Patents

Literature

68results about How to "Stable continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali-polishing efficient PERC battery and preparation process thereof

ActiveCN109888061AReduce usageEnvironmental protectionFinal product manufacturePhotovoltaic energy generationScreen printingSilicon dioxide

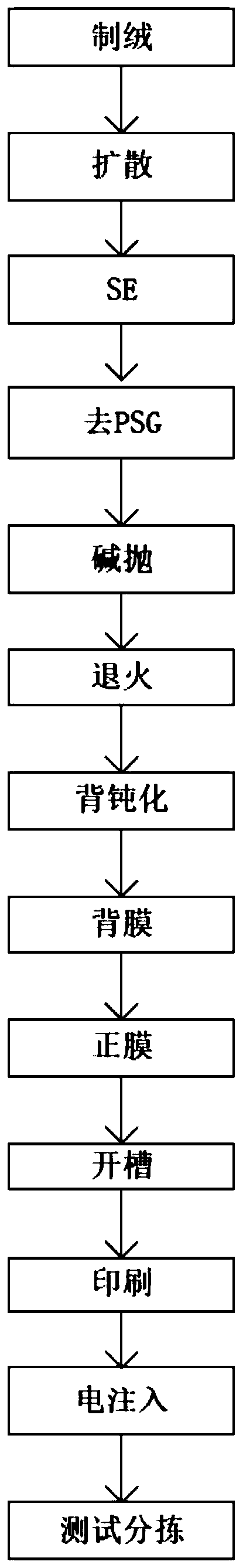

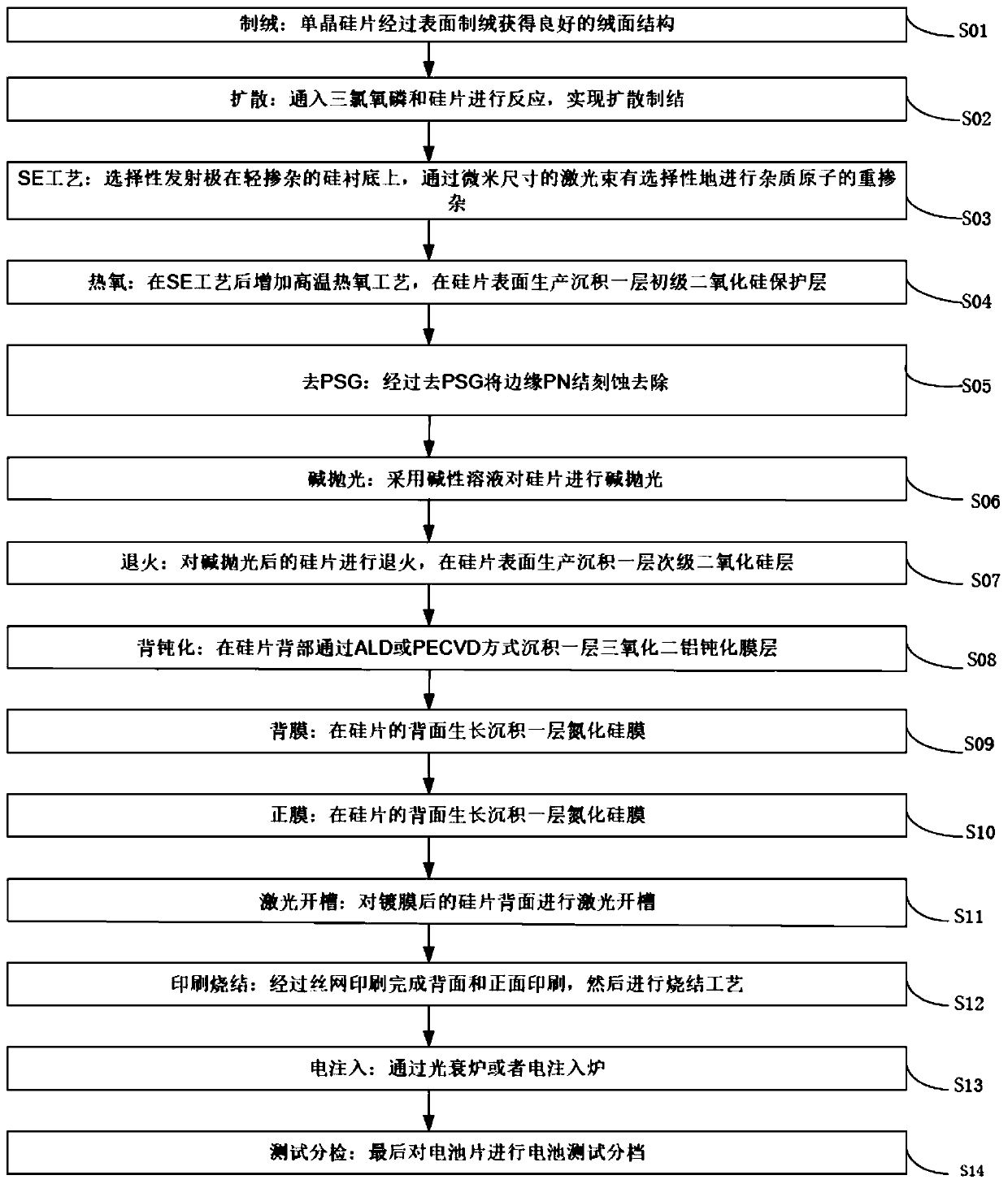

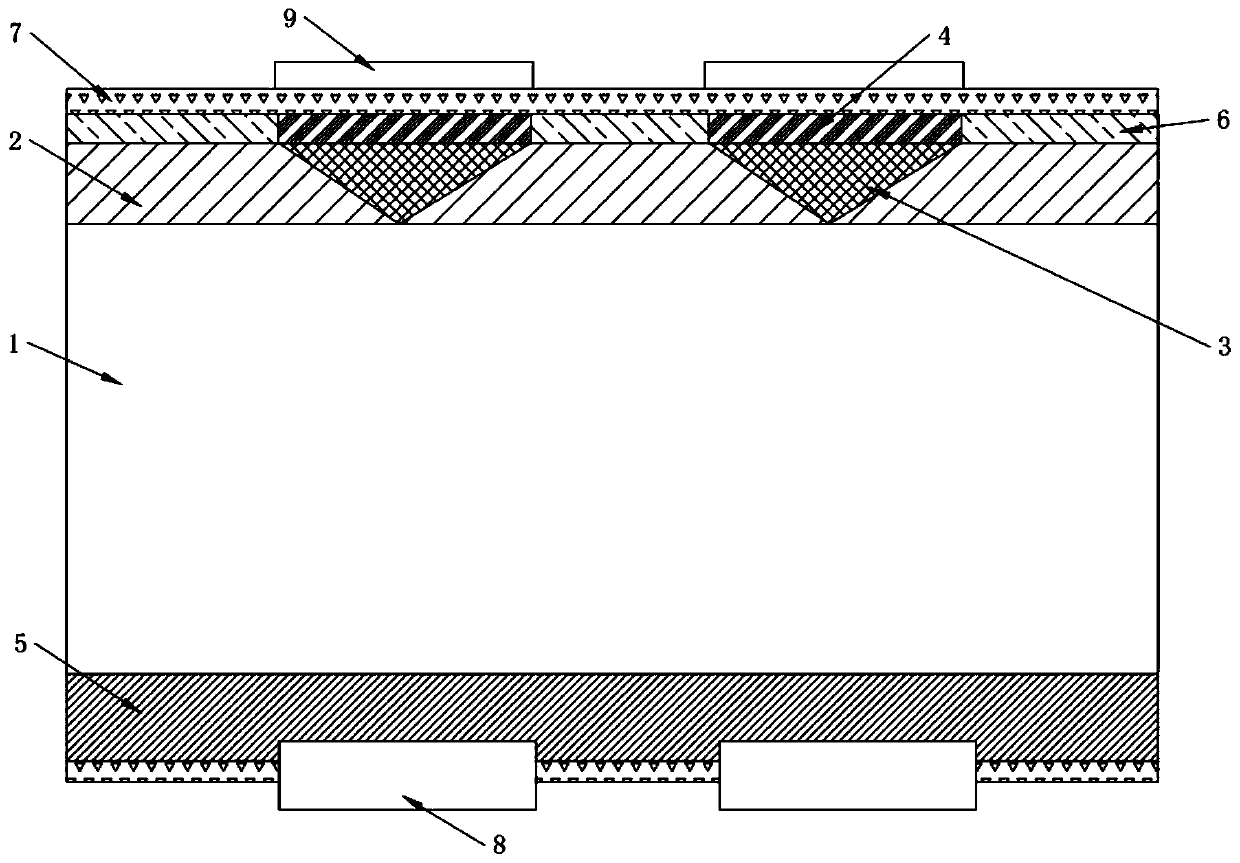

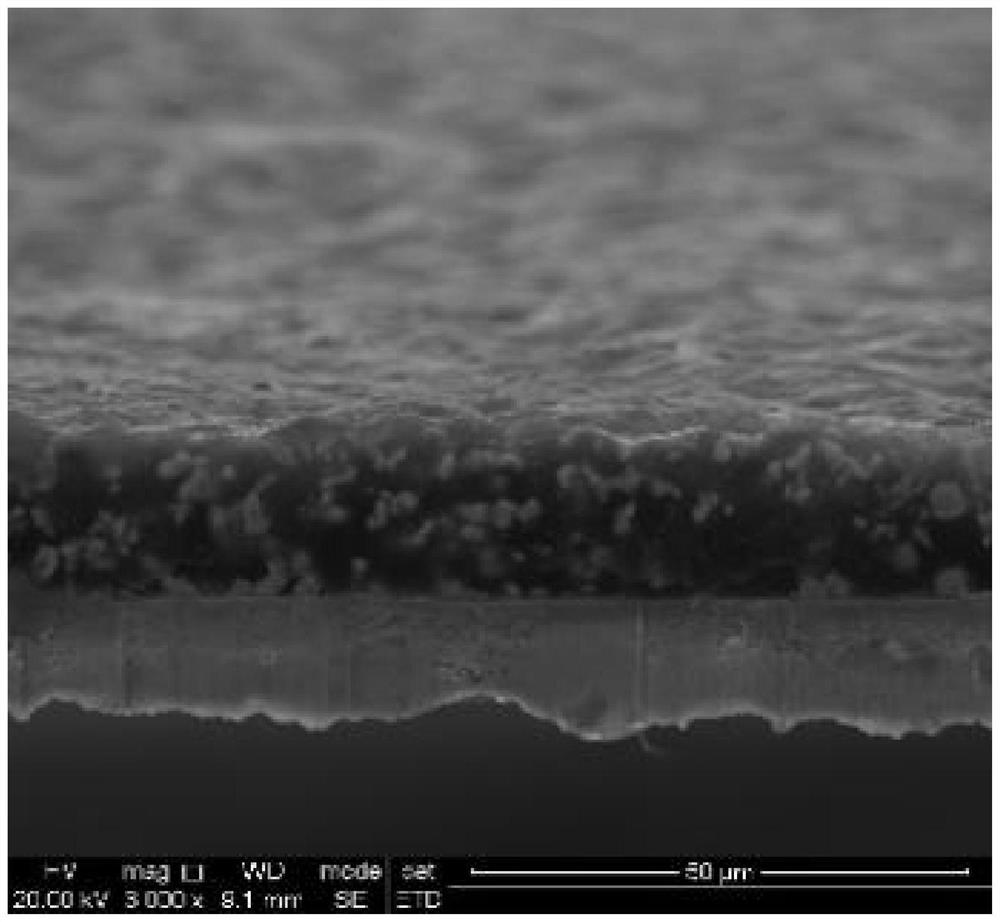

The invention discloses a preparation process of an alkali-polishing efficient PERC battery. The preparation process comprises the following steps: step S01, texturing; step S02, diffusing; step S03,SE process; step S04, thermal oxidation; step S05, removing PSG; step S06, alkali-polishing; step S07, annealing; step S08, back passivating; step S09, back film; step S10, front film; step S11, laserslotting; and step S12, printing and sintering: accomplishing the back printing and the back printing through silk-screen printing, and then performing sintering process; step S13, electric injection: electric injection: through a light attenuation furnace or an electric injection furnace; and step S14, testing and sorting: performing battery testing and sorting on the cell. The invention furtherdiscloses an alkali-polishing efficient PERC battery. By adding the high-temperature thermal oxidation process flow after the SE, a layer of silicon dioxide protection layer is grown at the front SEregion at high temperature, a pyramid textured surface of the SE region is effectively protected, and the process flow can guarantee that the stable and continuous production of the SE alkali-polishedPERC battery.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

