Cleaning device for filter belt of sludge electroosmosis dewatering machine

A cleaning device and electro-osmosis technology, applied in dehydration/drying/concentrated sludge treatment, filtration separation, filter regeneration, etc., can solve the problems of poor air permeability of the filter belt, unsmooth drainage, filter belt clogging, etc. Achieve the effect of saving water, reducing cleaning cost and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

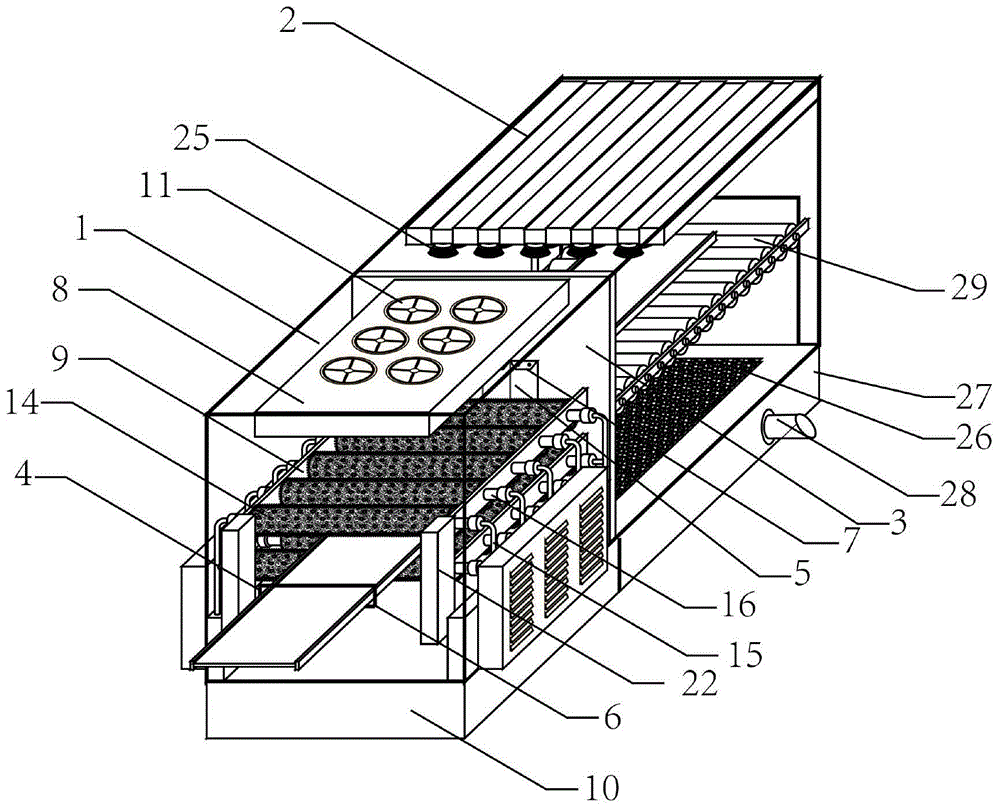

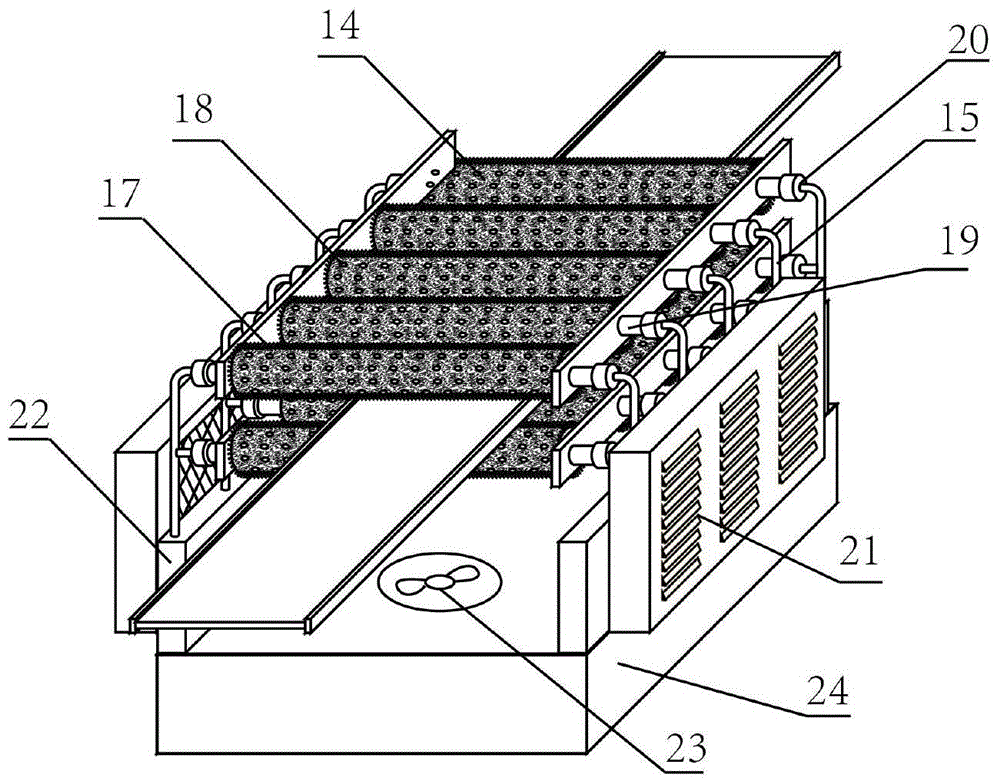

[0022] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

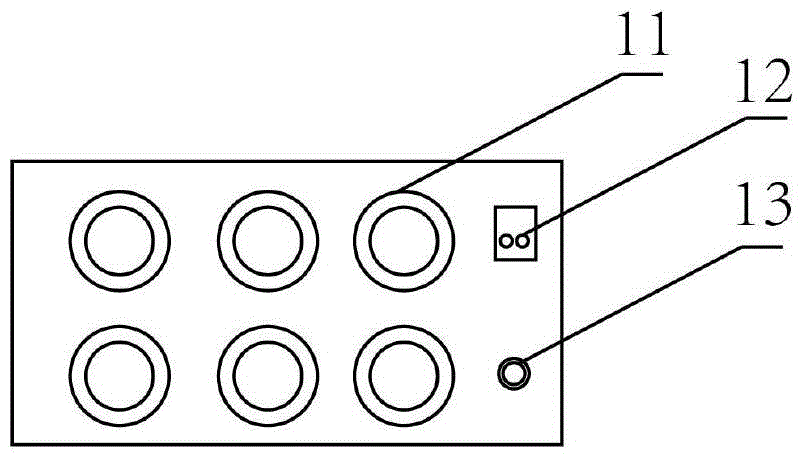

[0023] Such as figure 1 , figure 2 , image 3 Shown is a belt cleaning device for sludge electroosmosis dehydration machine filtration, which is characterized in that it includes a dry cleaning device 1 and a wet cleaning device 2, and a partition 3 is arranged between the dry cleaning device 1 and the wet cleaning device 2, The dry cleaning device 1 is a closed box, the left and right sides of the box are provided with a filter belt inlet 4 and a filter belt outlet 5, the filter belt inlet 4 is provided with a sealing strip 6, and the filter belt outlet 4 is provided with an anti- Dust curtain 7, temperature control device 8, brushing device 9 and dust collection device 10 are provided in the described box, and described temperature control device 8 is arranged on the top of box body, comprises infrared radiation lamp 11, temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com