Patents

Literature

374 results about "Methane yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The methane yield, defined as the amount of methane produced for a given quantity of organic matter removed, is the result of the activity of the anaerobic consortium of bacteria.

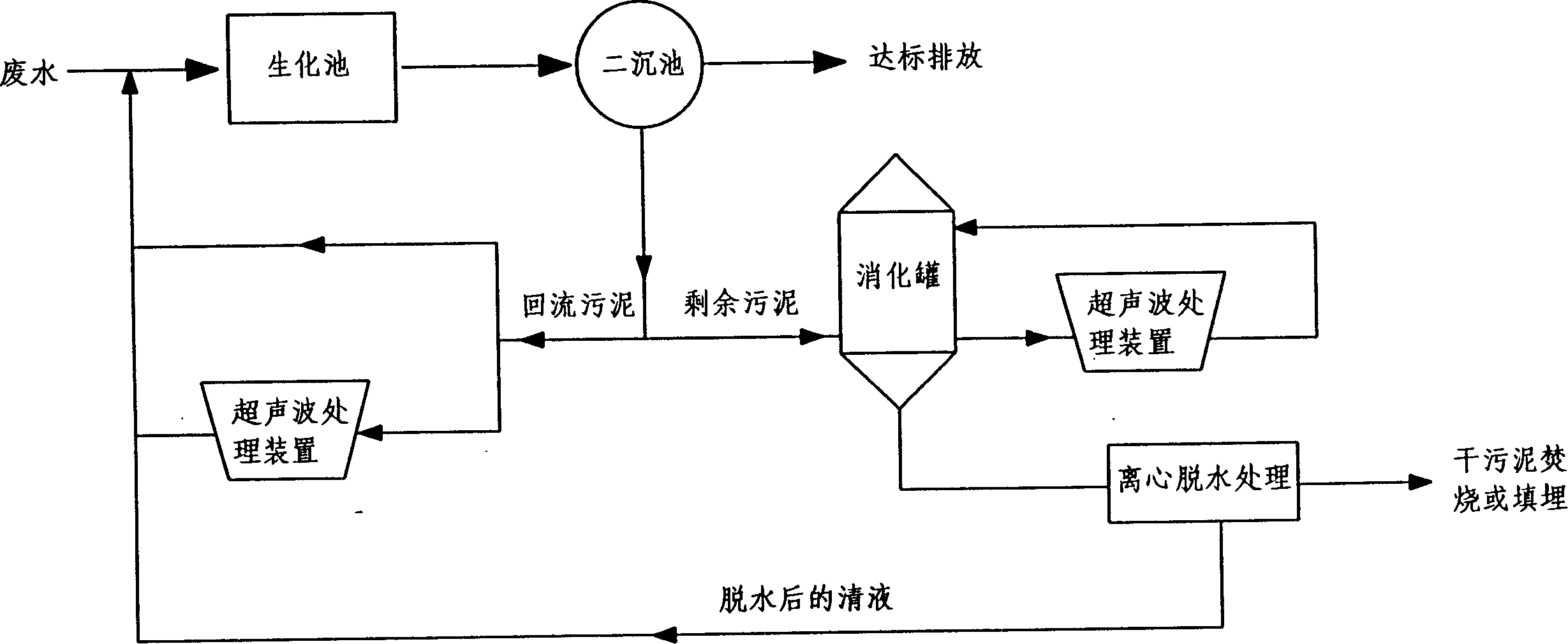

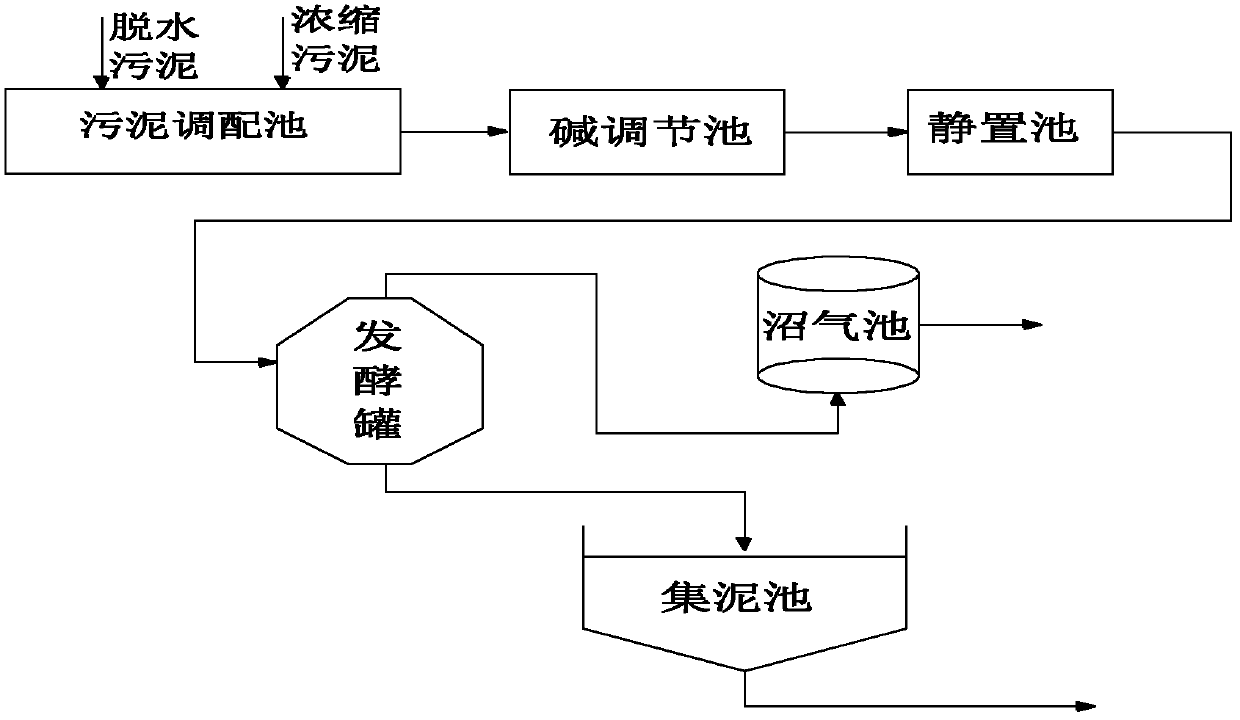

Combined pre-treatment method for improving sludge disintegration effect and strengthening subsequent anaerobic digestion

InactiveCN101565262AIncreased concentration of dissolved CODIncrease methane productionSludge treatment by de-watering/drying/thickeningGas production bioreactorsSolubilityHigh energy

The invention belongs to the technical field of solid waste treatment, in particular relates to a combined pre-treatment method for improving sludge disintegration effect and strengthening subsequent anaerobic digestion, comprising the following concrete steps of: gravity settling and thickening residual sludge generated in a secondary settling tank of a municipal sewage treatment plant, sending the thickened sludge into an ultrasonic reactor for ultrasonic irradiation and adding NaOH; sending the sludge into a sludge anaerobic digestion reactor for subsequent medium temperature anaerobic digestion after the combined action of ultrasonic and NaOH; and collecting methane generated by digestion and measuring the yield of the methane with a gas collection device. The method firstly uses ultrasonic and NaOH jointly for sludge treatment, the soluble COD concentration in sludge liquid phase after treatment is improved by about 52 times, the methane yield is improved by 40.6 percent, and the problem of limited application of ultrasonic due to high energy consumption is largely overcome; and the method is applicable to the treatment of residual sludge in sewage treatment plants, and can be achieved by making corresponding modification on the current treatment facilities of sewage treatment plants for different-scale sewage treatment plants, thus having wide application prospect.

Owner:TONGJI UNIV +1

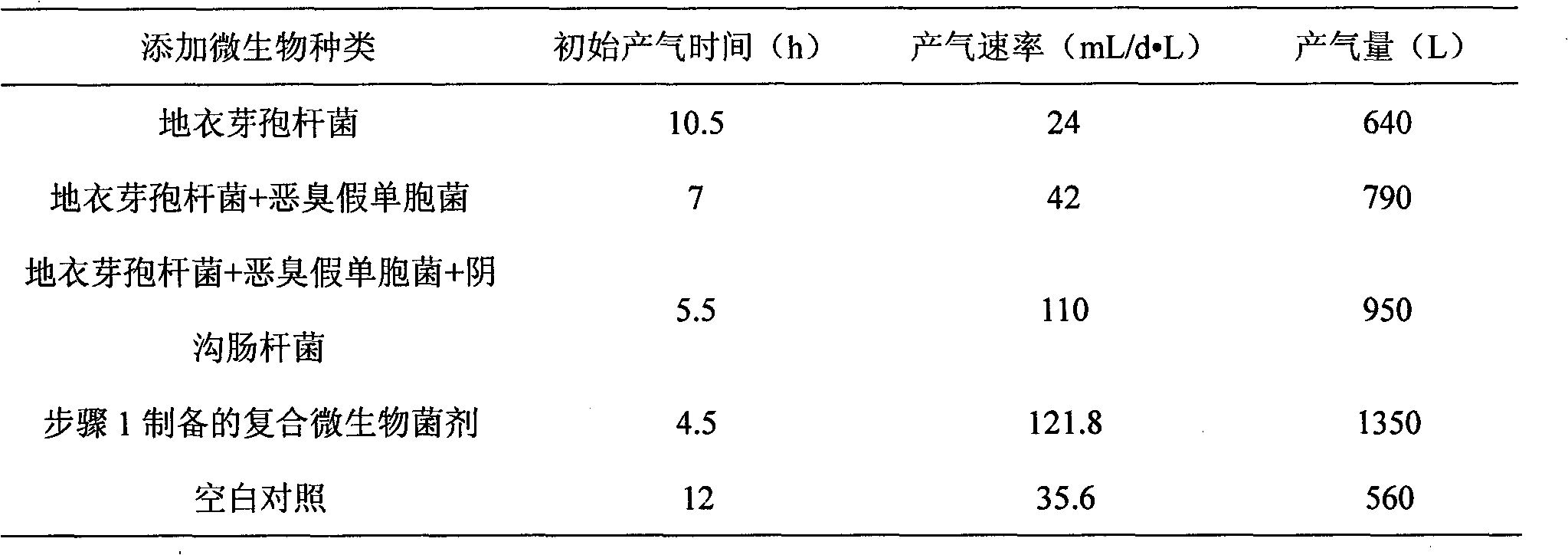

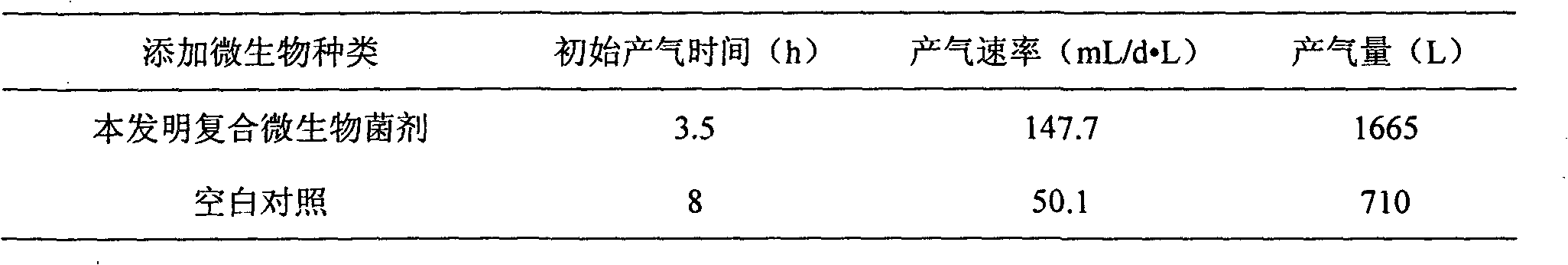

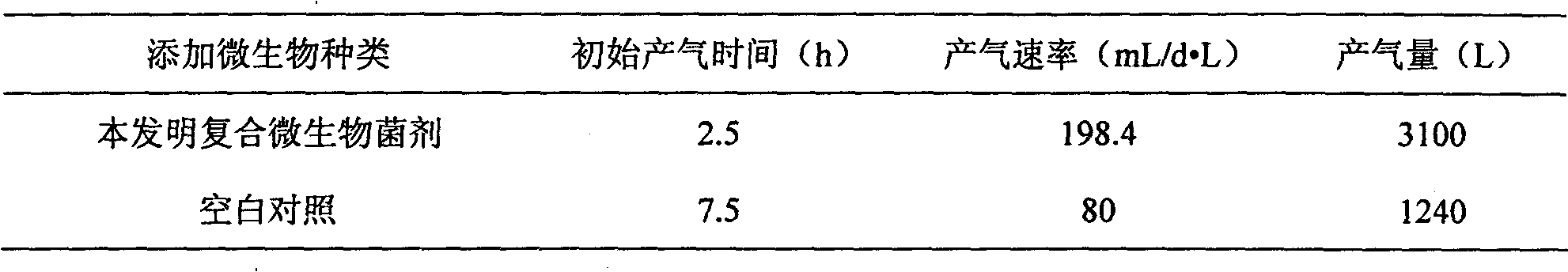

Compound microbial bacterial preparation and application thereof

InactiveCN101864362AOvercoming the problem of only targeting a single organic wastePromote enrichmentFungiBacteriaCelluloseBacillus licheniformis

The invention belongs to the technical field of environment protection and discloses a compound microbial bacterial preparation and application thereof. The compound microbial bacterial preparation consists of fermentation liquor of four bacteria, i.e. Bacillus licheniformis, Pseudomonas putida, Enterobacter cloacae and Candida valida. The compound microbial bacterial preparation provided by the invention has strong digestion power for various types of cellulose, proteins and fat macromolecules. The addition of the compound microbial bacterial preparation into excess sludge and / or kitchen waste can quicken enrichment of methanogen, shorten anaerobic digestion time and improve methane yield. Moreover, the synergetic effect of the four microbial strains is superior to the effect of any one, two or three strains of microorganisms.

Owner:江苏加德绿色能源有限公司

Method for sludge reduction using ultrasonic treatment

InactiveCN1765780AHigh yieldPromote degradationSludge treatment by de-watering/drying/thickeningWater/sewage treatment with mechanical oscillationsMethane yieldDigestion

The invention relates to a sludge-decrement method with ultrasonic wave, which comprises following steps: in biochemical unit, removing organic pollutant by microbe in sewage, translating organic compound into inorganic micromolecular material; in deposition unit, after the treated sewage enters second-deposition pond, depositing to separate sludge and water and condense sludge; in sludge anaerobic digestion unit, conveying the sludge from former pond into sealing tank to breed the anaerobe and amphimicrobe on sealing anaerobic condition for digestion; in ultrasonic treatment unit, treating the sludge with 20kHz-100kHz sonic wave; in sludge dewater unit, taking centrifugal dehydration to separate solid and liquid. This method increases greatly methane yield, decreases residual sludge of biochemical system, and has high economic benefit.

Owner:北京紫石千年环保设备有限公司

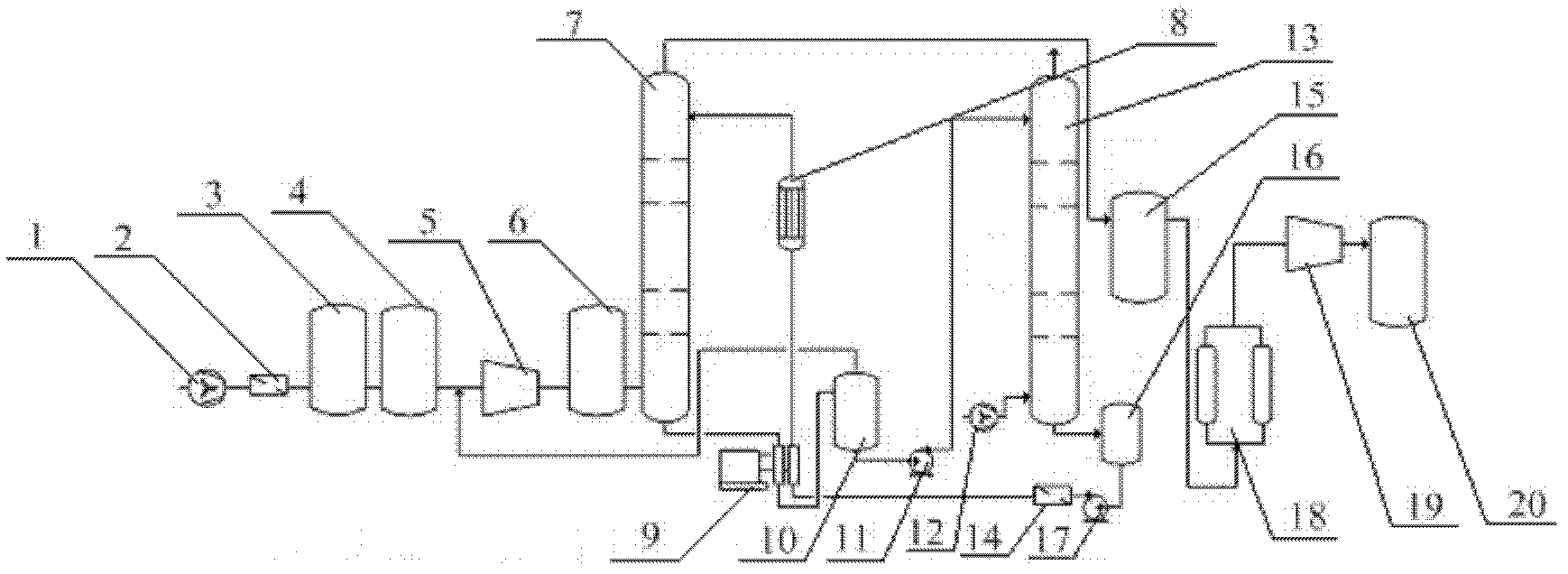

Methane purifying method and equipment thereof

The invention relates to a methane purifying method, comprising working procedures of pressurizing, filtering, biological desulphurizing, deoxidizing, absorbing, dehydrating, compressing, canning and the like. The implementation equipment of the methane purifying method comprises a fan used for conveying methane, a first filter, a biological desulphurization tank, a deoxidizing device, a first compressor used for increasing air pressure in a runner, a buffer tank, a filler tower used for absorbing carbon dioxide and hydrogen sulphide, a freeze drying machine, a fixed bed dehydrating device, a second compressor used for compressing purified methane and a purified methane storage tank which are sequentially connected. Two steps of absorption and adsorption are carried out to remove carbon dioxide and hydrogen sulphide, the advantages of low tower height and stable operation are realized, fixed bed catalytic deoxidation is adopted, and safety of the purified methane is greatly improved; meanwhile, less pollutant is discharged, thus the methane purifying method is more environmentally friendly, and methane yield is higher. The invention belongs to the fields of chemical engineering and technology, agricultural and forestry waste utilization, renewable energy source and the like.

