Patents

Literature

177results about How to "Shorten the cycle time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

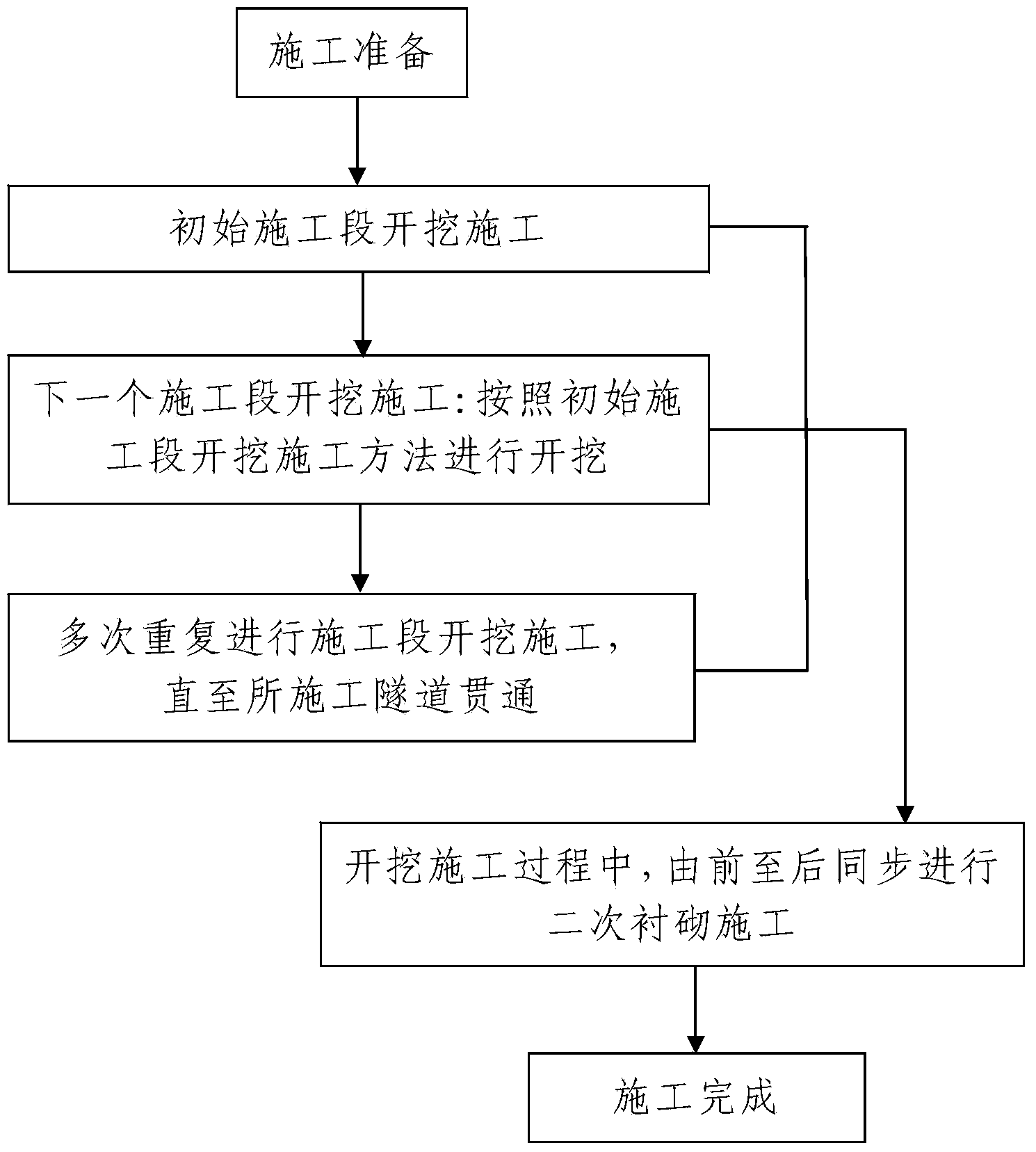

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

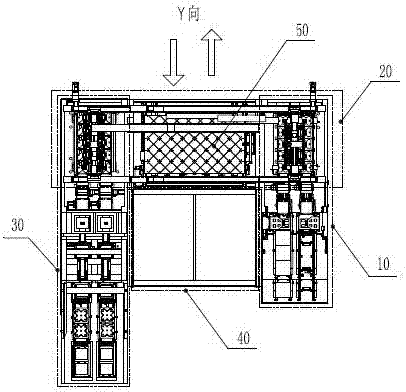

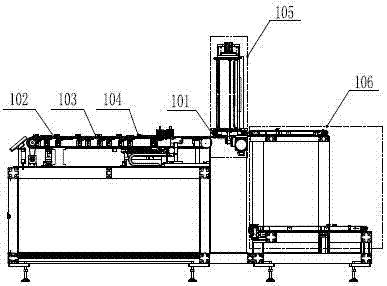

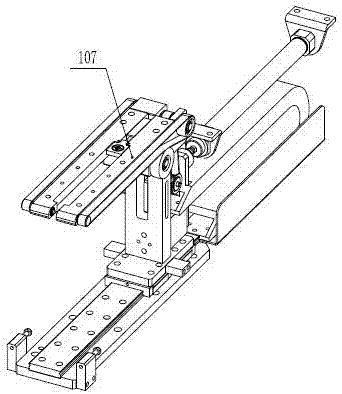

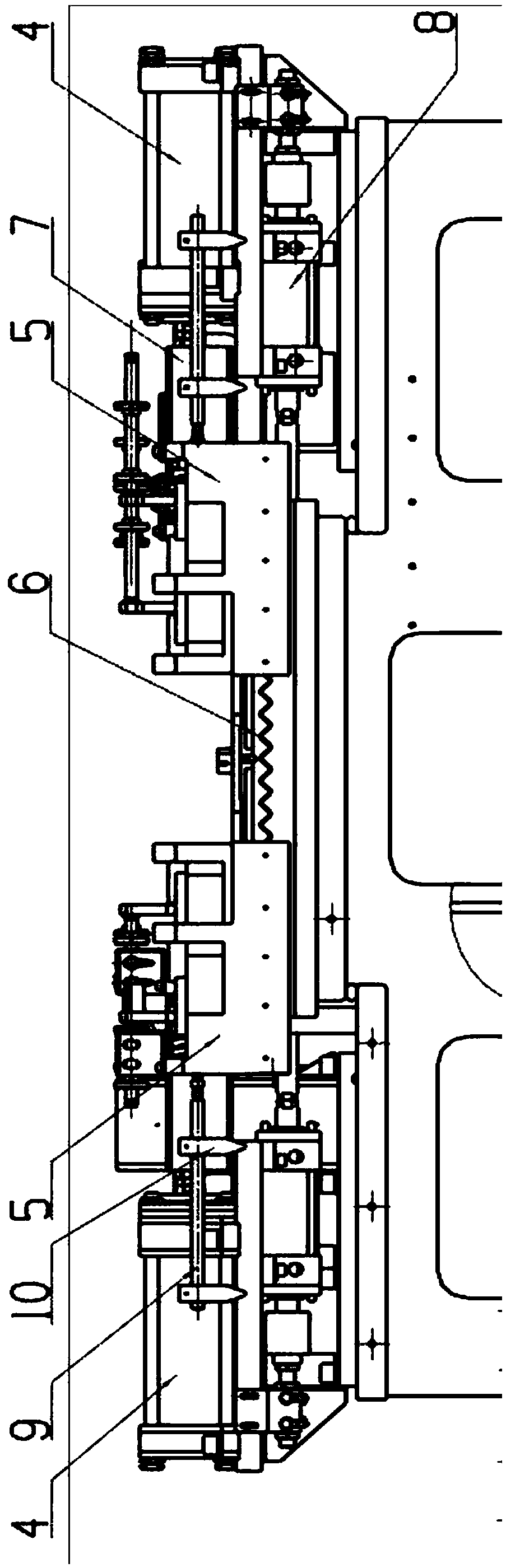

Solar silicon wafer two-in-one automatic loading and unloading equipment

PendingCN107093651AImprove work efficiencyShorten the feeding and discharging cycleSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringMechanical engineering

The invention discloses solar silicon wafer two-in-one automatic loading and unloading equipment, which is characterized in that a loading module and an unloading module are respectively located at two sides of a lifting platform, a transferring module is arranged above a discharging port of the loading module and a feeding port of the unloading module, the lifting platform is butted with a feeding and discharging end of main equipment along a Y moving direction of a carrier plate, the discharging port of the loading module and the feeding port of the unloading module respectively correspond to two sides in the X-direction of the feeding and discharging end of the main equipment; the lifting platform comprises an upper discharging station and a lower feeding station, the upper discharging station is butted with the discharging port above the feeding and discharging end of the main equipment in the Y-direction, and the lower feeding station is butted with the feeding port below the feeding and discharging end of the main equipment in the Y-direction; the unloading module comprises CCD detection module, an eliminating device and a lamination structure; and the lamination structure enables dropped silicon wafers to be neatly stacked by using a principle of automatic positioning of an oblique plane, thereby enabling the silicon wafer to be directly stacked into a block shape so as to be convenient for being directly packaged and transported, and greatly improving the product packaging efficiency.

Owner:江西比太科技有限公司 +1

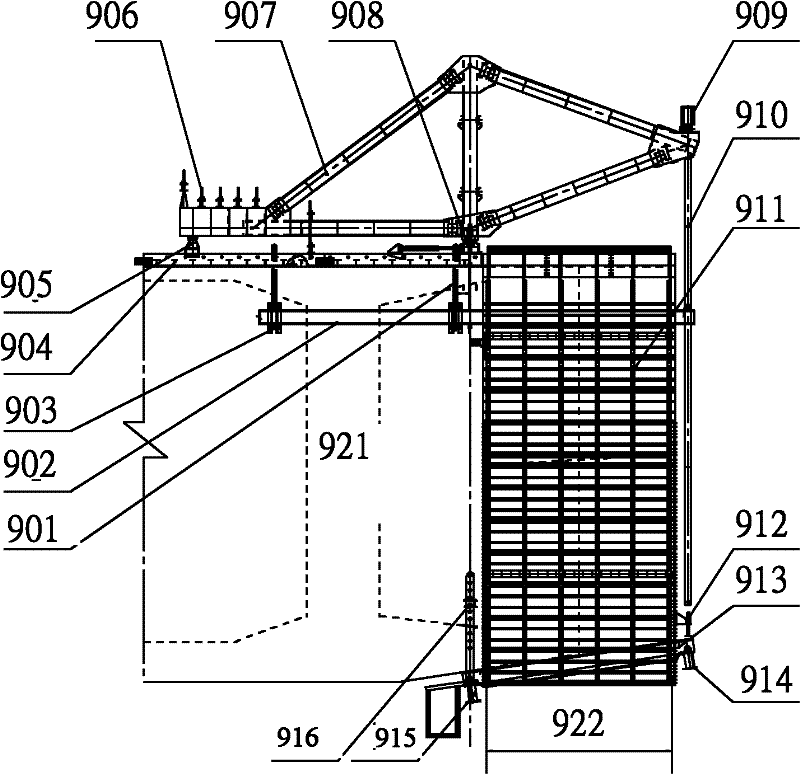

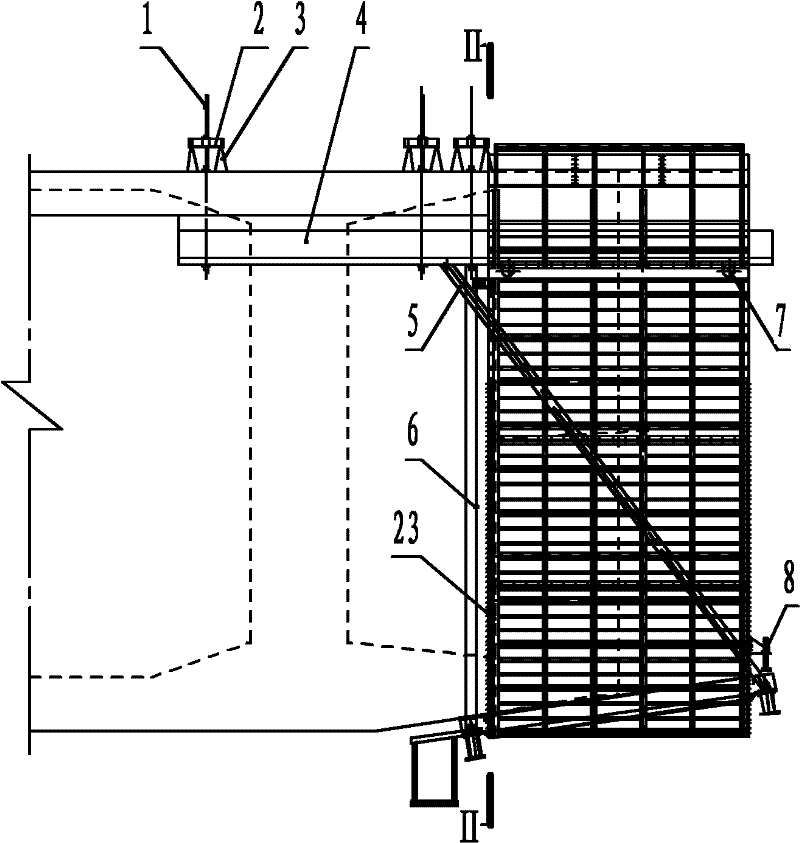

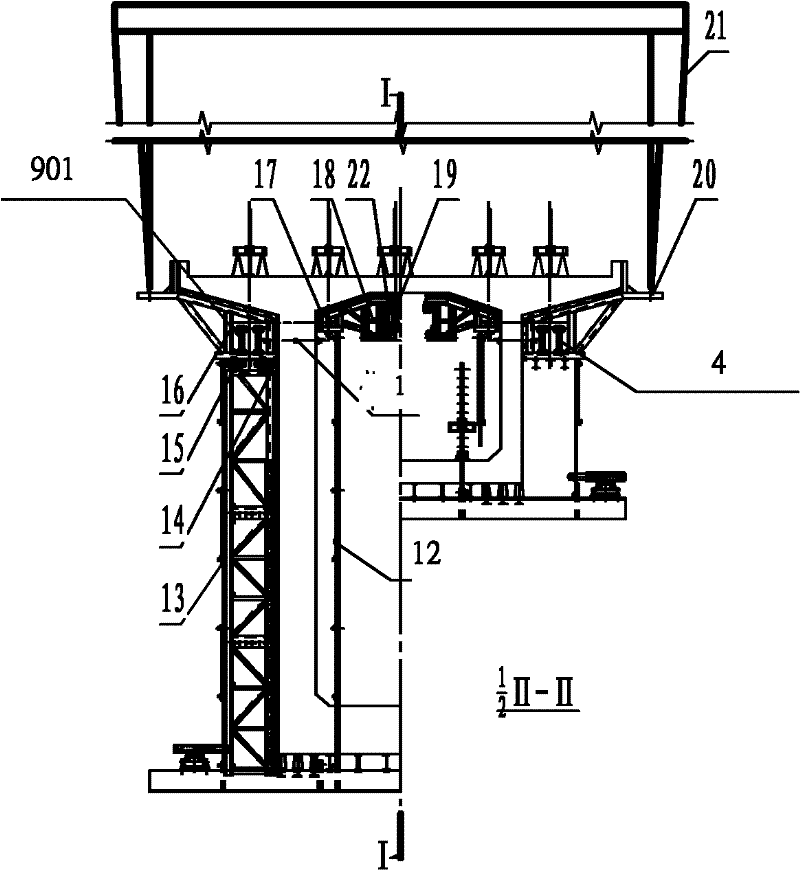

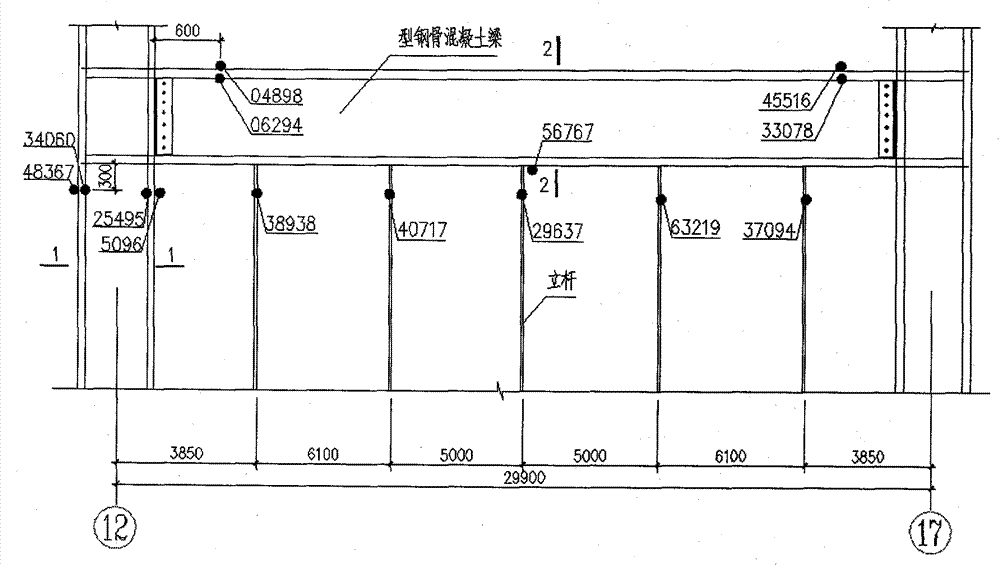

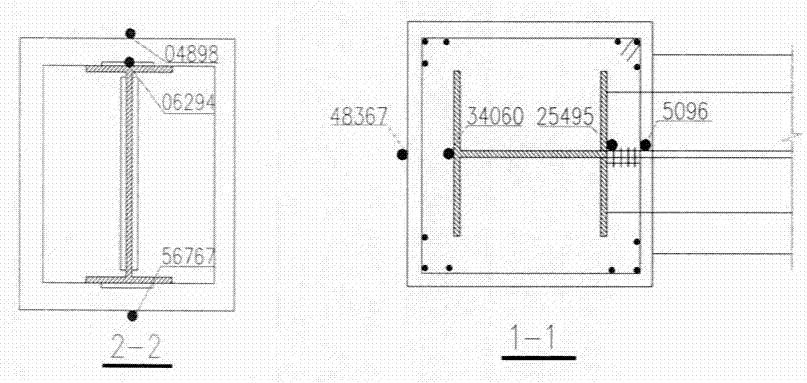

Cradle for pouring bridge cantilever and construction method of cradle

The invention relates to a cradle for pouring a bridge cantilever and a construction method of the cradle. The cradle comprises a bottom mould system, a side mould system, an inner mould system, an anchoring system, a traveling system and a hoisting system, wherein the bottom mould system, the side mould system and the inner mould system form an open-type cradle structure without a bridge floor support; and the hoisting system is used for hoisting reinforcement cages which are bound in advance. The construction method of the cradle comprises the following steps of: pouring concrete, maintaining, demolding and stretching prestressed reinforced bars; fixing when the side mould system and the bottom mould system run to a next bridge section position; hoisting the reinforcement cages which are bound in advance, connecting corrugated pipes and common reinforced bars, and installing a sawtooth mould board; fixing when the inner mould system runs to a next bridge section position; and adjusting and fixing the side mould system, the bottom mould system and the inner mould system again. According to the cradle and the construction method thereof, the advance binding and the integral hoisting of the reinforced bars can be realized; and therefore, the occupying time of the reinforced bars and the cycle period of pouring the cantilever are greatly shortened and greater effect on accelerating the speed of the bridge construction is achieved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

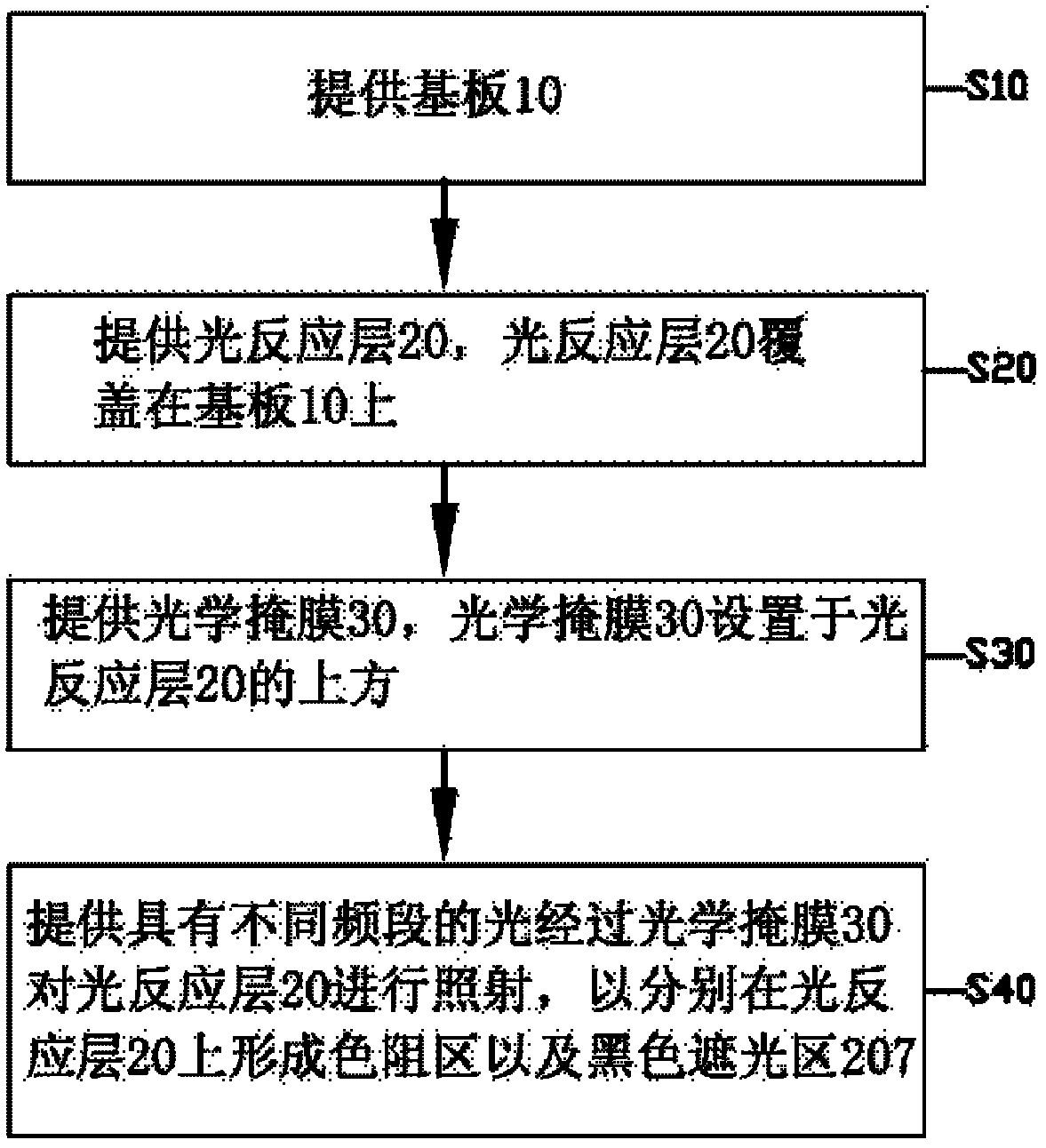

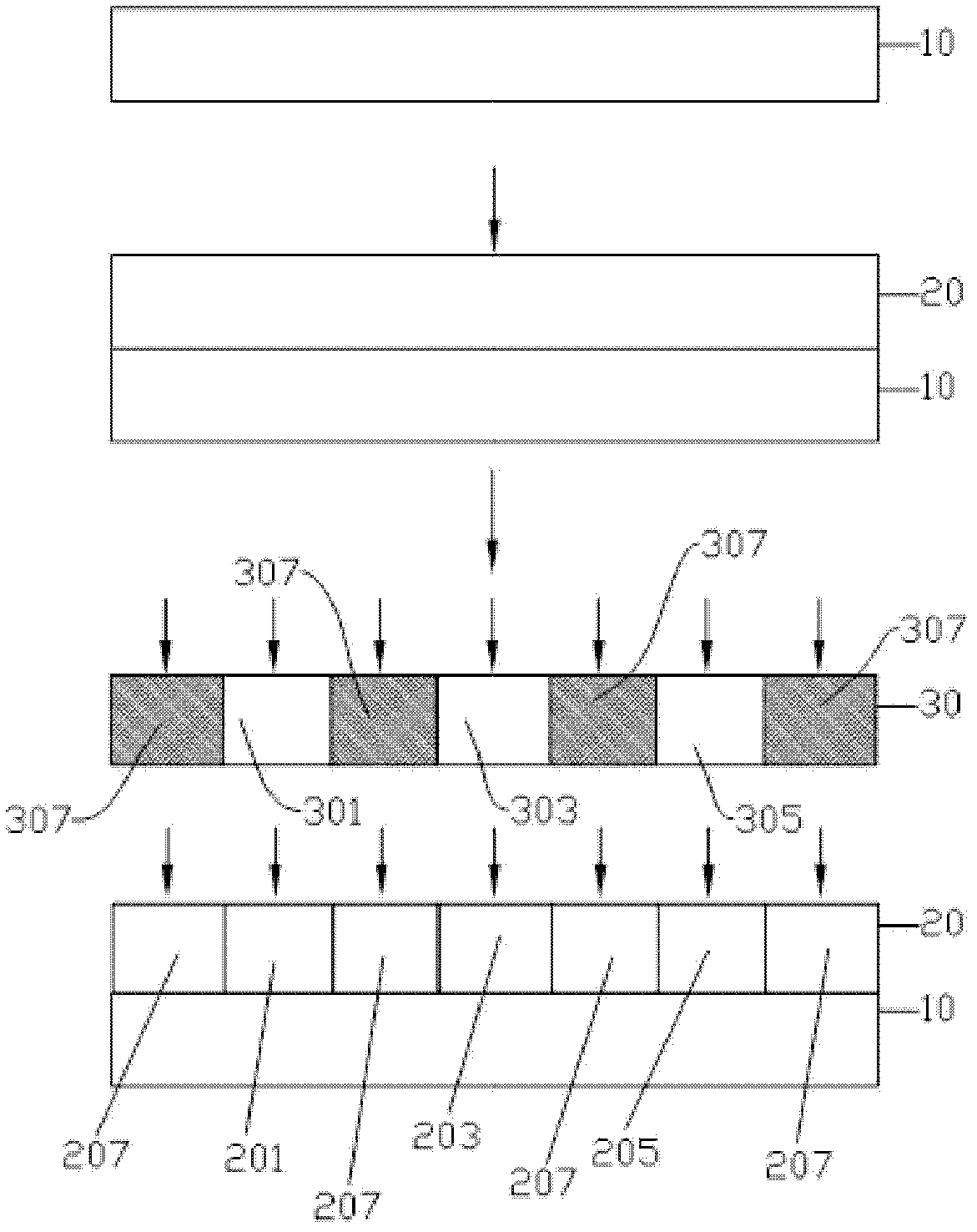

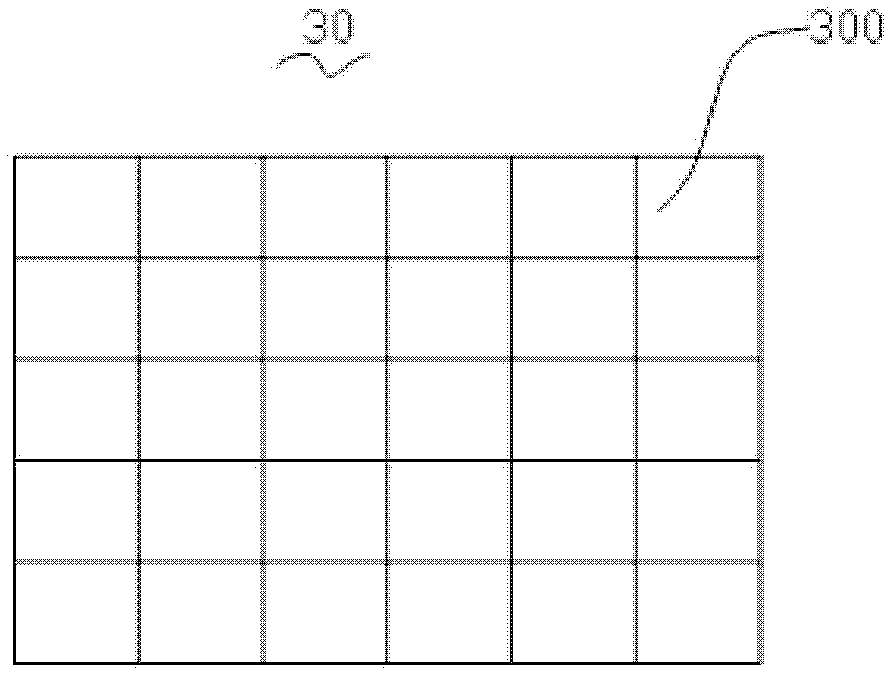

Method, optical mask and photoreaction layer for making substrate of color filter

