Chain plate caterpillar filter press

A technology of filter press and chain plate, which is applied in the field of sludge dehydration and separation, can solve the problems of lack of high-strength pressure application process and force application structure, and achieve the effects of sufficient separation, sufficient pressure force, and reduction of sludge voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

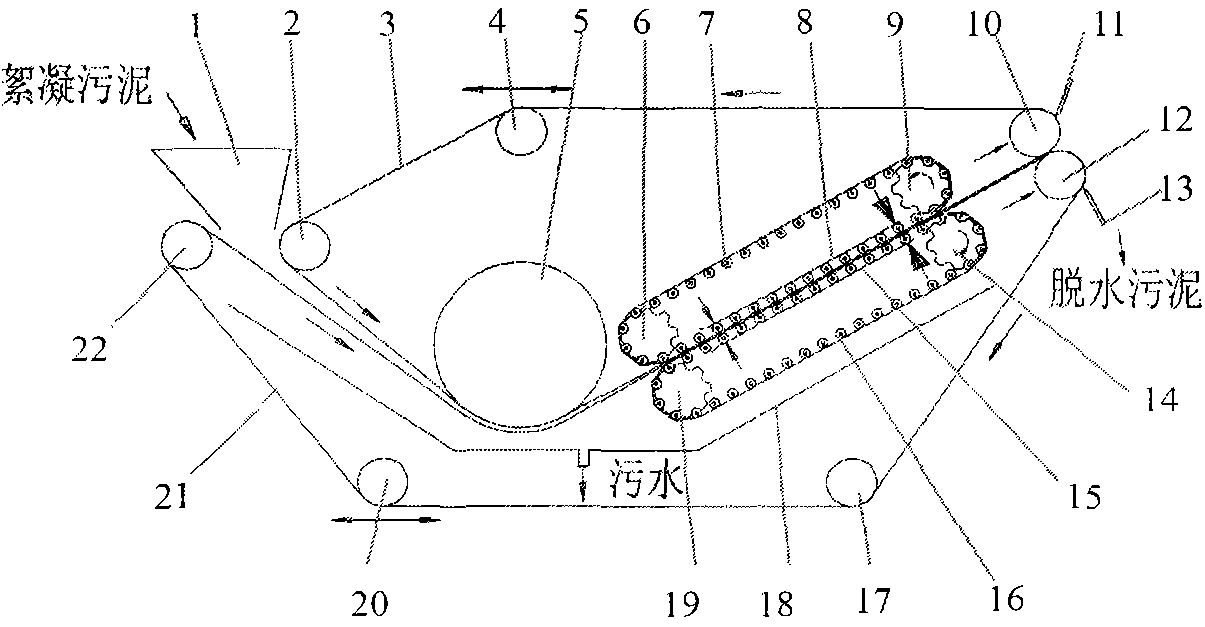

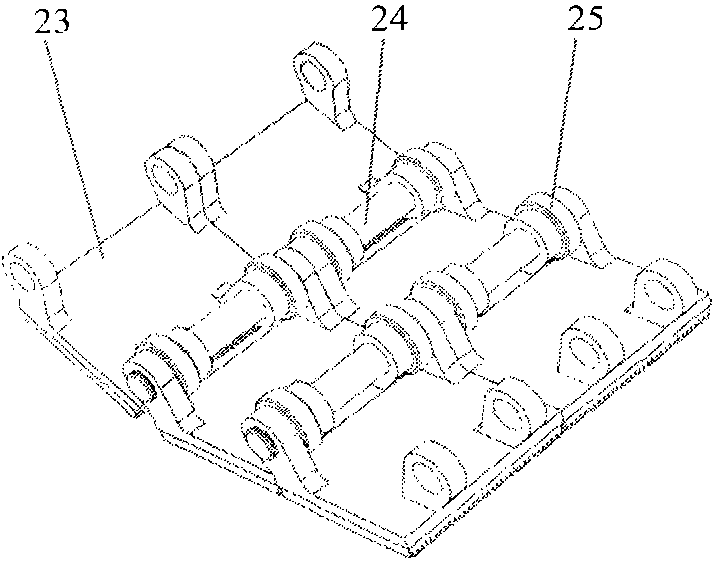

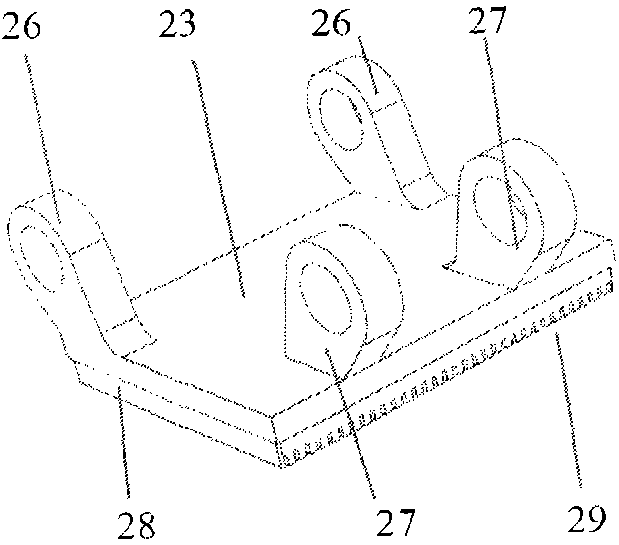

[0045] In the specific example of using this machine to dewater flocculated sludge, the chain plate crawler filter press consists of a cloth hopper (1), an upper filter belt folding roller (2), an upper filter belt (3), and an upper filter belt deflection roller (4), pressure roller (5), upper link track turning wheel (6), upper link track (7), upper link track pressure plate (8), upper link track driving wheel (9), upper filter Belt tension roller (10), upper filter belt scraper (11), lower filter belt tension roller (12), lower filter belt scraper (13), lower chain plate crawler drive wheel (14), lower chain plate crawler Pressing plate (15), lower chain plate track (16), lower filter belt folding roller (17), sewage bucket (18), lower chain plate track folding wheel (19), lower filter belt deflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com