Owner:ZHEJIANG UNIV OF TECH

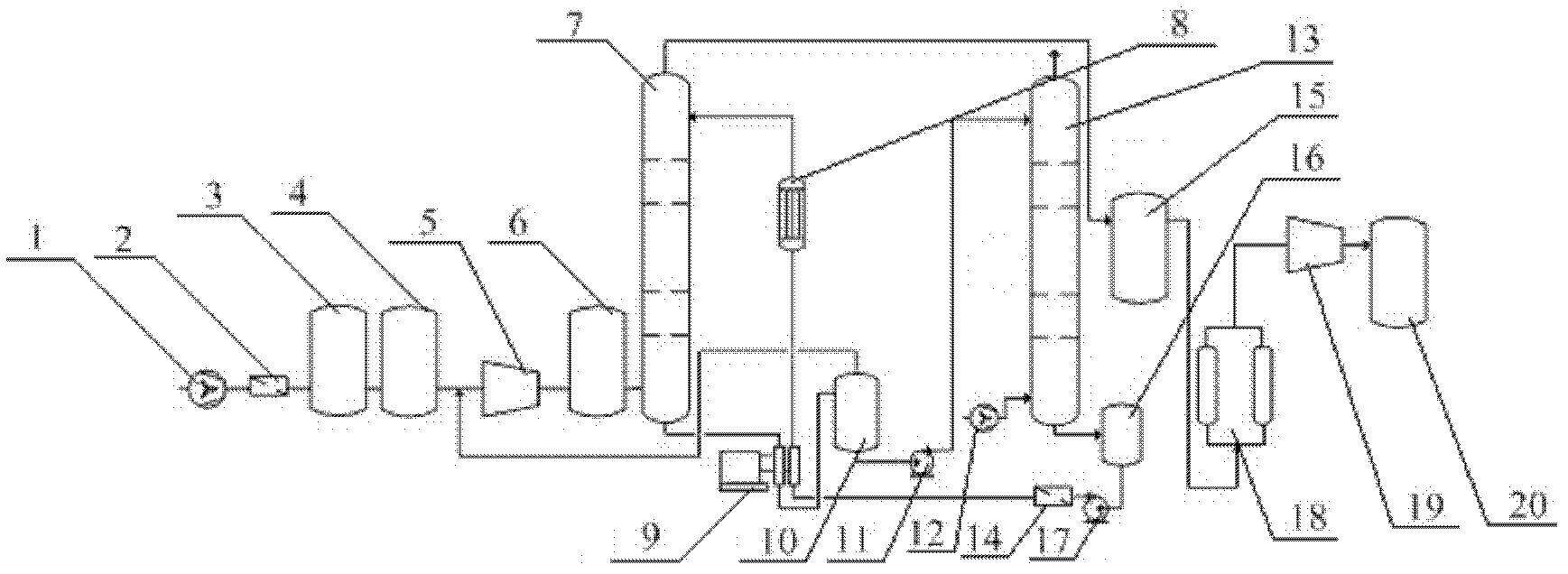

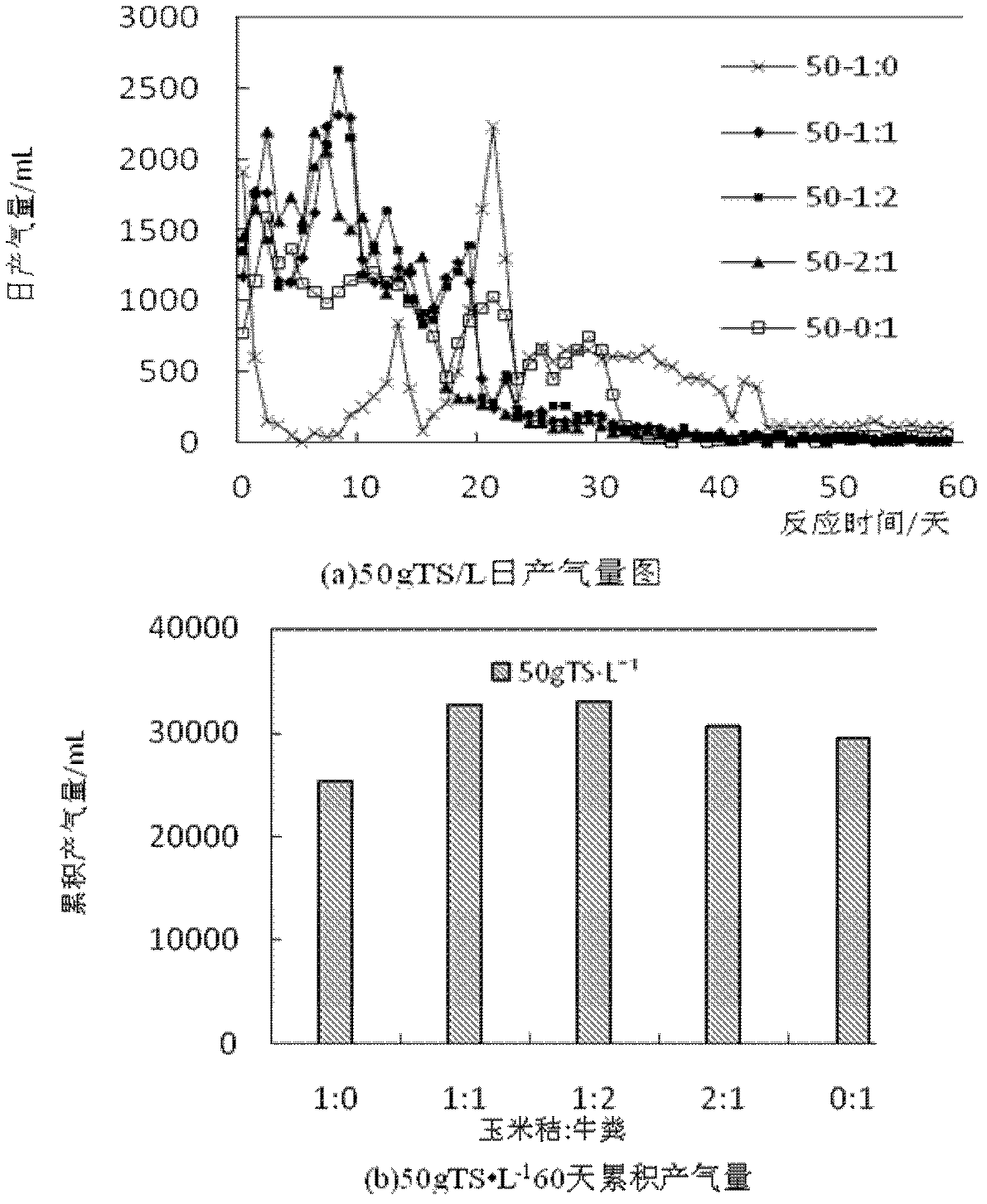

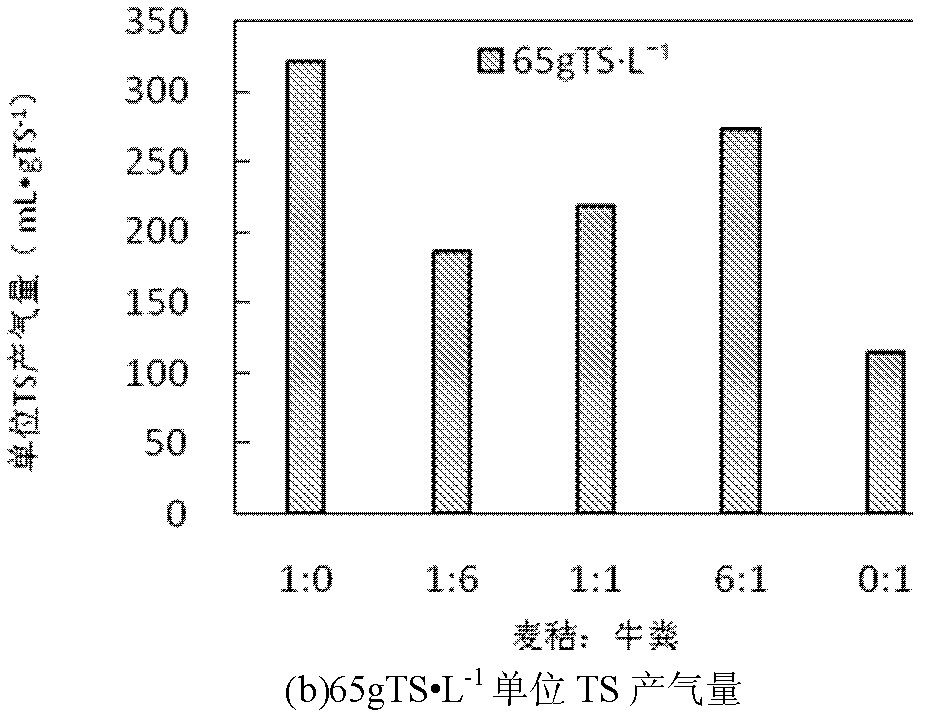

Method for improving methane-producing performance under synergistic action of mixed quasi-synchronous fermentation of multiple raw materials

ActiveCN102559773AExcellent digestionExcellent stabilityWaste based fuelFermentationMethane yieldOperability

The invention belongs to the field of treatment of organic solid wastes, and discloses a method for improving anaerobic gas-producing performance under the synergistic action of the mixed quasi-synchronous fermentation of multiple raw materials. By the method, organic wastes (straw, domestic garbage, excrement and the like) are subjected to the quasi-synchronous fermentation of multiple raw materials, namely the organic wastes are pretreated, so that the fermentation period of materials (such as the straw and the like) with a long fermentation period is shortened and is close to an average fermentation period of the mixed materials; the fermentation period of materials (such as garbage in restaurants and kitchens, excrement and the like) which are easy to digest is prolonged appropriate; and the pretreated materials are mixed, inoculated and subjected to anaerobic digestion to produce methane, so that the methane-producing period of the materials with the anaerobic digestion period is synchronous with that of the materials with the short anaerobic digestion period to realize the quasi-synchronous fermentation of the materials. The method is simple and high in operability; and by the method, two and more than two organic solid wastes are treated simultaneously, and the accumulative methane yield of unit volatile solid (VS) substances is improved by 15 to 60 percent averagely.

Owner:BEIJING UNIV OF CHEM TECH

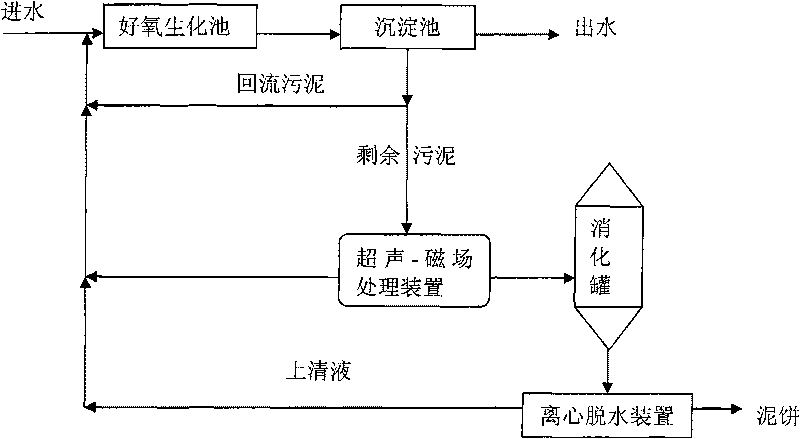

Method for reducing sludge by adopting ultrasound-magnetic field coupling to disrupt sludge

InactiveCN101704615AImprove the efficiency of anaerobic digestionShorten digestion timeSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesSound energyMagnetic field coupling

The invention belongs to the field of solid waste treatment and relates to a method for reducing sludge by adopting ultrasound-magnetic field coupling to disrupt sludge. The method comprises the following units: an aerobic biochemical unit is to remove organic pollutants through microbes in a biochemical tank; a sedimentation unit is to separate mud from water in a sedimentation tank; an ultrasound- magnetic field treatment unit is to disrupt rest of sludge by adopting ultrasonic wave and a magnetic filed to cooperate for more than 1 minute, wherein the frequency of the ultrasonic wave is 16-200kHz, the density of sound energy is 0.1-1.0W / mL, and the magnetic field strength is 300-20000Gs; an anaerobic digestion unit is to anaerobically digest the sludge in a digestion tank; and a sludge dehydration unit is to carry out solid-liquid separation by adopting centrifugal dehydration. The method greatly reduces the sludge disruption energy consumption, and the sludge is reduced by more than 80 percent when aerobic digestion is carried out to disrupt the sludge; in anaerobic digestion, the digestion time is reduced by more than 60 percent, the methane yield is increased by more than 35 percent, the sludge is reduced by more than 30 percent. The method has obvious economic benefits, thereby having popularization and application value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

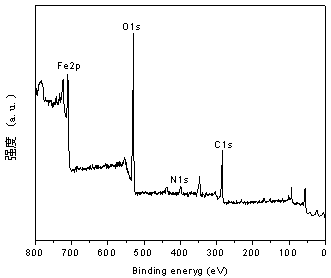

Preparing method and application of nitrogen-doped magnetic biochar

ActiveCN110171830AReduce manufacturing costImprove economyCarbon compoundsWaste based fuelPorosityAgricultural engineering

The invention discloses a preparing method of nitrogen-doped magnetic biochar and application of the nitrogen-doped magnetic biochar to enhancing anaerobic fermentation performance. According to the specific preparing process, with high-nitrogen-content agricultural and forestry waste as the substance basis in combination with industrial waste iron cement, through a hydrothermal carbonizing and high-temperature pyrolysis carbonizing method, an in-situ nitrogen-doped magnetic biochar carrier is prepared. The biochar carrier has the high specific surface area and porosity and high nitrogen and iron content, the pollutant removal and methane yield in the anaerobic fermentation process are remarkably improved, the inhibition of volatile acid in the fermentation process can be relieved, and thehigh efficiency and stability of the anaerobic fermentation performance are guaranteed. The high-additional-value resourceful utilization of agricultural and forestry waste is effectively solved, theanaerobic fermentation performance is better improved, and the method belongs to the economical, environment-friendly 'waste-control-by-waste' novel efficient anaerobic fermentation technology and issuitable for industrial application and popularization.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

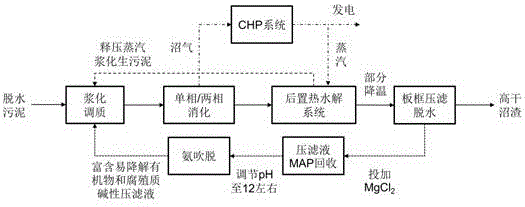

Sludge resource recovery method based on hydrothermal treatment of digested sludge

InactiveCN106746467AEfficient recyclingHigh yieldSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisRecovery methodFiltration

The invention discloses a sludge resource recovery method based on hydrothermal treatment of digested sludge. The method comprises the following steps: performing dehydration treatment on sludge so as to obtain dehydrated sludge with the solid content of 15-20%; mixing the dehydrated sludge and a press filtrate in which nitrogen and phosphorus are removed in a slurrying and tempering reactor, preheating, slurrying and tempering; pumping the sludge subjected to slurrying and tempering into an anaerobic digestion system so as to produce biogas; introducing the sludge subjected to anaerobic digestion into a pyrohydrolysis reactor for performing hydrothermal treatment, relieving pressure and cooling after pyrohydrolysis so as to obtain a mixed solution, and performing plate-frame pressure filtration dehydration so as to form high-dryness biogas residues; regulating the pH value of the press filtrate to 9-11, adding a magnesium salt to produce struvite so as to realize phosphorus recovery; regulating the pH value to 11-13, and performing ammonia stripping, thereby realizing nitrogen recovery; and refluxing the press filtrate in which nitrogen and phosphorus are removed back to the slurrying and tempering reactor, mixing with the dehydrated sludge, and performing cycle treatment. The method disclosed by the invention has the advantages that the sludge degradation rate and methane yield are effectively improved, and nitrogen and phosphorus resources are recovered.