InactiveCN102213785AShorten the cycle timeStrong penetrating powerOptical filtersOriginals for photomechanical treatmentDisplay contrastColor gel

The invention discloses a method, an optical mask and a photoreaction layer for making a substrate of a color filter. The method comprises the following steps of: providing the substrate; providing the photoreaction layer, wherein the photoreaction layer is coated on the substrate; providing the optical mask, wherein the optical mask is arranged above the photoreaction layer; and providing light of different frequency ranges to irradiate the photoreaction layer through the optical mask so as to respectively form a color resistance area and a black shading area on the photoreaction layer. The invention also provides the optical mask and the photoreaction layer for making a color resistance layer of the substrate of the color filter. By adopting the mode, the method has the advantages of shortening the cycle period of processing and improving the aperture opening ratio and the display contrast ratio.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

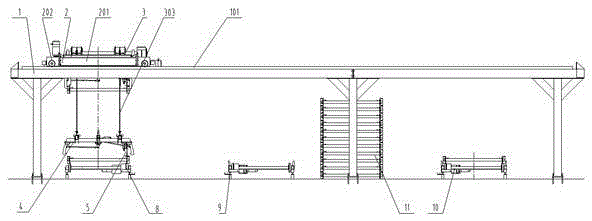

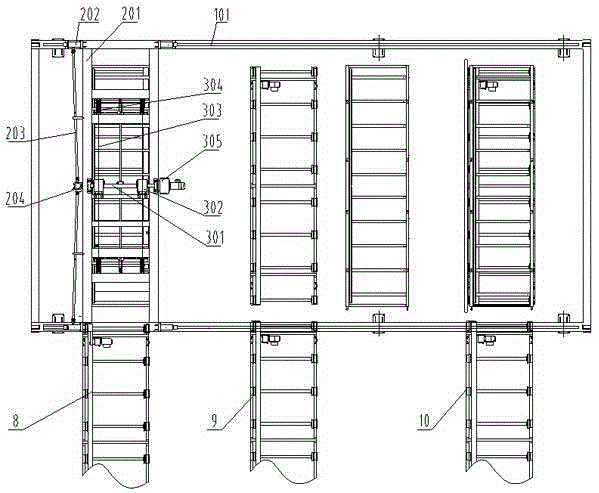

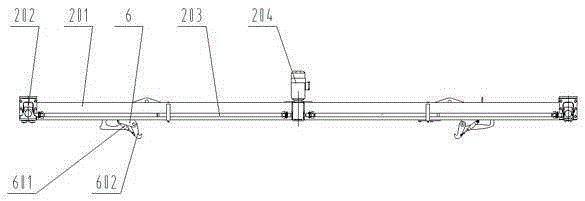

Stacking and unstacking machine for transferring pallets for autoclaved aerated concrete products

ActiveCN105347051AQuick stackGuaranteed to workConveyorsStacking articlesAutoclaved aerated concretePallet

Disclosed is a stacking and unstacking machine for transferring pallets for autoclaved aerated concrete products. The stacking and unstacking machine comprises a rack, a horizontal traveling mechanism, a vertical lifting mechanism and a gripping mechanism, wherein the horizontal traveling mechanism is disposed on the rack; the vertical lifting mechanism is disposed on the horizontal traveling mechanism; the gripping mechanism is disposed at the lower end of the vertical lifting mechanism; the horizontal traveling mechanism can drive the vertical lifting mechanism to move horizontally; the vertical lifting mechanism can drive the gripping mechanism to ascend or descend; the gripping mechanism is used for gripping and releasing the transferring pallets; the vertical lifting mechanism comprises a winding drum and four steel wire ropes which are wound on the winding drum; one end of each steel wire rope is connected with the winding drum, and the other ends of the steel wire ropes are correspondingly connected with the four corners of a gripping rack in the gripping mechanism respectively; the winding drum is driven through a lifting driving device; four gripping hooks are disposed on the lower end face of the gripping rack; the four gripping hooks can simultaneously clamp or release the transferring pallets. The production efficiency is high, the maintaining cost is low, and the demand for automatic safe production can be met.

Owner:洛阳腾和达智能装备有限公司

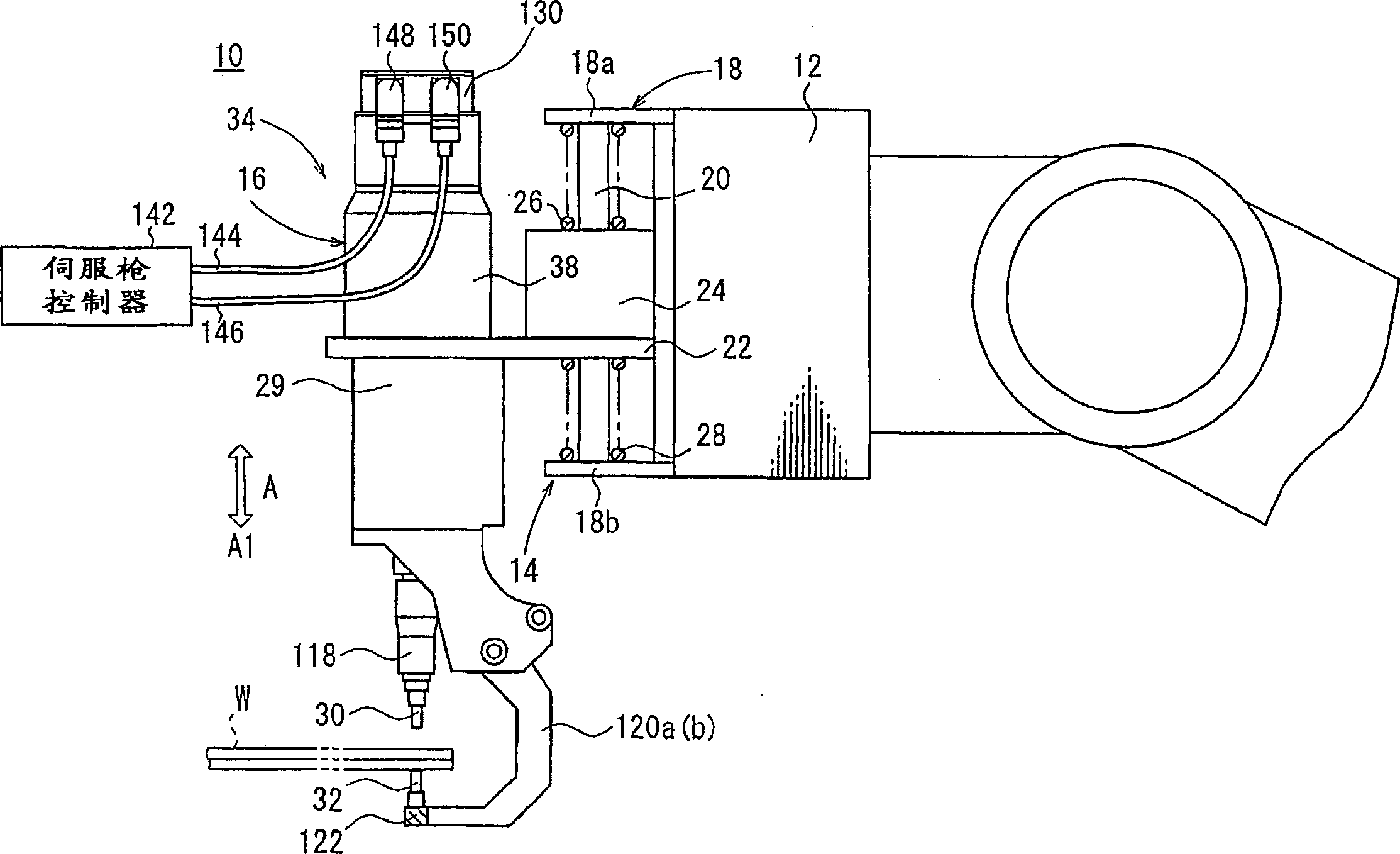

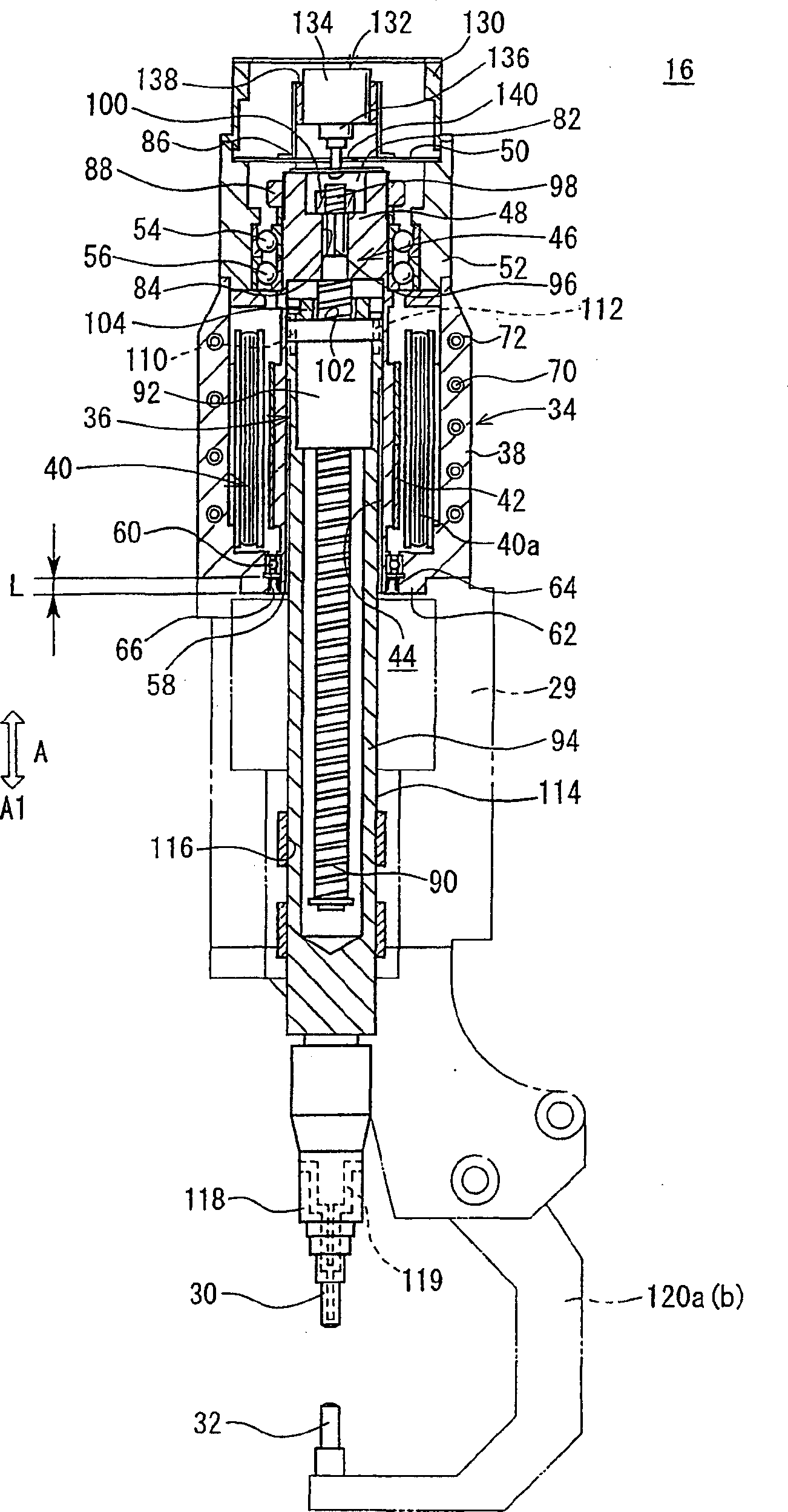

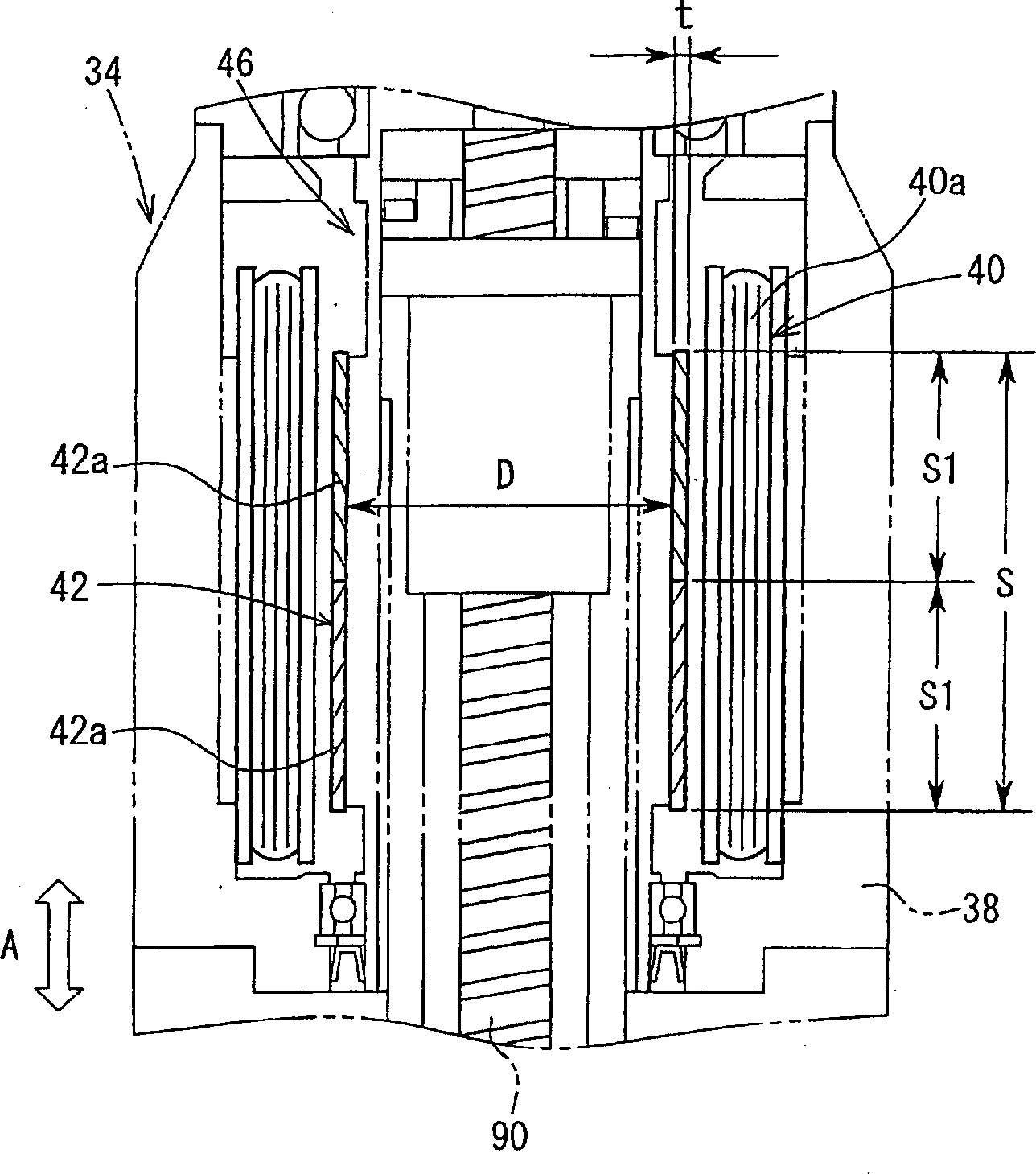

Motor driven resistance spot welding gun

InactiveCN1509218AHigh torqueLow costResistance electrode holdersGearingElectrical resistance and conductanceMotor drive

Owner:HONDA MOTOR CO LTD

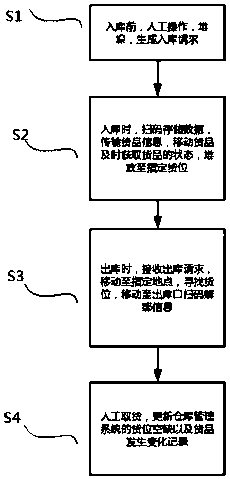

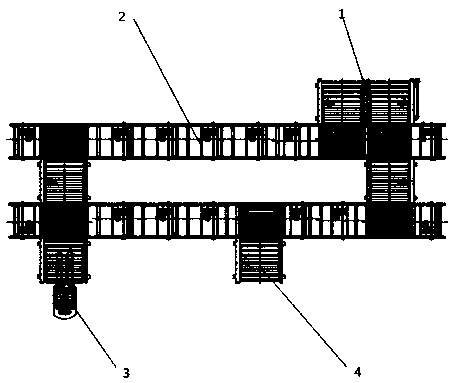

Logistics system and a working method of a dangerous goods transit warehouse

PendingCN109508926ARun fastDrive stabilityCo-operative working arrangementsLogisticsMobile vehicleLogistics management

The invention discloses a logistics system and a working method of a dangerous goods transit warehouse, The logistics system of the dangerous goods transit warehouse comprises a warehouse management platform, a storage rack and an AGV mobile vehicle, wherein the AGV mobile vehicle is connected with a server through a wireless communication mode, and the communication server is connected with the warehouse management platform, and the warehouse management platform is arranged on a PC terminal for display; The warehouse management platform is used for monitoring and querying the running status of the warehouse and tracking the goods request status in and out of the warehouse. The invention realizes the synchronous completion of incoming and outgoing warehouse through the transmission speed of the transmission table on the transmission mechanism, cooperates with the round-trip time of the AGV mobile vehicle, and sets the buffer location mode to solve the problem of low turnover efficiencyof the dangerous goods warehouse.