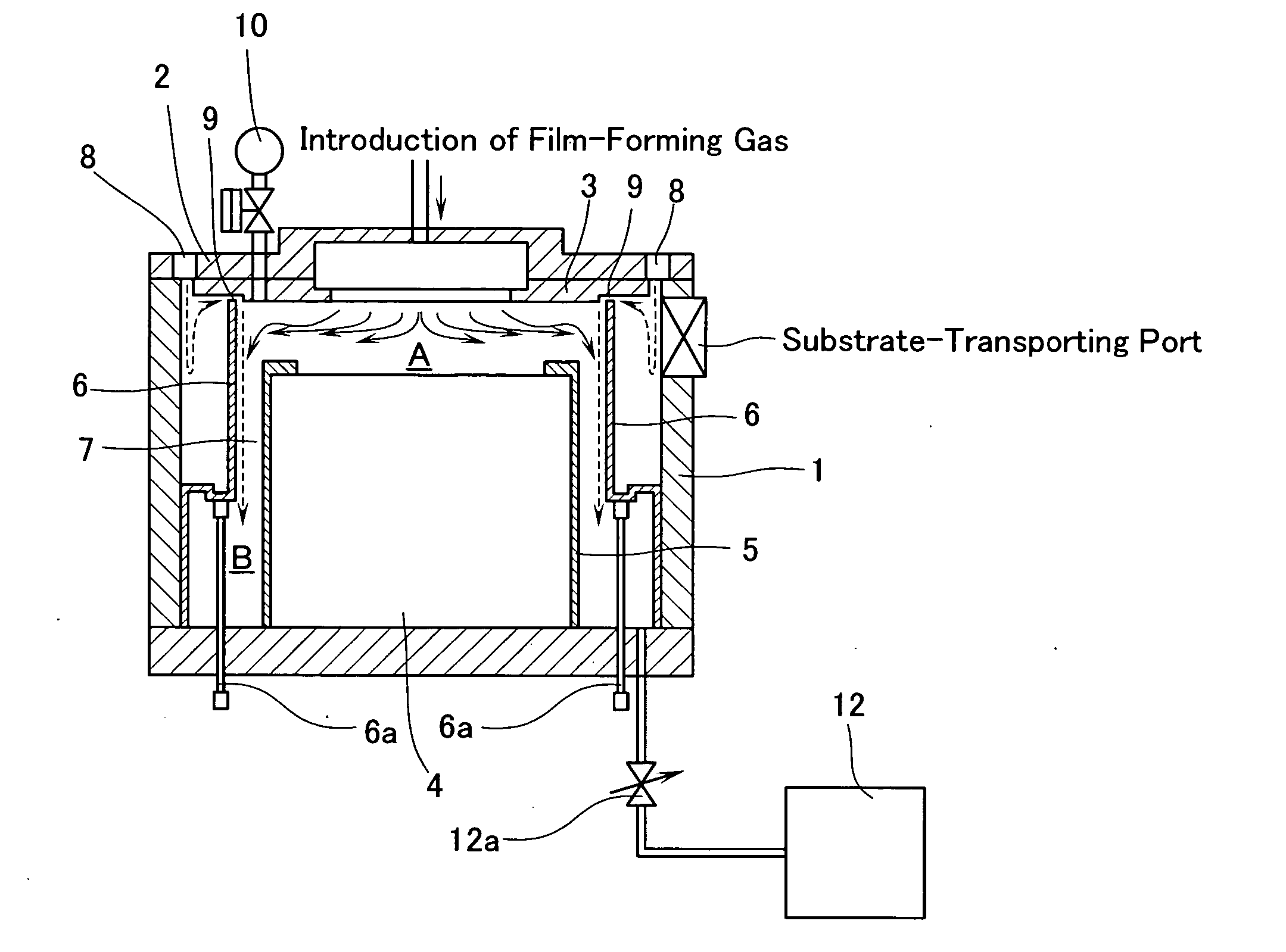

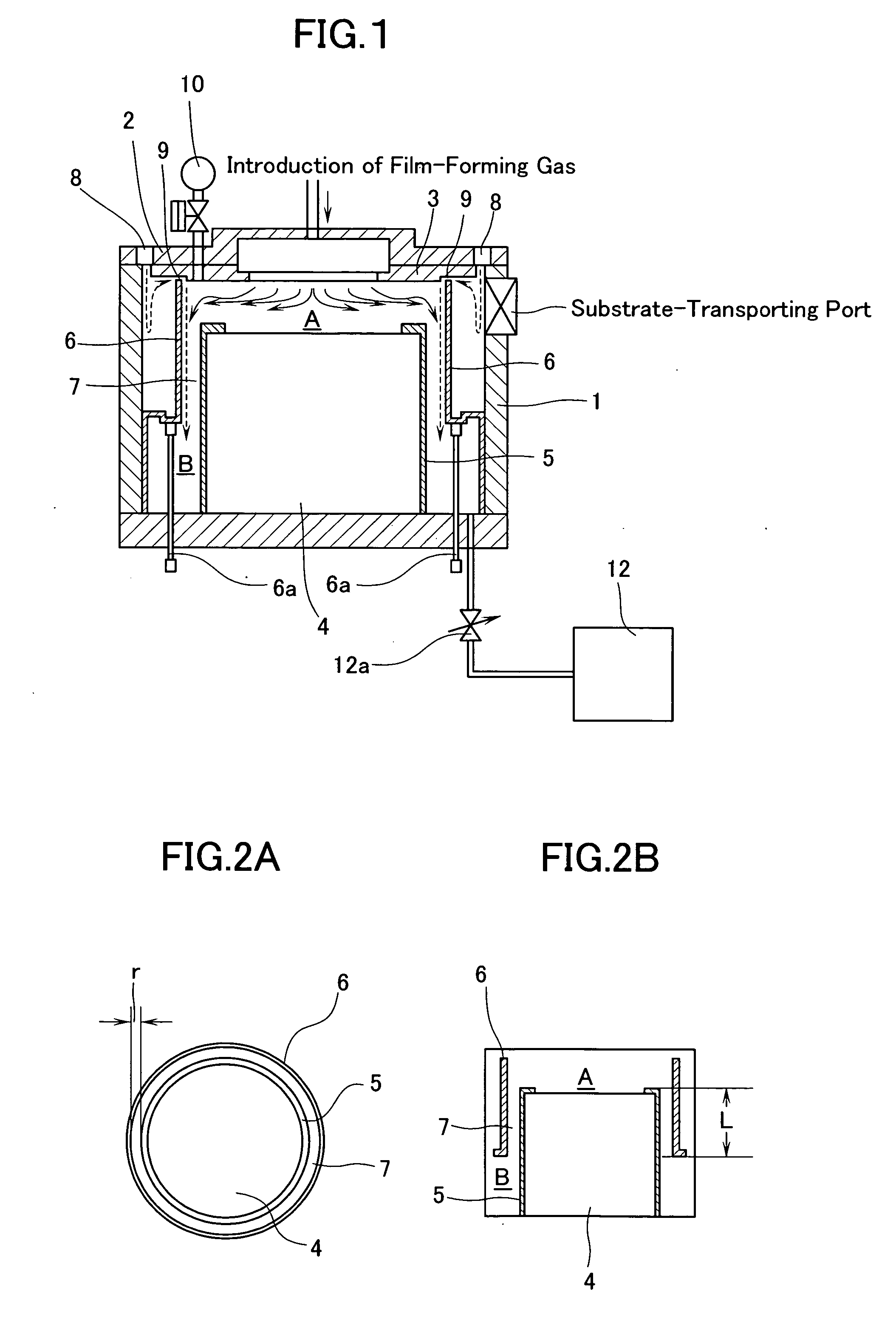

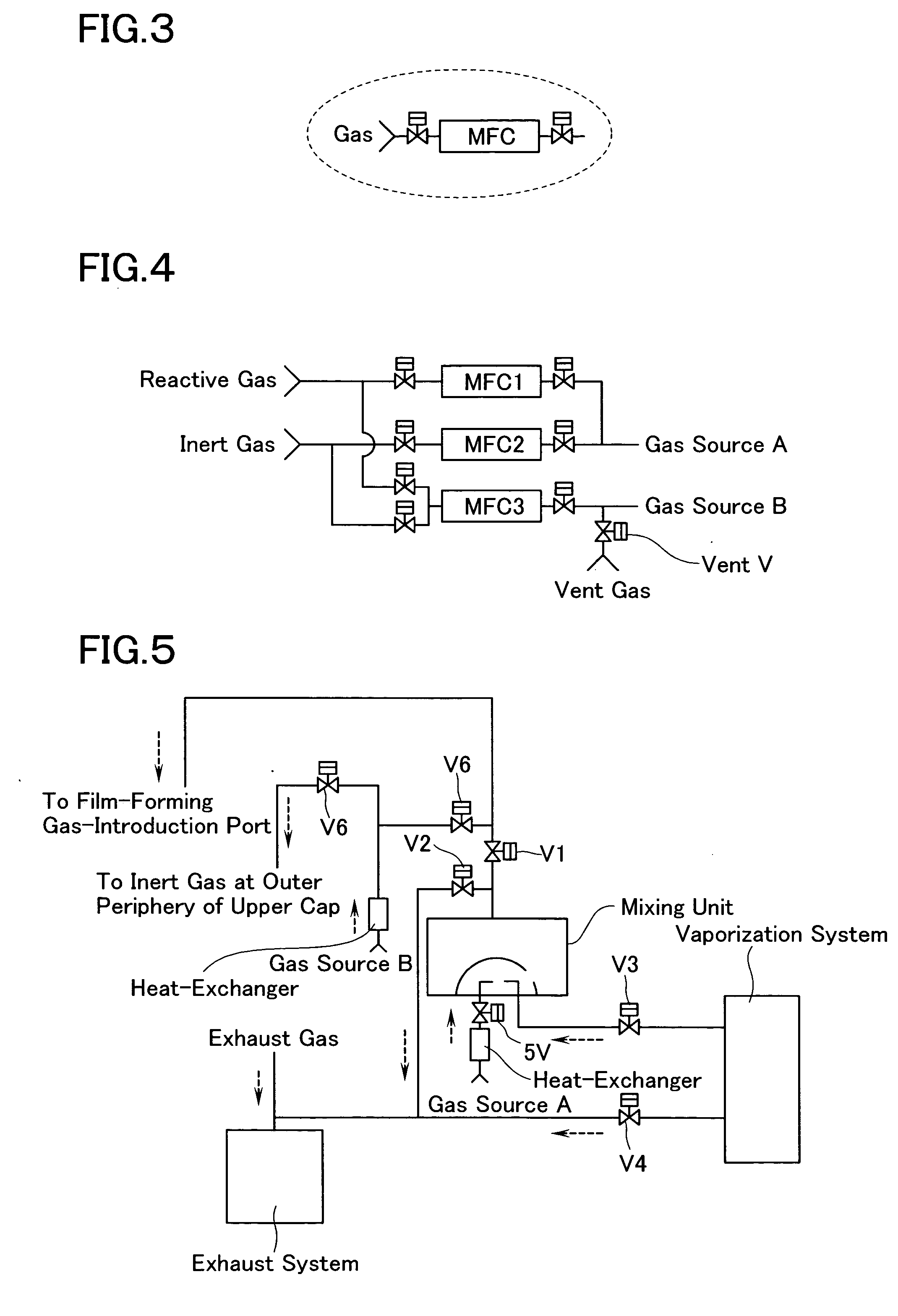

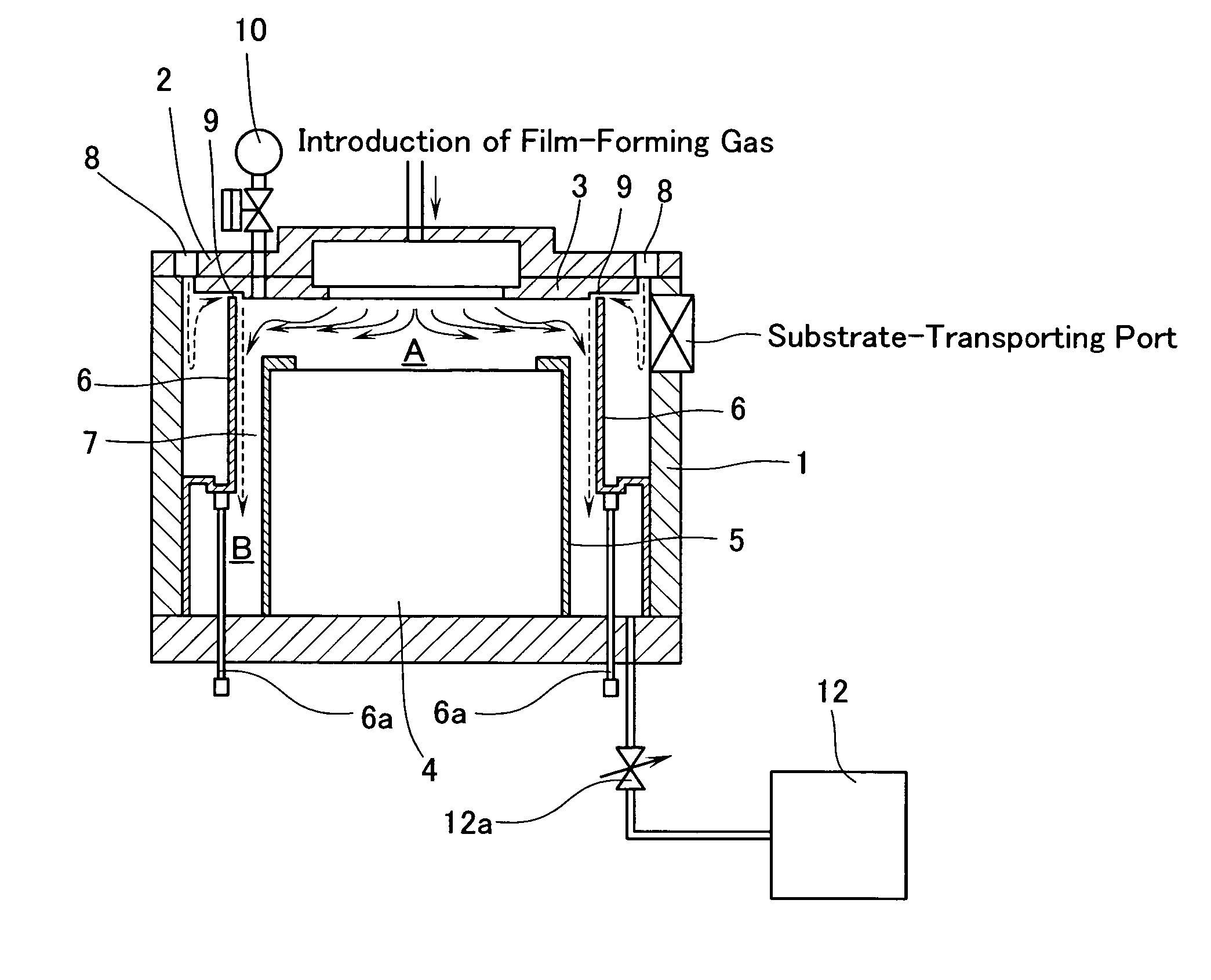

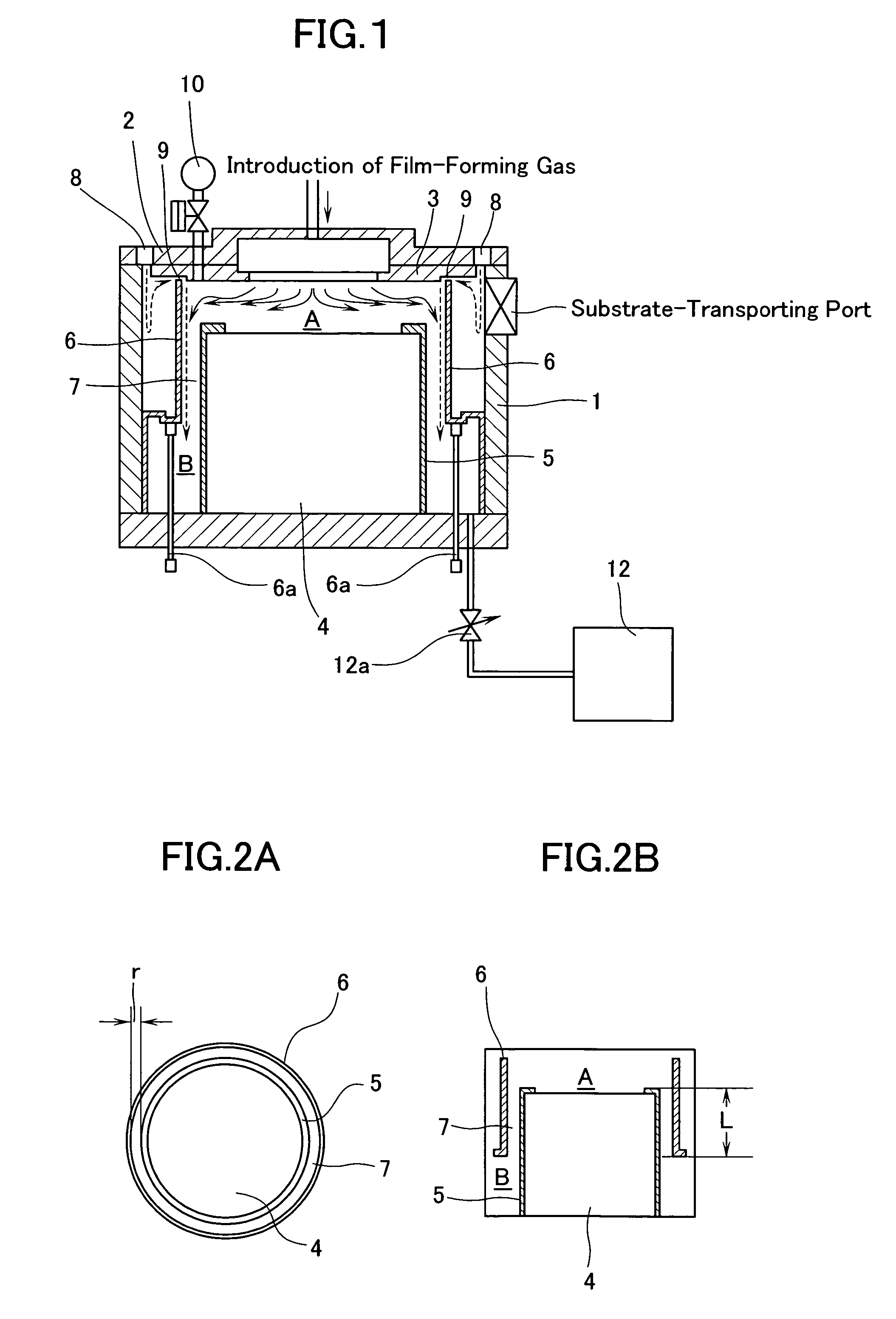

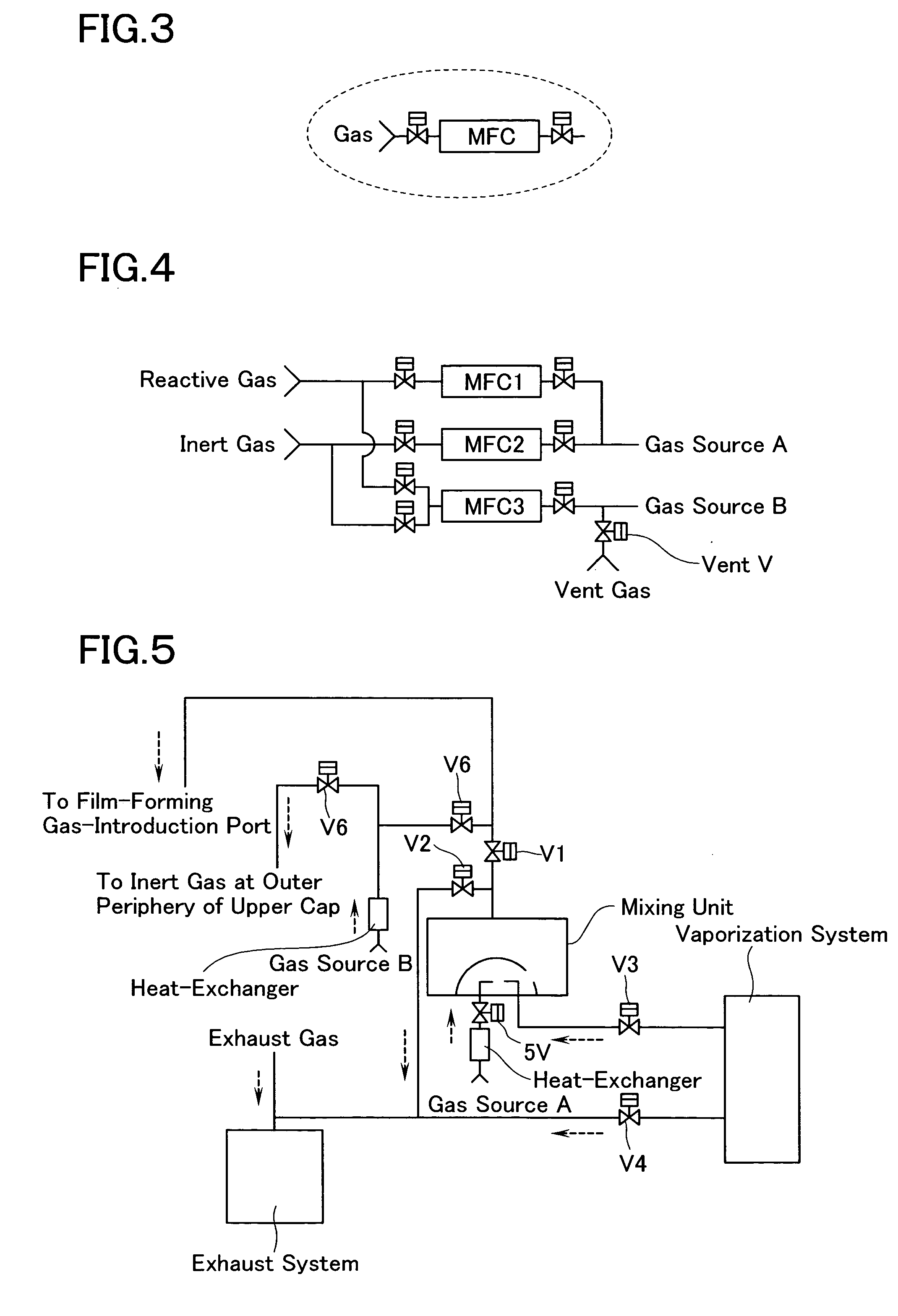

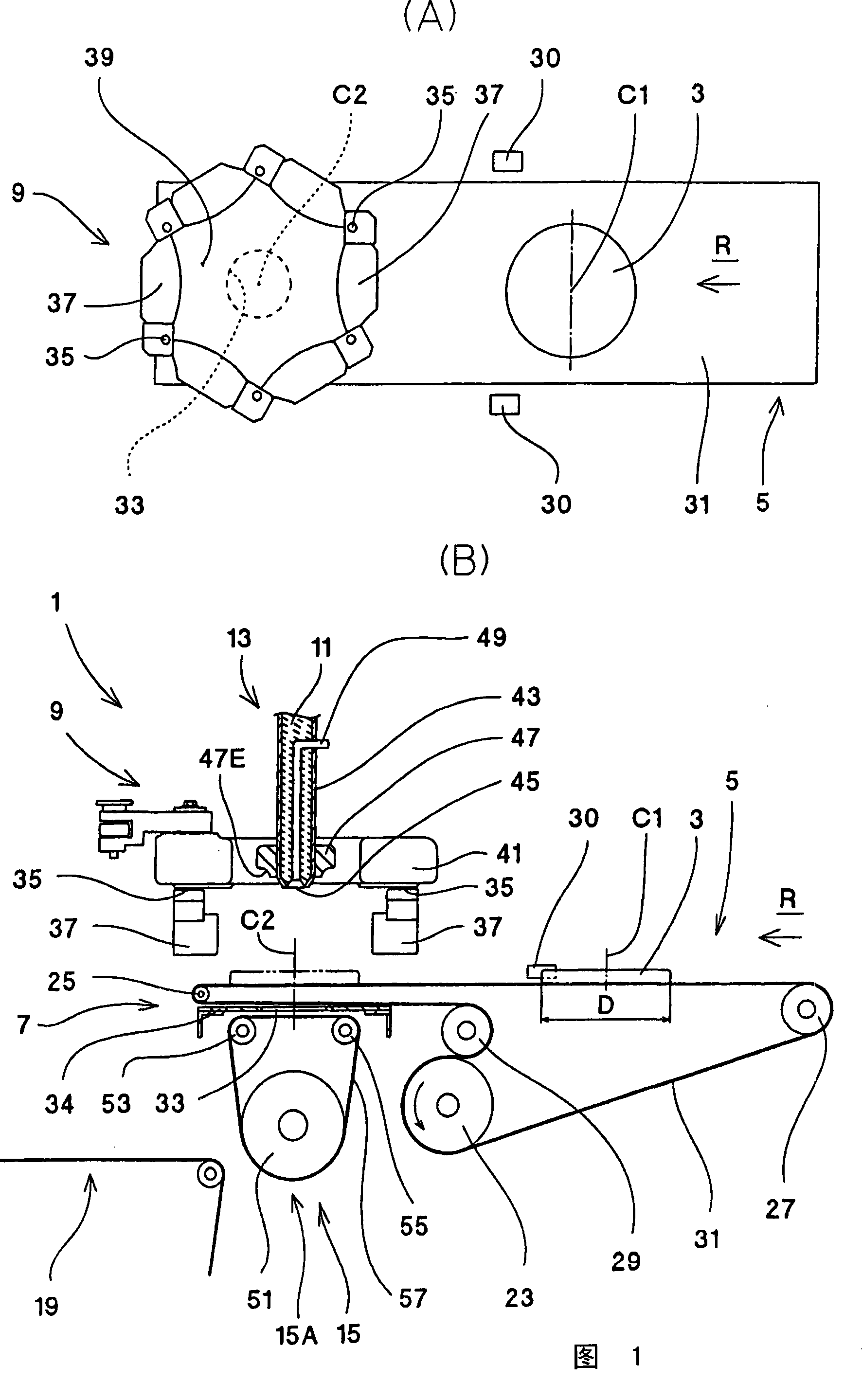

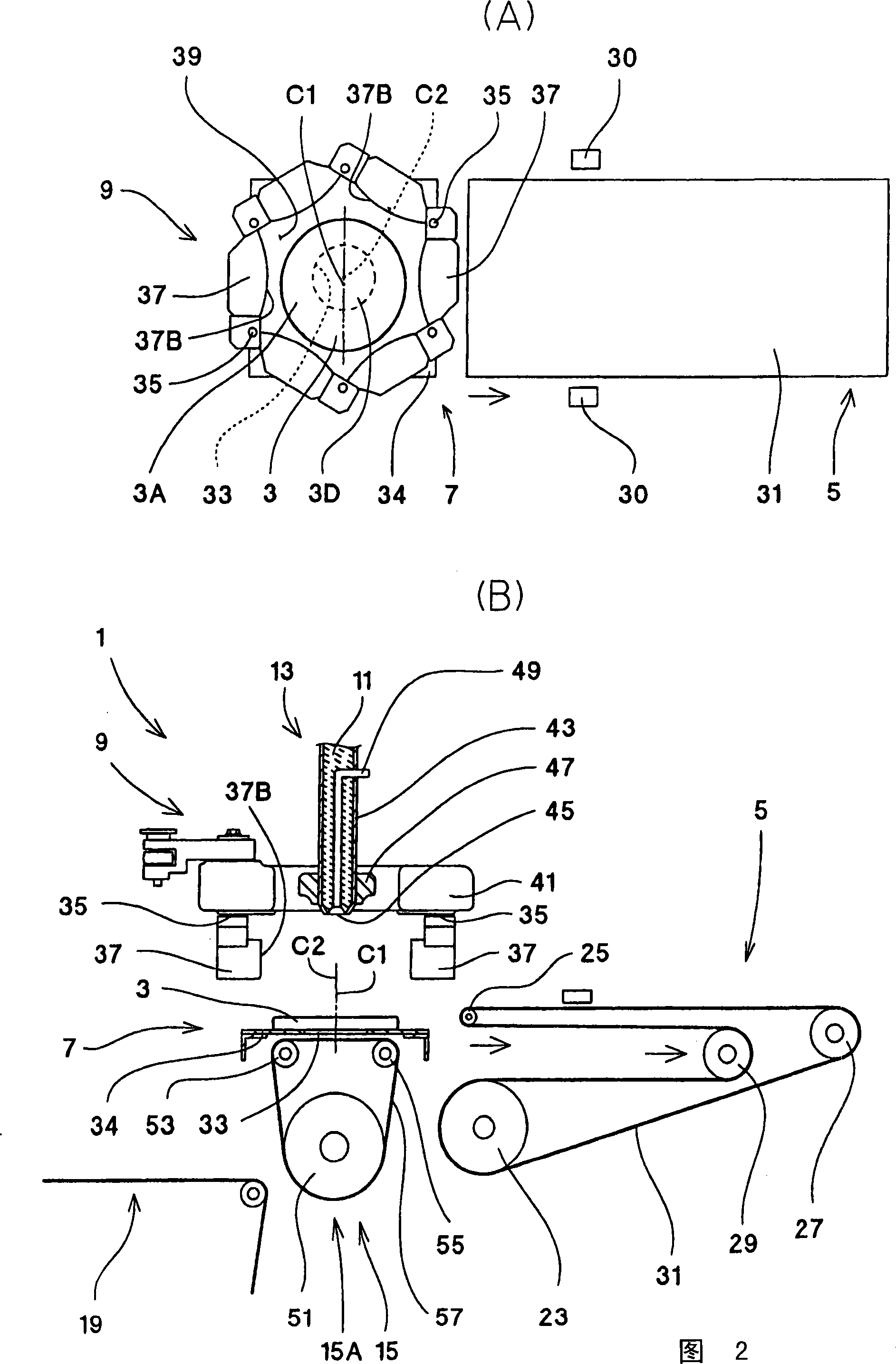

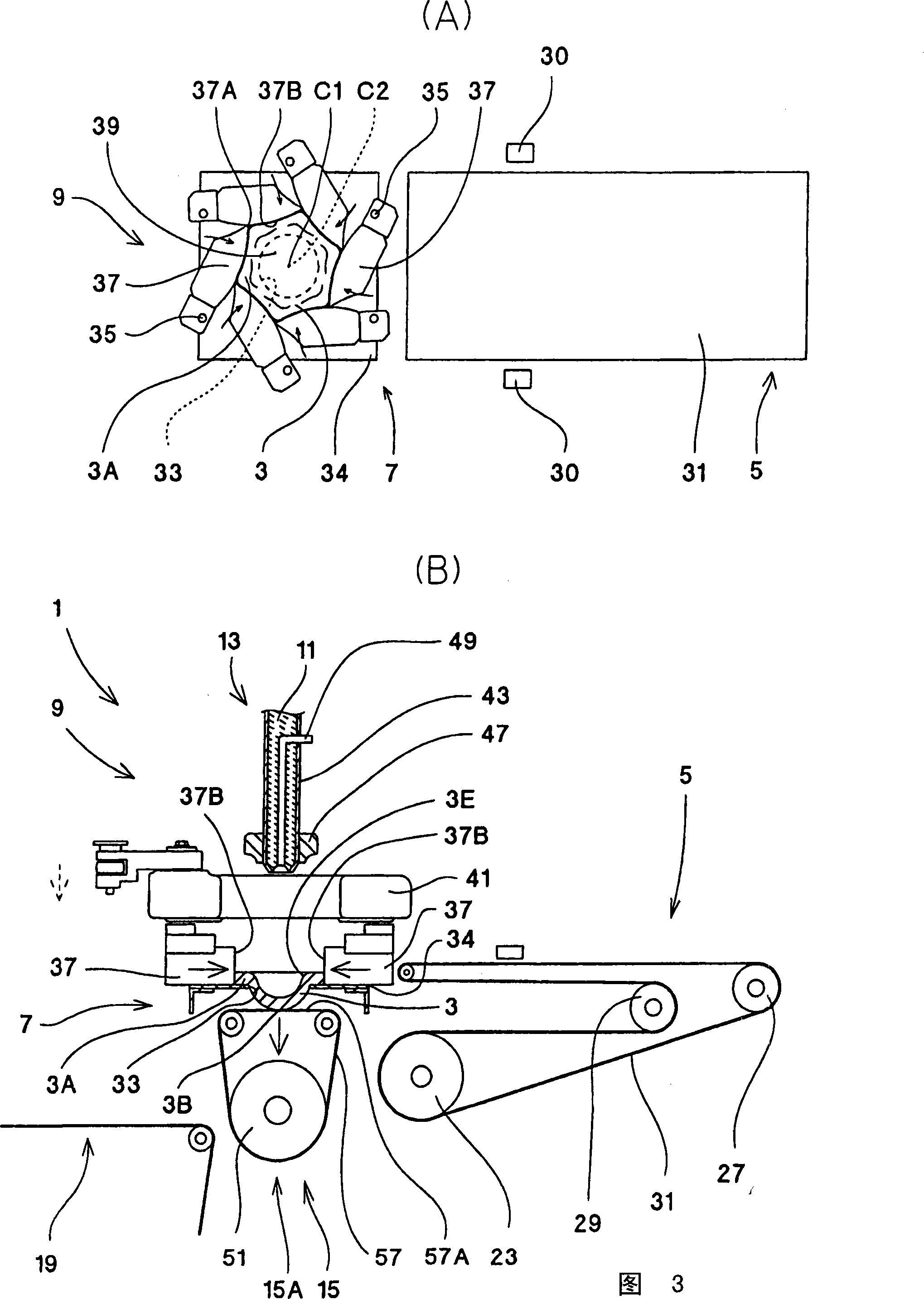

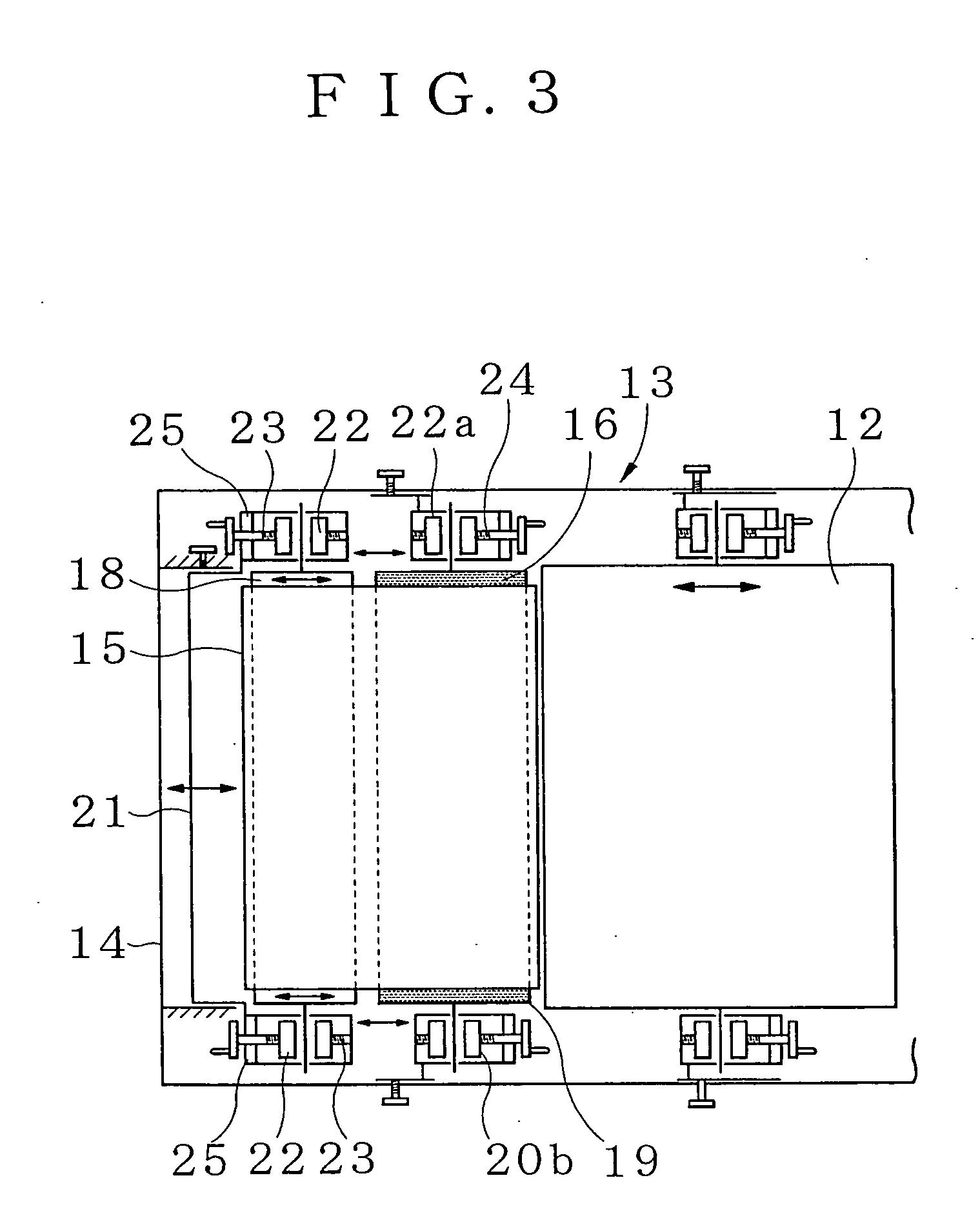

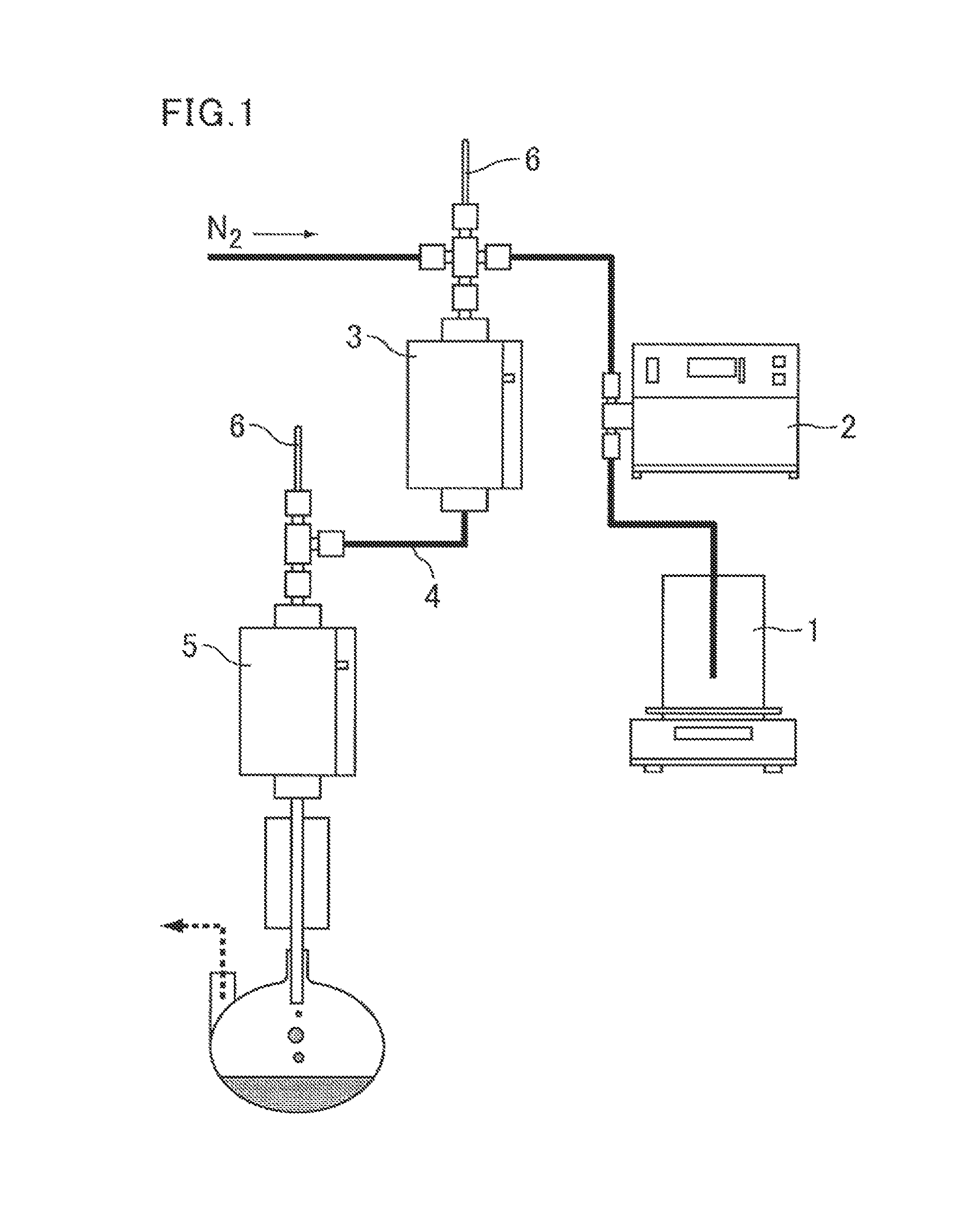

Device and method for manufacturing thin films

ActiveUS20050059246A1Stable and continuous formationGood film thickness distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateForming gas

The present invention herein provide a thin film-manufacturing device and a thin film-manufacturing method which are excellent in the mass-production ability and productivity, which permit the stable and continuous production of films over a long period of time while reproducing a good film thickness distribution, a good compositional distribution and a high film-forming rate and controlling the number of particles generated during the film-formation to a lower level. The device is one serving as a CVD device in which a film-forming gas is introduced into a reaction chamber from the upper portion of the chamber serving as a reaction space, through a shower head and a film is formed on a heated substrate, wherein the device is so designed that the upper reaction space is constructed by the substrate-supporting stage which is free of any rotational motion or free of any elevating motion, the shower head and a deposition-inhibitory plate, that the substrate-supporting stage and the deposition-inhibitory plate are so arranged as to form, between them, a concentric gap or interstice serving as a gas-exhaust path through which an inert gas can flow from the upper portion of the gas-exhaust path along the deposition-inhibitory plate and that a lower space is formed on the secondary side of the gas-exhaust path.

