Method for preparing high pure methyl acetate through adsorption of liquid phase

A technology of methyl acetate and liquid-phase adsorption, which is applied in the product refining of acetic acid and methanol esterification to produce methyl acetate, and the field of producing high-purity methyl acetate, can solve the problems of high price, limited application, unstable performance and the like , to achieve the effect of improving production efficiency, shortening cycle period and thorough regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a method for preparing high-purity methyl acetate from waste liquid or gas containing methyl acetate. The method is to produce high-purity methyl acetate from the waste liquid (gas) containing methyl acetate by means of liquid phase adsorption and variable temperature purging desorption regeneration, and obtain by-product methanol and other solvents at the same time; or from acetic acid and methanol High-purity methyl acetate was isolated from the esterification product.

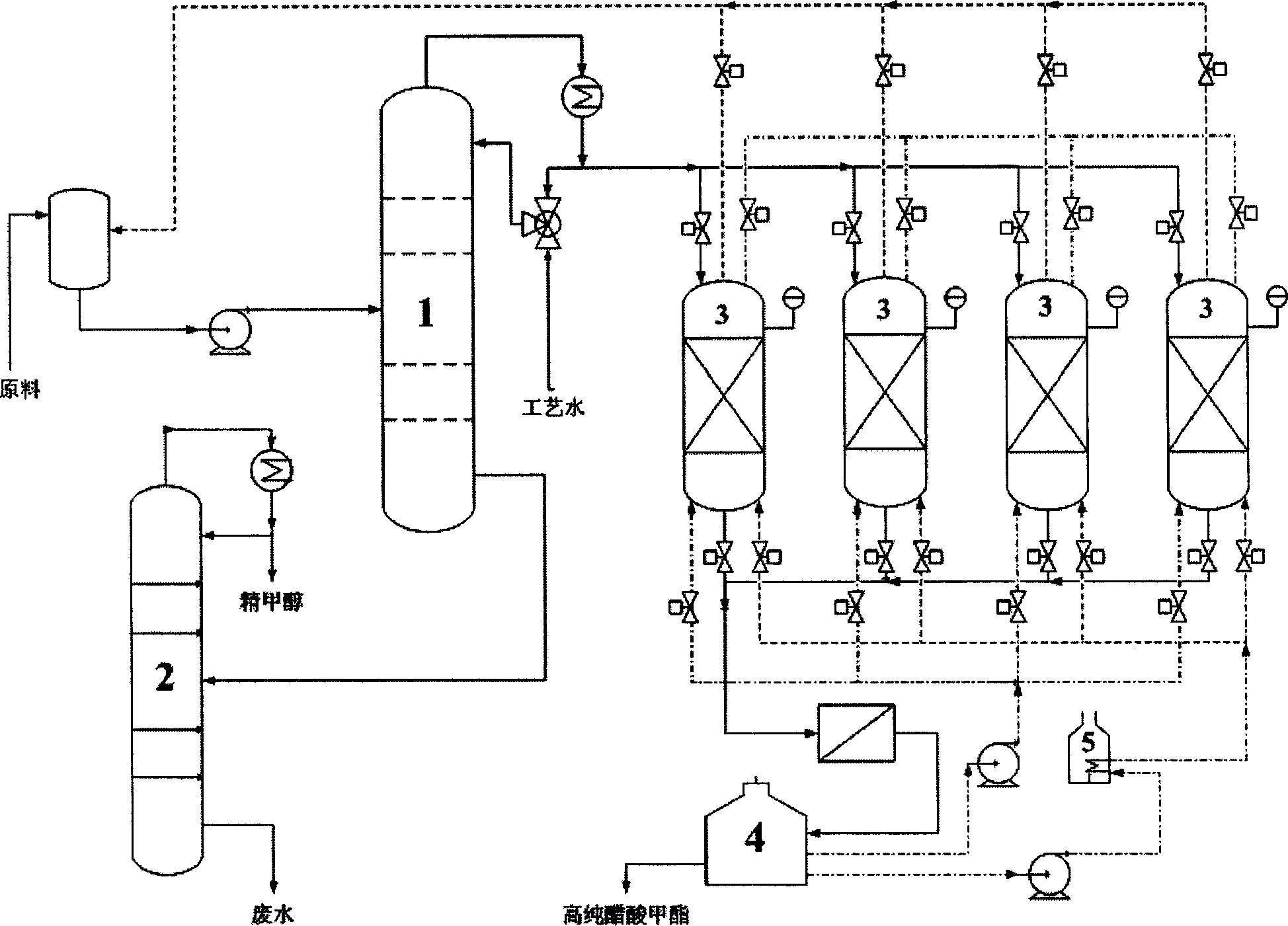

[0019] The production process of liquid phase adsorption method high-purity methyl acetate (as figure 1 shown) is:

[0020] 1). Extraction and rectification: Send the production waste liquid (gas) containing methyl acetate or the impure methyl acetate obtained after esterification of acetic acid and methanol into the methyl acetate extractive distillation tower 1, and the top of the tower is used to supplement part of the process The reflux condensate of water is used as the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com