Method for preparing formaldehyde-free ethylene vinyl acetate emulsion

A technology of ethylene copolymer and vinyl acetate, applied in monocarboxylate copolymer adhesives, adhesive types, coatings, etc., can solve problems such as yellowing and discoloration, and achieve strong initial adhesion and consistency , good rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

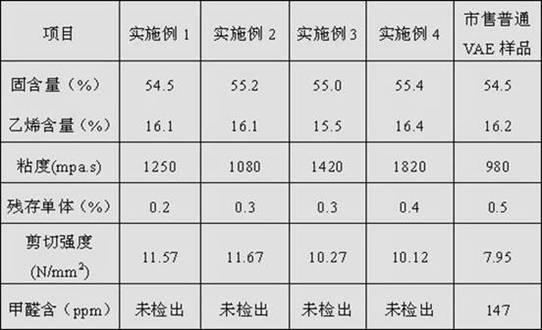

Examples

Embodiment 1

[0029] 120g of polyvinyl alcohol AIRVOL? 205 (degree of alcoholysis 88%, degree of polymerization 500), 77g of polyvinyl alcohol RS-1717 (Japan Kuraray company, degree of alcoholysis 92-94%, degree of polymerization 1700), 12g of polyvinyl alcohol Sodium isooctanoate buffer, 19g of sodium metabisulfite reducing agent and 0.05g of ferrous sulfate co-reducing agent are dissolved in 2255g of deionized water to prepare an aqueous phase, and the above-mentioned 2.5Kg aqueous phase is injected into a 10L container by metering pump a. In the autoclave; feed ethylene to replace the air in the autoclave, and then use ethylene to pressurize to 6MPa; start stirring, and use the reactor jacket water to raise the temperature of the material to the reaction temperature of 80°C; then use the metering pumps b and c to react respectively Inject monomer vinyl acetate (flow 3.75ml / min, monomer specific gravity 0.9342, equivalent flow 3.5g / min) and initiator tert-butyl hydroperoxide (flow 0.01m...

Embodiment 2

[0031]Basic process, parameter are identical with embodiment 1, just polyvinyl alcohol AIRVOL? 205 (degree of alcoholysis 88%, degree of polymerization 500) is adjusted to 110g; Polyvinyl alcohol RS-1717 is replaced by RS-1113 (Japan Kuraray company, the degree of alcoholysis is 97.5-99%, the viscosity of 4% aqueous solution is 16-22mpa.s), and the weight is 85g. The reaction temperature was set at 95°C.

Embodiment 3

[0033] The basic process and parameters are the same as in Example 1, except that polyvinyl alcohol AIRVOL? 205 is replaced by AIRVOL? 203 (degree of alcoholysis 88% polymerization degree 300); polyvinyl alcohol RS-1717 is replaced by RS-1113 (Japan Kuraray company, alcoholysis degree 97.5-99%, 4% aqueous solution viscosity 16-22mpa.s). The reaction temperature was 76°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com