Powder microwave chemical vapor phase coating equipment capable of realizing continuous production

A technology of microwave chemistry and gas phase coating, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of inability to achieve high-speed production, large batch differences, and uneven coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

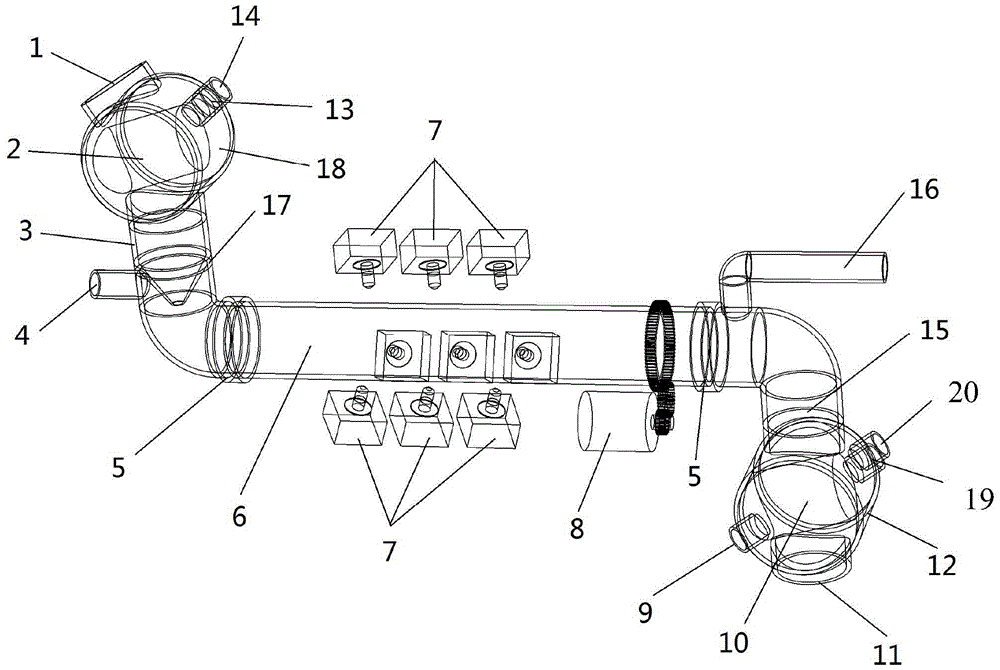

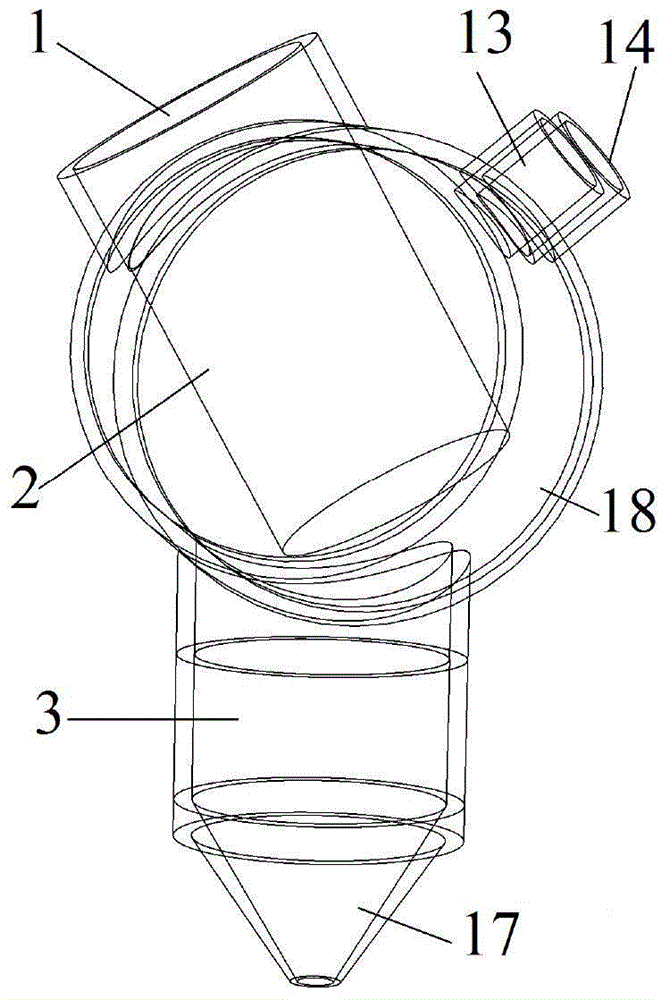

[0025] The continuous production powder microwave chemical vapor coating equipment will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0026] Such as figure 1 As shown, a continuous production of powder microwave chemical vapor coating equipment includes a feed valve 18, a reaction chamber 6 and a discharge valve 12; the reaction chamber 6 is a straight pipe with elbows connected through mechanical seals 5 at both ends , wherein the elbow I is connected to the feed valve 18 upwards, and the elbow II is connected to the discharge valve 12 downwards; the straight pipe is equipped with a rotary drive device 8, and a plurality of magnetrons 7 are installed on its side wall; An air inlet 14 is provided at the interface between the elbow I and the feed valve 18, and the upper side of the straight pipe near the elbow II is provided with a reaction chamber exhaust port 16; the feed valve 18 includes a housing and a feed valve arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com