Patents

Literature

38results about How to "Strong initial tack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

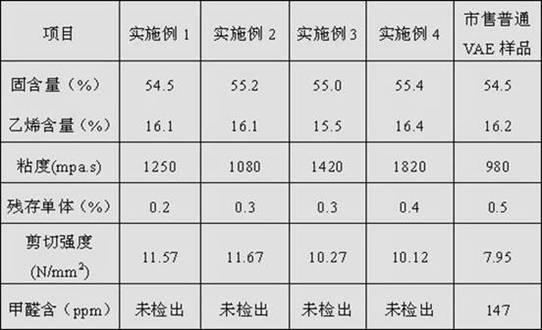

Method for preparing formaldehyde-free ethylene vinyl acetate emulsion

InactiveCN102603955ADelicate colloidImprove rheologyMonocarboxylic acid ester polymer adhesivesCoatingsCarvacryl acetateMonomer

The invention provides a method for preparing formaldehyde-free ethylene vinyl acetate emulsion. The ethylene vinyl acetate emulsion is obtained by copolymerization reaction of ethylene and / or polyvinyl alcohol with monomers such as vinyl acetate and the like in the existence of emulsifier and under the action of redox initiator, wherein pyrosulfite and / or sulfite serve as reducing agent, and organic hydrogen peroxide serves as oxidant. Ethylene vinyl acetate emulsion which completely contains no formaldehyde can be obtained by the method, the problems of yellowing, discoloring and the like can be avoided, and the formaldehyde-free ethylene vinyl acetate emulsion is uniform and stable in quality, wide in viscosity adjustable range, quick in curing, high in primary viscous force and wide in application range.

Owner:CHINA PETROCHEMICAL CORP

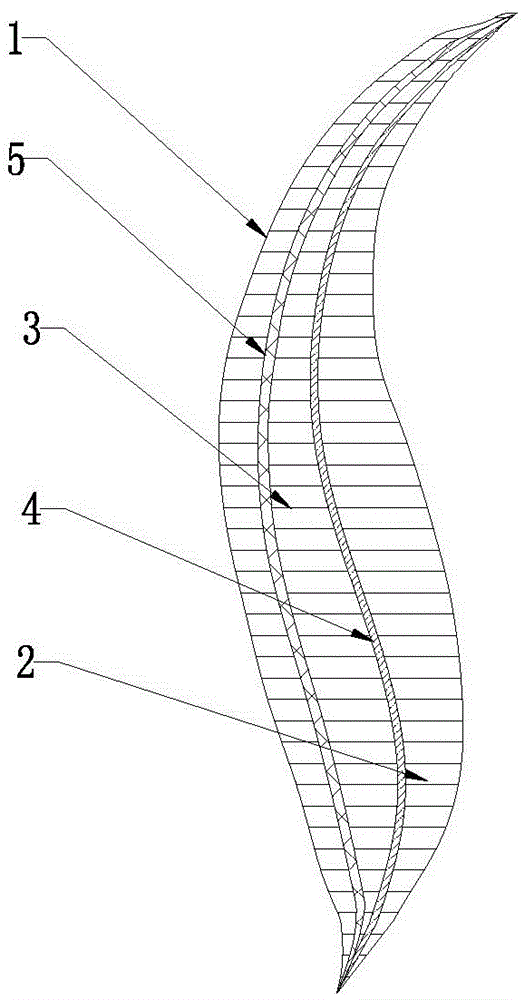

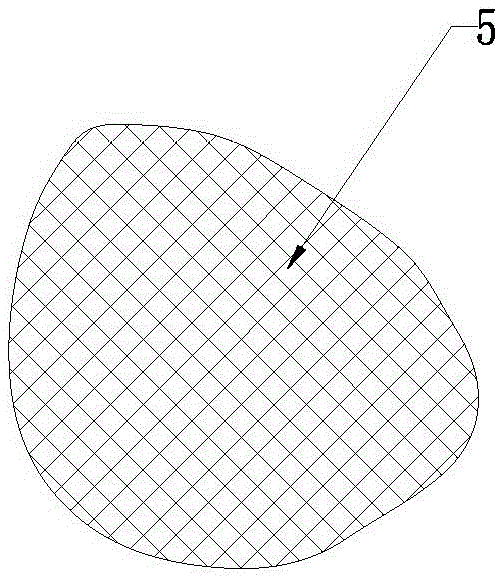

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

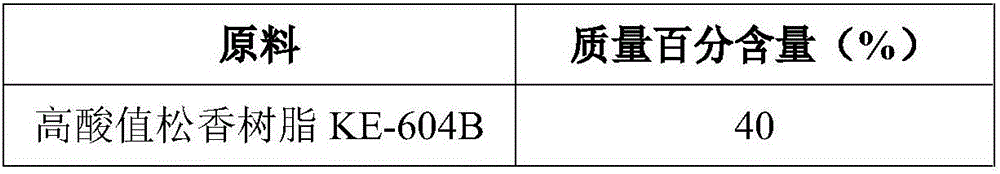

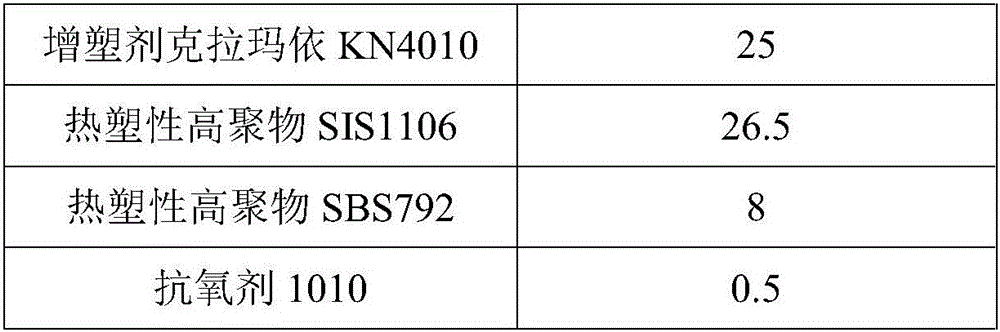

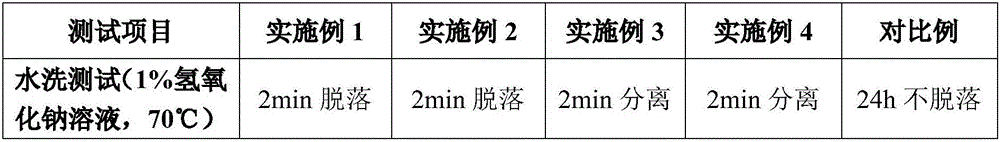

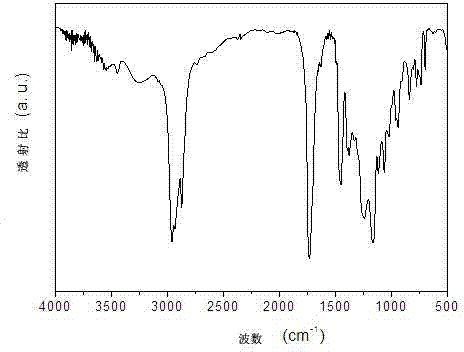

Washable hot melt adhesive and application thereof

InactiveCN106085351ASmall peeling forceIncrease usageNon-macromolecular adhesive additivesOil/fat/wax adhesivesSolid particleCompanion animal

The invention discloses a washable hot melt adhesive and application thereof. The hot melt adhesive is composed of the following raw materials by mass percentage: 30-80% of high-acid value resin; 0-40% of a plasticizer; 10-40% of a thermoplastic high polymer; and 0-1% of an antioxidant. The hot melt adhesive provided by the invention selects high-acid value resin as the tackifier, which contains carboxyl or hydroxyl and other hydrophilic functional groups, and can rapidly react with alkaline water so as to destroy the structure of the hot melt adhesive and lower the stripping force of the hot melt adhesive. The hot melt adhesive is partially dissolved and dispersed into small solid particles so as to completely break away from an adherend, thus being easily removed from the surfaces of PET, PP, PE, glass, ceramics, metals, leather, wood, paper products, plastic products, textile products or others. The washable hot melt adhesive provided by the invention has the bonding performance of conventional hot melt adhesives, and has the advantages of strong initial adhesion, environmental protection and safety, the preparation process is simple, the requirements for the process and equipment are low, the production efficiency is high, and the production cost is low.

Owner:GUANGZHOU THE BOND CHEM

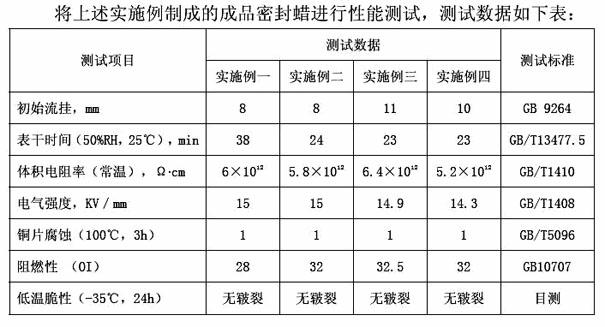

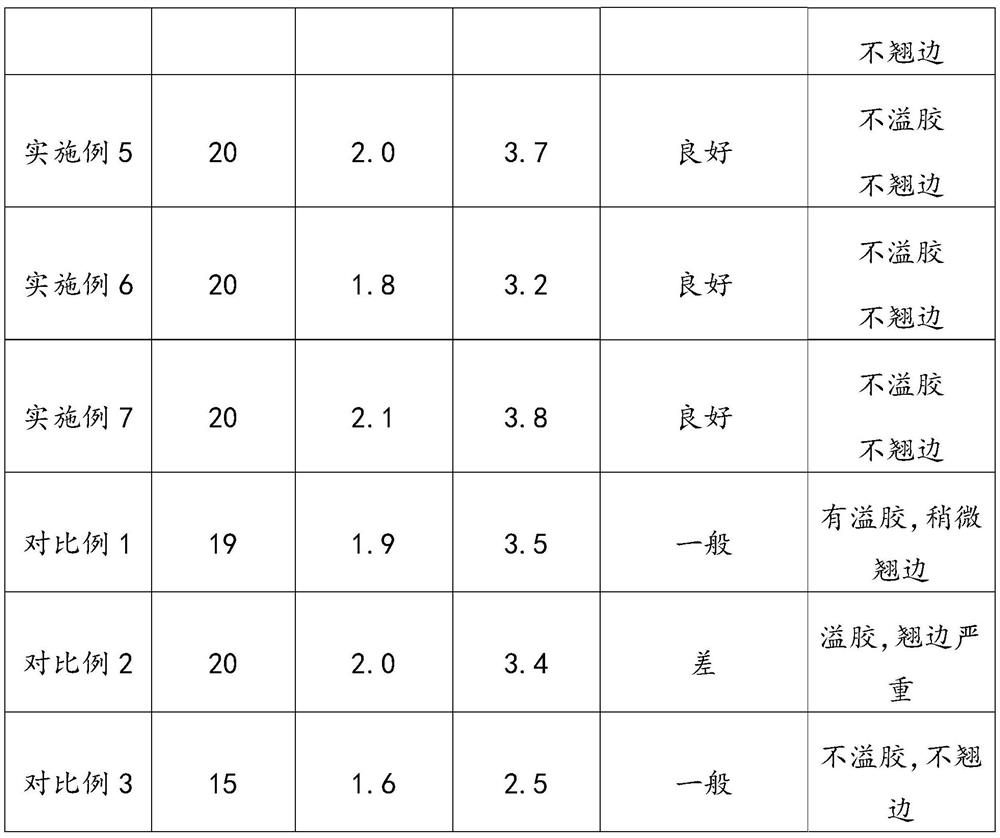

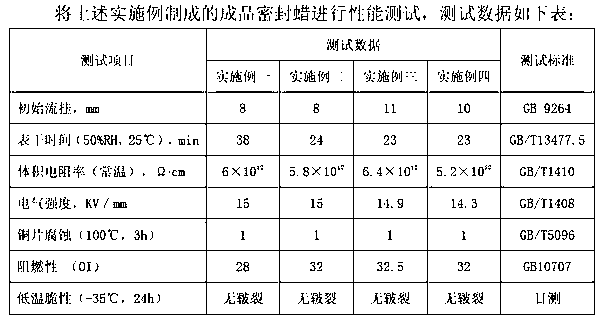

Seal wax composition for train end connector of motor train unit and preparation method thereof

The invention discloses a seal wax composition for a train end connector of a motor train unit. The seal wax composition comprises the following components in percentage by weight: 62-70% of wax material, 1-10% of tackifier, 15-25% of fire retardant, 5-15% of hydroxyl-terminated polydiorgaonsiloxane polymer, 1-5% of siloxane cross-linking agent and 0.1-3% of catalyst. The invention also discloses a preparation method of the seal wax composition. The seal wax composition prepared by the method contains no solvent and has good initial adhesion and favorable sealing, waterproofing, insulating and antiflaming properties; and the seal wax composition does not flow at the high temperature of 100 DEG C and does not crack at the low temperature of -35 DEG C, is in a paste state at room temperature and can be filled in a hose with a sharp mouth to be extruded, thereby facilitating construction. More importantly, the surface of the wax coating is not tacky and can become properly tackier along with elapse of time; the surface of the wax coating is in a plastic or rubber state, but the inside of the wax is still in a semi-solid state; and the original signal line can be replaced with a new one by simply removing the wax around the signal line and then refilling the seal wax.

