Integrated treatment method and system for sludge

A treatment method and technology of a treatment system are applied in the field of integrated treatment methods and systems of sludge, which can solve the problems of low degradation rate of organic matter, weak stability of high-temperature anaerobic operation, and wide area, and achieve high removal rate of organic matter, The effect of realizing sludge reduction and stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

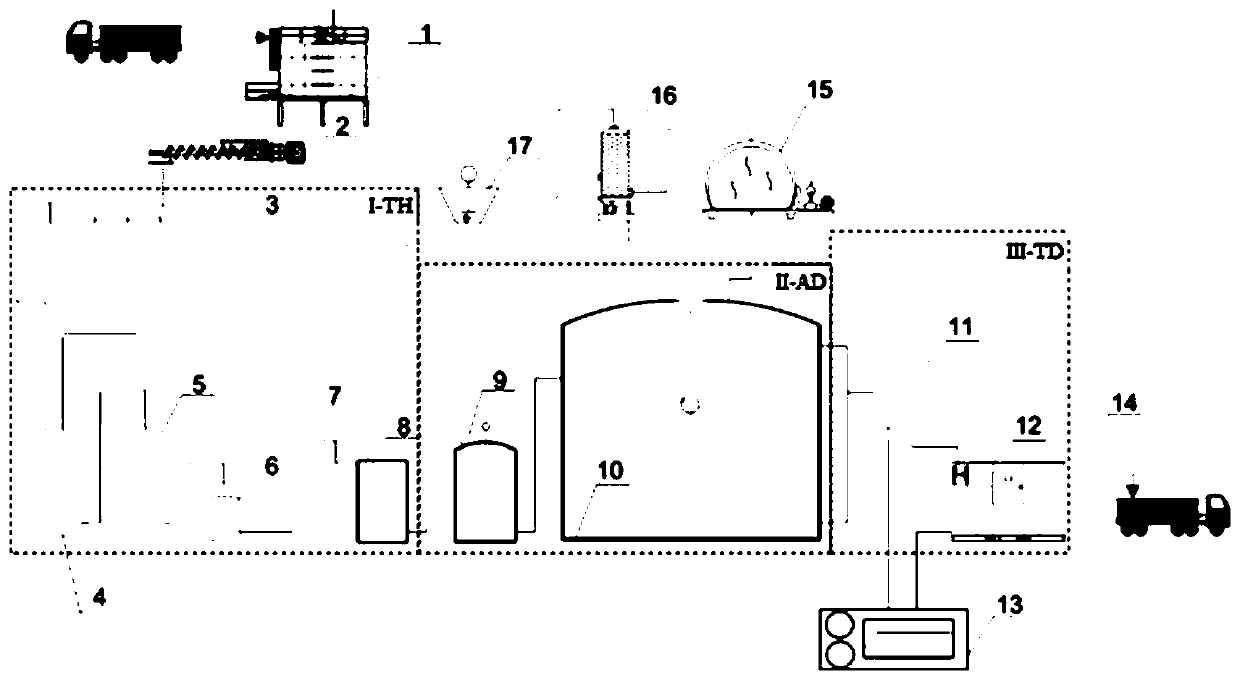

[0028] This embodiment provides an integrated treatment system for sludge, the schematic diagram of which is as follows figure 1 As shown, including thermal hydrolysis system (abbreviated I-TH system), anaerobic digestion system (abbreviated II-AD) and thermal drying system (abbreviated III-TD system), wherein, thermal hydrolysis system includes homogeneous pulping Integrated machine 3, thermal hydrolysis reaction tank 4, pressure relief flash tank 5, grit chamber 6, heat exchanger 7 and output buffer tank 8; anaerobic digestion system includes conditioning tank 9 and anaerobic tank 10; heat drying The chemical system includes a mechanical centrifugal dehydrator 11 and a dehumidification and drying machine 12; wherein the homogeneous slurry integrated machine 3, the thermal hydrolysis reaction tank 4 and the pressure relief flash tank 5 are all equipped with agitators; the integrated treatment system also includes sewage Mud receiving bin 1, screw conveyor 2, water treatment s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com