Owner:中外运化工国际物流有限公司

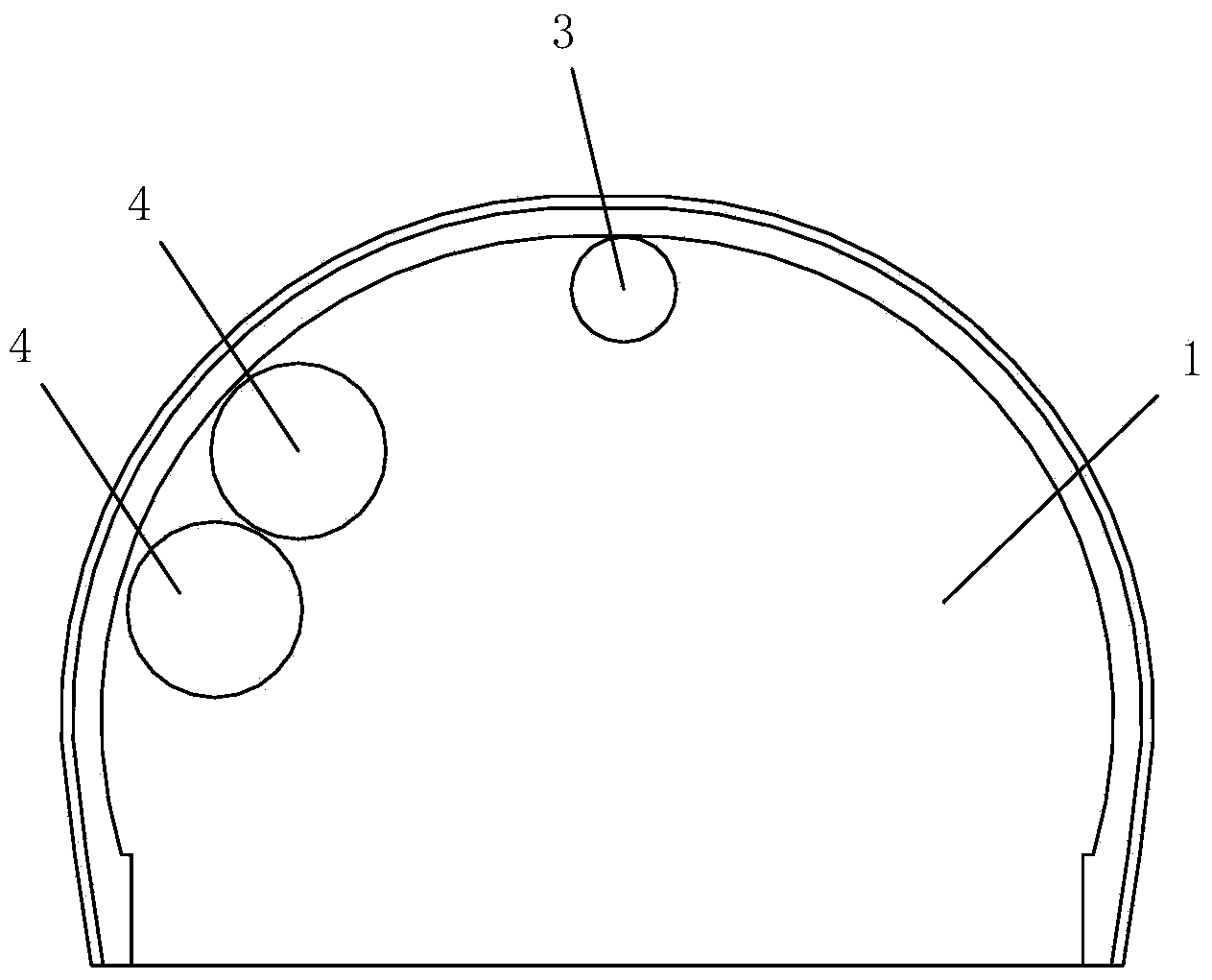

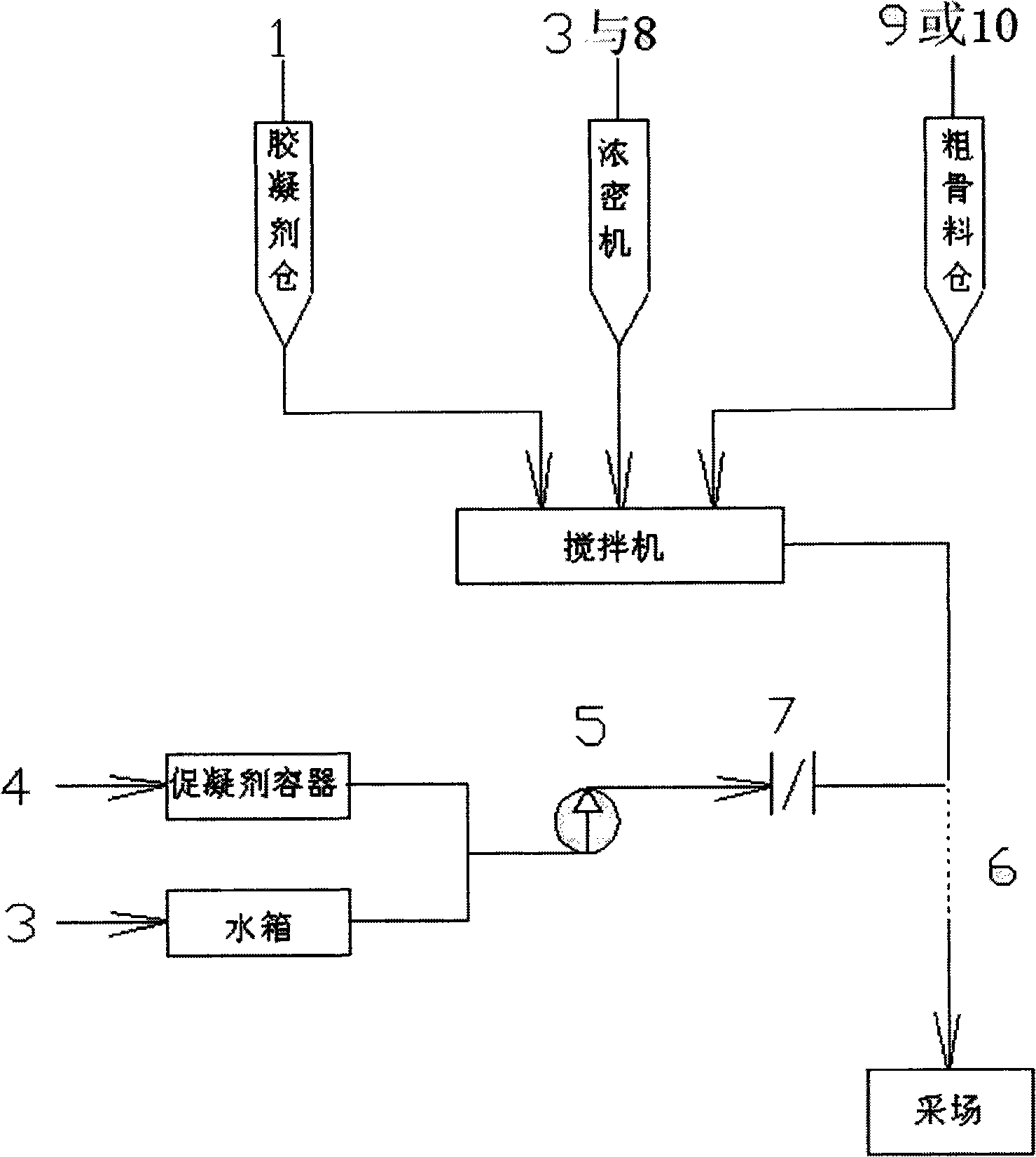

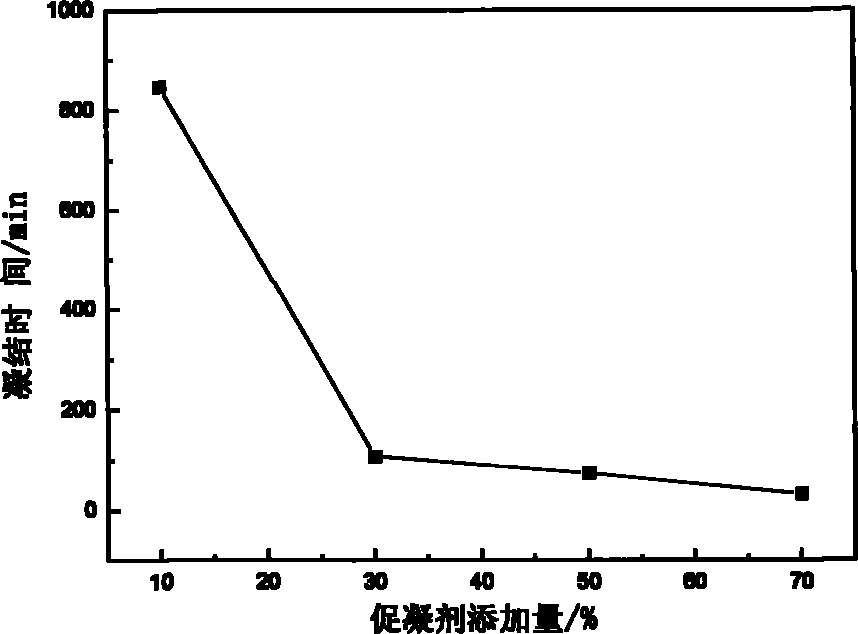

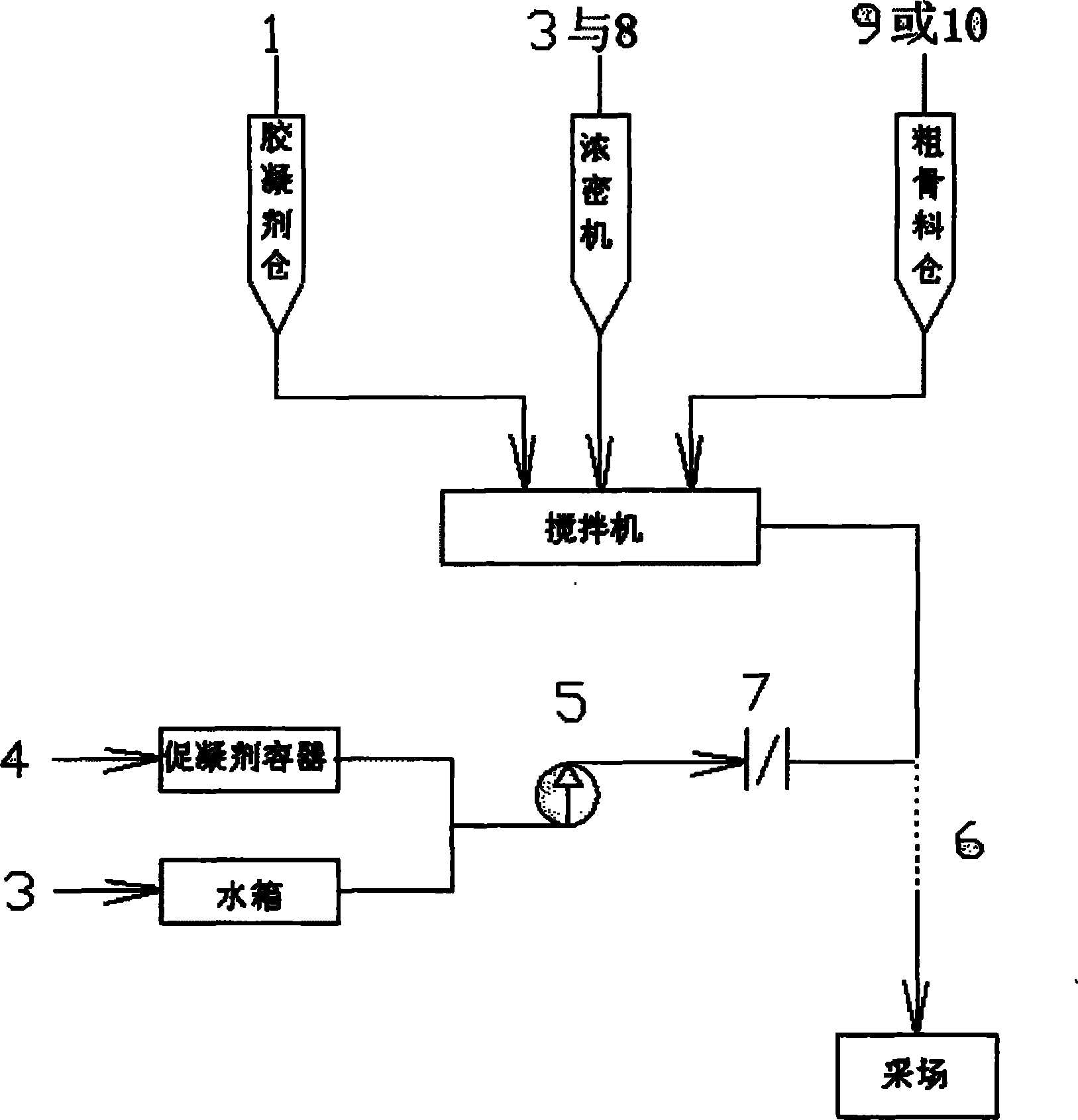

Full-tail paste composite material and preparation method thereof

The invention discloses a full-tail paste composite material and a preparation method thereof, which belong to the field of inorganic nonmetallic material. The composite material consists of the following raw materials in percentage by weight: 2.8 to 22.0 percent of gelling agent 1, 57.8 to 75.0 percent of filling aggregate 2, 14.8 to 24.8 percent of water 3 and the balance of coagulant 4 which is 10 to 30 percent of the weight of the gelling agent, wherein the filling aggregate 2 consists of full-tail sand 8, water granulated slags 9 or gravels 10; the gelling agent is continuously and uniformly added into a pasty sizing agent by a metering device 5; one end of the metering device 5 is connected with a coagulant container and a water tank, and the other end of the metering device 5 is connected with a section of small-diameter pipeline 6 on a filling main pipe; a one-way check valve 7 is arranged behind the metering device 5 to ensure the flow direction of the coagulant 4; and a small amount of gelling agent is added into the filling sizing agent, so that the setting time can be kept between 30 minutes and 1,200 minutes. By adopting the method, the setting time of the paste material can be adjusted, the cycle period of a slope is shortened, field operation is convenient, and a reliable effect is achieved. The method is suitable for all kinds of full-tail paste filling materials of metal mines.

Owner:UNIV OF SCI & TECH BEIJING

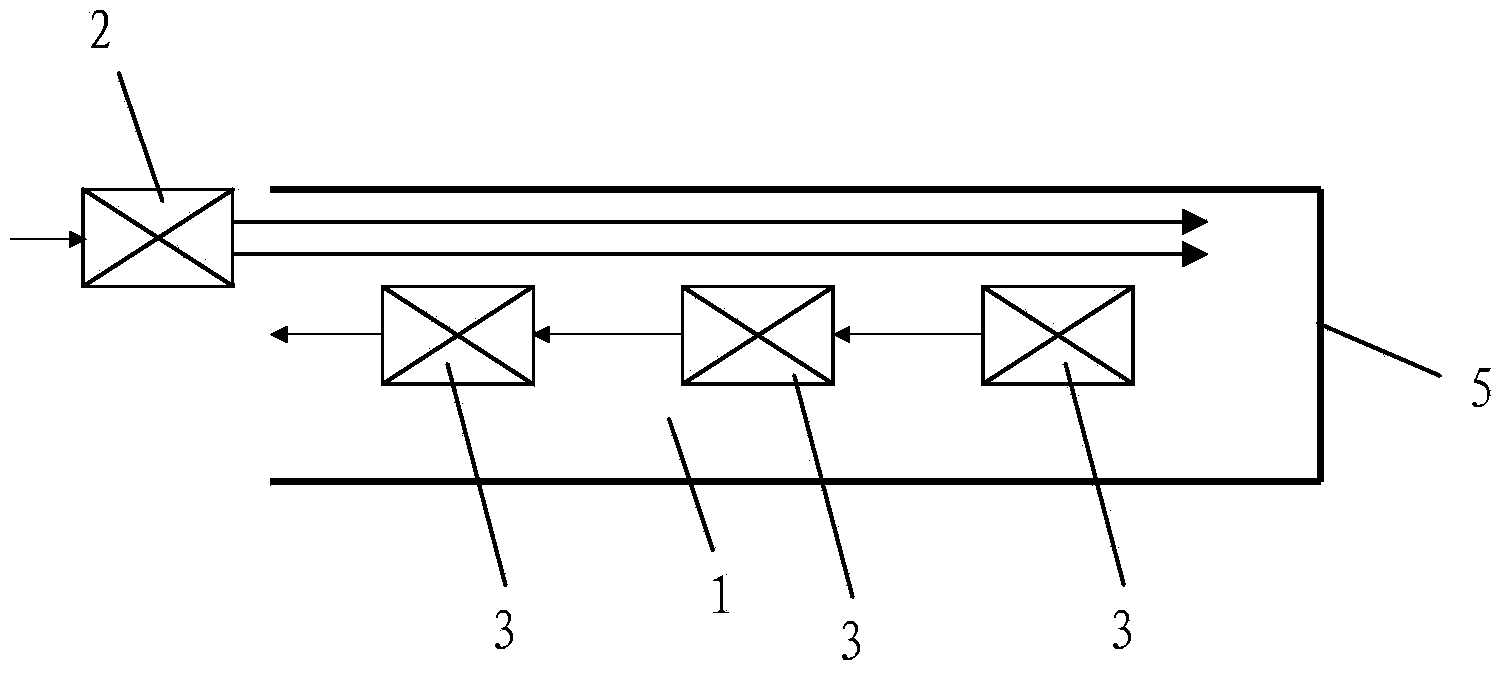

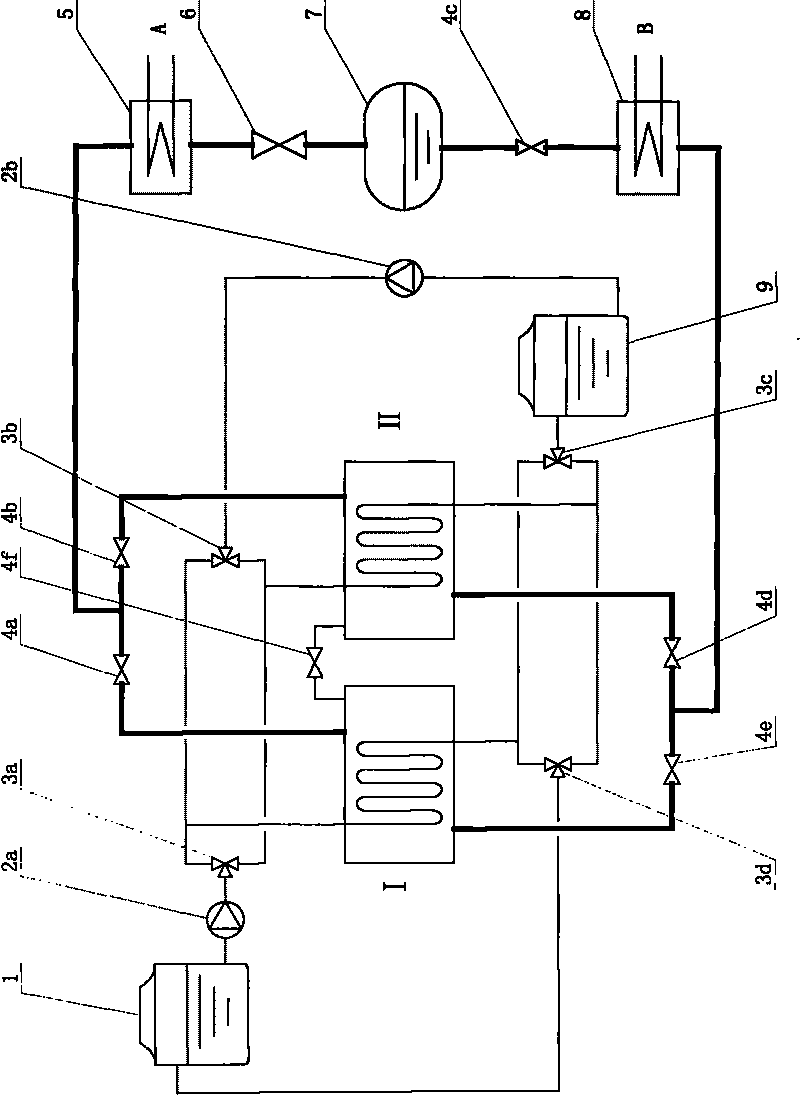

Micro-pressure operating adsorption refrigerating system

InactiveCN101737995AImprove cooling efficiencyReduce loadEnergy efficient heating/coolingClimate change adaptationAdsorption refrigerationHigh energy

The invention discloses a micro-pressure operating adsorption refrigerating system. An alkyl or amino working medium is taken as a refrigerant for the adsorption refrigerating system, so the adsorption refrigerating system works in the micro-pressure environment in the pressure range between 0.10 and 1.00MPa (absolute pressure), the load and manufacturing cost of equipment are reduced, and the stability of the adsorption refrigerating system for long-term work is improved; a fin tube type, plate-fin or heat pipe heat exchanger is adopted as an adsorption heat exchanger to improve the heat exchange efficiency and shorten the cycle period of the system; and the system adopts heat return and mass return circulation, and has high energy utilization rate and high refrigerating efficiency. The adsorption refrigerating system is in micro-pressure operation, has low requirement on the equipment of the refrigerating system, can be driven by low-temperature heat and can stably and reliably operate.

Owner:NANJING UNIV OF TECH

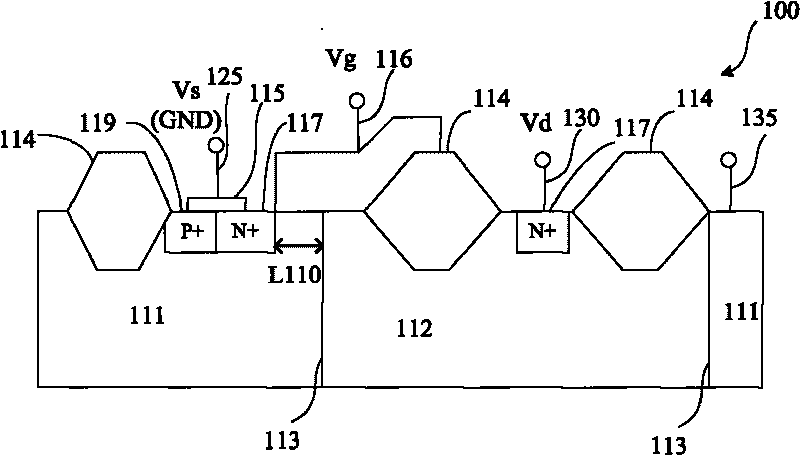

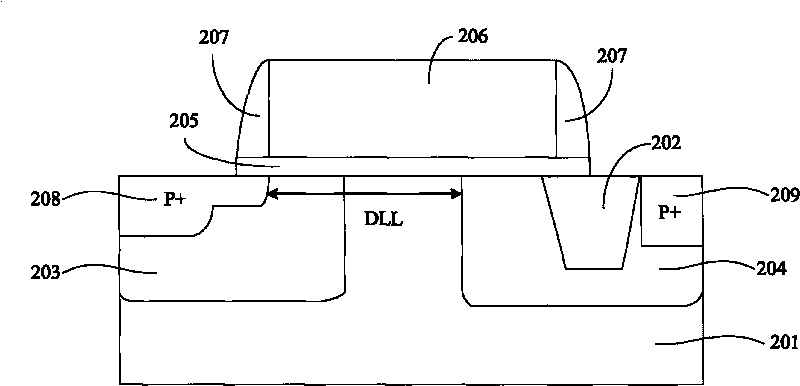

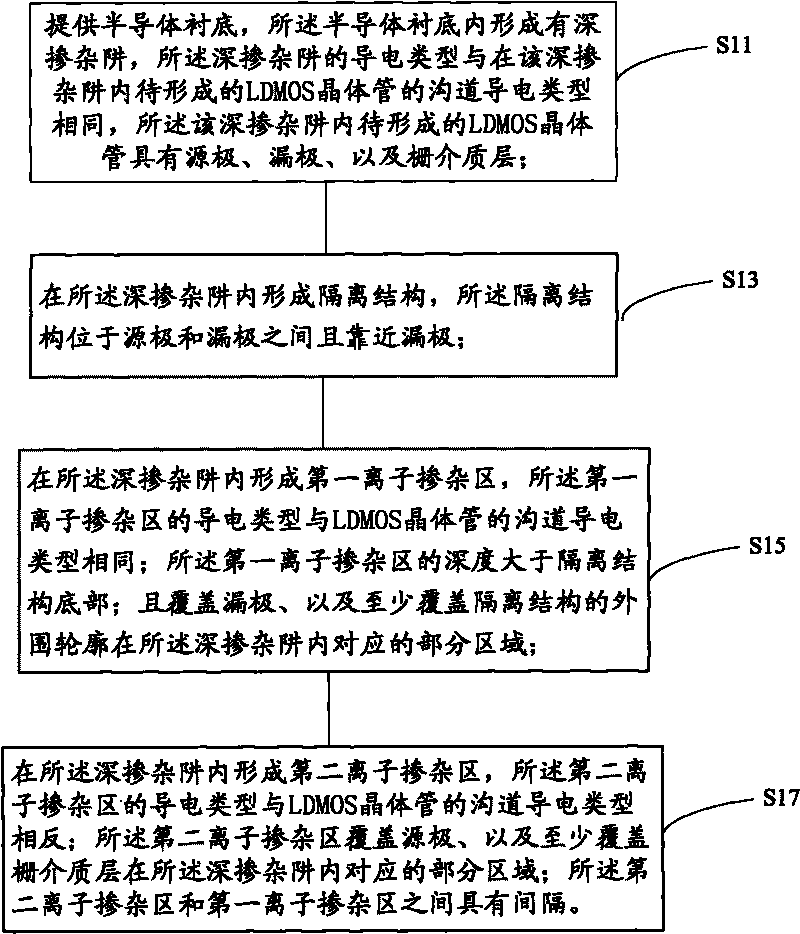

LDMOS (Laterally Diffused Metal Oxide Semiconductor) transistor, semiconductor device and manufacture method thereof

ActiveCN101740392AImprove pressure resistanceIncrease the doping concentrationSemiconductor/solid-state device manufacturingLDMOSEngineering

The invention relates to an LDMOS (Laterally Diffused Metal Oxide Semiconductor) transistor, a semiconductor device and a manufacture method thereof, wherein the manufacture method of the LDMOS transistor comprises the steps of: forming a deep-doped well in a semiconductor substrate; forming an isolation structure in the deep-doped well, wherein the isolation structure is arranged between a source electrode and a drain electrode and is close to the drain electrode; forming a first ion doping area in the deep-doped well; and forming a second ion doping area in the deep-doped well, wherein a space is reserved between the first ion doping area and the second ion doping area. By forming the deep-doped well which has the same channel conduction type with the LDMOS transistor to be formed in the semiconductor substrate, the invention can obtain higher breakdown voltage.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for preprocessing coal tar

ActiveCN101838550AReduce frequent switchingLess number of tanksTreatment with plural serial refining stagesPretreatment methodImpurity

The invention discloses a method for preprocessing coal tar. The method comprises the following steps of: mixing the coal tar and an extractant A in a mass ratio of 1:0.5-1:4, heating the mixture to the temperature of between 50 and 150 DEG C, and performing continuous centrifugal separation on the obtained mixed solution in a sedimentation type centrifuge to obtain soluble matters and impurity-containing extraction insoluble matters. The method has the advantages of good impurity-removing effect, high utilization ratio of the coal tar (over 96 percent), simple process, high automaticity, andlow labor intensity, and suitability for large-scale preprocessing of the coal tar and comprehensive utilization and deep processing of full-cut coal tar which is the byproduct in industries such as coal chemical industry, coal gasification industry and the like..