Owner:江苏泰尔新材料股份有限公司

Preparation technology for high-performance solvent copolymerization acrylate pressure-sensitive adhesive

ActiveCN104845565AThe average molecular weight is largeWide molecular weight distributionPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceAdhesive

Provided is preparation technology for a high-performance solvent copolymerization acrylate pressure-sensitive adhesive. The adhesive comprises the following components, by weight ratio: 65-90% of a soft monomer, 10-30% of a hard monomer, and 3-5% of a crosslinking monomer. The adhesive also comprises a solvent, the weight of which is 10% of the total weight of monomers at an initial reaction stage, is 10-20% of the total weight of monomers at an early stage of a growth stage, is 40-60% of the total weight of monomers at a later stage of the growth stage, and is 138-163% of the total weight of monomers at a final reaction stage, and an initiator, the weight of which is 0.03-0.5% of the total weight of monomers. According to the invention, the copolymerization acrylate is high in average molecular weight and wide in molecular weight distribution. The molecular weight of the copolymerization acrylate can be measured through gel permeation chromatography, and has a weight-average molecular weight in a range of 450-900 kg / mol and a molecular weight distribution index in a range of 4-20.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

Environmental protection oil solubility adhesive and preparation method thereof

InactiveCN1908106AStrong initial tackIncrease stickinessMonocarboxylic acid ester polymer adhesivesEthyl esterChemistry

the invention discloses an environmental-protective oil soluble adhesive and preparing method, which comprises the following parts: 20-40% Z-EMA, 30-75% EAM, 1-20% vinyl acetate (VAC), 1-15% BA, 0.5-15% AA and 0.05-5% EMA, wherein the raw materials are blended with initiator (BOP) to form the product, which satisfies the request of ROHS.

Owner:谢土根

Emulsion pressure-sensitive adhesive for protecting adhesive tape and preparation method thereof

InactiveCN103320065AAdvanced preparation technologyEasy to makeFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateHigh humidity

The invention provides an emulsion pressure-sensitive adhesive for protecting an adhesive tape and a preparation method thereof. The emulsion pressure-sensitive adhesive is prepared from butyl acrylate, 2-ethylhexyl acrylate, methyl methacrylate, styrene, crylic acid, hydroxy-propyl acrylate, an initiator, a buffer agent and an emulsifier in a polymerization manner. The preparation method of the emulsion pressure-sensitive adhesive comprises the following steps: a) selecting a synthetic material; b) preparing pre-emulsion; c) performing polymerizing emulsion; d) detecting a product. The invention discloses the emulsion pressure-sensitive adhesive for protecting the adhesive tape and the preparation method thereof. The emulsion pressure-sensitive adhesive is advanced in preparation technology, and simple in preparation process; the prepared emulsion pressure-sensitive adhesive not only has strong initial tension and high peel strength, but also has good high-temperature, high-humidity and aging resistance, and high application value.

Owner:KUNSHAN HANBAO TAPE TECH

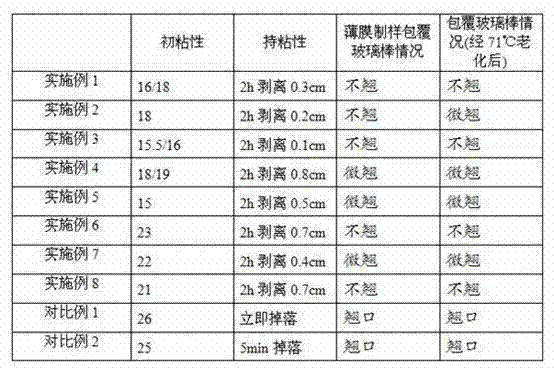

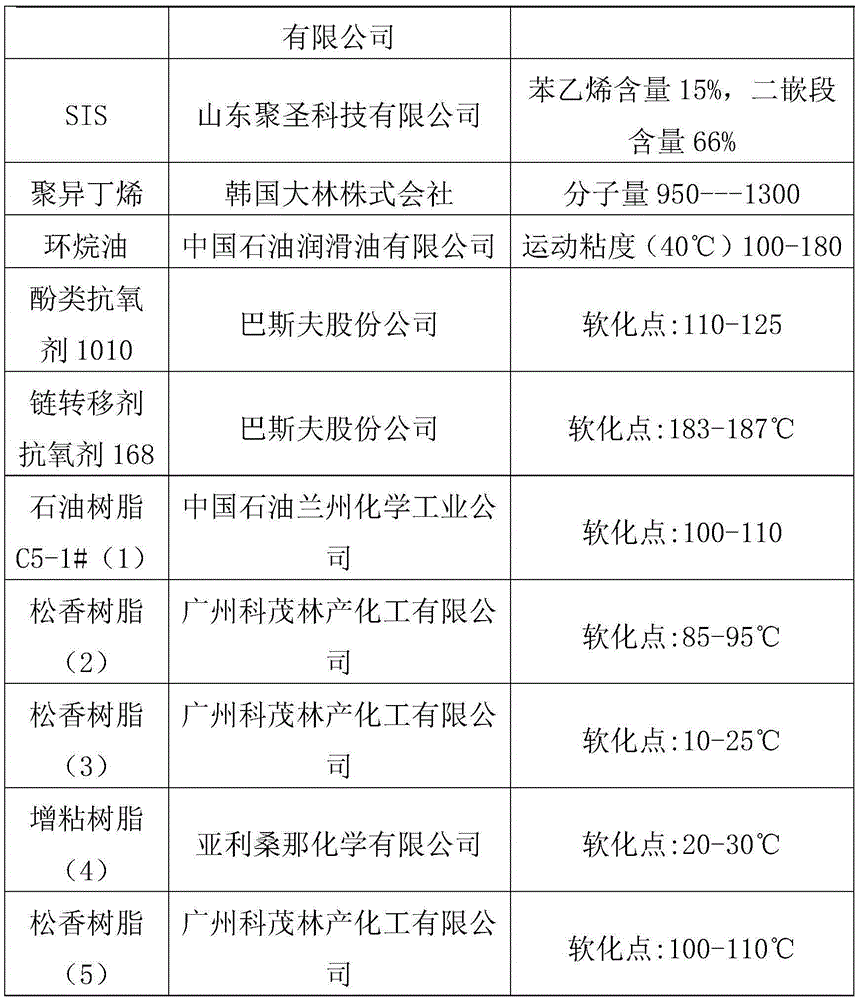

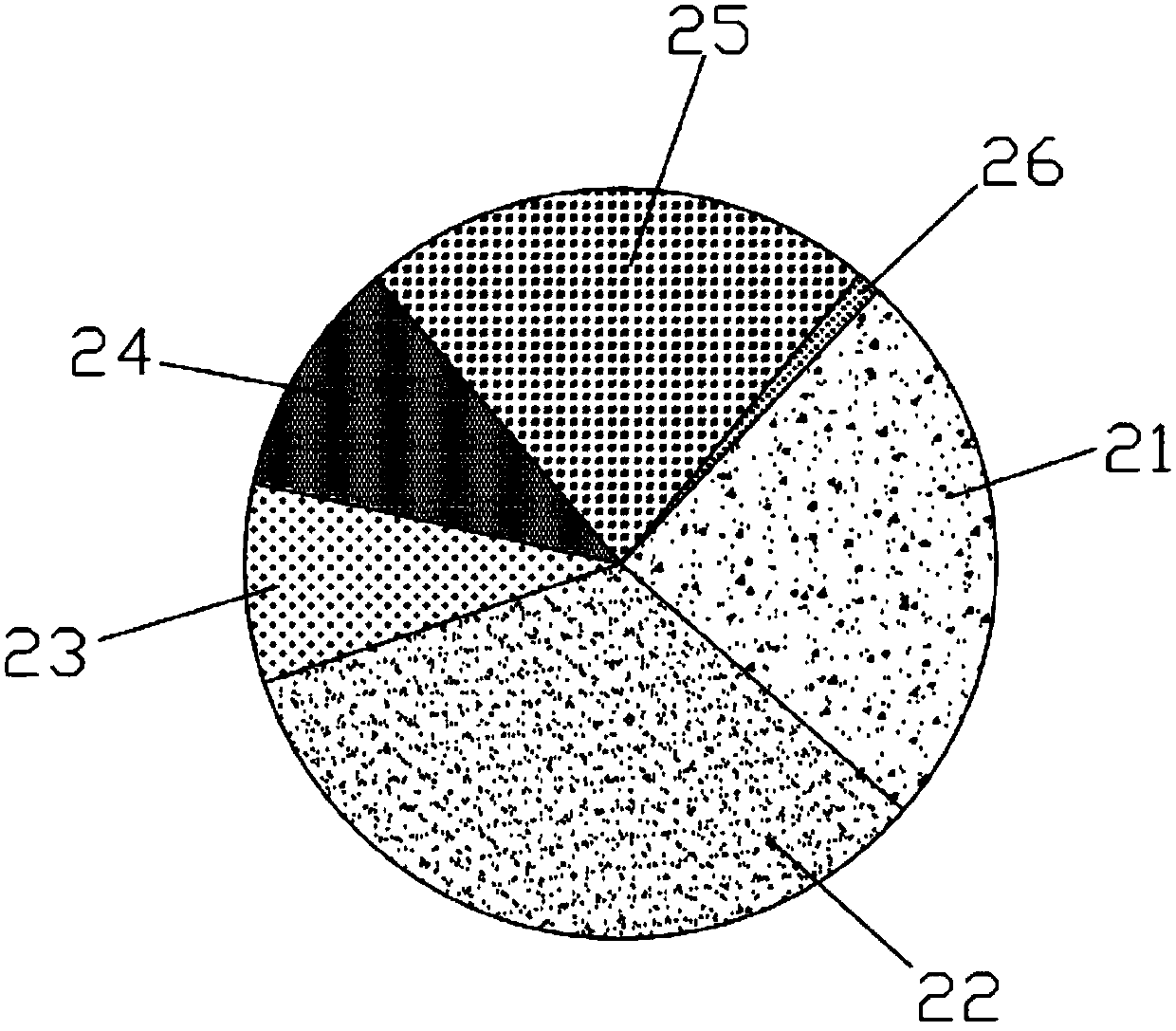

Hot-melt pressure-sensitive adhesive used for sealing brown paper/bubble bag and preparation method thereof

InactiveCN105419700AGood initial adhesionImprove peel forceMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesChemical industryThermoplastic elastomer

The invention discloses a hot-melt pressure-sensitive adhesive used for sealing a brown paper / bubble bag and a preparation method thereof, which belong to the field of chemical industry. The invention relates to the hot-melt pressure-sensitive adhesive, which solves the problems of low adhesive property and poor weatherability of the hot-melt pressure-sensitive adhesive used for sealing the brown paper / bubble bag. The hot-melt pressure-sensitive adhesive used for sealing the brown paper / bubble bag comprises the following components in parts by weight: 20-30 parts of a SIS thermoplastic elastomer, 5-10 parts of a SBS thermoplastic elastomer, 15-25 parts of naphthenic oil, 5-8 parts of polyisobutene, 40-55 parts of tackifying resin and 0.1-1 part of an anti-oxidant. The method has the advantages of simple process and easy operation, and the product has the advantages of strong bonding force, good initial adhesion, good weatherability and good stability.

