Patents

Literature

77results about How to "Uniform and stable properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic light emitting display device and method of manufacturing the same

ActiveUS20100176383A1High carrier concentrationStable and uniform functional propertyElectroluminescent light sourcesSolid-state devicesDisplay deviceLight-emitting diode

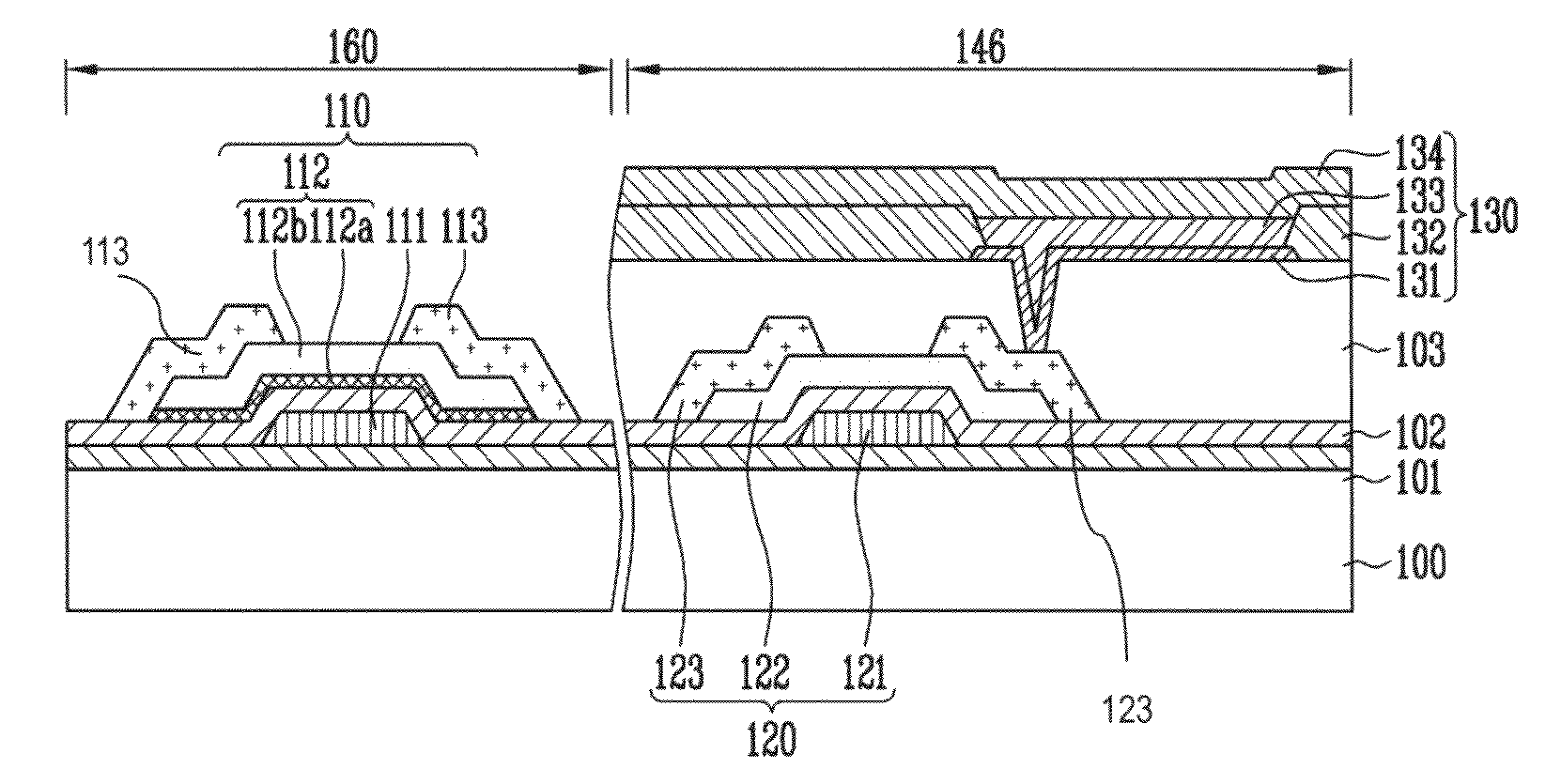

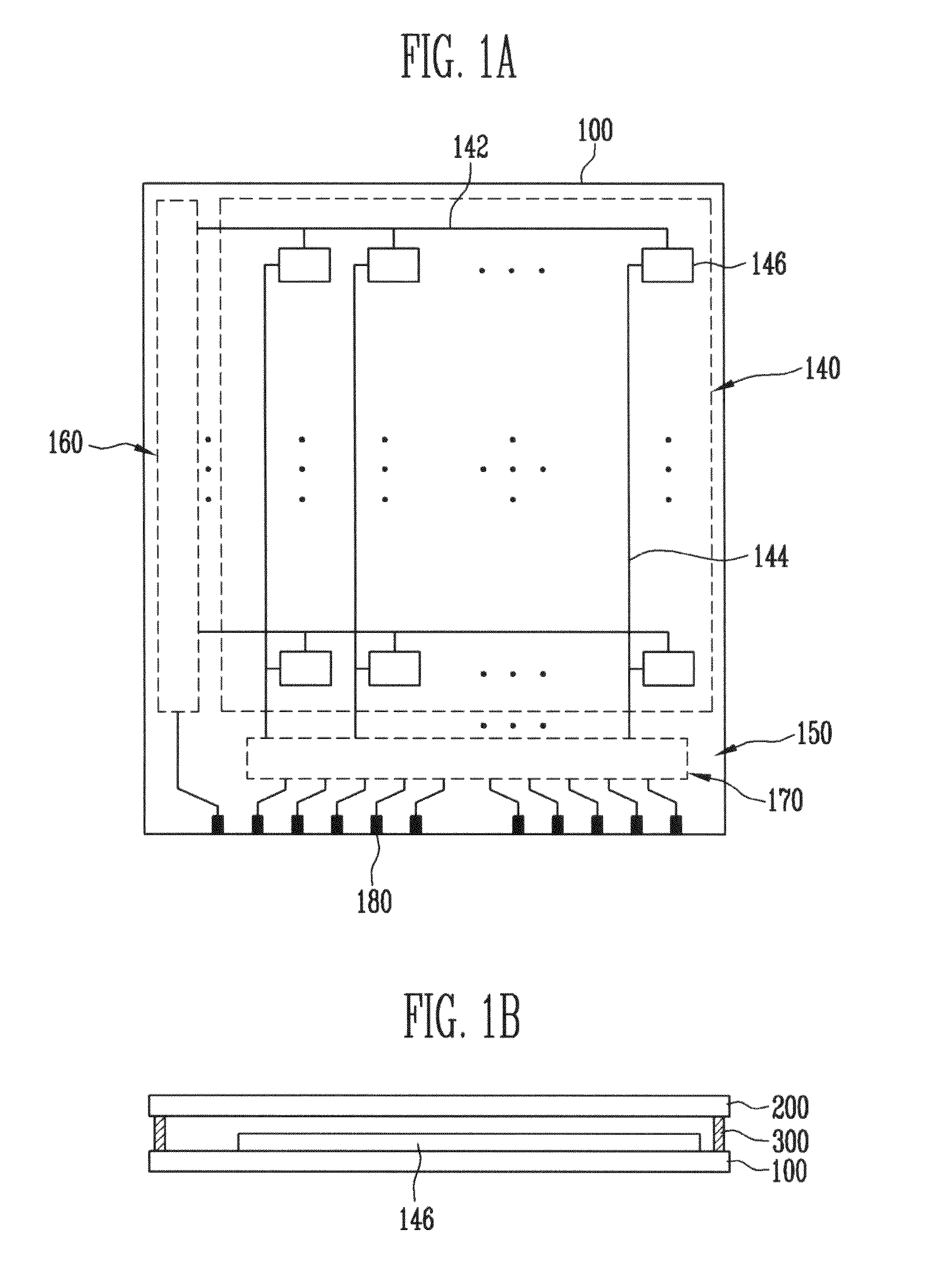

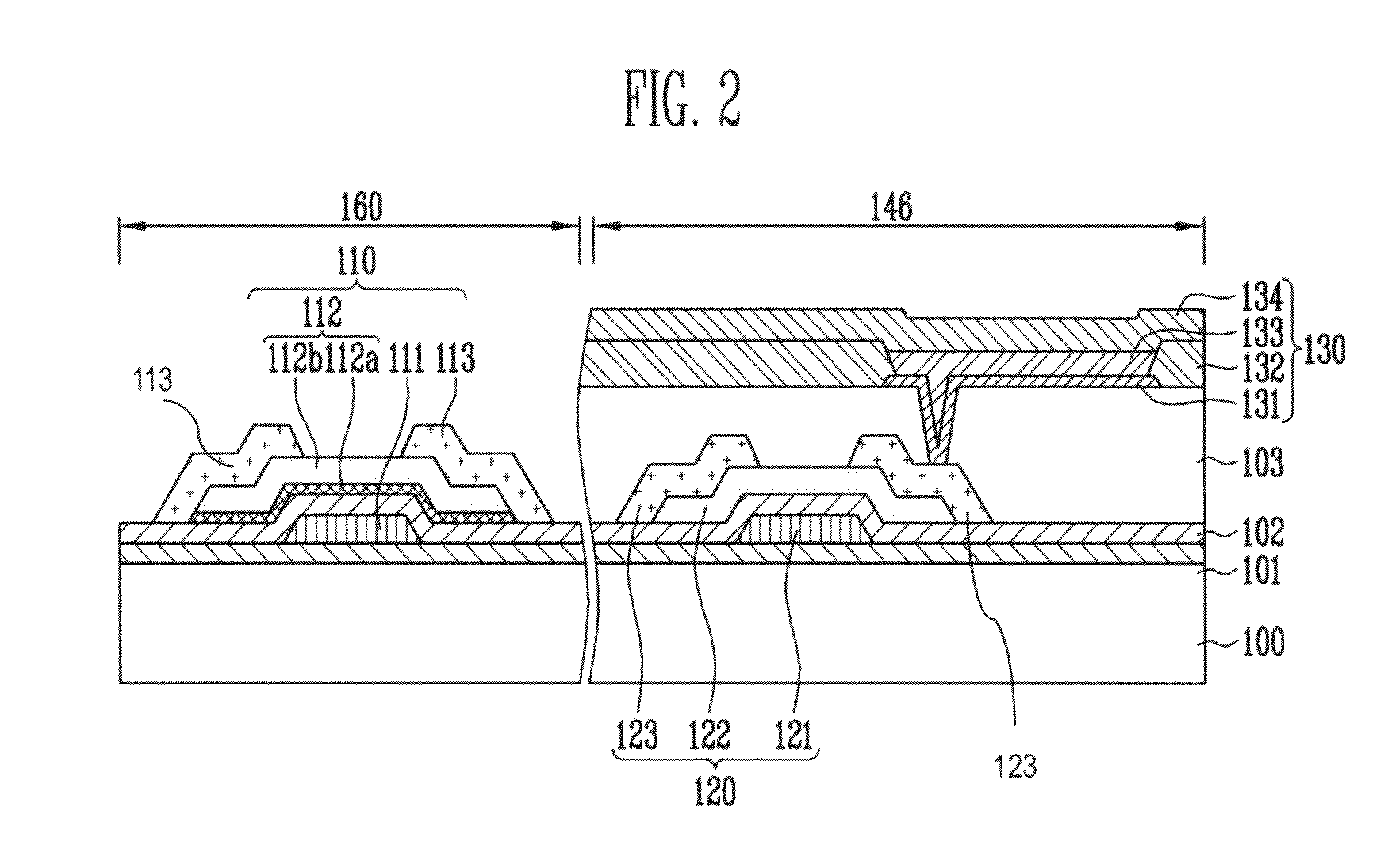

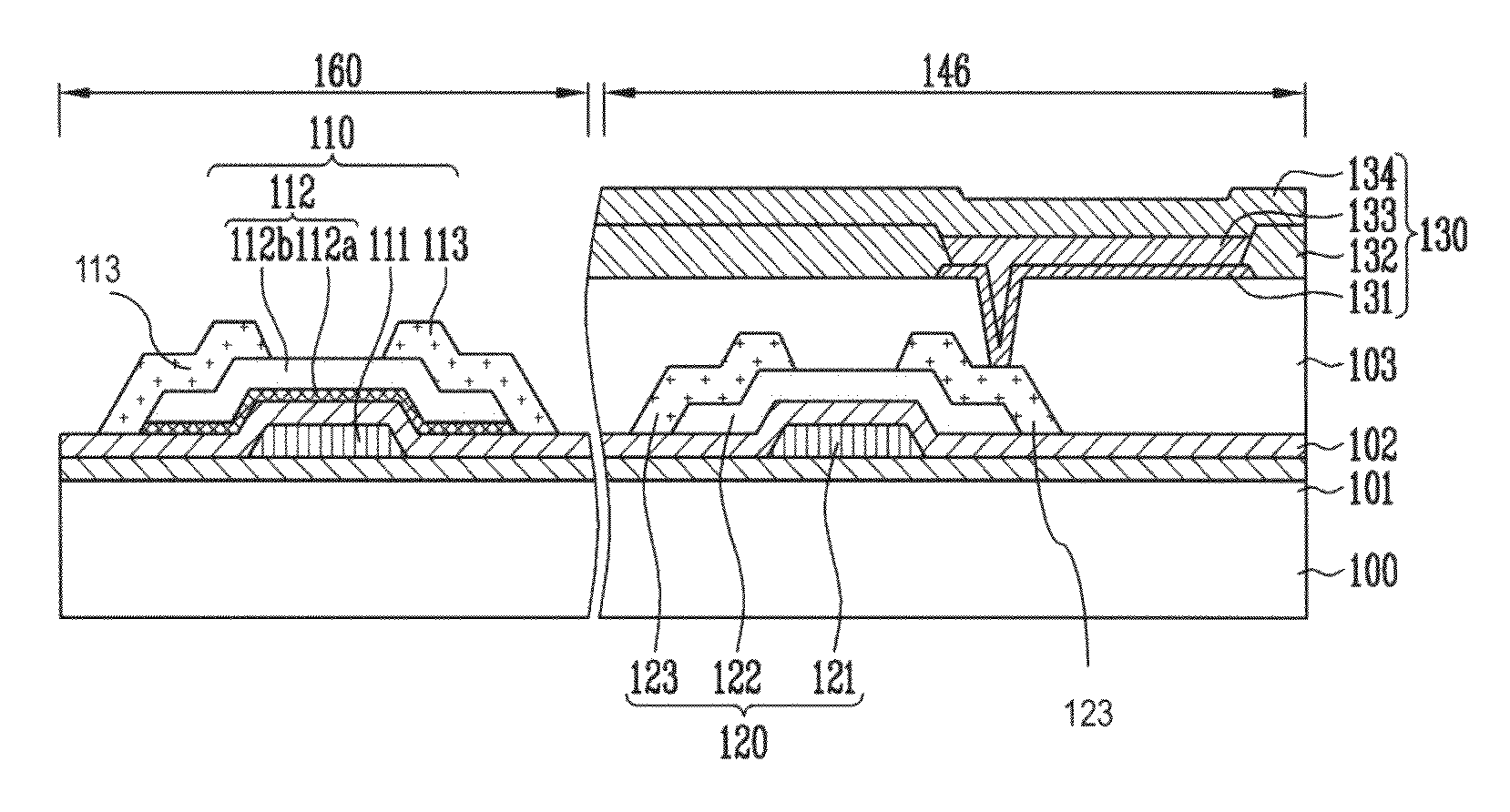

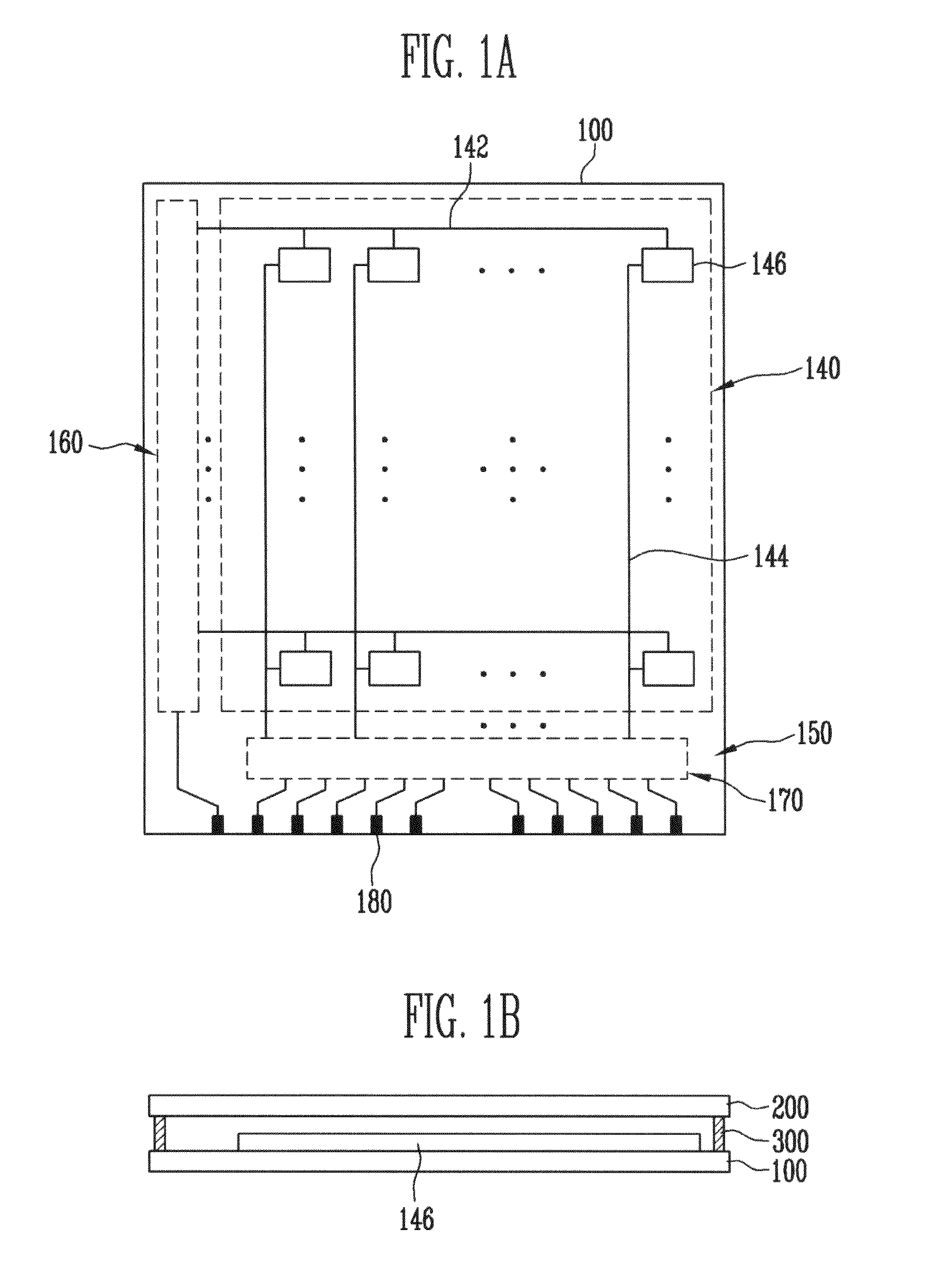

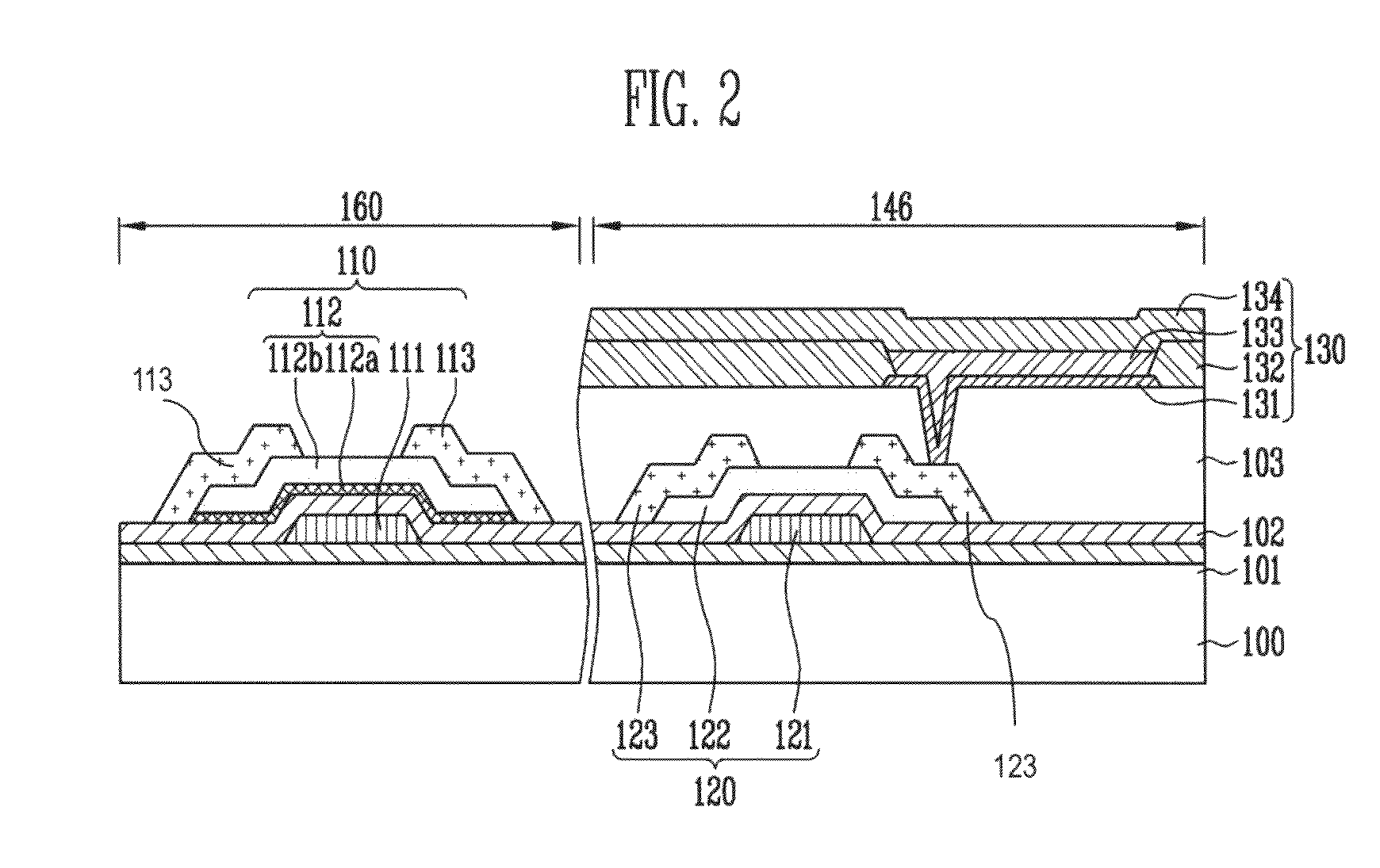

Disclosed is an organic light emitting display device and a method of manufacturing the same. The organic light emitting display device includes the thin film transistor of the drive unit that has the activation layer formed in a structure where the first oxide semiconductor layer and the second oxide semiconductor layer are stacked, the thin film transistor of the pixel unit that has the activation layer formed of the second oxide semiconductor layer, and the organic light emitting diode coupled to the thin film transistor of the pixel unit. The thin film transistor of the drive unit has channel formed on the first oxide semiconductor layer having a higher carrier concentration than the second oxide semiconductor layer, having a high charge mobility, and the thin film transistor of the pixel unit has a channel formed on the second oxide semiconductor layer, having a stable and uniform functional property.

Owner:SAMSUNG DISPLAY CO LTD

Organic light emitting display device and method of manufacturing the same

ActiveUS8436342B2Increase charge mobilityHigh concentrationElectroluminescent light sourcesSolid-state devicesDisplay deviceLight-emitting diode

Disclosed is an organic light emitting display device and a method of manufacturing the same. The organic light emitting display device includes the thin film transistor of the drive unit that has the activation layer formed in a structure where the first oxide semiconductor layer and the second oxide semiconductor layer are stacked, the thin film transistor of the pixel unit that has the activation layer formed of the second oxide semiconductor layer, and the organic light emitting diode coupled to the thin film transistor of the pixel unit. The thin film transistor of the drive unit has channel formed on the first oxide semiconductor layer having a higher carrier concentration than the second oxide semiconductor layer, having a high charge mobility, and the thin film transistor of the pixel unit has a channel formed on the second oxide semiconductor layer, having a stable and uniform functional property.