Owner:TONGJI UNIV

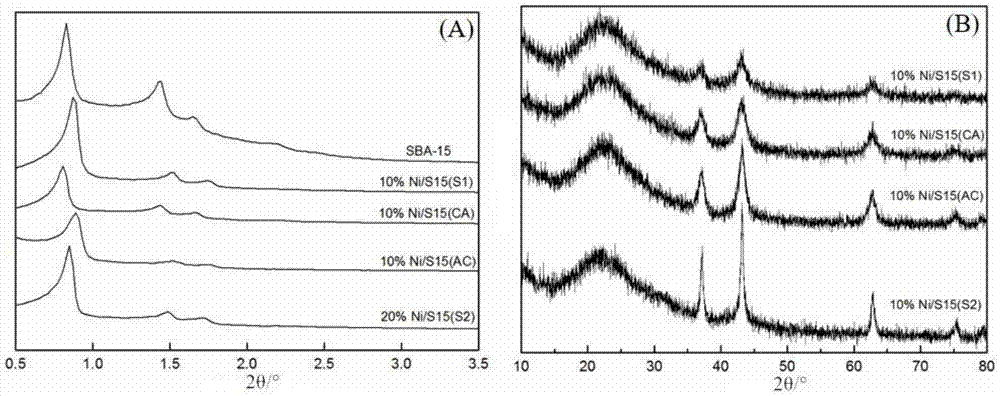

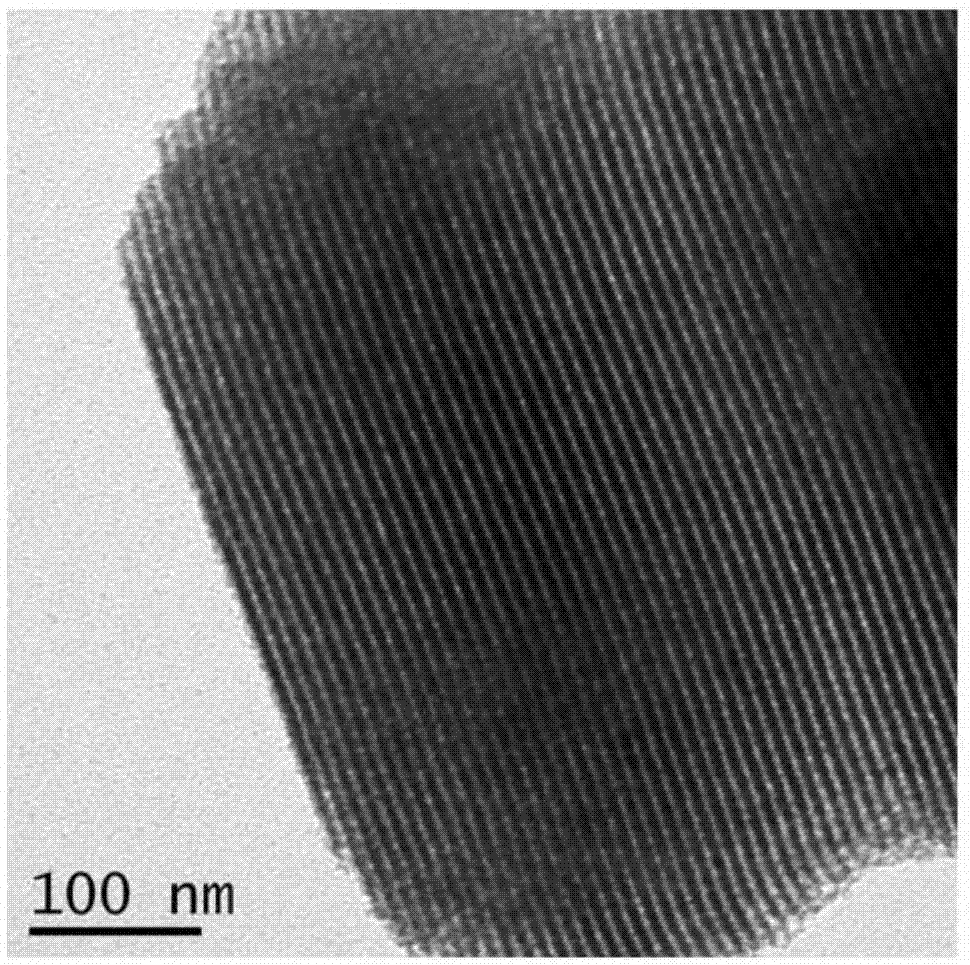

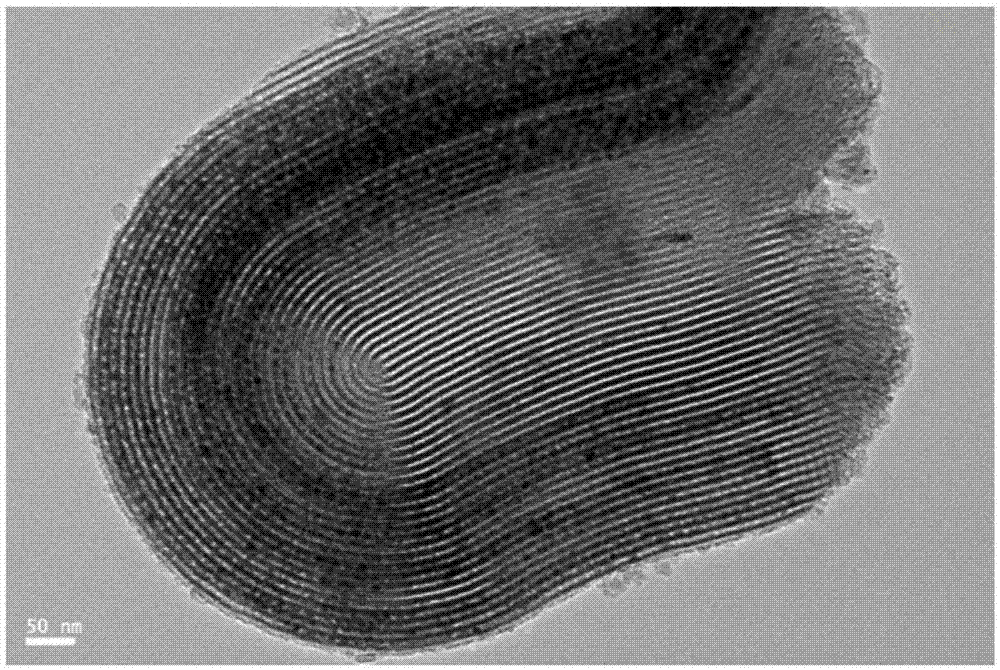

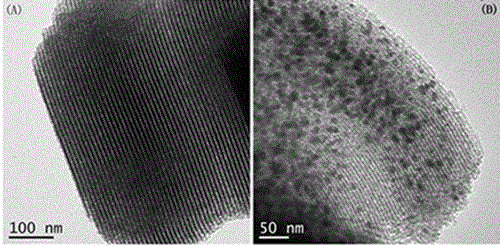

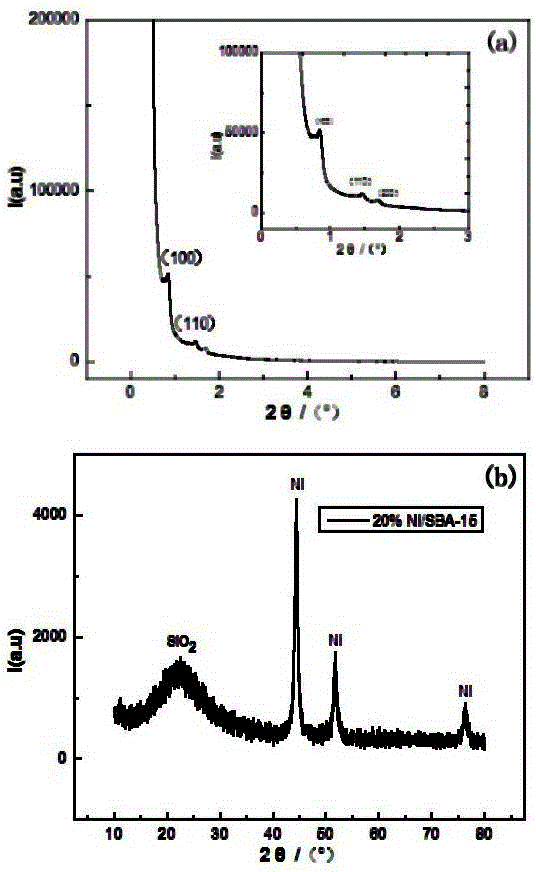

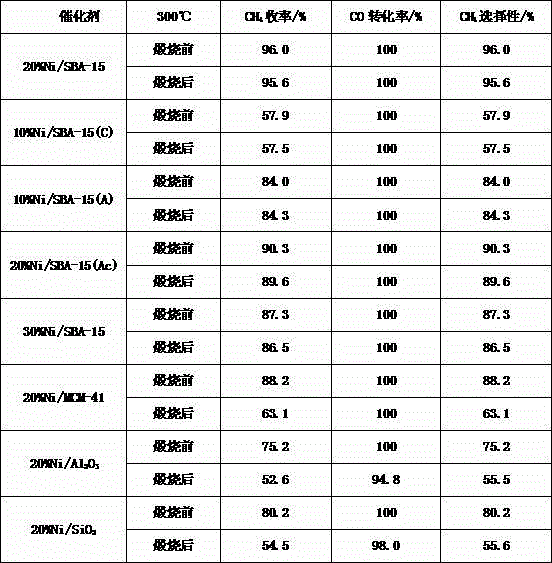

Nickel-based methanation catalyst dispersive in SBA-15 ducts and preparation and application thereof

ActiveCN107199047AHigh activityGood choiceMolecular sieve catalystsGaseous fuelsNickel saltMethanation

The invention relates to a nickel-based methanation catalyst dispersive in SBA-15 ducts and preparation and application thereof; the nickel-based methanation catalyst comprises, by 100 parts by weight, 5-20 parts of metallic nickel, 10-40 parts of an additive, and the balance of mesoporous molecular sieve SBA-15. The preparation comprises: preparing nickel salt solution, and adding an additive; in the nickel salt solution, soaking the SBA-15 in mixed liquid prepared in step A at room temperature, and calcining in vacuum after soaking to obtain the nickel-based methanation catalyst. By adding the additive and using the mesoporous molecular sieve SBA-15 with stable chemical properties, good thermal conductivity and large specific surface area as a support, the nickel-based metal catalyst with the active component dispersive in support ducts is prepared; the catalyst has the advantages of high catalytic activity, good methane selectivity, good thermal selectivity, long catalyst life and the like. Under optimal conditions, the catalyst may reach 100% in CO conversion rate, 99.9% in methane selectivity and 99.9% in methane yield, and has a promising industrial prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Coal bed methane horizontal well nitrogen foam fracturing mining technology

InactiveCN103590801AReduce the rate of filtrationReduce harmFluid removalMethane yieldFracturing fluid

The invention relates to the technical field of coal bed methane exploration and development, in particular to a coal bed methane horizontal well nitrogen foam fracturing mining technology. The technology comprises the steps that three times of well completion and horizontal section well fixation are adopted for a coal bed methane horizontal well, namely, firstly, a surface of a horizontal well is drilled, and a surface layer sleeve is placed in to seal and fix earth surface easy-leaking stratum; then, a coil layer is drilled to, and a sleeve is placed in to seal and fix stratum above the coal layer section; finally, the horizontal well is drilled, and a sleeve is used for fixing the well. When nitrogen foam fracturing is conducted, two sets of equipment are combined for the operation, one set of equipment is in charge of pumping and injecting fracturing fluid and propping agents, and the other set of equipment pumps and injects nitrogen. The fracturing fluid, the propping agents and nitrogen converge in a high-pressure pipeline at the front end of a wellhead and enter a well barrel through fracturing the well head. The technology achieves the purposes that the horizontal well can be communicated with more cleat and cracks, a single well is large in control area, nitrogen foam greatly reduces the speed of the fracturing liquid filtered into stratum, filter loss is reduced, the harm of the fracturing liquid to the stratum is reduced, the foam fracturing liquid is good in sand carrying performance, flowback effect is good, and coal bed methane yield and recovery efficiency are improved.

Owner:CNPC GREATWALL DRILLING ENG

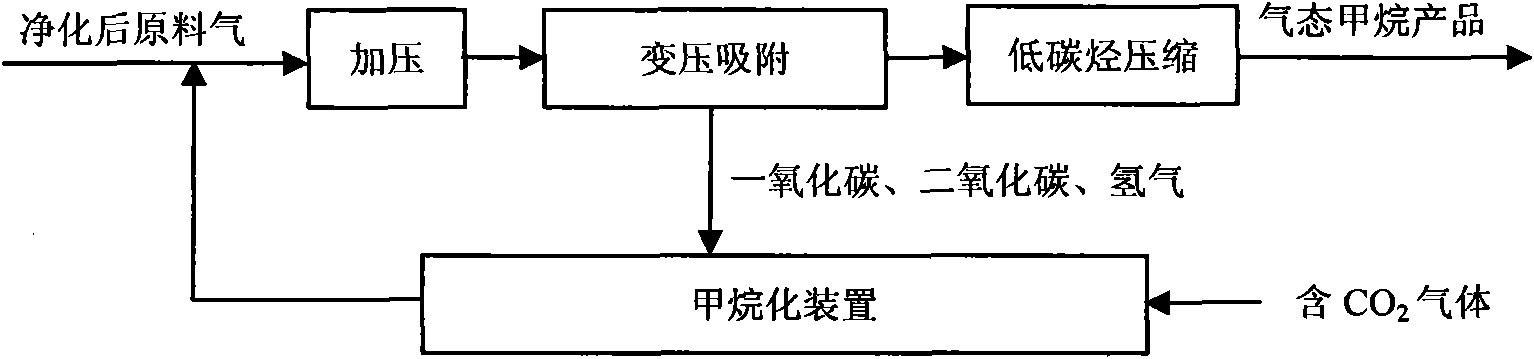

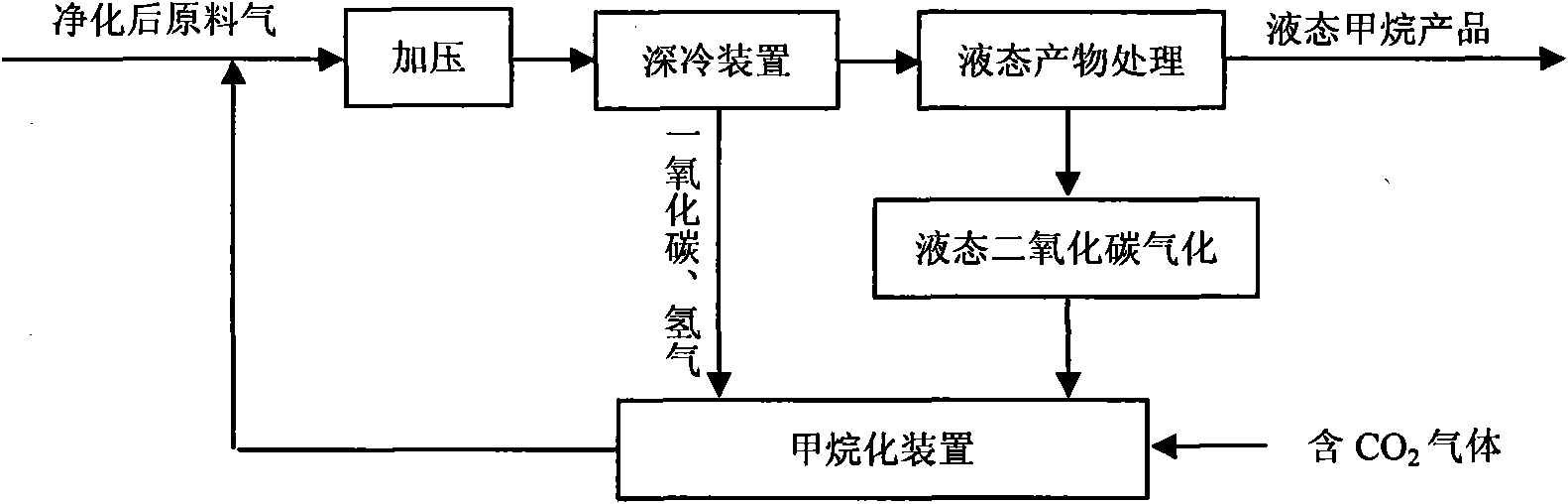

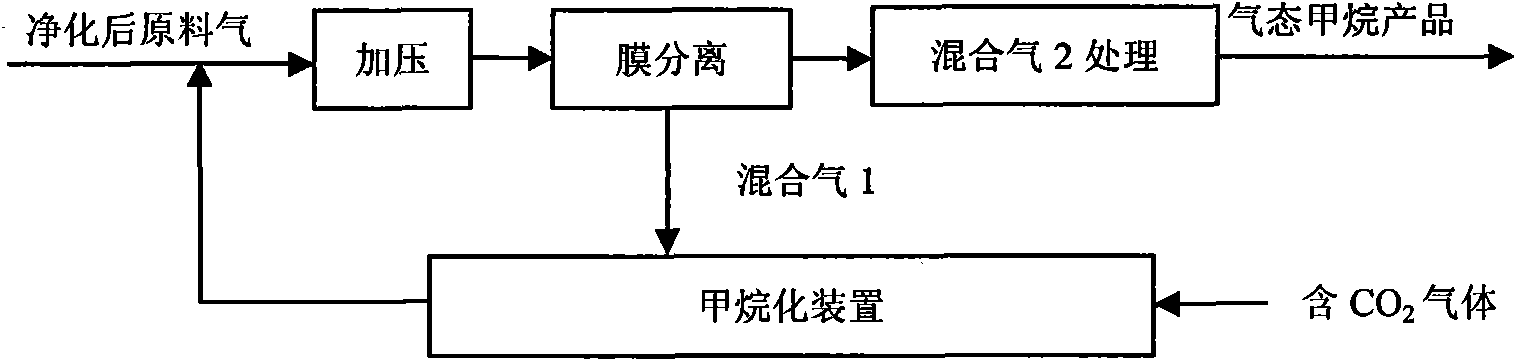

Process employing coke-oven gas for production of methane

InactiveCN101607859AEmission reductionReduce volumeHydrocarbon from carbon oxidesAdsorption purification/separationChemical synthesisMethanation

A process employing coke-oven gas for production of methane comprises the following steps: separating methane from the purified coke-oven gas to obtaining methane, performing methanation by using the mixture obtained by separation and a gas containing carbon dioxide, sending the obtained methane mixed gas back after the reaction for separating methane and recycling the above steps to prepare methane. The invention reasonablely combines the physical separation method and chemical synthesis method together, thus improving the methanation rate and the methane yield, reducing the volume of a reactor and the consumption of catalyst, realizing zero emission and zero pollution, and effectively adopting greenhouse gas carbon dioxide. The process has reasonable process route, thus being applicable to the production of methane by using the coke-oven gas generated from the dry distillation of coal.