Owner:SHENZHEN TONGDE NEW MATERIALS TECH CO LTD

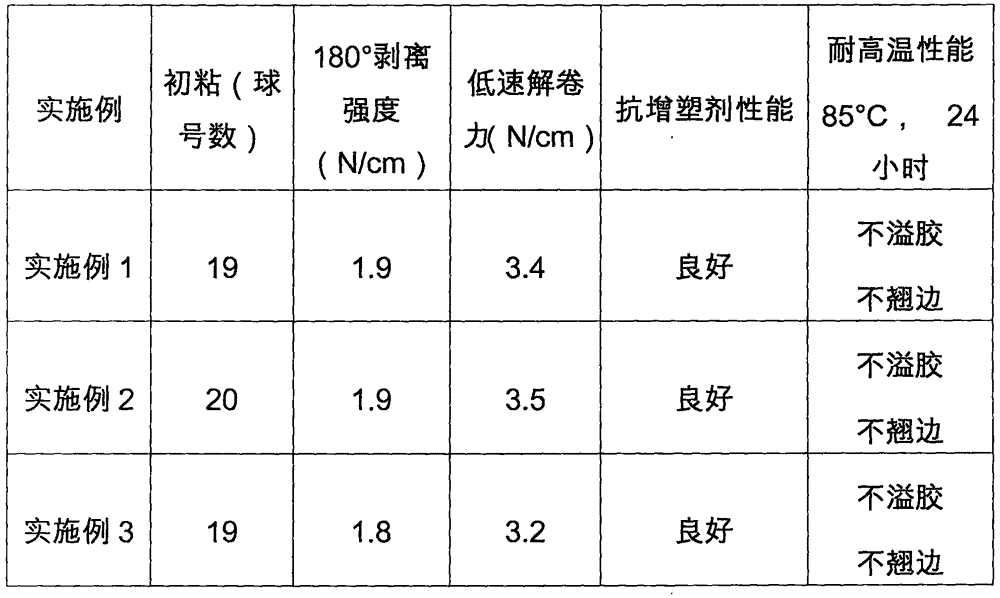

Pressure-sensitive adhesive applied to PVC (polyvinyl chloride) film as well as preparation method and application of pressure-sensitive adhesive

InactiveCN106085308AHigh viscosityGood high temperature resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPressure sensitiveChemistry

The invention provides a rubber-system pressure-sensitive adhesive applied to a PVC (polyvinyl chloride) film as well as a preparation method and an application of the pressure-sensitive adhesive. The rubber-system pressure-sensitive adhesive is mainly prepared from a block copolymer thermoplastic elastomer, a plasticizer, tackifying resin, pure C9 monomer resin and an antioxidant in specific parts by mass. The rubber-system pressure-sensitive adhesive can be applied at 150-160 DEG C, has good anti-plasticizer performance and high initial adhesion and is particularly applicable to preparation of flexible electrical insulation PVC tapes. The preparation method of the rubber-system pressure-sensitive adhesive is simple in process, high in production efficiency and applicable to mass production.

Owner:HEBEI YONGLE TAPE CO LTD

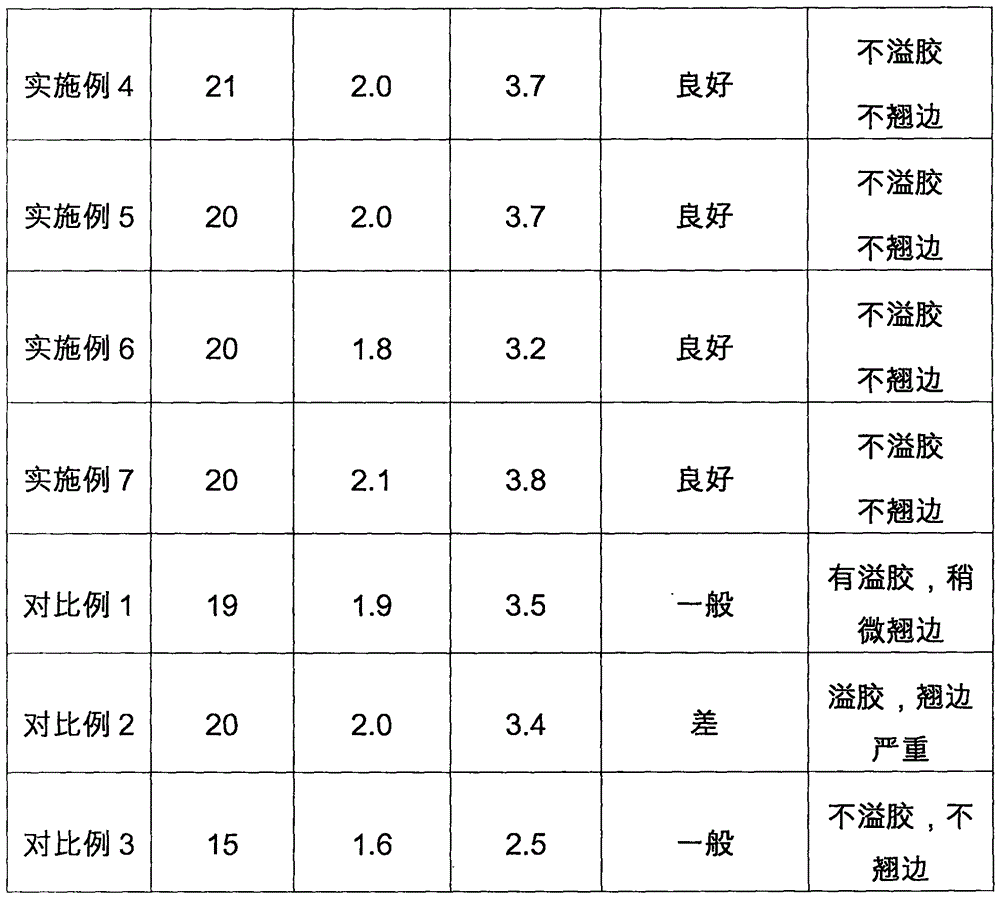

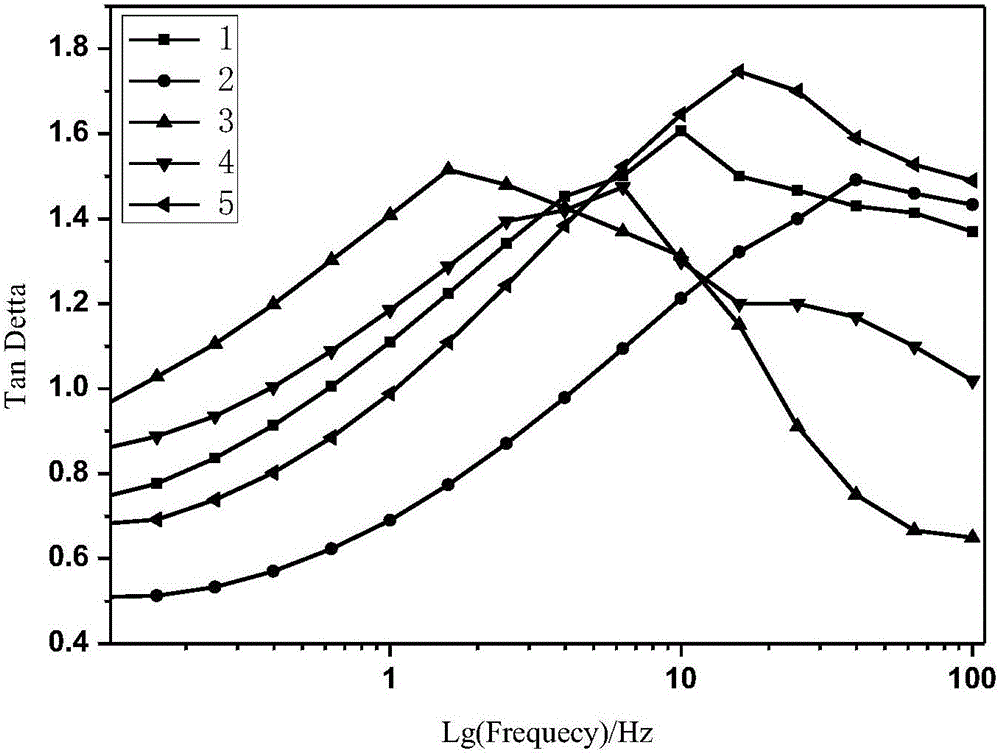

UV polymerization type body foamed damping material and preparation method thereof

ActiveCN105585985AImprove performanceLower glass transition temperatureNon-macromolecular adhesive additivesGraft polymer adhesivesFoaming agentSolvent free

The invention discloses a UV polymerization type body foamed damping material. The UV polymerization type body foamed damping material comprises components in parts by weight as follows: 20-30 parts of an acrylate copolymer, 70-75 parts of a reactive diluent, 0.5-0.8 parts of a photoinitiator and 1-5 parts of hollow inorganic nanoparticles. The high-performance damping material is prepared through UV polymerization, and a solvent-free and pollution-free product is realized thoroughly. The hollow inorganic nanoparticles are taken as an inorganic body foaming agent, the product density can be controlled precisely according to requirements through control of adding amount of the hollow inorganic nanoparticles, and the loss factor of the product can be controlled and increased. The damping material has the advantages of excellent initial adhesion, persistent adhesion, peel strength, interfacial wettability and high loss factor.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

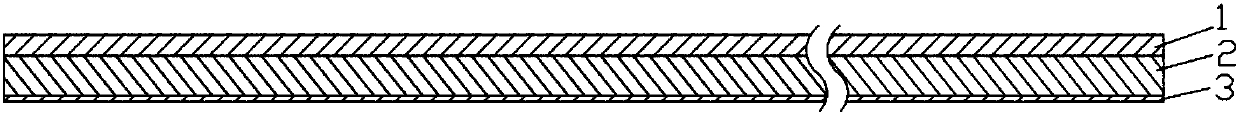

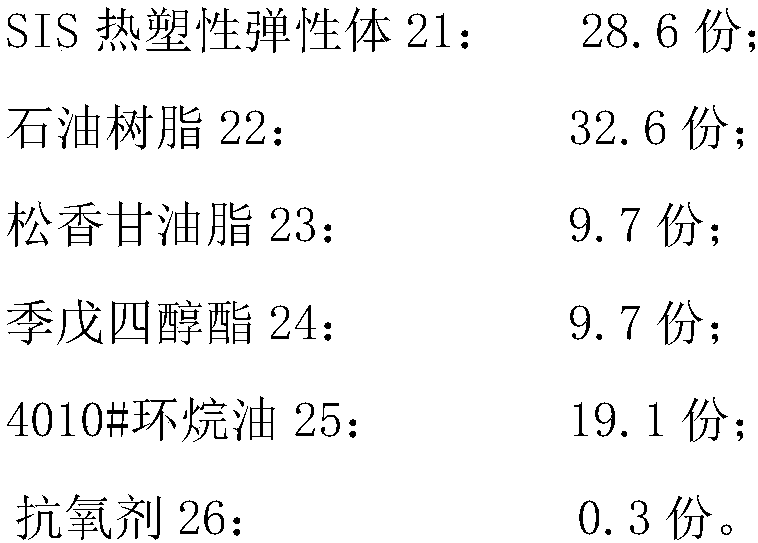

Strong non-drying adhesive label for sticking bubble express bag

InactiveCN107603536AStrong physical propertiesGood physical propertiesMineral oil hydrocarbon copolymer adhesivesStampsAntioxidantSolvent

The invention discloses a strong non-drying adhesive label for sticking a bubble express bag. The label comprises a surface paper layer, an anti-sticking bottom paper layer and a pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer is an intermediate layer, the pressure-sensitive adhesive layer adheres between the surface paper layer and the anti-sticking bottom paper layer, and the pressure-sensitive adhesive layer comprises the following components: 25-30 parts of an SIS thermoplastic elastomer, 30-35 parts of petroleum resin, 5-10 parts of rosin glyceride, 10-15parts of pentaerythritol ester, 15-20 parts of naphthenic oil and 0.3-0.4 part of an antioxidant. The strong non-drying adhesive label for sticking the bubble express bag disclosed by the invention has the advantages of good physical properties, good initial viscosity, high stripping strength and the like, and has stronger sticking performance on a pearlescent film bubble express bag and a woven bag, surface paper is damaged when the label is torn strongly after the label is stuck, the problem that the label falls off during an express logistics transportation process can be avoided, all indexes meet environmental protection requirements, and the adhesive used in the label is a hot-melt pressure-sensitive adhesive, has a solid content of 100% and does not contain any solvents. The non-drying adhesive label provided by the invention is environmentally friendly.