Owner:ULVAC INC

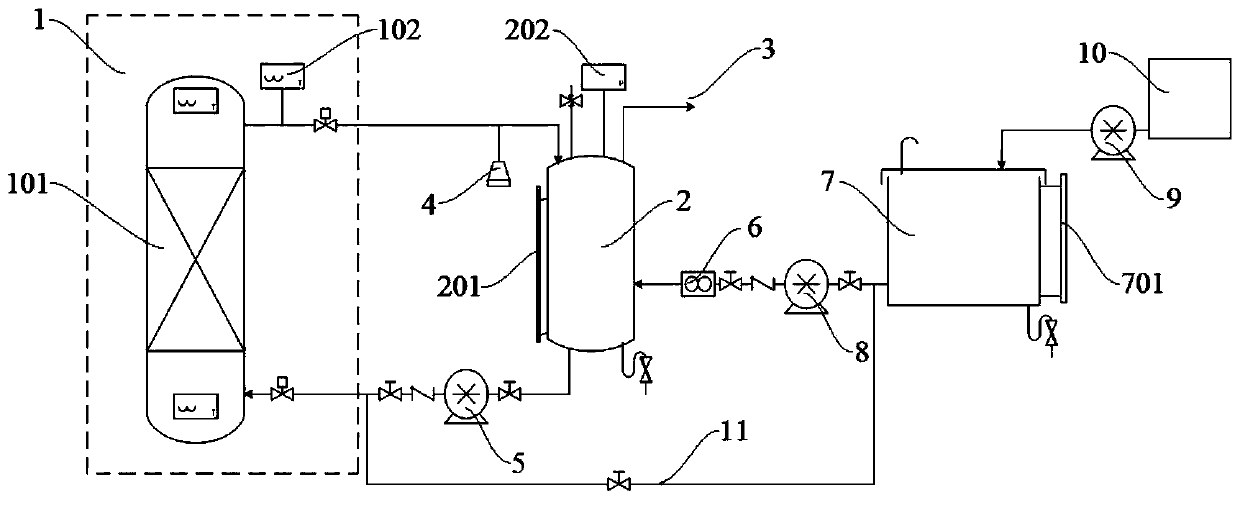

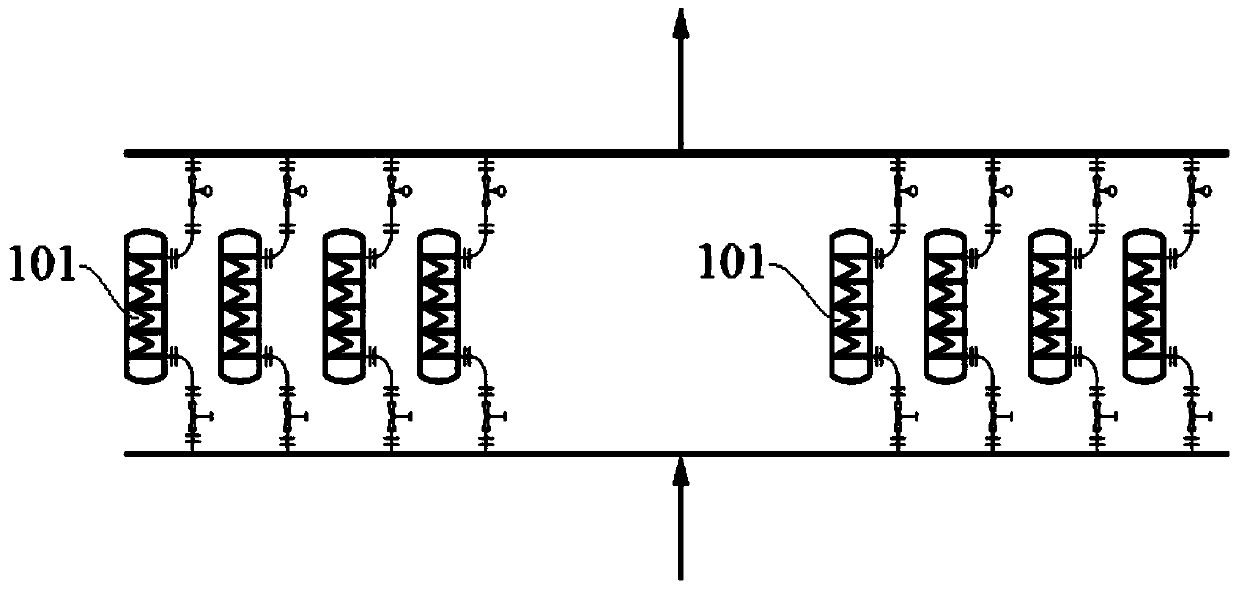

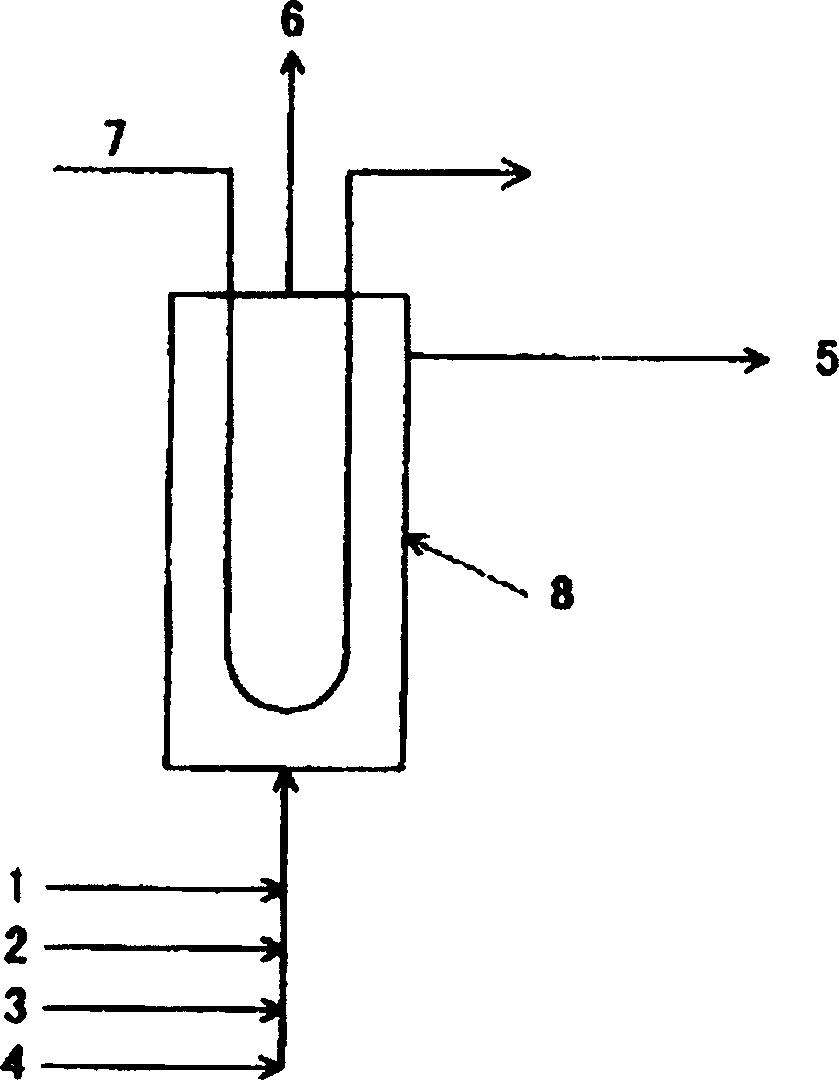

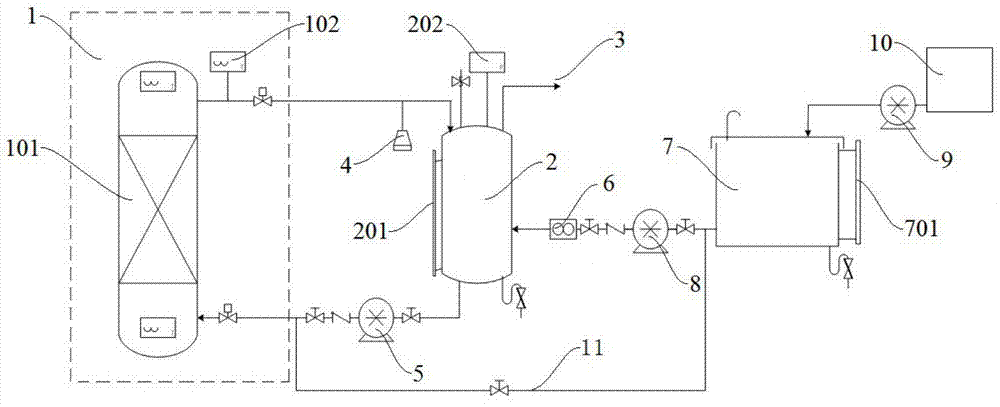

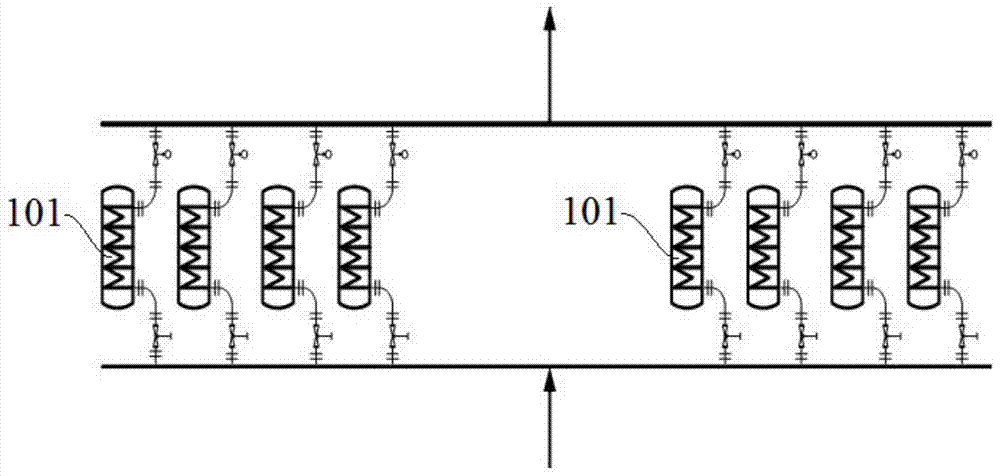

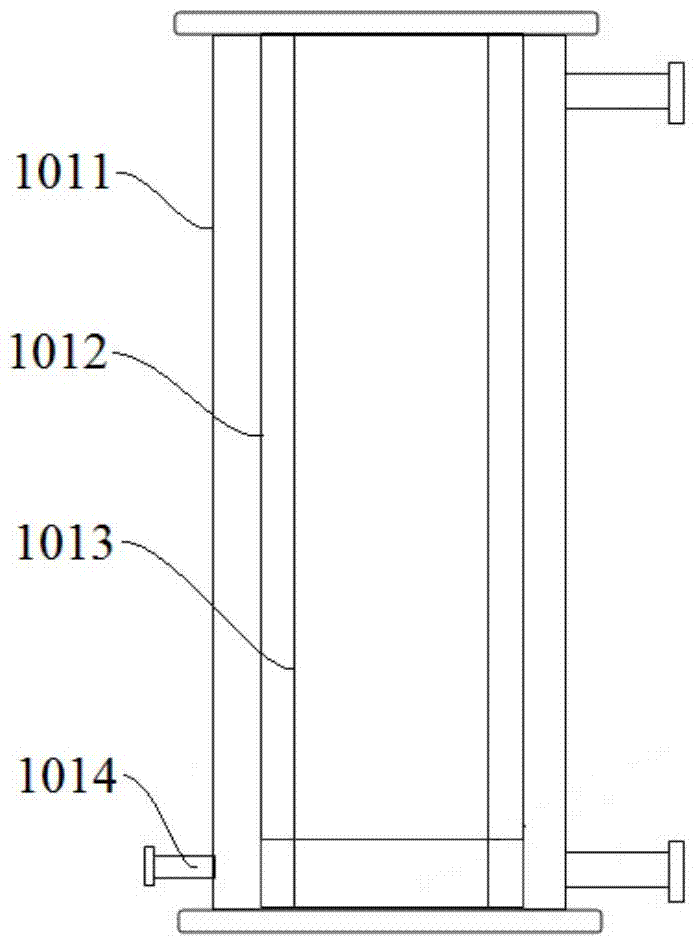

System for recycling raw gas afterheat of coke oven

ActiveCN103436271ALong-term continuous productionSafe continuous productionSteam generation using hot heat carriersDistillation gas withdrawalCirculator pumpProcess engineering

The invention discloses a system for recycling the raw gas afterheat of a coke oven, and belongs to the technical field of the recycling utilization of raw gas afterheat. The system for recycling the raw gas afterheat of the coke oven comprises a heat exchange medium circulating system and a water charging system, wherein the heat exchange medium circulating system comprises a heat exchanger set, a steam pocket and a forced circulation pump, a water inlet of the heat exchanger set is connected to a water outlet of the steam pocket through the forced circulation pump, a water outlet of the heat exchanger set is connected to a water inlet of the steam pocket, and a steam outlet in the steam pocket is connected to an external steam pipe network; the water charging system comprises a buffer water tank, a make-up pump, a feed pump and a desalting oxygen removal water tank, the feed pump is arranged between the buffer water tank and the desalting oxygen removal water tank, and the buffer water tank is connected to the steam pocket through the make-up pump. The system can be used for effectively, safely and reliably recycling the raw gas afterheat and circularly converting a heat exchange medium into middle and low pressure steam; the system operation can be effectively detected and controlled, so that the safe and normal operation of the system is ensured, and the accident rate is reduced.

Owner:江苏龙冶节能科技有限公司

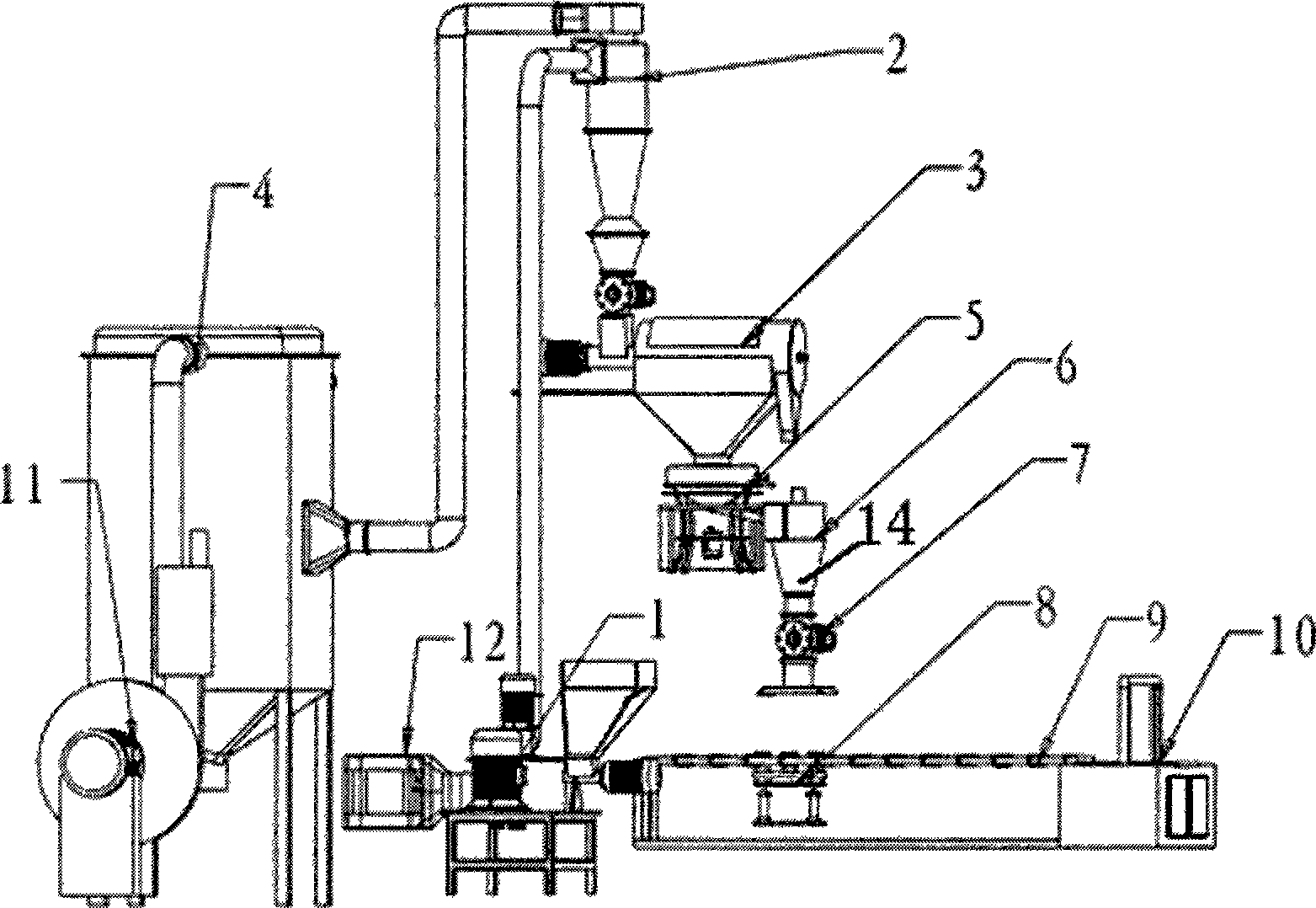

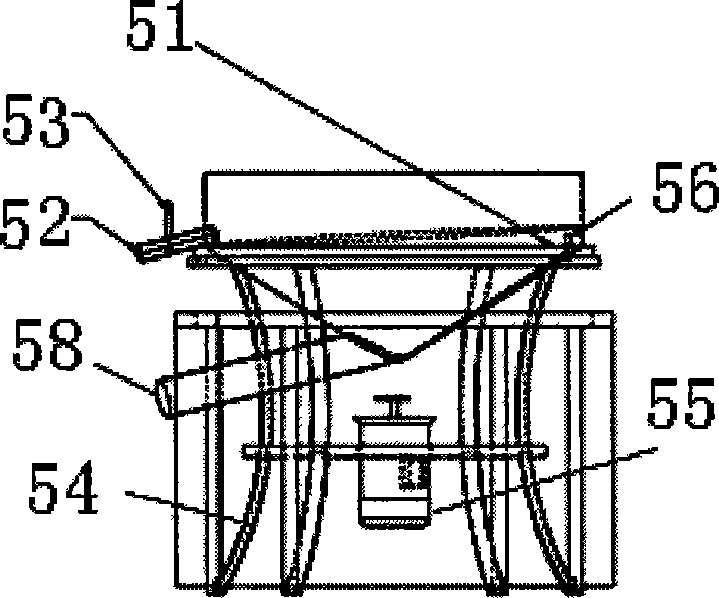

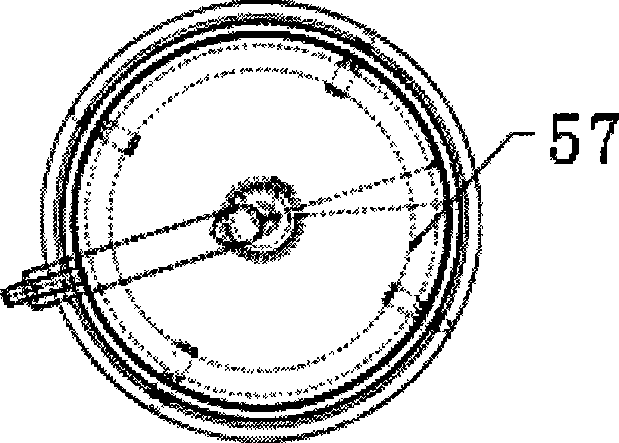

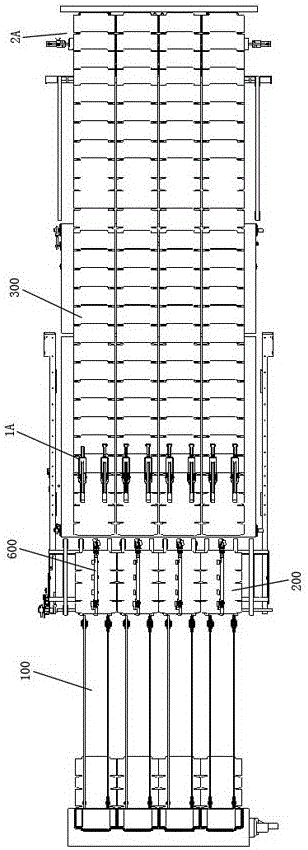

Automatic production apparatus for grinding powder paint

The invention relates to automatic production equipment for powder coating grinding, which belongs to the technical field of the automatic production equipment of power coating grinding. The equipment comprises a grinding head which is arranged inside a feed inlet and forms a grinding device, wherein the grinding head is connected with a cyclone separator through an induced air channel, an outlet of the cyclone separator is connected with a dust collector which is connected with a draught fan, and a lower outlet of the cyclone separator is connected with a gyrating sieve of powder coating with thicker grain diameters. The equipment is characterized in that the lower part of the gyrating sieve is connected with a vibration sieve, the vibration sieve is elastically connected with a small cyclone dust collector at the lower part of the vibration sieve, the lower part of the small cyclone dust collector is connected with a discharge outlet, the lower part of the discharge outlet is provided with a double-valve powder flow controller used to control the evenness and the connection / disconnection of the discharge, and the lower part of the double-valve powder flow controller corresponds to a powder packing case. The equipment can realize noise reduction, automatic sieving and alarming, dust removal, weighing and packing during the production of the powder coating, can realize safety of products and steady continuous production, reduce the leakage amount of dust, and avoid the pollution to the environment.