Owner:TAIYUAN UNIV OF TECH

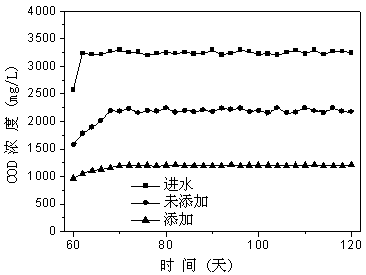

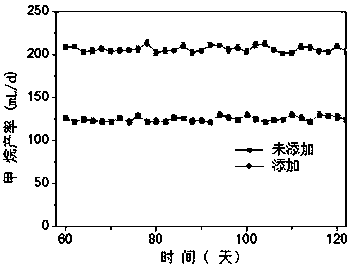

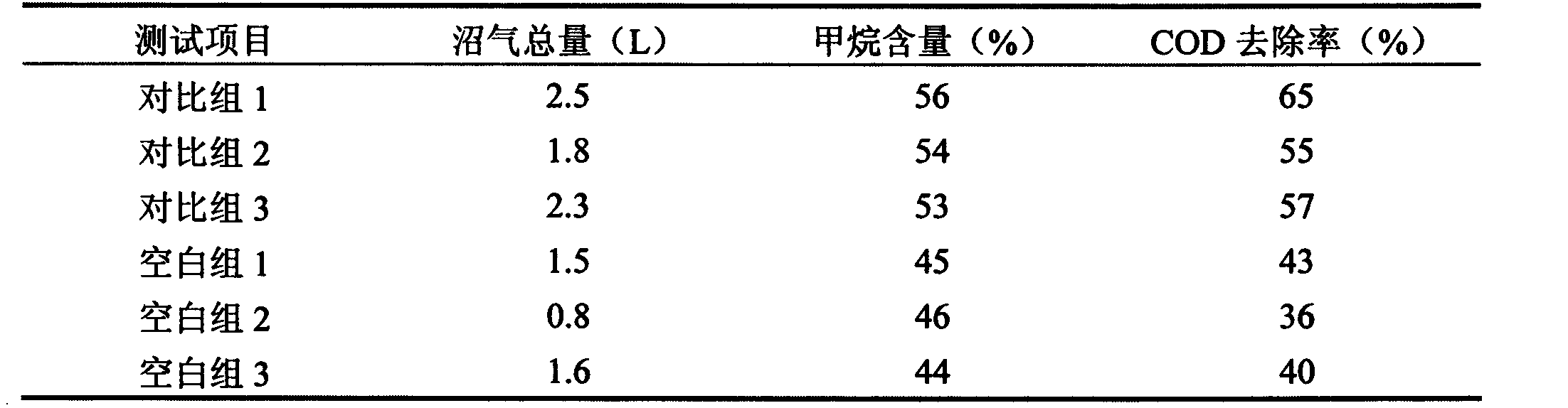

Biogas fermentation accelerant and preparation method thereof

InactiveCN103255179AThe promotion effect is obviousWaste based fuelFermentationChemical oxygen demandTrace metal

The invention discloses a preparation method of a biogas fermentation accelerant. The fermentation accelerant comprises trace metal elements such as Fe, Co, Ni and Zn. The preparation method comprise the following steps of preparing a thick salt solution in a chloride form; adding quantified thick salt solution into a fermenting methane pool every day, then stirring for well mixing the metal elements in fermentation liquor. The accelerant has good effect for biogas fermentation taking cow dung, pig manure and sheep manure as raw materials, and has good immediate effect on methanogens in biogas fermentation; if the accelerant is added in biogas fermentation, the methane yield can be improved and the methane content of the methane can be improved, the removal rate of COD (chemical oxygen demand), TS (thymidylate synthase) and VS can be obviously improved, and the accelerant has good prospect for promotion and application of the biogas fermentation.

Owner:SHIHEZI UNIVERSITY

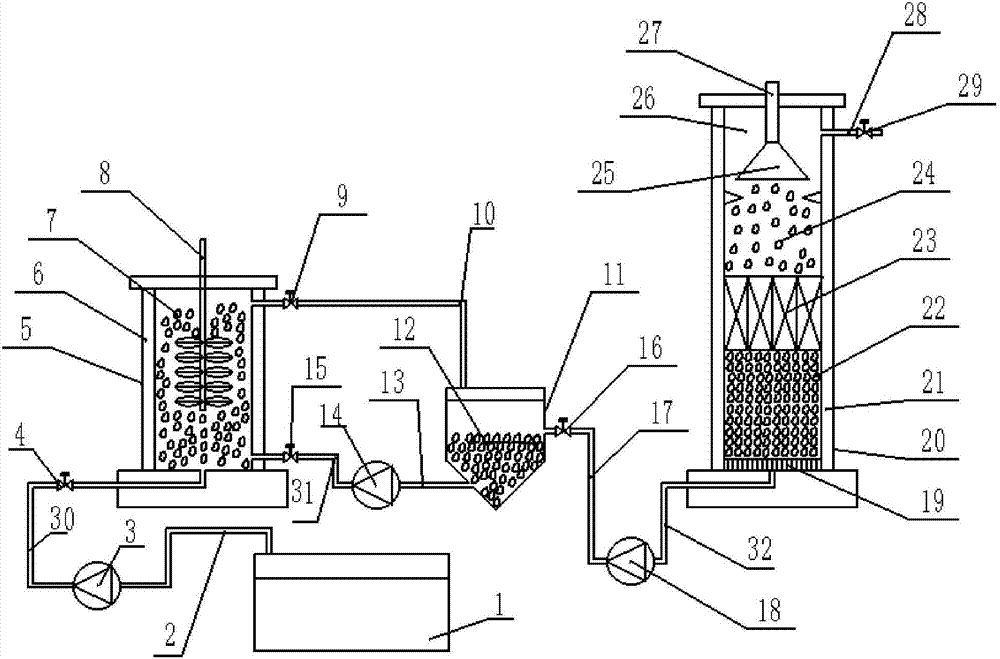

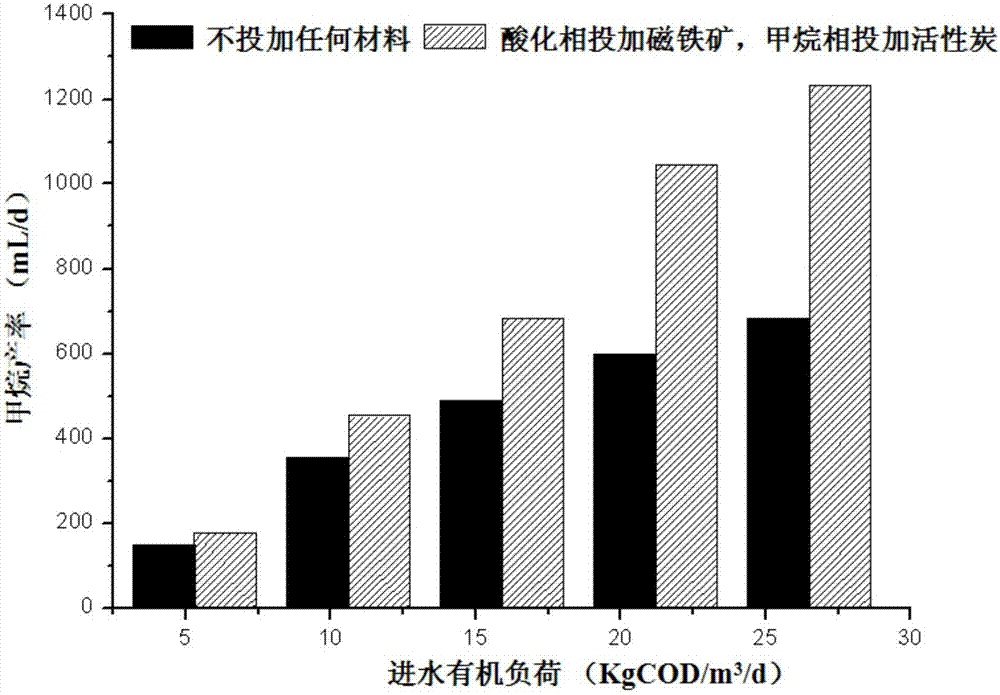

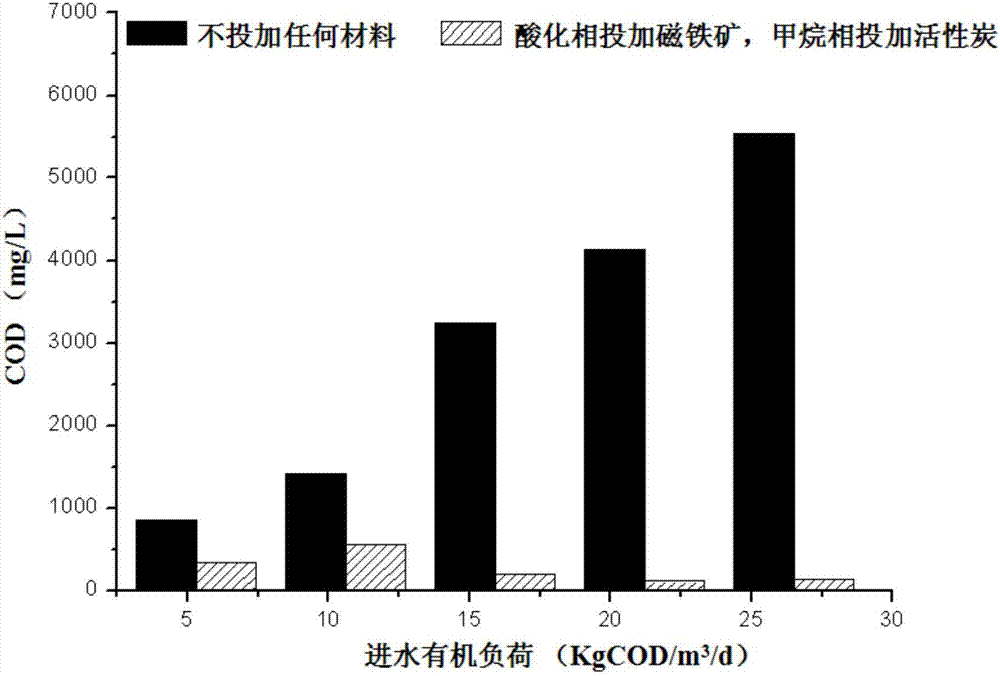

Two-phase anaerobic treatment device and technology based on magnetite and activated carbon reinforcement

The invention discloses a two-phase anaerobic treatment device based on magnetite and activated carbon reinforcement. The device is provided with an acidizing phase barrel body, a methane production phase barrel body and a stirring machine. Technological steps of the device comprises slowly adding FeCl3 and FeCl2 mixture into HCl solution, adjusting pH of mixed solution to be 6.5 to 7.5 through NaOH solution and obtaining black suspension precipitation namely magnetite; adding the magnetite into a suspension sludge area in an acidizing phase device and sealing the device; adding coal-quality columnar activated carbon into an activated carbon filling layer in a methane production phase device and sealing the device; respectively controlling hydraulic retention time of the acidizing phase device and the methane production phase device and pH and temperature in the devices. The two-phase anaerobic treatment device disclosed by the invention has the following effects of reinforcing acidizing phase complex organism decomposition, improving hydrolytic acidizing efficiency, quickening methane production phase organic aid and alcohol matter metabolism, maintaining acidity balance in the methane production phase and having an obvious effect of improving methane yield. The two-phase anaerobic treatment device has small invest cost, is simple to operate and can be applied to upgrading and reconstruction of an existing two-phase anaerobic technology to resist impact of high organic load wastewater.

Owner:DALIAN UNIV OF TECH

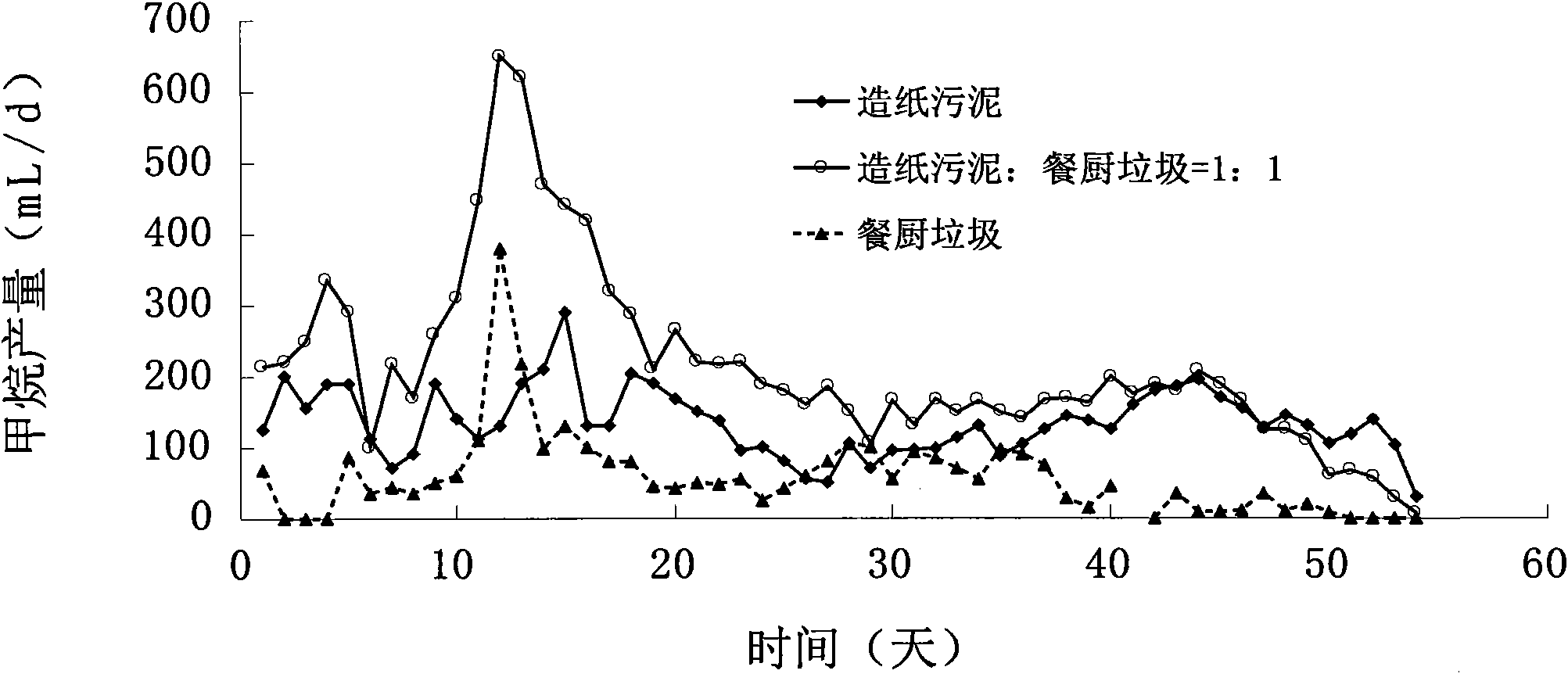

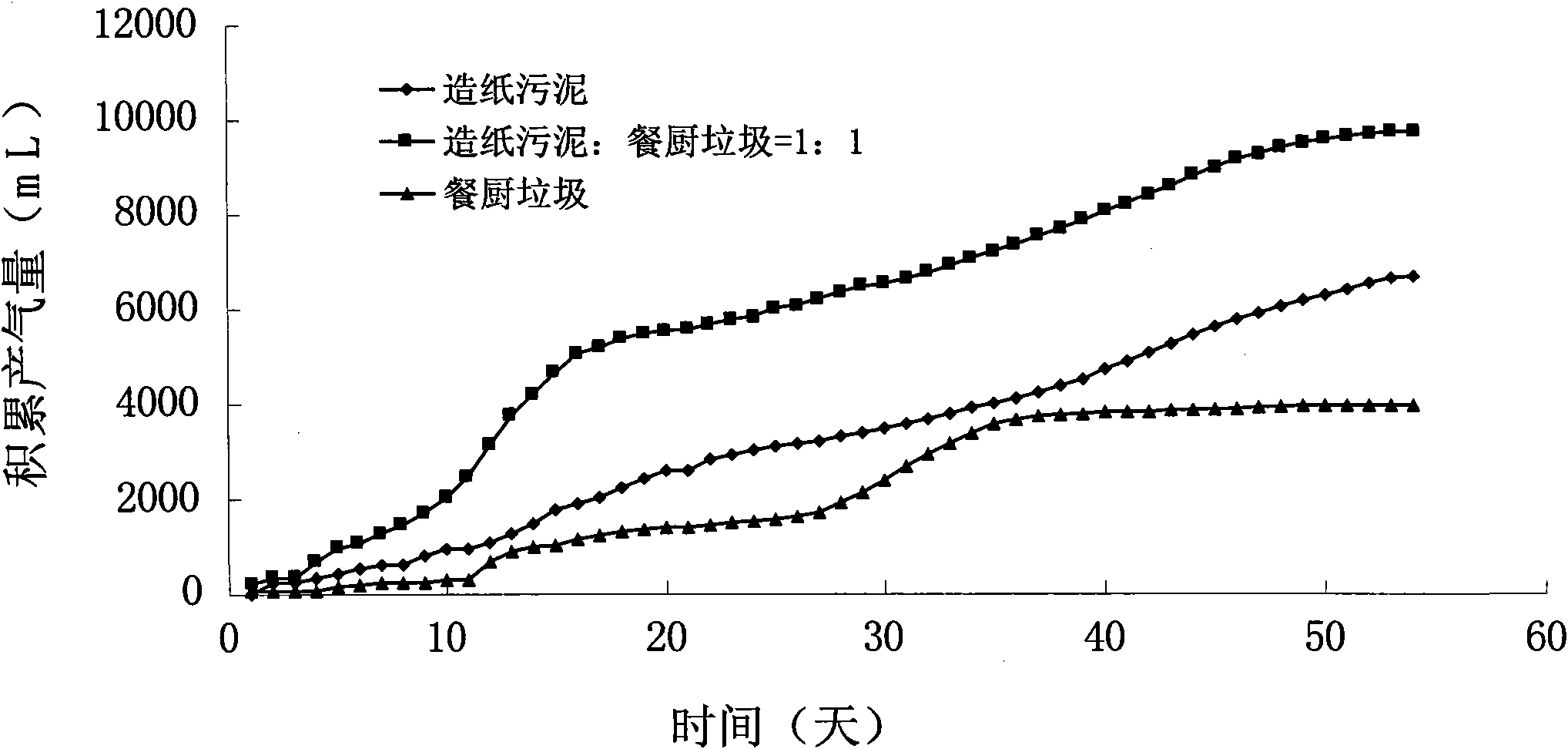

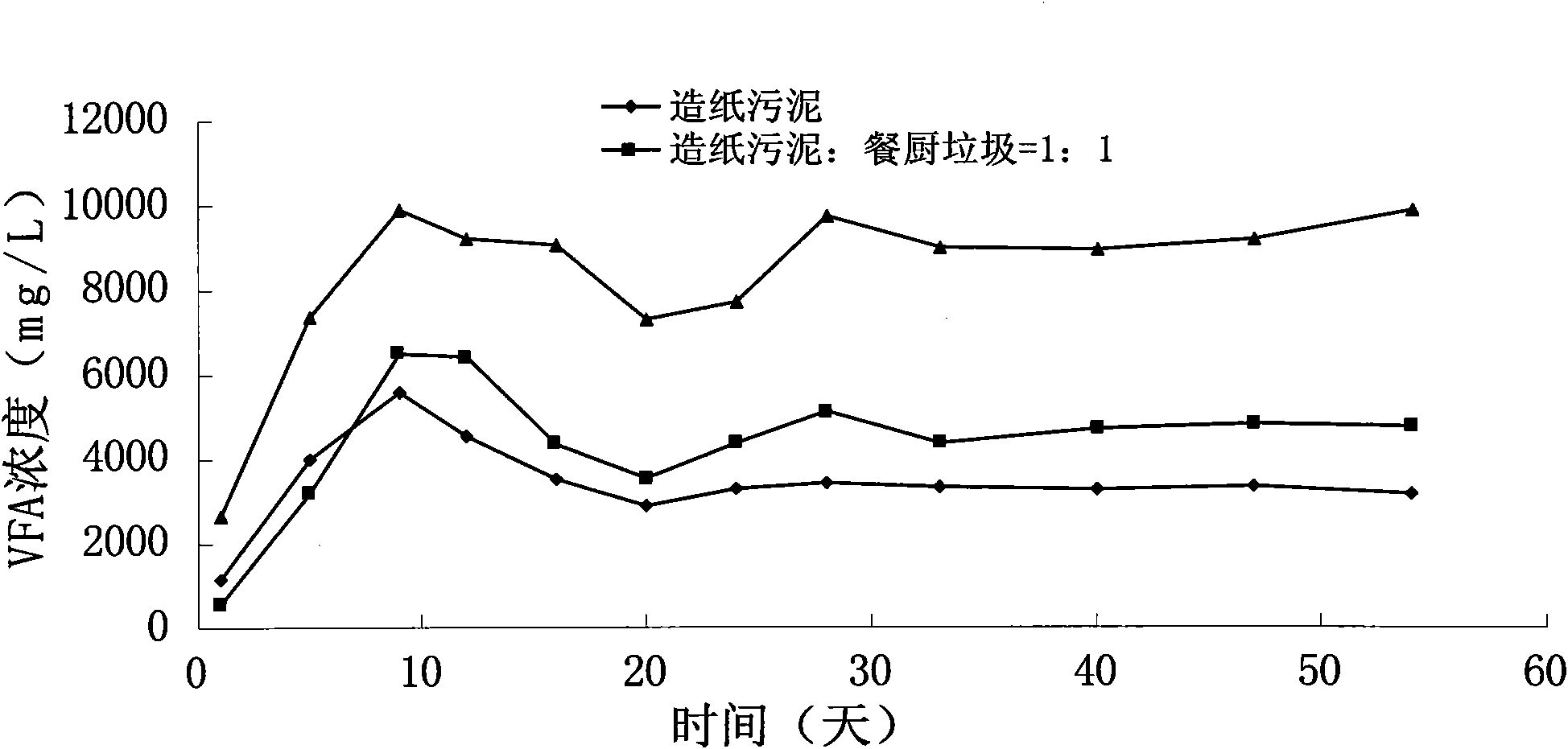

Method for producing methane by combination fermentation of paper mill sludge and food waste

