Special grease separation and extraction pressure filter and technique thereof

A technology of oil fractionation and filter press, which is applied in the direction of fat oil/fat refining, separation method, filtration separation, etc. It can solve the problems of low solid content of filter cake, blocking filter cloth, affecting filtration, etc., and achieves the purpose of increasing the content of filter cake Solid rate, to achieve complete dissolution, to solve the effect of low solid content of filter cake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

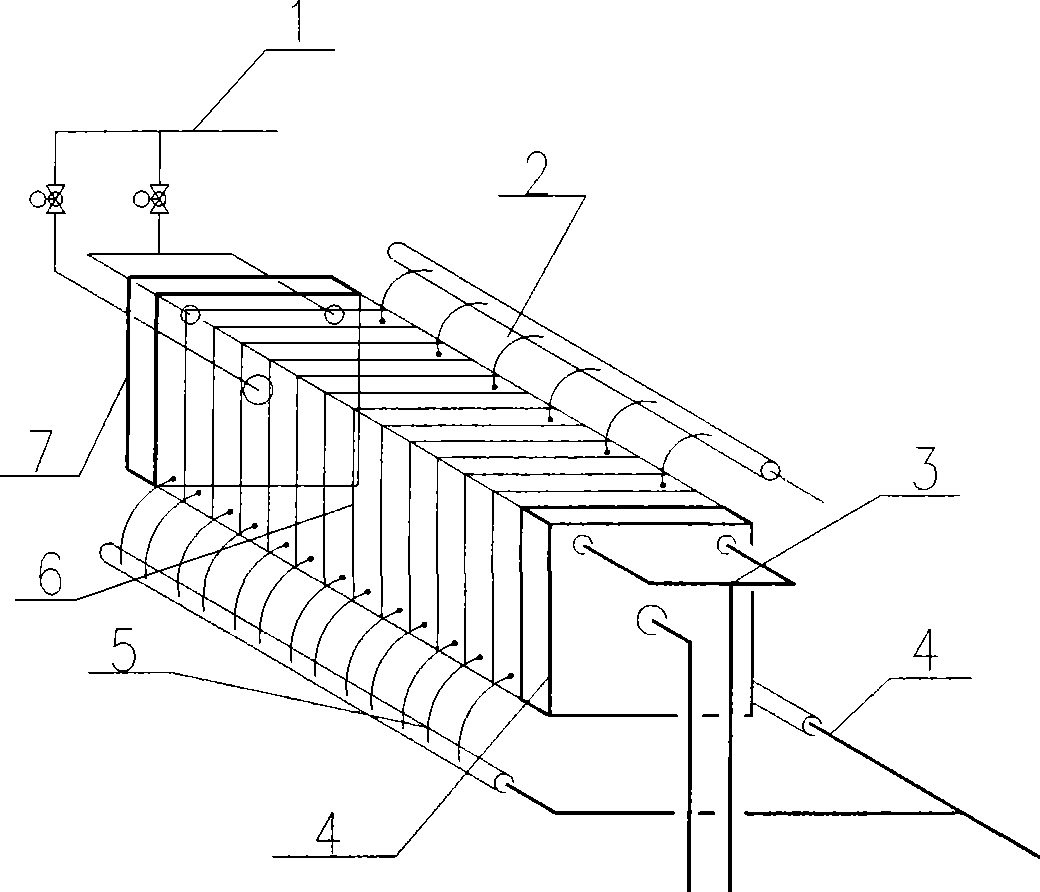

[0009] Embodiment 1: with reference to attached figure 1 . A special filter press for oil fractionation, which includes a filter press frame, the frame contains a thrust plate, a compression plate, a main beam, etc., and is a prior art, which will not be described here. The filter system 6 is located between the pressing plate 7 and the thrust plate 4 in the frame. The filter system 6 is composed of a plurality of diaphragm filter plates stacked and can be compressed or opened. Its structure and working method are prior art, here No narrative. The blowback system 1 is composed of a fluid generating source, a pipeline, and a valve. The outlet of the fluid generating source (air compressor or a nozzle for compressed air source) communicates with the inlet of the pipeline (pipeline), and the outlet of the pipeline passes through the valve and The pipes are respectively connected with the fluid inlets in the upper and middle parts of the pressure plate, and the purpose is to dry...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the fractionation process of the special filter press for oil fractionation, in the process of oil filtration, multiple diaphragms in the filtration system between the compression plate and the thrust plate in the frame Under the action of the hydraulic cylinder, the filter plate compresses the multiple diaphragm filter plates in the filtration system through the compression plate, and then starts the diaphragm pressing system, so that the diaphragm tympanic membrane in the diaphragm filter plate can perform tympanic compression on the formed filter cake, and filter The branched transparent hose in the transparent flow-to-dark flow system of the discharged oil is discharged into the main pipe and then discharged into the container from the main pipe. After the filtration is completed, the washing system washes the filter plate, and then starts the back blowing system to blow off the remaining oil. Dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com