Owner:东莞市旺力胶贴科技有限公司

High-performance hot-melt pressure-sensitive adhesive

InactiveCN103897634AImprove securityIncrease productivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermoplasticAntioxidant

The invention discloses a high-performance hot-melt pressure-sensitive adhesive. The high-performance hot-melt pressure-sensitive adhesive comprises thermoplastic styrene-butadiene rubber, a tackifier, a plasticizer, a filler, an antioxidant and a coupling agent, wherein the tackifier is rosin modified phenolic resin; the plasticizer is di(2-ethyl hexyl) phthalate; the filler is quartz powder; the antioxidant is bis(3,5- tert-butyl-4-hydroxyl phenyl) thioether; and the coupling agent is aminopropyl triethoxy silane. The product is prepared by adopting five additives including the hermoplastic styrene-butadiene rubber, the tackifier, the plasticizer, the filler, the antioxidant and the coupling agent; and the prepared adhesive composition has characteristics of good stickiness, strong initial stickiness, environmental friendliness, high safety, high production efficiency and low production cost.

Owner:广州充奇实业有限公司

A cigarette mouthpiece glue loaded with mint flavor efficiently and its preparation process

ActiveCN104312497BLong lasting fragranceHigh quality percentage contentMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionAdhesive

The invention provides an efficient cigarette connection adhesive with loading of a mint essence and a preparation process of the efficient cigarette connection adhesive. The efficient cigarette connection adhesive is prepared from the following components in percentage by weight: 40-60 percent of VAE emulsion, 15-40 percent of mint essence, 10-25 percent of mint essence-starch emulsion and 1-5 percent of water, wherein the mint essence-starch emulsion is prepared by mixing the mint essence and modified starch according to a mass ratio of 1: (1-4). The efficient cigarette connection adhesive is good in flowability, is strong in adhesive ability, is rapid in drying speed, is high in mint essence load, is stable in flavoring effect when applied to a cigarette, is obvious in spicy smell, is durable in fragrance, has obvious cooling characteristic of mint and is comfortable and pure in taste.

Owner:HUBEI CHINA TOBACCO IND +1

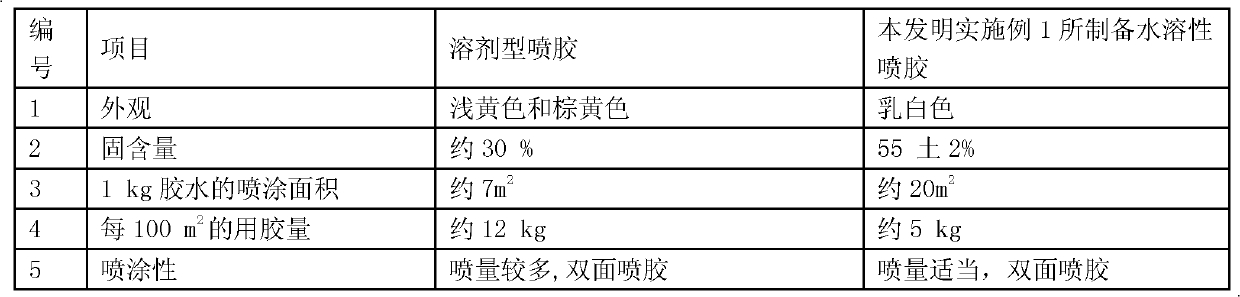

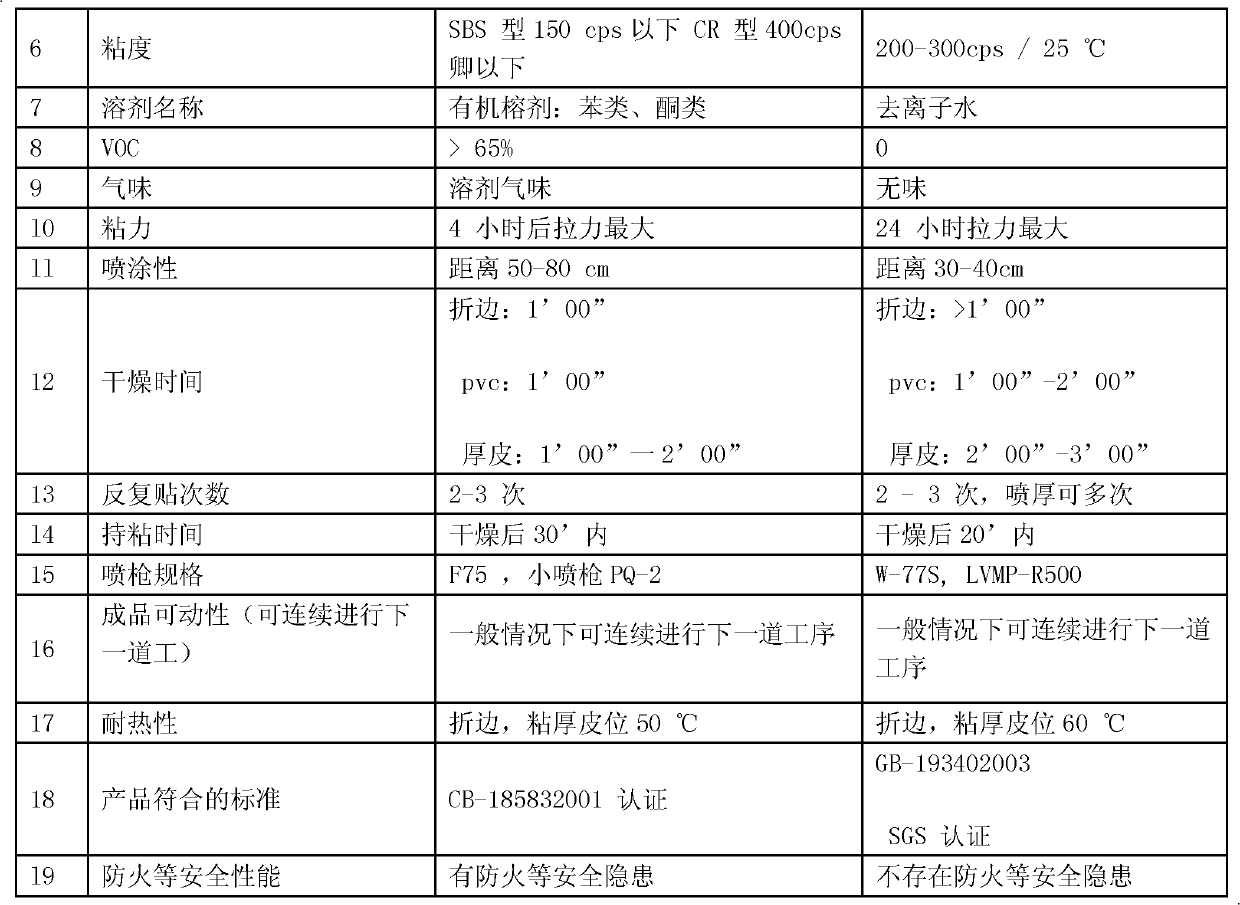

Two-component water-soluble environment-friendly spray gel and method for preparing same

ActiveCN102212320BHigh tensile strengthStrong initial tackRosin adhesivesChloroprene adhesivesAssociation typeDefoaming Agents

The invention provides two-component water-soluble environment-friendly spray gel and a method for preparing the same. The spray gel comprises the following components in part by weight: a component A: 60 to 80 parts of water-borne polychloroprene latex, 20 to 30 parts of acrylic acid latex, 20 to 30 parts of ethylene-vinyl acetate copolymer latex and 2 to 10 parts of sodium dodecyl benzene sulfonate; a component B: 5 to 20 parts of modified rosin latex, 1 to 5 parts of isocyanate, 5 to 10 parts of polyurethane association-type thickening agent, 2 to 8 parts of clay, 0.2 to 0.8 part of water-borne defoaming agent and 20 to 30 parts of deionized water; and the mass ratio of the component A to the component B is (3-6):1. The two-component water-soluble environment-friendly spray gel of the invention has the advantages of no organic solvents, no heavy metals, no smell, high bonding initial adhesion, quick drying, excellent heat resistance and anti-ageing property and the like; and the spray gel can be used for bonding not only leather, sponges or non-woven fabrics in same materials, but also sponges and wood, sponges and non-woven fabrics and wood and non-woven fabrics, so that the scope of application of water-borne spray gel in industries of furniture, decoration and leather is widened.