Owner:刁书才

Device and method for manufacturing thin films

ActiveUS7618493B2Stable continuous productionImprove abilitiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateForming gas

Owner:ULVAC INC

Method of converter smelting of low-phosphorous-content steel by adopting hot metal containing low silicon content

ActiveCN107058672AStable converter operationImprove the target hit rateManufacturing convertersProcess efficiency improvementSlagNitrogen gas

The invention discloses a method of converter smelting of low-phosphorous-content steel by adopting hot metal containing low silicon content. The method comprises the following steps: 1) before charging is carried out for the converter smelting every time, a converter slag remaining quantity is determined according to a terminal phosphorus content requirement and hot metal components of the type of steel to be smelted, and an adding total quantity of lime is calculated; 2) lime and ore adding quantities in the double slag earlier stage are determined according to the lime adding total quantity; 3) after blowing, operating personnel determine double slag oxygen lance lifting time according to a converter interior slagging situation monitored by an audio frequency slag melting instrument and with the combination of a situation monitored by a converter mouth camera; 4) after oxygen lance lifting is carried out, nitrogen is blown to a converter for carrying out iron brake operation; 5) the blowing is carried out after deslagging is finished, the left 50% of the lime and the ore are added, and secondary slag making and phosphor removal are carried out; and 6) converter blowing is carried out to a terminal, then the oxygen lance lifting is carried out, and converter turning-down and deslagging are carried out. A double slag control process is adopted for operation, the converter terminal phosphorus content fundamentality reaches the target requirement, converter supplementary blowing phosphor removal phenomena are reduced obviously, and a converter body state is improved obviously.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

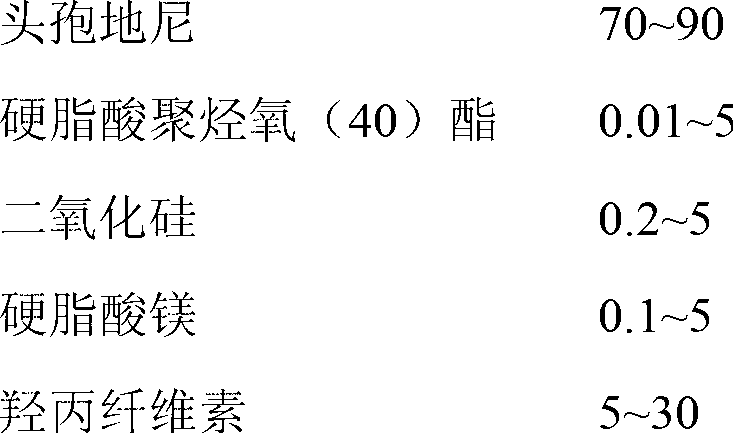

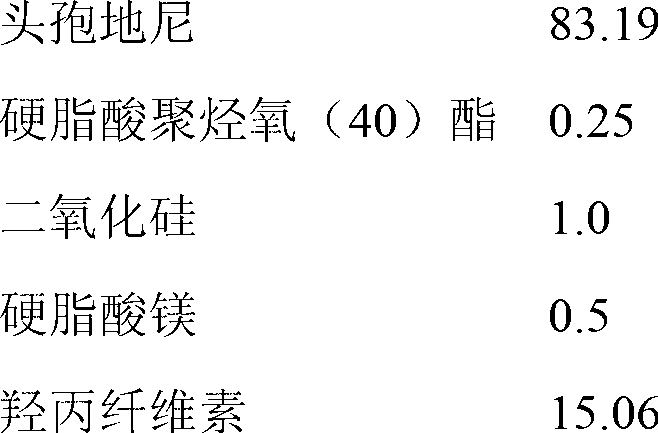

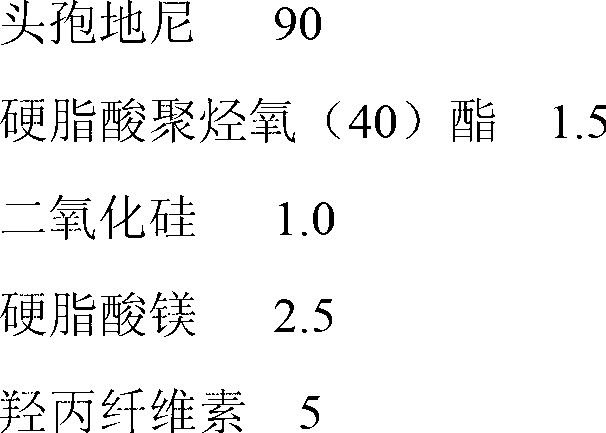

Cefdinir capsule and preparation method thereof

ActiveCN102935075AGood dissolution effectImprove liquidityAntibacterial agentsOrganic active ingredientsMedicineQuality control

The invention provides a cefdinir capsule and a preparation method of the cefdinir capsule. The content of the cefdinir capsule comprises the necessary components based on parts by weight: 70-90 parts of cefdinir, 0.01-5 parts of polyoxyl (40) ester stearate, 0.2-5 parts of silicon dioxide, 0.1-5 parts of magnesium stearate and 5-30 parts of hydroxypropyl cellulose. The medicine prepared by cefdinir capsule prescription is good in dissolution effect and fluidity, and stable in medicine effect; the provided preparation method is simple in technology; the product is less in introduced impurity, easy in quality control and good in reproducibility and uniformity; and the preparation method saves the energy and reduces the consumption, thus easily meeting the demand of mass production.

Owner:海南三叶美好制药有限公司

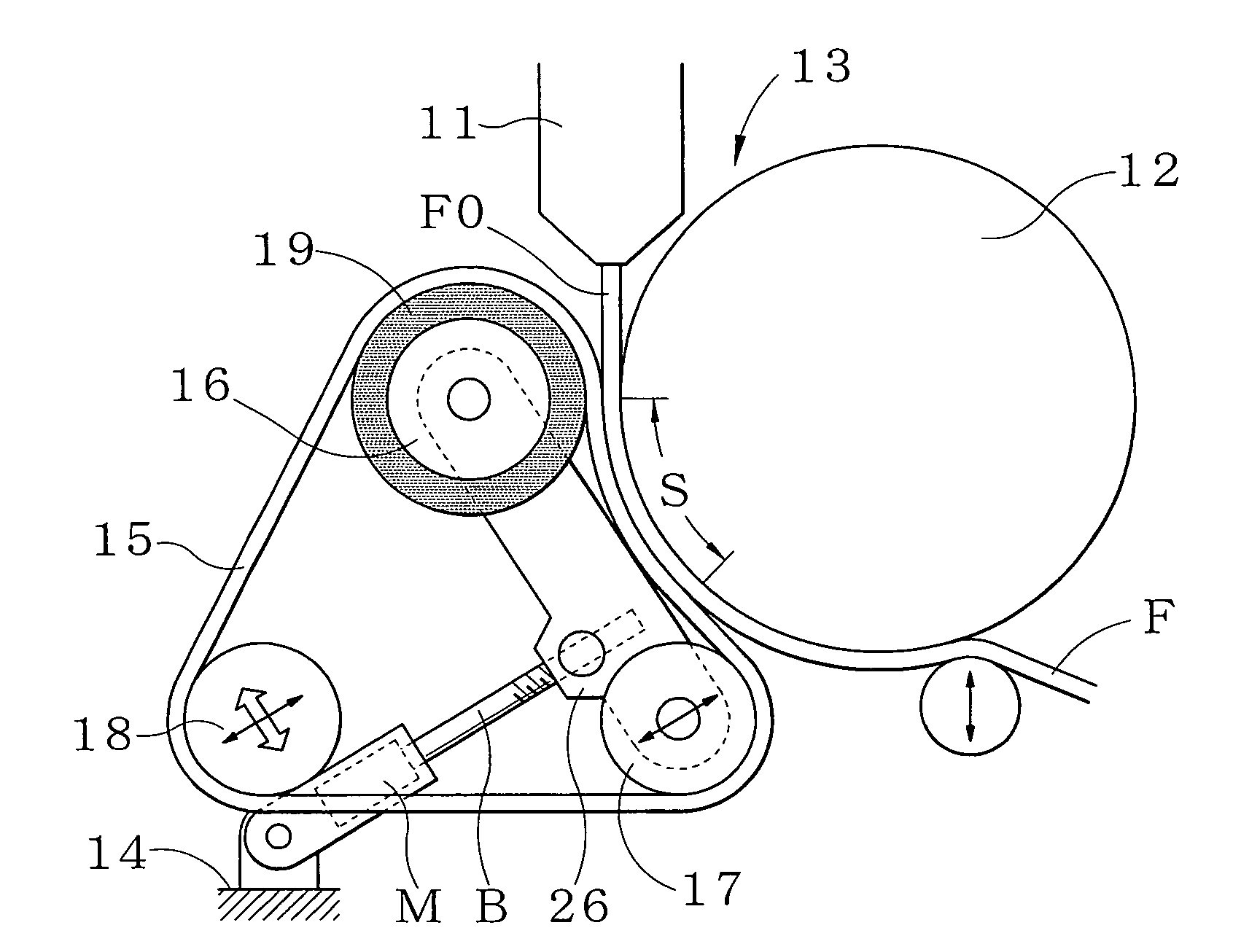

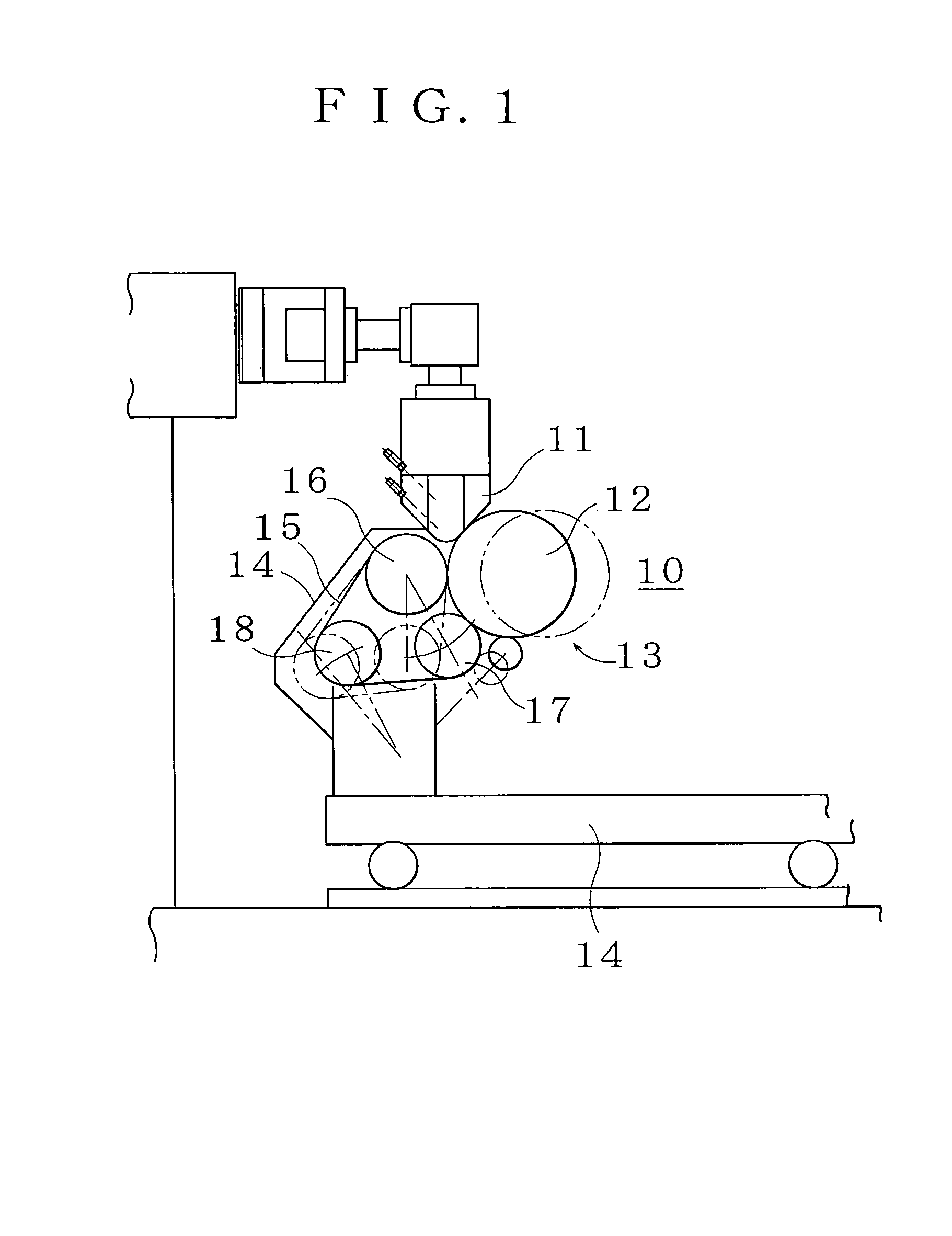

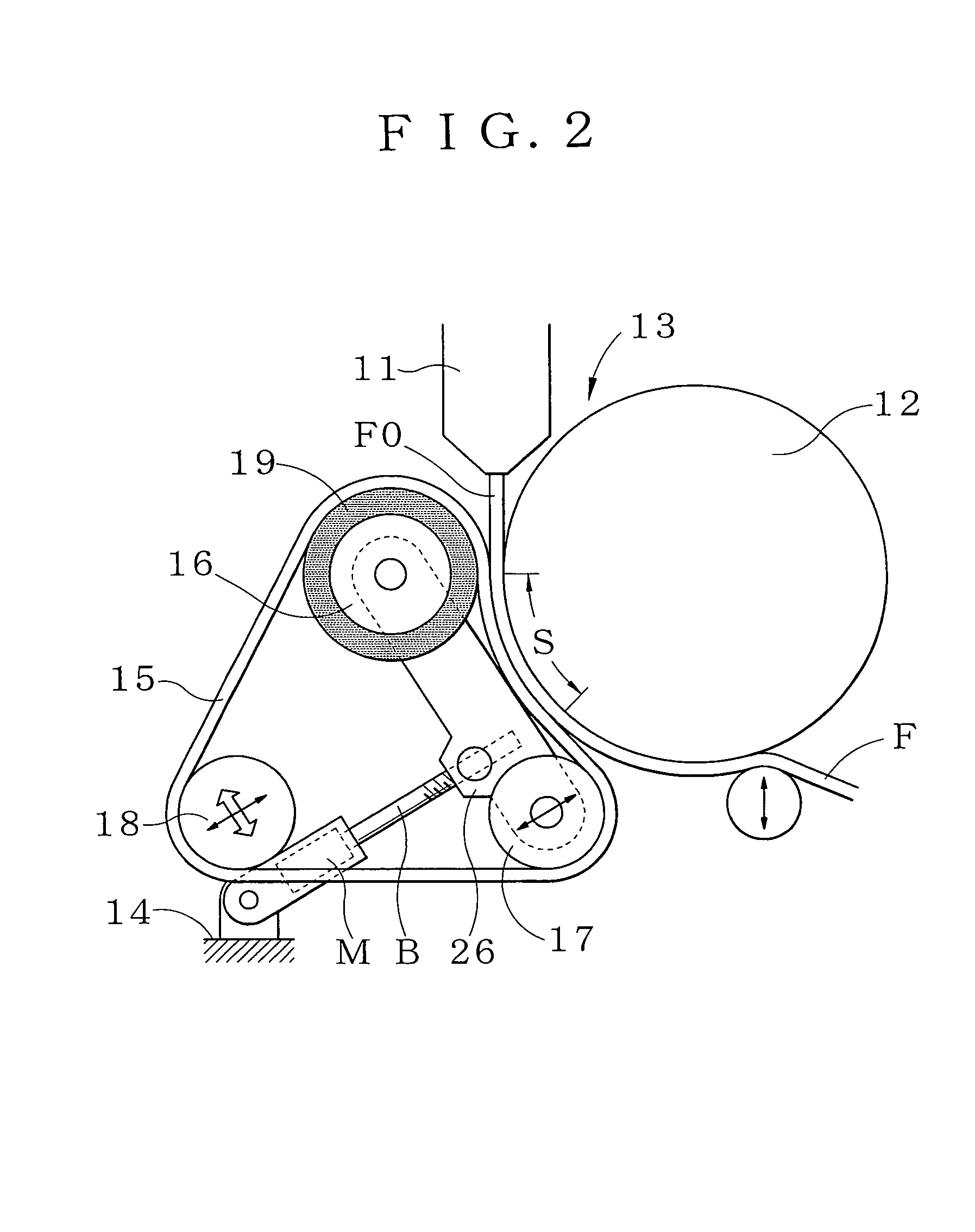

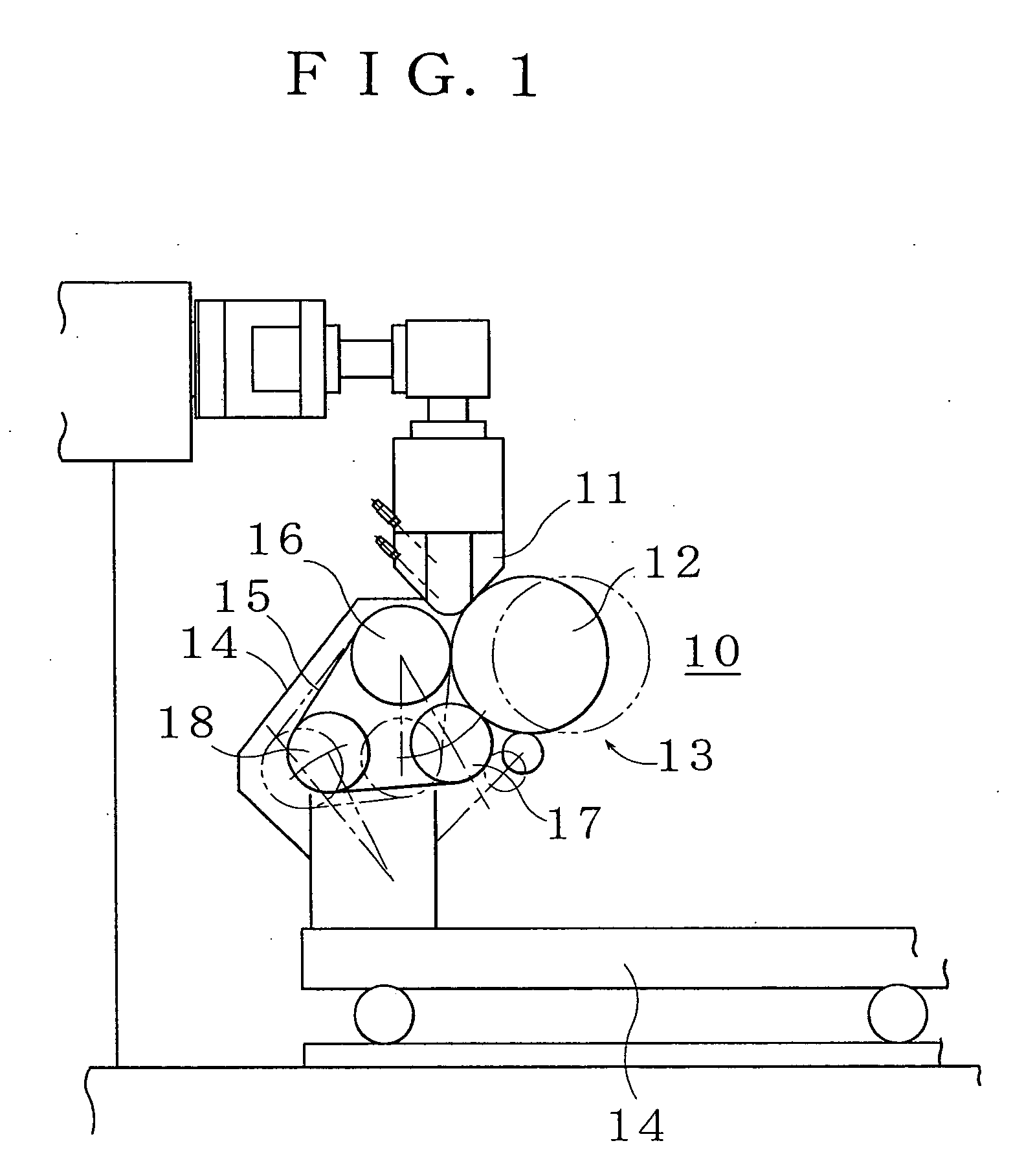

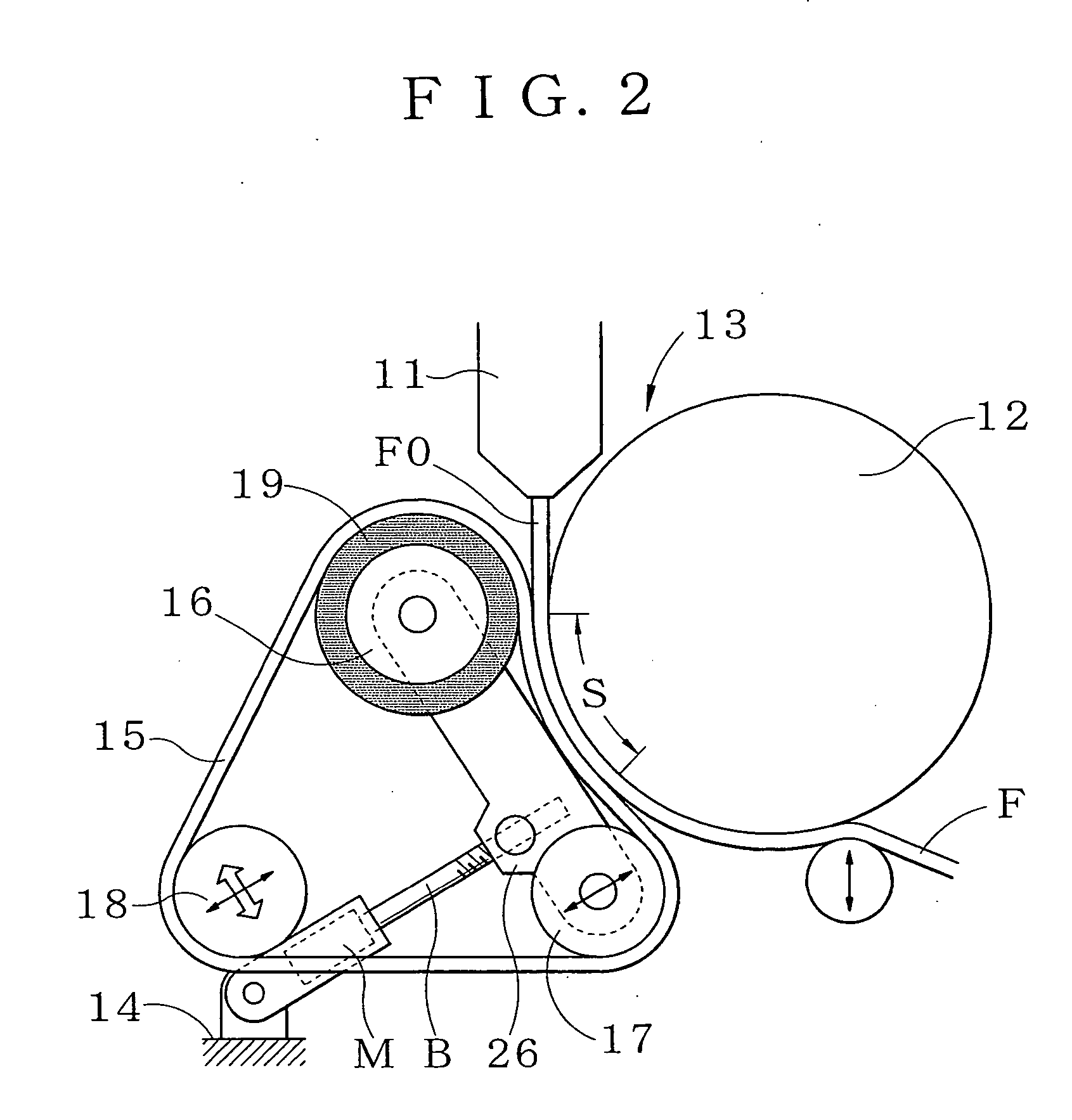

Method and apparatus for producing thermoplastic synthetic resin sheet or film

InactiveUS7427372B2High glossStable continuous productionDough-sheeters/rolling-machines/rolling-pinsConfectioneryRotational axisSpin casting

An apparatus for producing a thermoplastic synthetic resin sheet or film has a casting mechanism having support rollers each mounted to undergo rotation about a corresponding rotational axis and one of which is mounted to undergo non-rotational displacement relative to the other support rollers. A casting sleeve is entrained around the support rollers for rotation therewith. A casting roller is mounted for undergoing rotation relative to the casting sleeve. A synthetic resin material is fed between opposite and confronting outer peripheral surfaces of the casting sleeve and the casting roller while rotating the casting sleeve and the casting roller and while effecting non-rotational displacement of one of the support rollers to holdingly press the synthetic resin material between the casting sleeve and the casting roller and thereby form the synthetic resin material into a thermoplastic synthetic resin sheet or film.