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

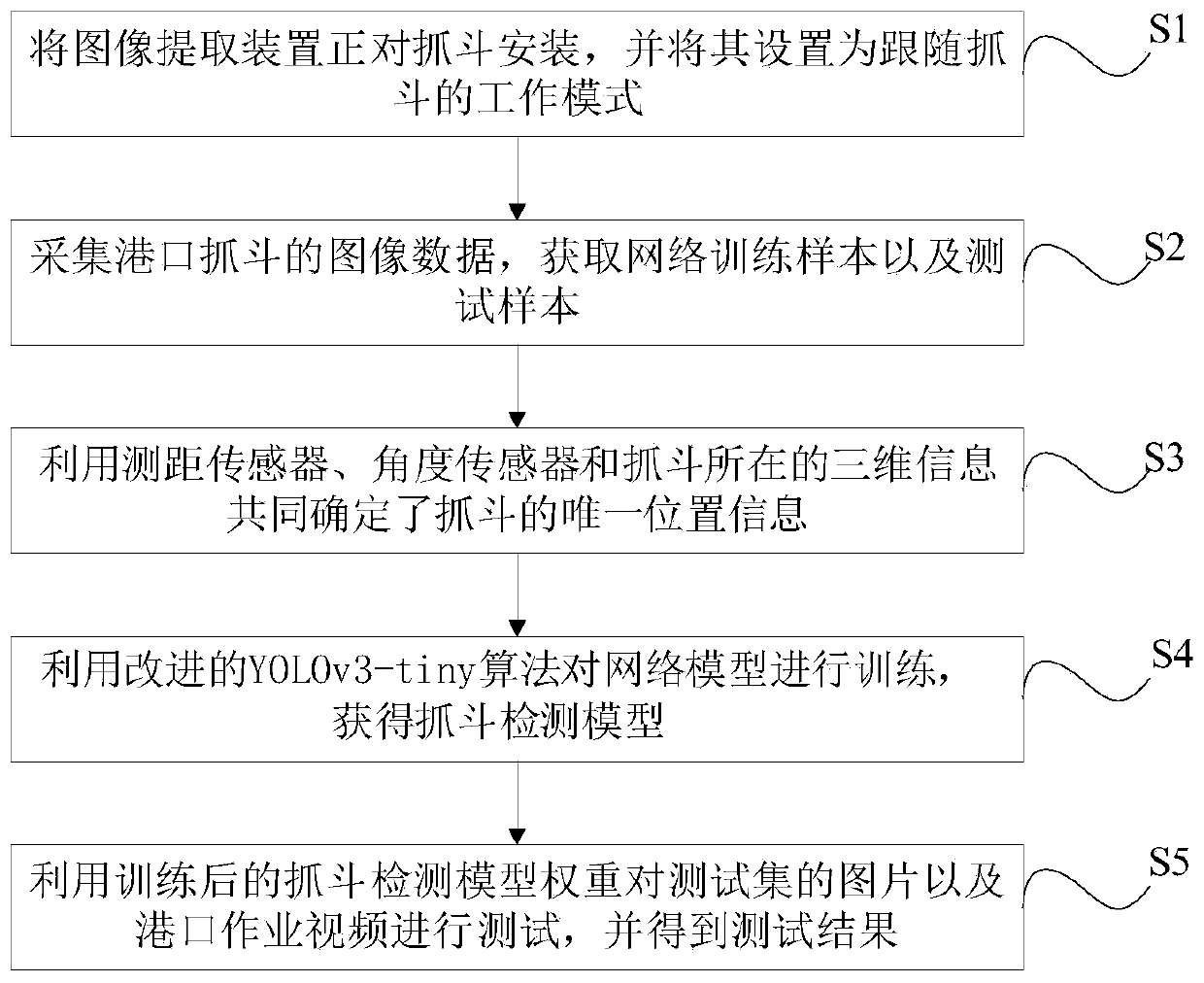

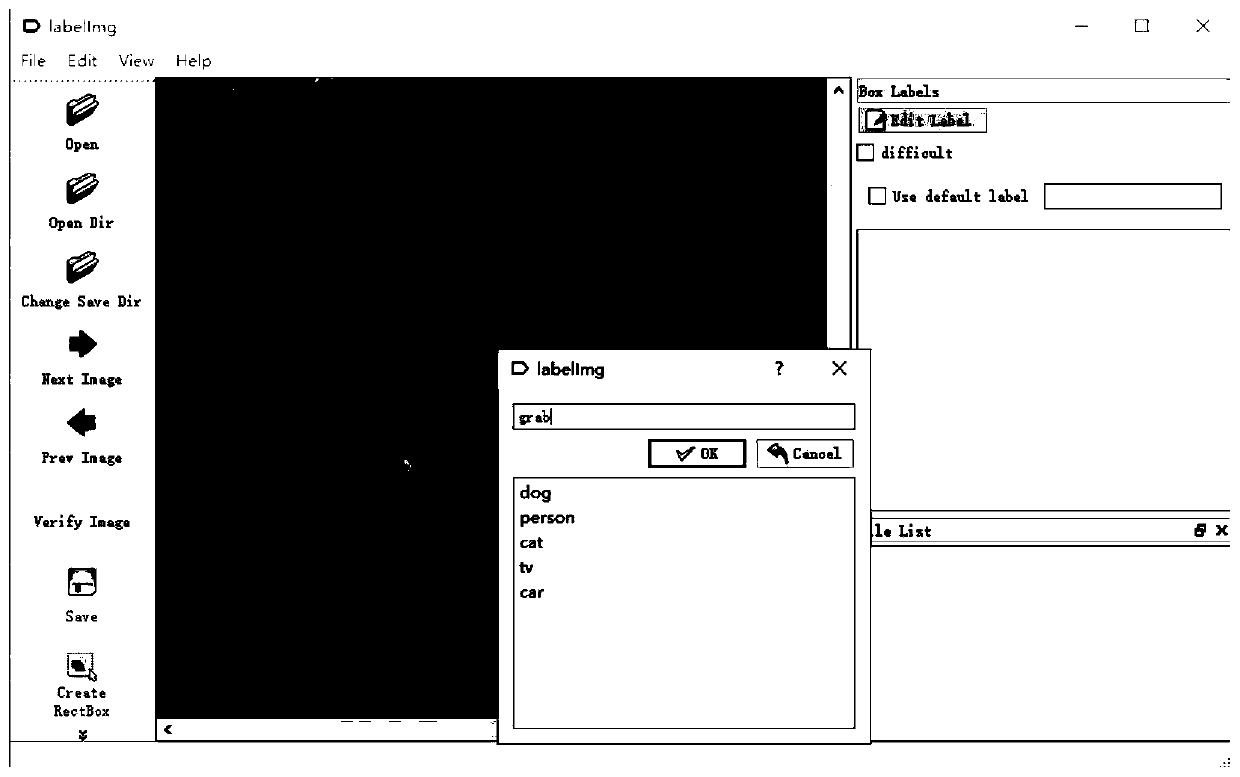

Port grab bucket detection method based on improved YOLOv3-tiny algorithm

ActiveCN110826520AImprove performanceImprove recallNeural architecturesThree-dimensional object recognitionImage extractionTest sample

The invention provides a port grab bucket detection method based on an improved YOLOv3-tiny algorithm, and the method comprises the steps: an image extraction device being just opposite to a grab bucket, and setting the image extraction device to be in a working mode of following the grab bucket; collecting image data of a port grab bucket, and obtaining a network training sample and a test sample; jointly determining unique position information of the grab bucket by large arm rotation angle information of a horizontal plane and a vertical plane measured by a distance measuring sensor and an angle sensor and three-dimensional information of the grab bucket; training the network model by using an improved YOLOv3-tiny algorithm to obtain a grab bucket detection model; and testing the pictures of the test set and the port operation video by using the trained grab bucket detection model weight, and obtaining a test result. In the grab bucket operation process, the operation speed is increased, the cycle period is shortened, real-time detection of the position of the grab bucket is automatically achieved, labor capital is saved while the operation efficiency is improved, and great valueand significance are achieved in the port operation aspect.

Owner:YANSHAN UNIV

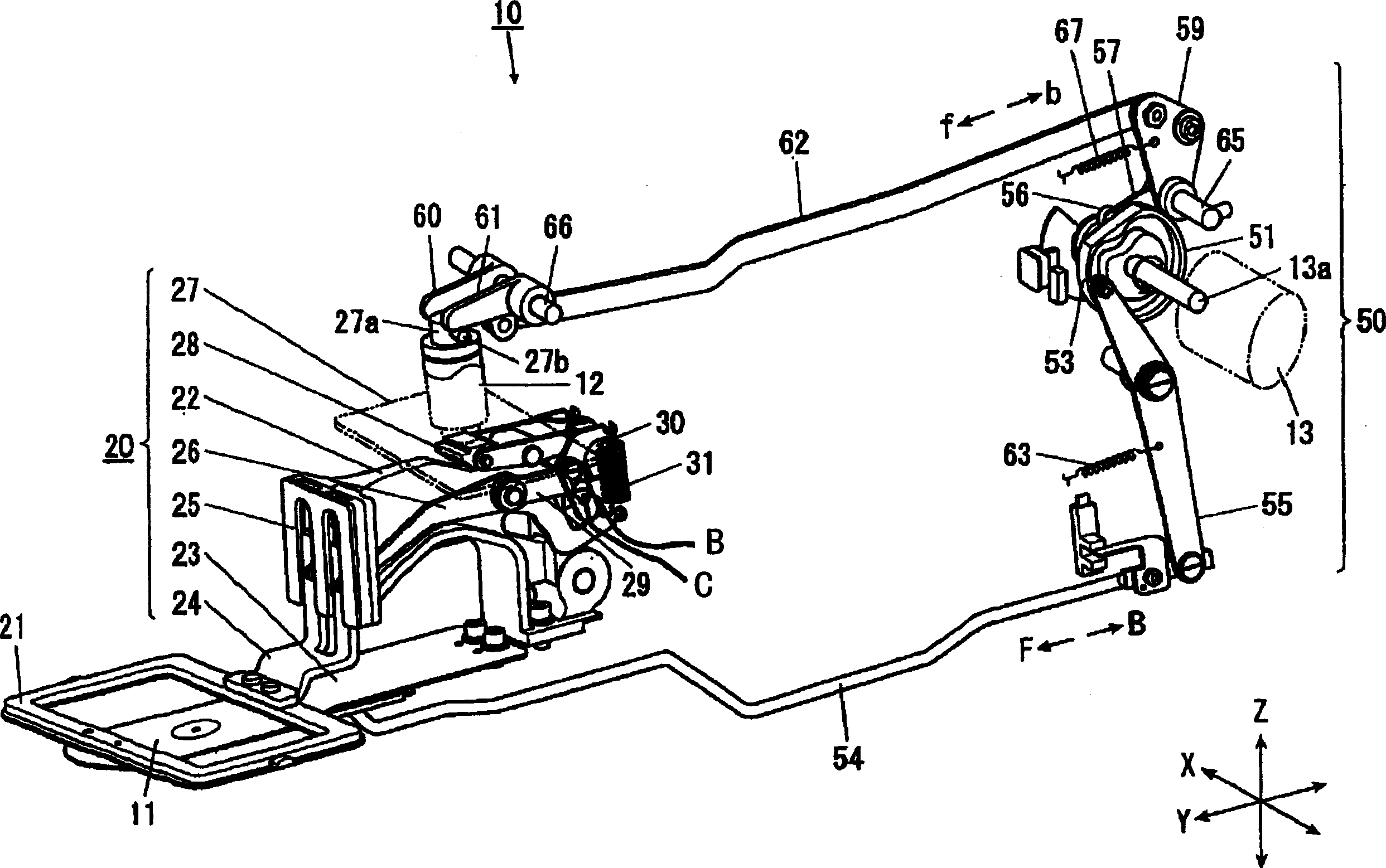

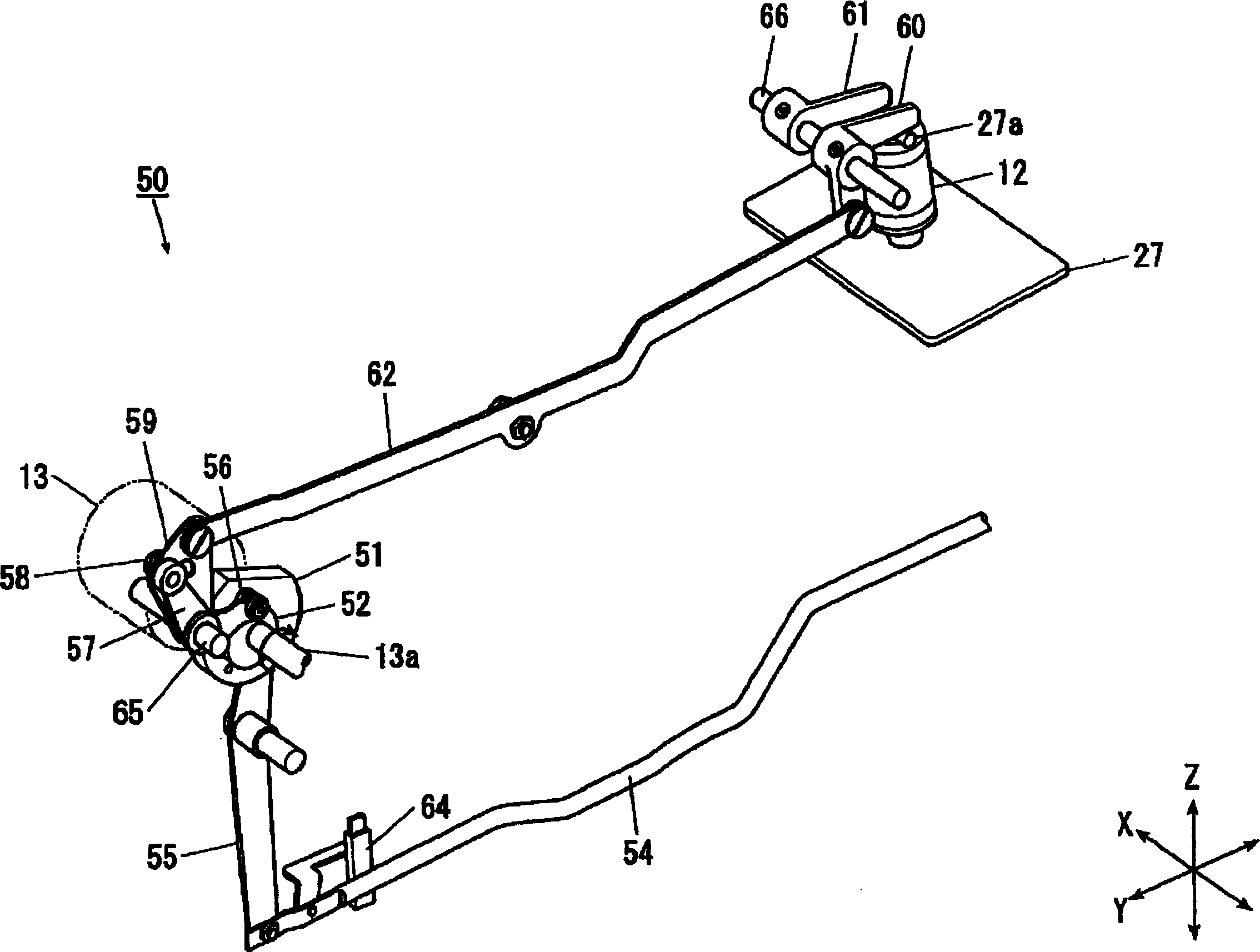

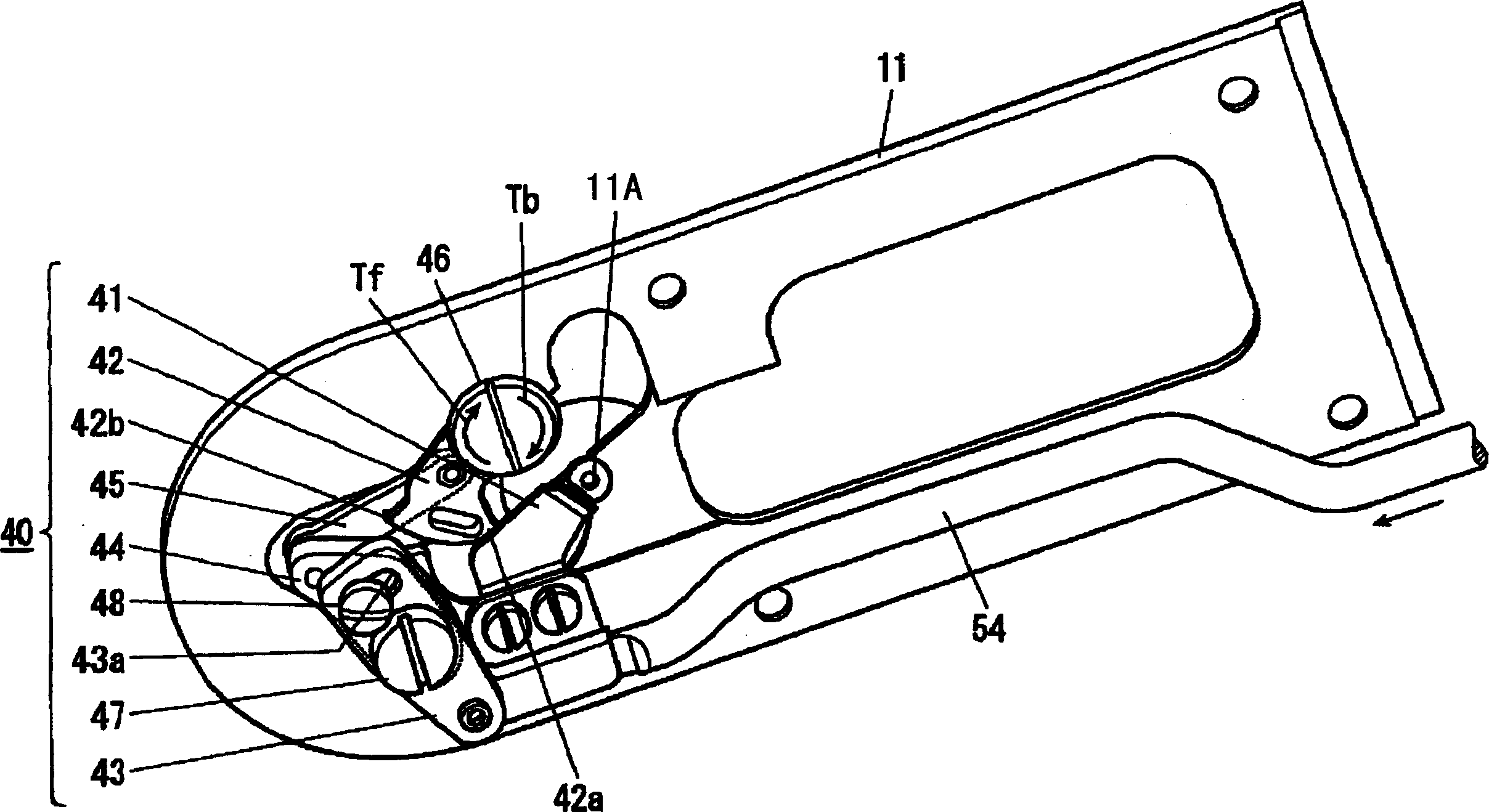

Sewing machine

InactiveCN1757809AShorten the cycle timeAppropriate rotation speedProgramme-controlled sewing machinesWorkpiece carriersYarnDrive motor

A seaming machine (10) comprises a cutter (4) for cutting suture line, a cloth press (20) for lifting compress foot (21), a pulse motor (13) driving the two devices, a ROM93 storing multiple rotation speed data (93c) defining the rotation speed of the pulse motor when the cutter cuts suture line, a rotation speed selector (as CPU91) for selecting the rotation speed data generating the drive torque capable of cutting suture line at least from the ROM, according to the suture line thickness input by a controller (98), relative to the drive voltage of a conchoids (81) driving a yarn change mechanism (80), and a drive controller (as CPU91) for controlling the rotary drive of the pulse motor according to the selected rotation speed data. The invention can optimize the rotation speed of the drive motor when cuts suture line to reduce rotation period.

Owner:JUKI CORP

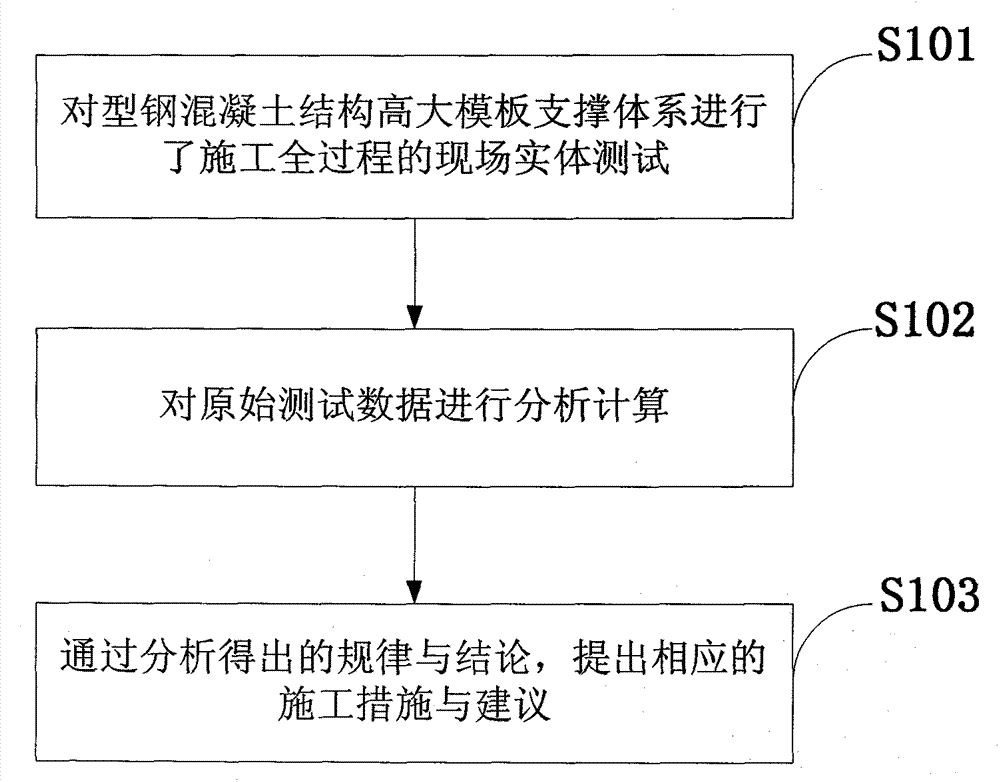

Actual deformation measurement method for high template support system of concrete structure

InactiveCN103674589AReduce support costsGuarantee the construction qualityStructural/machines measurementSupporting systemStructure system

The invention discloses an actual deformation measurement method for a high template support system of a concrete system. The method comprises the steps that in-situ real project measurement of the whole construction process is carried out on the high template support system of the section-steel concrete structure; original measurement data is analyzed and calculated; and corresponding construction measures and suggestions are provided based on rules and conclusion obtained via analysis. According to the method, the basis for a mechanical calculation model of the template support system is established by in-situ detecting and exploring the action mechanism of a time-dependent structure system which is supported by both the cast in situ structure and the template support during the construction stage, thereby providing basis for examining laboratory structure tests and theoretical analysis results, and also providing technical basis for mechanical analysis on the time-dependent structure system, controlling the safety of the template support system in the construction period and designing and optimizing a construction scheme; and template support is realized via the existing materials, thereby saving the cost of concrete template support, reducing the construction cost, increasing the construction speed, shortening the cyclic period, and ensuring the construction quality of the concrete structure.

