High-viscosity mildew-proof wallpaper glue

A wallpaper glue, high viscosity technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of user health hazards, oxidative deterioration, mildew, etc. , The effect of strengthening the bonding performance and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

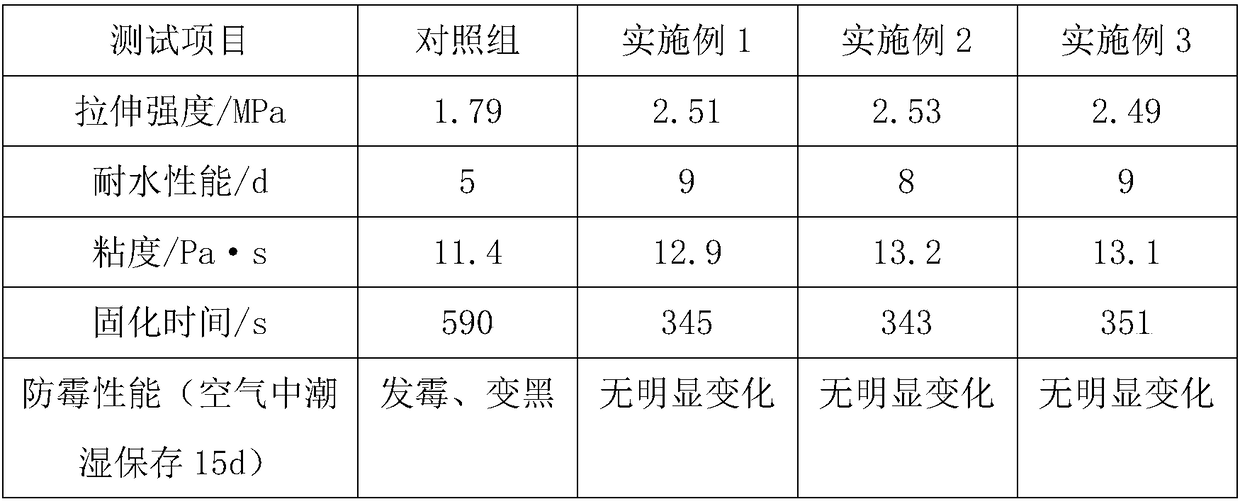

Examples

Embodiment 1

[0036] A high-viscosity anti-mildew wallpaper glue, according to the parts by mass, the components of the wallpaper glue include: 80 parts of water-based polyurethane resin, 25 parts of nano-calcium carbonate, 14 parts of composite tackifier, 3 parts of polyvinyl alcohol, chitosan 4 parts, 1 part of antifungal agent, 0.1 part of antibacterial agent, 1 part of defoamer, 25 parts of deionized water.

[0037] Among them, 1,2-benzisothiazol-3-one is selected as the antifungal agent.

[0038] The defoaming agent is polyoxyethylene polyoxypropanolamine ether.

[0039] The antibacterial agent is a nano-silver antibacterial finishing agent.

[0040] The preparation method of the wallpaper glue that present embodiment provides is:

[0041] According to the number of parts by mass, add the composite tackifier and antifungal agent into deionized water, disperse the slurry at a temperature of 65°C in the dispersion tank, and add the slurry to the water-based polyurethane resin; at the s...

Embodiment 2

[0043] A high-viscosity anti-mildew wallpaper glue, according to the parts by mass, the components of the wallpaper glue include: 90 parts of water-based polyurethane resin, 35 parts of nano-calcium carbonate, 18 parts of composite tackifier, 7 parts of polyvinyl alcohol, chitosan 6 parts, 3 parts of antifungal agent, 0.3 part of antibacterial agent, 2 parts of defoamer, 30 parts of deionized water.

[0044] Wherein, antifungal agent selects methylisothiazolinone.

[0045] The defoamer is polydimethylsiloxane.

[0046] The antibacterial agent is a nano-silver antibacterial finishing agent.

[0047] The preparation method of the wallpaper glue that present embodiment provides is:

[0048] According to the number of parts by mass, add the composite tackifier and antifungal agent into deionized water, disperse the slurry at a temperature of 70°C in the dispersion tank, and add the slurry to the water-based polyurethane resin; at the same time, add Nano-calcium carbonate, polyv...

Embodiment 3

[0050] A high-viscosity mildew-proof wallpaper glue, according to the parts by mass, the components of the wallpaper glue include: 86 parts of water-based polyurethane resin, 30 parts of nano-calcium carbonate, 16 parts of composite tackifier, 5 parts of polyvinyl alcohol, chitosan 5 parts, 1.8 parts of antifungal agent, 0.2 part of antibacterial agent, 1.6 parts of defoamer, 28 parts of deionized water.

[0051] Wherein, the fungicide is selected from 5-chloro-2-methyl-4-isothiazolin-3-one.

[0052] The defoaming agent is polyoxypropylene polyoxyethylene glyceryl ether.

[0053] The antibacterial agent is a nano-silver antibacterial finishing agent.

[0054] The preparation method of the wallpaper glue that present embodiment provides is:

[0055] According to the number of parts by mass, add the composite tackifier and antifungal agent into deionized water, disperse the slurry at a temperature of 68°C in the dispersion tank, and add the slurry to the water-based polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com