Fast curing reaction type hot melt adhesive and preparation method thereof

A fast-curing, reactive technology, applied in the direction of adhesive additives, non-polymer adhesive additives, polymer adhesive additives, etc., can solve the problems of complex preparation process, long curing time, low cohesion, etc. Achieve the effect of simple process, short curing time and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

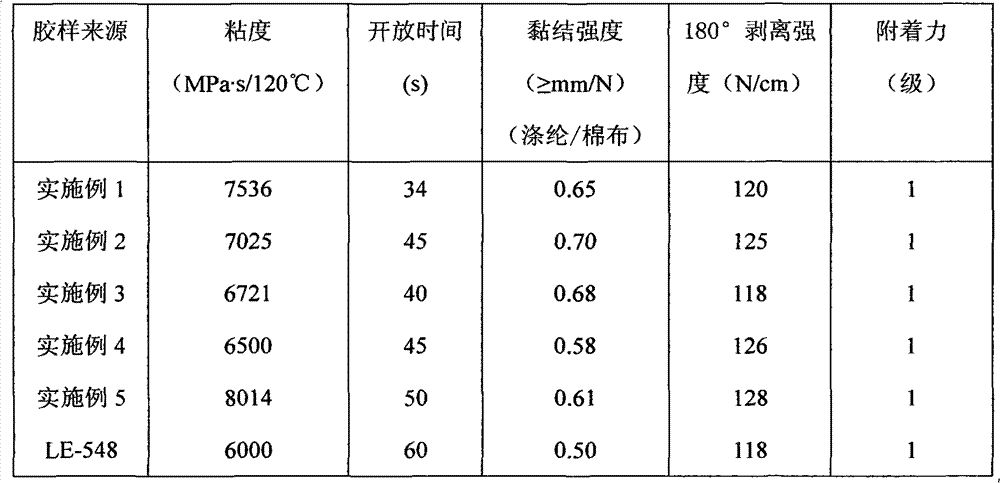

Examples

Embodiment 1

[0042] In terms of weight percentage, the content of relevant components involved in a fast-curing reactive hot-melt adhesive raw material is:

[0044] Isocyanate 20%

[0045] Adhesion Promoter 0.2%

[0046] Tackifier 6%

[0047] Thermoplastic resin 20%

[0048] Coupling agent 8%

[0049] Stabilizer 3%

[0050] Filler 8%

[0051] Catalyst 4.8%

[0052] Wherein, the polyester diol is polybutylene adipate with a molecular weight of 5600 and a hydroxyl value of 10 mgKOH / g. The coupling agent is vinyltriethoxysilane, the adhesion promoter is E-20 epoxy resin (sold by Guangzhou Xinghuan Chemical Co., Ltd.), the thermoplastic resin is polybehenyl methacrylate, and the tackifier It is C9 petroleum resin (sold by Guangzhou Game Chemical Co., Ltd.), the stabilizer is antioxidant 1010 (sold by Guangzhou Game Chemical Co., Ltd.), the filler is carbon black and active calcium carbonate (mass ratio 2: 1), and the catalyst is dilauric acid two Butyl tin....

Embodiment 2

[0058] In terms of weight percentage, the content of each component of a fast-curing reactive hot-melt adhesive raw material is:

[0060] Isocyanate 25%

[0061] Adhesion Promoter 0.2%

[0062] Tackifier 8%

[0063] Thermoplastic resin 15%

[0064] Coupling agent 5%

[0065] Stabilizer 3%

[0066] Filler 8%

[0067] Catalyst 0.8%

[0068] Wherein, the polyester diol is polydecyl sebacate with a molecular weight of 7000 and a hydroxyl value of 15 mgKOH / g. The coupling agent is vinyltrimethoxysilane, the adhesion promoter is E-20 epoxy resin (sold by Guangzhou Xinghuan Chemical Co., Ltd.), the thermoplastic resin is poly-n-butyl methacrylate, and the tackifier is rosin resin ( Guangzhou Duofeng Chemical Co., Ltd.), the stabilizer is antioxidant 1010 (Guangzhou Game Chemical Co., Ltd.), the filler is carbon black and activated calcium carbonate (mass ratio 1:2), and the catalyst is dibutyltin dilaurate.

[0069] The preparation method of this ...

Embodiment 3

[0074] In terms of weight percentage, the content of each component of a fast-curing reactive hot-melt adhesive raw material is:

[0075] Polyester diol 40%

[0076] Isocyanate 30%

[0077] Adhesion Promoter 1%

[0078] Tackifier 5%

[0079] Thermoplastic resin 15%

[0080] Coupling agent 4%

[0081] Stabilizer 2%

[0082] Filler 2%

[0083] Catalyst 1%

[0084] Wherein, the polyester diol is polybutylene succinate with a molecular weight of 8500 and a hydroxyl value of 18 mgKOH / g. The coupling agent is vinyltriethoxysilane, the adhesion promoter is E-20 epoxy resin (sold by Guangzhou Xinghuan Chemical Co., Ltd.), the thermoplastic resin is polybehenyl methacrylate, and the tackifier It is poly-alpha-methylstyrene (sold by Shandong Guangrun Chemical Co., Ltd.), stabilizer is antioxidant 1010 (sold by Guangzhou Game Chemical Co., Ltd.), filler is carbon black and active calcium carbonate (mass ratio 2: 1), catalyst Dibutyltin dilaurate.

[0085] The preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com