Owner:SAMSUNG DISPLAY CO LTD

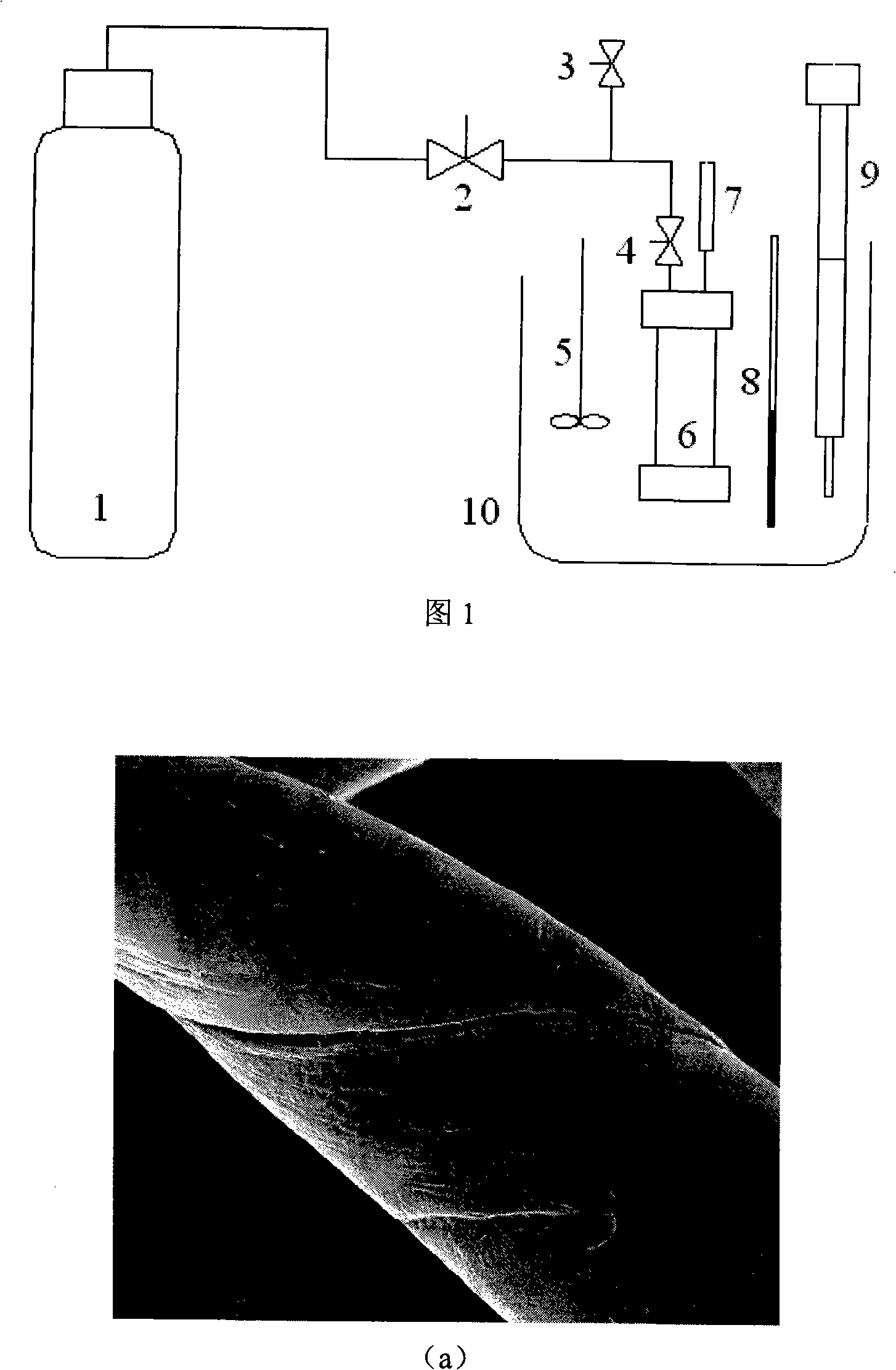

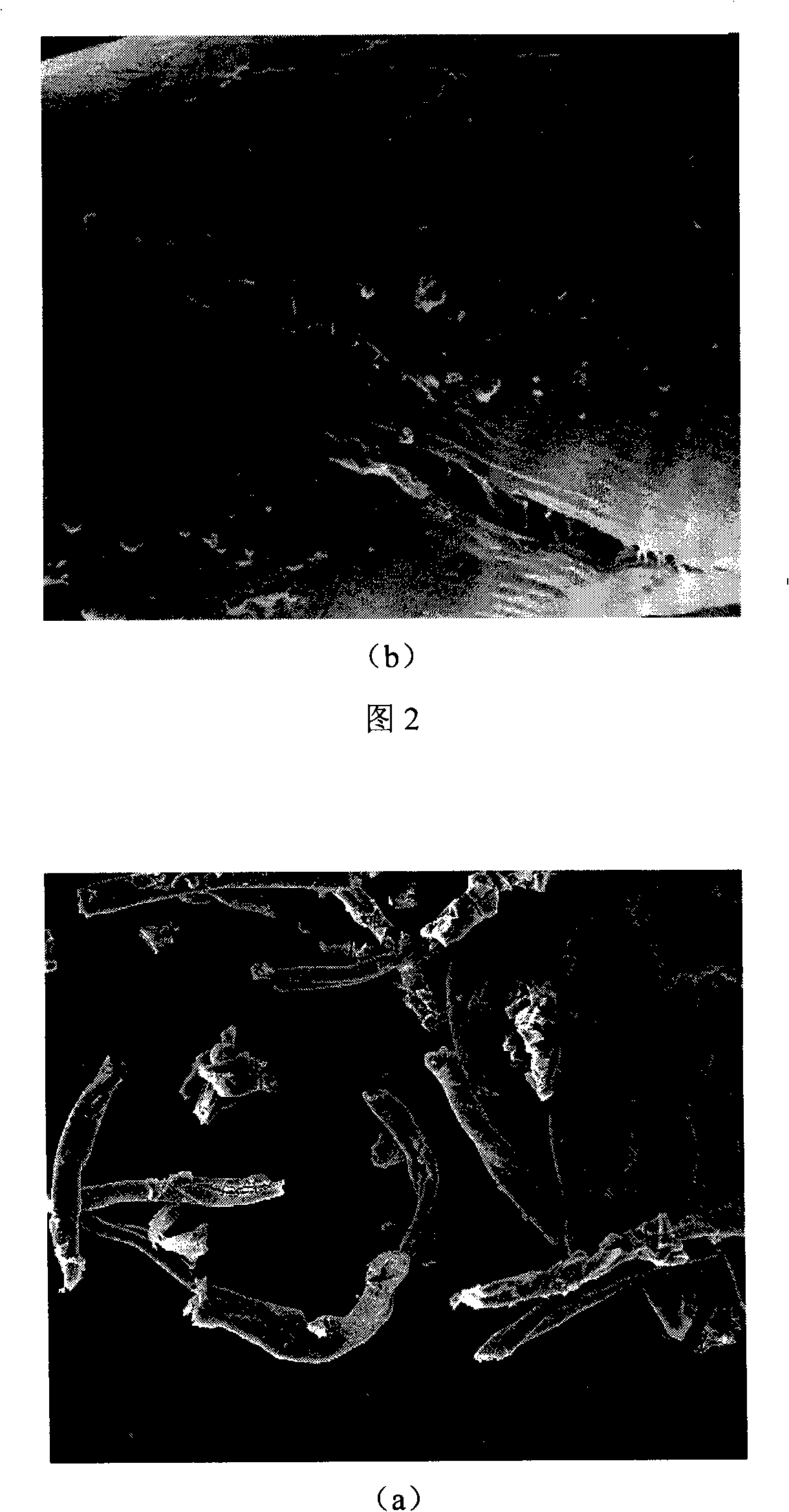

Method for preparing organic or inorganic composite fiber material with supercritical carbonic anhydride

The invention belongs to the technical field of organic and inorganic composite materials, in particular to a preparation method of organic and inorganic composite fibrous materials with supercritical carbon dioxide. The method includes pre-treatment and activation treatment of cellulose, doping of inorganic sol to the cellulose, etc. The invention makes use of the strong permeability of the carbon dioxide under supercritical conditions, can activate the cellulose with cosolvent, or lead nano particles in the inorganic sol to be absorbed and settled on the surface of the cellulose to form an even, continuous and stable coating layer; meanwhile, some sol particles penetrate into the fiber, so as to dope plenty of cellulose. The supercritical carbon dioxide adopted by the invention is safe, reliable, non-toxic, no pollutant and recyclable, and is environment friendly green solvent. The method of the invention is simple and easy to be operated, and the hybrid material has broad application prospect.

Owner:FUDAN UNIV

Homogeneous method for preparing wood fiber derivative under room temperature

The invention discloses a homogeneous method for preparing a wood fiber derivative under room temperature. The method comprises the following steps: drying ground wood fiber powder, suspending the dried wood fiber powder in a solvent, and stirring till the wood fiber is dissolved completely to obtain wood fiber solution; dissolving an acylation reagent in the same solvent, and stirring under the room temperature till the acylation reagent is dissolved completely to obtain acylation reagent solution; adding the acylation reagent solution into the wood fiber solution, and carrying out esterification reaction under the room temperature and a moisture isolated condition; and depositing the solution obtained after the esterification reaction, collecting, washing, freezing and drying deposits, and preparing to obtain the required wood fiber derivative. The invention has the advantages that homogeneous derivatization of wood fiber is realized under the room temperature; and not only can the homogeneity and the stability of the product be improved effectively, but also equipment requirements and energy requirements can be reduced. Therefore, the invention has a significant scientific value and practical significance on the development and the utilization of renewable resources such as wood fiber, biological substances and the like.