Owner:DONGGUAN SIDECO RESIN

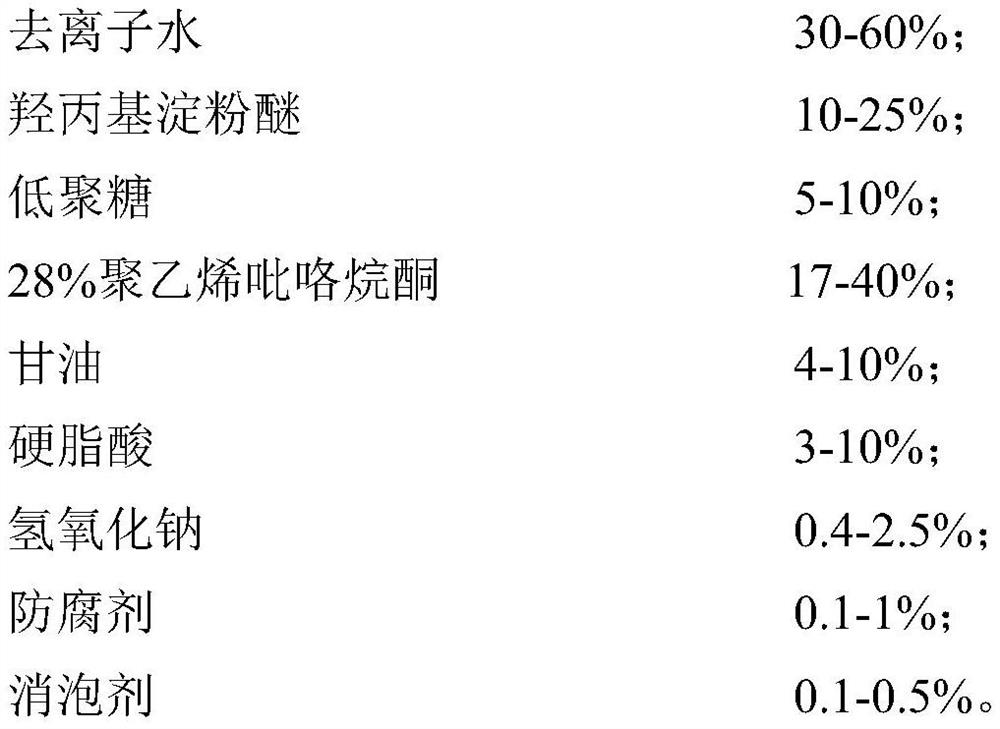

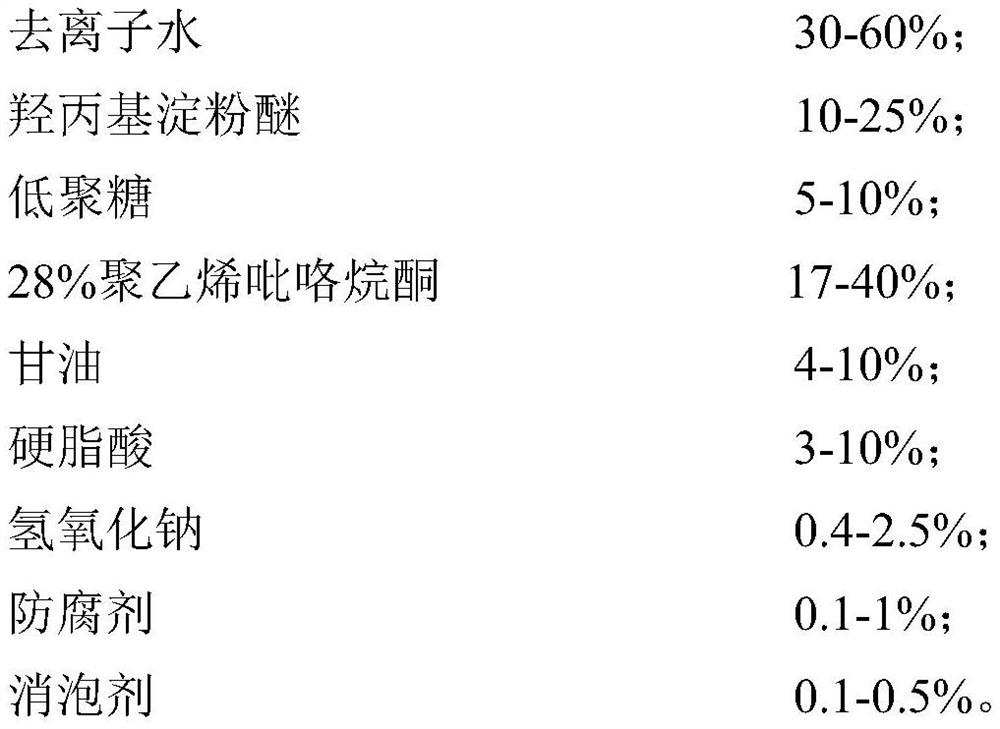

Environment-friendly degradable plant solid glue stick and preparation method thereof

PendingCN114213997AEasy accessReduce manufacturing costNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesivePyrrolidinones

The invention relates to an environment-friendly degradable plant solid glue stick which comprises the following components in percentage by weight: 30-60% of deionized water; 10 to 25% of hydroxypropyl starch ether; 5 to 10% of oligosaccharide; 17 to 40 percent of 28 percent polyvinylpyrrolidone; 4-10% of glycerin; 3-10% of stearic acid; 0.4 to 2.5 percent of sodium hydroxide; 0.1-1% of a preservative; and 0.1%-0.5% of a defoaming agent. Fatty acid salt is used as an excipient, glycerin is used as a humectant, raw materials are easy to obtain, the production cost is low, biodegradable plant starch hydroxypropyl starch ether and oligosaccharide are used as adhesives, the prepared solid glue stick has the original characteristics of a common solid glue stick, and the solid glue stick is easy and convenient to use, high in initial stickiness, large in bonding strength, good in adhesive force and capable of being used for a long time. The paint has the advantages of high drying speed, long adhesion time, no cracking, no shedding, safety, environmental protection and no harm to human bodies, is a novel environment-friendly product, accords with novel European and American stringent environmental protection laws and regulations, improves the competitiveness of the product, and undertakes the social responsibility of environmental protection.

Owner:DELI GROUP CO LTD

Quick-stick water-resistant adhesive for low-temperature production of corrugated board and preparation method of quick-stick water-resistant adhesive

ActiveCN106753065AMeet the requirements of low temperature productionLow costNon-macromolecular adhesive additivesUnsaturated alcohol polymer adhesivesCross-linkProduction line

The invention provides a quick-stick water-resistant adhesive for low-temperature production of a corrugated board. The quick-stick water-resistant adhesive is characterized in that water, a filler, polyvinyl alcohol, emulsified silicone oil, aluminum potassium sulfate, a cross-linking agent, a TL water-resistant agent, Kathon and sodium hexametaphosphate react according to a certain ratio, a certain process and requirements to form the quick-stick water-resistant adhesive. A cross-linking reaction between polyvinyl alcohol and the cross-linking agent is mainly adopted to generate certain initial adhesiveness and water resistance; then the TL water-resistant agent is added to further improve the water resistance of the adhesive, and different water-resistant requirements can be satisfied according to consumption; and the filler can improve the solid content of the adhesive and reduce the moisture content of the adhesive, so that the drying speed of the adhesive can be improved during production. The quick-stick water-resistant adhesive has the advantages of wide applicability, strong initial adhesiveness, low cost, excellent water resistance and the like, and meets the demand for low-temperature production of a corrugated board production line.

Owner:HENAN ZHONGBAO TECH

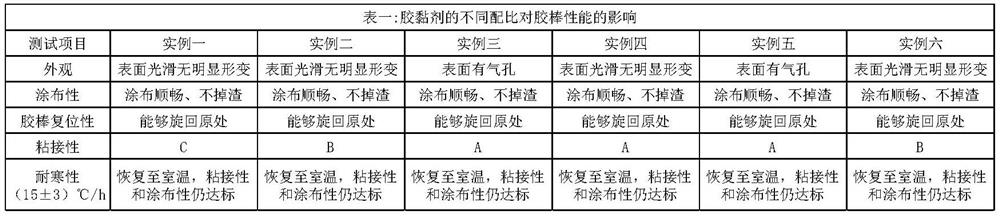

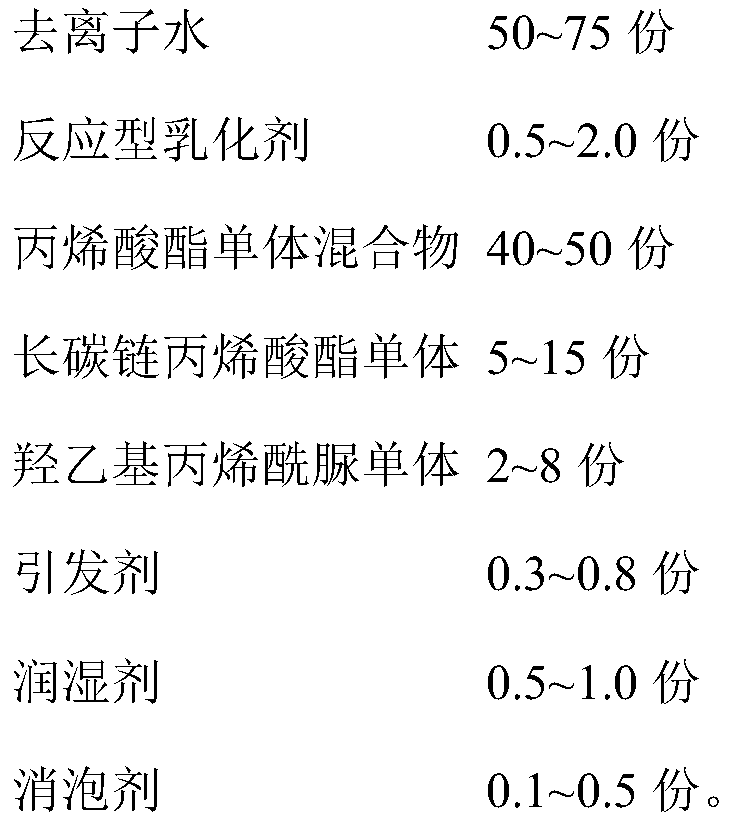

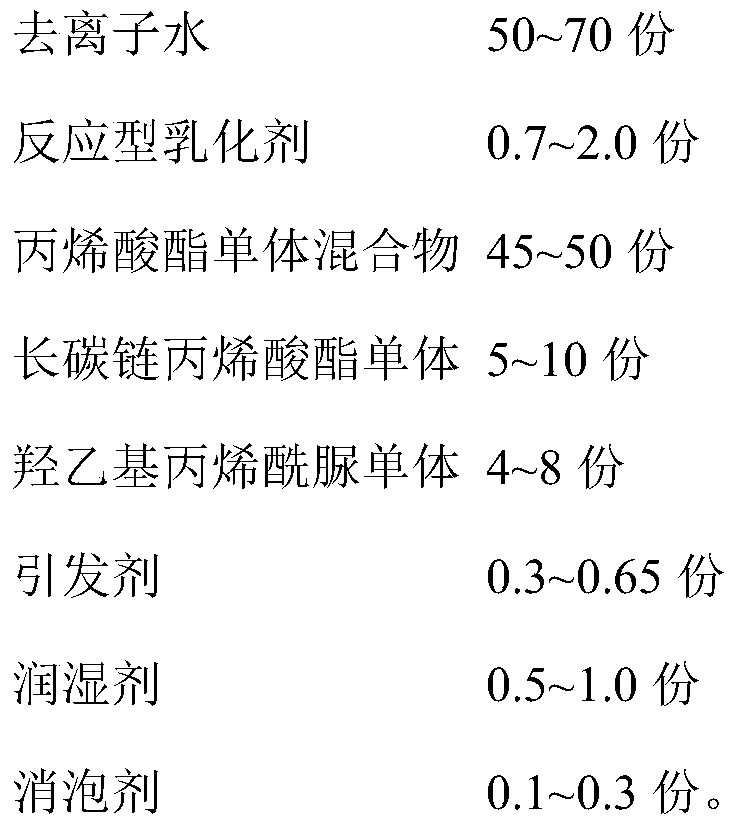

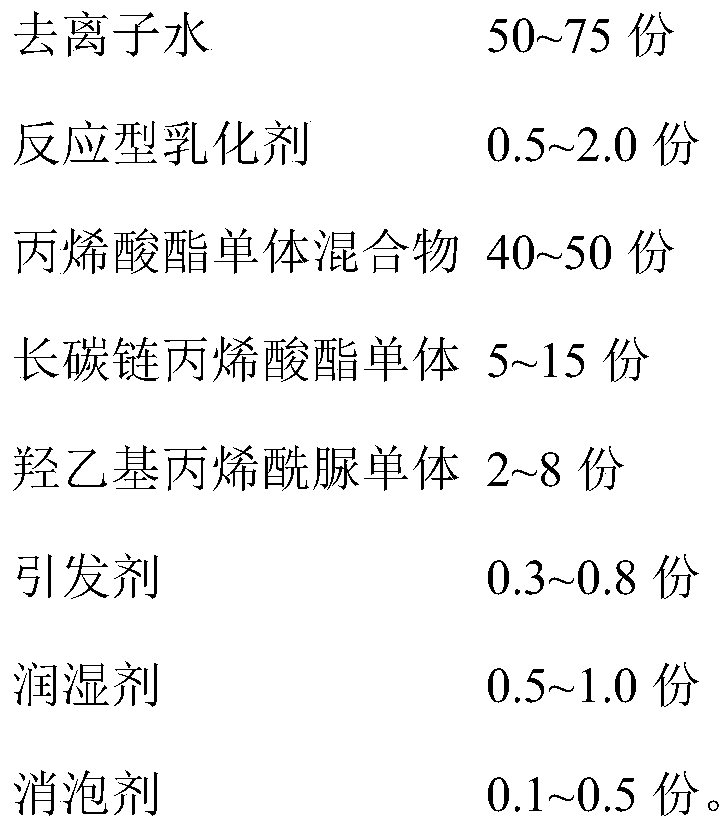

Water-based adhesive for deep embossed paper-plastic compounding, and preparation method thereof

ActiveCN109897576ALower glass transition temperatureStrong initial tackEster polymer adhesivesWater basedMolded pulp

The invention relates to the technical field of water-based adhesives, and concretely relates to a water-based adhesive for deep embossed paper-plastic compounding, and a preparation method thereof. The preparation method of the water-based adhesive comprises the following steps: preparing a monomer drop-by-drop addition solution from, by weight, 20-33 parts of deionized water, 0.4-1.5 parts of areactive emulsifier, 40-50 parts of an acrylate monomer mixture, 5-15 parts of a long carbon chain acrylate monomer, 2-8 parts of hydroxyethyl acryloyl urea and 0.2-0.6 part of an initiator; preparinga kettle bottom solution from 30-42 parts of deionized water, 0.1-0.5 part of the reactive emulsifier and 0.1-0.2 part of the initiator; and dropwise adding a part of the monomer drop-by-drop addition solution to the kettle bottom solution to prepare a seed emulsion, then dropwise adding the remaining monomer drop-by-drop addition solution, and carrying out a reaction under specific process conditions to prepare the water-based adhesive. The water-based adhesive can be stored at a high temperature of 50 DEG C and a high relative humidity of 85% for 120 h without generating white spots, foaming or degumming after being applied to paper-plastic compounding and deep embossing.