InactiveCN101913747ASimple processEasy to operateGas production bioreactorsWaste based fuelMethane yieldPulp and paper industry

Owner:SOUTH CHINA AGRI UNIV

Composite bacterial agent for methane fermentation

ActiveCN101948752AEasy to combineIncrease the average daily gas production rateBacteriaMicroorganism based processesBiotechnologyClostridium pasteurianum

The invention discloses a composite bacterial agent for methane fermentation, which relates to a composite preparation of microbial fermentation bacterial liquid. In the invention, the problem of lacking bacterial gent applicable to methane fermentation using cow dung as a main raw material and bacterial agent applicable to medium and large methane fermentation projects is solved. The composite bacterial agent comprises 8 to 15 weight parts of bacteroides cellulosolvens fermentation liquor, 12 to 20 weight parts of clostridium pasteurianum fermentation liquor, 30 to 45 weight parts of methanoculleussubmarinua fermentation liquor and 20 to 50 weight parts of methanosarcina mazei fermentation liquor. The number of the active bacteria of 1 milliliter of the fermentation liquor of each of the four kinds of bacteria is greater than 10<9>. The composite bacterial agent for the methane fermentation using the cow dung as the main raw material can make gas production earlier and improve gas yield and methane yield effectively.

Owner:黑龙江省昊千生物科技有限公司

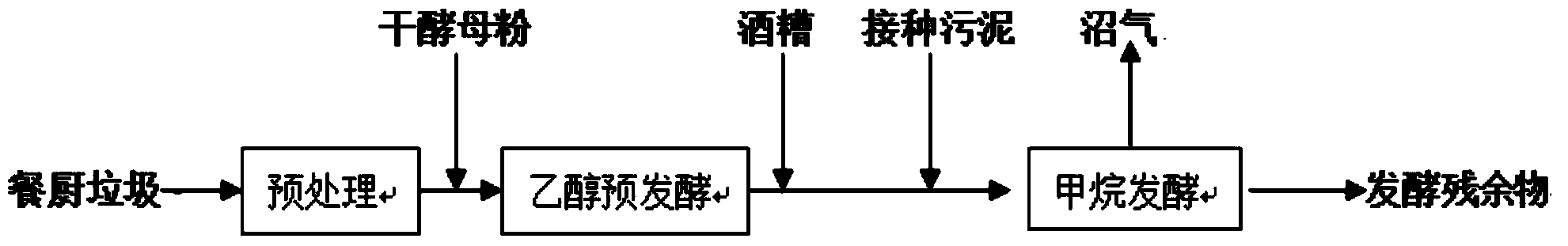

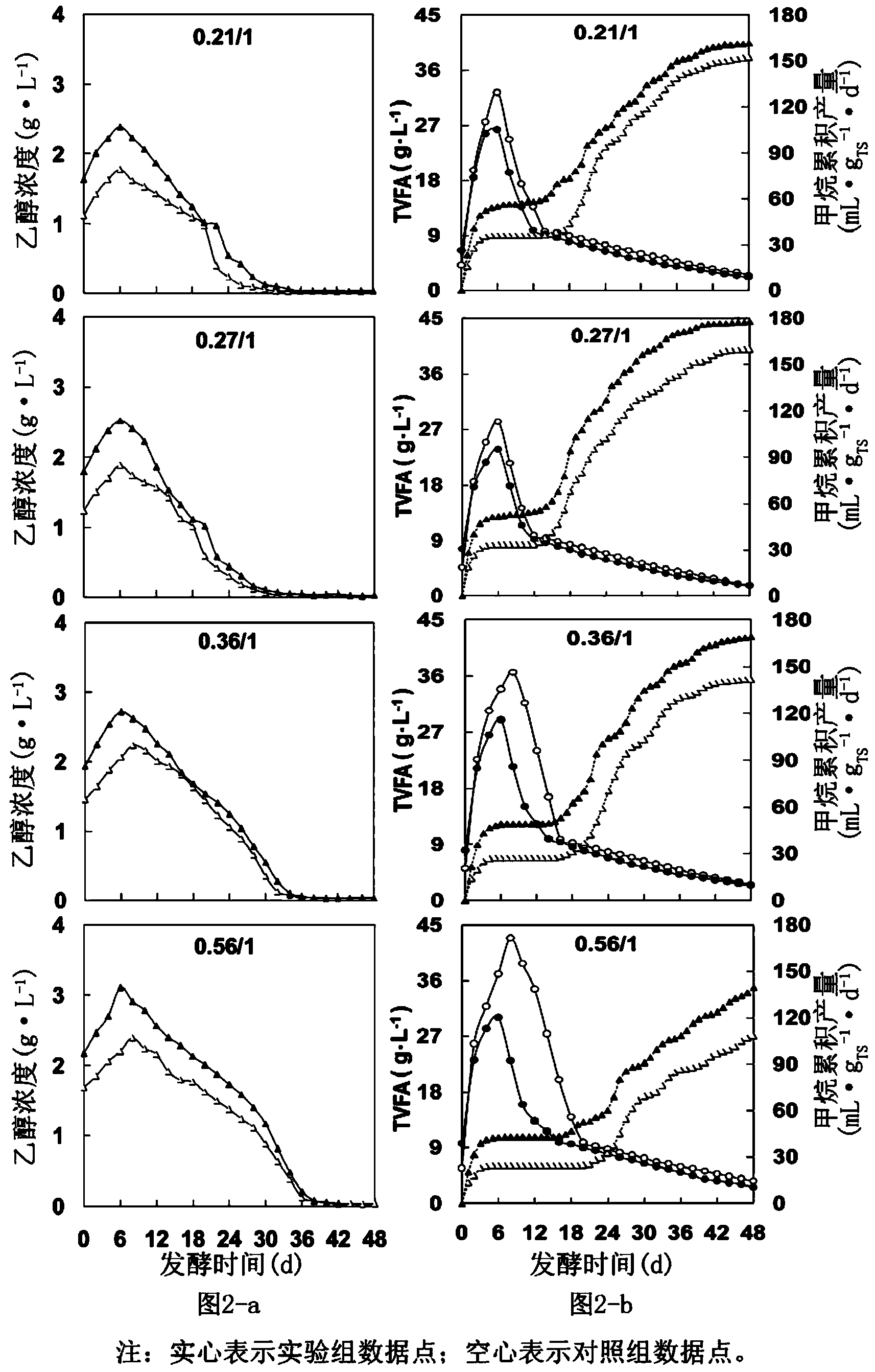

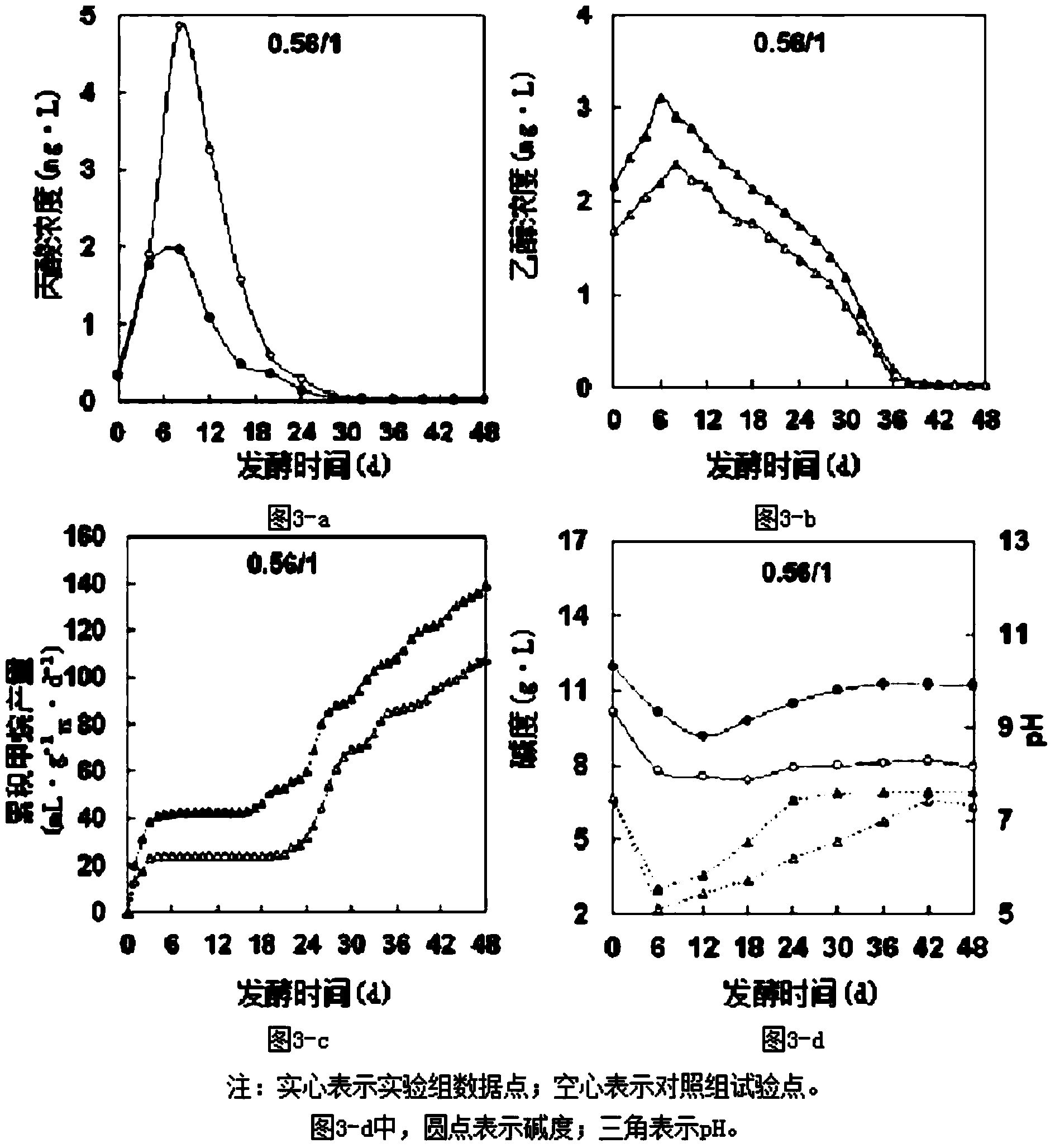

Method for producing marsh gas by two-phase dry-type mixed anaerobic fermentation

The invention provides a method for producing marsh gas by two-phase dry-type mixed anaerobic fermentation, belonging to the technical field of renewable energy sources. The method mainly comprises the following steps: ethanol prefermentation: inoculating a certain amount of dried yeast into kitchen waste to carry out ethanol prefermentation; and methane fermentation: mixing the kitchen waste subjected to ethanol prefermentation and vinasse in a ratio of 1:1 (on the basis of VS) as a substrate for subsequent anaerobic fermentation, and inoculating long-term acclimatized sludge in a ratio of 1:1 (sludge:substrate (on the basis of VS)). The method searches the possibility of optimizing methane anaerobic fermentation by ethanol prefermentation, and optimizes the experimental conditions for ethanol prefermentation. The method can effectively relieve the problem of volatile acid inhibition in the anaerobic digestion process, and obviously enhances the methane yield, thereby enhancing the energy recovery rate. The method is simple to operate, and thus, has high practical value.

Owner:UNIV OF SCI & TECH BEIJING

Method for accelerating anaerobic fermentation of organic waste water or organic castoff to prepare sludge gas

InactiveCN101319230AIncrease productionImprove bioavailabilityWaste based fuelTreatment with anaerobic digestion processesMethane yieldAnaerobic reactor

The invention relates to a method for promoting the anaerobic fermentation of organic waste water or organic wastes to produce biogas, belonging to the wastes biological treatment technical field. The method takes simulated organic waste water as a treatment object, and adds a trace metallic element sequestering agent into an anaerobic reactor to improve the bioavailability of the trace metallic element necessary for methanogens and to promote the growth and activity of the methanogens, thereby improving the methane yield and the contaminant conversion rate of a system. As the addition mount of the trace metallic element sequestering agent is very low, the method has not only simple and highly efficient operation, but also low cost, and can be expected to be widely applied to engineering practices.

Owner:JIANGNAN UNIV

Method for improving methane yield by organic waste water anaerobic fermentation

InactiveCN101157937AIncrease productionImprove bioavailabilityWaste based fuelFermentationChemical industryTransformation efficiency

The invention relates to a method used for raising the output of marsh gas by using anaerobic fermentation of organic effluent water, which pertains to the technical field of biological treatment of effluent water. The invention adopts simulated organic effluent water or practical wastewater from chemical industry as treatment objects, by adding trace metal element Co and metal ion chelating agent to an anaerobic reactor to improve the biological availability of trace metal elements which are essential for methanogen and promote the growth and activity of methanogen, thereby, methane output and transformation efficiency of contaminating material of the system is improved. The method needs only extreme micro-amount of trace metal element Co and metal ion chelating agent, therefore, the invention is not only convenient to be manipulated with high efficiency and but also low in cost which leads the invention to be extensively applicable in engineering practice.

Owner:JIANGNAN UNIV

Preparation method of nickel-based catalyst based on SBA-15 and application of nickel-based catalyst in SNG preparation

InactiveCN104549411AHigh activityGood choiceHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveNickel salt

The invention discloses a catalyst for carbon monoxide methanation and application of the catalyst in reaction of methane prepared from synthesis gas. The catalyst is characterized in that a mesoporous molecular sieve SBA-15 is used as a carrier; metal Ni is used as a main active ingredient; based on metallic elements, 100 parts by weight of the catalyst comprise10-30 parts by weight of nickel and the balance being a molecular sieve SBA-15. When the catalyst is prepared, the mesoporous molecular sieve SBA-15 is impregnated in a nickel salt solution, dried in vacuum, and roasted. In the invention, a traditional method, in which aluminium oxide is used as the carrier, for preparing the methanation catalyst is changed, the mesoporous molecular sieve SBA-15 is used as the carrier to prepare the catalyst which is high in catalytic activity, excellent in methane selectivity, and relatively long in catalyst service life, and the prepared catalyst also has the relatively good activity under low temperature; for the catalyst, the CO conversion rate is 100%, the methane selectivity is 96%, and the methane yield is 96% under the best condition, and thus the catalyst has a relatively wide industrial prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