Owner:广西南宁绿园北林木业有限公司

Thermo-sensitive self-assembled tri-block copolymer, pharmaceutical composition, and preparation method and application of pharmaceutical composition

ActiveCN102850532AAccurate and controllable molecular weightThe synthesis steps are simplePharmaceutical non-active ingredientsProsthesisDrug carrierPharmaceutical drug

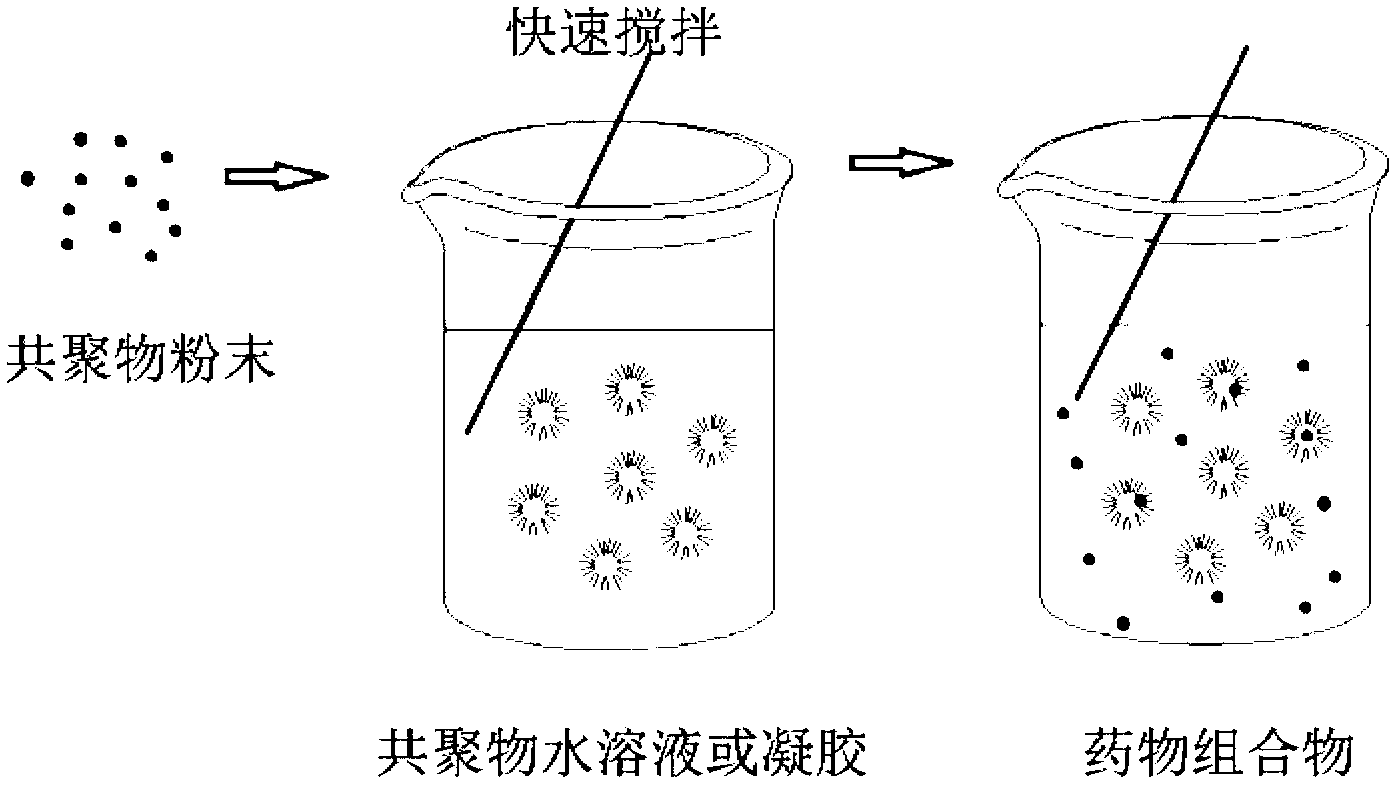

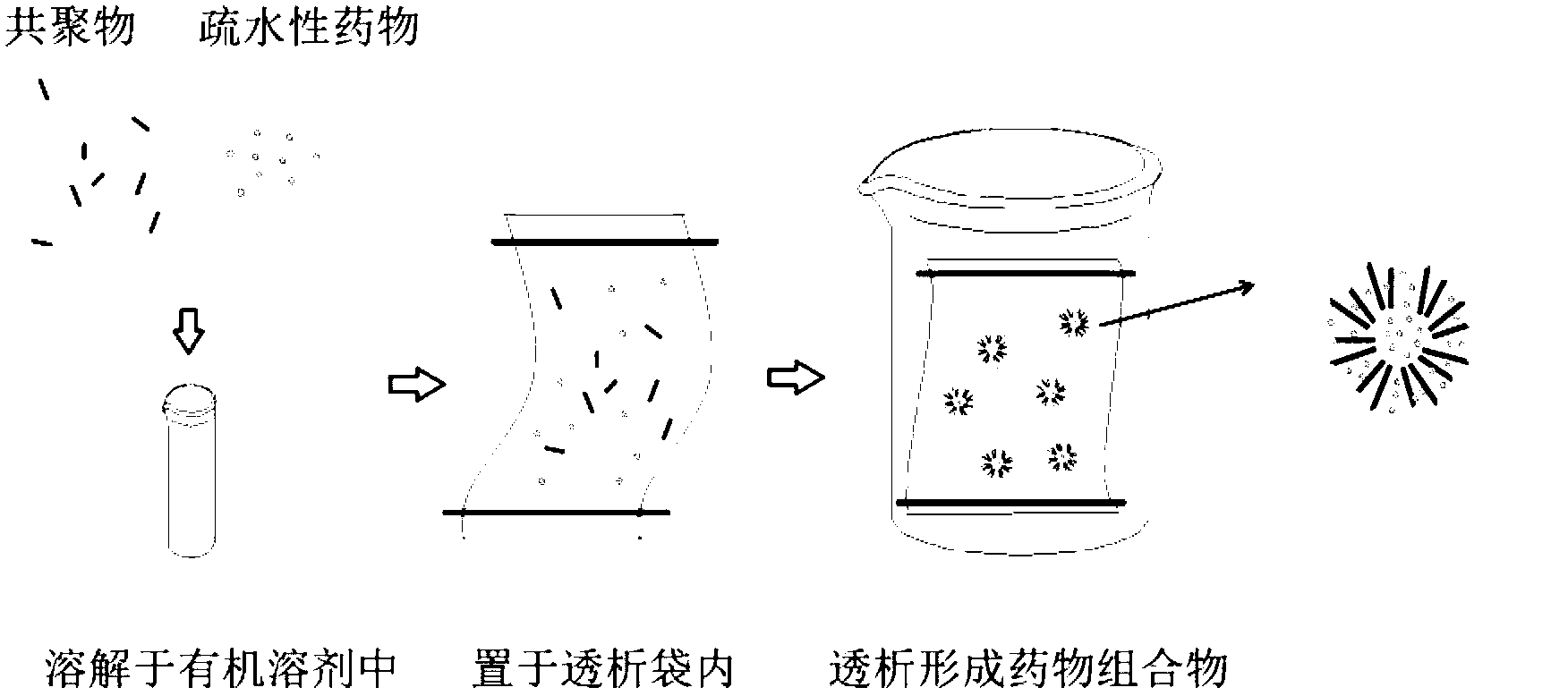

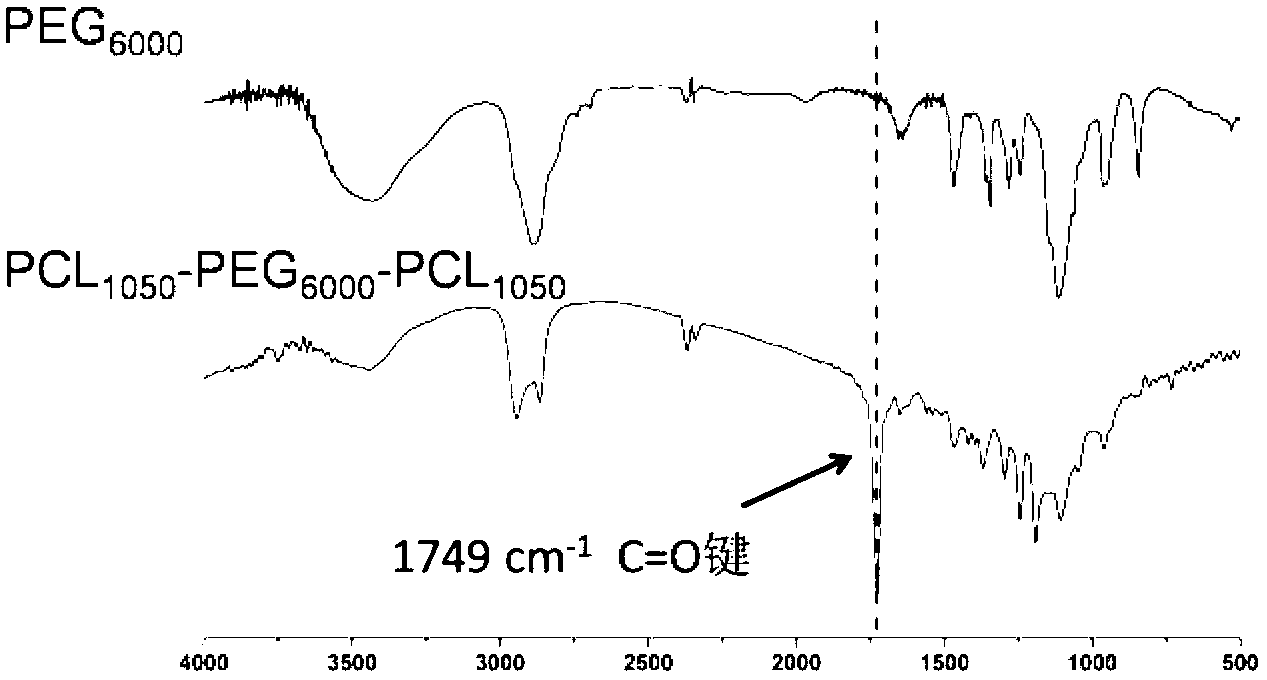

The invention provides a PCLm-PEG6000-PCLm thermo-sensitive self-assembled tri-block copolymer, wherein the copolymer presents two-phase transition characteristics, and can be applied to a controlled release drug delivery system as a drug carrier or can be applied to tissue engineering as a biodegradable material. The invention further provides a pharmaceutical composition containing the tri-block copolymer, and a preparation method and an application of the pharmaceutical composition. A system consisting of PCLm-PEG6000-PCLm tri-block copolymer and water can both load water-soluble drugs, and can efficiently load water-insoluble drugs, and has an excellent controlled-release effect.

Owner:ZHEJIANG UNIV

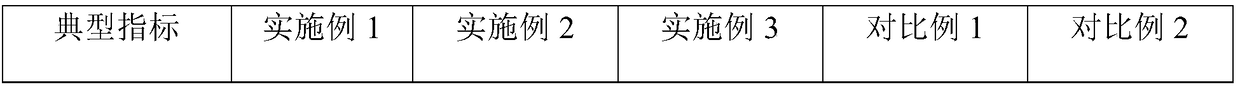

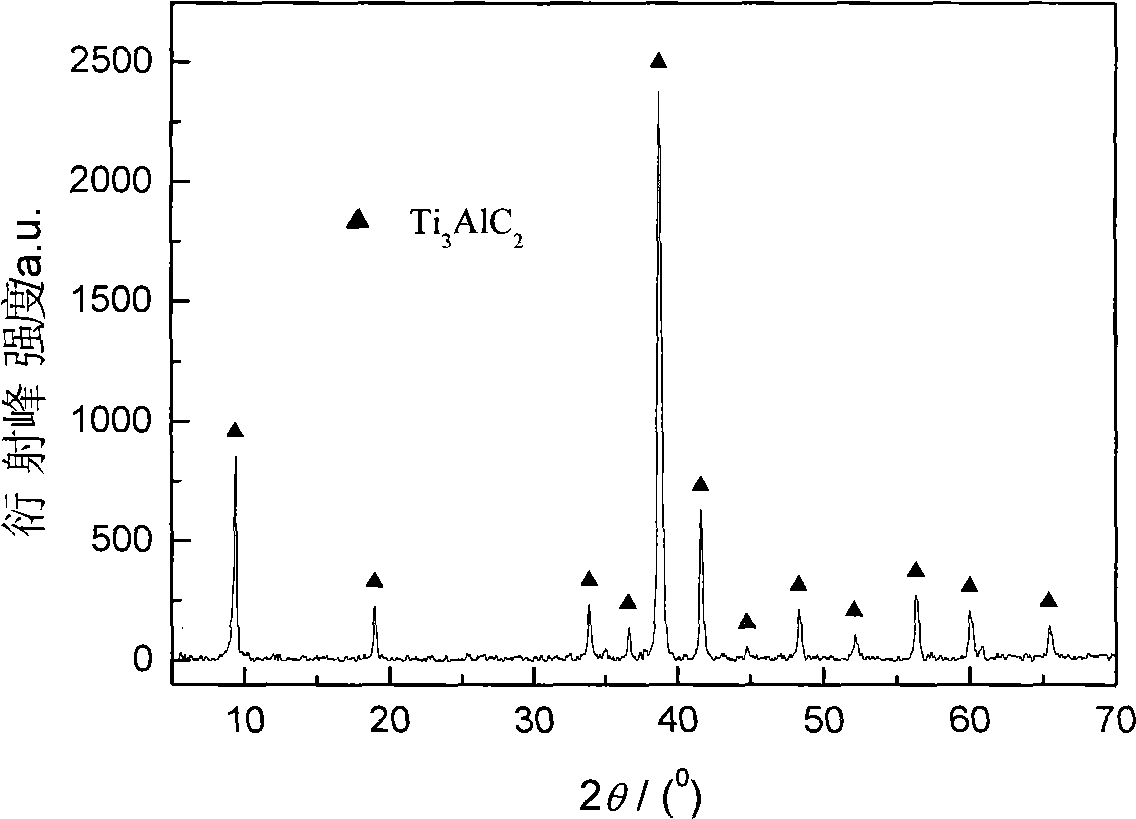

Coating and preparation method thereof as well as modified asphalt waterproof roll

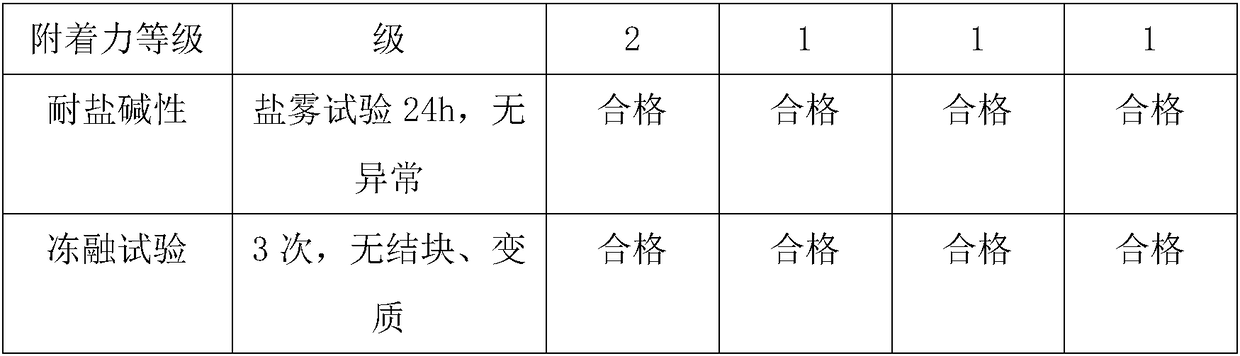

ActiveCN109401344AReduce production efficiencyLow production temperatureBuilding insulationsPetroleumButadiene-styrene rubber

The invention discloses a coating and a preparation method thereof as well as a modified asphalt waterproof roll. The coating is prepared from the following components in parts by weight: 10 to 50 parts of high-grade straight-run distillation petroleum asphalt, 10 to 50 parts of low-grade matrix asphalt, 5 to 40 parts of a macromolecular sizing material, 5 to 50 parts of a rubber powder sizing material, 1 to 20 parts of tackifying resin, 0.0001 to 0.02 part of graphene and 5 to 40 parts of filler. According to the coating, straight-run distillation asphalt with a relatively high grade is refined by adopting aryl hydrocarbon heavy oil and is used for pre-swelling difficult-to-swell macromolecular materials including SBS (styrene-butadiene-styrene block copolymer), rubber powder and the like. The graphene is added and high-thermal conductivity of the graphene is utilized so that the temperature is more uniform in a coating processing process and the processing efficiency is improved; theheating efficiency during hot-melt construction is improved; the emission of pollutants in the construction process is reduced and the ageing performance of a product is improved.

