Production method for (METH)acrylic acid or ester thereof

A manufacturing method and technology of acrylic acid, applied in the direction of carboxylate preparation, separation methods, chemical instruments and methods, etc., can solve the problems of high polymerizability, low density, device blockage, etc., achieve long-term stable continuous production, and prevent polymer failure Generated and stacked effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] The present invention will be described in more detail through examples below, but the present invention is not limited by the following examples. In addition, the following examples and comparative examples were carried out using test equipment, but the dimensions of each part are different from those of the actual machine.

[0074] For convenience of description, a comparative example will be given first.

Embodiment 1

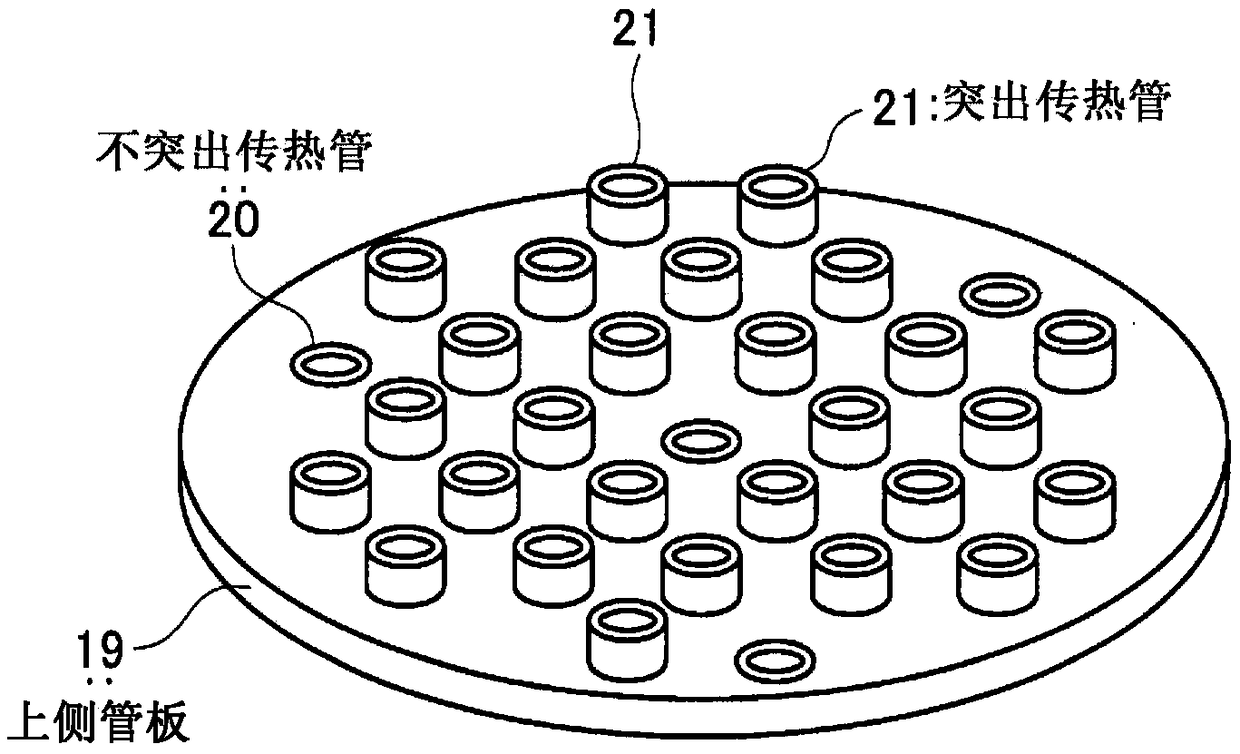

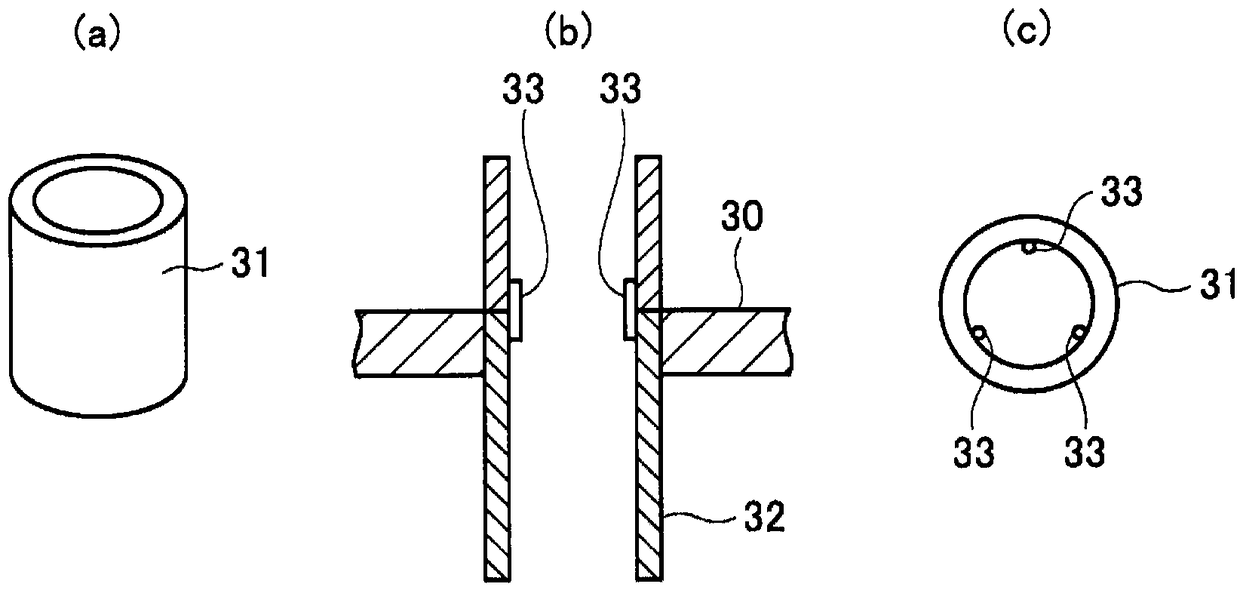

[0086] Operation was performed under the same conditions as those of Comparative Example 3 except that only one central part of the short tubes welded to the heat transfer tubes was removed. In this state, only the center one of the heat transfer tubes does not protrude, and the other 18 protrude by 10 mm. As a result, almost no captured matter was seen in the filter even after the 3-day operation. As a result of checking after washing with water, only a few lumps of polymer were confirmed on the outer peripheral portion of the upper tube sheet surface.

Embodiment 2

[0088] Further, three short tubes at the position symmetrical to the upper tube sheet surface among the short tubes near the outermost peripheral portion were removed, and the operation was carried out for 3 days under the same conditions as in Example 1. In this state, one of the heat transfer tubes in the center and three (4 in total) at equidistant positions on the outer periphery do not protrude from the heat transfer tube, and the other 15 protrude by 10 mm. During the operation period, no trapped matter was confirmed in the filter except for the dust that was considered to be mixed when it was opened. After washing with water, polymer lumps were not confirmed, and when all the short tubes were removed, streaks due to dirt were observed in about half of the joints of the short tubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com