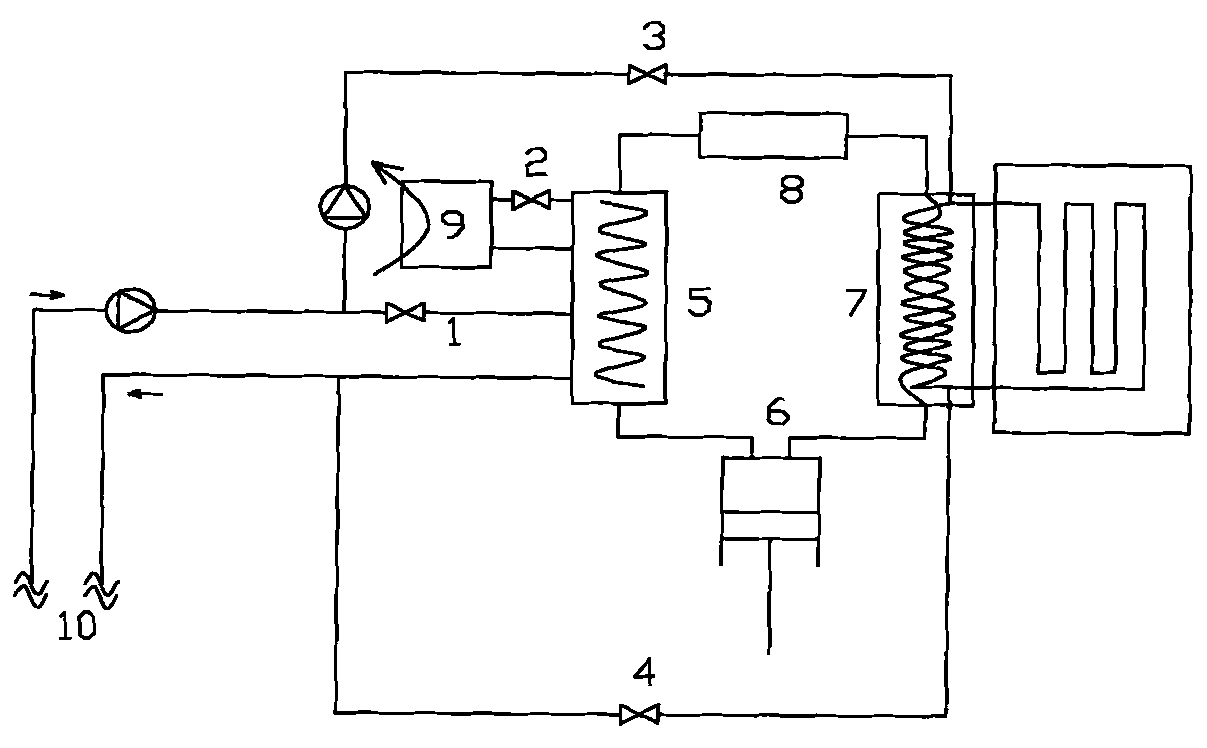

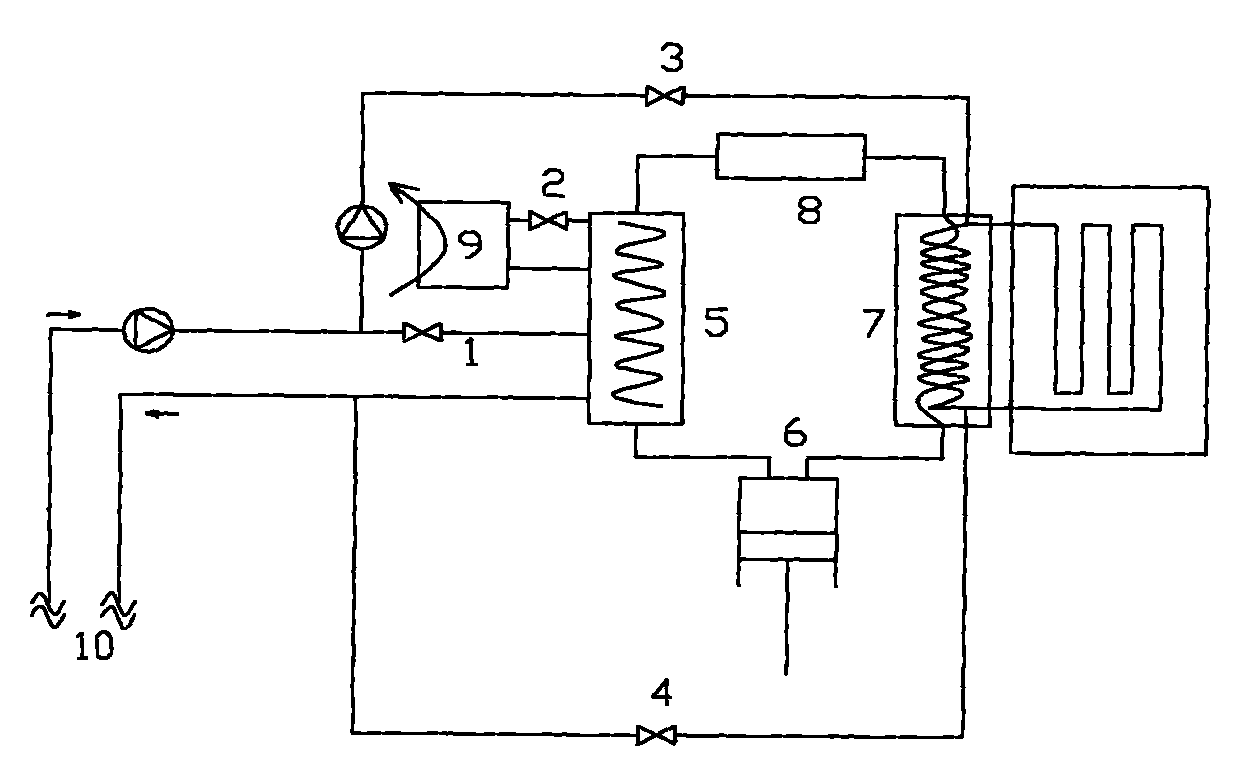

System for warming methane tank by ground source/air source heat pump and control method

InactiveCN101974420AEasy to operateEfficient use ofBioreactor/fermenter combinationsBiological substance pretreatmentsHigh energyMethane yield

The invention belongs to the field of energy conservation and in particular relates to a system for warming a methane tank by a ground source / air source heat pump and a control method. The system consists of an underground loop, air cooling equipment, a ground source / air source heat pump public unit and a control system. The control method comprises that: when the outdoor average temperature is below 20 DEG C for ten days successively, a ground source heat pump unit is started for heat exchange; when the outdoor temperature is higher than 20 DEG C for ten days successively, an air source heat pump unit is started for heat exchange; when the temperature in the methane tank is reduced to below 35 DEG C, the ground source / air source heat pump unit is automatically started and transfers the heat of the underground water into hot water in a heating coil in the methane tank by consuming electric energy; and when the water inlet and outlet temperature difference of the ground source / air source heat pump unit is 7.5 DEG C and the temperature of the methane tank is 35 DEG C, the ground source / air source heat pump unit automatically stops working. Medium-scale fermentation engineering is taken as an object, and a novel warming system for improving the utilization rate of the energy and reducing construction cost on the premise of ensuring methane yield, and a control method are explored; and the method has high energy-saving benefit and good environmental-protection effect.

Owner:TONGJI UNIV

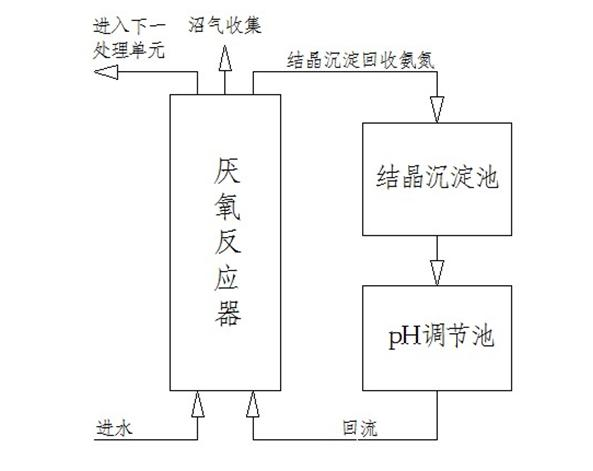

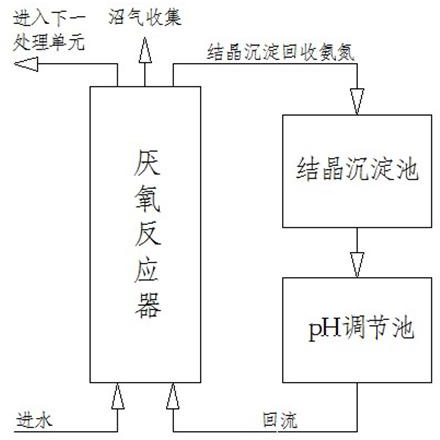

Method for improving activity of methanogens while reducing high-concentration ammonia nitrogen in anaerobic process

InactiveCN102249494AGuaranteed uptimeEfficient recyclingWaste based fuelTreatment with anaerobic digestion processesHigh concentrationMethanobacter

The invention discloses a method for improving the activity of methanogens while reducing high-concentration ammonia nitrogen in the anaerobic process, and belongs to the field of water treatment. The method comprises the following steps of: contacting high-concentration nitrogen-containing organic waste water with anaerobic microorganisms fully in an anaerobic reactor to perform reaction, and degrading to obtain a large amount of ammonia nitrogen; introducing the waste water into a crystallizing sedimentation tank partially, adding a dissoluble magnesium source and phosphates in a certain ratio, and regulating the pH value to 7.0 to 10.0, so that Mg<2+>, NH4<4+> and PO4<3-> in the waste water react to generate an ammoniomagnesium phosphate (MAP) crystal, and precipitating the MAP crystal; and stabilizing the pH value of treated supernatant to 6.5 to 8.0 by a pH regulating tank, and refluxing to the anaerobic reactor. By the method, ammonia nitrogen resources in the waste water can be recovered effectively, the phenomenon of the reduction of the activity of anaerobic sludge due to overhigh concentration of the ammonia nitrogen can be prevented, and the operation effect of the anaerobic reaction and the yield of methane can be improved.

Owner:NANJING UNIV

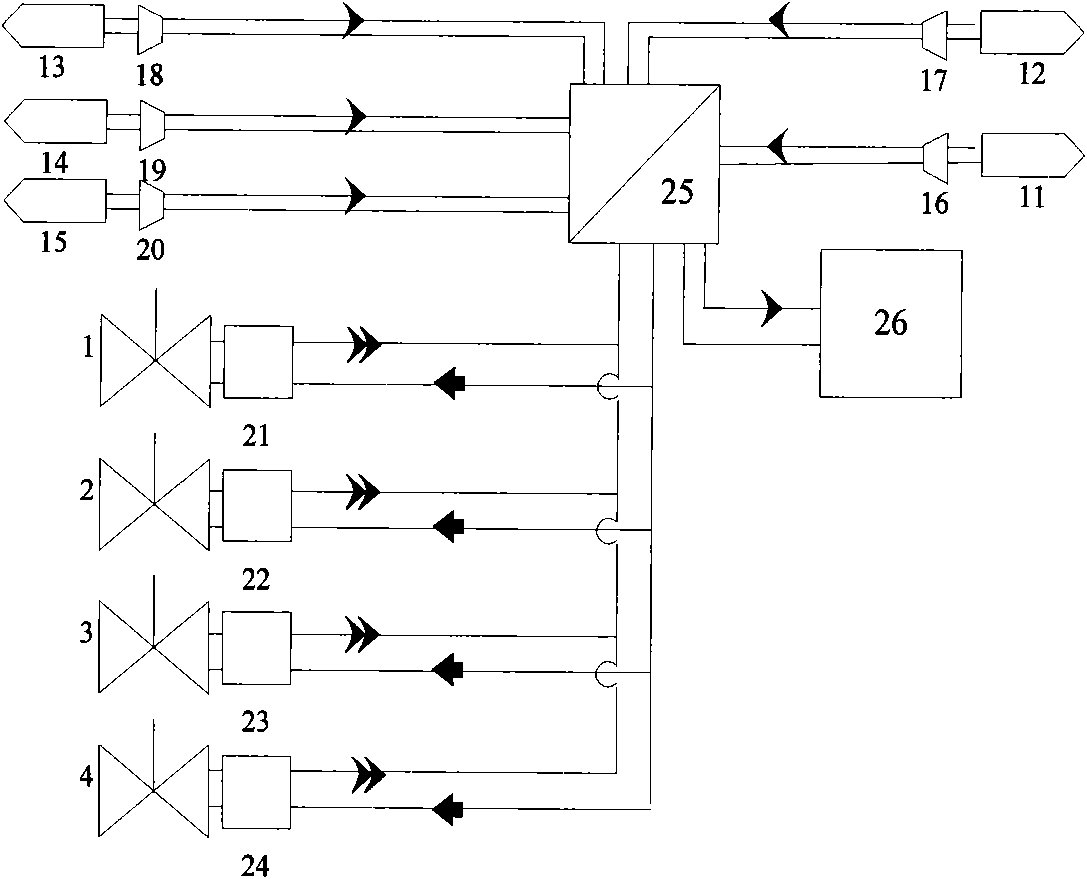

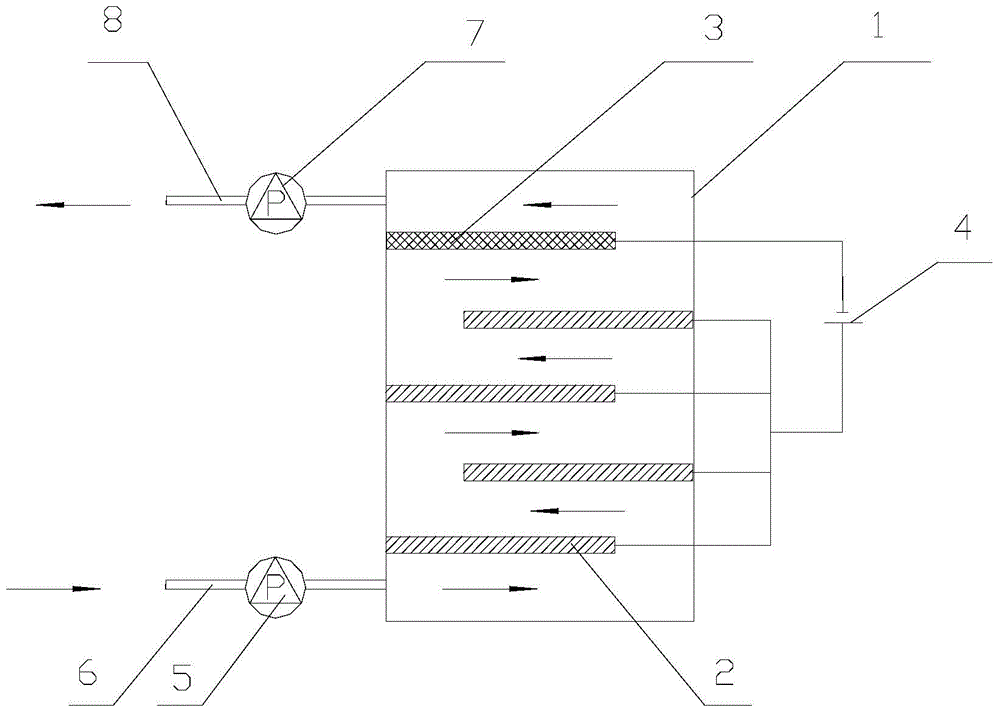

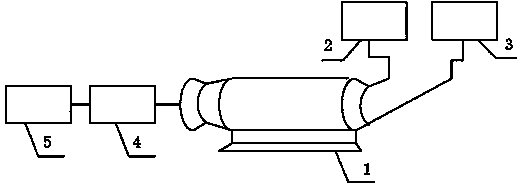

Novel external electrolysis device for promoting anaerobic digestion to produce methane

ActiveCN103555566APromote degradationIncrease productionBioreactor/fermenter combinationsElectrolysis componentsElectrolysisBiochemical engineering

The invention discloses a novel external electrolysis device for promoting anaerobic digestion to produce methane. The novel external electrolysis device structurally mainly comprises a charging tube, an electrode group, an external power supply and a discharging tube. The electrode group is arranged inside the device; the electrode group is composed of an iron plate and a carbon plate, the iron plate is used as an anode, and the carbon plate is used as a cathode. Each electrode plate is alternatively arranged in parallel. The external electrolysis device is connected with an anaerobic fermentation reactor by the charging tube and the discharging tube. The charging tube is provided with a charging pump. The discharging tube is provided with a discharging pump. An external power supply is started. The charging pump and the discharging pump are started, so that a material in an anaerobic digestion reactor enters the external electrolysis device through the charging tube, and is transported back to the anaerobic digestion reactor through the discharging tube after electrolytic reaction. The flow velocity of the charging pump is consistent with that of the discharging pump. The novel electrolysis device can be used for effectively promoting degradation of an organic substrate, stabilizing the activity of the produced methane and greatly improving the yield of the methane. Moreover, the device is small in size, convenient to install, suitable for upgrading and reconstructing of the existing anaerobic digestion reactor, and good in application prospect.

Owner:DALIAN UNIV OF TECH

Pretreatment method capable of improving straw biomass anaerobic digestion rate

InactiveCN103740767AImprove biodegradabilityIncreased rate of anaerobic digestionFermentationChemical treatmentPretreatment method

The invention belongs to the field of utilization of waste biomass resources, and discloses a pretreatment method capable of improving crop straw biomass anaerobic digestion rate, which mainly solves the problems of longer anaerobic digestion cycle, low digestion rate and the like of the existing crop straw. According to the invention, the straw is directly bundled and stored in the field, so the land occupation area of the methane engineering is reduced, the investment is reduced, and the like; meanwhile, the methane yield can be increased, and the economic benefits are good. The pretreatment method particularly comprises the following steps: after the integral straw is harvested, naturally airing the straw in the field to enable the water content to reach 35% to 40%; carrying out chemical treatment by a fermentation inhibiting agent, wherein the usage amount of the fermentation agent is 300 to 400 ml per 100 kg of a raw material, and reducing the pH value; after acidifying, mechanically compacting and bundling, wherein the straw bundling density is about 130 to 140 kg / m3; coating and sealing the straw by thin films, and storing for 20 to 30 days; taking the slightly stored straw and inoculating silt, inoculating according to the ratio of 1:10, and carrying out the anaerobic digestion reaction, wherein the reaction temperature is 38 to 40 DEG C and the reaction time is 15 to 20 days. The technique has broad application prospect in the straw methane engineering.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

