Modified lignin sulfosalt dispersant of water coal slurry

A lignosulfonate and dispersant technology, applied in chemical instruments and methods, liquid carbon-containing fuels, transportation and packaging, etc., can solve problems such as difficult to meet production requirements, strict coal type requirements, and naphthalene carcinogenicity, and achieve Low cost, good fluidity, anti-flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

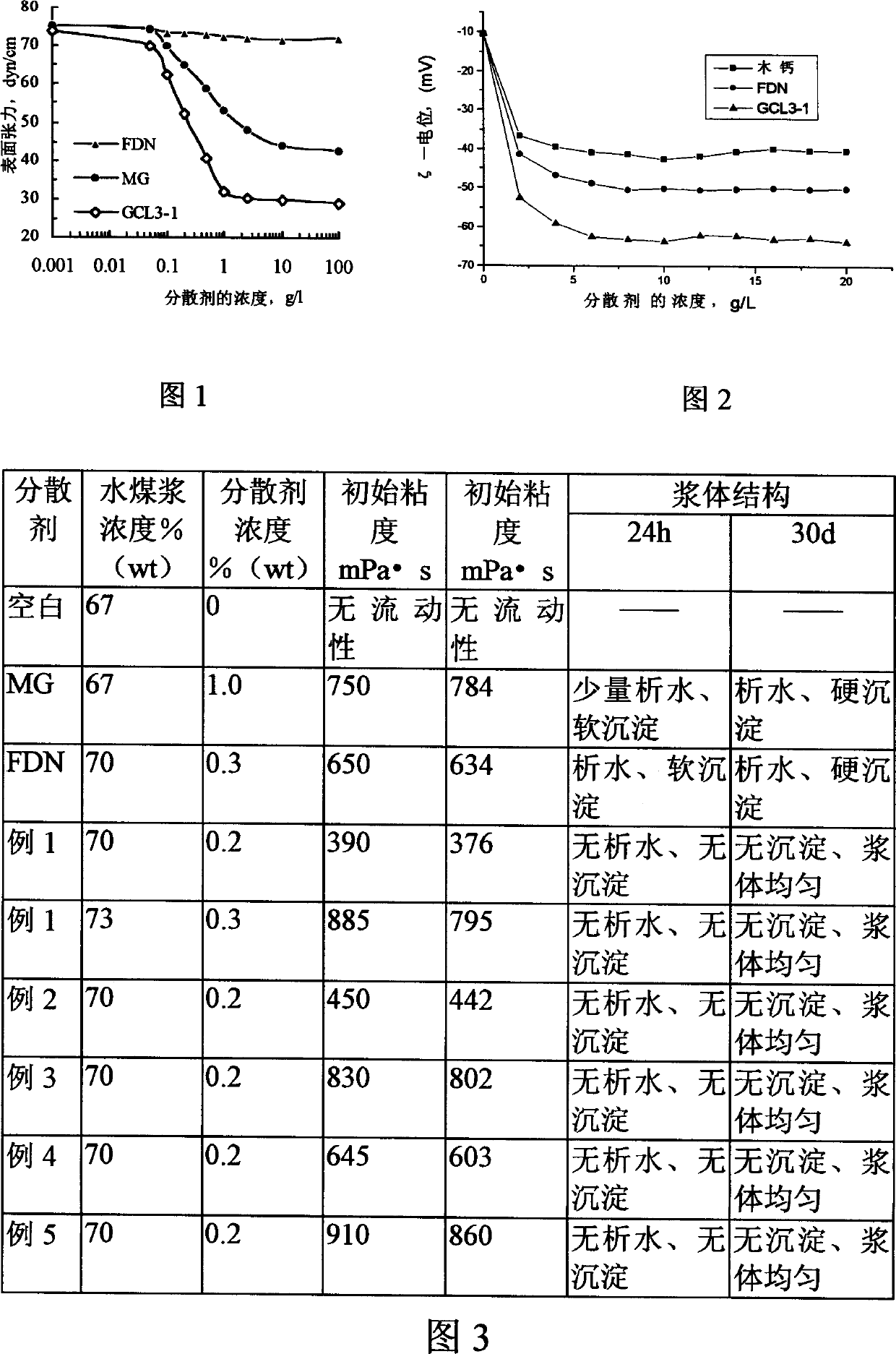

Embodiment 1

[0032] First, take 3000 grams of lignosulfonate solution with a solid content of 40%, add 30 grams of KOH and 100 grams of acrylic acid, adjust the pH value to 10-11, then heat to 80 ° C while stirring, and then add the initiator FeCl 2 2.2 g, Cu(NO 3 ) 2 1.8 g and oxidant KMnO 4 30 grams, catalytic reaction for 8 hours; finally add 50 grams of polyacrylic acid (molecular weight: 2500) and 5 grams of silicone oil, stir rapidly for 30 minutes, obtain liquid dispersant product after cooling, and then dry to obtain powder.

Embodiment 2

[0034] First take 2500 grams of lignosulfonate solution with a solid content of 40%, add 30 grams of NaOH, 200 grams of formaldehyde, and 200 grams of benzylphenol, adjust the pH value to 9-10, and then heat to 60 ° C while stirring, Then add initiating catalyst FeCl 2 3 g and oxidizer H 2 o 2 30 grams, catalyzed reaction for 1 hour; finally add 50 grams of polyacrylic acid (molecular weight 2500) and 2 grams of silicone oil, stir rapidly for 30 minutes, after cooling, the liquid product of coal water slurry dispersant is obtained, and then dried to obtain powder.

Embodiment 3

[0036] First, take 2000 grams of lignosulfonate solution with a solid content of 50%, add 40 grams of NaOH and 60 grams of acrylic acid, adjust the pH value to 9-10.5, then heat to 80 ° C while stirring, and then add the initiator FeCl 2 1 g, FeSO 4 1 g and oxidizing agent H 2 o 2 30 grams, catalytic reaction for 3 hours; finally add 3 grams of butanol, stir rapidly for 30 minutes, after cooling, the liquid product of coal-water slurry dispersant is obtained, and then dried to obtain powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com