Patents

Literature

600 results about "Molded pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molded pulp, also named moulded pulp or molded fibre, is a packaging material, typically made from recycled paperboard and/or newsprint. It is used for protective packaging or for food service trays and beverage carriers. Other typical uses are end caps, trays, plates, bowls and clamshell containers.

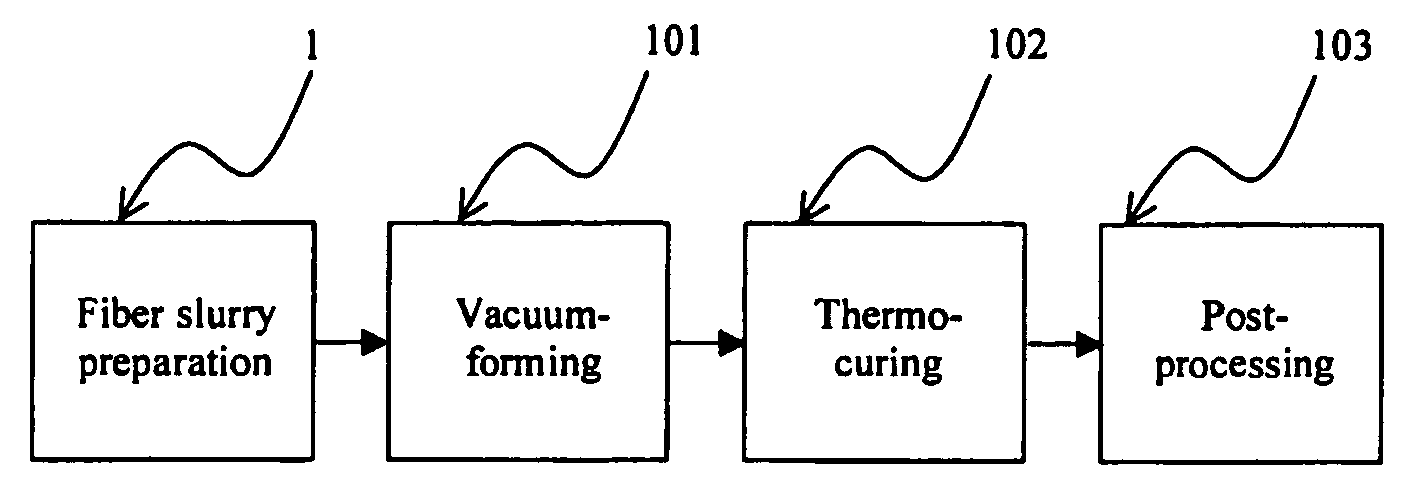

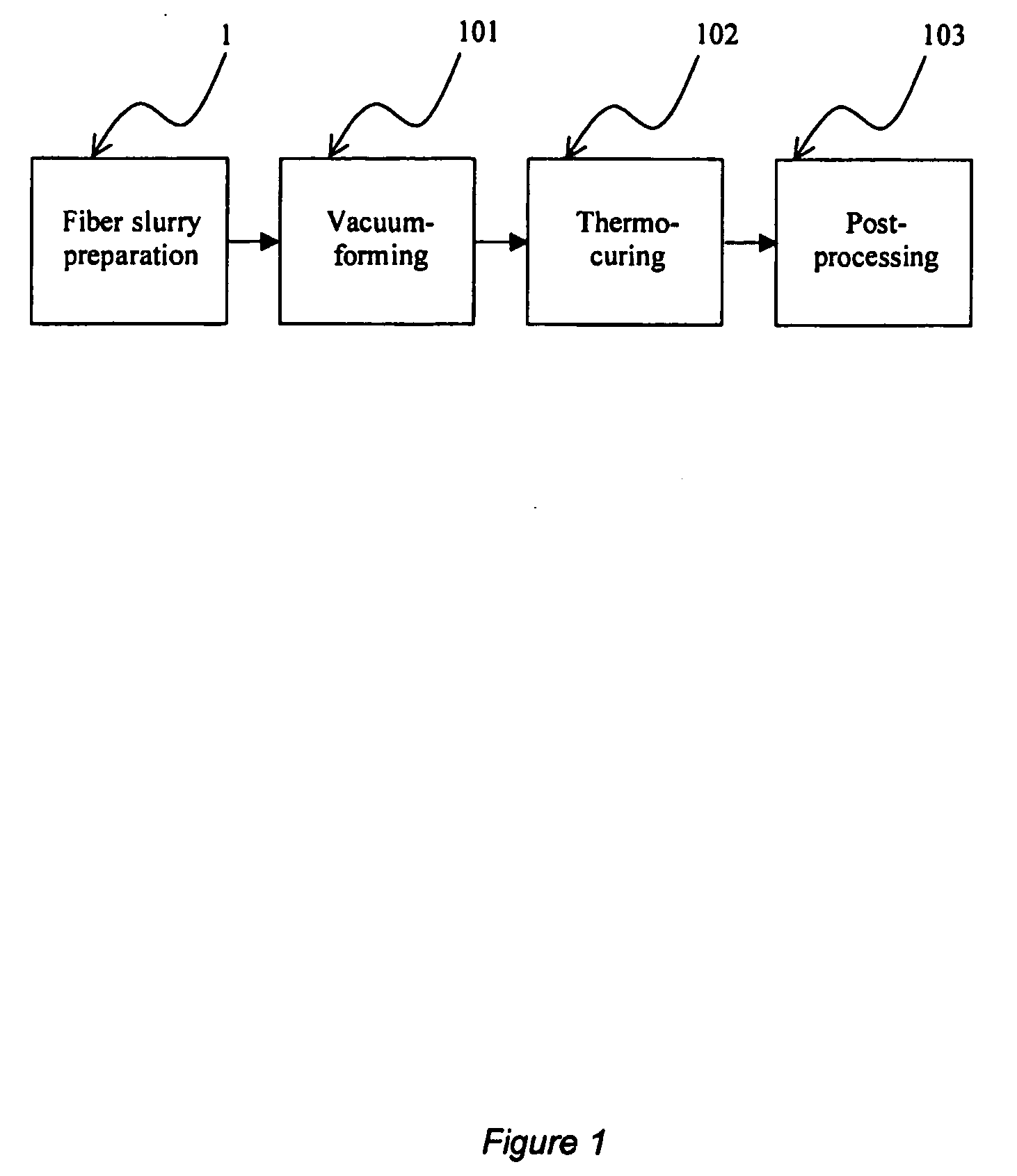

Molded fiber manufacturing

InactiveUS20050150624A1Reduce energy consumptionPrevent air infiltrationFibreboardWater-repelling agents additionFiberMolded pulp

Molded fiber products using agriculture residues are economical and environmentally beneficial. Molded fiber manufacturing is different from molded pulp. The present invention discloses a method of and an apparatus for the manufacturing of molded fiber shaped body (10) using low consistency fiber slurry (12) subject to vacuum-forming and thermo-curing. The use of porous material as mold inserts for both vacuum-forming (101) and thermo-curing (102) stations provides improved productivity and enables ease of mold release. The incorporation of self-cleaning techniques further ensures consistent performance of the manufacturing system.

Owner:GRENIDEA TECH PTE

Fiber-cast packaging with inner bag and method for the production thereof

InactiveUS20080210584A1Reduce air pollutionImprove water resistancePackage recyclingFlexible coversFiberMolded pulp

A package for free-flowing media comprising a molded pulp vessel partly or completely surrounding two or more film pouches or a film pouch having a plurality of chambers. An environmentally friendly package whose constituents can be reused without any great complexity.

