Full-tail paste composite material and preparation method thereof

A composite material and full tail paste technology, applied in the field of mine filling, can solve problems such as poor permeability, affecting the normal coagulation of cementitious slurry, and failure of normal coagulation of filling slurry, and achieves reliable results, convenient on-site operation, and shortened cycle time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

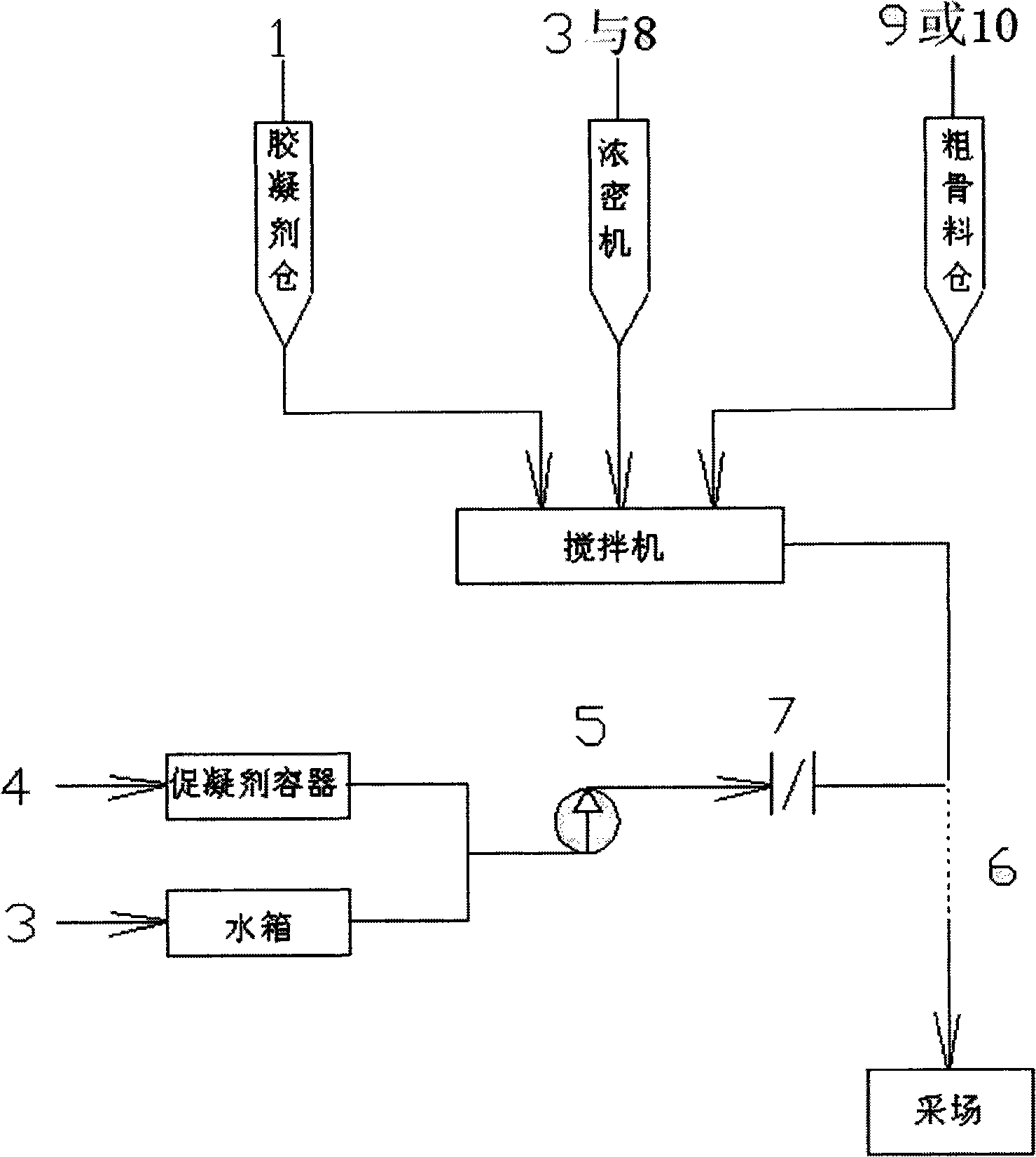

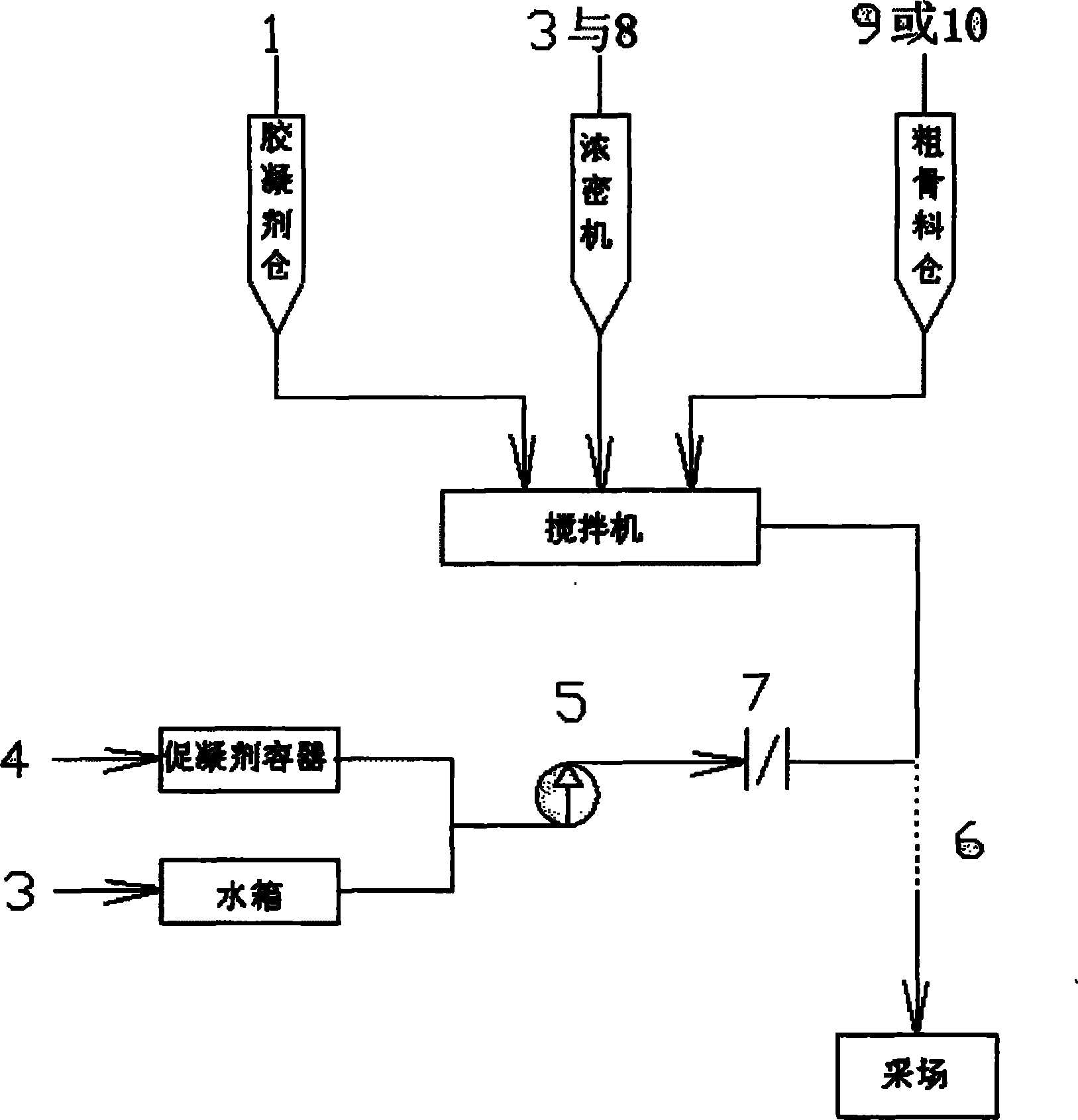

Embodiment Construction

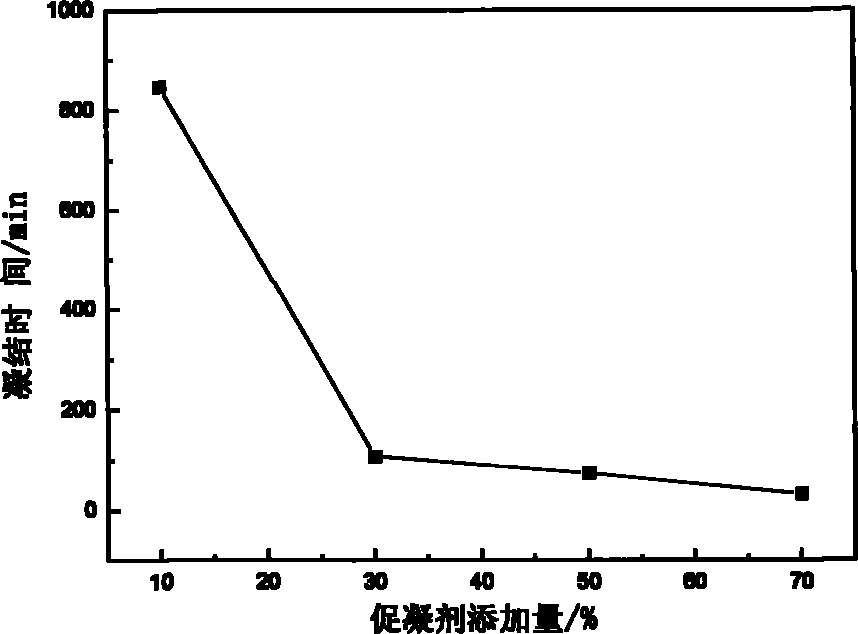

[0022] A mine uses full tailings-water quenched slag for paste filling. The fineness of the whole tailings is relatively fine, and the content of -20um is between (76% and 83%). The tailing mortar from the concentrator is flocculated and concentrated in the thickener, and then mixed with cement and water-quenched slag to prepare a paste, which is then transported to the underground stope by gravity. During the initial production stage, stope filling did not solidify many times, which affected the normal mining of nearby stopes. For this reason, various measures have been studied, including adding lime slurry, high-efficiency water reducer, and various early strength agents, but they cannot completely solve the problem of retarding the tailings. On the basis of fully analyzing the reasons for the retardation of the whole tailings, it is considered that the main reason for the retardation is that the fineness of the whole tailings is too fine, which affects the normal hydration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com