Owner:广东省六建集团有限公司

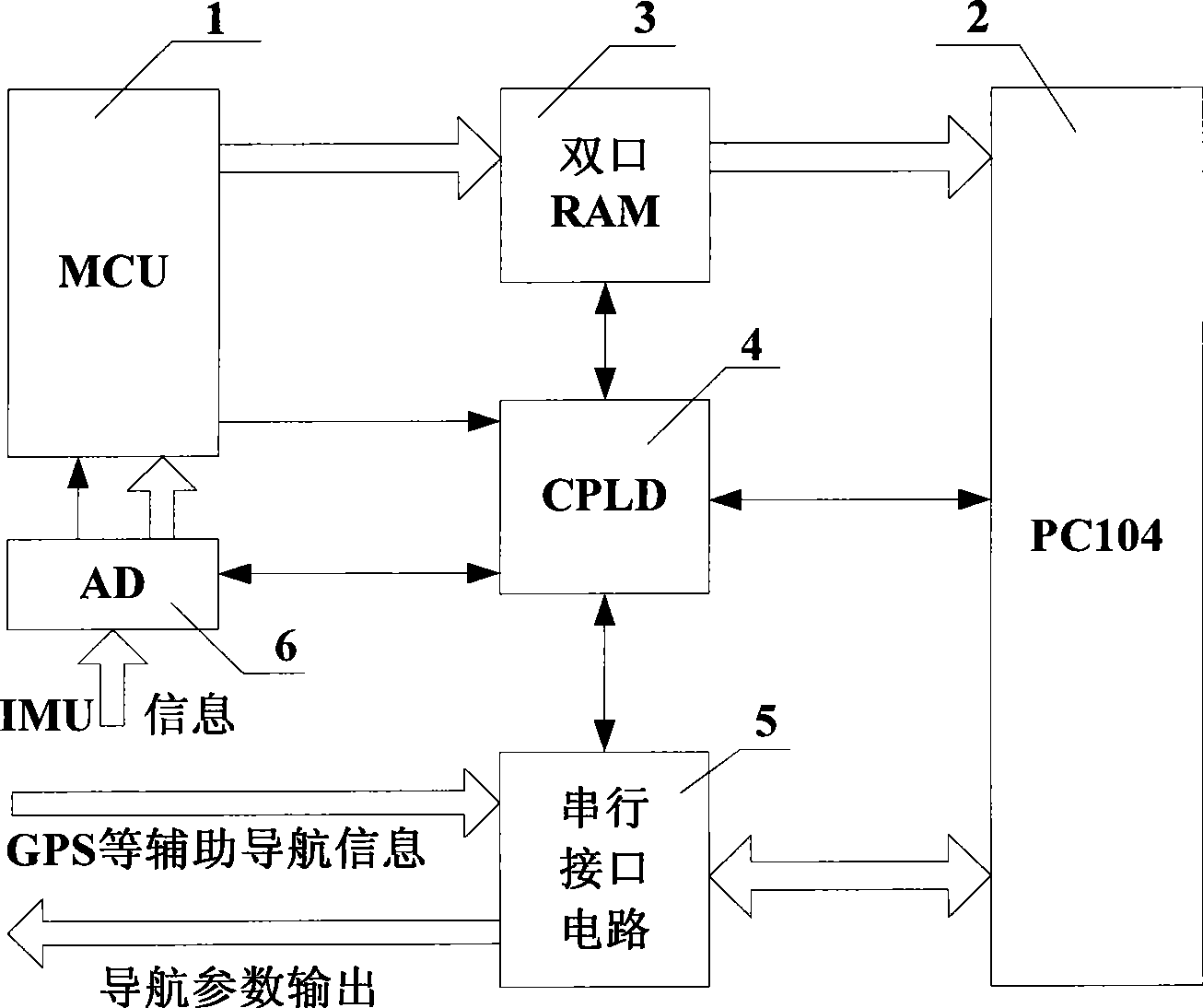

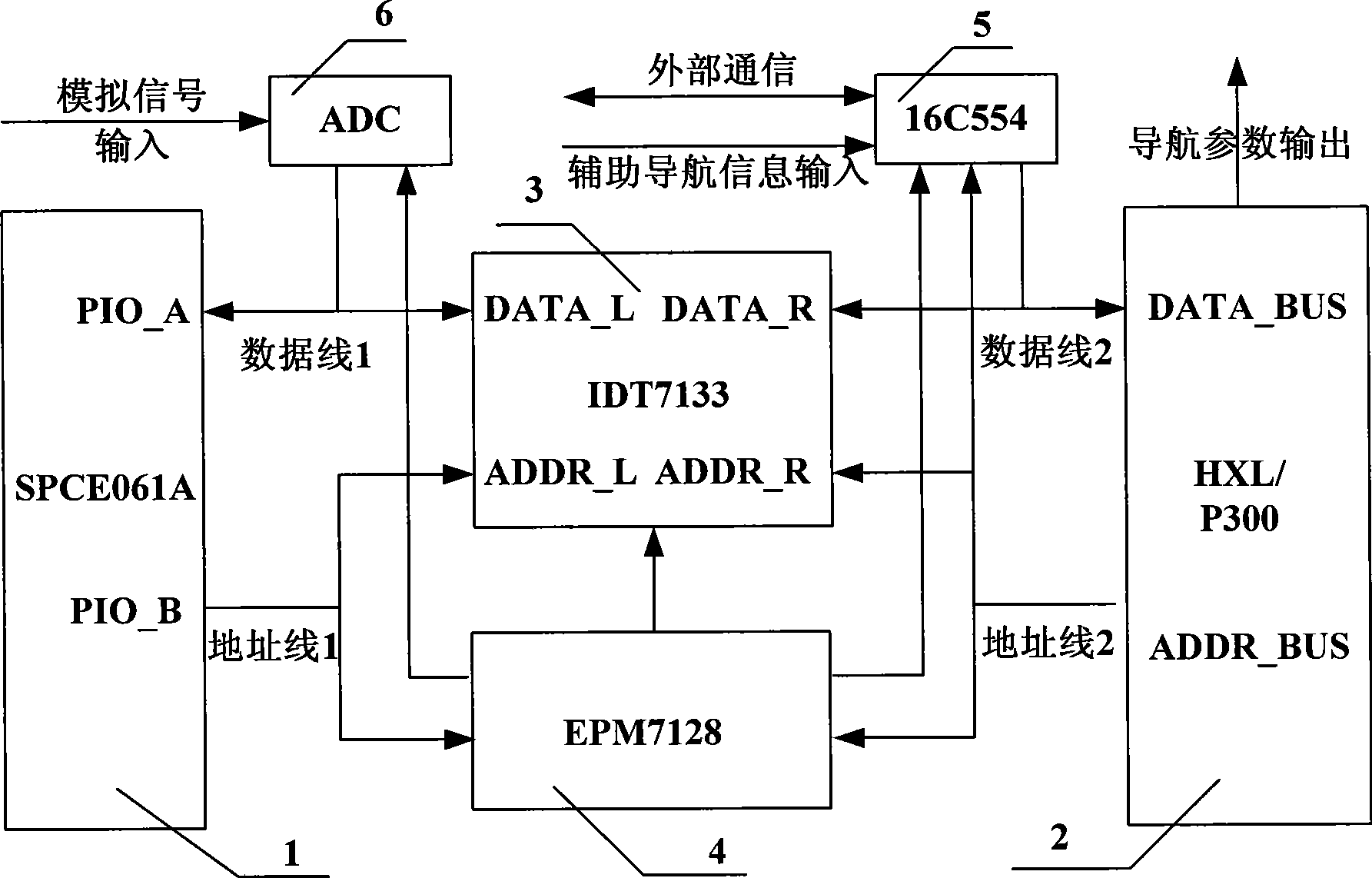

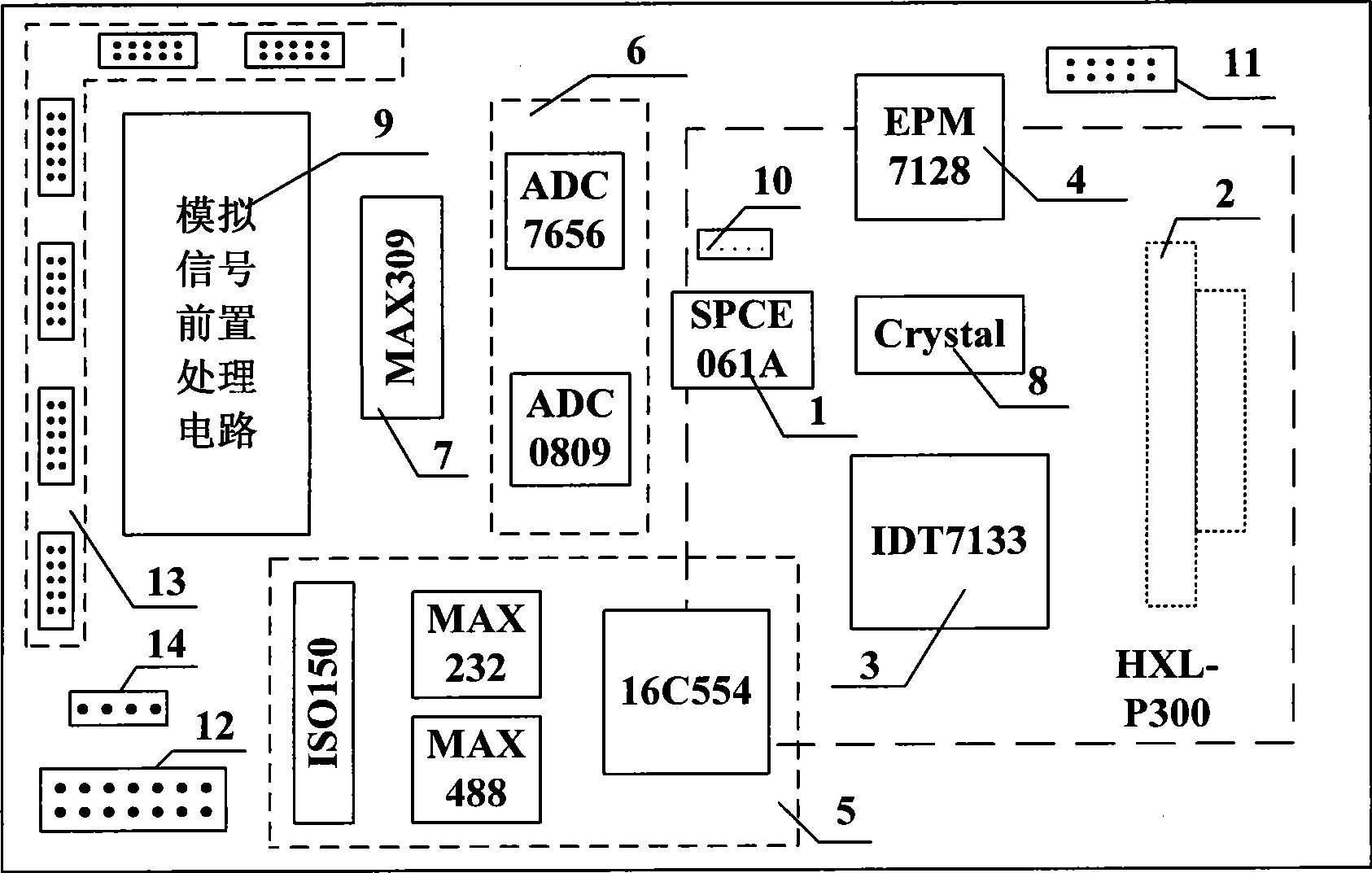

Dual-CPU embedded navigation computer

InactiveCN101469990AProcessing speedShorten the cycle timeNavigational calculation instrumentsInformation processingCommunication interface

The invention provides a dual-CPU embedded navigation computer, composed of a MCU module, a PC104 module, an A / D conversion module, a dual-port RAM data share module, a complex programmable logic device decoding module and a serial communication interface module. The IMU inertial sensor information is processed by A / D conversion into digital values to be input into the MCU module, buffered by the dual-port RAM and fed into the PC104; GPS and electronic compass navigation information are directly fed into the PC104 via interface circuit to process navigation data fusion, the calculation result is transmitted to external system via interface circuit or visually displayed via a man-machine interaction interface of the system; the data acquisition is completed under the combination control of the MCU module and the CPLD decoding module. The invention has the advantages that: (1) the dual-CPU embedded navigation computer has high navigation information processing speed; has many data acquisition channels; (3) has strong communication ability; (4) has small volume low cost, high reliability, simple operation and simple man-machine interaction.

Owner:HARBIN ENG UNIV

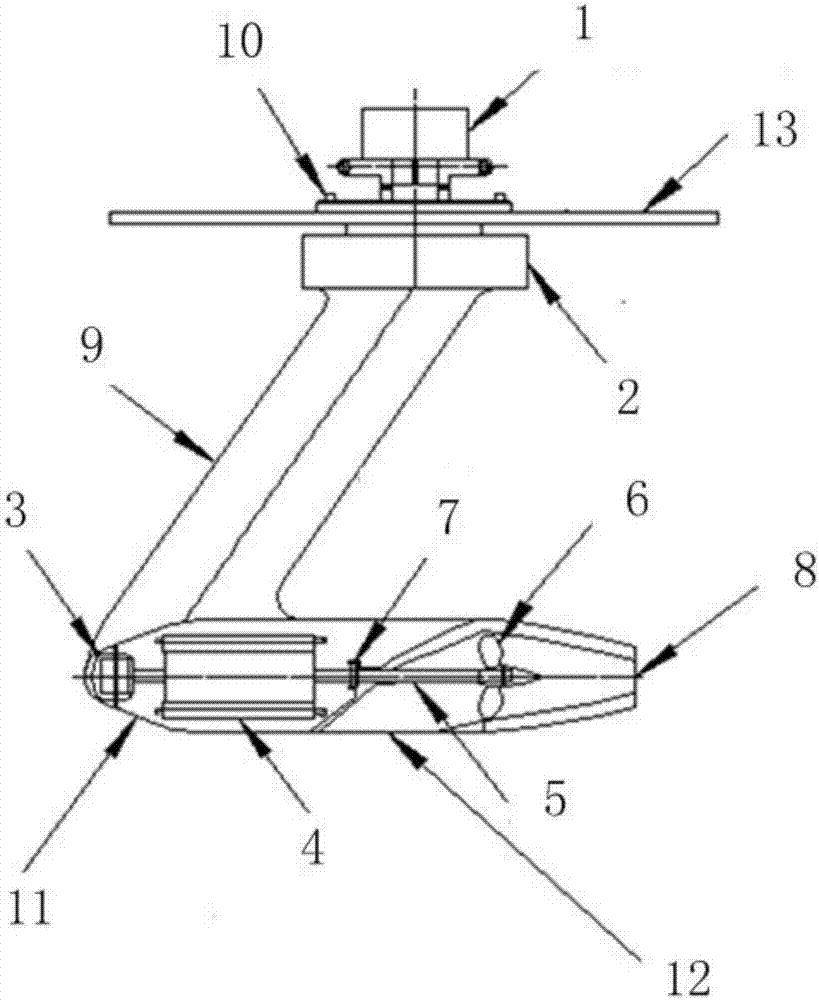

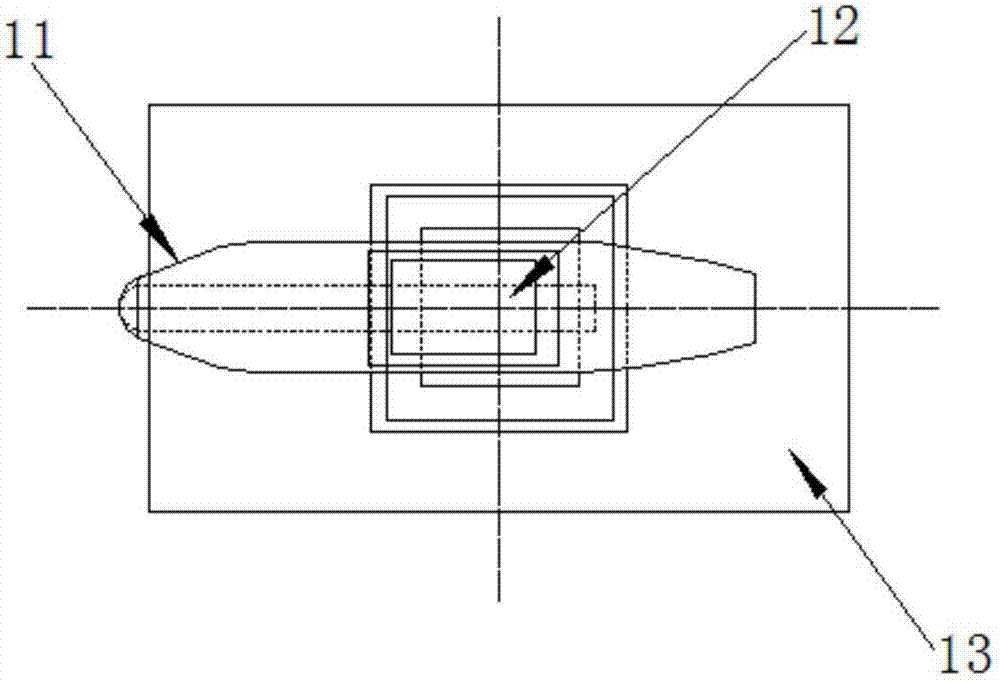

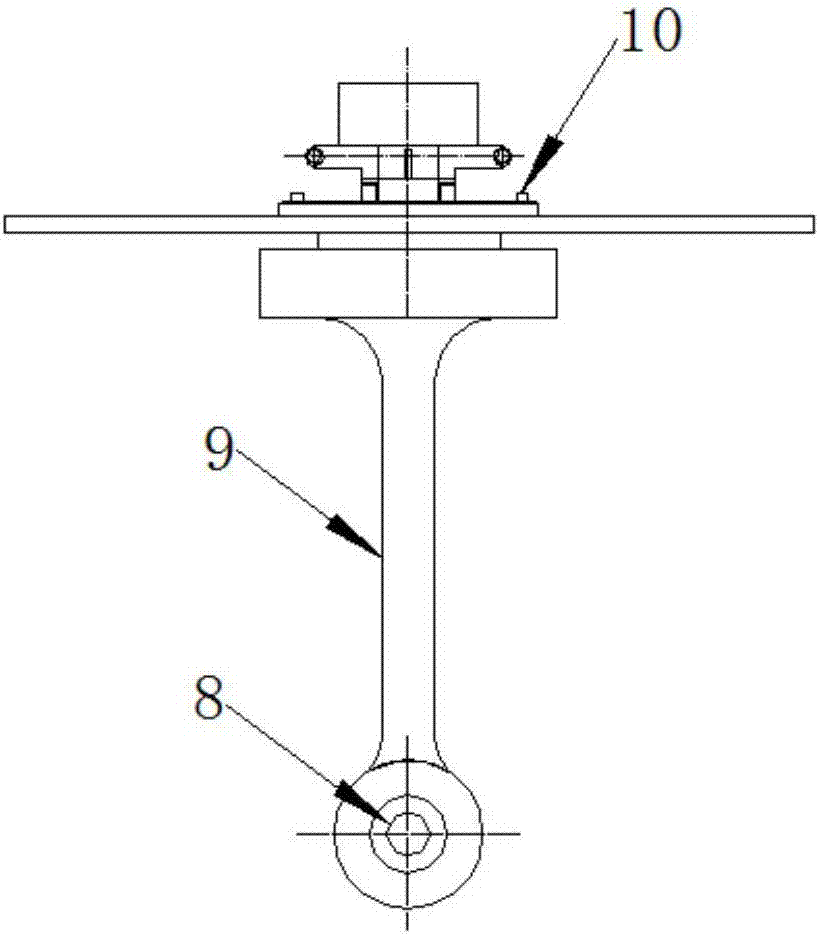

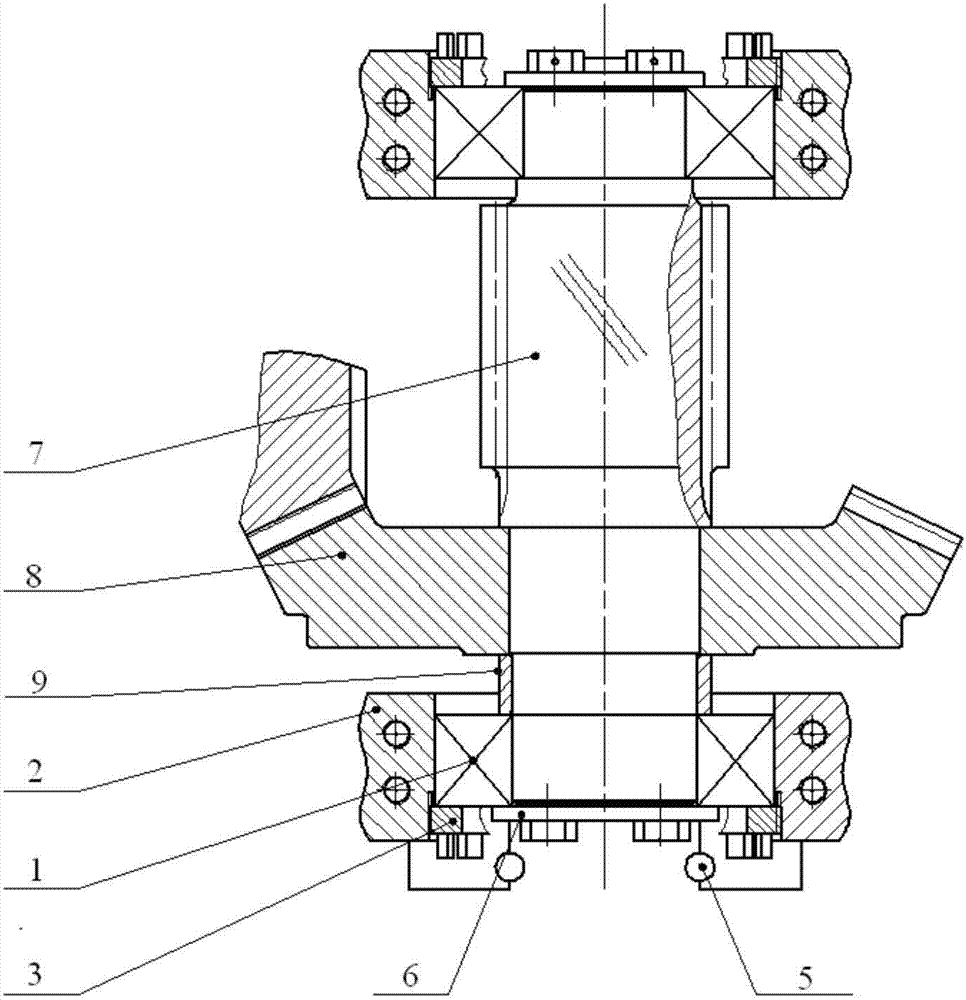

Pod-type water spraying propeller

InactiveCN107244405AStrong anti-cavitation abilityReduce vibrationPropulsive elementsPump-jetPropulsive efficiency

The invention provides a pod-type water jet propulsion unit, which comprises an installation platform, a pod propeller bracket arranged at the lower end of the installation platform, a pod propeller cabin body arranged at the lower end of the pod propeller bracket, a pod propeller cabin body arranged at the pod propulsion The motor base in the cabin body, the motor installed on the motor base, the transmission shaft connected to the output end of the motor, the water jet propulsion pump installed on the transmission axis, the lower end of the pod propeller cabin is provided with an inlet, a side A spout is provided, a flow channel is formed between the inlet and the spout, and the spout is set facing the water jet propulsion pump, and the upper end of the installation platform is provided with a data transmitter and a hydraulic steering device. The present invention is on the basis of maintaining the advantages of the original water jet propeller, adding the bracket, cabin body, electric propulsion system and steering device of the pod propeller, thereby reducing the complicated mechanical transmission mechanism and reversing device of the water jet propeller, further The propulsion efficiency and operational performance of the thrusters are improved, the noise is reduced and the stealth performance is enhanced.

Owner:HARBIN ENG UNIV

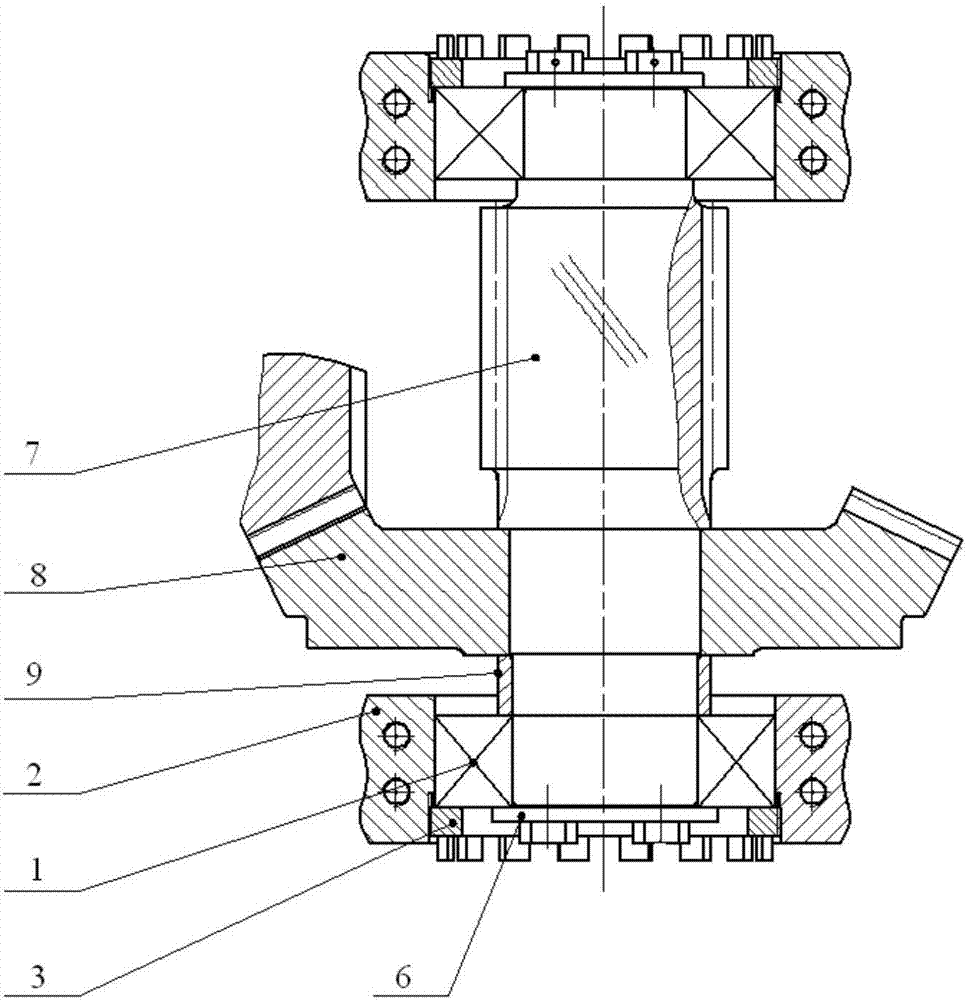

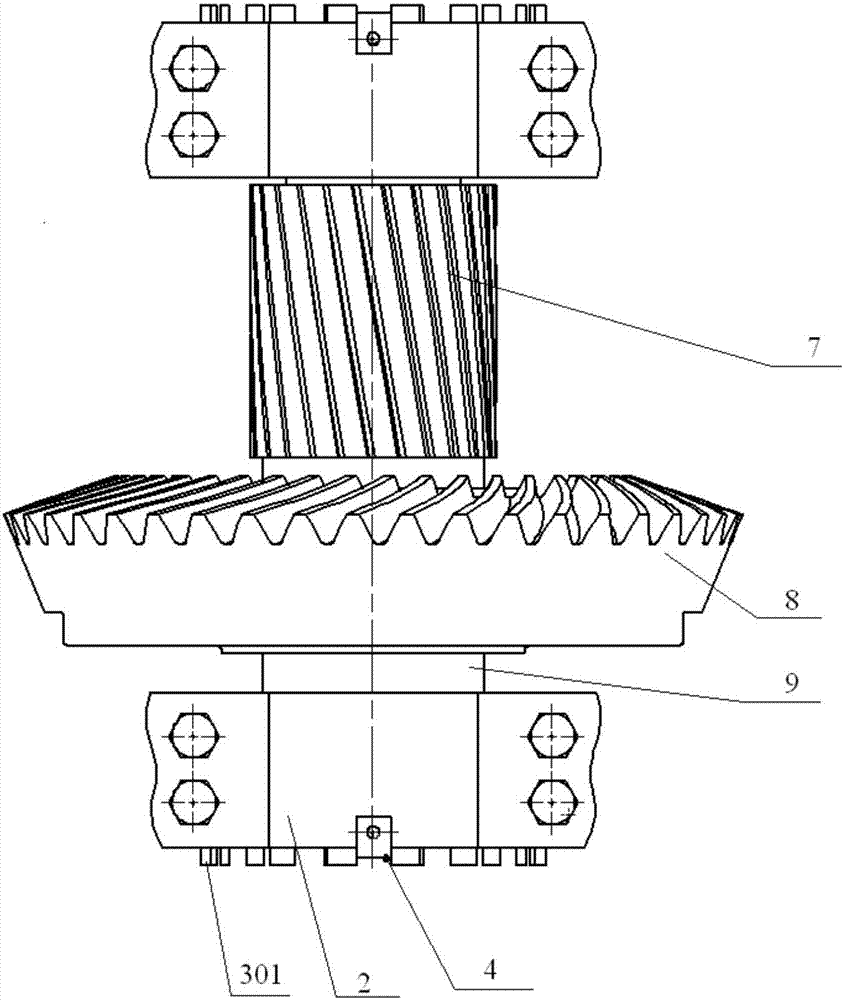

Roller-bearing preloading adjustment structure and method

InactiveCN107289030AEnsure clearanceEnsure preloadGearing detailsBearing unit rigid supportGear wheelDrive shaft

The invention discloses a roller bearing preload adjustment structure and method. The roller bearing preload adjustment structure includes: a roller bearing capable of being installed on a transmission shaft; a bearing seat supporting the roller bearing, and the bearing seat is installed in a box On the body, and the inner ring of the bearing seat is provided with an internal thread; the bearing lock nut is provided with an external thread that engages with the internal thread on the bearing seat, and the inner side of the bearing lock nut is in contact with the roller bearing the outer ring abutment. The roller bearing preload adjustment structure disclosed in the present invention adjusts the bearing lock nut when adjusting the axial positioning of the roller bearing. Since the bearing lock nut and the bearing seat are threaded, the bearing lock nut rotates One turn, forward or backward by one pitch, so as to ensure that the clearance and preload of the roller bearing meet the technical requirements, and realize the axial position adjustment of the transmission parts such as the gear on the transmission shaft. The use of grinding parts is reduced, and the adjustment can be realized only by rotating the bearing lock nut, which has high efficiency.

