Water-based adhesive for deep embossed paper-plastic compounding, and preparation method thereof

A paper-plastic composite and adhesive technology, which is applied in the direction of adhesive type, ester copolymer adhesive, etc., can solve the problems of aziridine curing agent toxicity, inconvenient application, waste, etc., and achieve enhanced hydrogen bond intermolecular interaction Strong force, strong cohesion, and strong initial tack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

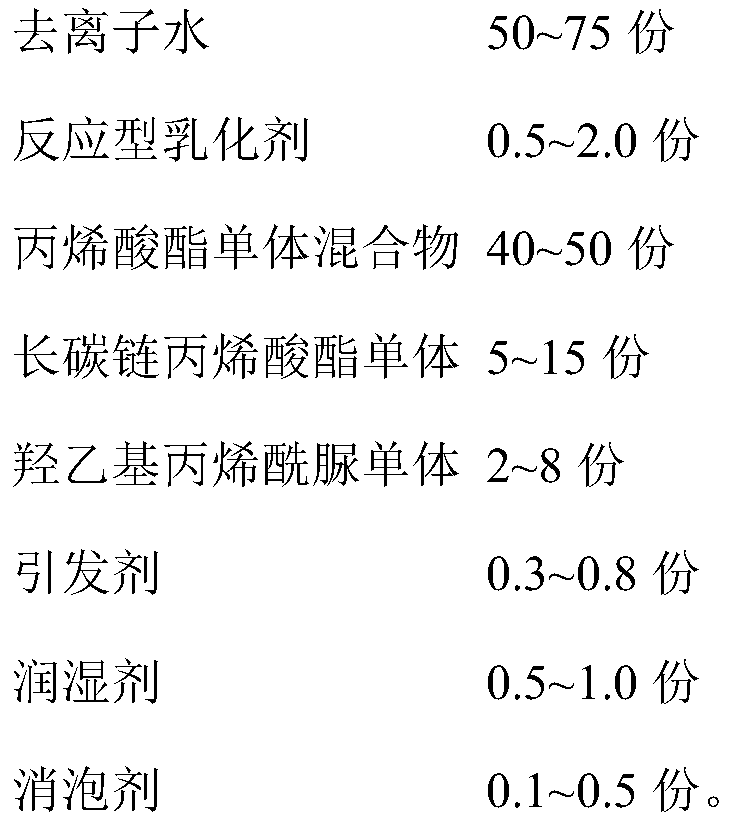

[0032] A kind of deep embossed paper-plastic composite water-based adhesive of this embodiment is prepared by the following steps (the following components are all calculated in parts by weight):

[0033] Step S1, take 20 parts of deionized water, 1.0 parts of reactive emulsifier, 45 parts of acrylate monomer mixture, 5 parts of long carbon chain acrylate monomer and 4 parts of hydroxyethyl acryloyl urea monomer for pre-emulsification to obtain a single Body pre-emulsion, then add 0.2 parts of initiator, stir evenly to obtain monomer dripping solution;

[0034] Step S2, adding 30 parts of deionized water, 0.2 parts of reactive emulsifier and 0.15 parts of initiator into the reactor and stirring evenly to obtain the bottom liquid;

[0035] Step S3, raise the temperature of the bottom liquid to 75°C, start to drop the monomer dripping liquid into the bottom liquid first, control 4 minutes to drop 1 / 10 of the total amount of the monomer dripping liquid, and then keep the temperat...

