Process employing coke-oven gas for production of methane

A technology for coke oven gas and methane, which is applied in the direction of adsorption purification/separation, membrane purification/separation, and hydrocarbon production from carbon oxides, etc. It can solve the problems of incomplete hydrogen reaction, low methane yield, and slow reaction rate. Achieve the effects of shortening the cycle period, increasing the yield of methane, and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The coke oven gas of the present invention is derived from low-temperature dry distillation, medium-temperature dry distillation or high-temperature dry distillation of coal, and is preliminarily purified coke oven gas, mainly containing methane, hydrogen, carbon monoxide, carbon dioxide and other gases.

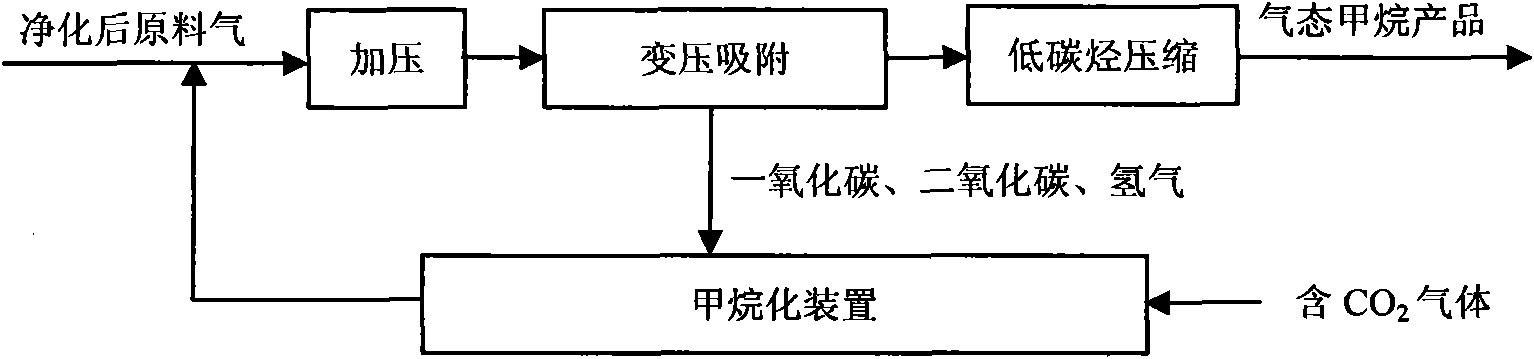

[0028] Such as figure 1 Among them, the coke oven gas produced by low-temperature carbonization of coal is subjected to purification processes of dust removal, naphthalene, ammonia, benzene group hydrocarbons, desulfurization, and detarring, and then pressurized to 4.4MPa at a temperature of 40°C and enters the pressure swing adsorption device. Pressure swing adsorption is carried out at a pressure of 2.0-4.4MPa and a temperature of 25-40°C to obtain low-carbon hydrocarbons, carbon monoxide, carbon dioxide and hydrogen. The low-carbon hydrocarbons are compressed to obtain gaseous methane products. Carbon monoxide, carbon dioxide and hydrogen enter the methanation unit...

