Dye binder composition

A technology of adhesives and compositions, applied in the field of textile dyeing and finishing, can solve the problems of poor stability of copolymers and/or polymers, large molecular weight distribution index, explosive polymerization and easy gelation, etc., and achieve perspiration fastness Good, good rheology, improve the effect of coating strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

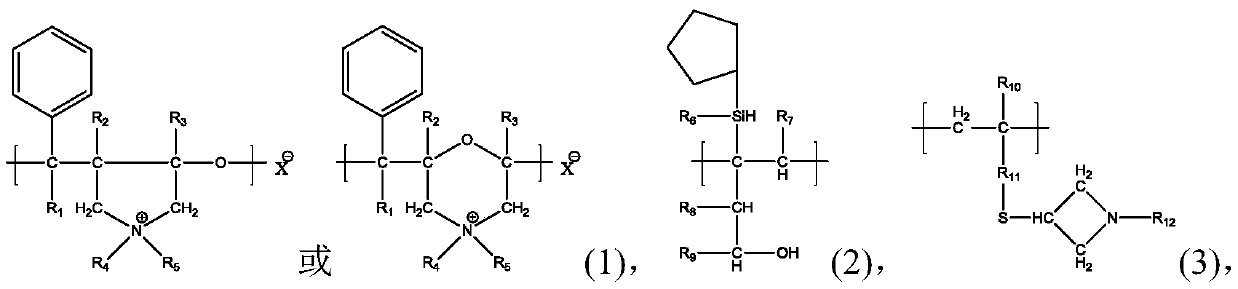

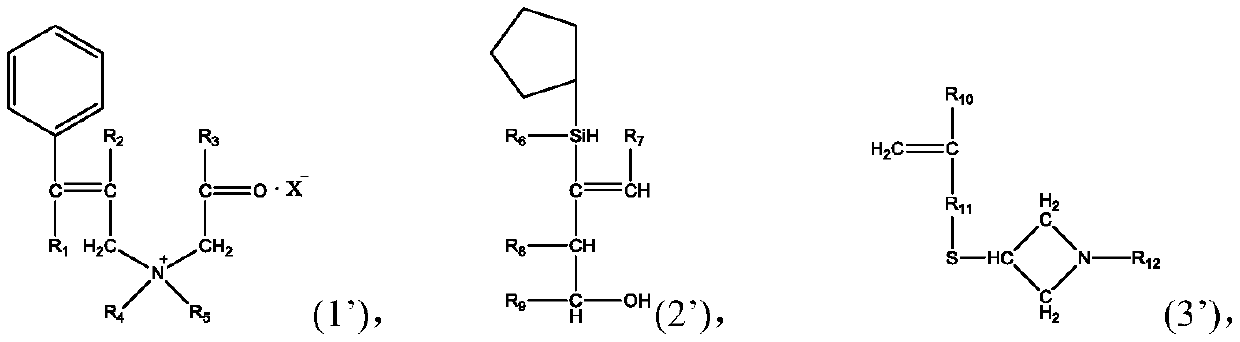

[0137] This embodiment provides a kind of copolymer that can be used for dye binder, and it comprises the repeating unit represented as following general formula (1), (2) and (3):

[0138]

[0139] In formula (1), R 1 , R 2 , R 3 , R 4 and R 5 Both are H, represents the counter ion Cl - ;

[0140]

[0141] In formula (2), R 6 , R 7 , R 8 and R 9 are both H, and

[0142]

[0143] In formula (3), R 10 and R 12 Both are H, R 11 is-CH 2 O-.

[0144] In terms of molar weight, in the copolymer, the molar ratio of the repeating units represented by the general formulas (1), (2) and (3) is 35:45:20.

[0145] In terms of weight average molecular weight, the weight average molecular weight of the copolymer is 15000-20000 g / mol.

[0146] The copolymer chain of the present invention has more branched chains and better polarity, and has good rheological properties. When it is used in dye adhesives, it can greatly improve the coating strength of adhesives on dye m...

Embodiment 2

[0162] [1] This embodiment provides a copolymer that can be used for dye binders, which includes repeating units represented by the following general formulas (1), (2) and (3):

[0163]

[0164] In formula (1), R 1 =R 2 =R 3 =-H,R 4 =-CH 3 , R 5 =-Cl, represents the counter ion Cl - ;

[0165] In formula (2), R 6 =R 7 =R 8 =-CH 3 , R 9 =-CH 2 CH 2 CH 3 ;

[0166] In formula (3), R 10 =-Cl,R 12 =-CH(CH 2 CH 3 )CH 3 , R 11 =-COO-.

[0167] In terms of molar weight, in the copolymer, the molar ratio of the repeating units represented by the general formulas (1), (2) and (3) is 60:35:5.

[0168] In terms of weight average molecular weight, the weight average molecular weight of the copolymer is 25000-30000 g / mol.

[0169] The copolymer chain of the present invention has more branched chains and better polarity, and has good rheological properties. When it is used in dye adhesives, it can greatly improve the coating strength of adhesives on dye molecules...

Embodiment 3

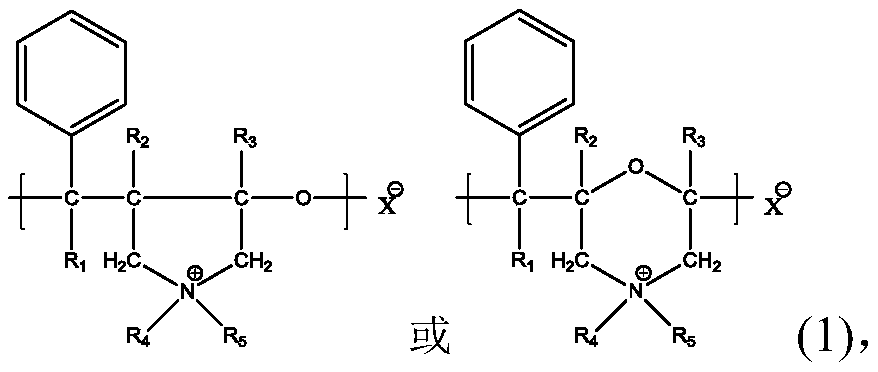

[0189] Embodiment 3 is basically the same as Embodiment 2, except that in Embodiment 3, the copolymerization unit of the copolymer that can be used for the dye binder is as follows: (1-3), (2-3) and (3- 3) As shown:

[0190]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com