Owner:DONGGUAN STAR COSM POLYMER

Goods stack film curtain sealing oxygen-concentration reduction method

InactiveCN112006007AAvoid puncture risks such as tramplingLow costDead plant preservationFood preservationThin membraneEngineering

The invention discloses a goods stack thin film curtain sealing oxygen-concentration reduction method. The goods stack thin film curtain sealing oxygen-concentration method comprises the following steps that step 1, thin films are cut according to the size of goods stacks, and the thin films are made into an upper curtain with a lower opening and a lower curtain with an upper opening through sealants; step 2, the lower curtain is placed on the ground, and then trays and the goods stacks on the trays are placed in the lower curtain; step 3, the upper curtain covers the goods stacks, and deoxidizing agents are put according to the volume ratio of the goods stacks; and step four, an opening of the upper curtain and an opening of the lower curtain are in smooth butt joint and then sealed through the sealants, and operation is completed. The sealing effect is safer in the operation process of film curtain glue sealing, the risks of poor sealing such as film wrinkle coking, micropore scalding and leaking and repeated heat sealing caused by other factors are reduced, and the oxygen-concentration reduction effect of the film curtain is guaranteed.

Owner:石乔

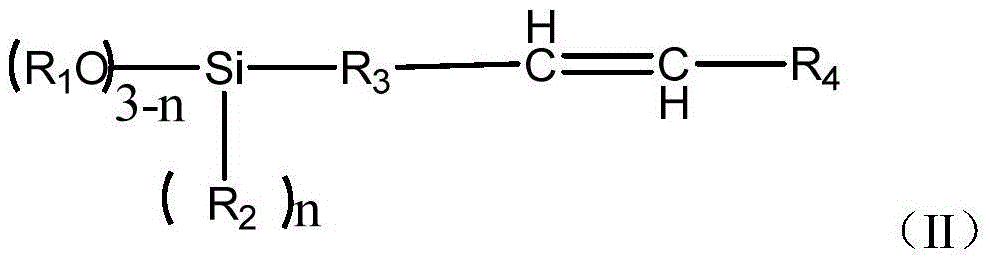

Fast curing reaction type hot melt adhesive and preparation method thereof

ActiveCN102010687BGood flexibilityStrong initial tackNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterVacuum drying

The invention discloses a fast curing reaction type hot melt adhesive and a preparation method thereof. The fast curing reaction type hot melt adhesive comprises the raw materials in percentage by weight: 30 to 60 percent of polyester glycol, 10 to 40 percent of isocyanate, 0.1 to 2 percent of adhesion promoter, 5 to 10 percent of tackifier, 7 to 20 percent of thermoplastic resin, 4 to 8 percent of coupling agent, 0.5 to 3 percent of stabilizer, 2 to 9 percent of filler and 0.1 to 5 percent of catalyst. The preparation method comprises the following steps of: adding the polyester glycol into the thermoplastic resin, the adhesion promoter, the tackifier, the coupling agent, the stabilizer and the filler, mixing, heating, stirring, blending, performing vacuum drying dehydration at the temperature of between 100 and 130 DEG C, adding the isocyanate and the catalyst under nitrogen protection, thermostatically stirring at the temperature of between 70 and 80 DEG C, and reacting for 3 to 5 hours to prepare the fast curing reaction type hot melt adhesive. The product of preparation method has short crosslinking and curing time and high viscosity and is nontoxic, harmless and environmentally-friendly.

Owner:SOUTH CHINA UNIV OF TECH

High-performance UV-cured polyacrylate self-foamed damping material and preparation method thereof

The invention discloses a high-performance UV-cured polyacrylate self-foamed damping material, which comprises the following components, by weight part, 20-30 parts of polyacrylate elastomer, 70-75 parts of a reactive diluent, 0.5-0.8 part of a photoinitiator, and 1-5 parts of nanometer hollow inorganic particles. UV polymerization is adopted for preparing the high-performance damping material, and the damping material is completely free of solvent and causes no pollution. Nanometer hollow inorganic particles are taken as an inorganic bulk foaming agent, and through control of the addition amount of the nanometer hollow inorganic particles, the density of the damping material can be accurately controlled according to the requirement, and the loss factor of the damping material can be increased at the same time. The damping material is excellent in initial adhesion, lasing adhesion, peel strength, and interfacial wettability and high in loss factor.

Owner:JIANGSU DAOQ NEW MATERIAL TECH CO LTD

Urea-formaldehyde resin adhesive with ultra-low formaldehyde release and preparation process thereof

ActiveCN104629662BReduce volatilityStable in natureNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberPolyvinyl alcohol

The invention relates to an ultralow-formaldehyde-release urea-formaldehyde resin adhesive and a preparation process thereof. The preparation process comprises the following steps: adjusting the pH value of a formaldehyde solution by using sodium hydroxide; then adding urea for reaction, and dropwise adding formic acid during the reaction to control the reaction pH value; then under a certain viscosity, adjusting the pH value by using sodium hydroxide; adding hydroxyl methyl cellulose, and adding aluminum sulfate for reaction; adjusting the pH value by using formic acid; adding polyvinyl alcohol and pure water for reaction; and cooling to room temperature to obtain the ultralow-formaldehyde-release urea-formaldehyde resin adhesive. According to the ultralow-formaldehyde-release urea-formaldehyde resin adhesive and the preparation process provided by the invention, the obtained urea-formaldehyde resin adhesive has the characteristics of low formaldehyde release quantity, good pre-pressing property, long opening depositing time, strong initial viscosity and the like, and meanwhile, the solid content is greatly improved, so that the urea-formaldehyde resin adhesive is suitable for production of veneers, shaving boards, fiber boards and ecological boards.

Owner:BEIHUA UNIV

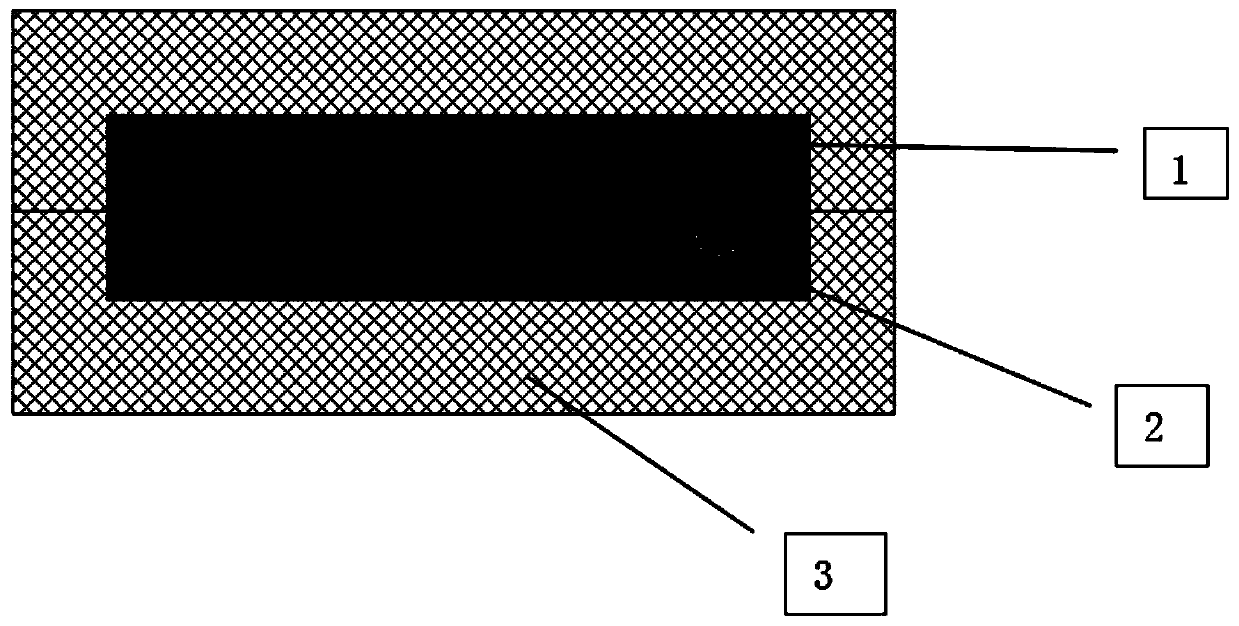

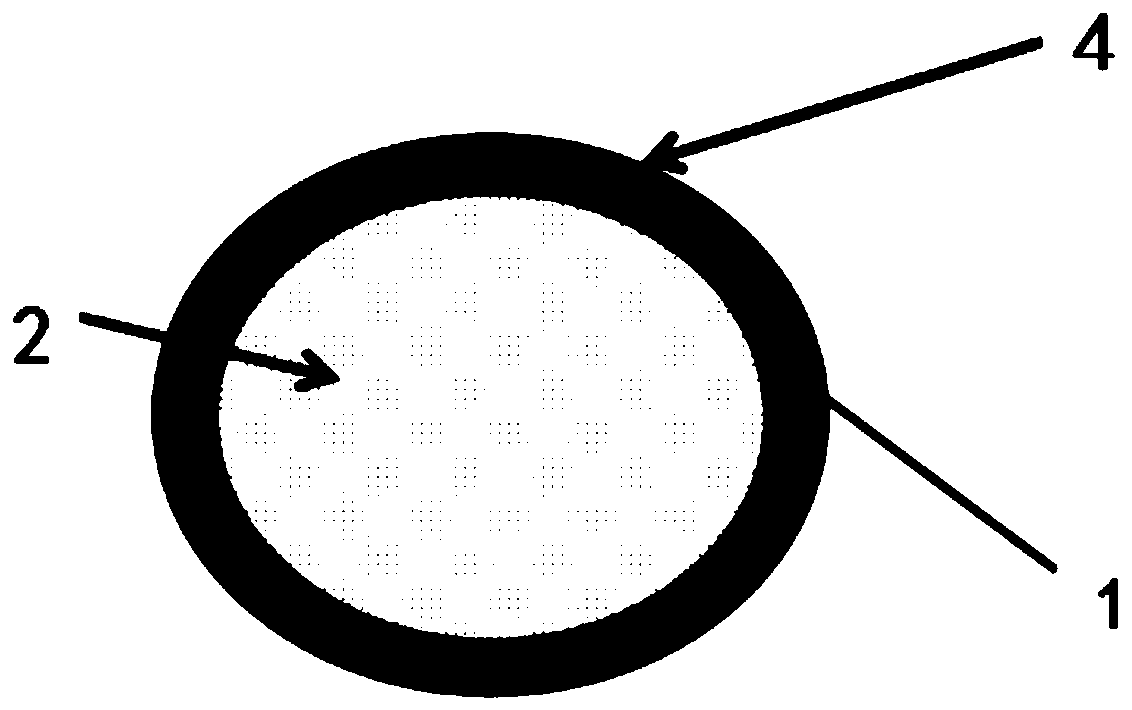

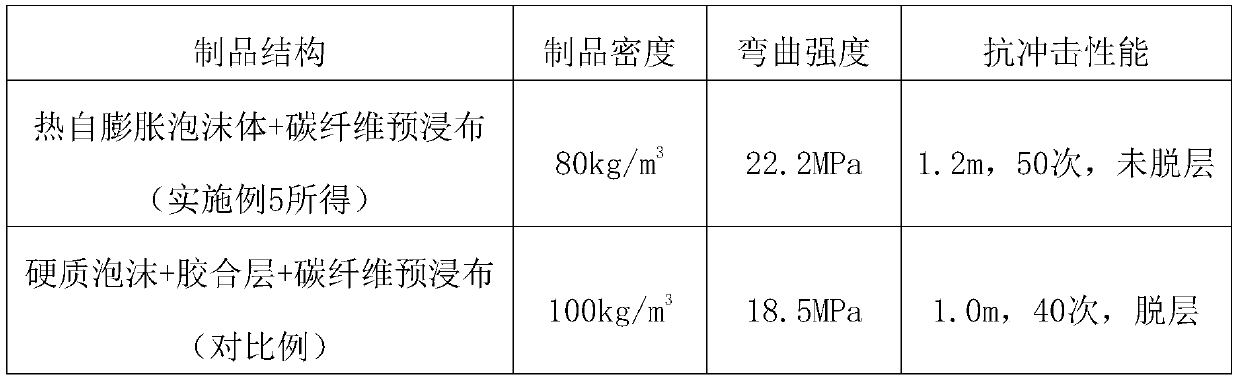

Foam body with thermal self-expansion function and preparation method thereof

PendingCN111016213AStrong initial tackEliminate interlayer air bubblesBinding forcePolymer chemistry

