Method for preparing high performance Ti3AIC2 ceramic powder

A ceramic powder, high-performance technology, applied in the field of preparation of new structural ceramic materials, can solve the problems of complex process flow, harsh synthesis conditions, and high preparation temperature, and achieve the effects of uniform reaction process, uniform and stable properties, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

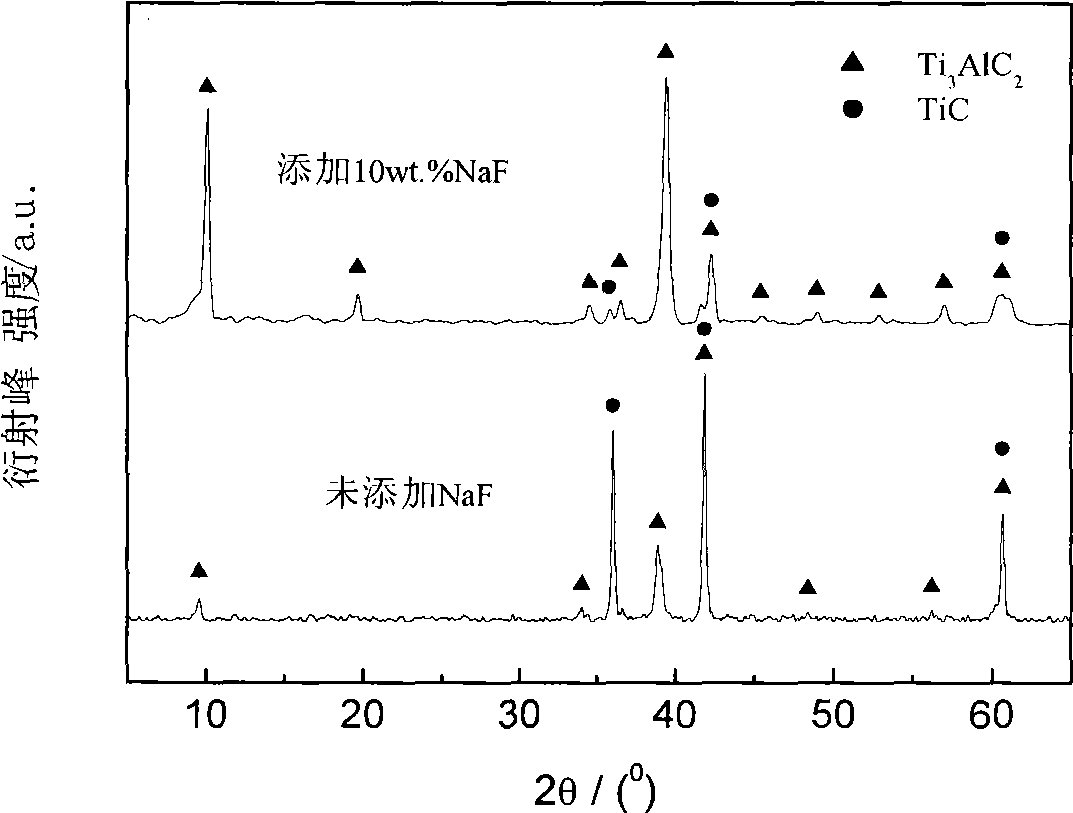

[0022] Weigh 22.1418g of Ti powder with a purity greater than 99.7wt.%, 4.1602g of 99.6wt.% Al powder, and 3.6980g of 99.5wt.% carbon black with a molar ratio of Ti:Al:C of 3:1:2. The additive NaF is Ti, 10 wt.% of the total mass of Al and C (30 g) was added to 3.0000 g. Use anhydrous ethanol as the medium to ball mill on a planetary ball mill for 8 hours at 70°C or dry naturally, then ignite the reactants with a tungsten wire coil under the protection of argon, and cool naturally, the obtained product is Ti 3 AlC 2 Powder.

[0023] The X-ray diffraction analysis detection result of the product obtained in this example is shown in figure 1 , at a diffraction angle 2θ of 9.5 0 There is Ti 3 AlC 2 The characteristic peaks, suggesting that the synthesis is Ti 3 AlC 2 substance.

[0024] In this example, when the additive NaF is added at 0.5wt.% and 20wt.% of the total mass (30g) of Ti, Al and C, respectively, the obtained results are roughly the same.