Owner:CTE

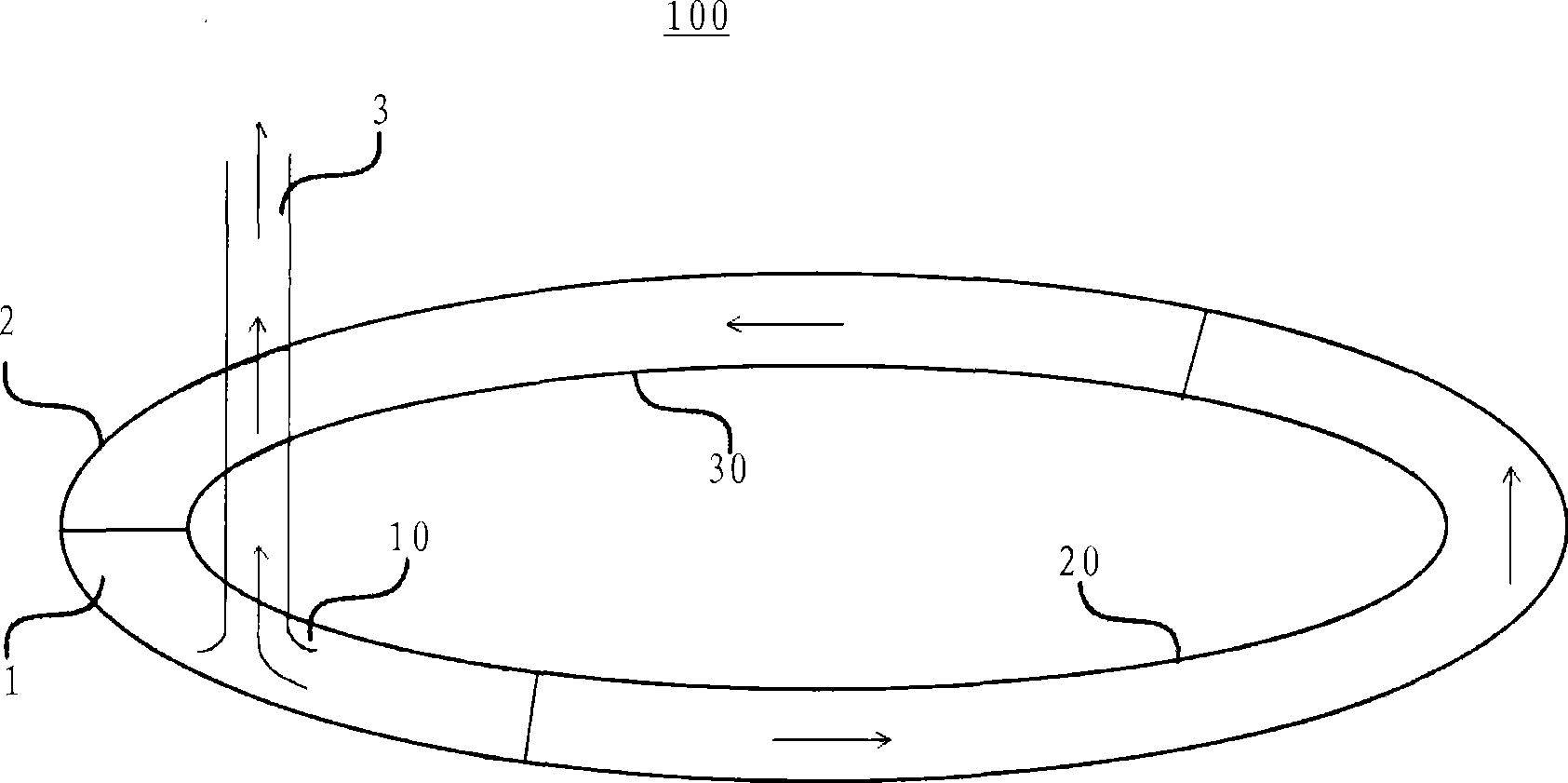

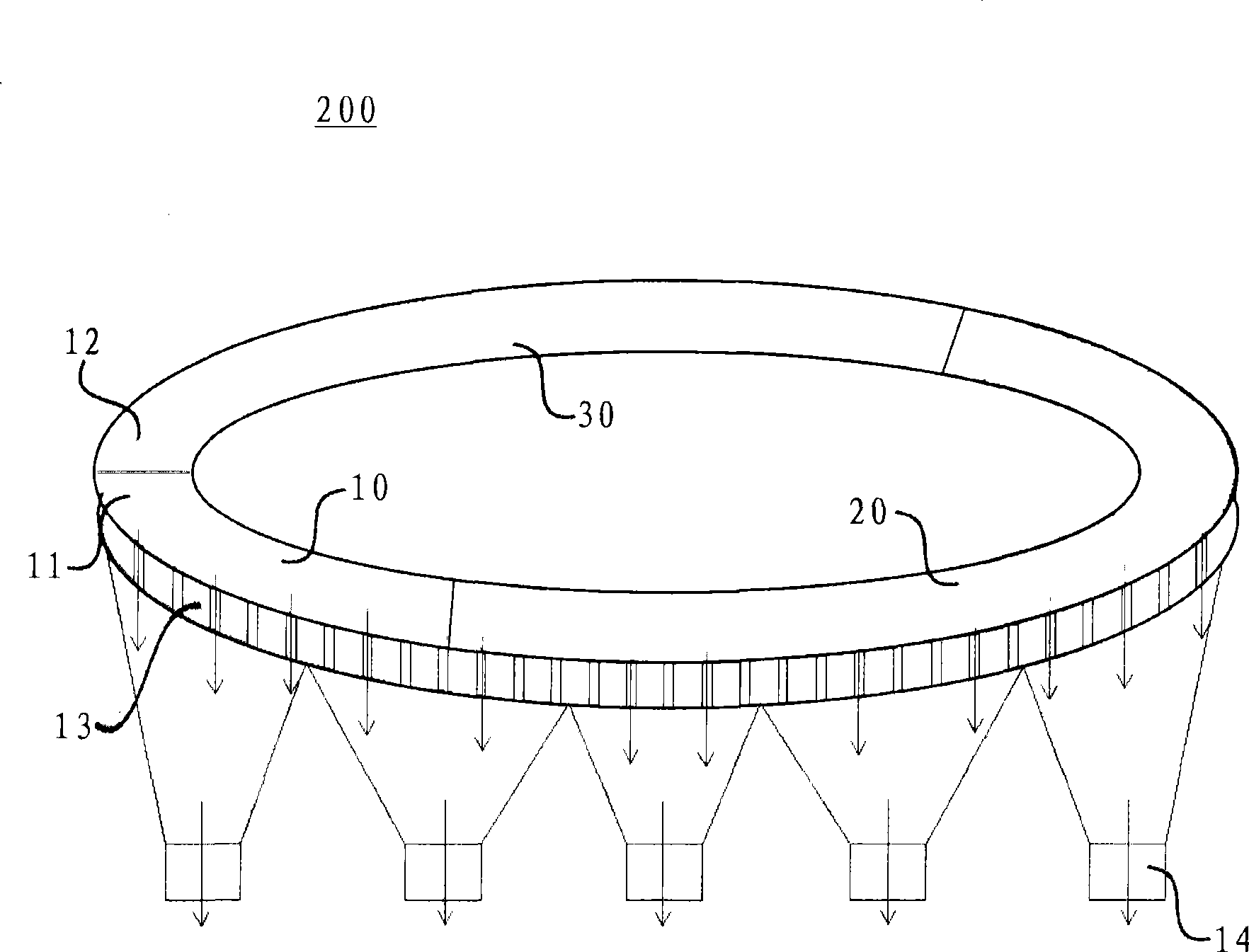

Rotary hearth furnace and rotary hearth furnace waste gases utilization method

The invention discloses a rotary hearth furnace and a waste gas utilization method thereof. The invention is characterized in that, a waste gas utilization apparatus is arranged at the bottom of the rotary hearth furnace, namely, an air extractor and gas permeable bricks are arranged at the bottom of the rotary hearth furnace; when the rotary hearth furnace is working, hot waste gas generated by the rotary hearth furnace is extracted by the air extractor, therefore convection heat transferring by hot waste gas is formed in the materials in the rotary hearth furnace, a forced pre-heating of the materials is performed and heat quantity is provided for material reduction, therefore, the reduction of the materials at the reduction segment can be promoted, and the thickness of material layer is up to 100mm-300mm.By adopting the rotary hearth furnace and the waste gas utilization method of the invention, exhaust heat of the waste gas generated by a rotary hearth furnace can be utilized efficiently, heat transmission speed of the materials is fast and the material layer is thick, therefore, a stable continuous production with a high production efficiency can be realized.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

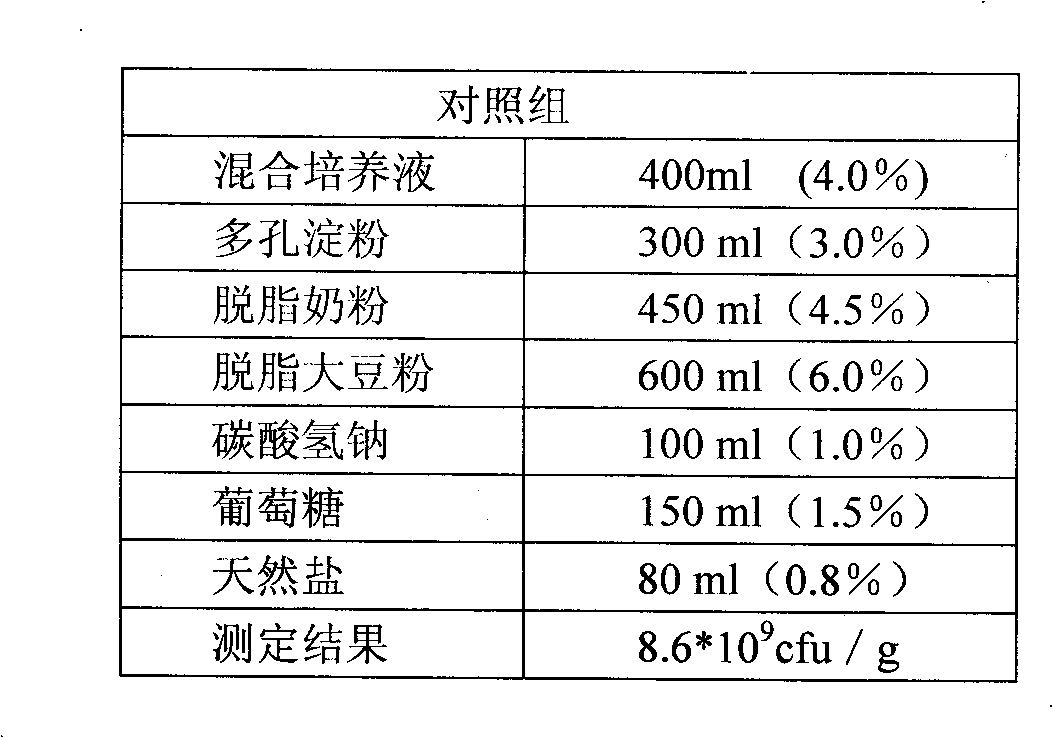

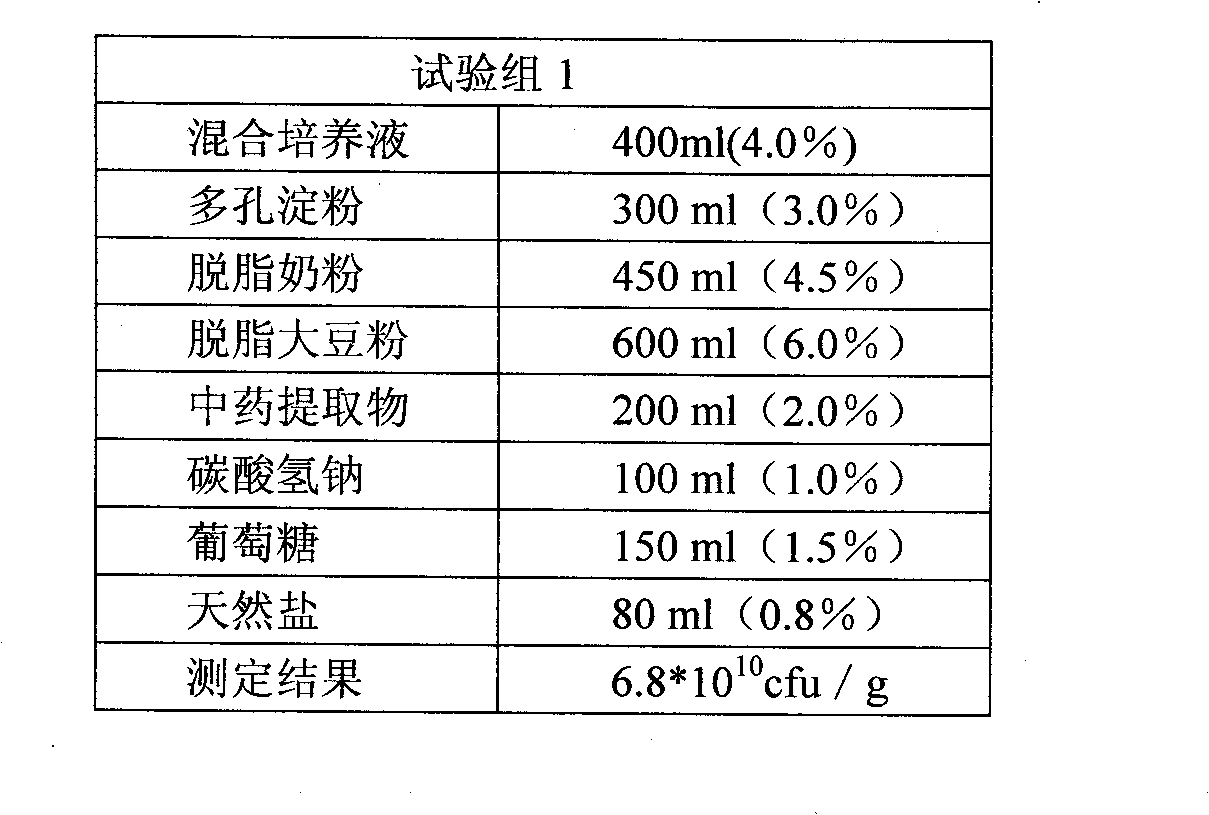

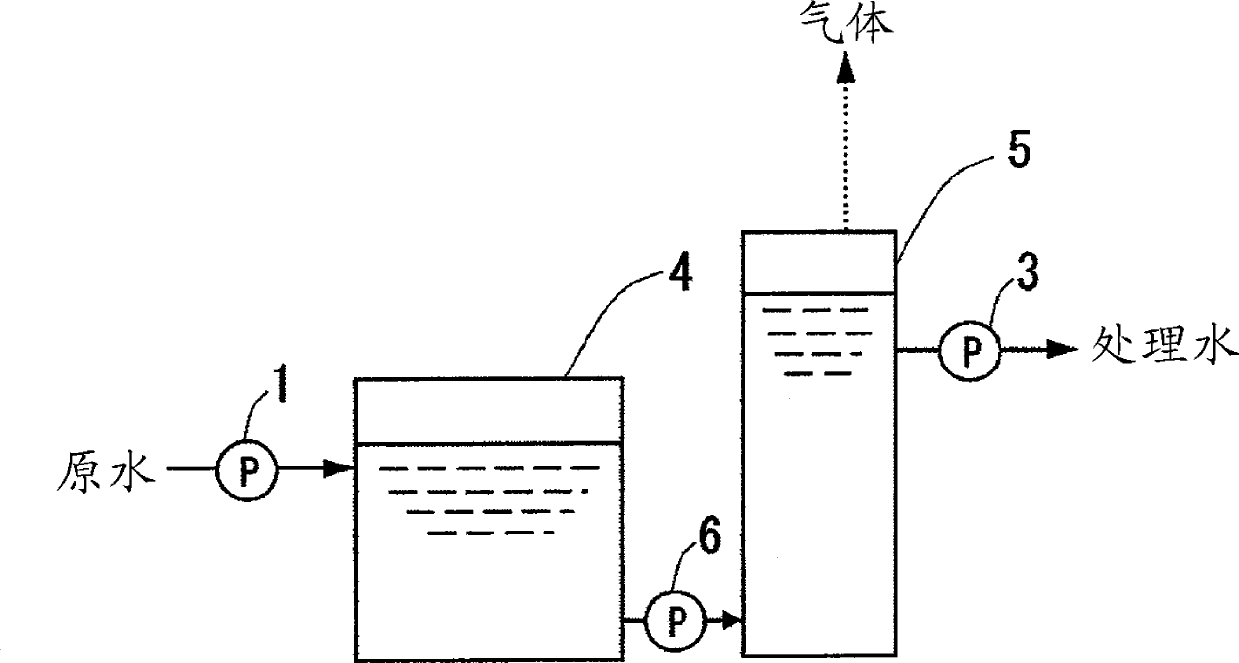

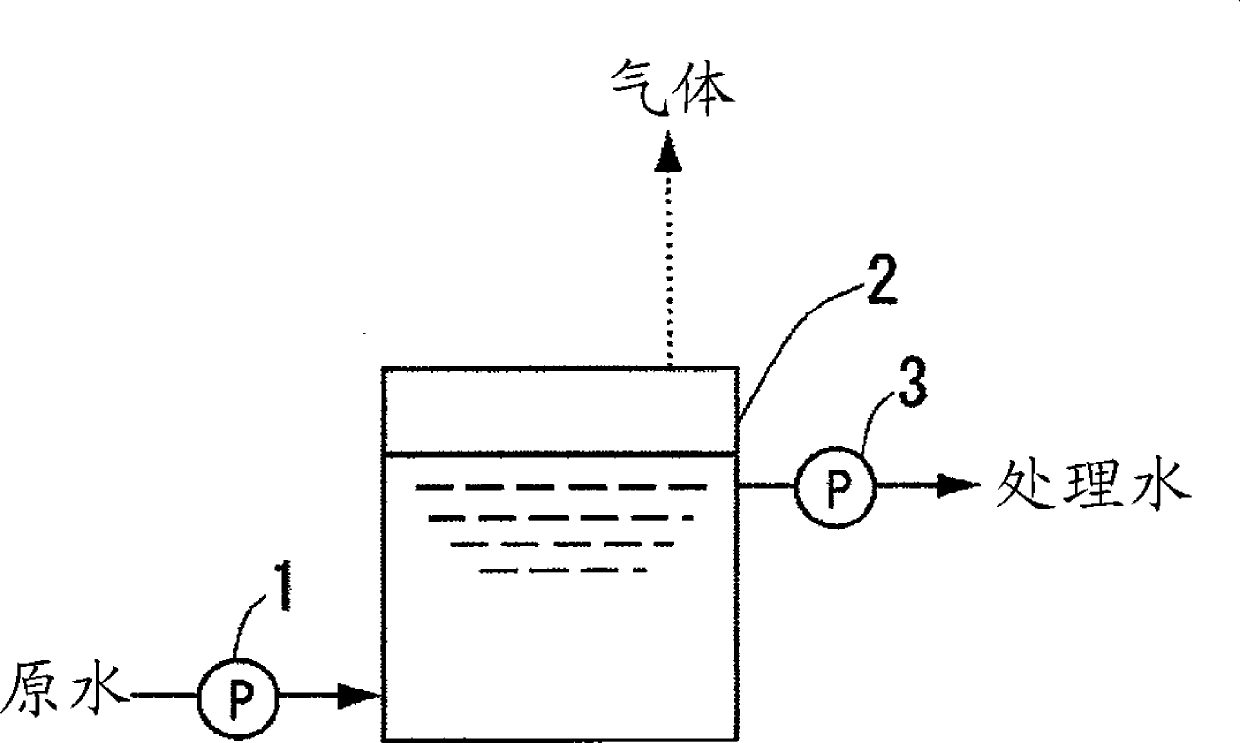

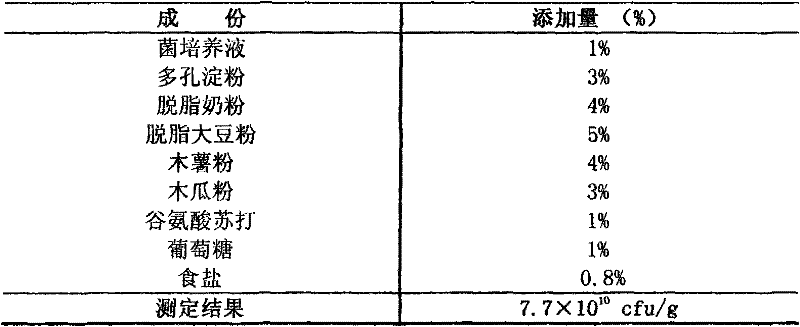

Hybrid probiotic desiccate and preparation method thereof

InactiveCN101773207AHigh bacteria rateGood bacteria rateAnimal feeding stuffBiotechnologySalt resistance

The invention discloses a hybrid probiotic desiccate and a preparation method thereof. The hybrid probiotic desiccate has high bacteria rate and viable count being up to 9.2*109-6.8*1010cfu / g. because of having double protection functions of porous starch and saccharides, and the powder of the hybrid probiotic desiccate has good acid, high-temperature and salt resistance and can be stored for a long time. Chinese medicinal herb extracts are used in a culture medium, echinacea purpurea polysaccharides and astragalus polysaccharides not only increase the content of saccharides required by the growth of flora, but also can enhance the immunity of cells, can obviously increase the quantity and the efficacy of the flora, and has more complete and effective health care function.

Owner:鲁东梁 +2

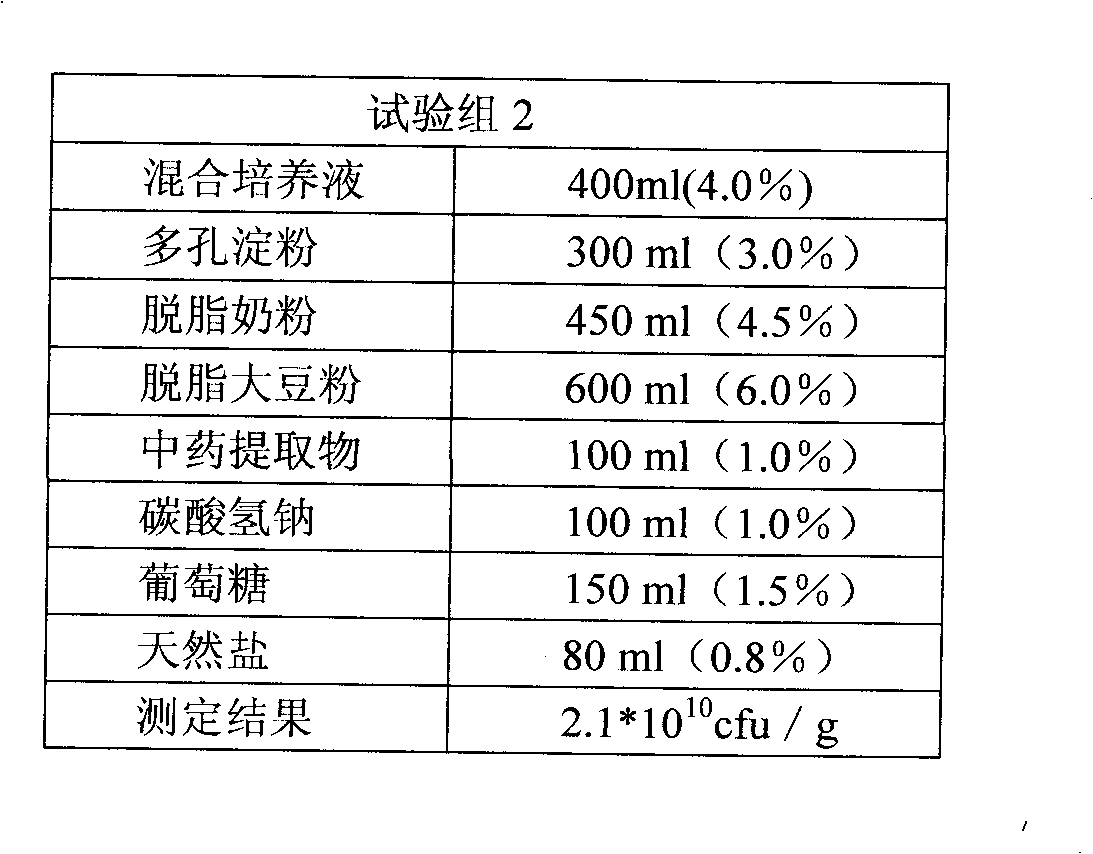

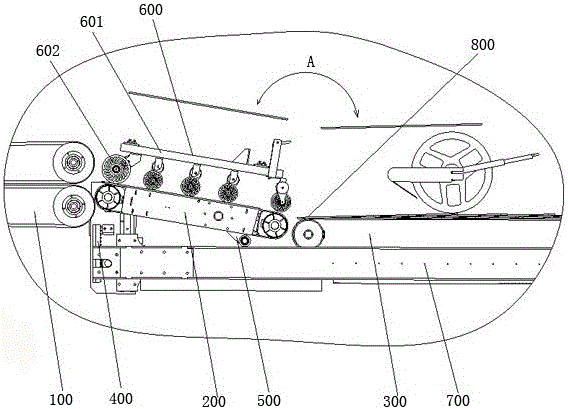

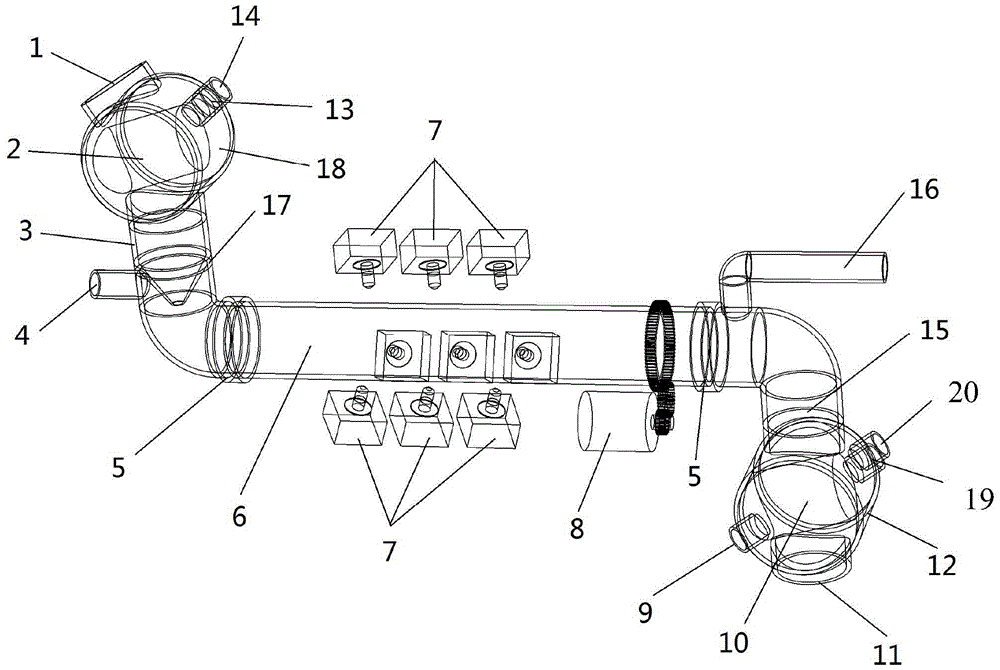

Induction heating quenching and tempering system

InactiveCN103421936ARealize automatic controlEffective controlIncreasing energy efficiencyControl systemElectrical control

The invention discloses an induction heating quenching and tempering system which is used for quenching and tempering heat treatment of car rack blanks or connecting rod rods. The system comprises an adjustable conveying system and an electrical control system which are mutually connected, wherein a feeding mechanism, an induction hardening heating unit, an adjustable spray coil type quenching and cooling mechanism, an induction tempering and heating unit and a discharging structure are sequentially arranged on the adjustable conveying system; the adjustable conveying system is used for advancing and rotating of workpieces connected one after another; the electrical control system is used for controlling the induction heating quenching and tempering system. The system can effectively improve the uniformity and precision of the workpiece heating, and allows the workpiece to be more uniformly cooled and have small, even no, deformation. When the workpiece is subjected to tempering, no deformation is caused during uniform cooling. Due to the adoption of the system, the rigidity difference between the surface and core of the automobile rack blank is small, deformation is small or even can be avoided, and mass and stable continuous production is realized.