Owner:苏州东方雨虹建筑材料有限公司

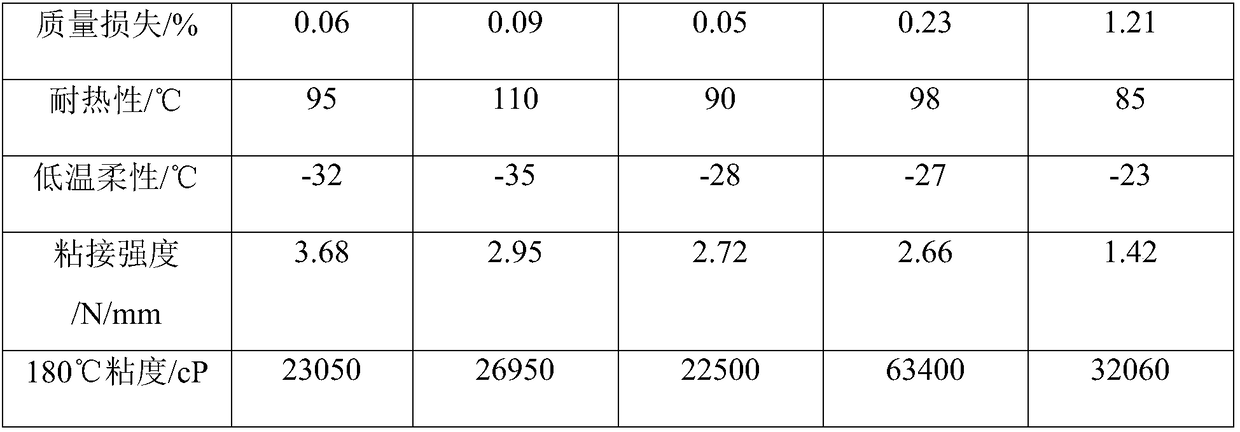

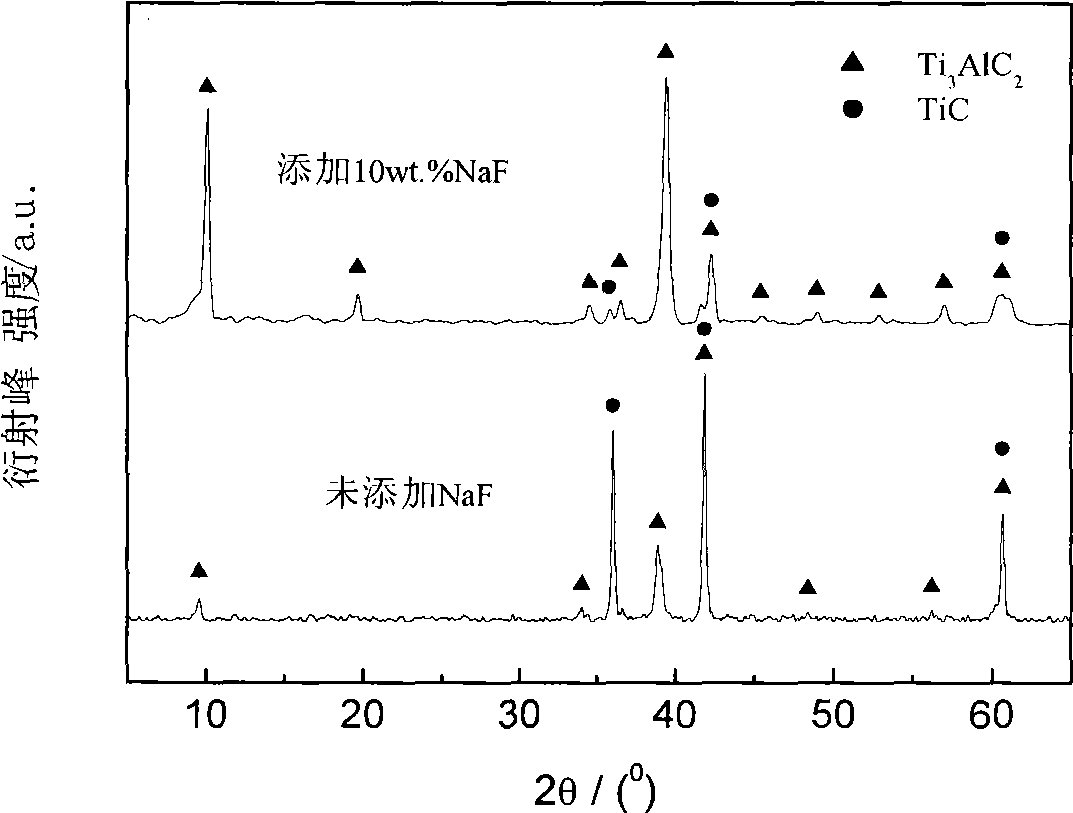

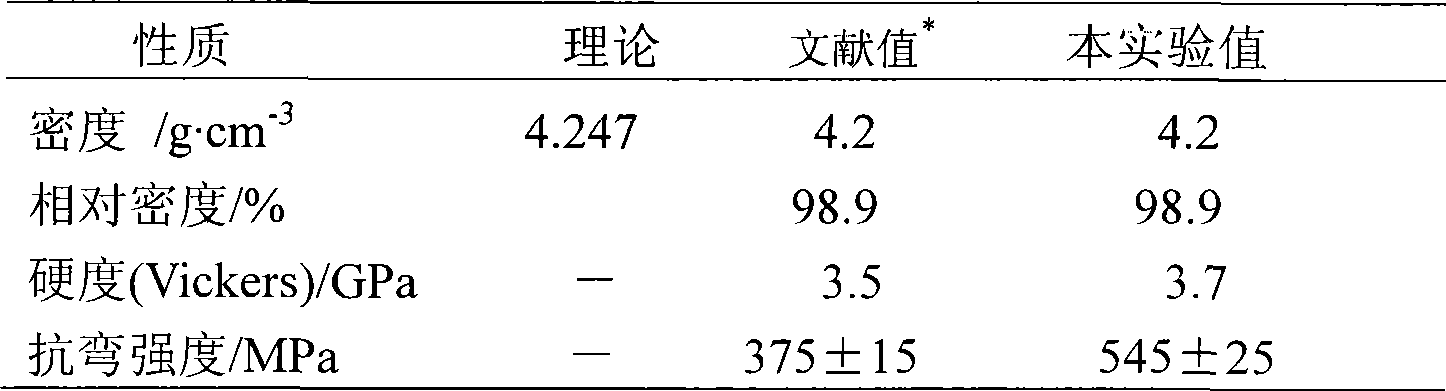

Method for preparing high performance Ti3AIC2 ceramic powder

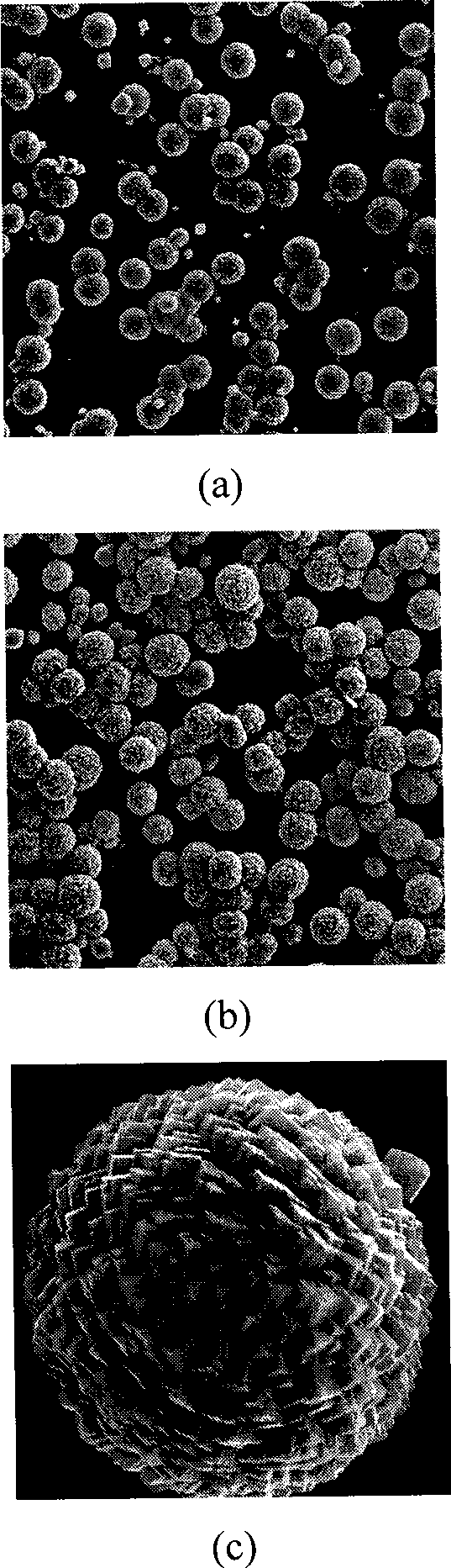

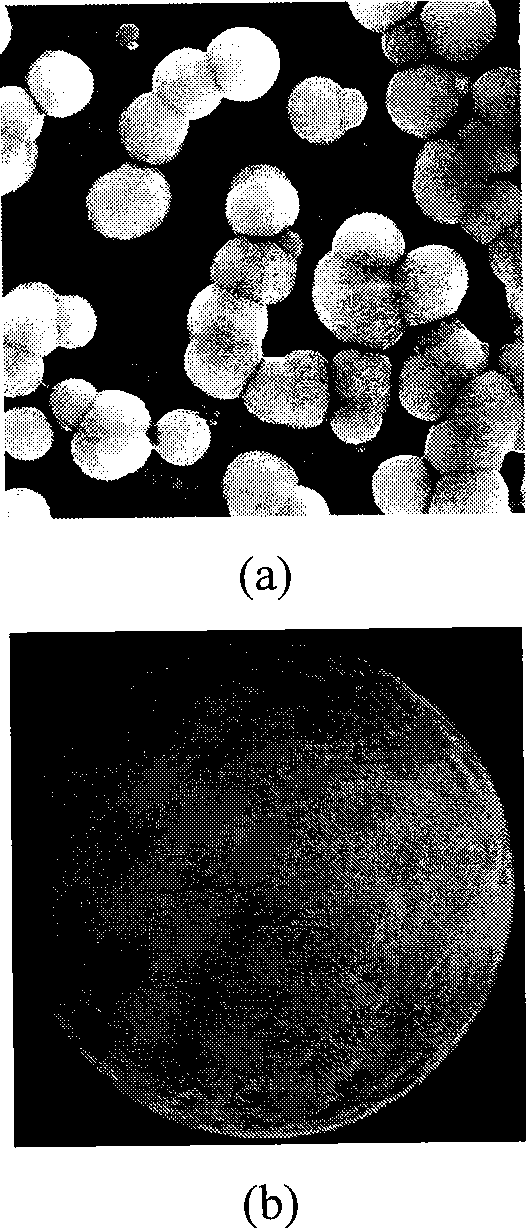

The invention relates to a method for preparing high performance Ti3AIC2 ceramic powder, comprising the following steps: Ti powder, Al powder and C powder are provided with the mol ratio of Ti3AIC2 chemical formula featuring Ti:Al:C equaling to 3:1:2; additive NaF is added by superaddition method to control purity of Ti3AIC2; NaF recruitment is 0.5-20wt.% of the total quality of Ti powder, AI powder and C powder; the material and additive powder are placed in a ball-milling jar, absolute ethyl alcohol is added to the ball-milling jar for carrying out wet mixing for 4-12 hours; material powder is obtained either by natural drying or by baking at the temperature of 60-80 DEG C; the material powder is placed in a cylindrical-tile-shaped material boat and in a combustion synthesis system, titanium carbon mixture is placed at an ignition part in front of the material powder as ignition powder; with the protection of argon, electrified tungsten filament ring is used for igniting the reactant, after natural cooling, the obtained product is Ti3AIC2 powder. The invention is characterized by rapid reaction, simple process, low cost, direct use of low-melting-point material as the material of the reactant, no generation of melting and reunion thereof, uniform reaction course, easy control and uniform and stable property of the synthetized Ti3AIC2.

Owner:HONGHE COLLEGE +1

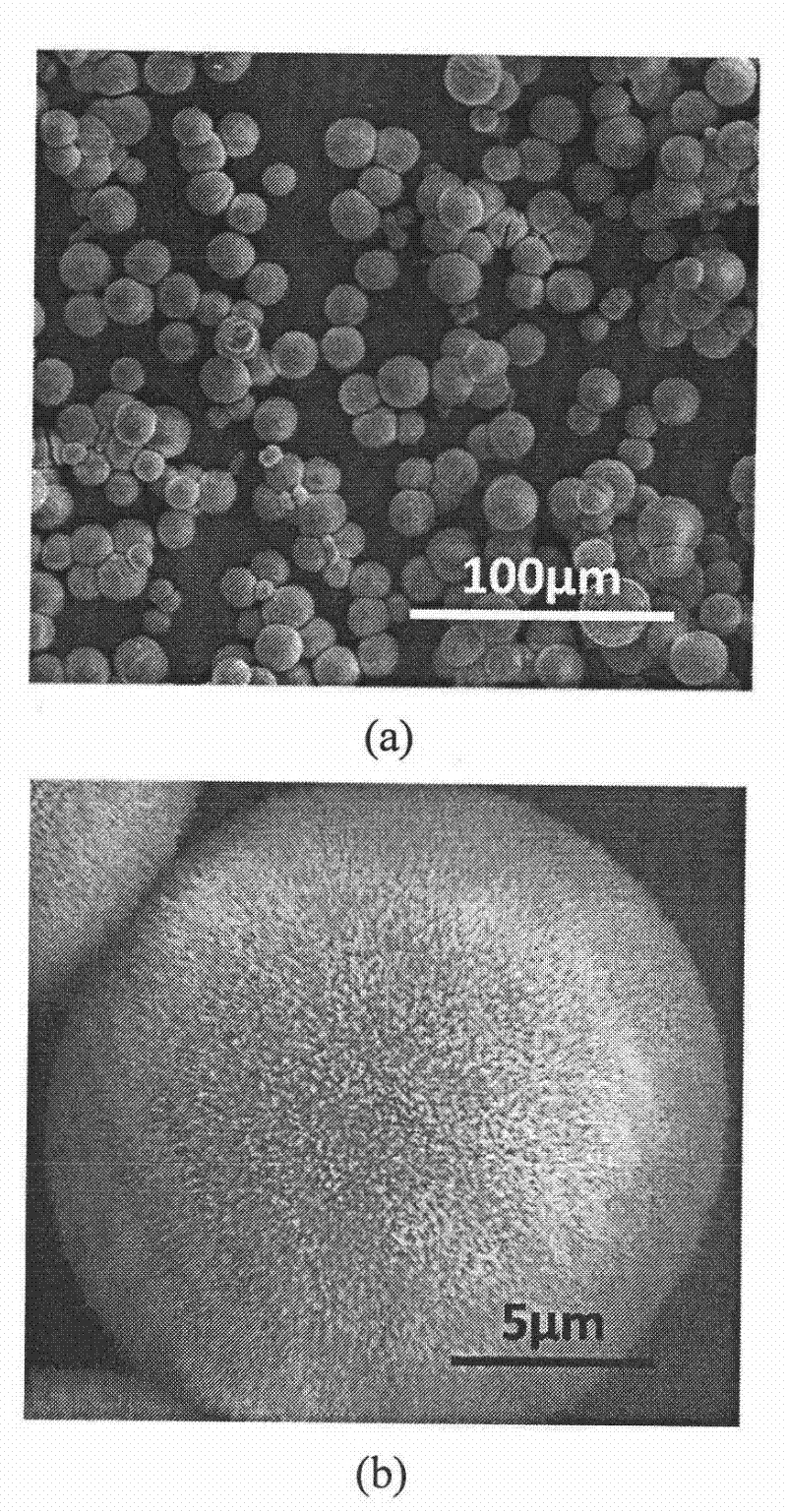

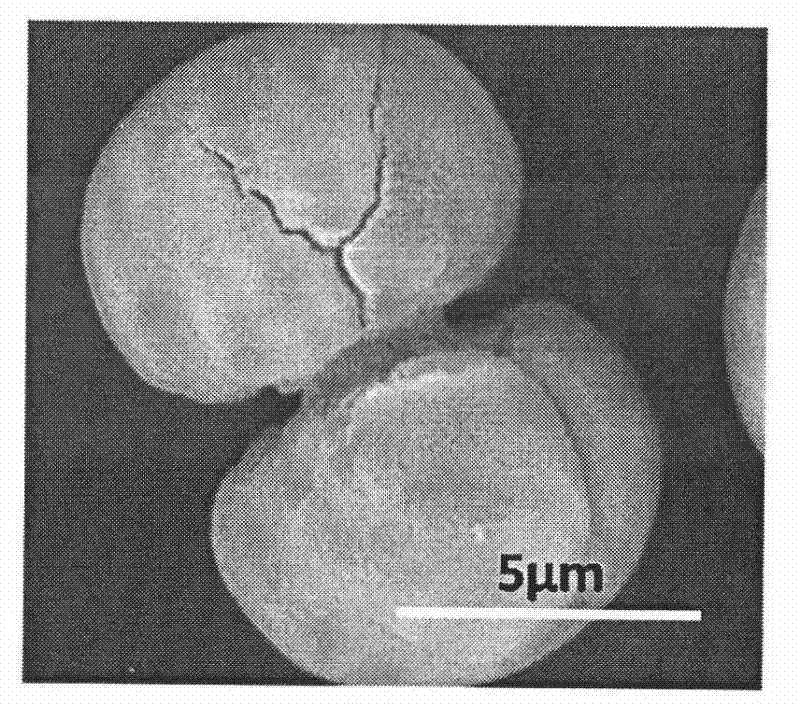

Process for producing monodisperse polymer/calcium carbonate composite fine particle

InactiveCN101429284AComplex and uniqueUniform particle sizePigment treatment with macromolecular organic compoundsPolymer scienceDecomposition

The invention belongs to the technical field of an organic and inorganic composite material, in particular to a method for preparing monodisperse polymer / calcium carbonate composite particles. The method comprises the following steps: a glass apparatus is pretreated, a polymer solution the concentration of which is between 0.001 and 10 grams per liter is prepared, and 0.001-1 mol / liter calcium salt is added into the polymer solution to prepare a calcium salt / polymer mixture; the mixture stands, the pH value of the mixture is adjusted to between 6 and 13, and 10<1> to 10<3> milliliters of the mixture is taken out and filled into a beaker; a beaker with grinded carbonate is arranged inside a sealing system at a temperature of between 10 and 60 DEG C, and a layer of film is coated on the beaker to control the speed of decomposition and generation of carbon dioxide; a layer of film is coated on a mouth of the beaker which is filled with the mixture, and is provided with a plurality of holes by a pin, and the beaker is placed into the sealing system, reacts for 0.5 hours to 15 days, is taken out for separation of products; and the products are separated and dried to obtain the required products. The raw materials have wide sources and low cost; the solvent adopted has small pollution and no toxic action; and the preparation method is simple and easy to operate, accords with the requirement of green chemistry, and has the potential of large-scale production.

Owner:FUDAN UNIV

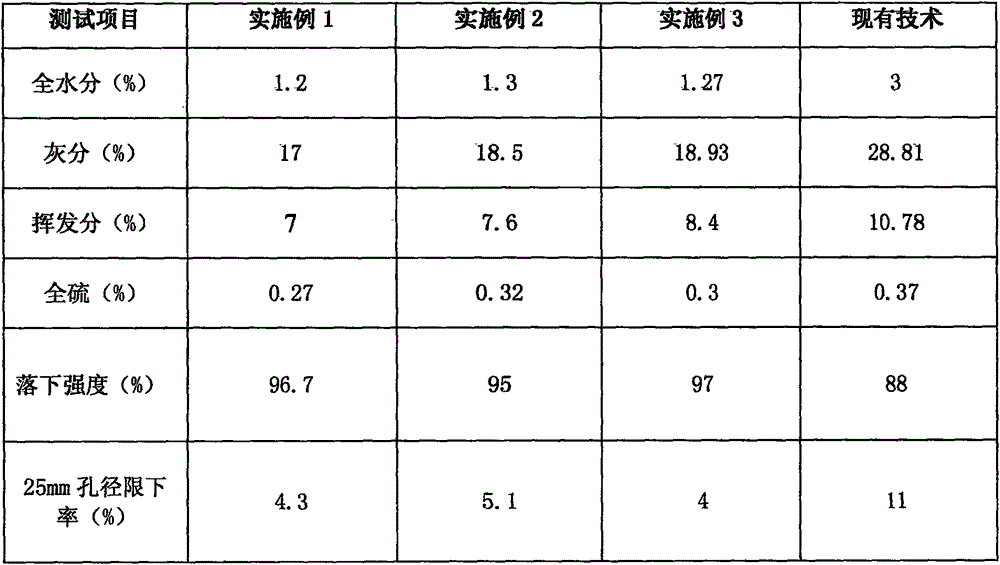

Biomass binder for clean briquette and preparation method thereof

InactiveCN106190394ASimple preparation equipmentSimple processSolid fuelsWaste based fuelCoal briquetteSodium Bentonite

The invention discloses biomass binder for clean briquette. The biomass binder is prepared from the following raw materials in parts by weight: 10-20 parts of corn starch, 5-15 parts of corn stalks, 5-10 parts of sawdust, 3-8 parts of bentonite, 10-20 parts of sodium hydroxide and 40-80 parts of water. Furthermore, the invention discloses a method for preparing the biomass binder for clean briquette. According to the method, corn stalks, sawdust and other industrial and agricultural waste are turned into wealth, and are matched with corn starch to improve the utilization of agricultural and forest waste biomass; and high-additional-value deep processing means is provided to corn development. When the biomass binder is used for producing a clean briquette, the cold strength, heat strength and heat stability can be improved after a coal briquette is molded, and the undersize fraction is reduced; and the preparation method has the advantages of simple manufacture equipment, convenience in process, short time consumption and small preparation risk.