The invention discloses a foam body with a thermal self-expansion function and a preparation method thereof. The inner layer of the foam body with the thermal self-expansion function is rigid foam, and the outer layer is thermal self-expanding resin. The thermal self-expanding resin and the rigid foam are integrally formed, interface bubbles are fewer, the binding force is stronger, and uniformlyimproving the strength of products is facilitated. Meanwhile, the integrally formed foam structure has an effect suitable for forming shaped products. The foam body with the thermal self-expansion function is used for the preparation of sandwich composite structural parts, has excellent properties such as high strength, light weight, good interlayer adhesion, resistance to delamination and splitting and impact resistance, and can be applied to the field of sandwich structure composite parts of complex structures.

Owner:XIAMEN HOWER MATERIAL

A glutinous rice environment-friendly starch type adhesive and a preparing process thereof

InactiveCN106916550ADry fastStrong initial tackStarch adhesivesHydrocarbon polymer adhesivesAdhesiveOffice chair

A glutinous rice environment-friendly starch type adhesive and a preparing process thereof are disclosed. The adhesive comprises following raw materials by weight: 55-110 parts of glutinous rice flour, 40-60 parts of chloroprene latex, 30-55 parts of synthetic resin, 1-10 parts of an additive and 1-8 parts of an auxiliary agent. The adhesive is prepared by cleaning and soaking the glutinous rice flour, adding deionized water into the glutinous rice flour, cooking the mixture until slurry is formed, filtering the cooked glutinous rice flour to obtain a glutinous rice adhesive precursor, mixing other raw materials, adding deionized water into the raw material mixture, fully stirring the raw material mixture, then adding the precursor into the raw material mixture, and heating and stirring the obtained mixture. The adhesive is an efficient water-soluble adhesive, and has advantages of no toxicity, capability of being non-combustible and environment-friendly, rapid drying, high initial adhesive force, good heat resistance, good ageing resistance, and the like. The adhesive is suitable for manufacturing furniture, office chairs, mattresses, sofas, pillows and other soft furniture, and for manufacturing automotive trim, bags, suitcases, and leather products, and can be used for adhering various polar water-absorbing materials. According to the adhesive and the process, the adopted raw materials are simple, the preparing process is easy to operate and control, the production cost is low and the adhesive and the process are suitable for large-scale production.

Owner:DONGGUAN JINMING FURNITURE

A high-performance hot-melt pressure-sensitive adhesive

InactiveCN103897634BImprove securityIncrease productivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermoplasticAntioxidant

The invention discloses a high-performance hot-melt pressure-sensitive adhesive. The high-performance hot-melt pressure-sensitive adhesive comprises thermoplastic styrene-butadiene rubber, a tackifier, a plasticizer, a filler, an antioxidant and a coupling agent, wherein the tackifier is rosin modified phenolic resin; the plasticizer is di(2-ethyl hexyl) phthalate; the filler is quartz powder; the antioxidant is bis(3,5- tert-butyl-4-hydroxyl phenyl) thioether; and the coupling agent is aminopropyl triethoxy silane. The product is prepared by adopting five additives including the hermoplastic styrene-butadiene rubber, the tackifier, the plasticizer, the filler, the antioxidant and the coupling agent; and the prepared adhesive composition has characteristics of good stickiness, strong initial stickiness, environmental friendliness, high safety, high production efficiency and low production cost.