Owner:SHANGHAI BEITE TECH

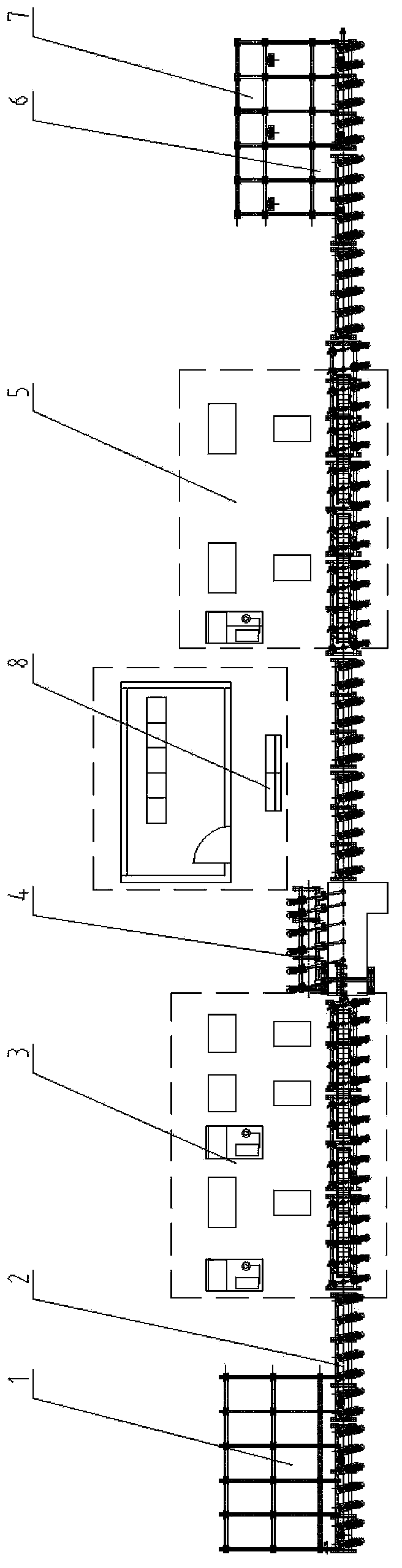

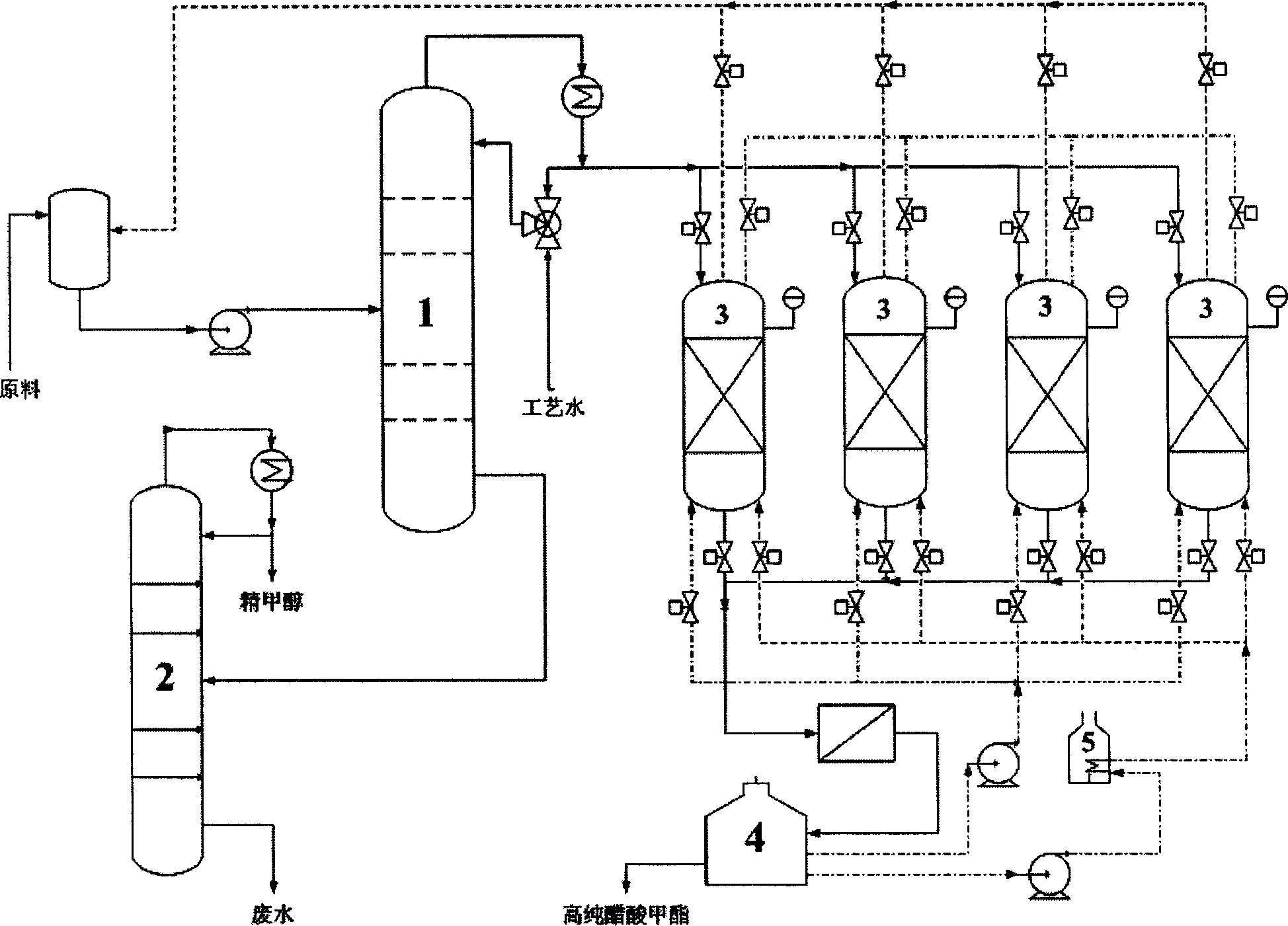

Method for preparing high pure methyl acetate through adsorption of liquid phase

InactiveCN1687002AHigh yieldShorten the cycle timeOrganic compound preparationCarboxylic acid esters preparationAlcoholDesorption

The present invention utilizes the processes of extraction rectification, liquid-phase adsorption, variable temperature purge desorption regeneration and methyl alcohol rectification to conveniently and high-effectively prepare high-purity methyl acetate with high value from industrial waste liquid (gas) containing methyl acetate, at the same time, said invention can obtain another main components in waste liquid (gas)-methyl alcohol.

Owner:TSINGHUA UNIV

Porous water-containing gel molded article, method for producing same, and use of same

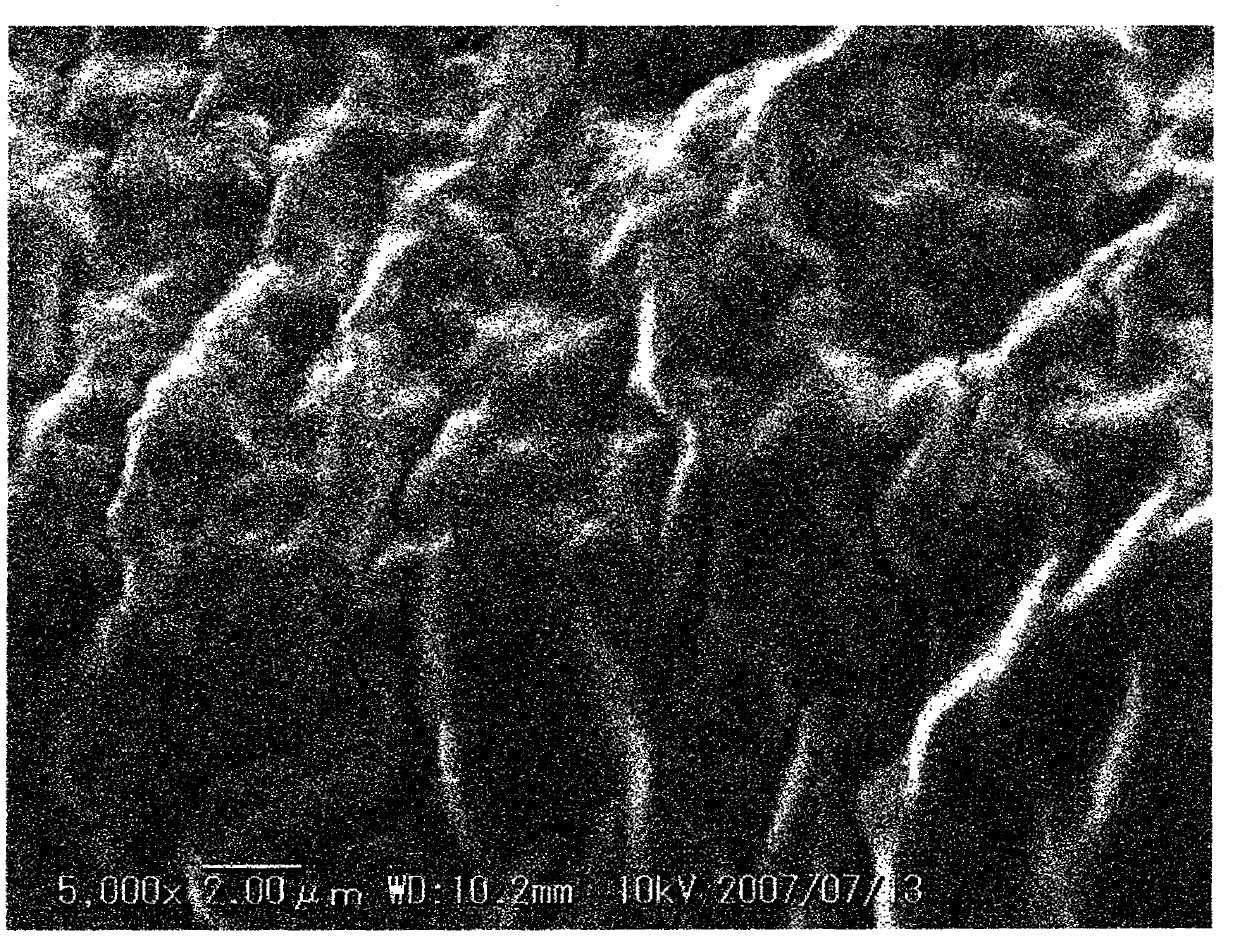

InactiveCN103998499AHigh strengthStable continuous productionSustainable biological treatmentThin material handlingPolymer scienceFreeze-drying

Provided is a porous water-containing gel molded article that contains a poly(vinyl alcohol) that has been acetalized by means of a dialdehyde, and that is characterized in that the pore diameter of a freeze-dried product of the molded article is 0.1 to 50 [mu]m. Here, it is preferable for the porous water-containing gel molded article to further contain a water-soluble polysaccharide. It is preferable for the degree of acetalization of the poly(vinyl alcohol) to be 1 to 50 mol%. It is preferable for the porous water-containing gel molded article to be in the form of particles, with the sphere equivalent diameter of the particles being 1 to 20 mm. This type of porous water-containing gel molded article exhibits high strength and good inhabitation properties for microorganisms.

Owner:KURARAY CO LTD

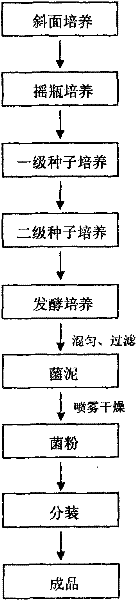

Microbial compound preparation and preparation method thereof

ActiveCN102210454AImprove securityUnique functionBacteria material medical ingredientsFood preparationBiotechnologyPorous starch

The invention relates to a microbial compound preparation containing Lactobacillus acidophilus and a processing technology thereof. The microbial compound preparation contains a Lactobacillus acidophilus fermentation culture; the Lactobacillus acidophilus is taken as an active ingredient; and the viable count of the Lactobacillus acidophilus in the microbial compound preparation is more than 7.7*10<10>cfu / g, and the average particle size is less than 10mu m. The Lactobacillus acidophilus fermentation culture is obtained by culturing in a fermentation culture medium containing 3 to 5 percent of porous starch, 4 to 5 percent of defatted milk powder, 5 to 7 percent of defatted soybean powder, 4 to 6 percent of tapioca flour, 3 to 5 percent of papaya powder, 1 percent of glutamic acid soda, 1to 2 percent of glucose, and 0.8 percent of table salt. Production processes are simple, and production cost is low. The microbial compound preparation can be prepared into medicinal preparations, health-care products, foods and nutritional supplements, can be taken as a core functional ingredient in feed additives, and has a broad application range.

Owner:SHANGHAI HONGYUAN BIOTECH

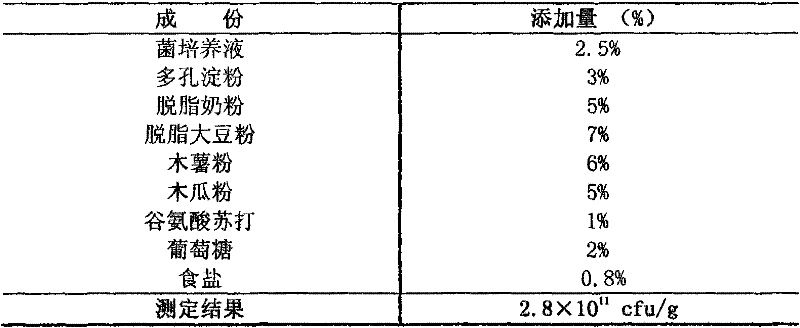

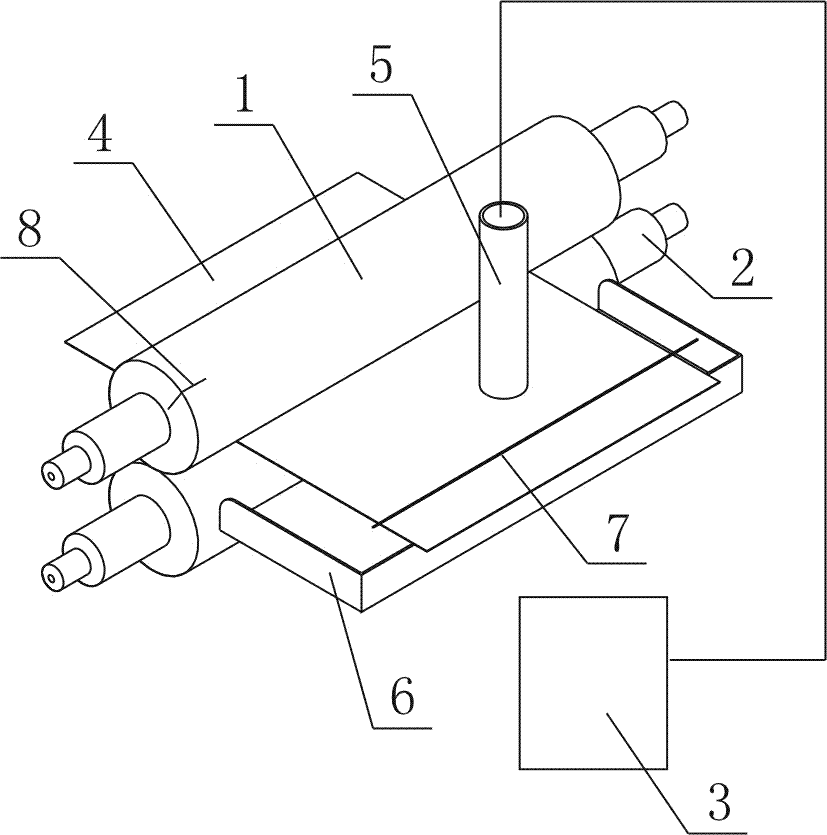

Coating machine for coating silicon-steel magnesium oxide coating liquid

InactiveCN103480535ADisappear wearDisappearing qualityLiquid surface applicatorsCoatingsStrip steelOxide coating

The invention discloses a coating machine for coating silicon-steel magnesium oxide coating liquid. The coating machine comprises a frame, an upper coating roll, a lower coating roll, a magnesium oxide coating liquid circulating device and a nozzle pipe, and also comprises a coating liquid drainage apparatus and a baffle, wherein the coating liquid drainage apparatus is arranged on one side of the lower coating roll and installed on the frame; the coating liquid drainage apparatus at least comprises one bottom plate; the side of the bottom plate, which is towards the lower coating roll, adopts a drainage side; the other sides of the bottom plate adopt collecting sides; the width of the bottom plate of the coating liquid drainage apparatus is larger than the width of strip steel arranged between the upper coating roll and the lower coating roll; the drainage side of the liquid drainage apparatus is used for draining magnesium oxide coating liquid overflowing from the upper surface of the strip steel to the lower coating roll; and the baffle is arranged below the nozzle pipe and arranged on the upper surface of the strip steel in an inclined way. The coating machine has the benefits that the magnesium oxide coating liquid overflowing from the surface of the strip steel is directly drained to the lower coating roll through the coating liquid drainage apparatus, the flowability of the coating liquid is good, the leveling of the coating liquid coating the surface of the strip steel is uniform, and the continuous production efficiency and the material yield of oriented silicon steel are improved.

Owner:武汉钢铁有限公司

Food manufacturing device

The present invention relates to an apparatus for preparing the following foods (production) continuously, the foods is made by packaging inner material composed of foods such as stuffing or fruit jam etc. by tegmen material composed of foods blank such as bread etc. A blank pressing component is formed integratedly on the peripheral of a nozzle component for extruding inner material, the peripheral part of the tegmen material locating on the upper surface of a carrying component with hatch is clipped between the blank pressing component and the carrying component, and the upper opening of the bowl-shaped tegmen material is closed by the nozzle component and the blank pressing component, so as to prevent the inner material from leaking from the upper opening by maintaining the clipping state when ejecting the inner material into the inner of the tegmen material, and to prevent inner material from leaking to manufacture no good production when sealing the peripheral of the tegmen material. In addition, due to prevent inner material from polluting food manufacture device, it is able to prepare foods continuously without stop the running of the device.

Owner:RHEON AUTOMATIC MASCH CO LTD

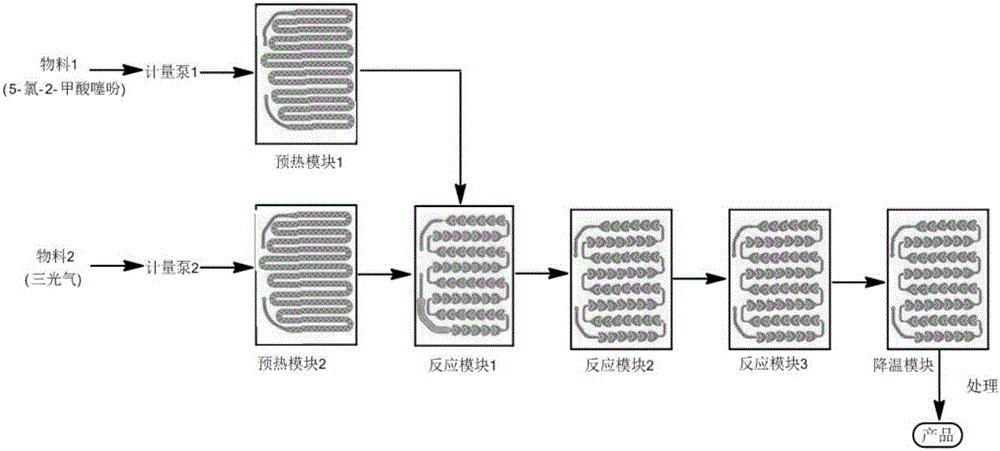

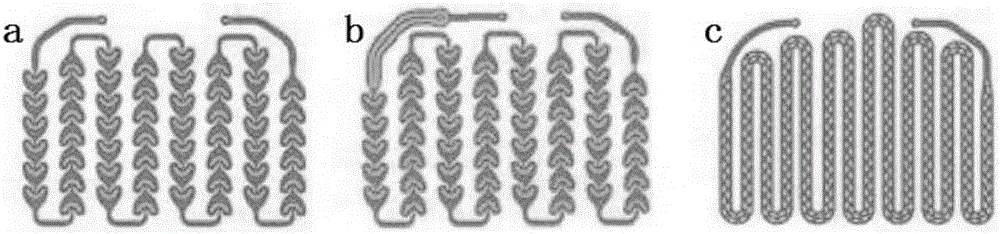

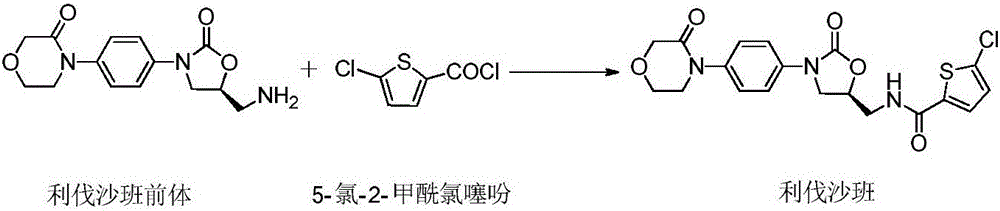

Method for synthesizing 5-chlorin-2-formyl chloride thiofuran by micro-channel reactor

The invention provides a method for synthesizing 5-chlorin-2-formyl chloride thiofuran by a micro-channel reactor. The micro-channel reactor is formed by sequentially connecting preheating modules, a reaction module group and a temperature reducing module in series, wherein more than two preheating modules are respectively connected in series with the same reaction module group. The method comprises the reaction steps that raw materials of 5-chlorin-2-formic acid thiofuran are dissolved in a solvent to form a 5-chlorin-2-formic acid thiofuran solution; DMF (dimethyl fumarate) is added to be prepared into a material 1; triphosgene is dissolved in a solvent to be prepared into a triphosgene solution to obtain a material 2; the material 1 and the material 2 respectively enter different preheating modules; after being preheated, the materials enter the reaction module group for reaction, then enter the temperature reducing module and flow out of the reactor; reaction liquid is collected; after reduced pressure distillation, the 5-chlorin-2-formyl chloride thiofuran is obtained. The method provided by the invention has the advantages that the reaction temperature is accurate; the feeding proportion can be conveniently controlled; the reaction period is short; green and environment-friendly effects are achieved.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

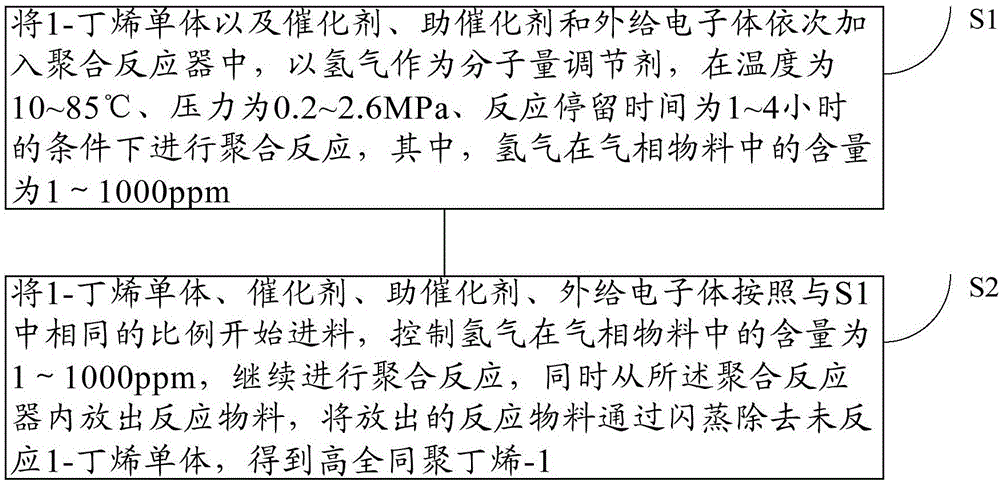

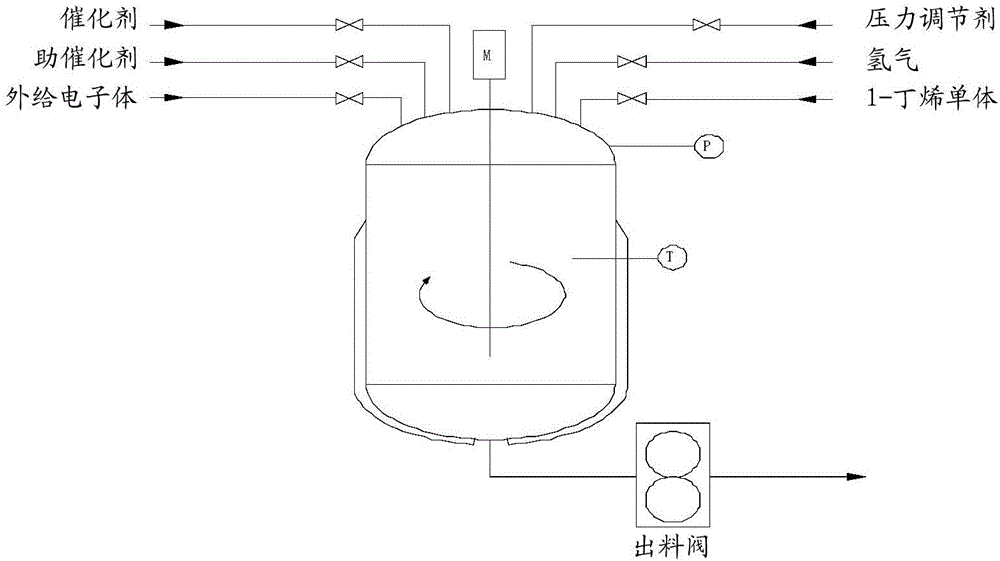

A continuous production method for highly isotactic poly(1-butene)

A continuous production method for highly isotactic poly(1-butene) is provided in embodiments of the invention and belongs to the field of polymers. Continuous stable production of the highly isotactic poly(1-butene) is achieved, continuous stability of product quality can be ensured and the molecular weight distribution of products is controlled. The method includes S1) adding a 1-butene monomer, a catalyst, a cocatalyst and an external electron donor into a polymerization reactor in order, and performing polymerization at 10-85 DEG C under 0.2-2.6 MPa with hydrogen being adopted as a molecular weight adjusting agent, reaction residence time being 1-4 h and the content of the hydrogen in a gaseous material being 1-1000 ppm; and S2) charging according to a ratio same as the ratio in the steps S1), controlling the content of the hydrogen in the gaseous material to be 1-1000 ppm, continuing polymerization, discharging the reaction material from the polymerization reactor at the same time, and removing the unreacted 1-butene monomer from the discharged reaction material through flash evaporation to obtain the highly isotactic poly(1-butene). The method can be used for industrial production of the highly isotactic poly(1-butene).