Owner:CHONGQING GEARBOX

Absorption liquid for gas desulfurization and desulfurization method thereof

InactiveCN101613089AShort regeneration timeOvercoming the problem of slow real lifeDispersed particle separationSulfur preparation/purificationOrganic sulfide compoundCatalyst degradation

The invention relates to an absorption liquid for gas desulfurization and a desulfurization method thereof, solving the problems that catalysts in the prior art have slow regeneration, absorption tower clogging, high degradation speed of desulfurater and the like. Phenol, quinine, microbial enzyme, vanadium and complex preparation serve as catalysts; under the condition of alkaline compounds, gas is led in to quickly oxidize inorganic sulphide and organic sulphide in absorption liquid to be sulphur. The gas desulfurization method of the invention has the advantages of small amount of catalyst, high regeneration efficiency of catalyst, low degradation speed of catalyst, no absorption tower clogging and the like.

Owner:苏喜太

Huangshan goldenrain tree tissue culture method

ActiveCN104273038APromote proliferationPromote growthPlant tissue cultureHorticulture methodsShoot apexCycle time

The invention relates to a Huangshan goldenrain tree tissue culture method. The Huangshan goldenrain tree tissue culture method comprises the following steps: (1) preparation of a Huangshan goldenrain tree leaf extracting solution; (2) primary induction culture: inoculating a Huangshan goldenrain tree stem explant on a primary induction culture medium for culture, wherein the primary induction culture medium is added with the Huangshan goldenrain tree leaf extracting solution; (3) secondary proliferation culture: inoculating a stem or a stem tip of a Huangshan goldenrain tree aseptic seedling obtained by the primary induction culture on a secondary proliferation culture medium in an aseptic manner for culture, wherein the secondary proliferation culture medium is added with the Huangshan goldenrain tree leaf extracting solution; (4) tissue culture seedling rooting: cutting a Huangshan goldenrain tree aseptic clump seedling obtained by the proliferation culture into individual plants and inoculating the individual plants on a rooting medium, wherein the rooting medium is added with the Huangshan goldenrain tree leaf extracting solution; (5) domestication and transplanting of test-tube seedlings. By adopting the scheme, the cycle time can be shortened by 15%, the cost can be saved by 20%, and the Huangshan goldenrain tree tissue culture method is applicable to factory production.

Owner:济宁高新科达科技项目服务有限公司

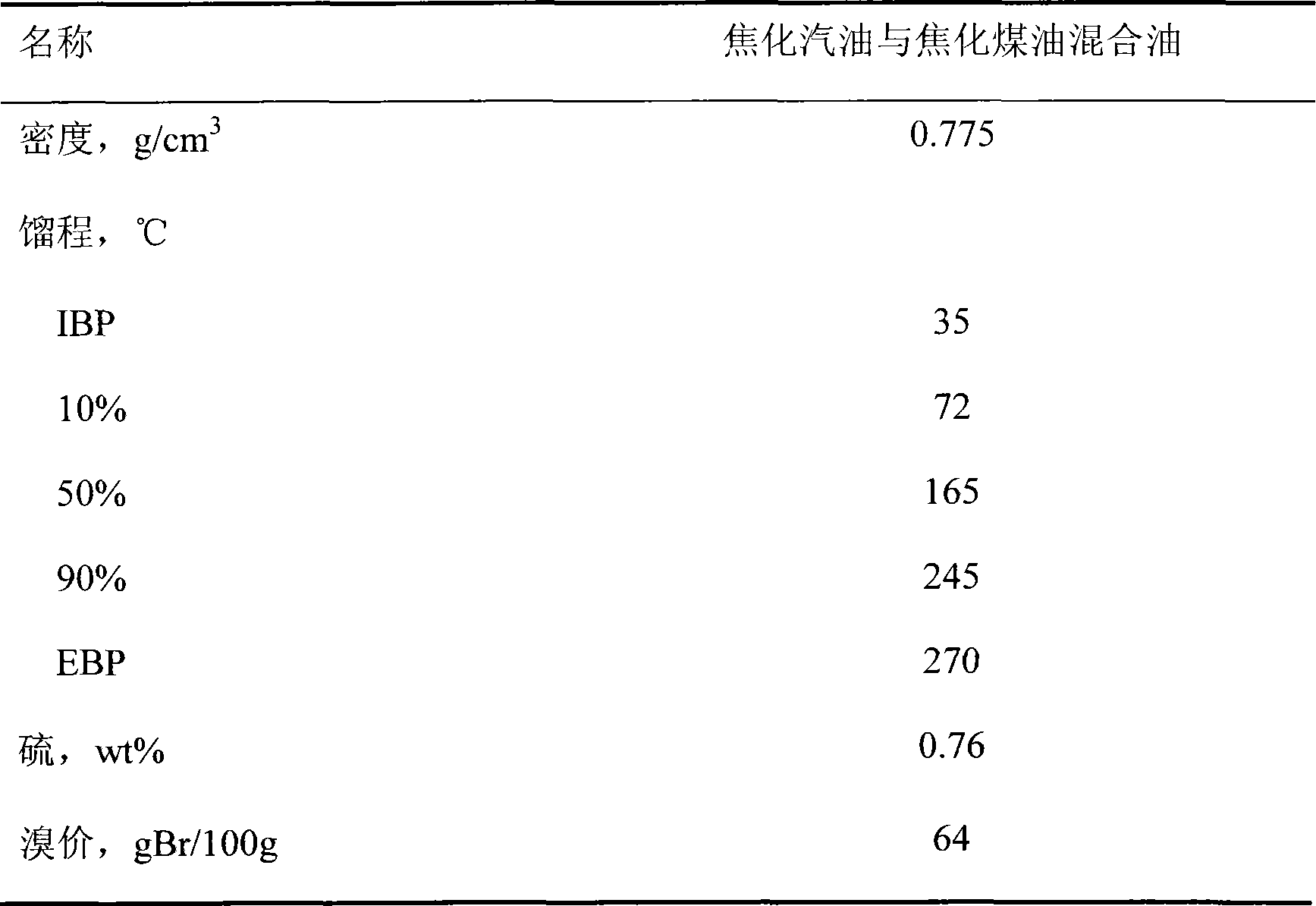

Mixed hydrogenation process for coker gasoline and coking kerosene

ActiveCN101434851AImprove product qualityHigh priceHydrocarbon oils refiningGasoline stabilisationNaphthaKerosene

The invention provides a hydrogenation process by mixing coking gasoline and coking kerosene, comprising the steps as follows: the operation conditions of the fractionation system of a delayed coking device are adjusted; suitable cutting point is adopted; the coking gasoline and the coking kerosene components are not separated and directly enter a special hydrogenation device so that hydrofining is carried out; the coking gasoline and the coking kerosene are disposed by adopting a normal hydrogenation type. Compared with respective hydrogenation and mixing hydrogenation of various coking distillate, the process carries out the hydrogenation by mixing the coking gasoline and the coking kerosene, produces naphtha and aviation kerosene to the most extent, prolongs the service life of the catalyst, improves the operation flexibility of the device, thus obviously improving the economical benefits of the oil refining enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

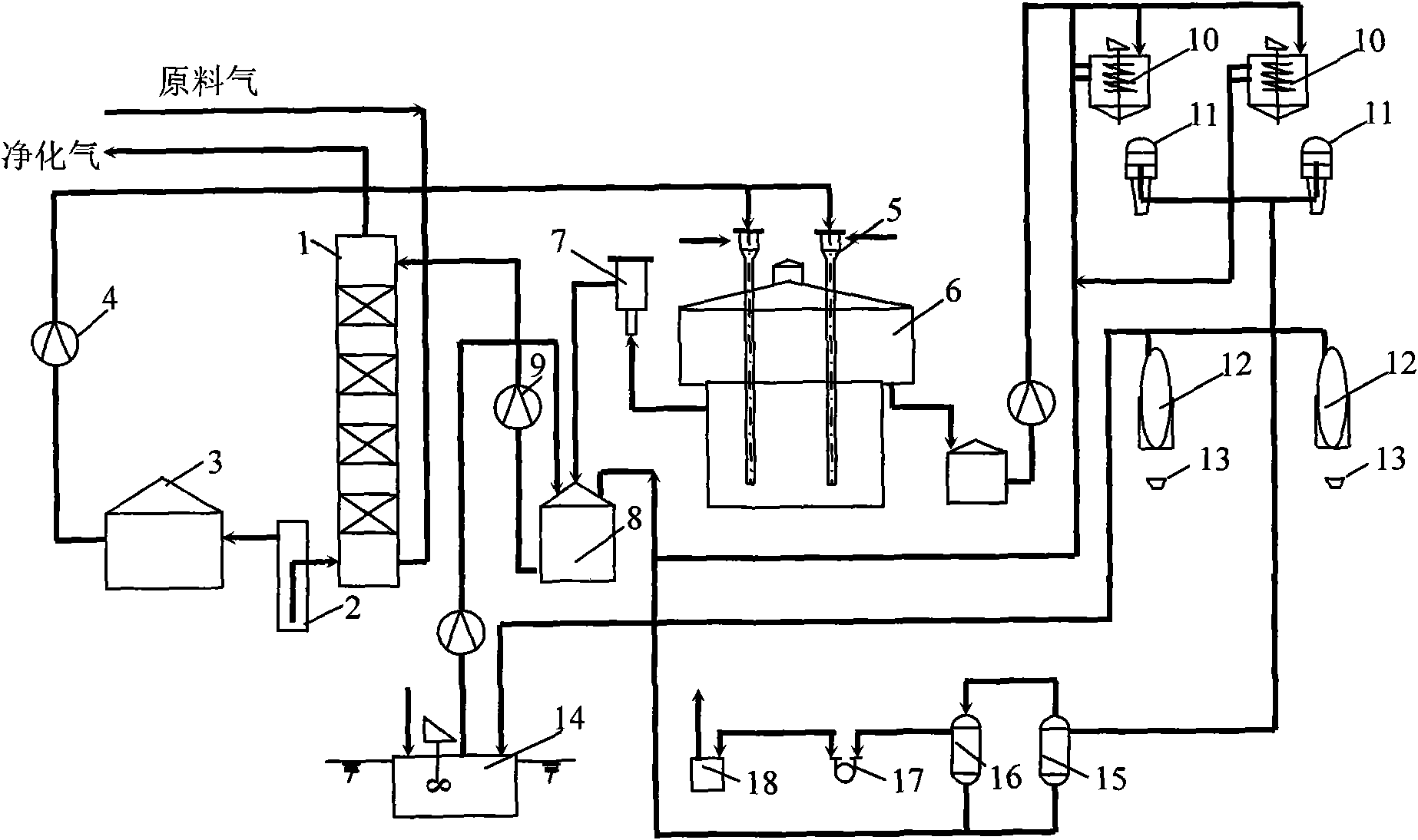

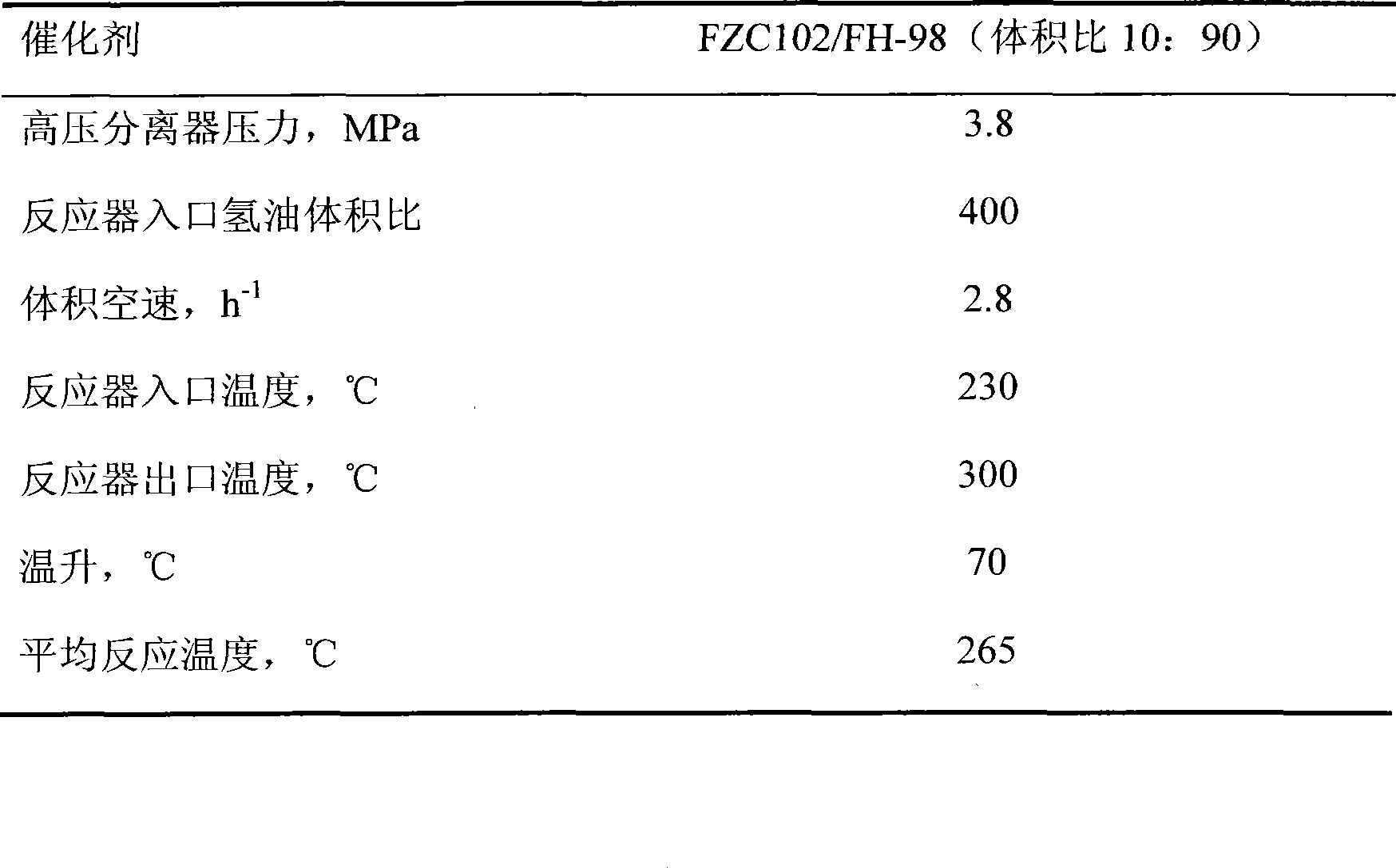

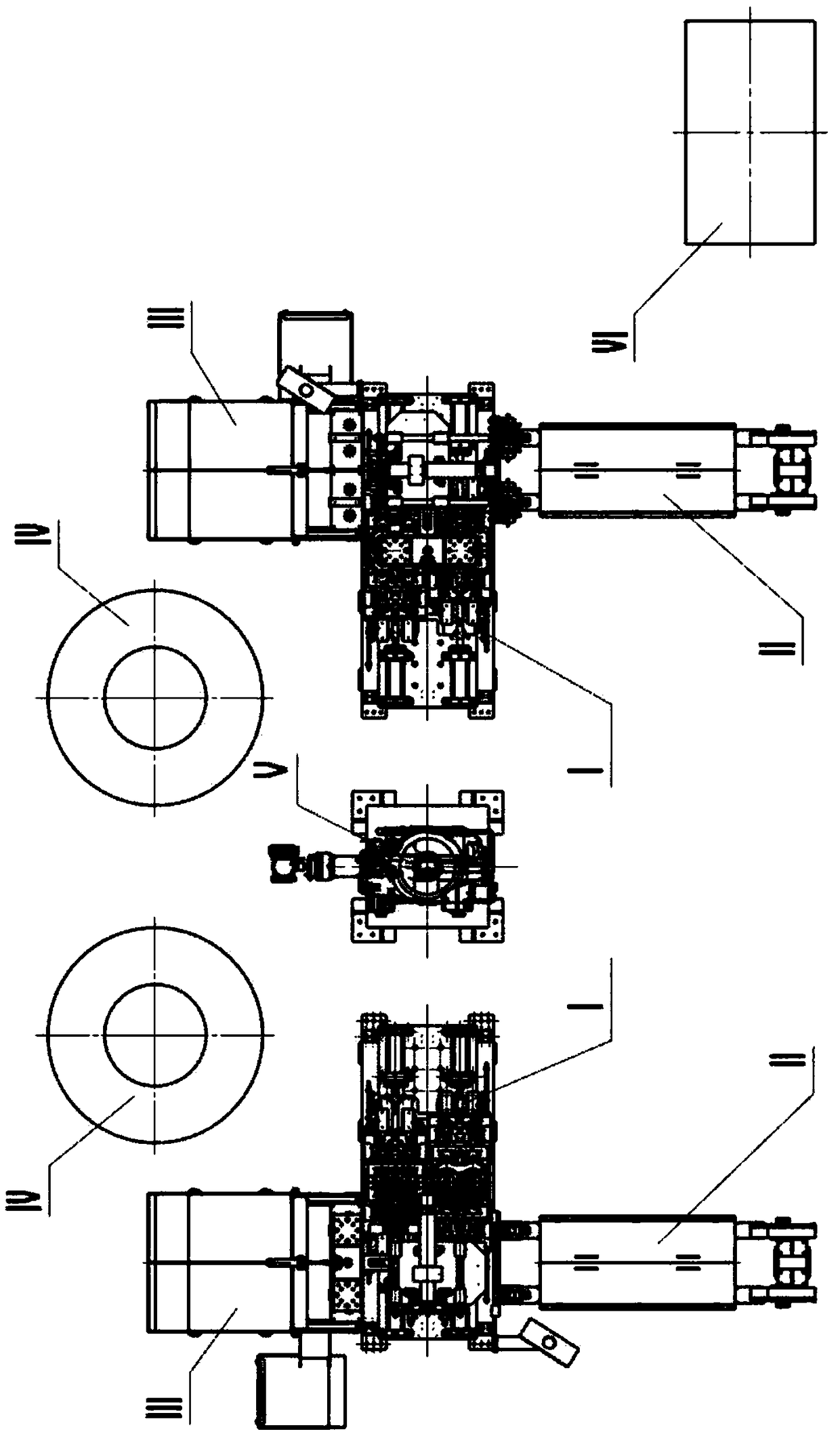

Full-automatic casting equipment for aluminum pistons of gasoline engines

The invention provides full-automatic casting equipment for aluminum pistons of gasoline engines. The full-automatic casting equipment comprises at least two main casting machines; and each main casting machine comprises a bed body support, a bed body mounted on the bed body support, a central core mechanism, a slewing mechanism, an outer mold mechanism, a top mold mechanism and a casting taking,casting and quenching manipulator. The full-automatic casting equipment for the aluminum pistons of the gasoline engines further comprises at least two filtering net conveying devices, at least two casting and quenching mechanisms, at least two molten aluminum temperature holding furnaces, a pouring robot and a hydraulic station; each filtering net conveying device is connected with one side of the corresponding main casting machine; each casting and quenching mechanism is connected with the other side of the corresponding main casting machine and is opposite to the corresponding filtering netconveying device; the molten aluminum temperature holding furnaces are adjacent to the main casting machines; the pouring robot is arranged between the two main casting machines and is adjacent to the molten aluminum temperature holding furnaces; and the hydraulic station is adjacent to the filtering net conveying devices. According to the technical scheme, full-automatic casting of four molds inone machine is realized, the production efficiency is high, the production cost is reduced, and the safety performance is improved.

Owner:BINZHOU BOHAI PISTON CO LTD +1

Heat processing method for improving axle yield strength by using continuous furnaces

InactiveCN101649389AHigh yield strengthImprove mechanical propertiesFurnace typesHeat treatment process controlUltimate tensile strengthMechanical property

The invention relates to a heat processing method for improving axle yield strength by using continuous furnaces, belonging to the technical field of heat processing of axles of trains. The inventionprovides a heat processing method for improving axle yield strength by using continuous furnaces, which improves the comprehensive mechanical property of the heat processed axle and meets other technical indexes. The heat processing method comprises the steps of primary normalizing, secondary normalizing and tempering, wherein a normalizing furnace and a tempering furnace which are used in the heat processing are suspended continuous furnaces. The invention is applied to the heat processing of axles of trains.