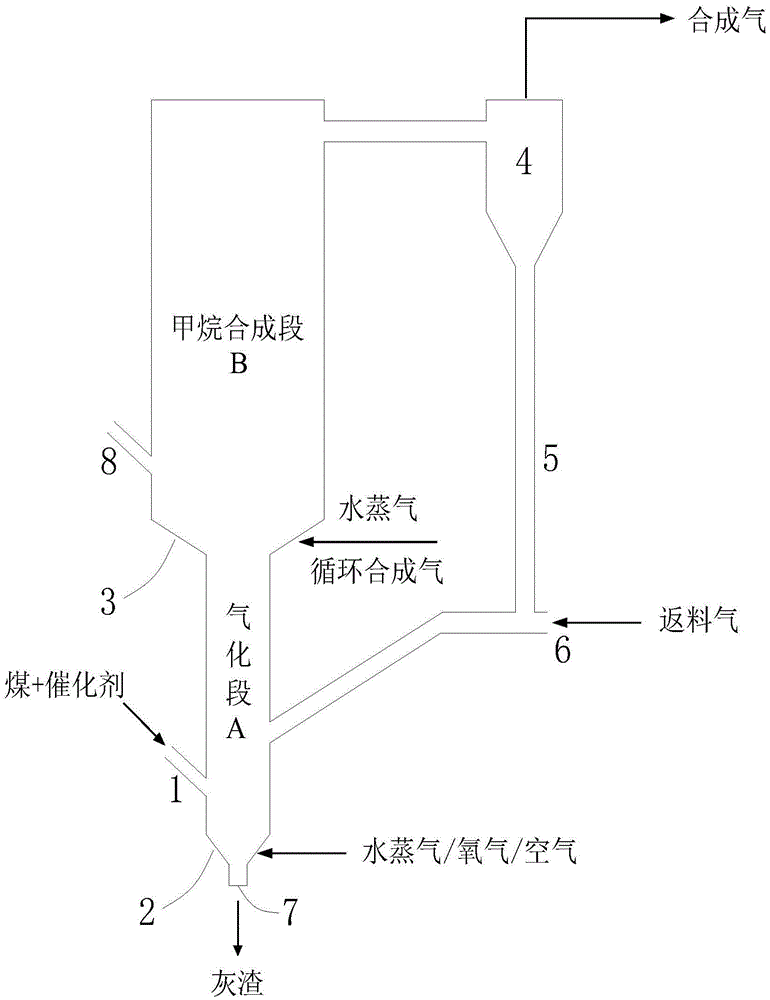

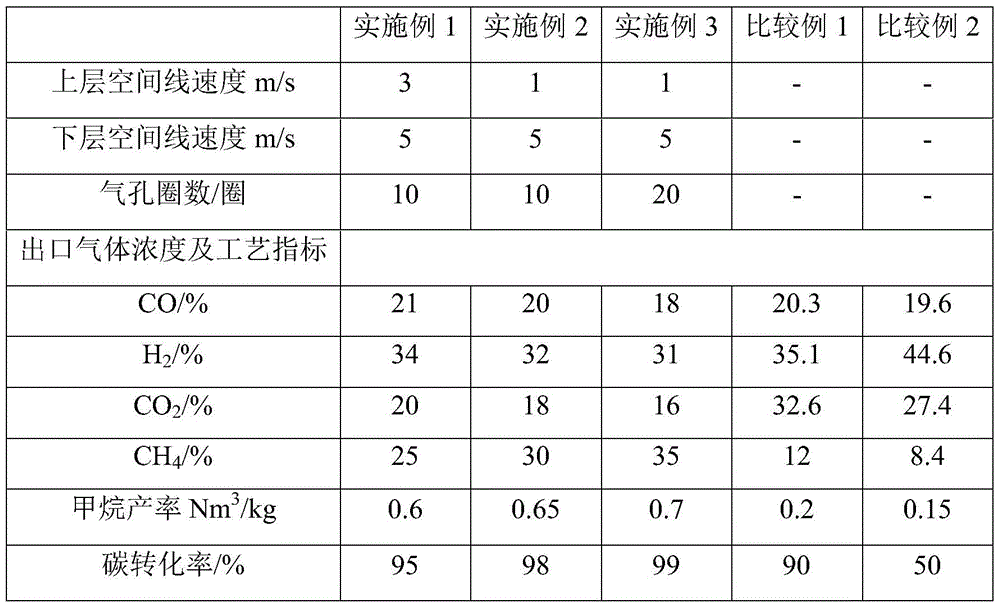

Fluidized bed reaction device and reaction method for coal catalytic gasification for producing methane-rich synthetic gas

ActiveCN106590761AExtended stayIncrease production capacityBulk chemical productionGranular/pulverulent flues gasificationWater vaporHigh energy

The invention relates to a fluidized bed reaction device and reaction method for coal catalytic gasification for producing methane-rich synthetic gas. The problems of low carbon conversion rate, low methane yield, high energy consumption and complex structure in the prior art are solved in the invention. The device is formed by a lower space gasification reaction segment and an upper space methane synthesis segment, the internal diameter of the upper space is greater than the internal diameter of the lower space, and the bottoms of the two spaces are respectively provided with a primary gas distributor and a secondary gas distributor. The method comprises the following steps: raw coal, a catalyst, an oxygen-containing gas and water vapor undergo a combustion gasification reaction in the lower space, synthetic gas generated in the gasification reaction is mixed with parts of circulating synthetic gas in the upper space, and a methanation reaction is carried out in order to generate the methane-rich synthetic gas. The device and the method well solve the problems, and can be applied to the field of coal-to-natural gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

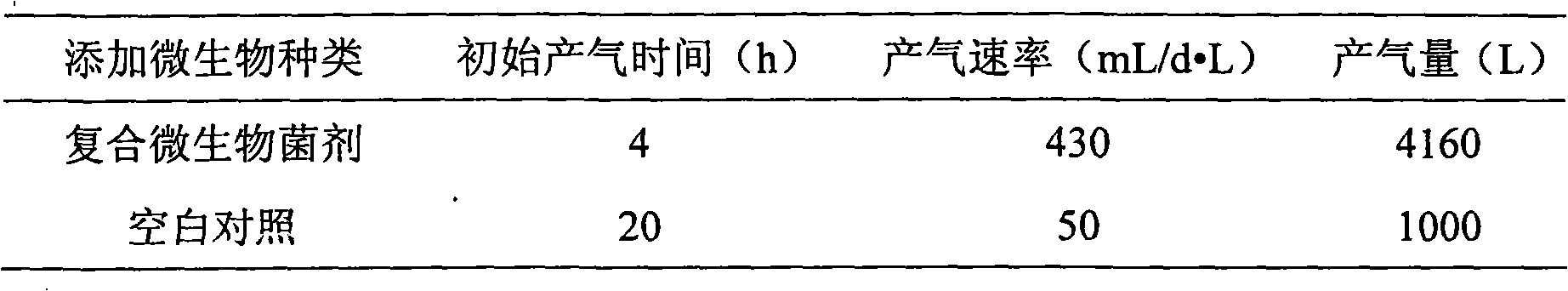

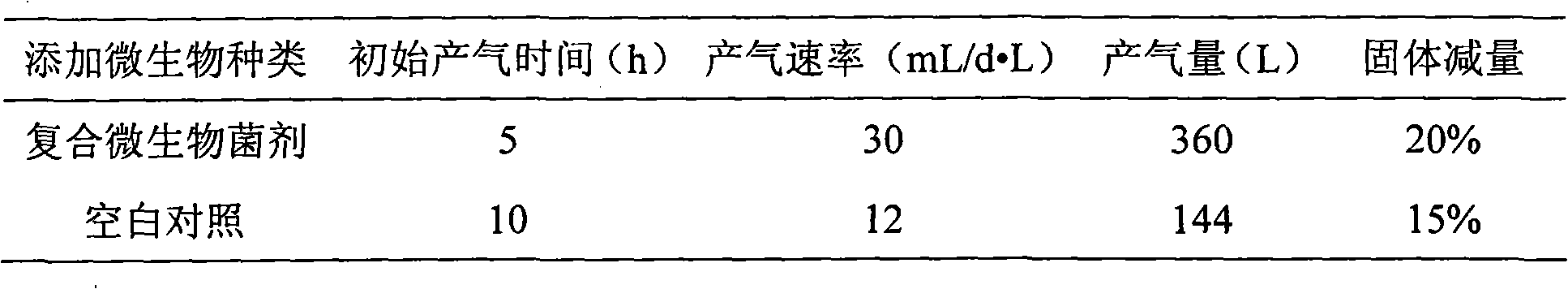

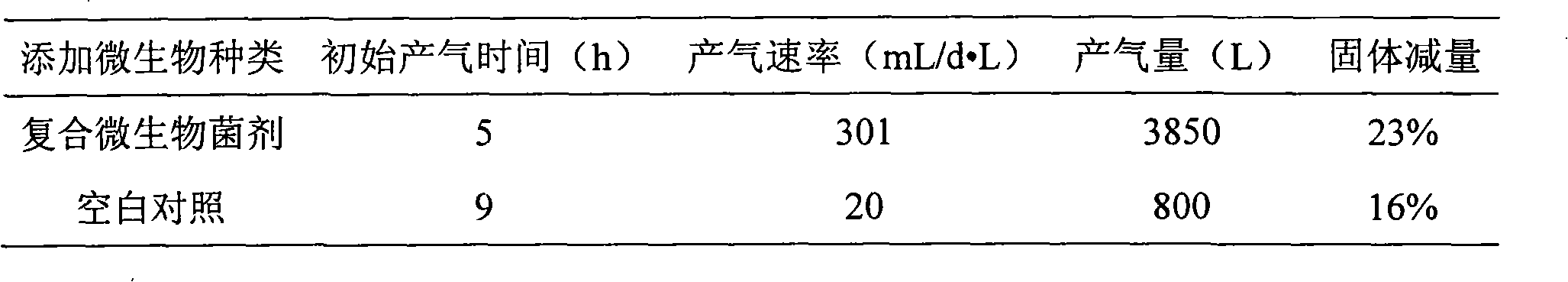

Complex bacterial preparation and application thereof

The invention belongs to the technical field of the agricultural microbiology and discloses a complex bacterial preparation and application thereof. The complex bacterial preparation is prepared by mixing the following components: 1 to 3 parts of fermentation liquor of Escherichia.coli, 2 to 3 parts of fermentation liquor of Trichoderma virens, 1 to 4 parts of fermentation liquor of Pseudomonas fluorescens and 4 to 6 parts of fermentation liquor of Bacillus subtilis. The complex bacterial preparation provided by the invention not only can improve the methane yield of straws and cow dung and improve the methane generating speed, but also can further reduce content of solid waste by 30 percent. The method has the advantages of quick response, low cost, simple using method, easy popularization and the like and can be popularized and used.

Owner:江苏加德绿色能源有限公司

Method for increasing methane yield by preprocessing rice straw through rumen microorganisms

InactiveCN105505995AReduce outputIncrease productionWaste based fuelFermentationWater bathsMethane yield

The invention discloses a method for increasing methane yield by preprocessing rice straw through rumen microorganisms, and belongs to the fields of biotechnologies and renewable energy. The method includes the steps of filtering fresh rumen fluid, storing filtrate at a certain temperature, mixing rice straw powder with a nutrient solution according to a certain proportion, inoculating rumen fluid of a certain proportion, placing the mixed fluid in a constant-temperature oscillation water bath kettle, conducting anaerobic cultivation at a certain temperature and a certain rotating speed, conducting rumen microorganism preprocessing, inoculating a certain proportion of anaerobic digestion inoculated sludge containing methanogens in the fermentation liquid after preprocessing ends, and conducting anaerobic digestion methanogenesis at a certain anaerobic digestion temperature and within the initial pH range. The rice straw biomass material is preprocessed through rumen microorganisms, hydrolytic acidification of the raw material is promoted, the high methane yield is obtained, and the reaction time is shortened; meanwhile, pressure for processing wastewater of slaughter houses on sewage treatment plants is relieved. Compared with the contrast group (not preprocessed), the methane yield is increased by 55.4-87.3%, the anaerobic digestion time is shortened by 3-10 days, the degradation rate of cellulose is increased by 20.3-33.6%, and the degradation rate of semi-cellulose is increased by 15.6-25.7%.

Owner:HUNAN UNIV

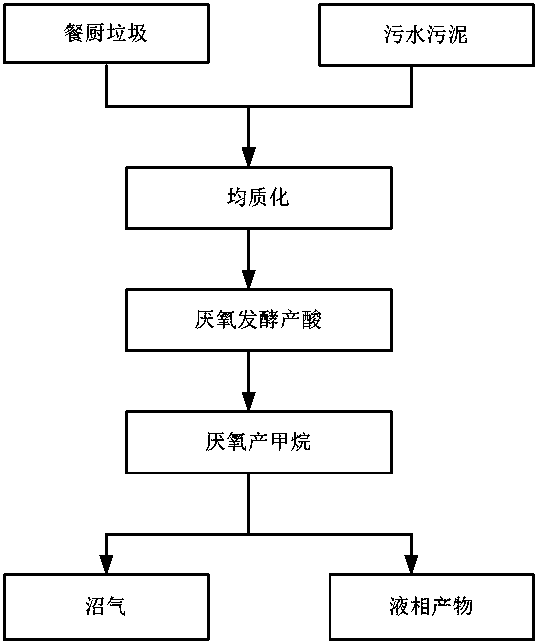

Sewage sludge and kitchen waste treatment device and treatment method

ActiveCN103508643AGuaranteed uptimeStable and homogeneous feedSolid waste disposalWaste based fuelMethane yieldSewage

The invention provides a sewage sludge and kitchen waste treatment device and a treatment method. The device comprises a homogenizing and pulpifying treatment reactor, a sewage sludge pretreatment device and a kitchen waste pretreatment device. The method comprises the following steps that 1, the kitchen waste pretreatment device pretreats kitchen waste and adjusts water content; 2, a dehydrated mud cake pretreated by the sewage sludge pretreatment device and the kitchen waste treated in Step 1 are mixed in proportion, enter the homogenizing and pulpifying treatment reactor for homogenizing and pulpifying treatment, and then become acid production phase feed; 3, the acid production phase feed is added to an acid production phase reactor for hydrolization and acidification, and then becomes acid production phase outlet mud; and 4, the acid production phase outlet mud is added to a methane production phase reactor for anaerobic fermentation, and methane is generated. The sewage sludge and kitchen waste treatment device and the treatment method effectively solve the problems existing in separate treatment of sewage sludge and kitchen waste, and have higher methane yield and organic matter degradation efficiency.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

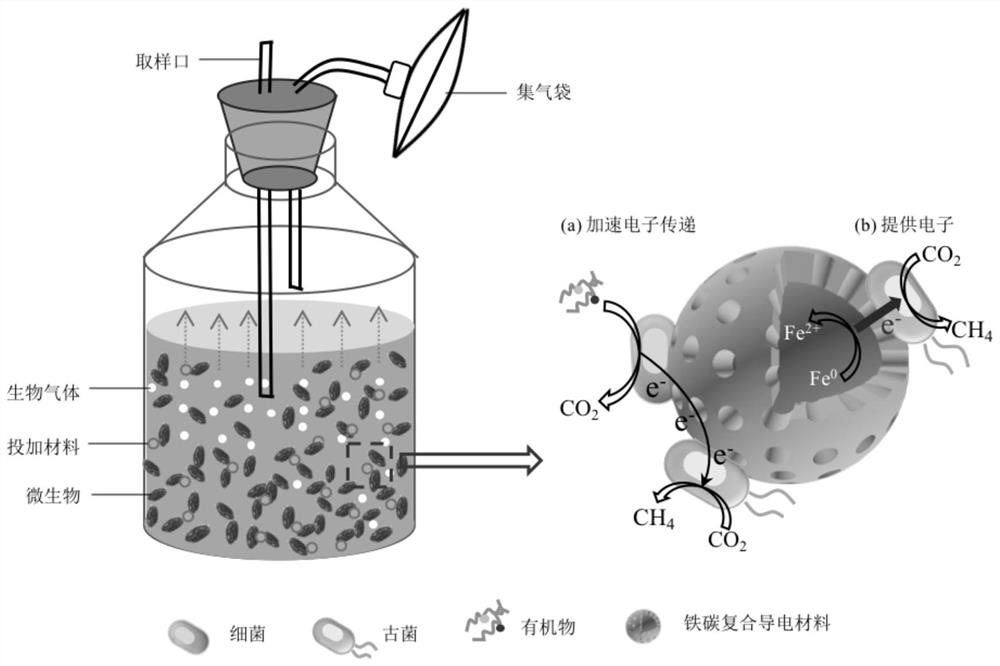

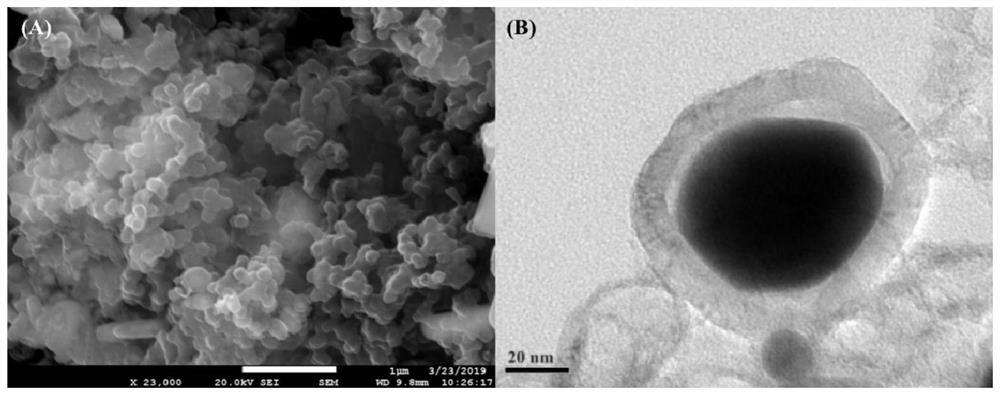

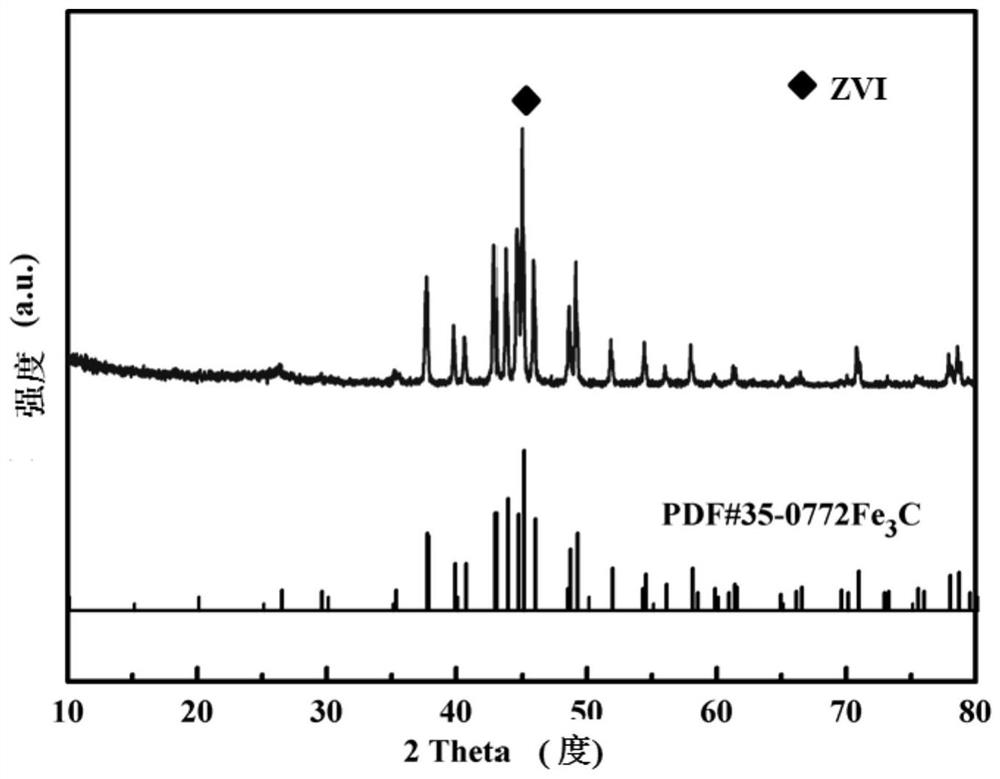

Method for producing methane by enhancing anaerobic digestion of municipal sludge based on electron transfer

ActiveCN112094012AEnhanced Electroactive InteractionLarge specific surface areaWaste based fuelBiological sludge treatmentCarbon compositesCarbon layer

The invention relates to a method for producing methane by enhancing anaerobic digestion of municipal sludge based on electron transfer, which comprises the following steps: adding an iron-carbon composite conductive material with zero-valence iron as a core and a carbon material as a coating layer into an anaerobic digestion system, and enhancing the electron transfer rate of the anaerobic system, thereby promoting the hydrolysis acidification process and methane production process of sludge, and increasing the methane production. Compared with the prior art, the method has the advantages that the electron transfer rate among electro-active microorganisms in the sludge anaerobic system is increased through compounding of iron and carbon; the carbon layer can provide a good attachment point for microorganisms, meanwhile, the carbon layer is used as a protective layer of zero-valence iron to effectively control the dissolution amount of iron and reduce the loss amount of iron, and ironreduction type hydrolysis acidification bacteria can be enriched to promote degradation of organic matters while the zero-valence iron core provides electrons and improves the conductivity of the composite material. The method has the advantages of being low in cost, high in yield and stable in effect, the electron transfer rate in the anaerobic digestion process is increased, and the methane yield is increased.