Owner:李达 +1

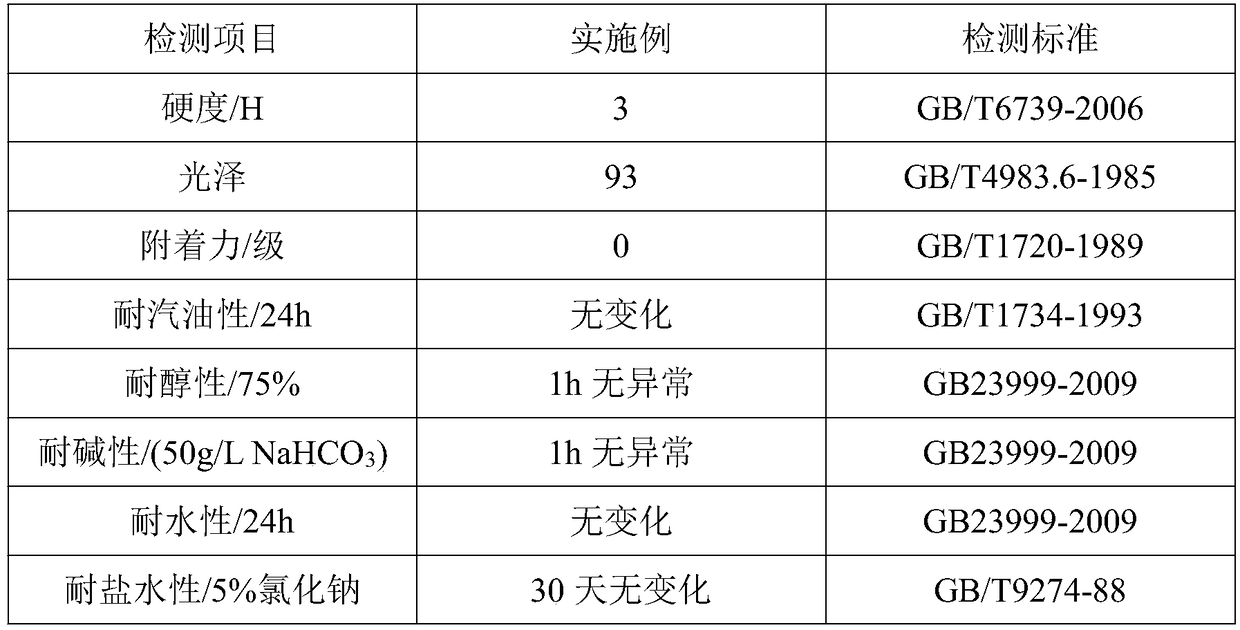

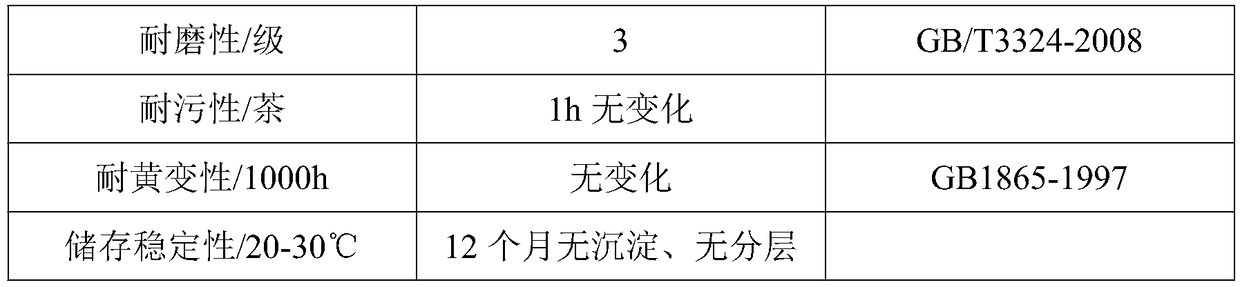

Waterborne UV (Ultraviolet) furniture coating and preparation method thereof

InactiveCN109233605ALow viscosityImprove diffusivityAntifouling/underwater paintsPaints with biocidesNational standardHigh pressure

The invention discloses a preparation method of waterborne UV (Ultraviolet) furniture coating. The preparation method comprises the following steps: firstly, conveying a waterborne acrylate pre-polymer and an active diluting agent into a high-pressure reaction kettle; introducing carbon dioxide and enabling carbon dioxide to be at a supercritical fluid state through adjusting pressure and temperature in the high-pressure reaction kettle; keeping the pressure and temperature in the high-pressure reaction kettle unchanged; adding other auxiliary agents in sequence according to the ratio; sufficiently stirring and reacting to obtain a finished product. The waterborne UV furniture coating prepared by the method has the advantages of easiness for controlling the viscosity, good storage stability, convenience for construction, green and environment-friendly preparation technology and high production efficiency; the waterborne UV furniture coating can be completely dried after being irradiated through an ultraviolet lamp for several seconds; a dried paint film has high rigidity, good toughness, good water resistance, good wearing resistance, good pollution resistance and good plumpness; all indexes meet national standards, and a decoration effect and a protection effect are strong; the waterborne UV furniture coating has a good adhesive force on various base materials and is applicable to coating of various high-end indoor wood furniture and indoor wood floors.

Owner:安徽科纳家居饰材有限公司

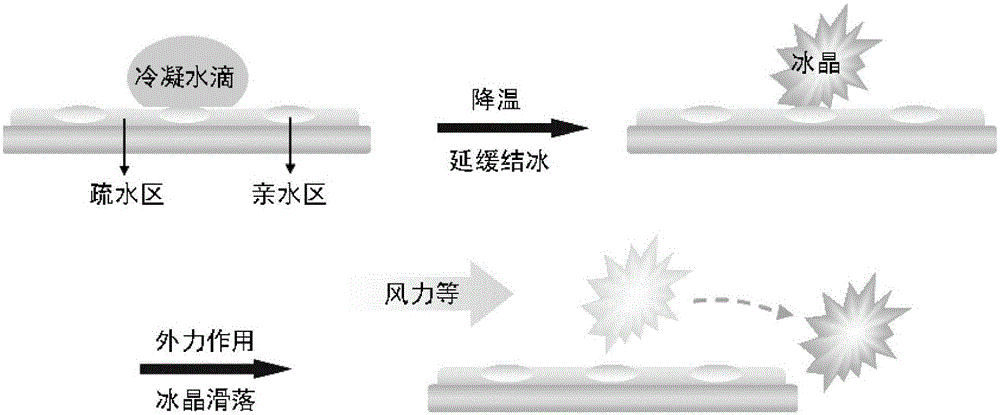

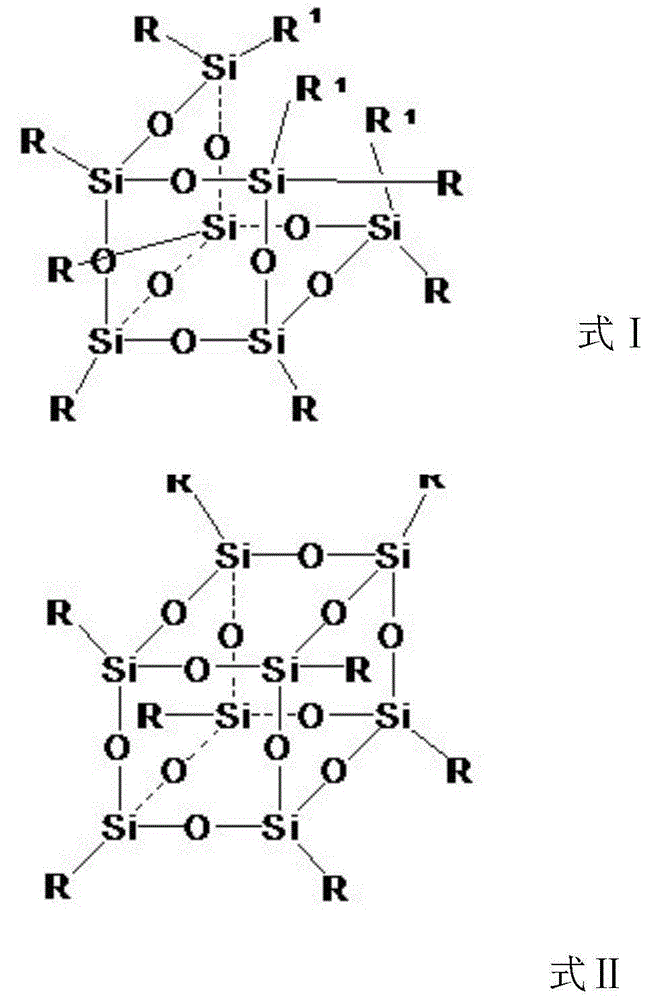

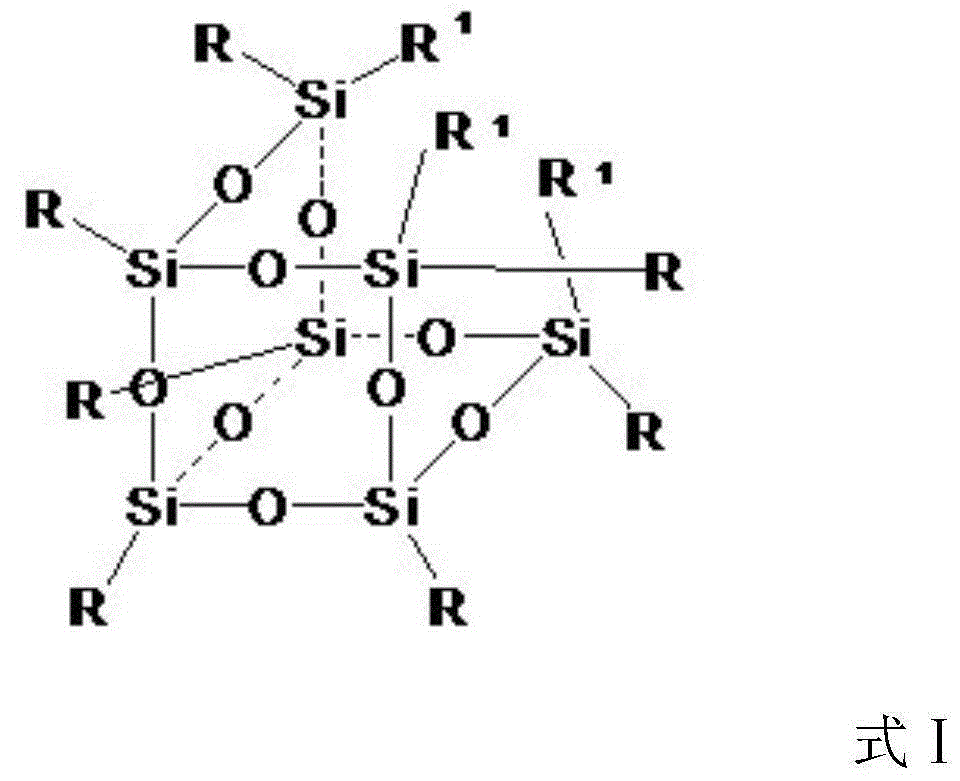

Amphiphilic anti-freeze molecule based on silsesquioxane, preparation method thereof and anti-icing surface material

ActiveCN105131092AImprove frost resistanceImprove stabilityOther chemical processesDepsipeptidesAntifreeze proteinSilsesquioxane

The invention provides an amphiphilic anti-freeze molecule based on silsesquioxane, a preparation method thereof and an anti-icing surface material and belongs to the technical field of anti-icing surface materials. The invention solves the problem of an instable anti-icing effect of an anti-icing surface material in the prior art. The amphiphilic anti-freeze molecule is prepared by combining the silsesquioxane with an anti-freeze protein or an anti-freeze polypeptide. The invention also provides the preparation method of the amphiphilic anti-freeze molecule based on silsesquioxane. The method includes the steps of preparing the silsesquioxane having reactive groups and hydrophobic groups, and performing a coupling reaction to combine the silsesquioxane with an anti-freeze protein or anti-freeze polypeptide to prepare the amphiphilic anti-freeze molecule based on the silsesquioxane. The invention also provides the anti-icing surface material prepared from the amphiphilic anti-freeze molecule based on the silsesquioxane. The anti-icing surface material has the anti-icing characters of both a hydrophobic material and a hydrophilic material, enlarges a temperature window of the anti-icing surface material and is improved in anti-icing performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Fireproof repairing agent for industrial kiln

The invention relates to the technical field of high temperature refractories, in particular to a fireproof repairing agent for an industrial kiln. The fireproof repairing agent includes alumina micropowder, nano silica, kyanite powder, nano zirconia, ceramic fiber, polyvinyl alcohol, aluminum silicon sol, deionized water, metal quantum dot composite, carboxymethyl cellulose sodium, polyethylene glycol and dispersing agent, wherein the alumina micropowder is alpha type alumina with a grain size of 20-40 nm; the dispersing agent is one of ammonium polyacrylate, sodium tripolyphosphate and sodium hexametaphosphate; the ceramic fiber is selected from a group consisting of a high alumina fiber, an aluminum oxide polycrystalline fiber and aluminum silicate fiber; and the ceramic fiber has a fiber length of 2-4 mm. The repairing agent has the advantages of high refractoriness, good adhesion, large bonding strength, good thermal expansion and outstanding erosion resistance.

Owner:来安县瑞傲源新材料有限公司

Method for preparing heavy metal ion adsorbent using maleic acylation wood fibers at room temperature

ActiveCN103506087ARealize the comprehensive utilization of all componentsSimple processOther chemical processesFiberSorbent

The invention discloses a method for preparing a heavy metal ion adsorbent using maleic acylation wood fibers at room temperature and belongs to the field of biomass chemistry and renewable resource utilization. The method disclosed by the invention comprises the following steps: completely dissolving ball-milled wood fiber powder in a room-temperature solvent system, adding maleic anhydride for reaction at room temperature, performing precipitation, washing and freeze-drying after the reaction is completed, so as to obtain a heavy metal ion adsorbent containing wood fiber derivatives. According to the adsorbent preparation method used in the invention, the wood fiber dissolution and modification procedures are both performed at room temperature without heating, so as to reduce the equipment requirement and energy consumption. The prepared adsorbent can effectively adsorb heavy metal ions in a solution, and has an important scientific value and practical significance in development and utilization of wood fiber biomass and other renewable resources.

