Textile dye fixing agent and application thereof

A technology for textile dyes and color-fixing agents, applied in the field of textile printing and dyeing auxiliaries, can solve problems such as decreased color fastness, and achieve the effects of increased crosslinking density, excellent blister fastness, and improved blister fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

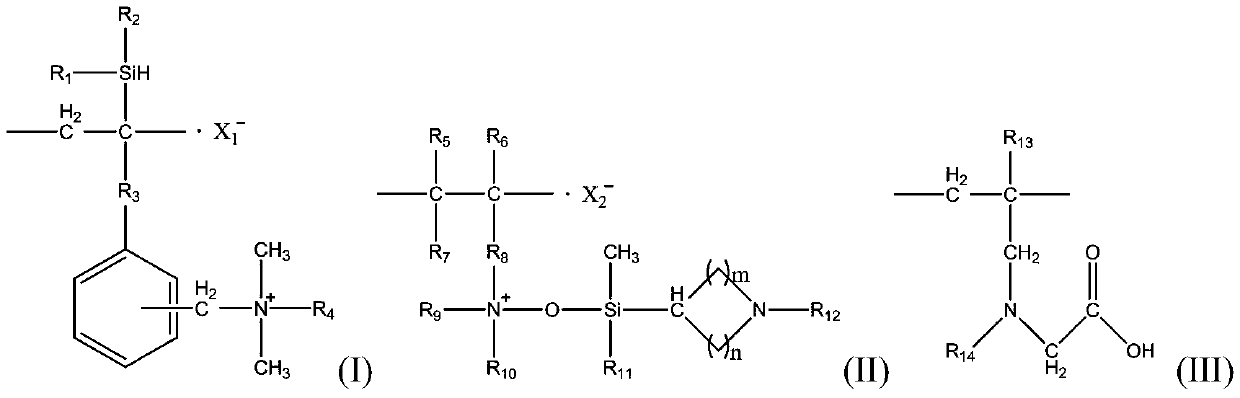

[0104] This embodiment provides a textile dye fixing agent, which specifically comprises a mole of a copolymerization unit represented by formula (I-1), b mole of a copolymerization unit represented by formula (II-1), and c mole of a copolymerization unit represented by formula (II-1) and c mole of a copolymerization unit represented by formula Polymers of copolymerized units shown in (III-1):

[0105]

[0106] In the formula, the R 1 , R 2 , R 5 , R 6 are hydrogen, R 7 is-CH 2 CH 3 , R 11 is-CH 2 CH 2 OH, R 13 is -C(O)O CH 2 CH 3 ; the R 4 is-CH 2 CH 2 SH, R 12 is-CH 2 SH, R 14 is-CH 2 CH 2 CH 2 SH; the R 9 is-CH 3 , R 10 is-CH 2 CH 2 COOH; the R 3 Yes -C(O)O-, R 8 It is -C(O)NH-; said m and n are both 1; said Indicates the counter ion, all are Cl - .

[0107] In terms of molar weight, the molar ratio of a:b:c is 1:1.5:2; in terms of weight average molecular weight, the weight average molecular weight of the textile dye fixing agent is 30000~...

Embodiment 2

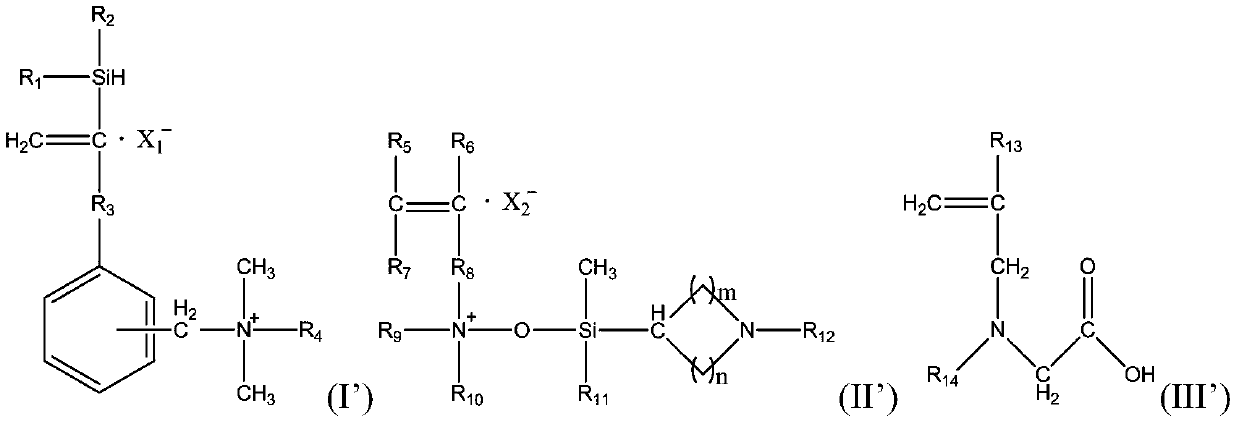

[0131] This embodiment provides item [1]: a textile dye fixing agent, which specifically comprises a mole of a copolymerization unit shown in the following formula (I-2), b moles of a copolymerization unit shown in the following formula (II-2) And the polymer of the copolymerization unit shown in c mole following formula (III-2):

[0132] The present embodiment also provides item [2]: as described in item [1], is used for the preparation method of the polymer of textile dye fixing agent, comprises polymerizing following formula (I'-2), (II) in the presence of initiator The monomer represented by '-2) and (III'-2), wherein the copolymerization unit as shown in formula (I-2) described in item [1] is derived from the following formula (I'-2), item [1] The described copolymerization unit shown in formula (II-2) is obtained by the following formula (II'-2), and the copolymerization unit shown in formula (III-2) described in item [1] is obtained by the following formula (III'-2) ) ...

Embodiment 3

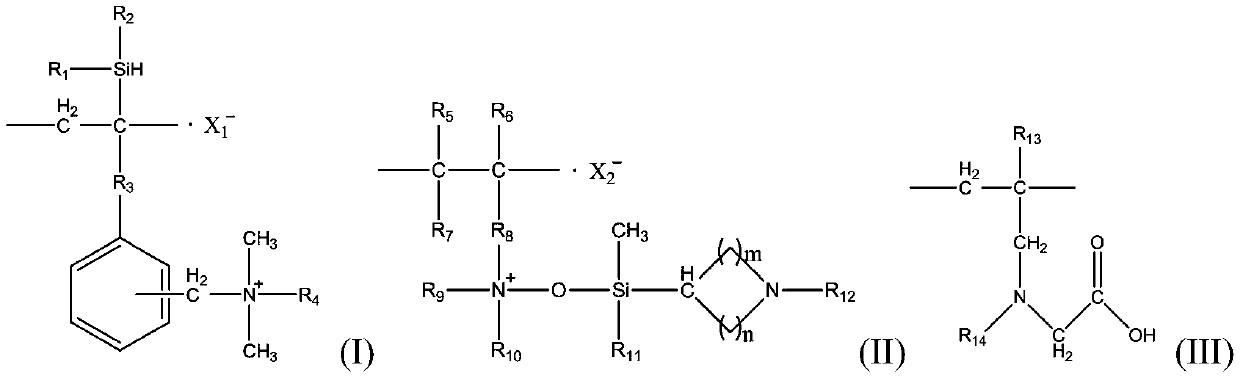

[0151] Embodiment 3 is substantially the same as embodiment 2, except that (I'-2), (II'-2) and (III'-2), therefore, the copolymerization unit thereof is the corresponding copolymerization unit formed after the carbon-carbon double bond of the corresponding monomer is opened.

[0152]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com