Embodiment 2

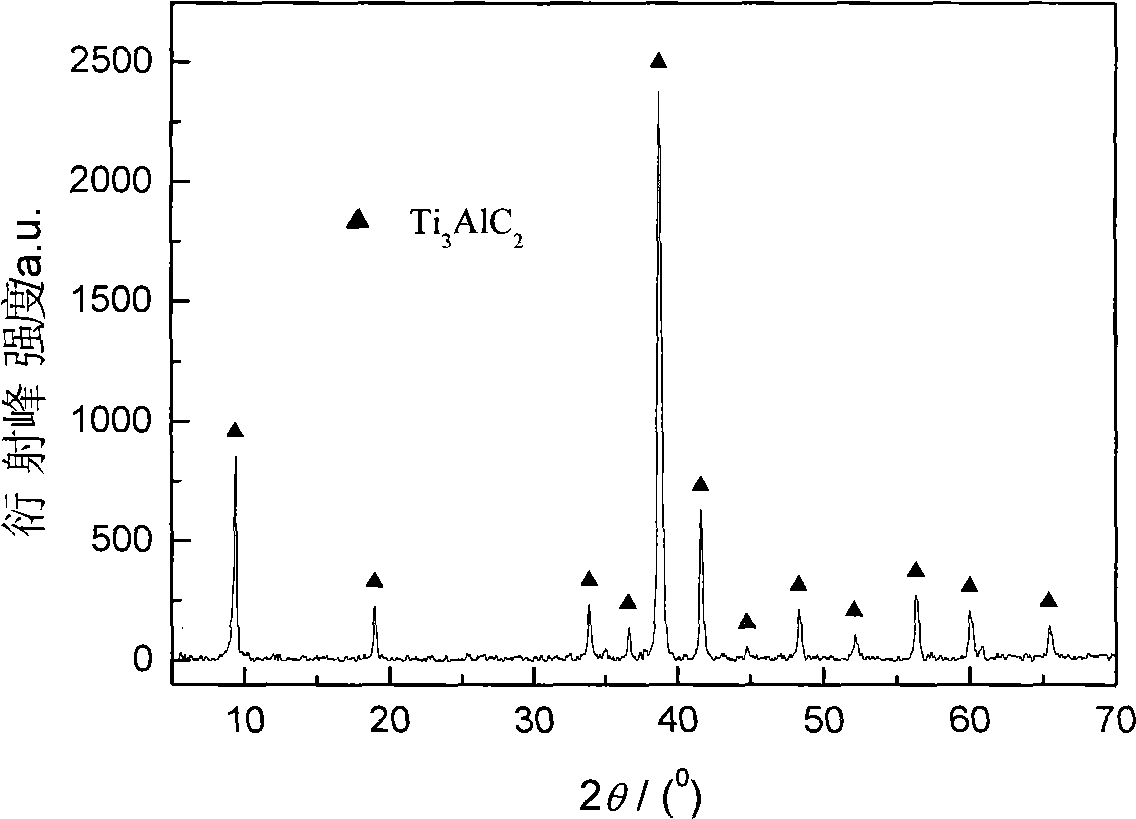

[0026] Under the condition of keeping the molar ratio of Ti:Al:C 3:1:2 unchanged, weigh 17.3438g of Ti powder with a purity greater than 99.7wt.%, 4.1602g of 99.6wt.% Al powder, and 2.4960g of 99.5wt.% carbon black 20wt.% of the total mass of the system (30g) was added to burn and synthesize homemade TiC6.0000g, and the NaF additive was added according to 3wt.% of the total mass of Ti, Al, C and TiC (30g), which was 0.9000g. Use anhydrous ethanol as the medium to ball mill on a planetary ball mill for 8 hours at 70°C or dry naturally, then ignite the reactants with a tungsten wire coil under the protection of argon, and cool naturally, the obtained product is Ti 3 AlC 2 Powder.

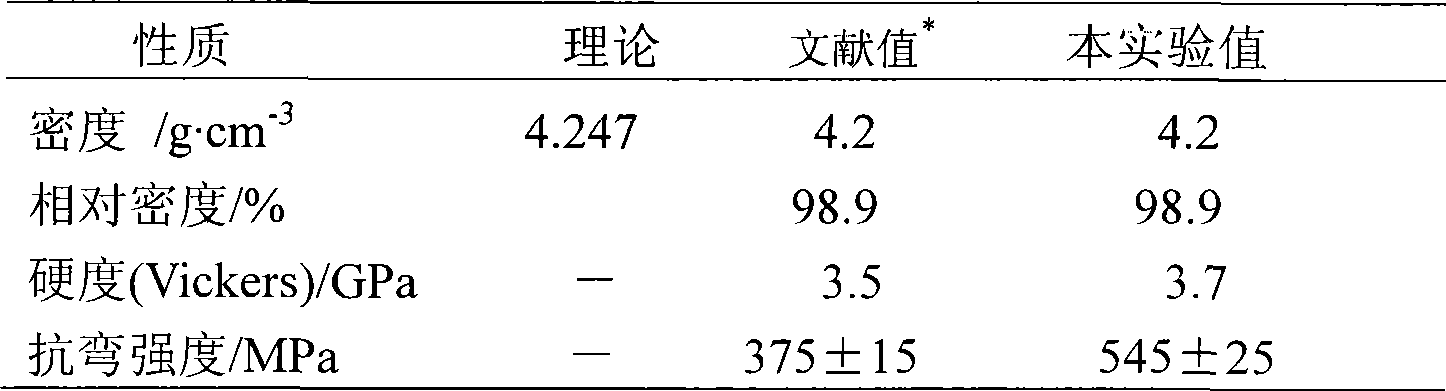

[0027] Ti 3 AlC 2 The powder is put into a φ50mm graphite mold, and sintered by hot pressing at 1400°C and 25Mpa, with argon as the protective atmosphere. The heating process is as follows: the temperature is raised to 1200°C in 30 minutes, the temperature is raised to 1400°C after half an hour, a...

Embodiment 3

[0034] According to Ti: Al: C molar ratio 3: 1.2: 2, weigh the purity greater than 99.7wt.% Ti powder 21.5442g, 99.6wt.% Al powder 4.8576g and 99.5wt.% carbon black 3.5982g, NaF additive according to Ti, Al and 5 wt.% of the total mass of C (30 g) was added to 1.5000 g. Use anhydrous ethanol as the medium to ball mill on a planetary ball mill for 8 hours at 70°C or dry naturally, then ignite the reactants with a tungsten wire loop under the protection of argon, and cool naturally, the obtained product is Ti 3 AlC 2 Powder.

[0035] In this example, the molar ratios of Ti:Al:C were changed to 3:1:1.8, 3:1.3:1.8 and 3:1.3:2.0 respectively, and the obtained products were basically the same when other conditions remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com