Waterborne UV (Ultraviolet) furniture coating and preparation method thereof

A furniture coating, water-based technology, applied in the field of coatings, can solve the problems of poor water resistance, wear resistance and solvent resistance of the paint film, poor storage stability, and difficult coating of substrates, etc., to achieve high curing efficiency and high production efficiency , the protective effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

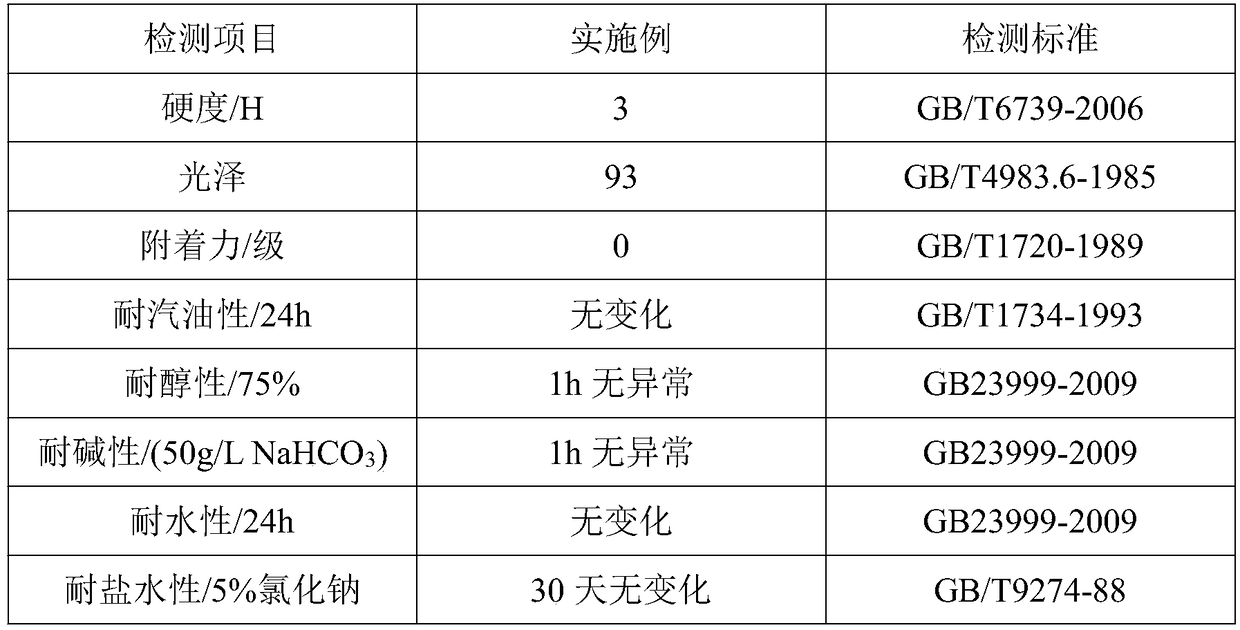

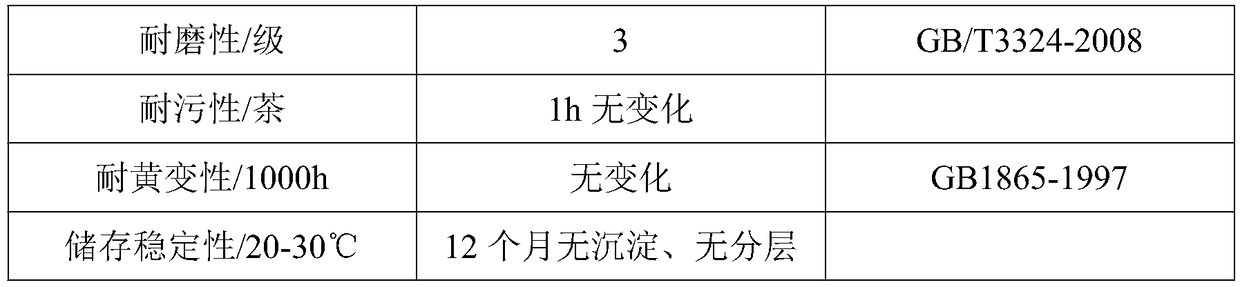

Examples

Embodiment

[0028] A method for preparing a water-based UV furniture coating, comprising: a water-based UV primer attached to the surface of the furniture and a water-based UV topcoat attached to the surface of the coating cured from the primer;

[0029] The water-based UV primer comprises the following components by weight percentage: 55% of water-based acrylate prepolymer, 25% of reactive diluent, 2% of photoinitiator, 2% of film-forming auxiliary agent, 1% of nanometer auxiliary agent, and 10% of pigment %, water 5%;

[0030] The water-based UV topcoat comprises the following components by weight percentage: 60% of water-based acrylate prepolymer, 25% of reactive diluent, 2% of photoinitiator, 2% of film-forming auxiliary agent, 1% of nanometer auxiliary agent, 10% of water %.

[0031] Wherein, the water-based acrylate prepolymer is composed of water-based polyurethane acrylate and water-based epoxy acrylate in a weight ratio of 1:1.

[0032] Wherein, the reactive diluent is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com