Embodiment 2

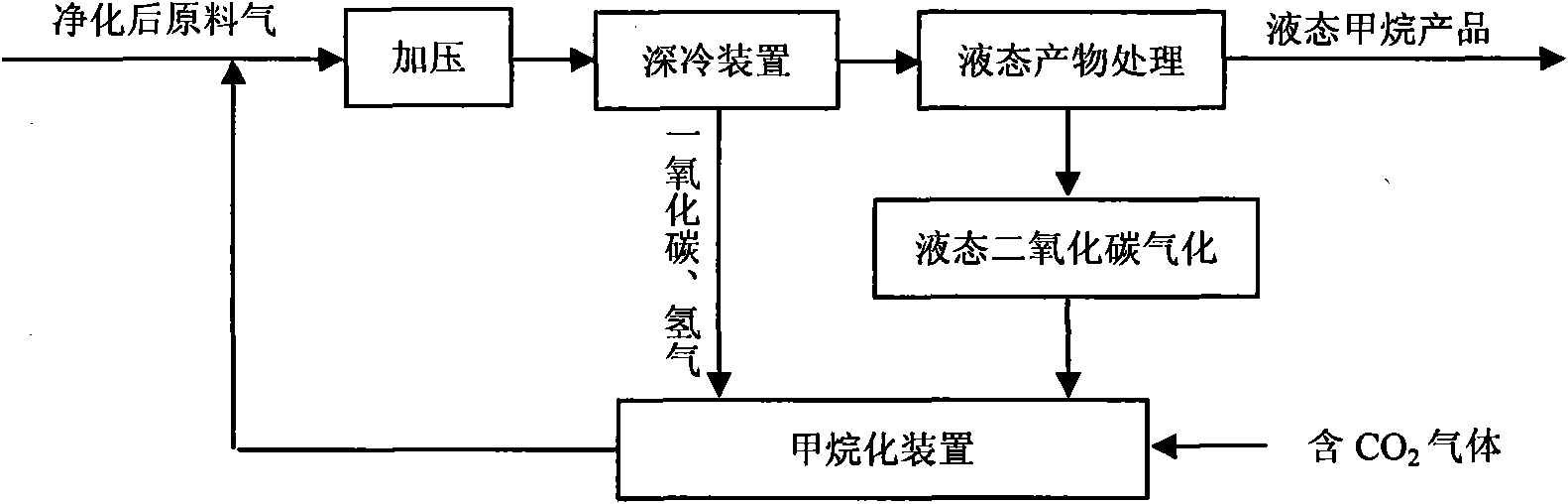

[0030]The coke oven gas produced by medium-temperature dry distillation of coal is subjected to purification processes of dust removal, naphthalene, ammonia, benzene group, desulfurization, and detarring, and then pressurized to 5.0 MPa at 0-15°C and enters the condensing device. Condensation is carried out at a pressure of 3.5-5.0 MPa and a temperature of -170-15°C to obtain a liquid mixture of methane and carbon dioxide and a gaseous mixture of carbon monoxide and hydrogen. After the liquid mixture is processed, the liquid methane product is obtained. After the liquid carbon dioxide is gasified and the gaseous mixture enters the methanation reaction device for reaction, the gas containing 55-60% carbon dioxide is replenished to the methanation device. 28-30%. After the reaction is completed, the methane mixed gas returns to the pressurizing device, pressurizes together with the purified coke oven gas to 5.0MPa at 0-15°C, and then condenses at a pressure of 3.5-5.0MPa and a t...

Embodiment 3

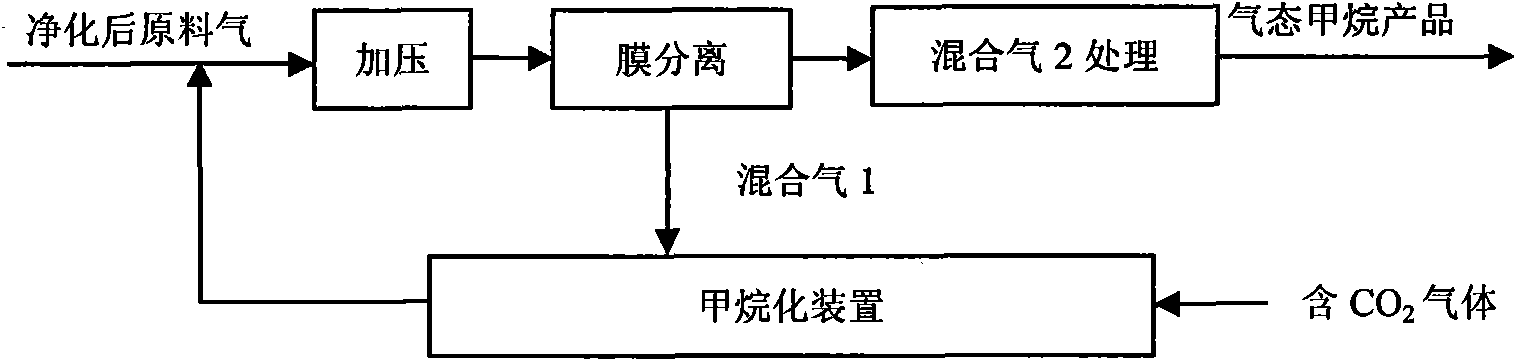

[0032] The coke oven gas produced by medium-temperature dry distillation of coal is desulfurized, detarred, and impurity-removed and purified, then pressurized to 5.0MPa at 20°C and enters the membrane separation device. Membrane separation is carried out at a pressure of 4.0-5.0 MPa and a temperature of 15-25°C to separate mixed gas 1 and mixed gas 2. Mixed gas 1 is mainly composed of hydrogen, carbon monoxide, and carbon dioxide, and contains a small amount of methane. Mixed gas 2 is Mainly methane, also contains a small amount of hydrogen, carbon monoxide, carbon dioxide. The gaseous methane product is obtained after the mixed gas 2 is processed, and the mixed gas 1 enters the methanation device for reaction, and the gas containing 80-85% carbon dioxide is supplemented to the methanation device, and the replenishment amount is 40-45% of the total gas entering the methanation device. After the reaction is completed, the methane mixed gas returns to the pressurizing device, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com