Owner:SOUTH CHINA AGRI UNIV

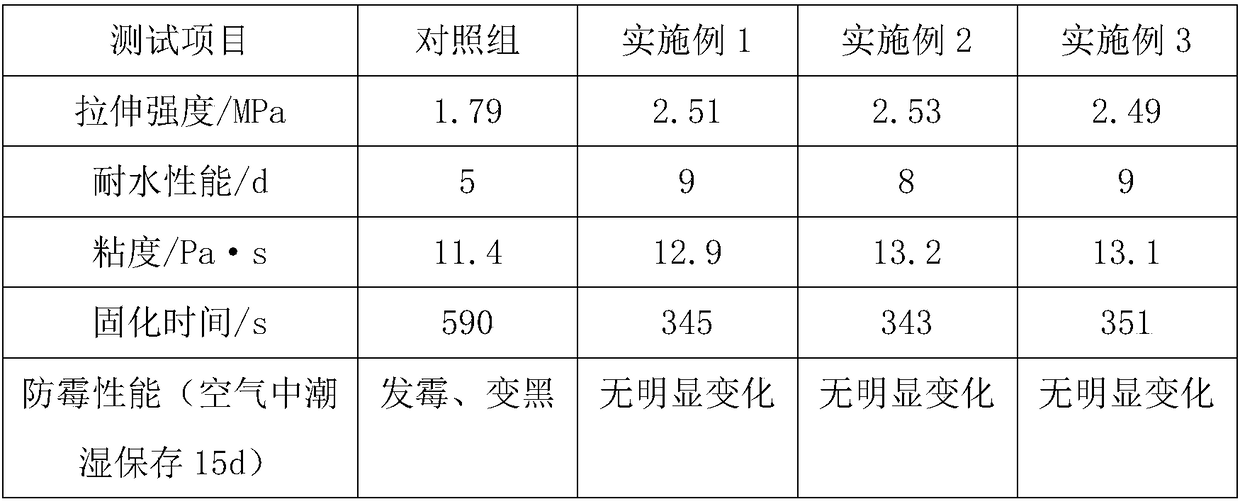

High-viscosity mildew-proof wallpaper glue

InactiveCN108913080AAdhesive reinforcementImprove waterproof performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveDimethyl siloxane

The invention relates to the technical field of adhesives, in particular to high-viscosity mildew-proof wallpaper glue. The wallpaper glue includes the components of aqueous polyurethane resin, nano calcium carbonate, a composite tackifier, polyvinyl alcohol, chitosan, a mildew inhibitor, a bacteriostatic agent, a defoamer and deionized water, wherein the composite tackifier is a special composition prepared by compounding mucopolysaccharide, modified cellulose, modified starch and other substances, and the mildew inhibitor is one selected from 1,2-benzisothiazole-3-one, methyl isothiazolinoneand 5-chloro-2-methyl-4-isothiazolin-3-one; and the defoamer is polyoxyethylene polyoxypropanolamine ether or polydimethylsiloxane or polyoxypropylene polyoxyethylene glyceryl ether, and the bacteriostatic agent is a nano silver antibacterial finishing agent. The wallpaper glue has the advantages of excellent bonding performance, good anti-aging performance, long service life, outstanding anti-oxidation and an outstanding anti-mildew effect.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

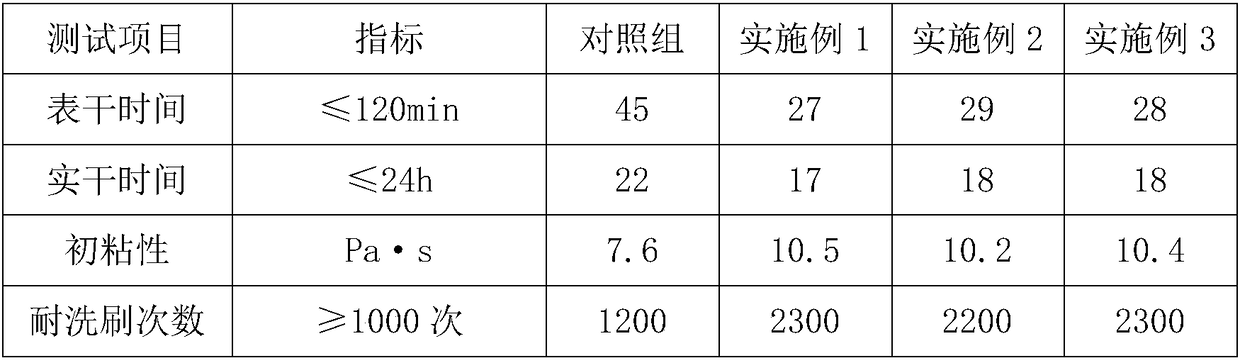

Highly-adhesive elastic emulsion paint

InactiveCN109082184AGuaranteed water resistanceGuaranteed anti-agingAntifouling/underwater paintsPaints with biocidesPolyacrylamidePolytetrafluoroethylene

The invention relates to the technical field of painting, particularly to a highly-adhesive elastic emulsion paint. The highly-adhesive elastic emulsion paint is composed of pure acrylic emulsion, styrene-acrylic emulsion, inorganic filler, compound thickening agent, polytetrafluoroethylene-polyurethane copolymer, polyacrylamide, nanometer titanium dioxide, preservative, defoamer, leveling agent and deionized water, wherein the compound thickening agent is a special combination prepared by compounding materials such as mucopolysaccharides, modified cellulose and modified starch; the organic filler is a mixture of titanium dioxide, talcum powder and light calcium carbonate; the preservative is 1, 2-benzisothiazolin-3-one, methylisothiazolinone or 5-chloro-2-methyl-4-isothiazolinone-3-one. The highly-adhesive elastic emulsion paint is high in adhesiveness and easy to dry and cure and can form coating high in elasticity, strength and washing resistance.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

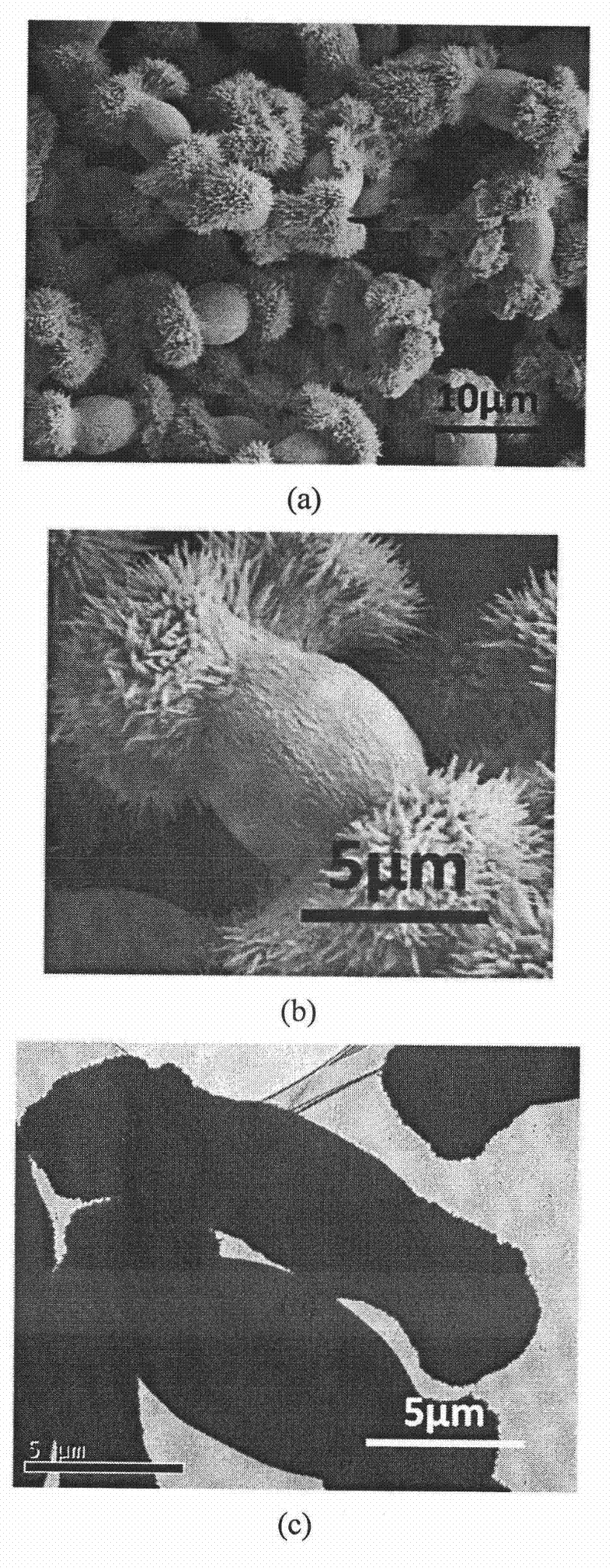

Method for preparing structure controllable barium carbonate composite particles

InactiveCN102127237AUnique structure and controllableLarge particle sizePigment treatment with macromolecular organic compoundsMicroparticleSolvent

The invention belongs to the field of organic and inorganic composite materials, and provides a method for preparing polymer / barium carbonate composite particles of needle-like agglomerates by taking carbon dioxide as a carbonate radical source. The carbon dioxide obtained by decomposing carbonate, or high pressure carbon dioxide is directly used as the carbonate radical source, is diffused into a reaction system, and is combined with barium ions under the control of polymer to form the composite particles with unique agglomerate structures. The structure, appearance, polymer content and the like of the composite particles can be controlled by changing corresponding experimental parameters easily; and the products are easy to separate, uniform in property and stable, and have potential application prospect in the fields such as electronics, glass, ceramic industry and the like. In the method, raw materials are wide in sources and low in prices; and the preparation method is easy to operate, and the adopted solvent is light in pollution, does not have any harmful effect, and meets the requirement of green chemistry.

Owner:FUDAN UNIV

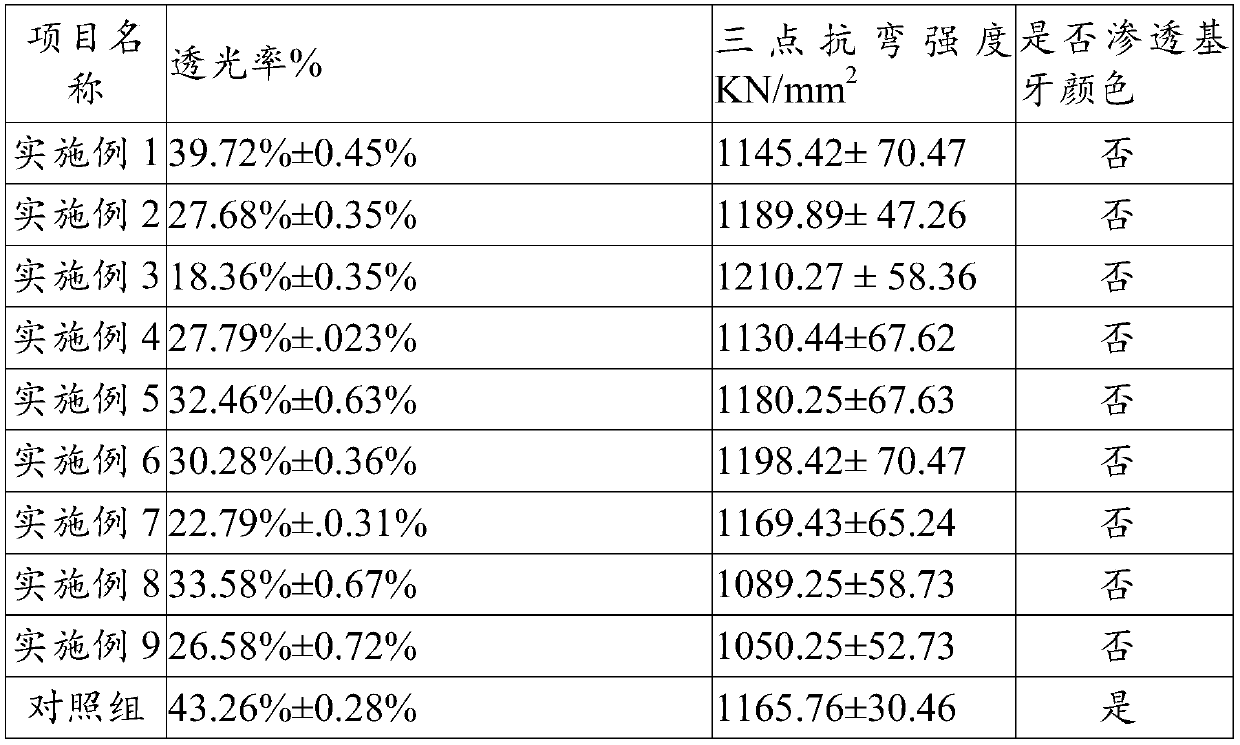

Masking liquid for dental zirconium oxide ceramic as well as preparation method and application thereof

The invention discloses a masking liquid for a dental zirconium oxide ceramic. The masking liquid comprises a masking agent, a color indicating agent, an additive and deionized water. The masking liquid can reduce the transparency in a tooth restoration without affecting the color effect out of the restoration. Meanwhile, the invention also discloses a preparation method of the masking liquid forthe dental zirconium oxide ceramic. The preparation method has the obvious advantages of simple process, low manufacturing cost and good repeatability. Moreover, the invention also discloses application and an application method of the masking liquid for the dental zirconium oxide ceramic. The problem that the transparency in the dental zirconium oxide ceramic is too high can be improved obviously, so that the finally obtained tooth restoration can obtain a natural emulational effect.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

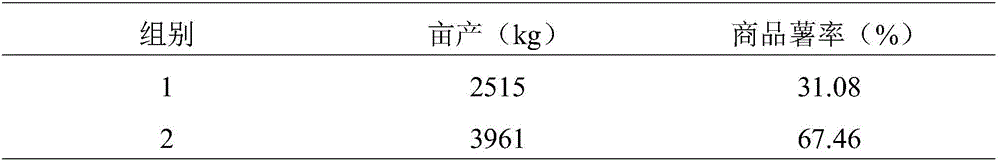

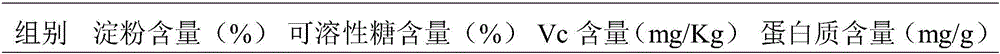

Soilless culture method for potato seedlings

InactiveCN106212225AActive promotionAvoid pollutionCalcareous fertilisersBio-organic fraction processingAgricultural scienceSolanum tuberosum

The invention belongs to the field of agriculture cultivation, and particularly relates to a soilless culture method for potato seedlings. Local agricultural wastes mostly existing in the Inner Mongolia are used, and the seedling soilless culture method is make according to the actual conditions of local potato planting and is suitable for seedling growth, low in cost and simple in step; limits to soil cultivation are removed, the cultivation field of potatoes is enlarged, factory-like and automation development of potatoes are promoted better and faster, and the method has wider market prospects and higher application value.

Owner:INNER MONGOLIA JIAHENG AGRI TECH CO LTD

Solid-lubrication protection grease applied to mechanical telescopic structure

InactiveCN108251191AImprove the protective effectImprove the lubrication effectLubricant compositionOil and greaseAntioxidant

The invention belongs to the technical field of lubrication grease and specifically relates to solid-lubrication protection grease applied to a mechanical telescopic structure. The lubrication protection grease is prepared from the ingredients of base grease, solid-lubrication base grease, molybdenum disulfide, micro-powder graphite, lead dibutyl dithiocarbamate, crystalline flake graphite, a thickening agent, an extreme-pressure anti-wear reagent, an antioxidant and a structure stabilizer, wherein the base grease is hydrocarbon mineral oil or synthetic oil, and the solid-lubrication base grease contains one or more of compound calcium-based grease, lithium-based grease, aluminum-based grease, polyurea lubricating grease and compound barium-based grease. The lubrication grease can improveevenness and stability of materials by high-temperature reaction and ultrasonic dispersion treatment. The lubrication protection grease has the advantages of good lubrication, pressure-resistant and anti-wear performance, good high-temperature-resistant, antioxidant and sealing waterproof effects and very excellent comprehensive performance.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Method for causticizing corn starch

The invention provides a method for causticizing corn starch, which is characterized in that under the condition that the temperature of corn starch feeding water is 40-50 DEG C, materials are simultaneously fed and stirred, and after material feeding is completed, the obtained mixture is fully and uniformly mixed so as to form a suspension liquid; a sodium hydroxide solution with weight and volume percentages of 20% is added into the suspension liquid, and then a sodium hydroxide solid is added into the obtained substance, wherein the mass ratio of the sodium hydroxide solid to corn starch is 4:100; after the temperature of the obtained mixture rises to 65-75 DEG C, the obtained mixture is causticized for one hour; and after water is added into the causticized mixture for constant volume, a corn starch solution is obtained, and then subjected to heat preservation for later use. The corn starch solution prepared by using the method for causticizing corn starches disclosed by the invention is uniform and stable in properties, easy to store and uneasy to go bad; in case that the corn starch solution is used as an iron mineral inhibitor, no 'clustering' phenomenon occurs in the process of preparation, so that the starch utilization rate is high; and the consumption of a beneficiation reagent is reduced by over 5%, and because the causticizing temperature is lowered, the energy consumption is reduced.