Owner:JINXI AXLE CO LTD

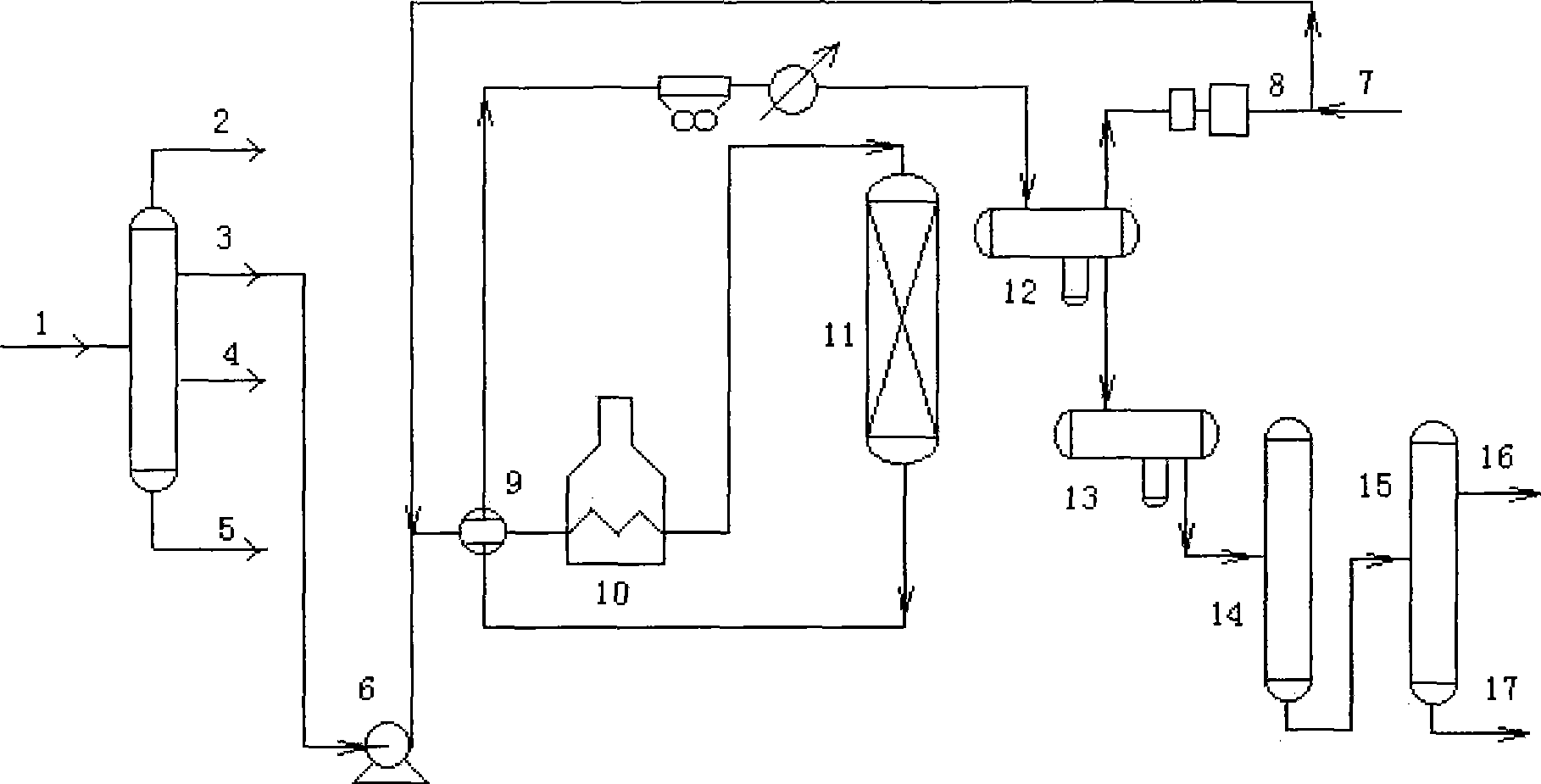

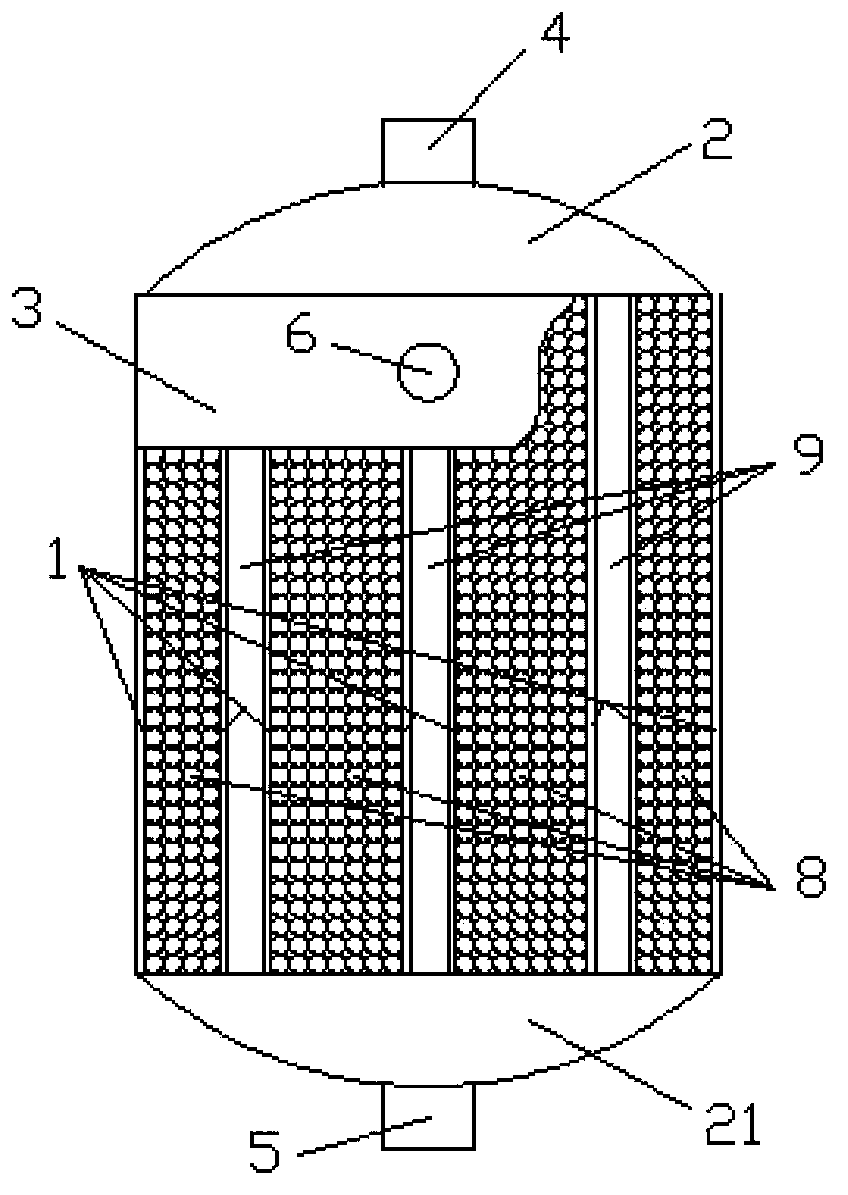

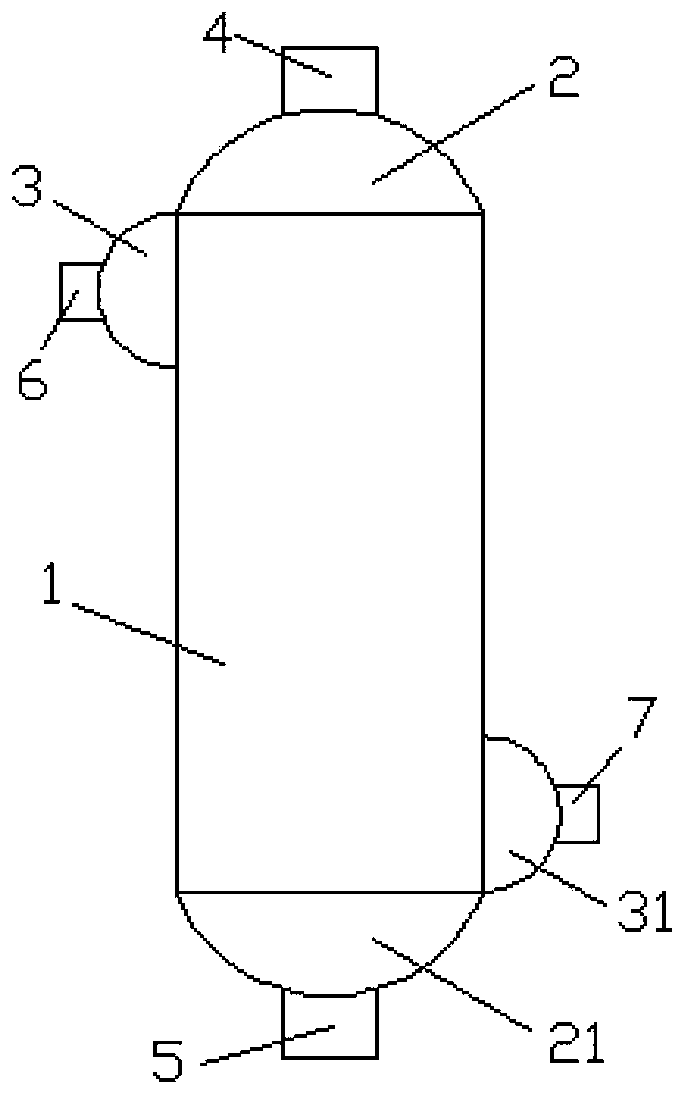

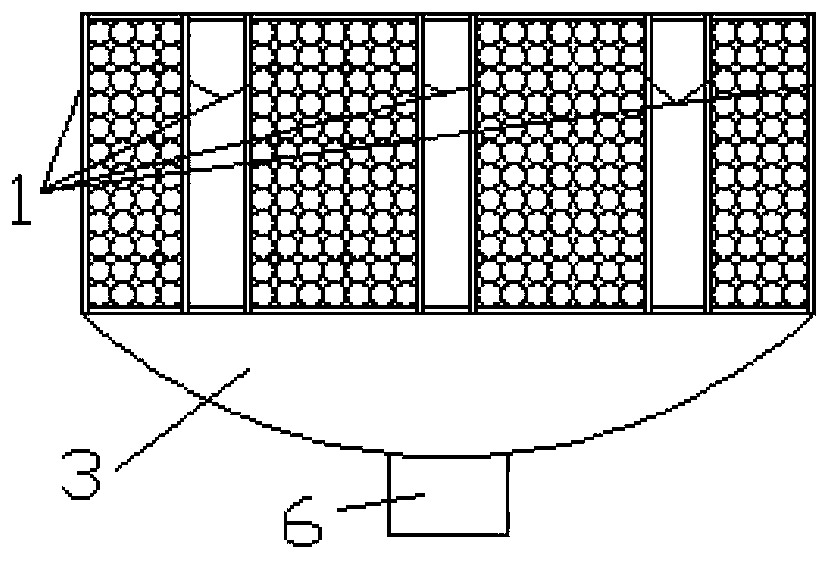

Molecular sieve adsorption tower provided with heat transferring medium channels

InactiveCN103463926AReduce fill volumeReduce wasteDispersed particle separationMolecular sieveSorbent

The invention discloses a molecular sieve adsorption tower provided with heat transferring medium channels. The molecular sieve adsorption tower comprises vertical separator plates arranged in a adsorption tower container; space flow channels are formed by adjacent vertical separator plates, and a plurality of the space flow channels distributed at intervals are filled with a molecular absorbent, and are called as process gas channels; the rest space flow channels are taken as the heat transferring medium channels; the upper end and the lower end of the adsorption tower are provided with an upper process gas shell cover and a lower process gas shell cover respectively; the ends of the upper process gas shell cover and the lower process gas shell cover are provided with a process gas inlet and a process gas outlet respectively; two opposite side walls of the container are provided with an upper heat transferring medium shell cover and a lower heat transferring medium shell cover respectively; the ends of the upper heat transferring medium shell cover and the lower heat transferring medium shell cover are provided with a heat transferring medium inlet and a heat transferring medium outlet respectively; the process gas inlet and the process gas outlet are communicated with the process gas channels via the process gas shell covers respectively; and the heat transferring medium inlet and the heat transferring medium outlet are communicated with the heat transferring medium channels via the heat transferring medium shell covers respectively. The molecular sieve adsorption tower is provided with the heat transferring medium channels, so that the molecular sieve can be heated or cooled by the heat transferring medium, molecular sieve regeneration time and adsorption cycle period are shortened, and regeneration gas consumption is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

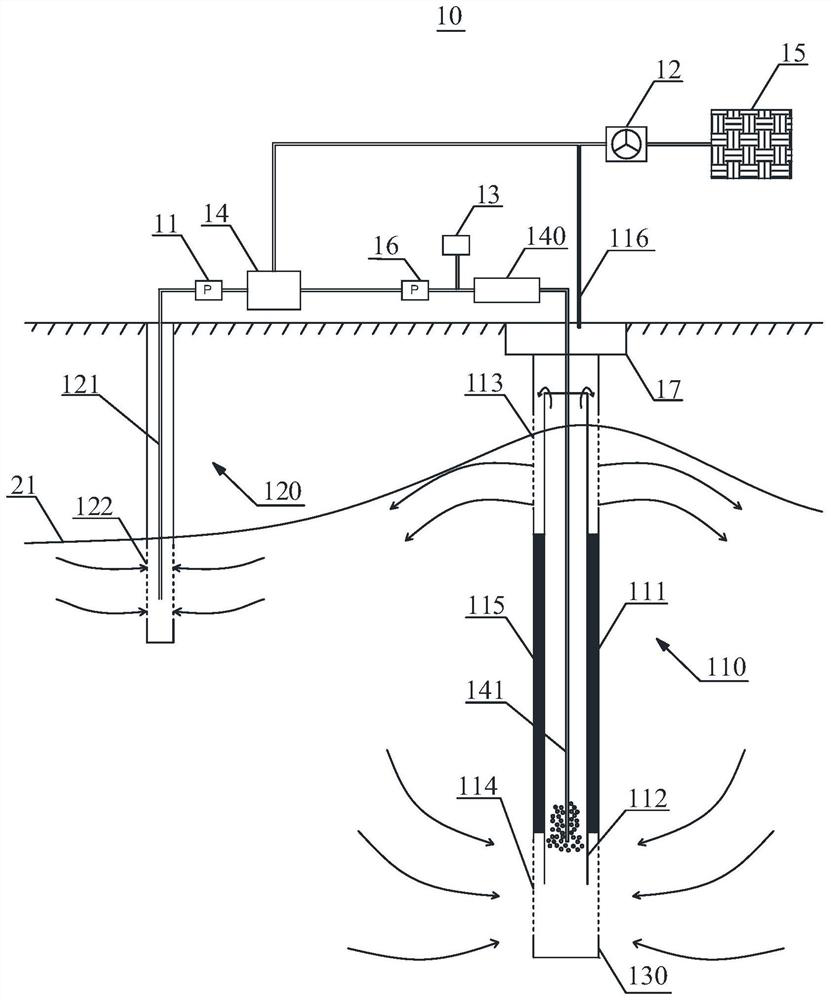

Underground water circulation well structure and repairing system and method

ActiveCN113860662AImprove aeration stripping efficiencyIncrease radius of influenceTreatment using aerobic processesWater contaminantsSoil remediationWater circulation

The invention relates to the technical field of underground water and soil remediation, and discloses an underground water circulation well structure, and a repairing system and method. The system comprises a circulating well, a pumping well, an aeration pipe, an exhaust pipe, a dosing system and a tail gas treatment device. The circulating well comprises an outer well pipe and an inner well pipe which are sequentially arranged from outside to inside, the pipe walls of the upper end and the lower end of the outer well pipe are each provided with a plurality of screen holes, a separator is arranged between the inner well pipe and the outer well pipe and located between the first screen holes and the second screen holes, the aerator pipe extends into the lower portion of the inner well pipe, and the exhaust pipe is communicated with the top of the circulating well; and the pumping well is located near the circulating well, the well wall of the lower end of a pumping well pipe is provided with screen holes, and a pumping pipe opening in the pumping well pipe is slightly lower than the underground water level. The underground water repairing method is an operation method for carrying out remediation on a remediation site based on the remediation system. Based on the specific structure arrangement of the circulating well, underground water can achieve inside-outside three-dimensional circulation of the circulating well, the influence radius of the circulation can be enlarged in cooperation with the pumping well, and the repairing effect is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

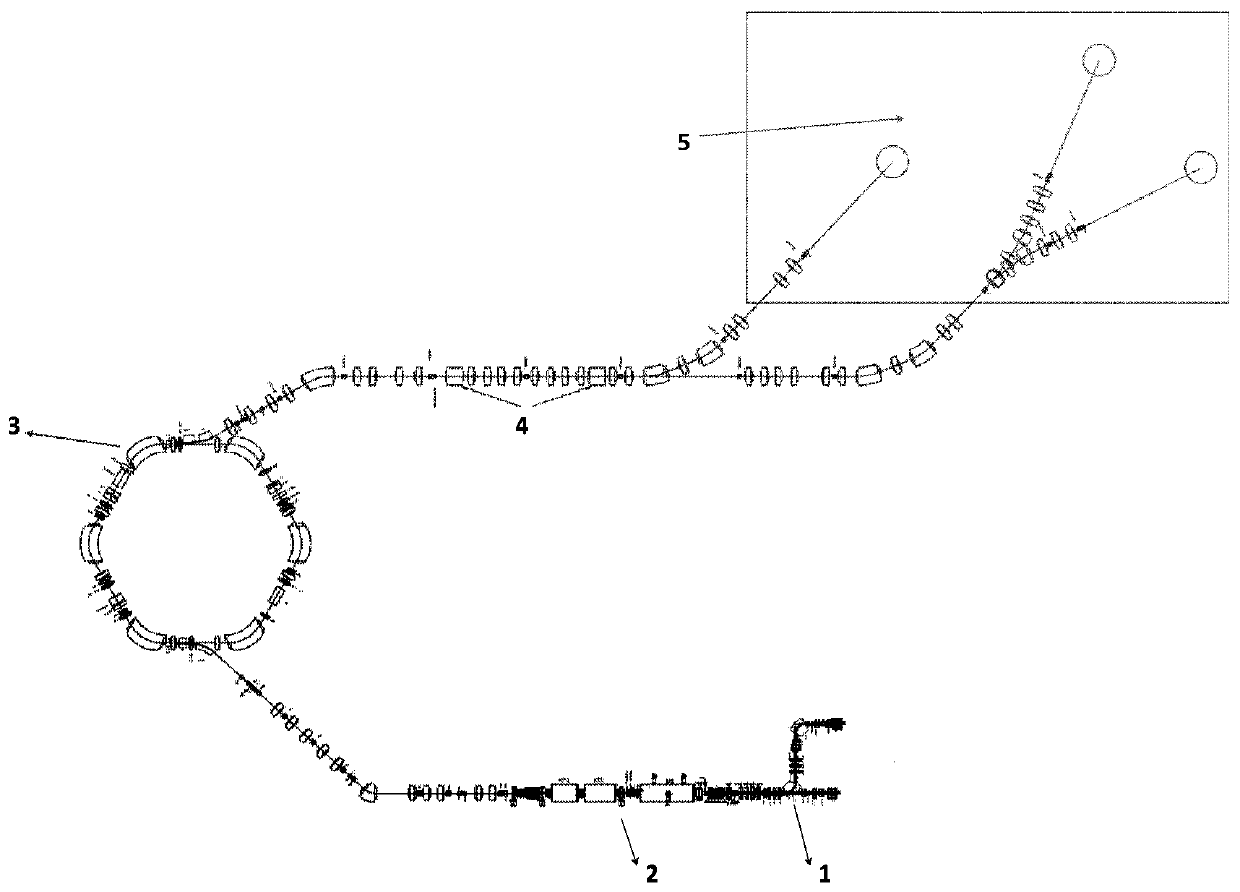

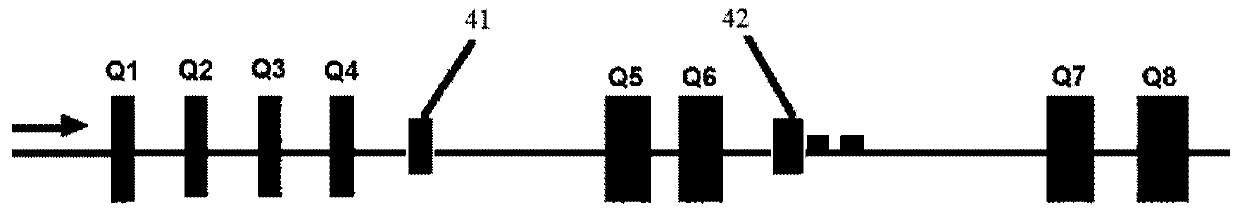

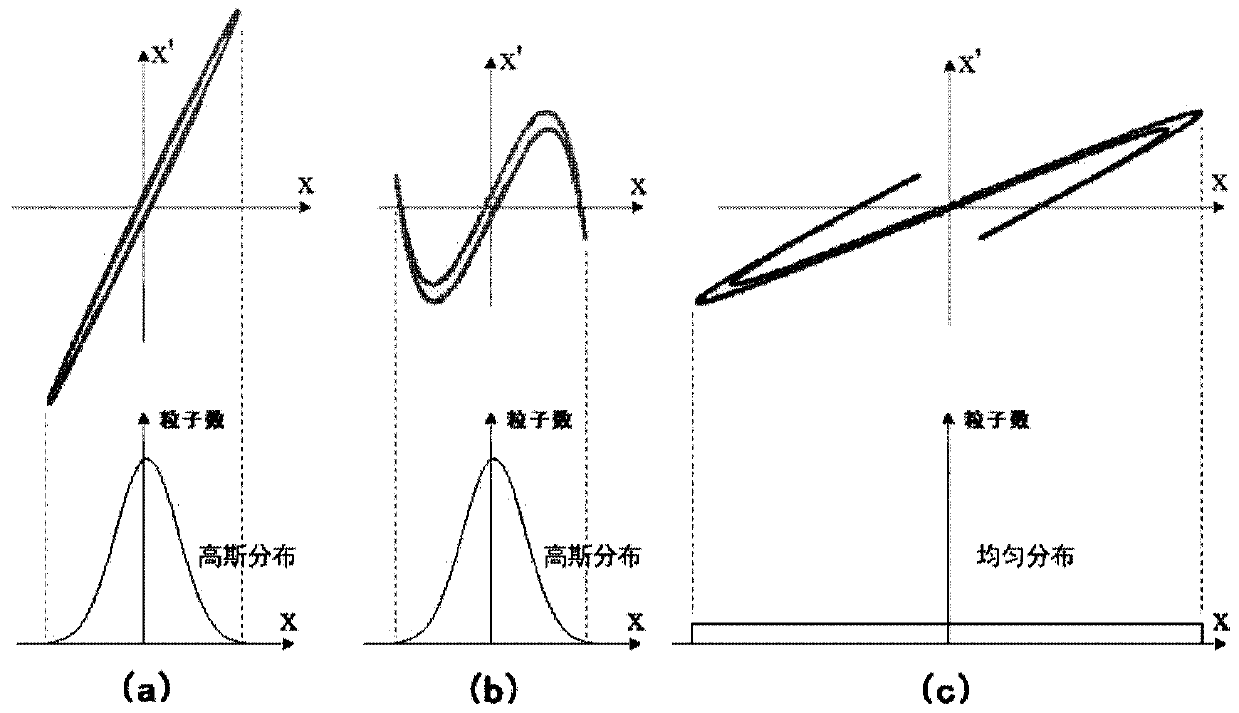

Fast cycle synchrotron with homogeneous transverse beam current, and accelerator system

ActiveCN109842986AShorten the cycle timeIncreased average beam intensityMagnetic resonance acceleratorsCapacitanceElectricity

The invention provides a fast cycle synchrotron with a homogeneous transverse beam current. The fast cycle synchrotron comprises a plurality of magnets, a magnet power supply, a vacuum pipeline, a beam current diagnostic unit and an ion extraction unit, wherein the plurality of magnets are used for synchronously accelerating ions, and the plurality of magnets comprises a two-pole magnet, a quadrupole magnet and a six-pole magnet; the magnet power supply is electrically connected with the magnets; the vacuum pipeline is configured to connect the plurality of magnets and limit moving trajectories of the ions; the beam current diagnostic unit is configured to monitor operating states of the accelerator and the beam current; and the ion extraction unit is connected to the vacuum pipeline, is used for extracting the accelerated ions and comprises a nonlinear multi-pole magnet arranged on an ion beam line, and the nonlinear multi-pole magnet is used for homogenizing the extracted beam current. The synchrotron adopts a full-capacitance energy storage magnet power supply technology, combines a multi-pole magnet transverse beam current homogenization technology, shortens the cycle period and greatly improves the average beam current intensity.

Owner:惠州离子科学研究中心 +1

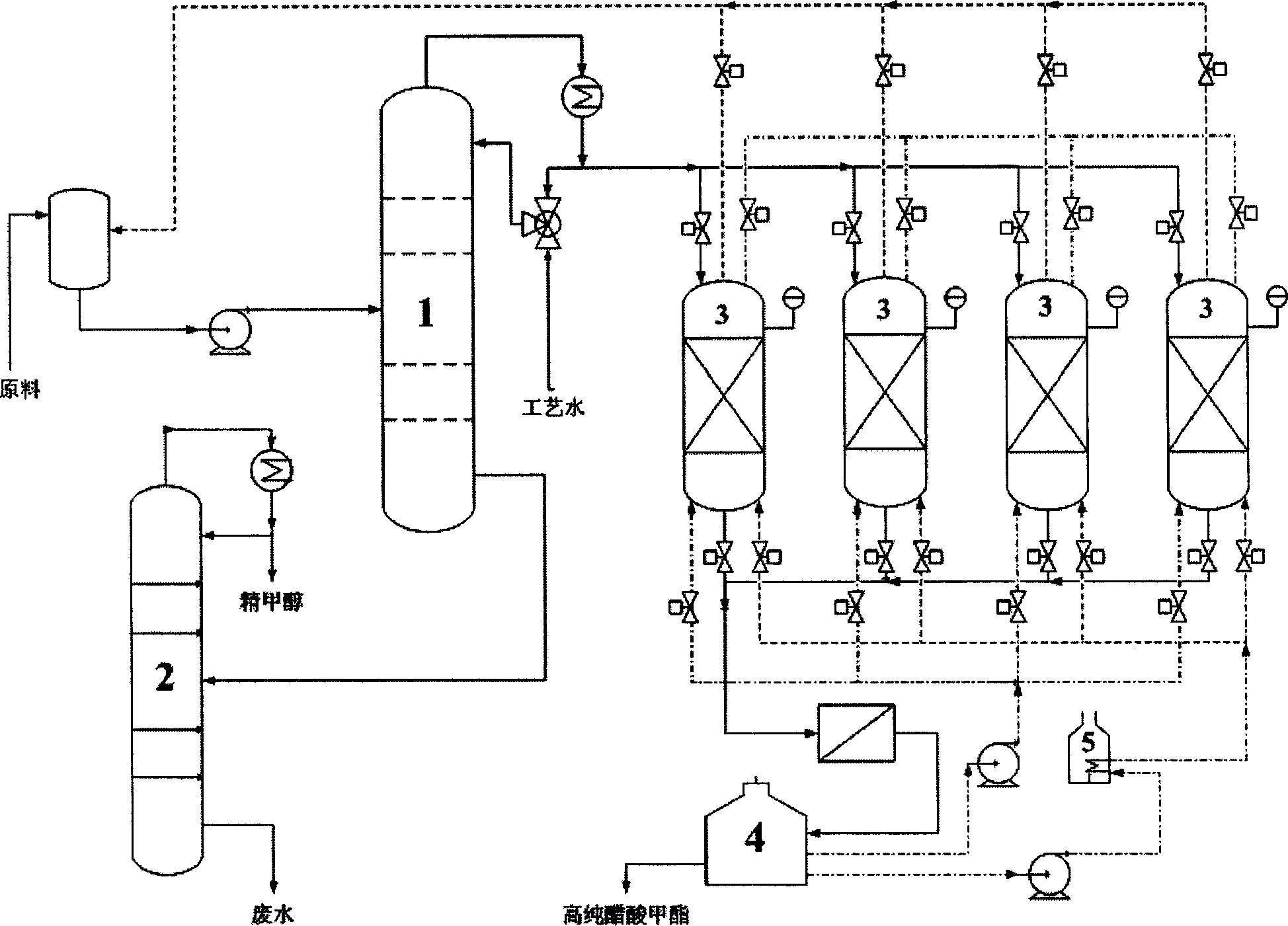

Method for preparing high pure methyl acetate through adsorption of liquid phase

InactiveCN1687002AHigh yieldShorten the cycle timeOrganic compound preparationCarboxylic acid esters preparationAlcoholDesorption

The present invention utilizes the processes of extraction rectification, liquid-phase adsorption, variable temperature purge desorption regeneration and methyl alcohol rectification to conveniently and high-effectively prepare high-purity methyl acetate with high value from industrial waste liquid (gas) containing methyl acetate, at the same time, said invention can obtain another main components in waste liquid (gas)-methyl alcohol.