Owner:山东省滕州瑞达化工有限公司

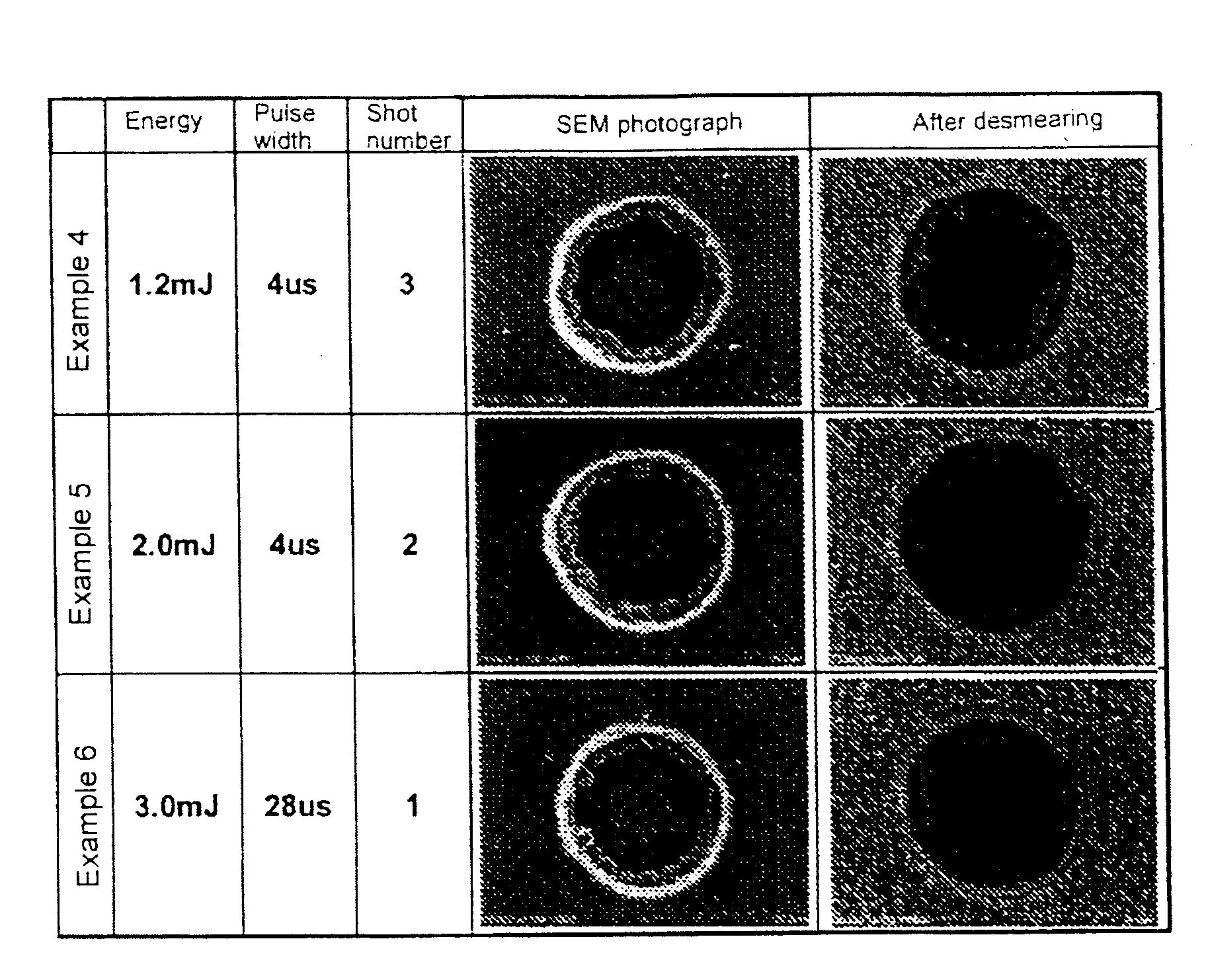

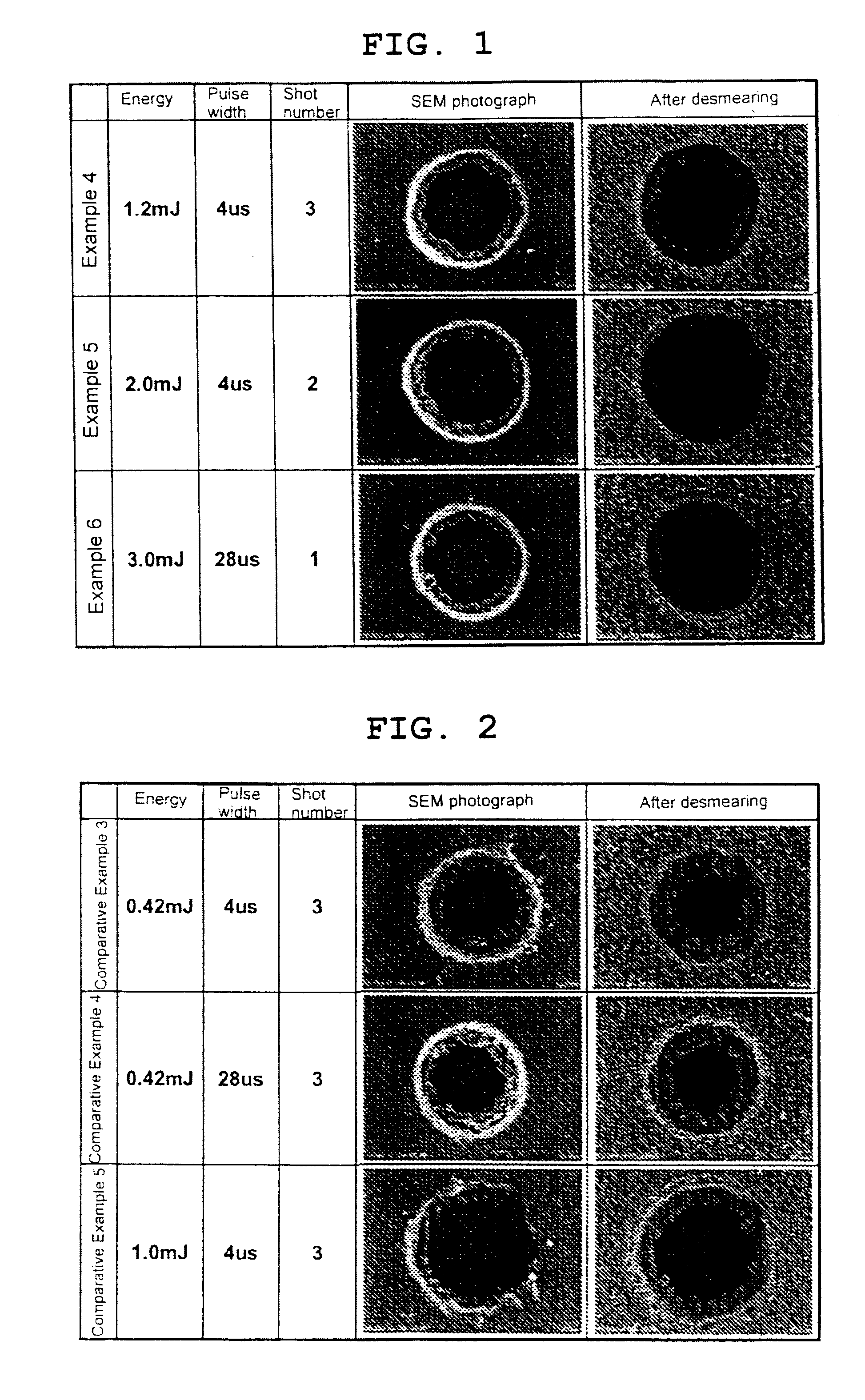

Process for producing multilayer printed wiring board

ActiveUS20100206471A1Improve productivityHigh mechanical strengthAdhesive processesLamination ancillary operationsEngineeringContinuous production

A production method of a multi-layer printed wiring board containing the following steps (1)-(5):(1) a temporary fitting preparatory step including conveying an adhesive sheet from an adhesive sheet roll wherein an adhesive sheet having a prepreg formed on a support film is wound in a roll and placing the adhesive sheet such that a prepreg surface contacts one or both of the surfaces of a circuit board,(2) a temporary fitting step for temporarily fitting the adhesive sheet to the circuit board, including partially adhering the adhesive sheet to the circuit board by heating and pressing a part of the adhesive sheet from the support film side, and cutting the adhesive sheet according to the size of the circuit board with a cutter,(3) a laminating step including heating and pressing the temporarily fitted adhesive sheet under reduced pressure to laminate the adhesive sheet on the circuit board,(4) a thermal curing step including forming an insulating layer by thermally curing the prepreg, and(5) a detaching step including detaching the support film after the thermal curing step,enables continuous production of an insulating layer of a multi-layer printed wiring board with a prepreg and without using a single wafer.

Owner:AJINOMOTO CO INC

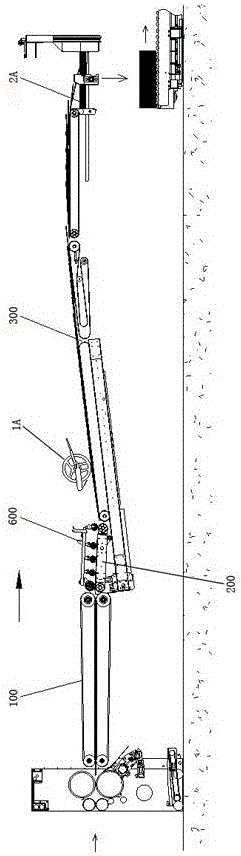

Novel carton device and control method thereof

ActiveCN105731046AEasy to transport angleHigh degree of automationConveyorsPile receiversCartonAutomation

The invention relates to the technical field of corrugated paper, in particular to a novel carton device. The novel carton device comprises a front conveying mechanism, a transitional conveying mechanism connected with the front conveying mechanism, a rear conveying mechanism connected with the transitional conveying mechanism and a beating and tidying mechanism connected with the rear conveying mechanism. A paper pressing mechanism is arranged on the transitional conveying mechanism, and a big wheel adjusting mechanism is arranged on the rear conveying mechanism. According to an adjusted conveying table of the novel carton device, cartons can be kept at the best conveying angle in the production process and can achieve continuous production stably at a high speed. The novel carton device achieves the functions of separating and putting the cartons. The original small gap delta 1 between the cartons is changed to be a big gap delta 2; the cartons do not collide in the last stage of conveying process after the gap is enlarged, and conveying is smoother. The novel carton device enables all the cartons falling into a stacking area to be beaten tidily, and is high in automation degree and convenient to operate.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

Method and apparatus for manufacturing thermoplastic synthetic resin sheet or film

InactiveUS20050173828A1High glossStable continuous productionFlat articlesRotational axisSpin casting

An apparatus for producing a thermoplastic synthetic resin sheet or film has a casting mechanism having support rollers each mounted to undergo rotation about a corresponding rotational axis and one of which is mounted to undergo non-rotational displacement relative to the other support rollers. A casting sleeve is entrained around the support rollers for rotation therewith. A casting roller is mounted for undergoing rotation relative to the casting sleeve. A synthetic resin material is fed between opposite and confronting outer peripheral surfaces of the casting sleeve and the casting roller while rotating the casting sleeve and the casting roller and while effecting non-rotational displacement of one of the support rollers to holdingly press the synthetic resin material between the casting sleeve and the casting roller and thereby form the synthetic resin material into a thermoplastic synthetic resin sheet or film.

Owner:CTE

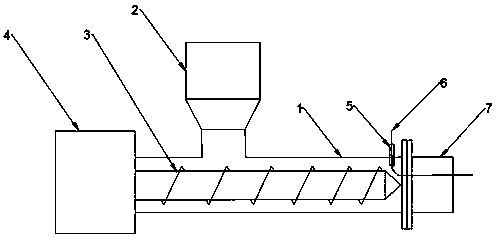

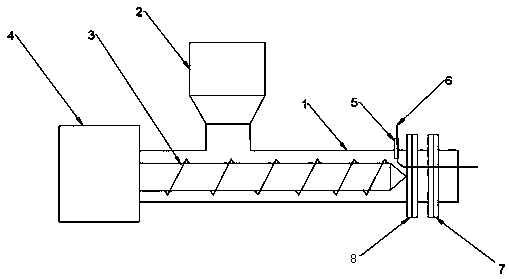

Forming method of hard alloy bar with spiral hole

The invention discloses a forming method of a hard alloy bar with a spiral hole. According to the forming method, hard alloy powders and a polymer wire are used as raw materials, a hard alloy blank with the polymer wire is formed after the raw materials are extruded and molded through a screw, and the hard alloy bar with the spiral hole is obtained after the hard alloy blank is sintered. Accordingto the forming method, through cooperation of a screw extruder and a rotary die head, stable and continuous production of the hard alloy bars is achieved, and the diameter and number of the spiral holes on the hard alloy bar can be controlled through adjusting the diameter and the number of thread lines, so that it is ensured that the diameter and the spiral lifting angle of the spiral hole are stable.

Owner:HUNAN UNIV OF TECH

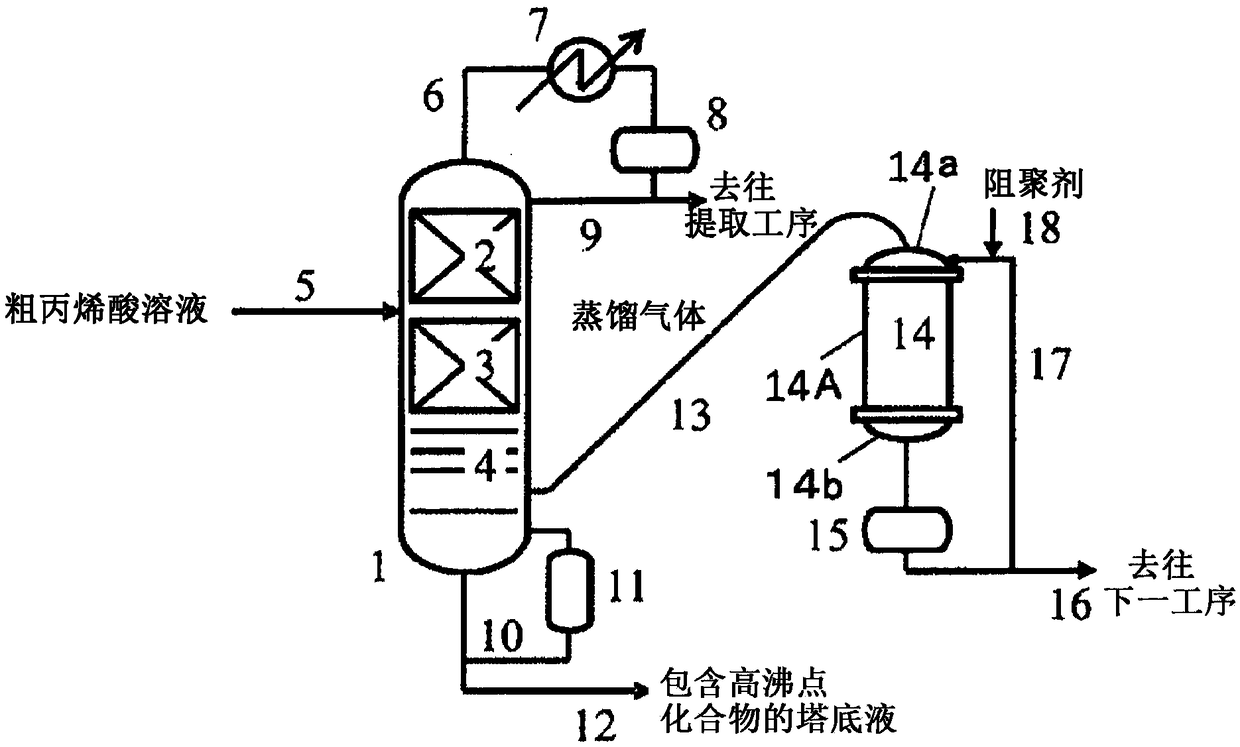

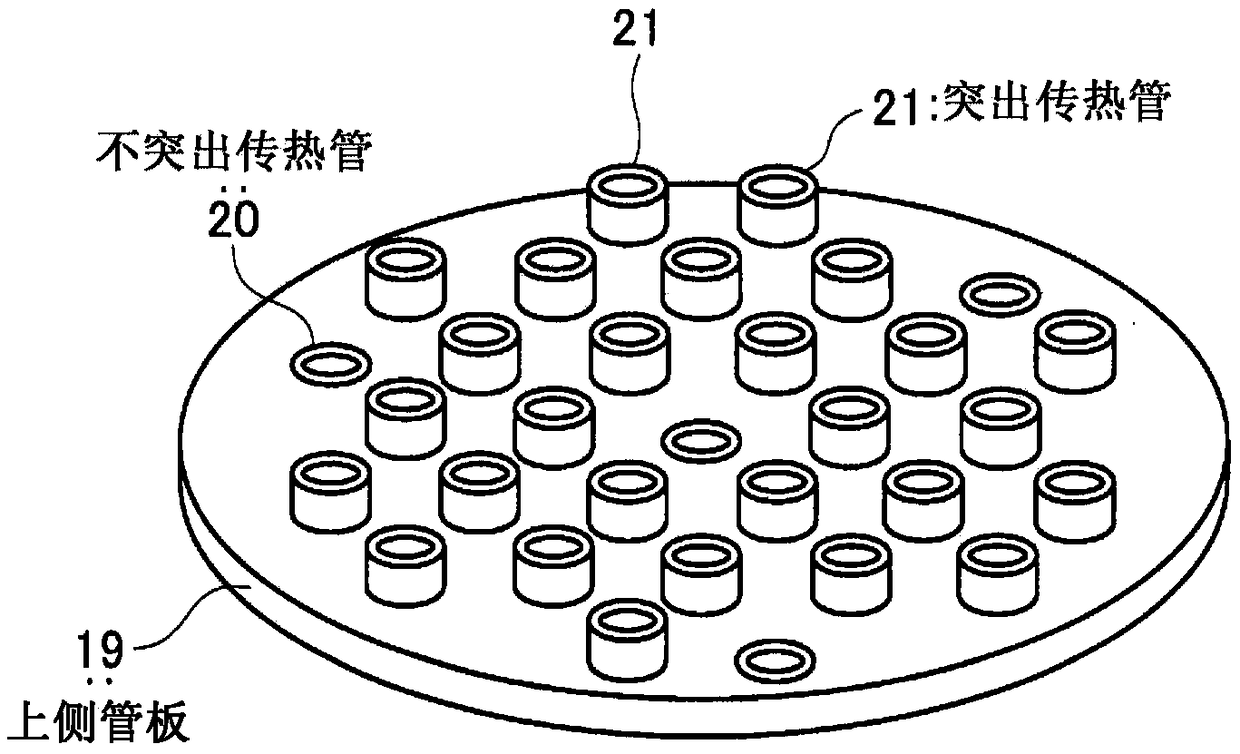

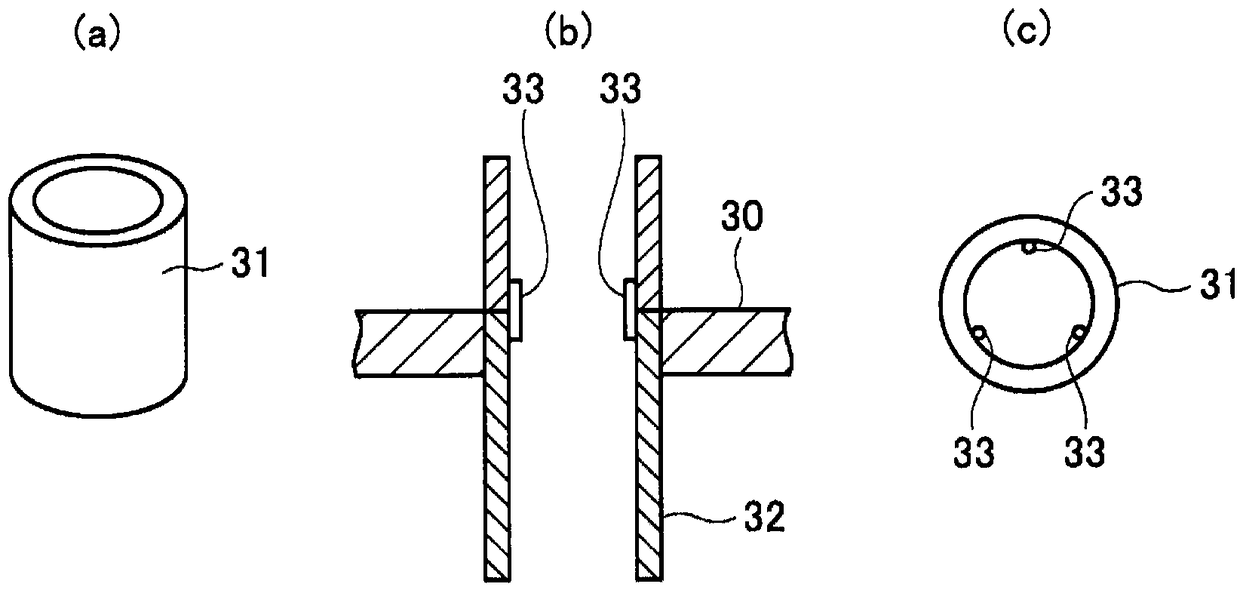

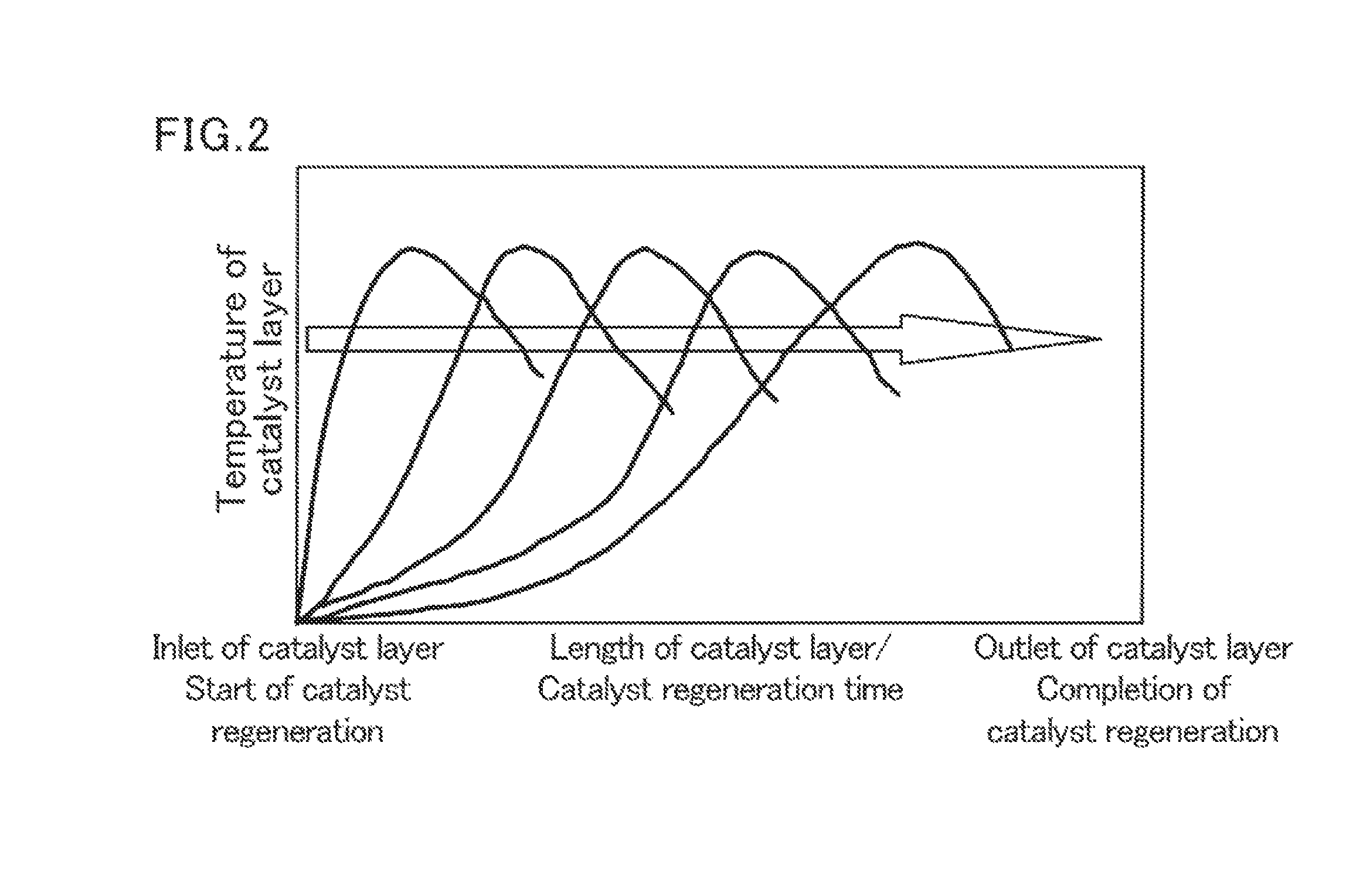

Production method for (METH)acrylic acid or ester thereof

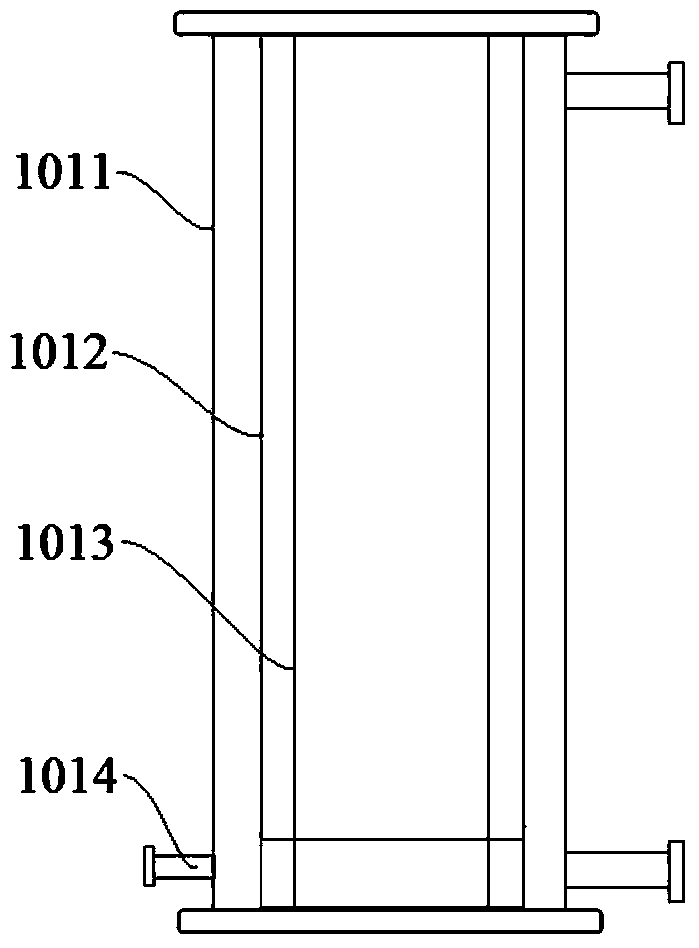

ActiveCN109415292AStable continuous productionAvoid generatingOrganic compound preparationCarboxylic acid esters preparationMeth-Distillation

The method comprises steps of: using a vertical multi-tubular heat exchanger having a tubular body, an upper side tube plate and a lower side tube plate disposed on the upper extremity side and the lower extremity side of the tubular body respectively, a plurality of heat-transfer tubes erected between the upper-side tube plate and the lower-side tube plate, and lid parts each disposed on the upper side of the upper-side tube plate and the lower side of the lower-side tube plate, the upper-side tube plate and the lid part forming a receiving chamber whereinto a distillation gas is introduced,which is then cooled while passing through the interior of the heat-transfer tubes and turned into a condensation solution; and introducing into the receiving chamber a solution containing a polymerization inhibitor. Some of the plurality of heat-transfer tubes have upper ends thereof protruding above the upper-side tube plate while the rest are non-protruding. The solution containing the polymerization inhibitor, which has come in contact with the distillation gas inside the receiving chamber, forms a liquid-flow layer of a predetermined liquid depth above the upper side tube plate.