Owner:ANSTEEL GRP MINING CO LTD

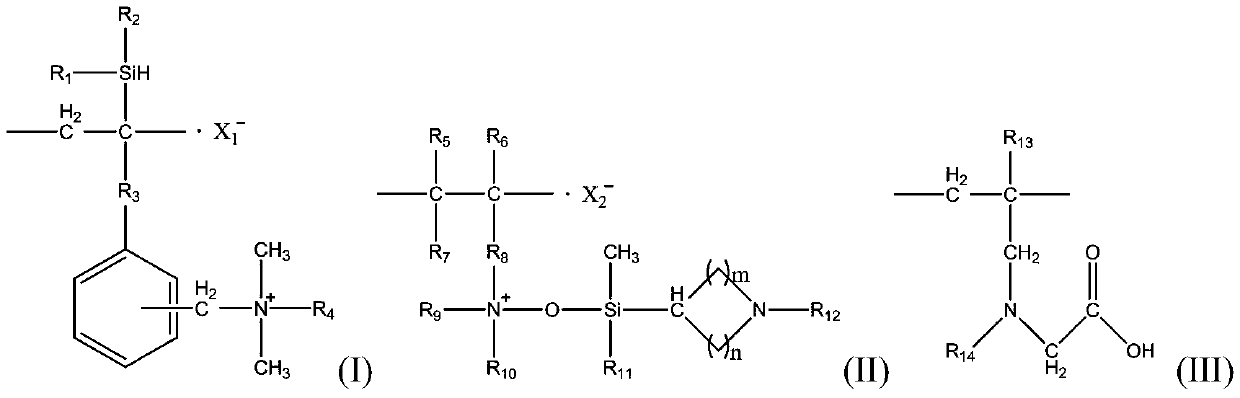

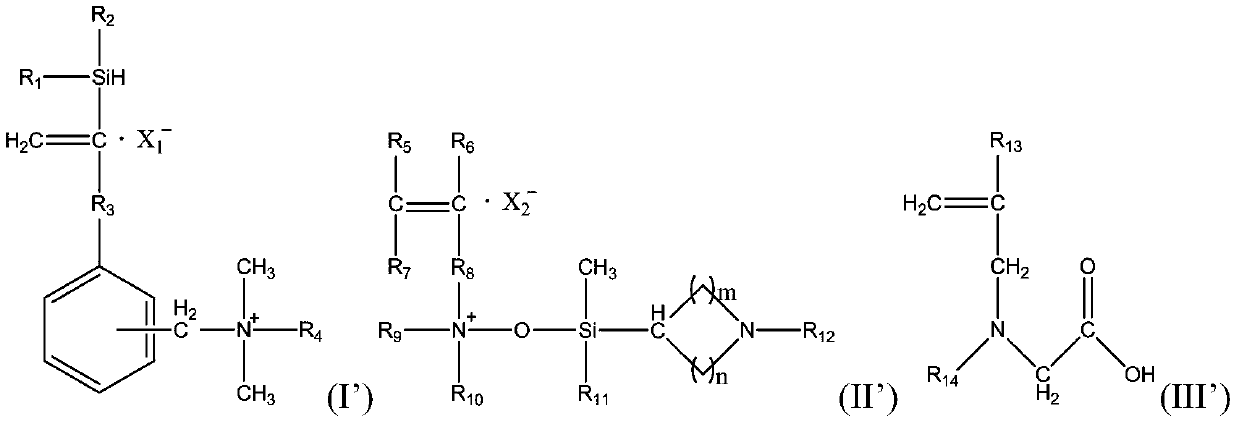

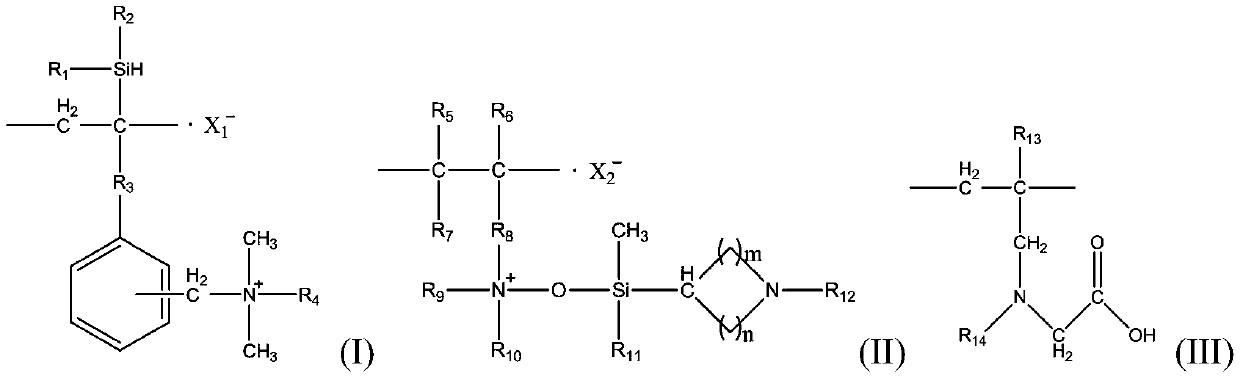

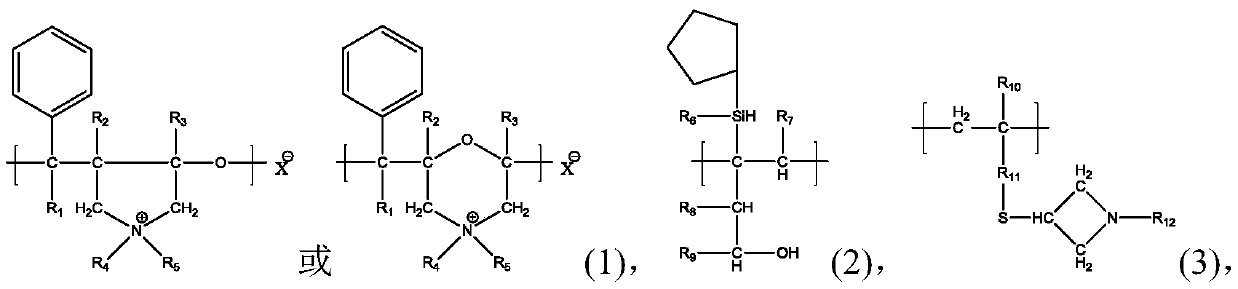

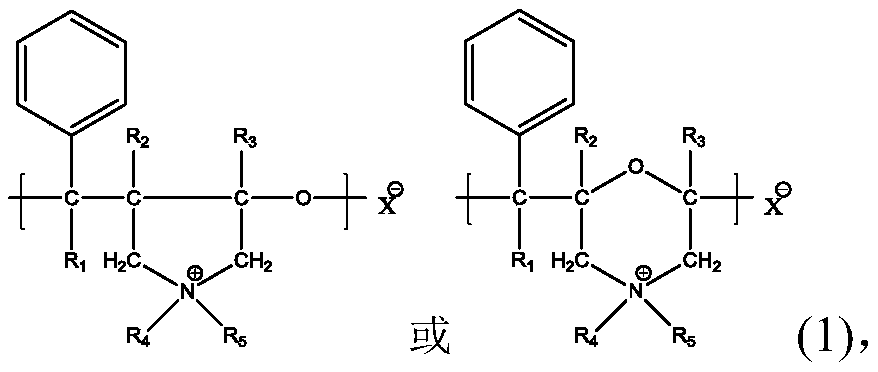

Textile dye fixing agent and application thereof

The invention provides a textile dye fixing agent and application thereof, and belongs to the technical field of textile printing and dyeing assistants. Specifically, the textile dye fixing agent comprises a mole of at least one copolymerized unit shown as formula (I), b mole of at least one copolymerized unit shown as formula (II) and c mole of at least one copolymerized unit shown as formula (III); the beneficial effects are that: the textile dye fixing agent disclosed by the invention is a polymer; the preparation method is simple, the reaction is mild, the phenomena of implosion, gelling and the like are avoided, a new branched structure containing silicon-carbon chains, nitrogen-carbon chains, particularly silicon-oxygen chains is introduced, and sulfydryl is introduced and condensedinto disulfide bonds, so that the crosslinking density of the textile dye fixing agent is further increased, and the resistances such as wear resistance, water soaking resistance and the like are greatly improved.

Owner:浙江新海天生物科技有限公司

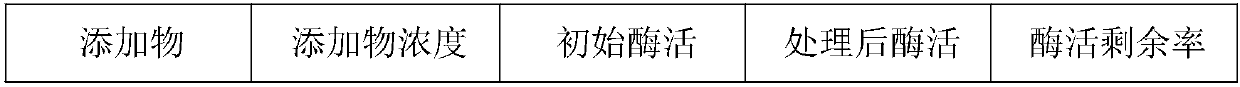

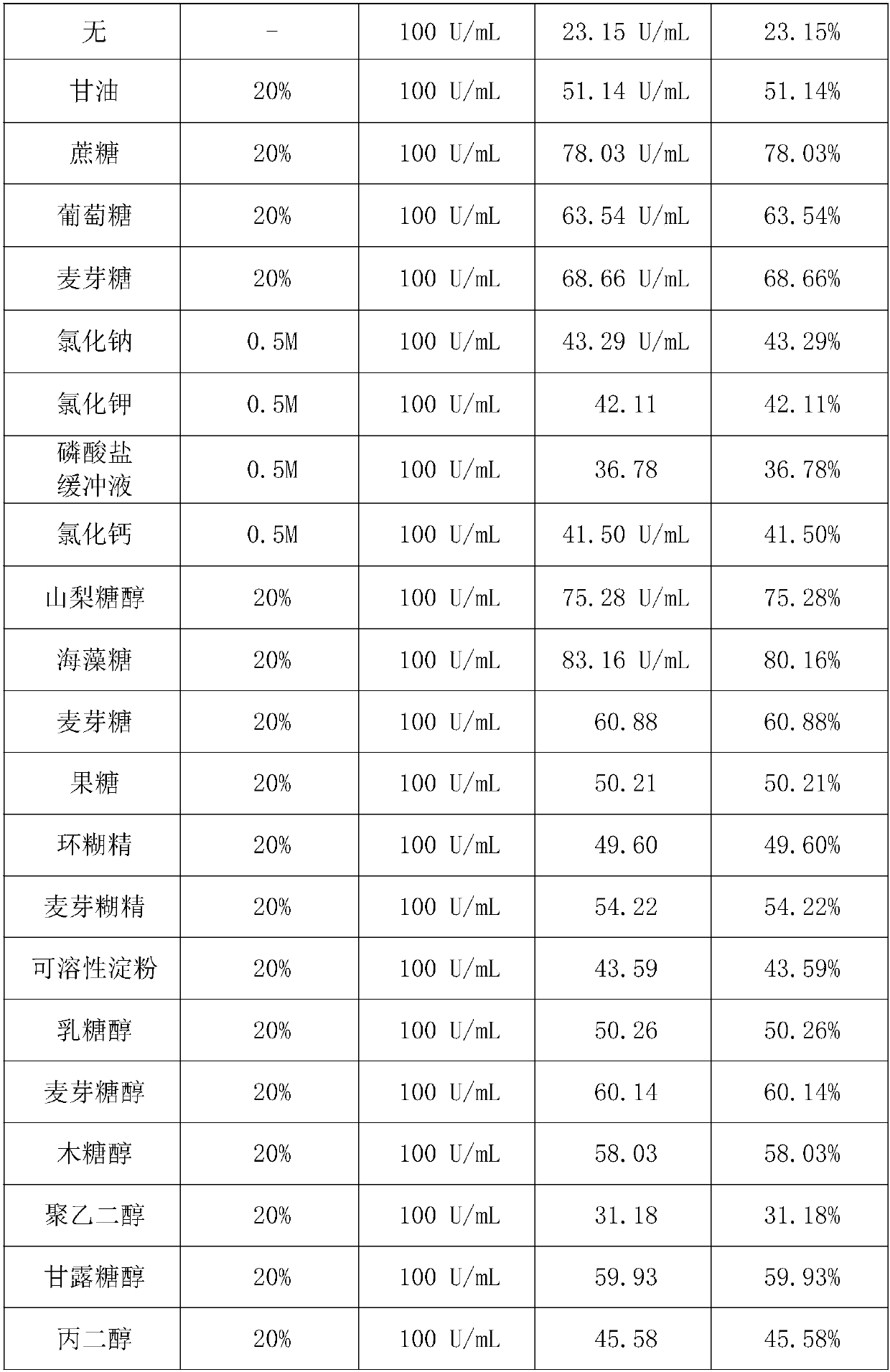

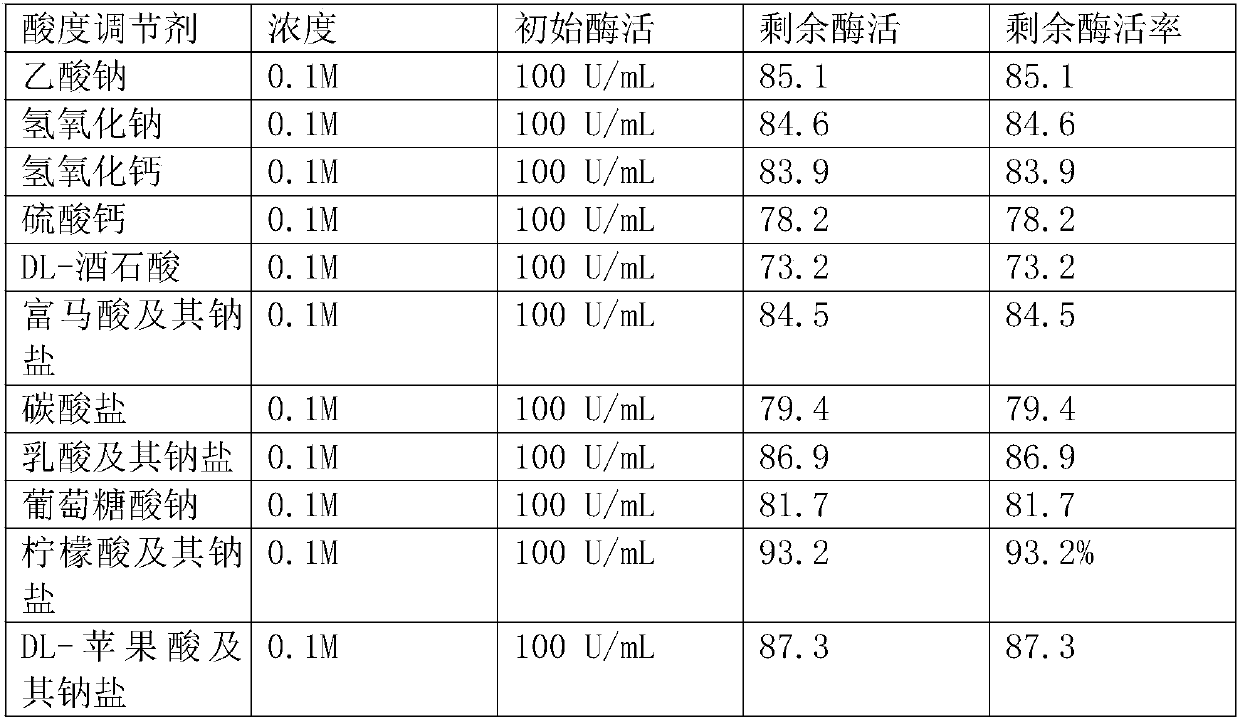

Preparation for stabilizing activity of liquid glutamine transaminase

InactiveCN110205309AStable traitsQuality is not affectedEnzyme stabilisationAcyltransferasesGlutamine aminotransferaseAnti oxidant

The invention discloses a preparation for stabilizing the activity of liquid glutamine transaminase. The compositions of the preparation include glutamine transaminase, carbohydrates and / or alcohols,an anti-oxidant, a water activity regulator and an acidity regulator. The technical problems of extremely unstable liquid enzyme of the glutamine transaminase at high room temperature (30 DEG C) and hard preservation for a long time can be solved; the enzyme activity of the liquid glutamine transaminase preparation preserved 3 months under 30 DEG C can remain more than 85%, the enzyme activity preserved 6 months under normal temperature can remain more than 90%, and the state of a solution is stable; and the preparation has wide application prospects and great meanings on popularizing, applying and developing.

Owner:TAIXING DONGSHENG FOOD TECH

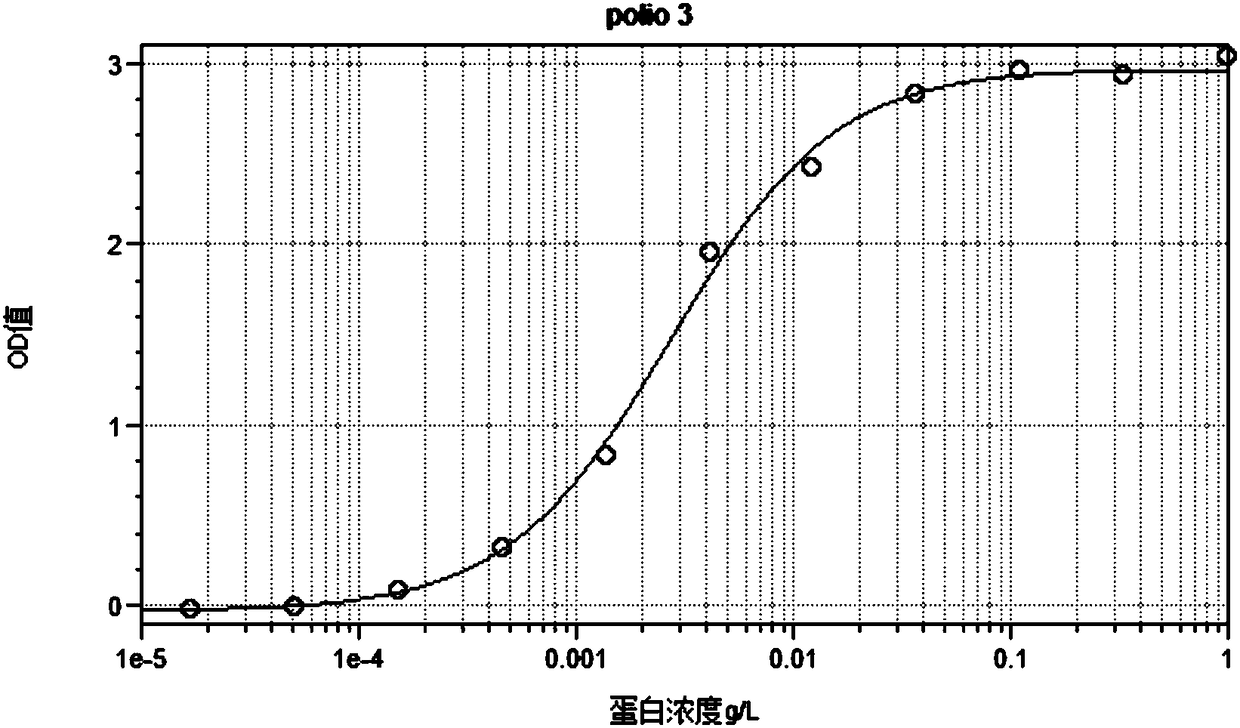

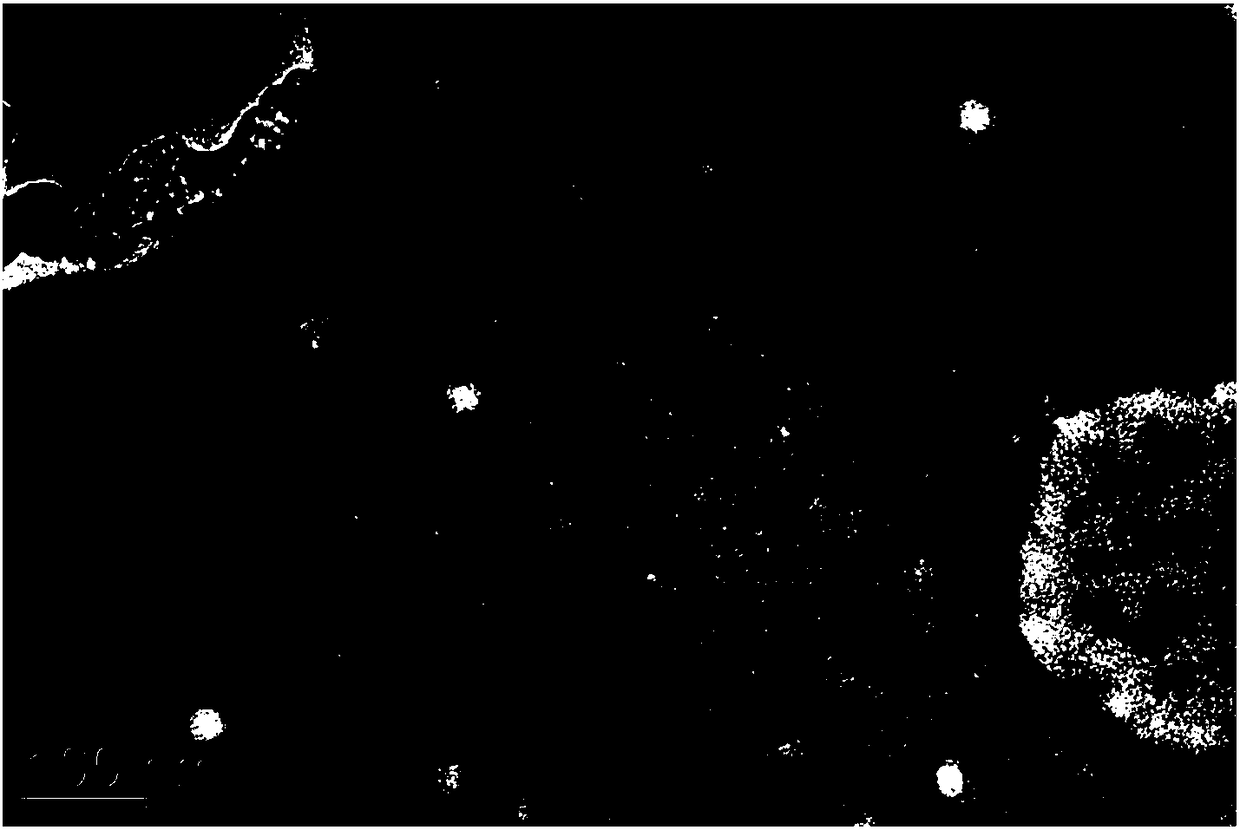

Recombinant polio type-3 VLP (virus-like particles)

PendingCN108130332AFold preciselyThe basic structural units are clearly visibleFungiSsRNA viruses positive-senseYeastPoliovirus

The invention discloses a codon-optimized gene for encoding a precursor protein of a type-3 wild polio virus coat and a gene for encoding 3CD protein of type-1 attenuated polio virus. The genes are transferred into yeast cells and can be efficiently and spontaneously assembled into VLP (virus-like particles) in the cells through coexpression. The invention further discloses a macromolecule with immunogenicity. The macromolecule is mainly prepared from the genes in the yeast cells by expressing. The invention also discloses an application and composition of the macromolecule with immunogenicity.