Owner:TSINGHUA UNIV

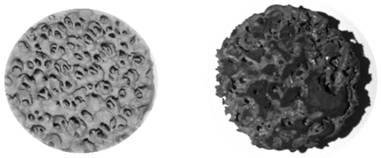

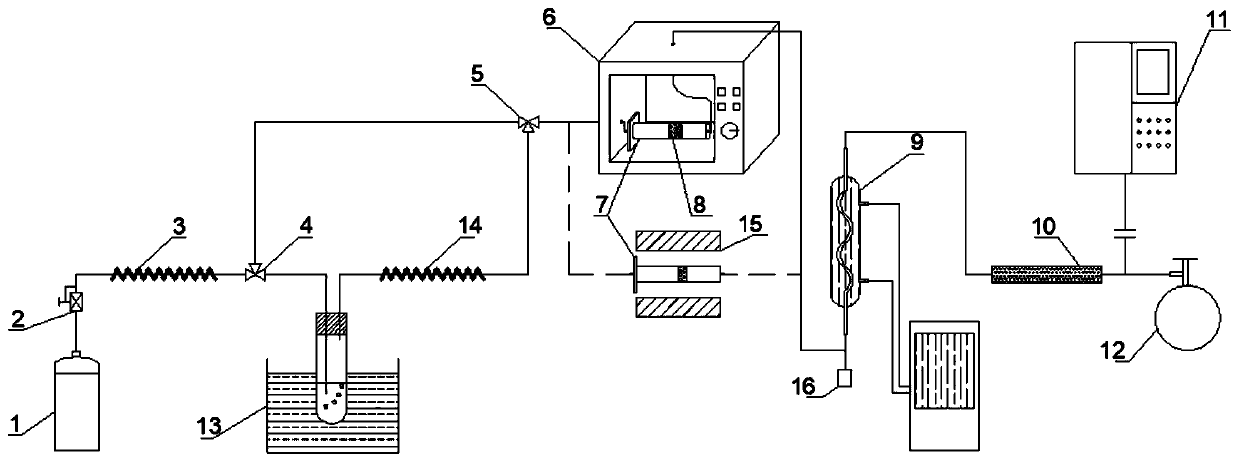

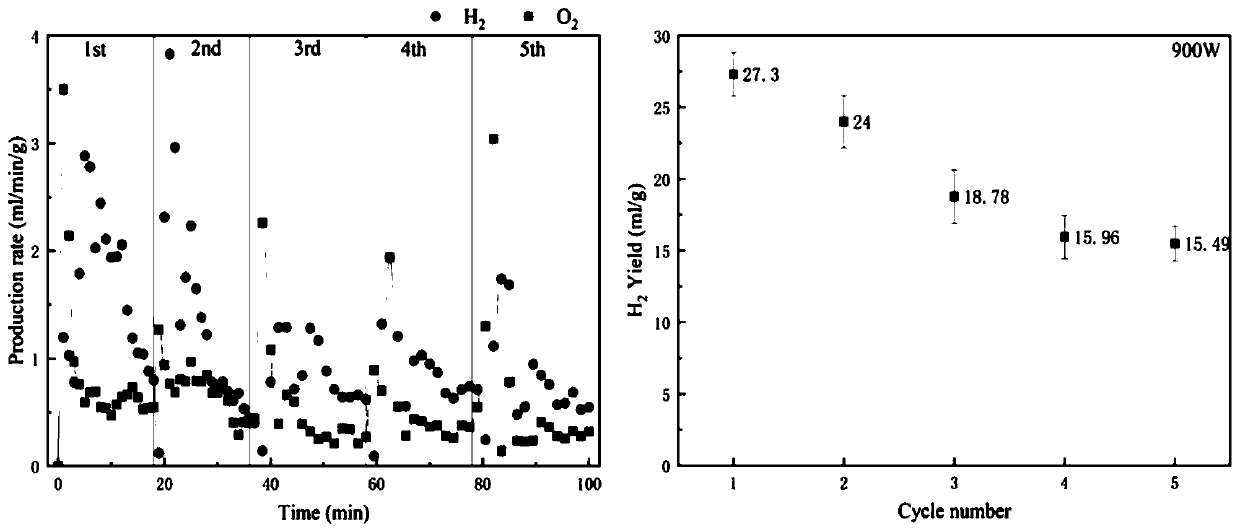

Thermochemical hydrogen production system based on microwave heating and hydrogen production method and application thereof

ActiveCN111302302ARealize continuous regenerationSolve the problem of long heat treatment timeHydrogen productionThermodynamicsMicrowave pyrolysis

The invention belongs to the technical field of thermochemical hydrogen production, and particularly relates to a thermochemical hydrogen production system based on microwave heating and a hydrogen production method and application thereof. A hydrogen production device is characterized in that an inlet of a preheater is communicated with a carrier gas storage device, a flow controller is arrangedbetween the preheater and the carrier gas storage device, an outlet of the preheater is respectively communicated with an inlet of the steam generator and one end of a second three-way valve through afirst three-way valve, the other two ports of the second three-way valve are respectively communicated with an outlet of a superheater and an inlet of the reactor, the reactor is arranged in a microwave generation device, an outlet of the steam generator is communicated with the outlet of the superheater through a pipeline, an outlet of the reactor, a condenser, a drying device and a collecting device are sequentially communicated, and a chromatographic instrument is arranged on the communicating pipeline between the drying device and the collecting device. The microwave pyrolysis of the metal oxide is short in heating time, low in power consumption and low in experiment cost, the repeated experiment period is shortened, and the effective energy utilization rate is greatly improved.

Owner:SHANDONG UNIV

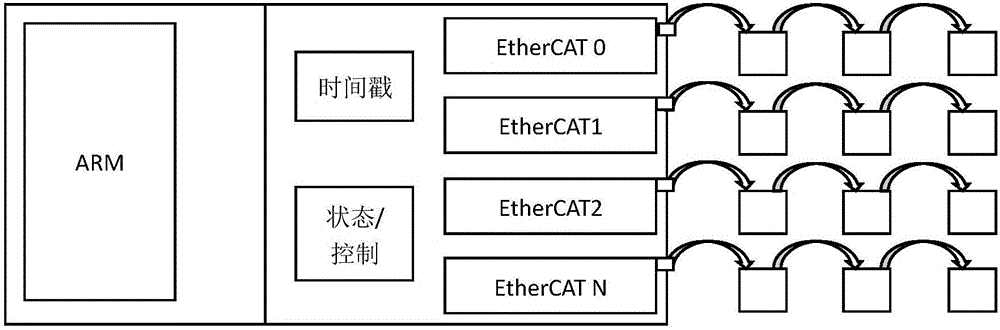

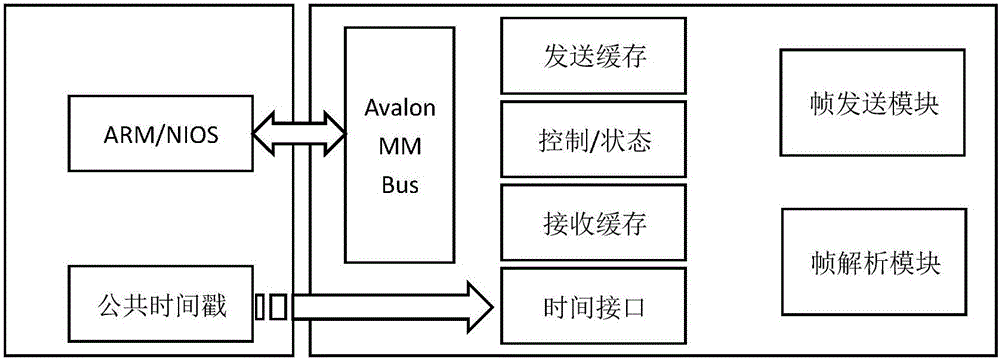

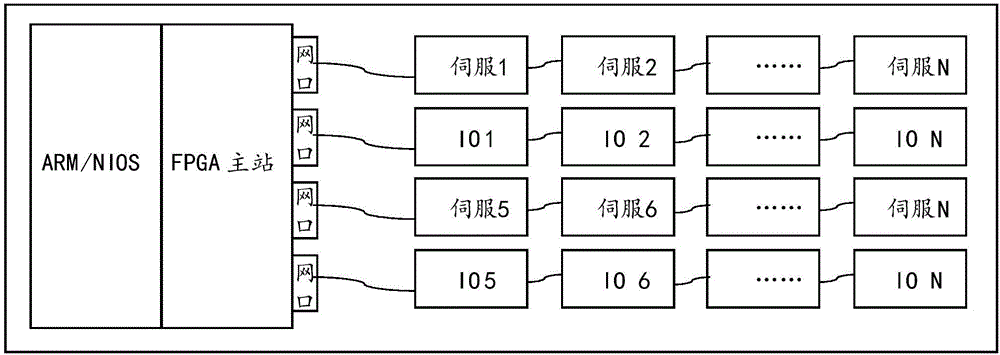

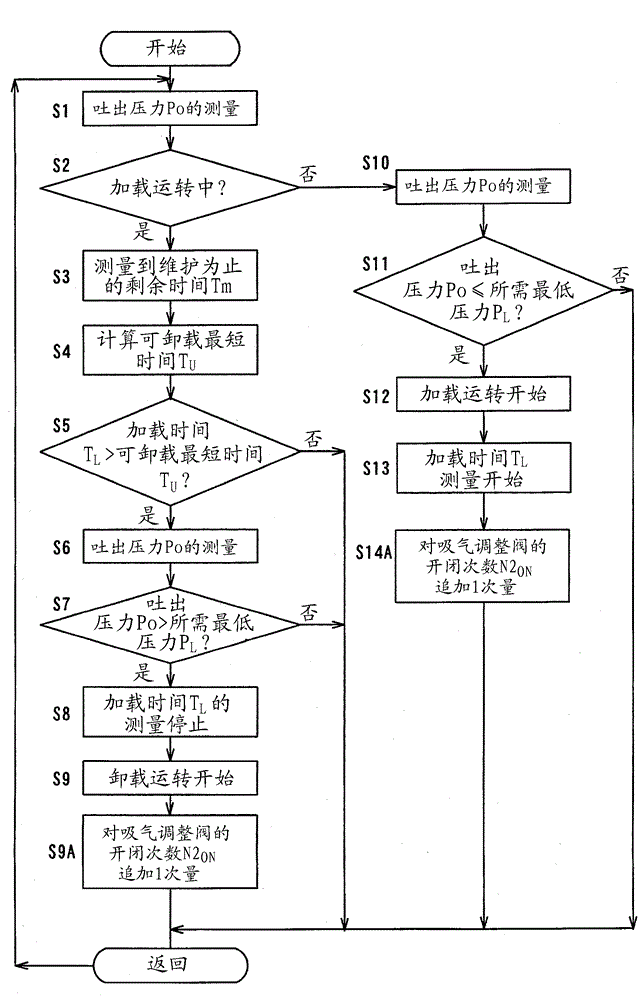

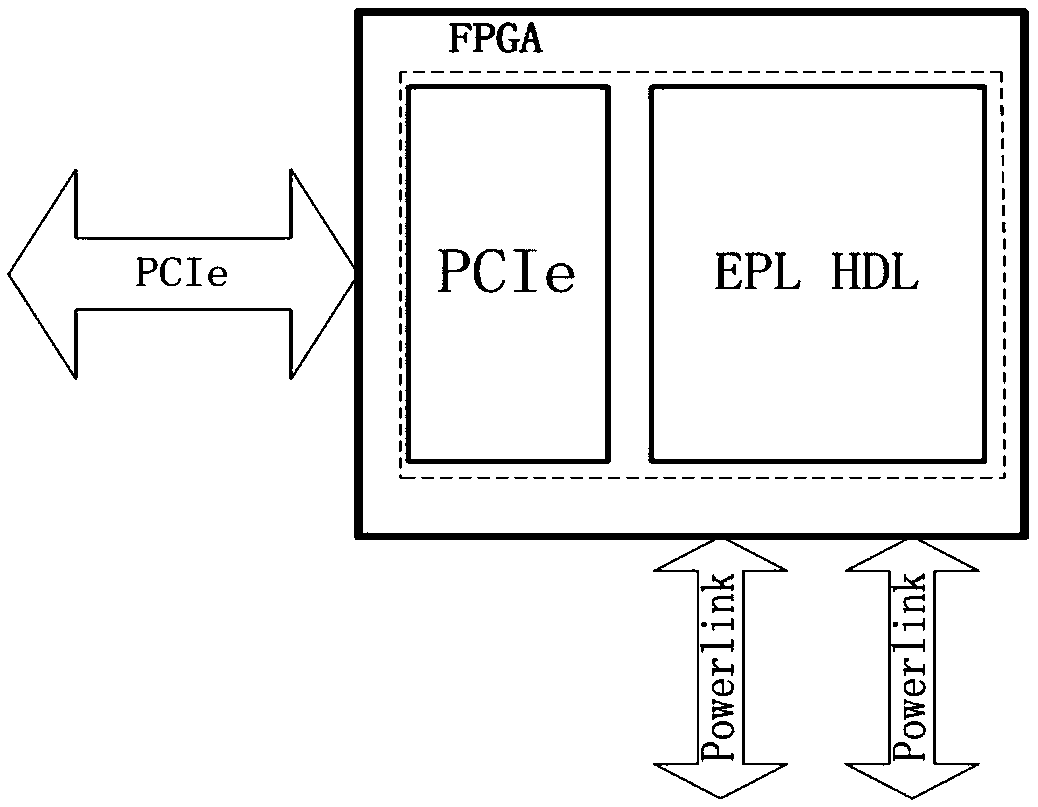

Site synchronization system and method for industrial Ethernet

ActiveCN106230541AEasy to handleShorten the cycle timeTime-division multiplexBus networksIndustrial EthernetOperational system

The invention discloses a site synchronization system and method for an industrial Ethernet, wherein the problem of inaccurate time due to jittering of an operating system and a protocol stack can be solved; a process for a processor to process packet sending and unpacking is avoided by sending a packet in a timed manner and analyzing a received industrial Ethernet packet in real time; the processing capability of the whole system is improved; the problem of low real-time processing capability due to jittering of the operating system and a software protocol stack can be solved; a timing function of a master station can also be provided; and synchronous operation between slave stations can be cooperative. The site synchronization system and method for the industrial Ethernet disclosed by the invention comprise: a clock counter is set in an FPGA; the master station is connected to a main control processor; a reference clock parameter is provided for the master station by the clock counter; the master station is used for performing clock synchronization through the reference clock parameter sent by the clock counter, and also used for sending a clock synchronization packet to the corresponding slave station; and the slave station corresponding to the master station is used for performing clock synchronization according to the clock synchronization packet sent by the master station. The site synchronization system and method disclosed by the invention are suitable for site control.

Owner:深圳市骏龙电子有限公司

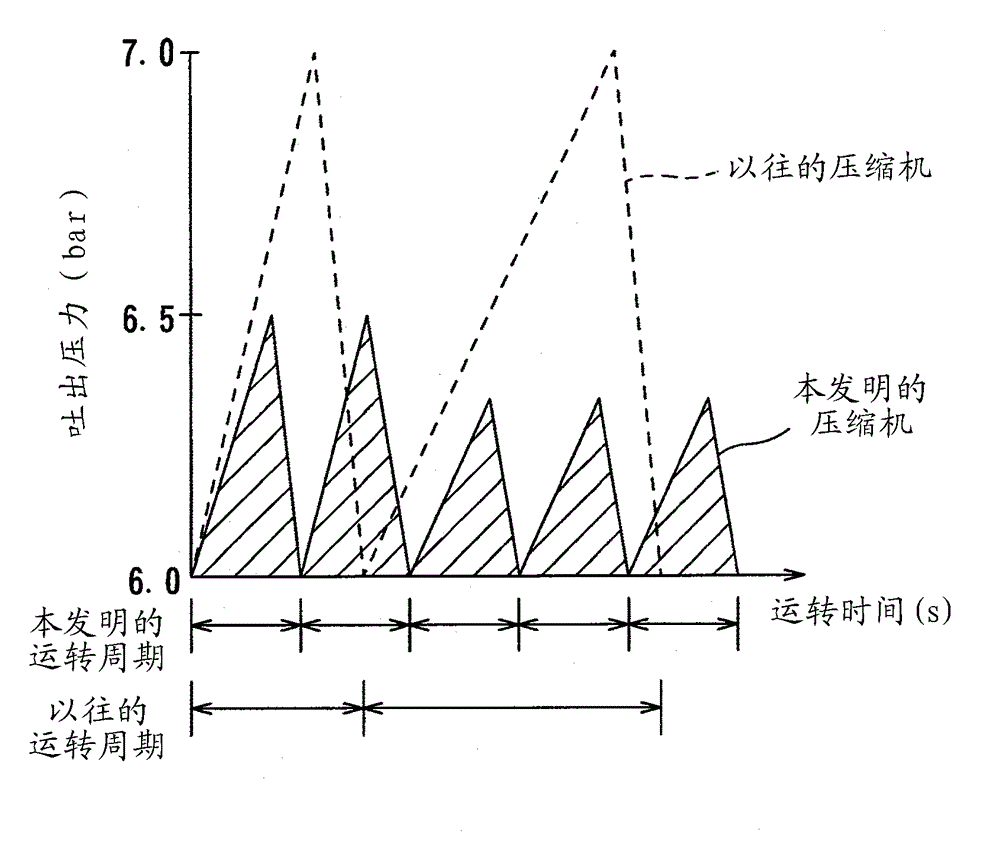

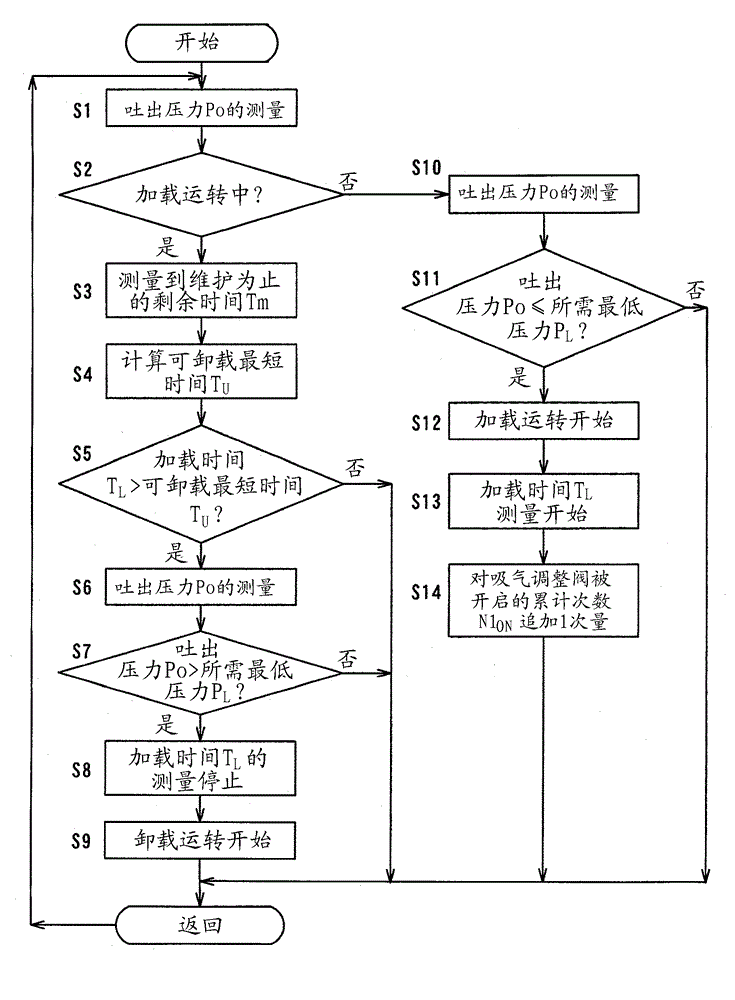

Compressor and pressure control method thereof

ActiveCN104421142AShorten the cycle timeSmall boostPump controlPositive-displacement liquid enginesEngineeringDischarge pressure

The invention provides a compressor and a pressure control method thereof, which can shorten the operation period, suppress the boosting during the loading operation, and perform the operation in an energy-saving way. The compressor includes an intake flow path (2), a suction adjusting valve (4) maintained after specified operation, a maintenance time measuring mechanism (11), a work time measuring mechanism (13), a loading operation time measuring mechanism (12), and a control mechanism (18) for switching the opening or closing of the suction adjusting valve. When the loading operation is under a discharge pressure greater than the lowest pressure required by the discharge side, the control mechanism switches the operation to unloading operation if the loading operation time measuring mechanism measures that the time lasting from the starting of the loading operation exceeds the shortest time for unloading. The shortest time for unloading is determined based on the residual time of the suction adjusting valve maintenance, the allowed work frequencies of the suction adjusting valve, and the cumulative work frequencies of the suction adjusting valve.

Owner:코벨코컴프레서가부시키가이샤

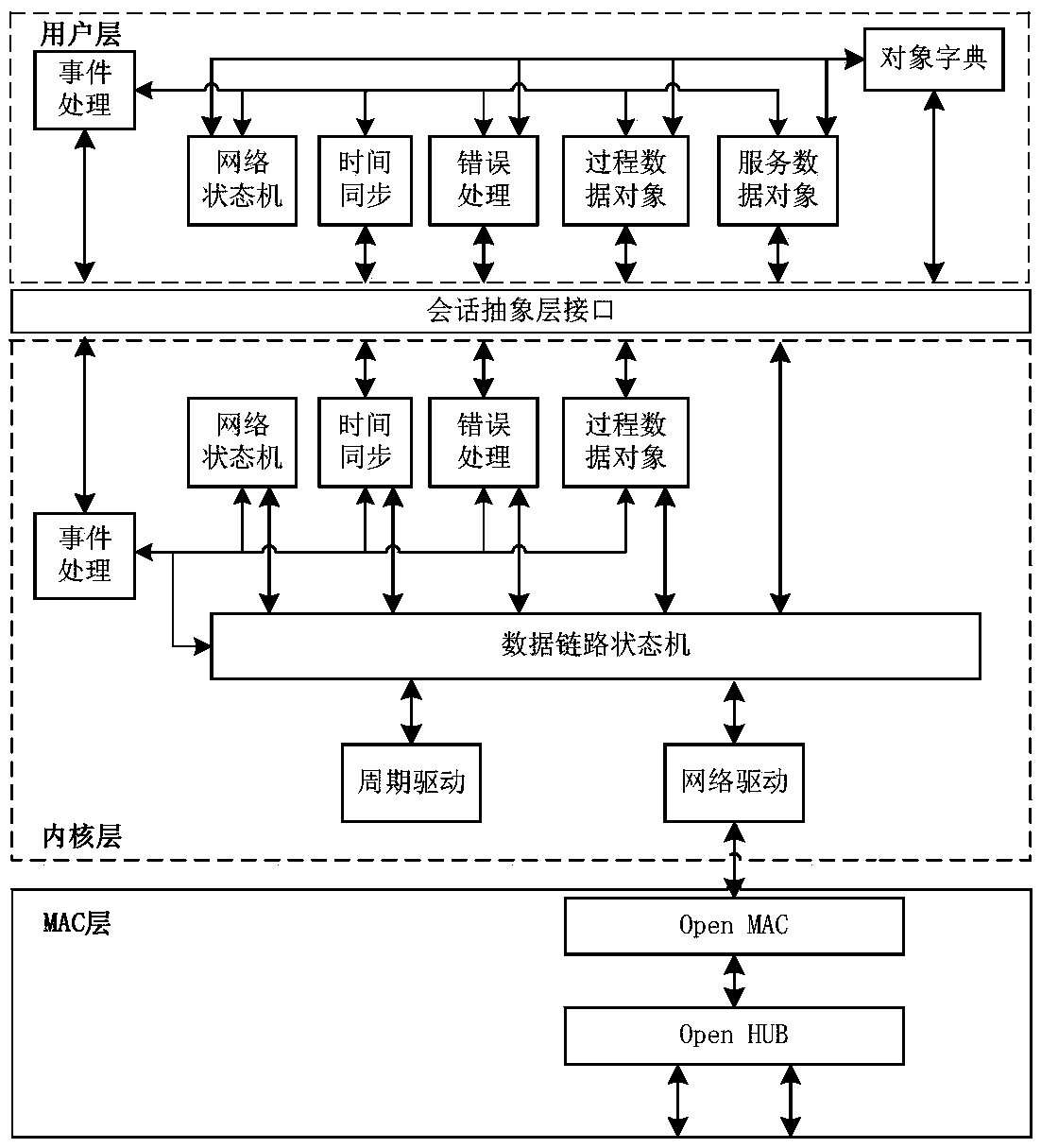

Design method of master/slave station cards for implementing Powerlink industrial real-time Ethernet communication

ActiveCN108833241AGuaranteed stabilityImprove real-time performanceBus networksMegabyteMaster station

The invention discloses a design method of master / slave station cards for implementing Powerlink industrial real-time Ethernet communication. The master / slave station cards can be configured to be a Powerlink industrial real-time Ethernet communication master station card or slave station card. During the designing process, a kernel layer and an MAC layer of a Powerlink protocol stack are constructed inside an FPGA and a CAL driver is also constructed and is connected with the kernel layer. When the master / slave station cards are used, a gold finger is inserted into an upper computer main board CAL mother base and the upper computer operates the CAL interface driver and a user layer and an application program of the Powerlink protocol stack. According to the invention, with the high-speedserial differential signal CAL interface inside the Powerlink protocol stack, the high-speed transmission of over one hundred megabyte as well as the signal stability is guaranteed, the communicationrate is increased, and the cycle time is shortened, so that the communication real-time performance is improved.

Owner:中工科安科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com