Owner:TONGJI UNIV

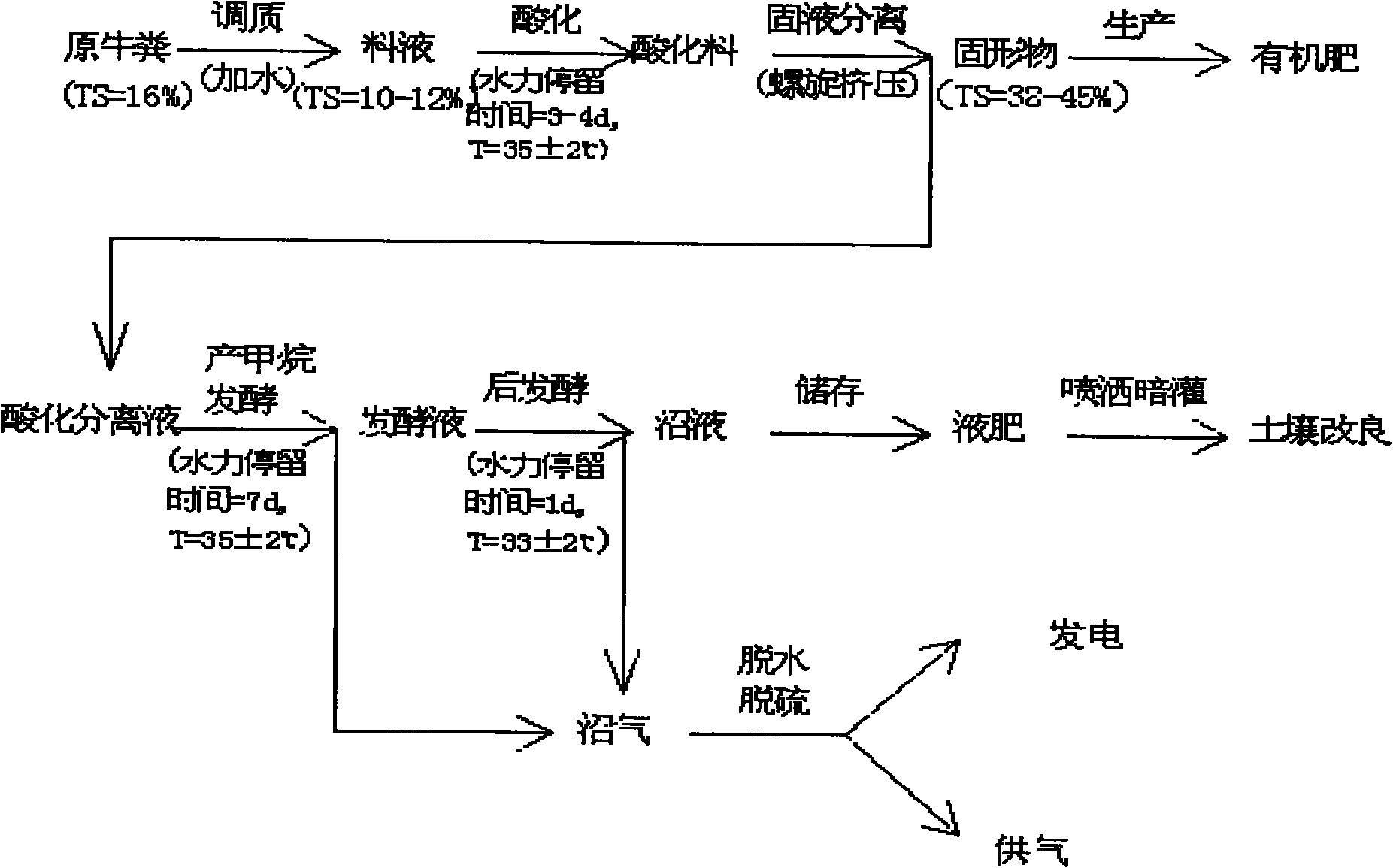

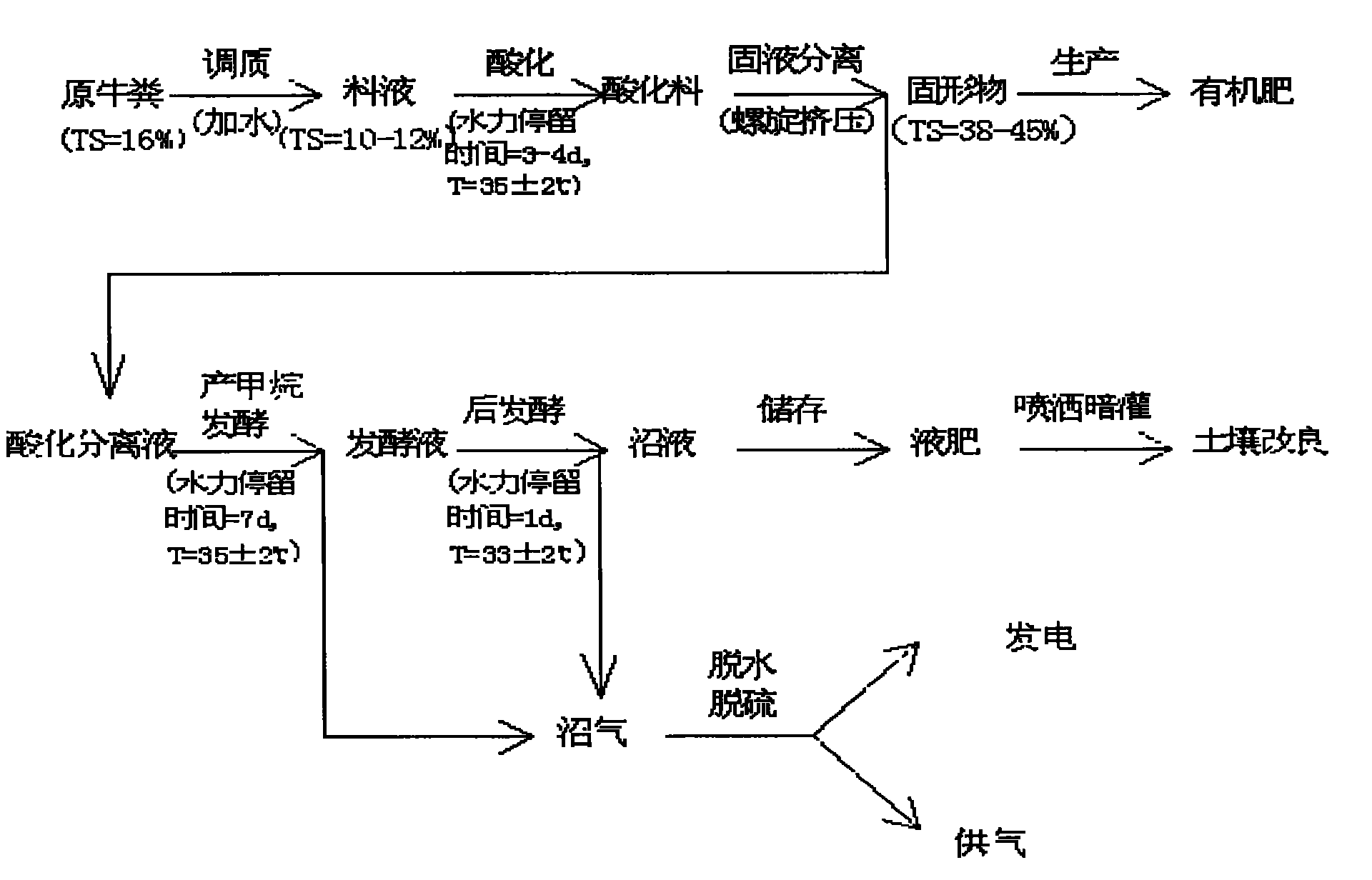

Separation and anaerobic fermentation technology of cow dung subject to acidification

ActiveCN101973684AHigh yieldShort hydraulic retention timeWaste based fuelBiological sludge treatmentFiberTotal solid content

The invention relates to a separation and anaerobic fermentation technology of cow dung subject to acidification. In the technology, fiber in the cow dung subject to intermediate temperature acidification is separated from fermented liquid raw materials by using a spiral squeeze solid-liquid separator, wherein the acidification technology parameters are as follows: the ratio of cow dung to water is 2:1 for tempering, the tempered total solid content TS is 10-12%, and acidification is carried out at the intermediate temperature condition of 33 DEG C-37 DEG C for 3-4 days; the acidized feed liquid is separated by using the solid-liquid separator; the total solid content TS of the separated solid matters is 38%-45%; organic compound fertilizer and bioorganic compound fertilizer are directly produced; the separated liquid TS is 6.6%-7.4%; and methane producing anaerobic fermentation is carried out by using the separated liquid, wherein the fermentation temperature is 33 DEG C and 37 DEG C, the inoculating amount is 30% when a methane producing phase starts, the charging rate is one seventh of the effective volume of a methane producing reactor, waterpower retention period is 7 days, the feed liquid discharged from the methane producing reactor is post-fermented for 1 day so that the components capable of producing methane in the feed liquid are fully fermented, and the total waterpower retention period is 11-12 days. The technology can improve the methane yield in sludge gas.

Owner:黑龙江库恩环境修复开发有限公司

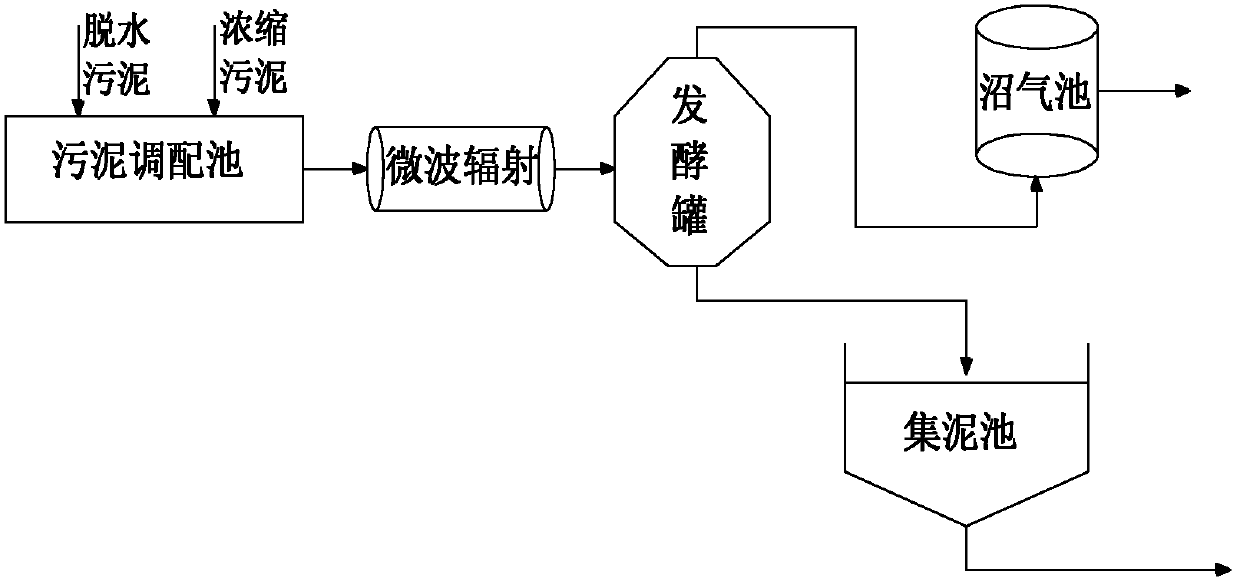

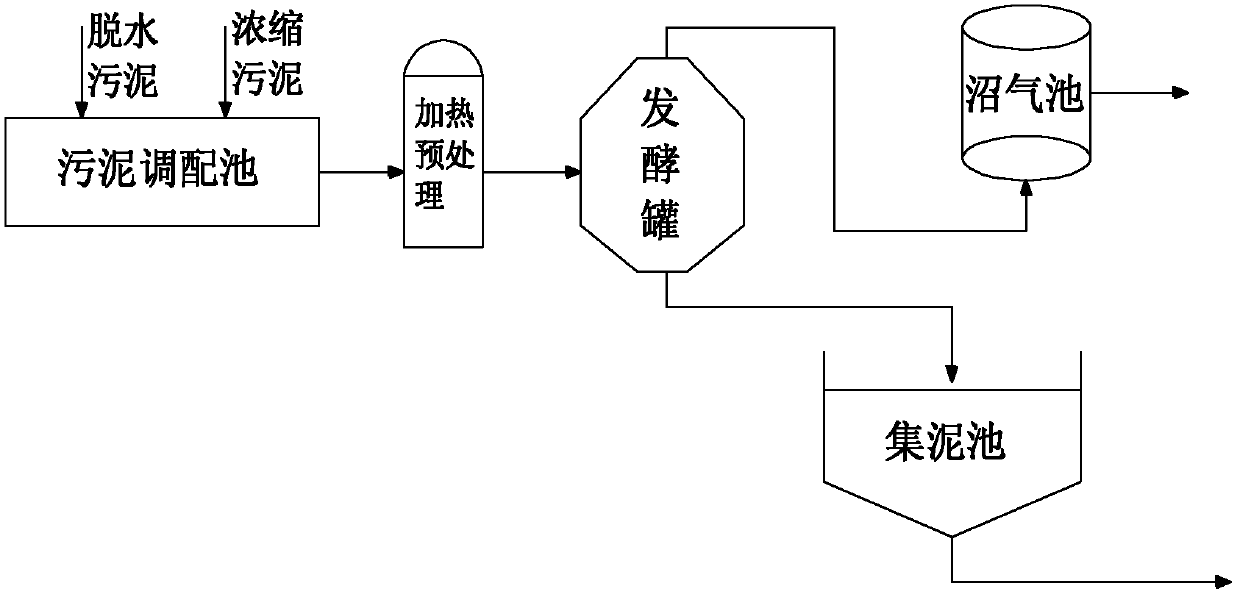

Method for improving methane yield through anaerobic fermentation of low organic matter sludge by pretreatment

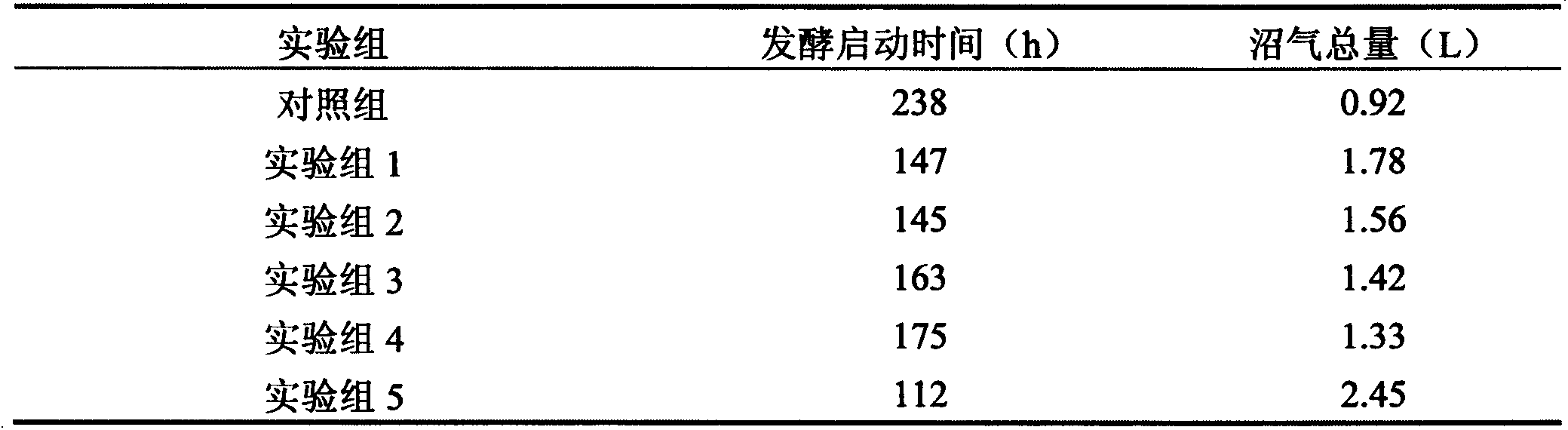

InactiveCN102603141AImprove the efficiency of anaerobic fermentation gas productionPromote resource utilizationWaste based fuelBiological sludge treatmentStart timeMethane yield

The invention belongs to the technical field of solid waste reclamation, and discloses a method for improving methane yield through anaerobic fermentation of low organic matter sludge by pretreatment. The method comprises the following steps of: preparing concentrated sludge and dewatered sludge into mixed sludge for pretreatment; carrying out anaerobic fermentation on the mixed sludge as a feedstock and discharging sludge the volume of which is the same as that of the mixed sludge; and collecting methane. By using the method, the efficiency of producing methane by anaerobic fermentation of the low organic matter sludge is improved, methane production quantity is stable, the energy consumption is low, the application is convenient, and further, and the sludge reclamation is further promoted; the anaerobic starting time of the low organic matter sludge is shortened, the total quantity of methane produced by anaerobic digestion of the low organic matter sludge is increased, and the reclamation utilization of the low organic matter sludge is promoted.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com