Embodiment 2

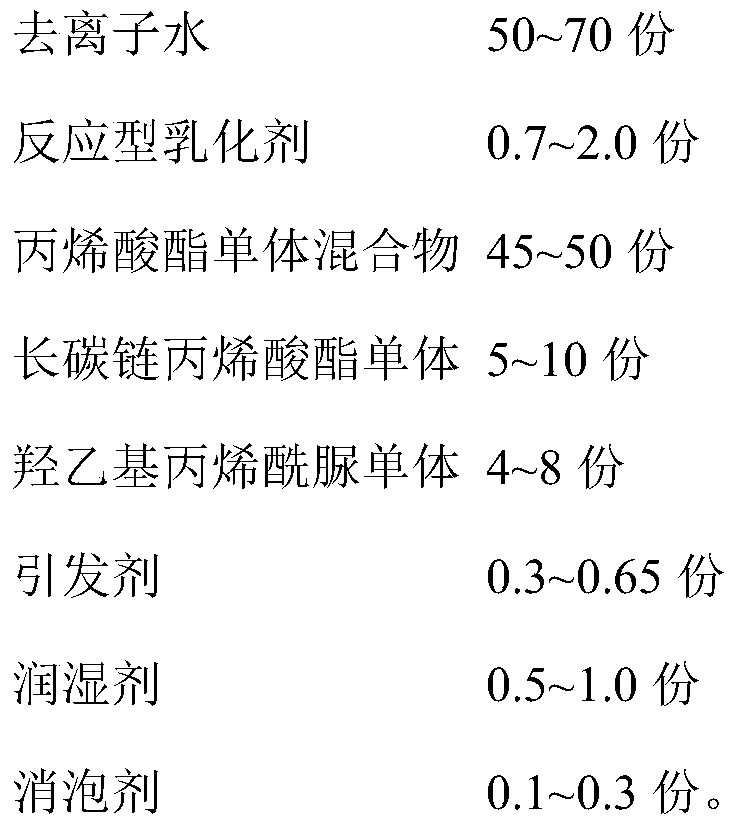

[0046] A kind of deep embossed paper-plastic composite water-based adhesive of this embodiment is prepared by the following steps (the following components are all calculated in parts by weight):

[0047] Step S1, pre-emulsify 30 parts of deionized water, 1.5 parts of reactive emulsifier, 50 parts of acrylate monomer mixture, 10 parts of long-chain acrylate monomer and 8 parts of hydroxyethyl acryloyl urea monomer to obtain a single Body pre-emulsion, then add 0.5 part of initiator, stir to obtain monomer dripping solution;

[0048] Step S2, adding 40 parts of deionized water, 0.5 part of reactive emulsifier and 0.1 part of initiator into the reactor and stirring evenly to obtain the bottom liquid;

[0049] Step S3, raise the temperature of the bottom liquid to 70°C, start to drop the monomer dripping liquid into the bottom liquid first, control 6 minutes to drop 1 / 10 of the total amount of the monomer dripping liquid, and then keep the temperature for 25 minutes, Prepare see...

Embodiment 3

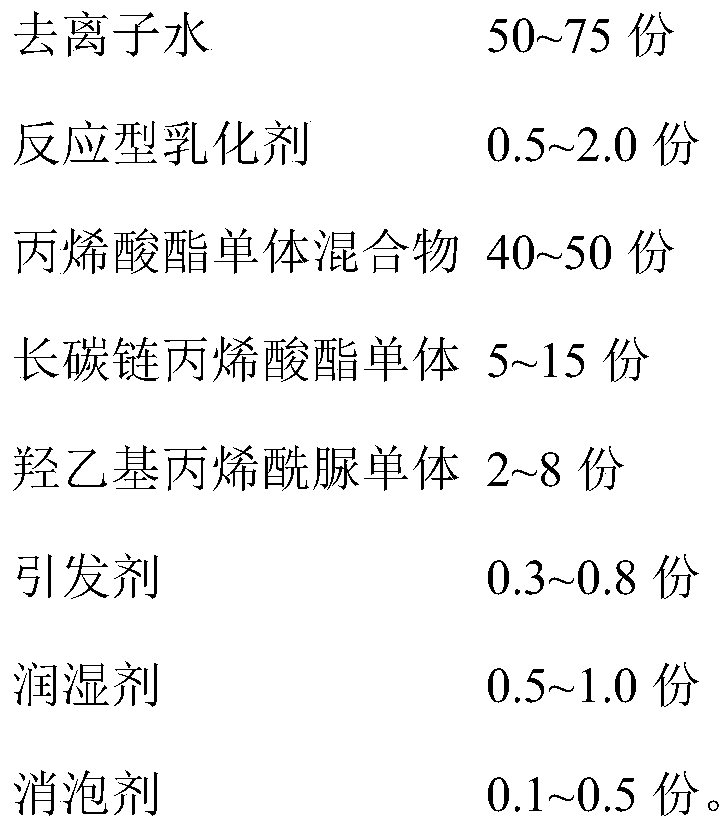

[0060] A kind of deep embossed paper-plastic composite water-based adhesive of this embodiment is prepared by the following steps (the following components are all calculated in parts by weight):

[0061] Step S1, take 26 parts of deionized water, 0.5 parts of reactive emulsifier, 48 parts of acrylate monomer mixture, 7 parts of long carbon chain acrylate monomer and 6 parts of hydroxyethyl acryloyl urea monomer for pre-emulsification to obtain a single Body pre-emulsion, then add 0.3 part of initiator, stir evenly to obtain monomer dripping solution;

[0062] Step S2, adding 35 parts of deionized water, 0.4 parts of reactive emulsifier and 0.12 parts of initiator into the reactor and stirring evenly to obtain the bottom liquid;

[0063] Step S3, raise the temperature of the bottom liquid to 72°C, start to drop the monomer dripping solution into the bottom liquid first, control 5 minutes to drop 1 / 10 of the total amount of the monomer dropping liquid, and then keep the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com