Owner:广州充奇实业有限公司

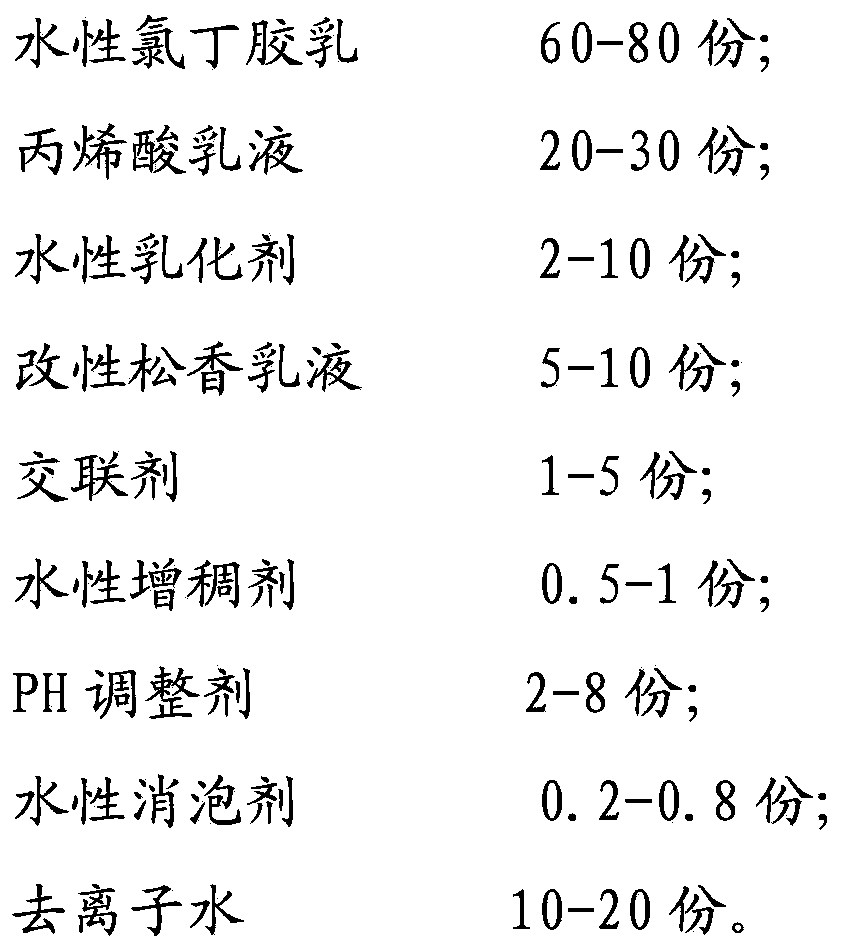

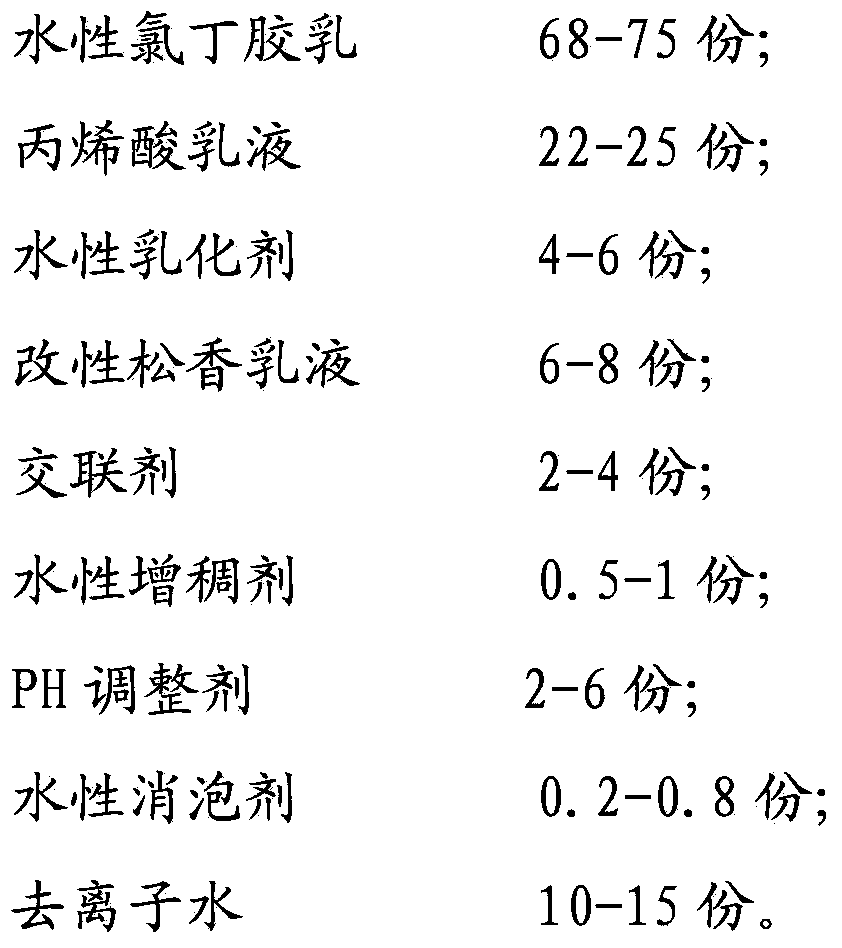

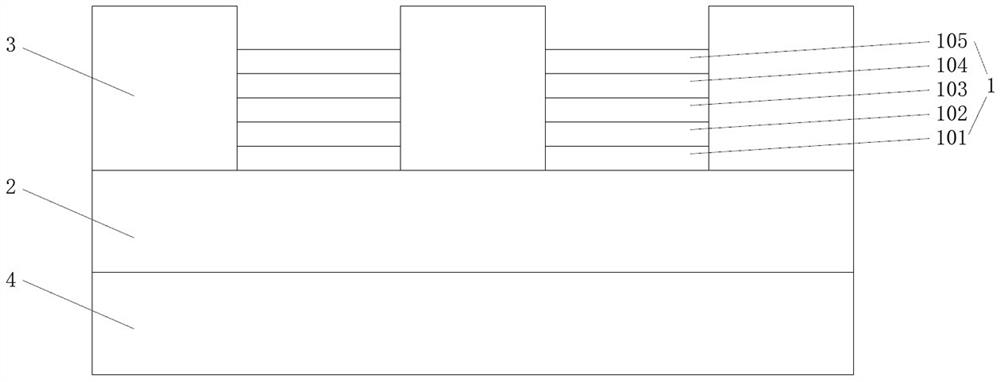

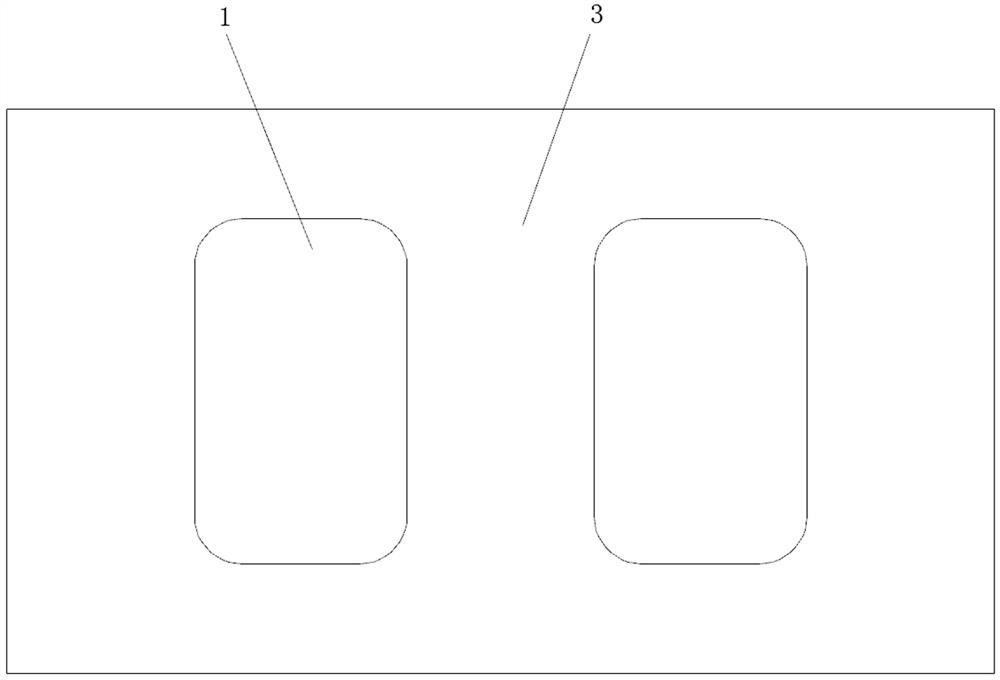

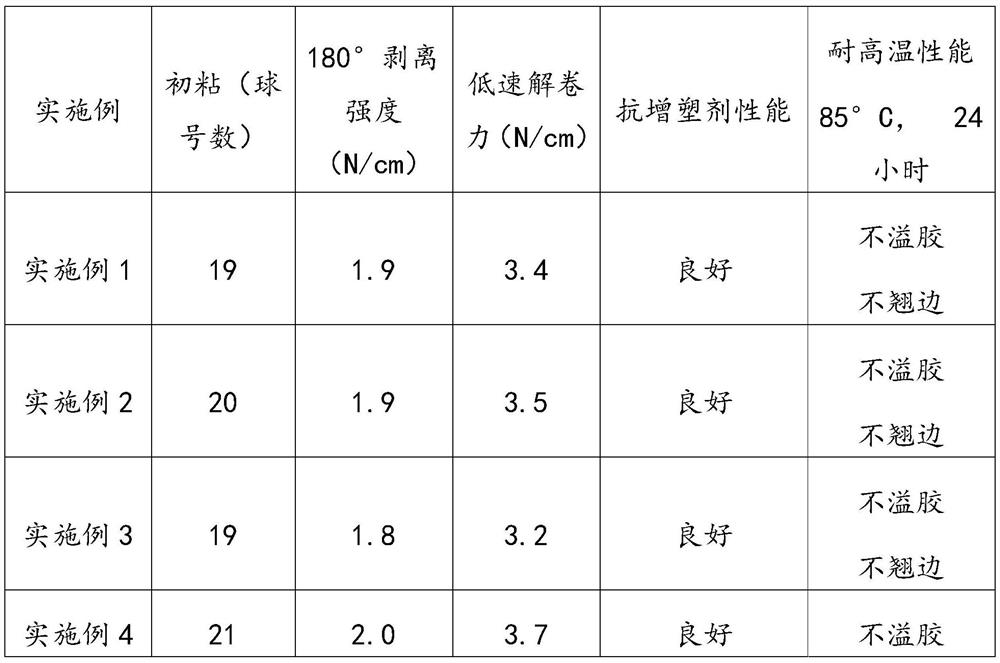

Single-component water-soluble environmentally-friendly roller adhesive and preparation method thereof

ActiveCN102492374BStrong initial tackGood initial adhesionRosin adhesivesChloroprene adhesivesEmulsionAdhesive

The invention provides a single-component water-soluble environmentally-friendly roller adhesive and a preparation method thereof. The single-component water-soluble environmentally-friendly roller adhesive comprises the following components in parts by weight: 60-80 parts of aqueous chloroprene rubber latex, 20-30 parts of an acrylic acid emulsion, 2-10 parts of an aqueous emulsifier, 5-10 parts of a modified rosin emulsion, 1-5 parts of a crosslinking agent, 0.5-1 part of an aqueous thickening agent, 2-8 parts of a pH regulating agent, 0.2-0.8 part of an aqueous antifoaming agent and 10-20 parts of deionized water. Due to the adoption of the single-component water-soluble environmentally-friendly roller adhesive, the same material selected from leather, sponge and a non-woven fabric can be bonded, different materials selected from sponge and wood, sponge and nylon cloth as well as wood and a non-woven fabric can be bonded, and the defects of mist caused by aqueous spraying, non-uniform thickness caused by manual spraying, failure in mechanical automatic operation production and the like are overcome. Moreover, the single-component water-soluble environmentally-friendly roller adhesive has the advantages of avoidance of skin formation during rolling, particle resistance, high initial adhesion, high operating efficiency, saving in labor force and suitability for sponge material operation in a large-area range.

Owner:DONGGUAN SIDECO RESIN

Heat-conducting photoresist and application thereof

PendingCN112631073AEasy to useExtend your lifePhotosensitive materials for photomechanical apparatusPolymer scienceUltraviolet lights

The invention relates to a heat-conducting photoresist which is prepared by adding a submicron heat-conducting filler into a resin photoresist sensitive to ultraviolet light. The heat-conducting filler does not need to be pretreated, and can be directly and uniformly mixed and dispersed with resin photoresist according to a set mass ratio. The heat-conducting photoresist is applied between LED pixel points on a display device. The heat-conducting photoresist is beneficial to improving the heat dissipation effect of the display device, thereby improving the performance and prolonging the service life of the display device.

Owner:FUZHOU UNIV +1

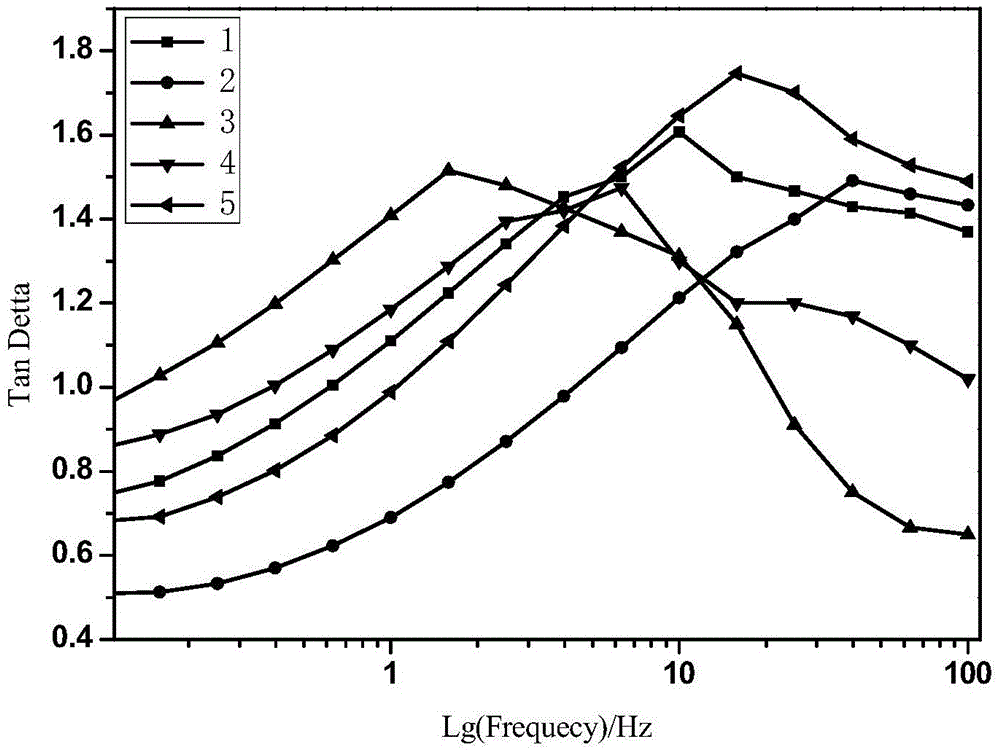

Pressure-sensitive adhesive applied to polyvinyl chloride film as well as preparation method and application of pressure-sensitive adhesive

PendingCN112341967AExcellent resistance to plasticizersStrong initial tackMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention discloses a pressure-sensitive adhesive applied to a polyvinyl chloride film as well as a preparation method and application of the pressure-sensitive adhesive. The invention provides arubber system hot-melt pressure-sensitive adhesive applied to a polyvinyl chloride film as well as a preparation method and application of the pressure-sensitive adhesive. The rubber system hot-melt pressure-sensitive adhesive is mainly prepared from a segmented copolymer thermoplastic elastomer, a plasticizer, tackifying resin, pure C9 monomer resin and an antioxidant in specific parts by mass. The rubber system hot-melt pressure-sensitive adhesive disclosed by the invention can be used for coating at 150-160 DEG C, has good plasticizer resistance and strong initial adhesion, and is particularly suitable for preparing a soft electrical insulation PVC adhesive tape. The preparation method of the rubber system hot-melt pressure-sensitive adhesive is simple in process, high in production efficiency and suitable for large-scale production.

Owner:HEBEI YONGLE TAPE CO LTD

A kind of production method of film adhesive and film adhesive thereof

ActiveCN104140766BStrong initial adhesionEasy to peelFilm/foil adhesivesOther rubber adhesivesElastomerPolymer science

The invention discloses a production method of a film-like adhesive, which comprises the following steps: (1), at normal temperature, add: solvent 6# extraction solvent naphtha, 120 solvent naphtha, methylcyclohexane, acetone, Mix evenly; (2), then add: add emulsifier OP-10, dispersant NUOSPERSE W-20, and carry out solvent modification to make it have certain characteristics, after the modification is qualified; (3), then add: polyethylene Alcohol, synthetic rubber TPR, thermoplastic elastomer, neoprene, react and modify, synthetic rubber and elastomer are modified by graft polymerization to obtain the product. Compared with the prior art, the production method of the film adhesive of the present invention and the film adhesive thereof, the film adhesive product has fast drying at room temperature, good initial tack, strong adhesion, fast surface drying, long adhesion time, no Cracking, no falling off, easy to peel off, no damage to the surface of the adhesive, etc.

Owner:JIANGSU XINGDA STATIONERY GRP

Seal wax composition for train end connector of motor train unit and preparation method thereof

The invention discloses a seal wax composition for a train end connector of a motor train unit. The seal wax composition comprises the following components in percentage by weight: 62-70% of wax material, 1-10% of tackifier, 15-25% of fire retardant, 5-15% of hydroxyl-terminated polydiorgaonsiloxane polymer, 1-5% of siloxane cross-linking agent and 0.1-3% of catalyst. The invention also discloses a preparation method of the seal wax composition. The seal wax composition prepared by the method contains no solvent and has good initial adhesion and favorable sealing, waterproofing, insulating and antiflaming properties; and the seal wax composition does not flow at the high temperature of 100 DEG C and does not crack at the low temperature of -35 DEG C, is in a paste state at room temperature and can be filled in a hose with a sharp mouth to be extruded, thereby facilitating construction. More importantly, the surface of the wax coating is not tacky and can become properly tackier along with elapse of time; the surface of the wax coating is in a plastic or rubber state, but the inside of the wax is still in a semi-solid state; and the original signal line can be replaced with a new one by simply removing the wax around the signal line and then refilling the seal wax.

Owner:江苏泰尔新材料股份有限公司

Novel waterborne environment-friendly leather carving plate binder and preparation method thereof

PendingCN107793963ALow VOCHigh viscosityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionPreservative

The invention provides a novel waterborne environment-friendly leather carving plate binder. The binder is characterized by comprising, by weight, 50-150 parts of VAE emulsion, 10-40 parts of rosin resin solution, 0.01-0.1 part of preservative, 0.1-1 part of dispersant and 0.1-0.5 part of defoamer. A preparation method of the binder includes steps: adding the dispersant and the defoamer into the VAE emulsion in a reaction kettle; stirring while slowly adding the rosin resin solution and light calcium carbonate; adding the preservative, stirring for 30-45min, and discharging to obtain the binder. The binder has the advantages of being formaldehyde-free and low-VOC and is safe and environment-friendly.

Owner:BENGBU CIGARETTE MATERIAL FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com