Owner:MITSUBISHI CHEM CORP

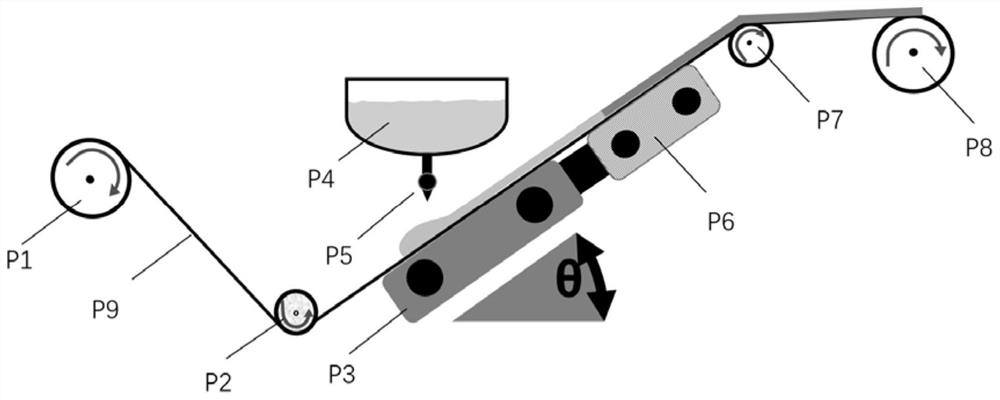

Ultrathin lithium-rich alloy with embedded three-dimensional skeleton structure as well as preparation method and application of ultrathin lithium-rich alloy

ActiveCN114204001AStable continuous productionEfficient continuous productionCell electrodesLi-accumulatorsAlloyLarge range

The invention discloses an ultrathin lithium-rich alloy with an embedded three-dimensional skeleton structure and a preparation method and application of the ultrathin lithium-rich alloy, and belongs to the technical field of lithium batteries. The ultrathin lithium-rich alloy with the embedded three-dimensional skeleton structure is prepared by changing the types of dissimilar substances and the proportion of the dissimilar substances to lithium element and matching with a casting substrate with a certain inclination angle, movement speed and cooling speed; and the adhesive force and wettability of the lithium-rich alloy solution on the casting substrate and the phase separation behavior in the cooling process are jointly regulated and controlled, so that the thickness and the surface state of the lithium-rich alloy layer, the bonding state of the lithium-rich alloy layer and the casting substrate and the morphology structure of a three-dimensional framework are regulated. The ultrathin lithium-rich alloy with the embedded three-dimensional skeleton structure is prepared by adopting the inclined melting tape casting method, the thickness of the film can be changed in a relatively large range, and the method has the characteristics of simplicity, high efficiency, wide application range and capability of realizing batch continuous production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Process for prepn. of dialkyl formanmide

ActiveCN1519228AAvoid accumulationAddresses shortcomings of existing methods that make reaction temperature control difficultOrganic compound preparationOrganic chemistry methodsReaction temperatureOxygen

Provided is a method for producing a dialkylformamide suppressing the accumulation of crystalline by-products with time and free from the problem of conventional process comprising the difficult control of the reaction temperature and enabling stable continuous production over a long period. A dialkylformamide is produced from a dialkylamine and carbon monoxide by using an alkali metal alcoholate as a catalyst. The reaction is carried out at an oxygen concentration of <=0.5 vol.% in the mixed raw material gas and an oxygen molar ratio of <=2 in the mixed gas based on the alkali metal alcoholate.

Owner:MITSUBISHI CHEM CORP

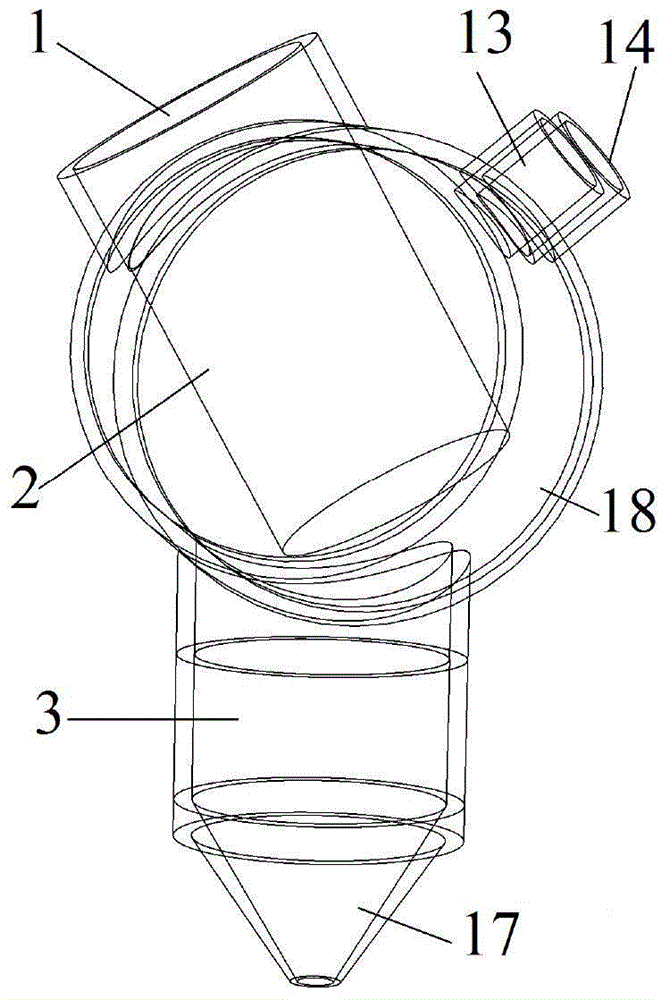

Powder microwave chemical vapor phase coating equipment capable of realizing continuous production

ActiveCN104878368APromote generationGenerate uniformChemical vapor deposition coatingMicrowaveStraight tube

The invention discloses powder microwave chemical vapor phase coating equipment capable of realizing continuous production. The microwave chemical vapor phase coating equipment comprises a feeding valve, a reaction chamber and a discharging valve which are sequentially connected, wherein the reaction chamber is a straight tube of which two ends are provided with elbows; a rotary driving device and a plurality of magnetrons are arranged on the straight tube; an air inlet I and a reaction chamber exhaust outlet are correspondingly formed in two ends of the reaction chamber; the feeding valve comprises a casing, a feeding valve rotor inside the casing as well as a feed opening, a feeding valve air inlet, a feeding valve exhaust outlet and a feeding speed-regulating valve which are arranged on the same plane together with the feeding valve rotor; the feeding valve rotor can freely rotate inside the casing and is tangent to the inner wall of the casing to form the sealing; the discharging valve is similar to the feeding valve in structure, and can also realize material transfer by the rotation of the rotor and keeps the sealing property of the reaction chamber; both the feeding valve rotor and a discharging valve rotor are of structures of which one ends are opened. According to the powder microwave chemical vapor phase coating equipment, the continuous production can be realized; in addition, prepared products are provided with uniform coating layers and are homogeneous and stable in property.

Owner:成都巴莫科技有限责任公司

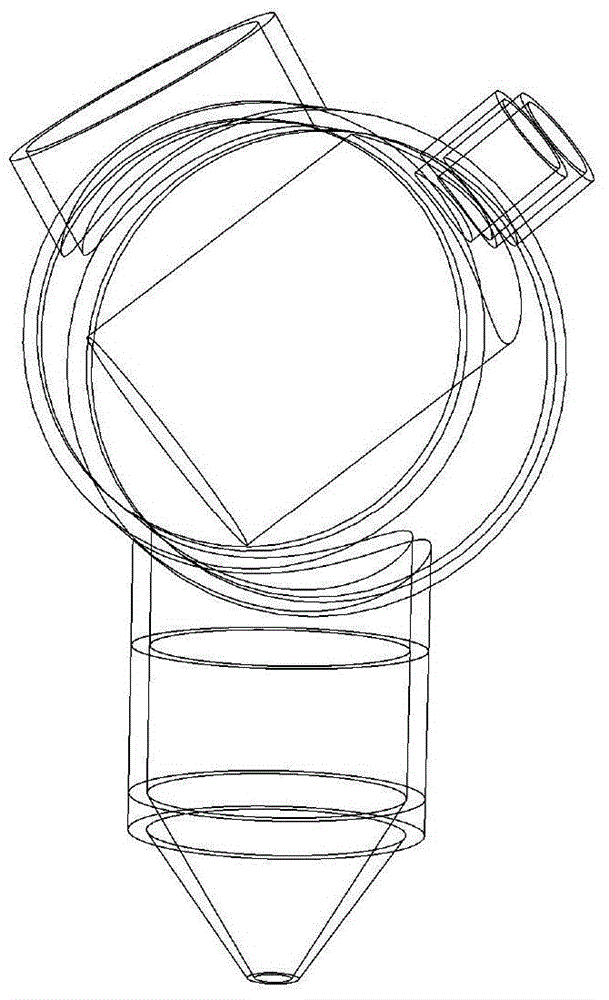

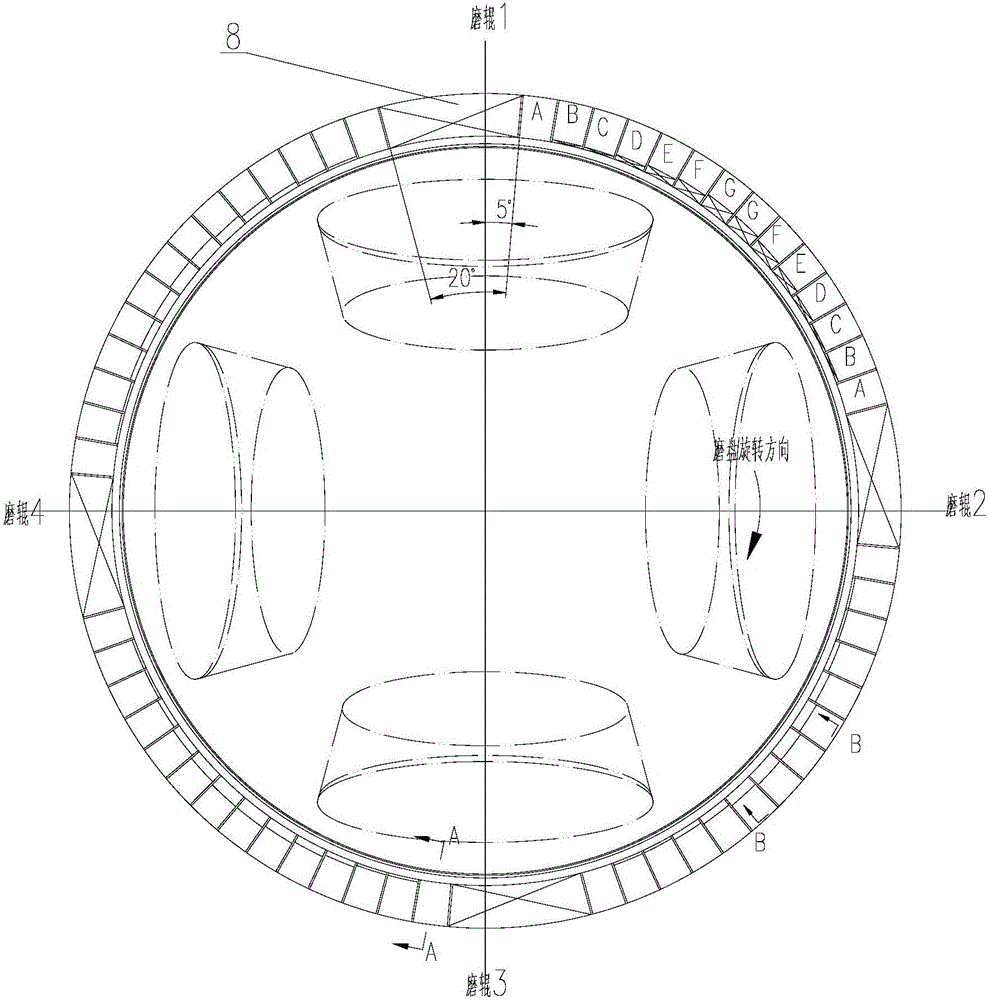

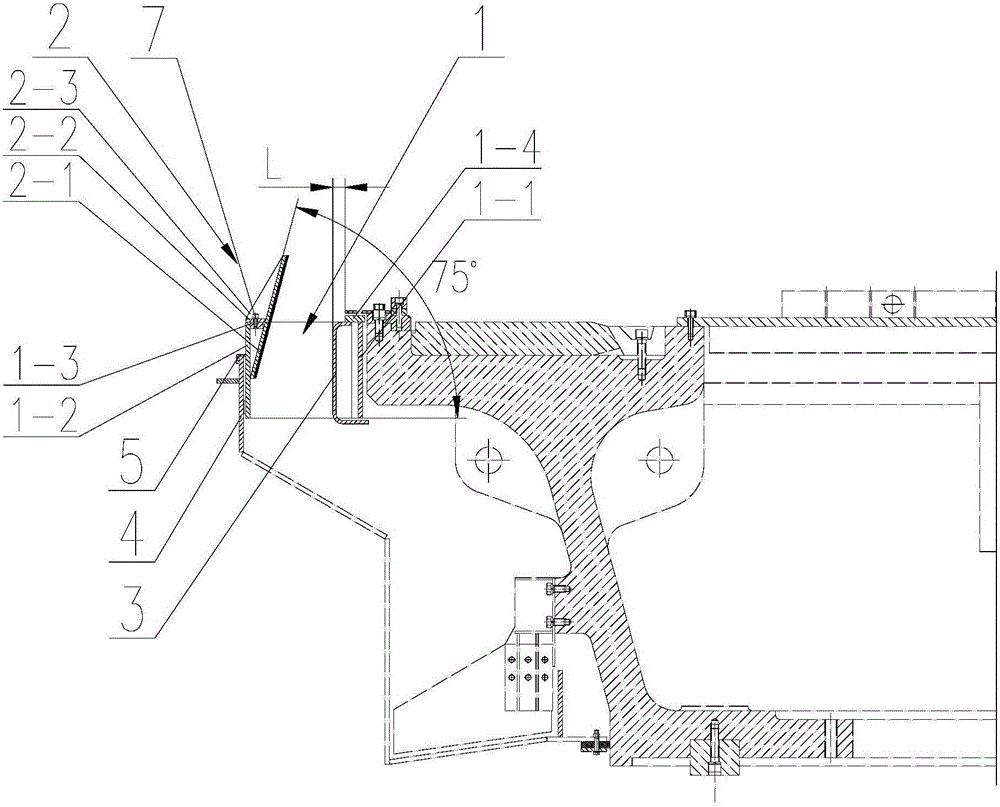

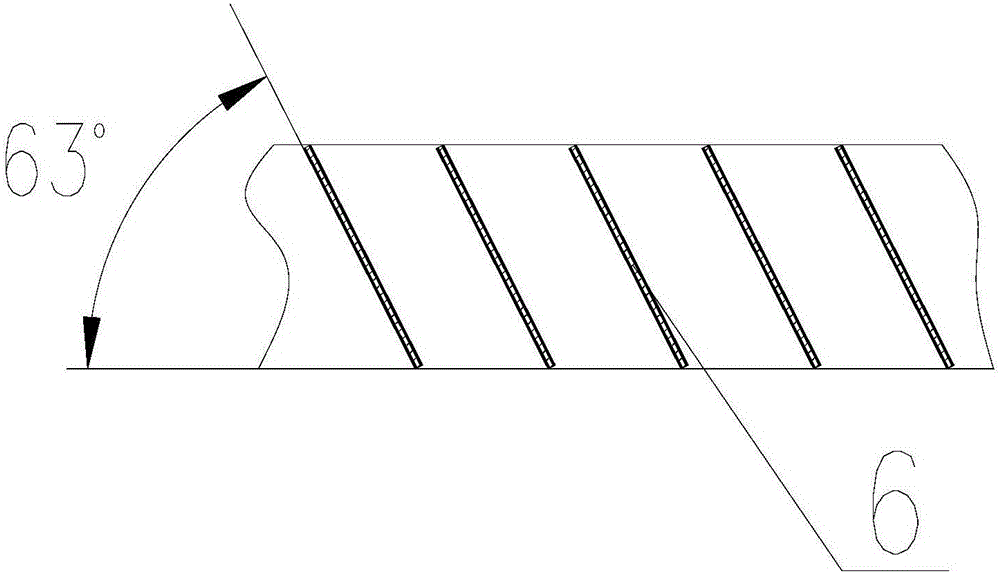

Vertical roller mill air guide ring device

The invention relates to a vertical roller mill air guide ring device, which comprises an air ring, an air guide ring, an air adjusting plate and an air flue, wherein the air ring is fixedly arranged at the upper part of the air flue through an L-shaped suspension plate; the air ring comprises an inner side annular plate, an outer side annular plate and a shutter guide plate; the shutter guide plate is located between the inner side annular plate and the outer side annular plate; an included angle of 63 degrees is formed between the shutter guide plate and the horizontal direction; the air guide ring is arranged on the outer side annular plate through a fastener and inclines by 75 degrees towards the center of a roller mill; and the air guide ring comprises an air guide plate, a connection plate and a reinforcing rib plate. By dopting the technical scheme, the ventilation area of the air ring is easily adjusted when different materials are ground; and the balance of the material amount in the mill and a gas in the mill is ensured, so that a stable material inner cycle number is formed in the mill. Meanwhile, the extension length of the air adjusting plate can be quickly adjusted at the air speed of the actual working condition of grinding different materials, and continuous production is not affected by exchange of the air adjusting plate and the air guide plate after the air adjusting plate is abraded, so that a pressure difference in the vertical mill is reduced; and the requirements of stable production and energy consumption reduction are met.

Owner:中材(天津)粉体技术装备有限公司 +1

System for recycling raw gas afterheat of coke oven

ActiveCN103436271BLong-term continuous productionSafe continuous productionSteam generation using hot heat carriersDistillation gas withdrawalControl systemProcess engineering

The invention discloses a system for recycling the raw gas afterheat of a coke oven, and belongs to the technical field of the recycling utilization of raw gas afterheat. The system for recycling the raw gas afterheat of the coke oven comprises a heat exchange medium circulating system and a water charging system, wherein the heat exchange medium circulating system comprises a heat exchanger set, a steam pocket and a forced circulation pump, a water inlet of the heat exchanger set is connected to a water outlet of the steam pocket through the forced circulation pump, a water outlet of the heat exchanger set is connected to a water inlet of the steam pocket, and a steam outlet in the steam pocket is connected to an external steam pipe network; the water charging system comprises a buffer water tank, a make-up pump, a feed pump and a desalting oxygen removal water tank, the feed pump is arranged between the buffer water tank and the desalting oxygen removal water tank, and the buffer water tank is connected to the steam pocket through the make-up pump. The system can be used for effectively, safely and reliably recycling the raw gas afterheat and circularly converting a heat exchange medium into middle and low pressure steam; the system operation can be effectively detected and controlled, so that the safe and normal operation of the system is ensured, and the accident rate is reduced.

Owner:江苏龙冶节能科技有限公司

Methods for producing acrylic acid and/or ester thereof and polymer of the acrylic acid and/or ester thereof

ActiveUS9029596B2Stable productionLow residual monomer contentOrganic compound preparationOrganic chemistry methodsPolymer sciencePtru catalyst

A method for producing acrylic acid and / or an ester thereof from a raw material composition containing hydroxypropionic acid and / or an ester thereof, the method including the steps of: (a) evaporating the raw material composition; and (b) dehydrating the evaporated raw material composition by contact with a dehydration catalyst, wherein the total amount of hydroxypropionic acid and / or an ester thereof supplied in the step (b) is controlled to be 70% by mass or more based on 100% by mass of the total amount of hydroxypropionic acid and / or an ester thereof supplied in the step (a).

Owner:NIPPON SHOKUBAI CO LTD

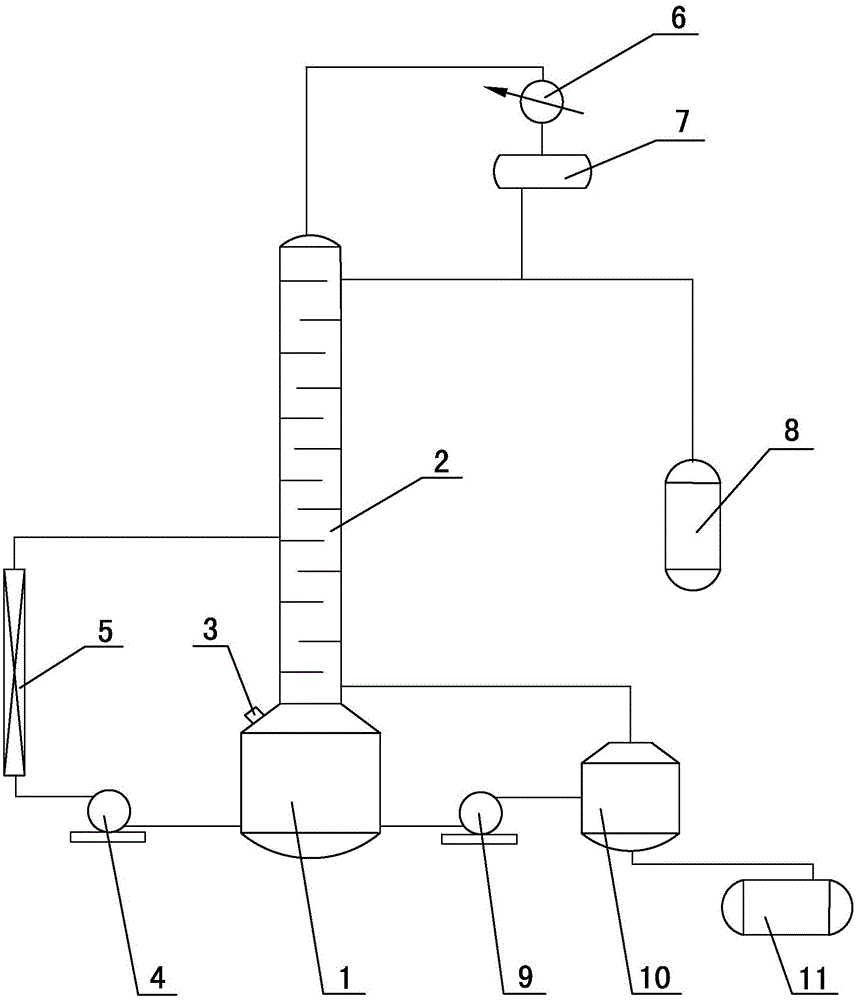

Method for continuously producing 2,3-dimethyl-1-butylene through 2,3-dimethyl-2-butylene

ActiveCN105152845AEasy temperature controlEasy to operateHydrocarbon by isomerisationDistillation purification/separationChemical synthesisBoiling point

The invention belongs to the technical field of chemical synthesis, and particularly relates to a method for continuously producing 2,3-dimethyl-1-butylene through 2,3-dimethyl-2-butylene. The 2,3-dimethyl-2-butylene takes isomerization reaction to generate the 2,3-dimethyl-1-butylene through a reaction tube containing isomerization catalysts; then, the 2,3-dimethyl-1-butylene enters a rectifying tower to be rectified; partial materials in a distillation kettle enter a heavy ingredient distillation kettle; high-boiling-point ingredients generated by side reaction are removed; then, the materials return to the rectifying tower; the 2,3-dimethyl-2-butylene is continuously added into the distillation kettle; the 2,3-dimethyl-1-butylene is continuously produced out from the rectifying tower. The method has the advantages that the isomerization catalysts are contained in the reaction tube; the isomerization reaction temperature can be conveniently controlled; the byproducts are reduced; in addition, the catalysts can be more favorably replaced; the adoption of the reaction kettle for isomerization reaction is avoided; the technical flow process operation is reduced; the continuous production is realized; the product quality is ensured; the production cost is reduced.

Owner:山东广浦生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com