Owner:SHANGHAI ZERUN BIOTECHNOLOGY CO LTD

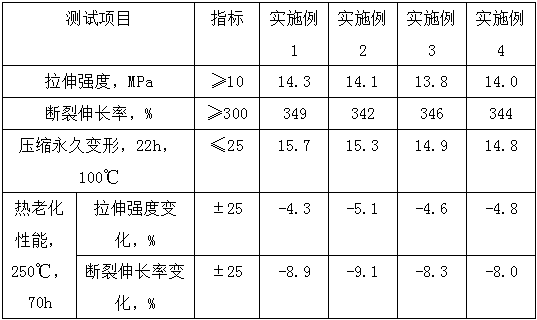

High-temperature-resistant pressing-resistant anti-deformation rubber used for mining machinery buffering cushion

The invention belongs to the technical field of rubber materials, and particularly relates to a high-temperature-resistant pressing-resistant anti-deformation rubber used for a mining machinery buffering cushion. The rubber is prepared from the following ingredients: matrix rubber, silicone oil, butadiene, zinc powder, silicon dioxide powder, aluminium oxide, white carbon black, magnesium oxide, stearic acid, a high-temperature modifier, an antiager, a coupling agent, a cross-linking agent and a catalyst, wherein the matrix rubber comprises butadiene rubber, nitrile rubber, chloroprene rubberand butadiene styrene rubber; the antiager selects an antiager RD or an antiager BLE; the coupling agent is a silane coupling agent; the cross-linking agent is methyl tripropanone oxime silane. The rubber is treated through multiple technologies including kneading, mixing, banburying, calendaring, vulcanization and the like. The rubber has excellent high-temperature-resistant performance and pressing-resistant performance and good material rebound resilience and is very suitable for manufacturing buffering cushions used for large equipment including mining machinery and the like.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

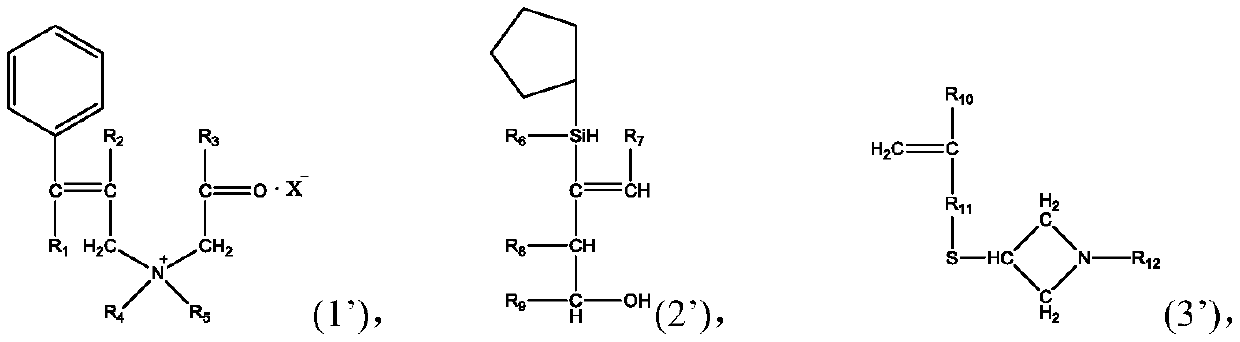

Dye binder composition

The invention provides a dye binder composition, and belongs to the technical field of textile dyeing and finishing. The composition includes repeating unit copolymers which are shown as a formula (1), (2) and (3). The copolymers of the composition include many strong polar active bonds, so that the copolymers are good in rheological property and can greatly enhance the cladding strength of a binder on dye molecules when being used for the dye binder, the abrasion fastness and water fastness of fabrics and / or clothing after dyeing can be significantly enhanced, and good soaping fastness, perspiration fastness and rubbing fastness can be achieved; and the fabrics are small in discoloration and soft in hand feeling.

Owner:佛山市晟世纺织科技有限公司

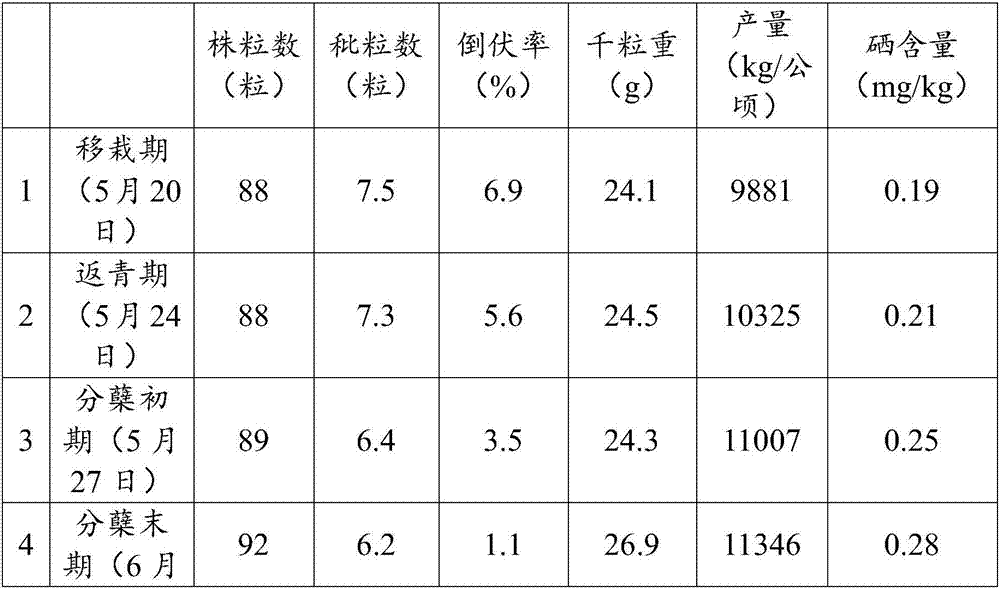

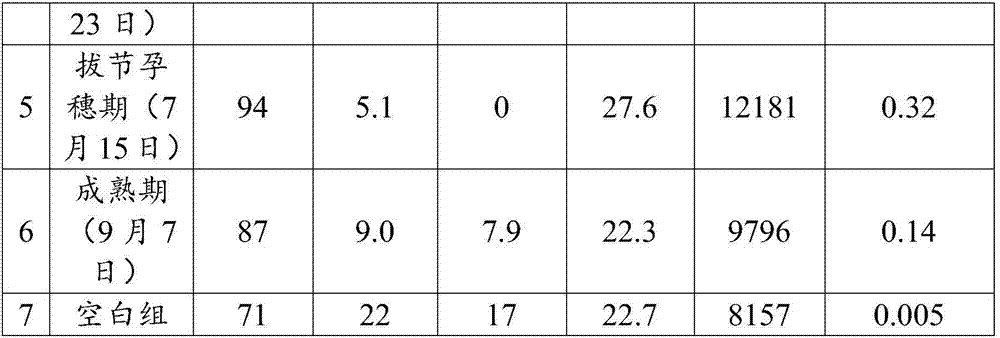

Selenium-rich spray solution as well as preparation method and application thereof

InactiveCN107353117ALow costImprove seed setting rateFertilising methodsOrganic fertilisersNutrient solutionPoisonous effects

The invention discloses a selenium-rich spray solution as well as a preparation method and application thereof, which relate to the technical field of plant nutritional solutions, and solves the technical problems in the prior art that the selenium-containing nutritional solution is high in production cost, poor in effect on crops and easy to produce poisonous effect on the human body. The selenium-rich spray solution is mainly prepared from the following components by volume percent: 0.6 to 1.2 percent of organic selenium extract and the balance of water. The selenium-rich spray solution comprises the organic selenium extract, and is mainly sprayed in an irrigation period after earing and blossoming of the crops, can effectively improve setting percentage and stress resistance of the crops, can increase the yield of the crops and can increase the selenium content in seeds or fruits. The selenium-rich spray solution provided by the invention is low in cost, capable of ensuring that the selenium content of the crops to reach or exceed the national selenium limit standard in food (State Hygiene Standard LB13105-91), and is nontoxic and harmless to the human body, and safe.

Owner:北京慈明堂医学研究院

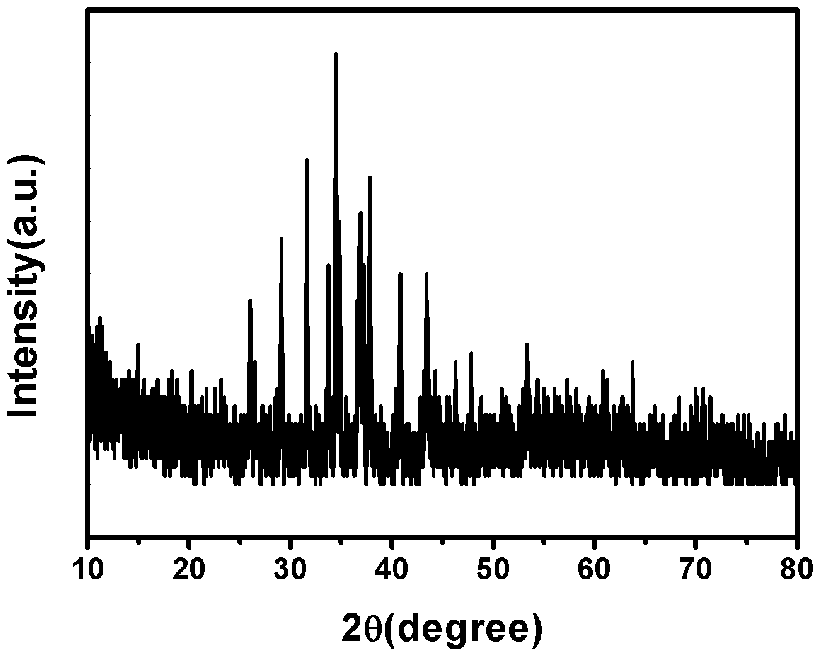

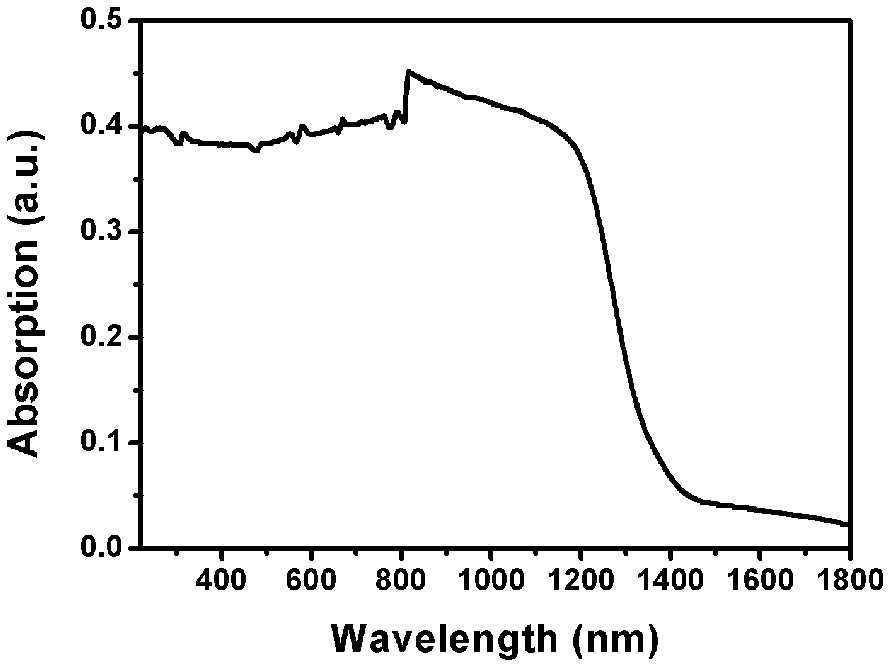

Combining method of Ag2S photoelectric detection material

InactiveCN102701264AGood photoelectric response characteristicsSimple and fast operationSilve compoundsSemiconductor materialsInorganic compound

The invention relates to a combining method of a Ag2S photoelectric detection material and belongs to the technical field of preparation of inorganic compound semiconductor materials. The method includes mixing sulfocompound and silver nitrate according to the molar ratio of 3-4:1, adding a stabilizer into the mixture, dissolving the mixture into water to prepare mixed solution, conducting reaction for 4-6 hours under the condition of 160-180 DEG C and conducting washing, centrifuging and drying to obtain Ag2S photoelectric detection material powder. The sulfocompound is thiocarbamide or sodium thiosulfate preferably, and the stabilizer is lauryl sodium sulfate or glutathione preferably. The combining method adopts a hydrothermal synthesis method, and is simple in whole operation process, good in repeatability and low in cost. Prepared Ag2S has good photoelectric response characteristics-wide band and high photoelectric response and can be applied to optical detectors.

Owner:JILIN UNIV

Metallic paint for protecting plastic shell of electric equipment

InactiveCN108373625AImprove the protective effectGood compatibilityAnti-corrosive paintsReflecting/signal paintsUltraviolet lightsElectric power

The invention relates to the technical field of higher molecular coatings and particularly relates to metallic paint for protecting a plastic shell of electric equipment. The metallic paint contains the following components: acrylic acid and copolymer emulsion, chlorinated polyolefine, an emulsion, water, modified zinc chelate, nano-titanium dioxide, asilane coupling agent, pearlescent pigments, acuring modifying agent, a wetting dispersion aid, a light stabilizer, an ultraviolet light absorber, a defoaming agent and a film forming aid, wherein the curing modifying agent is cellulose acetatebutyrate or aliphatic hexamethylene diisocyanate; the pearlescent pigments are formed by mica particles coated with a titanium dioxide layer, and the particle sizes of the pearlescent pigments are 10-15 microns; and the film forming aid is propanediol butyl ether or propylene glycol methyl ether acetate. The metallic paint has strong adhesion force to the surface of plastic, is unlikely to fall, has good scratch resistance, corrosion resistance and aging resistance and is suitable for protecting the plastic shell of outdoor electric equipment.

Owner:合肥市闵葵电力工程有限公司

Preparation method of soft capsules containing Chinese caterpillar funguses

InactiveCN105079044AImprove immunityImprove fatigue resistanceAntinoxious agentsPharmaceutical non-active ingredientsFiltrationGlycerol

The invention relates to a preparation method of soft capsules containing Chinese caterpillar funguses and belongs to the technical field of pharmaceutical preparation. The method includes the steps that gelatin, glycerin and pure water serve as raw materials, the glycerin and the pure water are injected into a sol tank, heated and stirred, then the gelatin is added and continues to be evenly stirred, then vacuum defoaming is performed, and capsule bodies are made; fruiting bodies of Cordyceps militaris are smashed and extracted, leaching liquor is obtained after filtration, then the leaching liquor is subjected to decompressing concentration and spraying drying, and extract powder is obtained; sea cucumbers are steamed through steam, and the steamed sea cucumbers are ground into micro powder after being dried; the extract powder, the sea cucumber micro powder, grape mannose, algin, polyethylene glycol (peg) and glycerin are mixed, mixtures are ground through a colloid mill, and the evenly-mixed contents are obtained; the contents and the capsule bodies are subjected to pelleting, sizing, pellet washing, drying, pellet picking and subpackage, and the soft capsules containing Chinese caterpillar funguses are prepared.

Owner:李杰

Rubber adhesive and preparation method thereof

ActiveCN111394015AReduce crystallinityImprove solubilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberPolymer science

The invention provides a rubber adhesive and a preparation method thereof. The preparation method of the rubber adhesive comprises: step S100, preparing a first mixture from a graphene filler, an inorganic filler, a fiber filler, an organic filler and a rubber main material; step S200, fully mixing the first mixture obtained in the step S100, 1,6-hexanediol diacrylate and dibutyltin dilaurate at 20-30 DEG C in a mass ratio of (92-96):(2-4):(2-4) to obtain a second mixture; step S300, curing the second mixture obtained in the step S200 at the temperature of 60-80 DEG C for 12-18 hours to obtainthe rubber adhesive. The rubber adhesive provided by the invention has excellent high temperature resistance and mechanical properties.

Owner:SHANDONG HUIDA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com