water storage and dust filtering device so as to fulfill the functions of reducing air pressure in the dustbin and delivering the swept wastes and dust into the dustbin easily.

Owner:张珉

Vacuum belt press filter

InactiveCN101612805BEasy to cleanRealize automatic continuous operationCleaning using liquidsPressesFiltrationPulp and paper industry

The invention relates to a vacuum belt press filter, comprising a rack, a vacuum filtration assembly, a press assembly and a filtration belt assembly, wherein the filtration belt assembly comprises an upper filtration belt, a lower filtration belt, and a cleaning device A and a cleaning device B which are used for respectively cleaning the upper filtration belt and the lower filtration belt; the cleaning device B comprises a front guide roller and a rear guide roller on the motion direction of the lower filtration belt, the front guide roller is arranged on the upper face the lower filtrationbelt, closely contacts the lower filtration belt and enables the lower filtration belt to form a V shape, the rear guide roller is arranged on the lower face of the lower filtration belt and is provided with a plurality of pinpricks, the size of each pinprick is matched with the size of a filtration pore of the filtration belt, and the rear guide roller contacts with the lower filtration belt by the pinpricks; and the cleaning device B is provided with a plurality of spray heads, and the spray heads are distributed on the upper face and the lower face of the lower filtration belt. The vacuum belt press filter of the invention has the advantage of favorable cleaning effect of the filtration belts, and belongs to the technical field of press machines.

Owner:HUZHOU HEHONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com