Owner:HENKEL KGAA

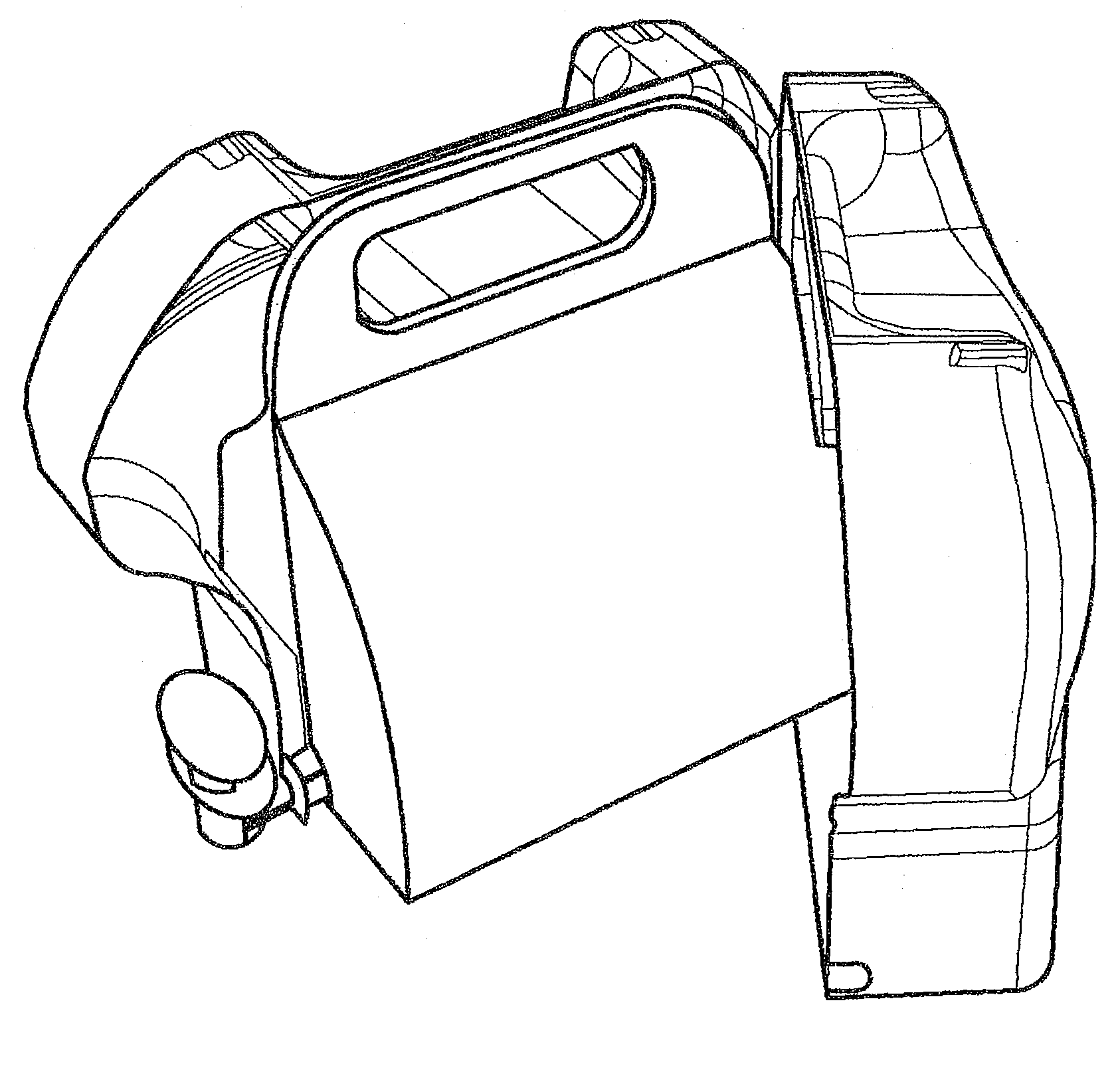

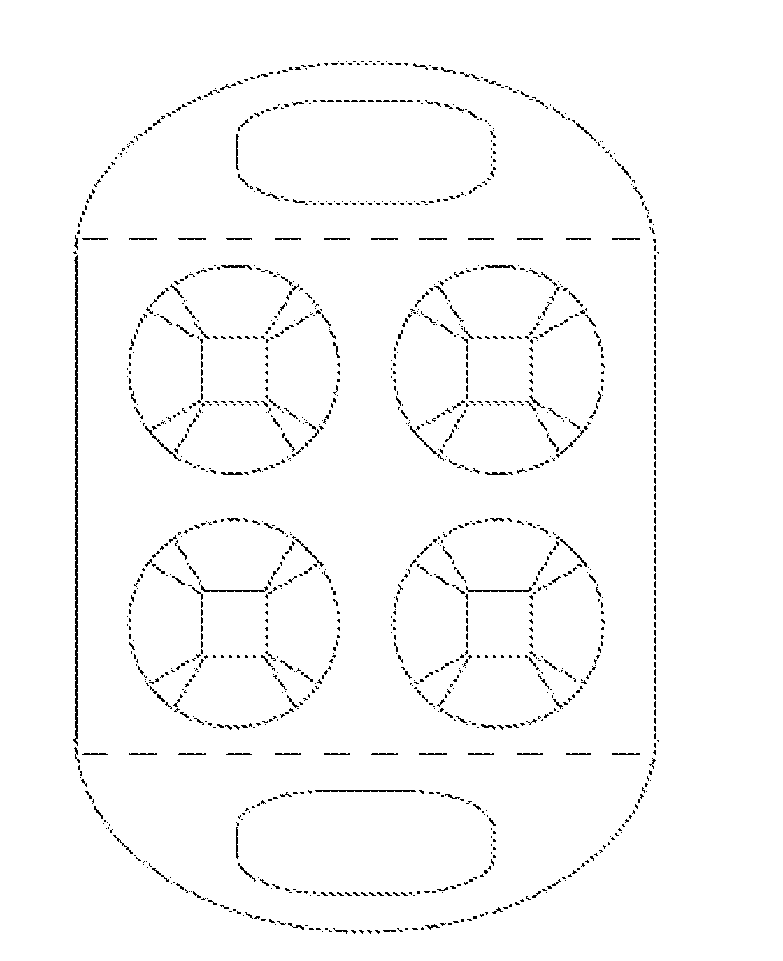

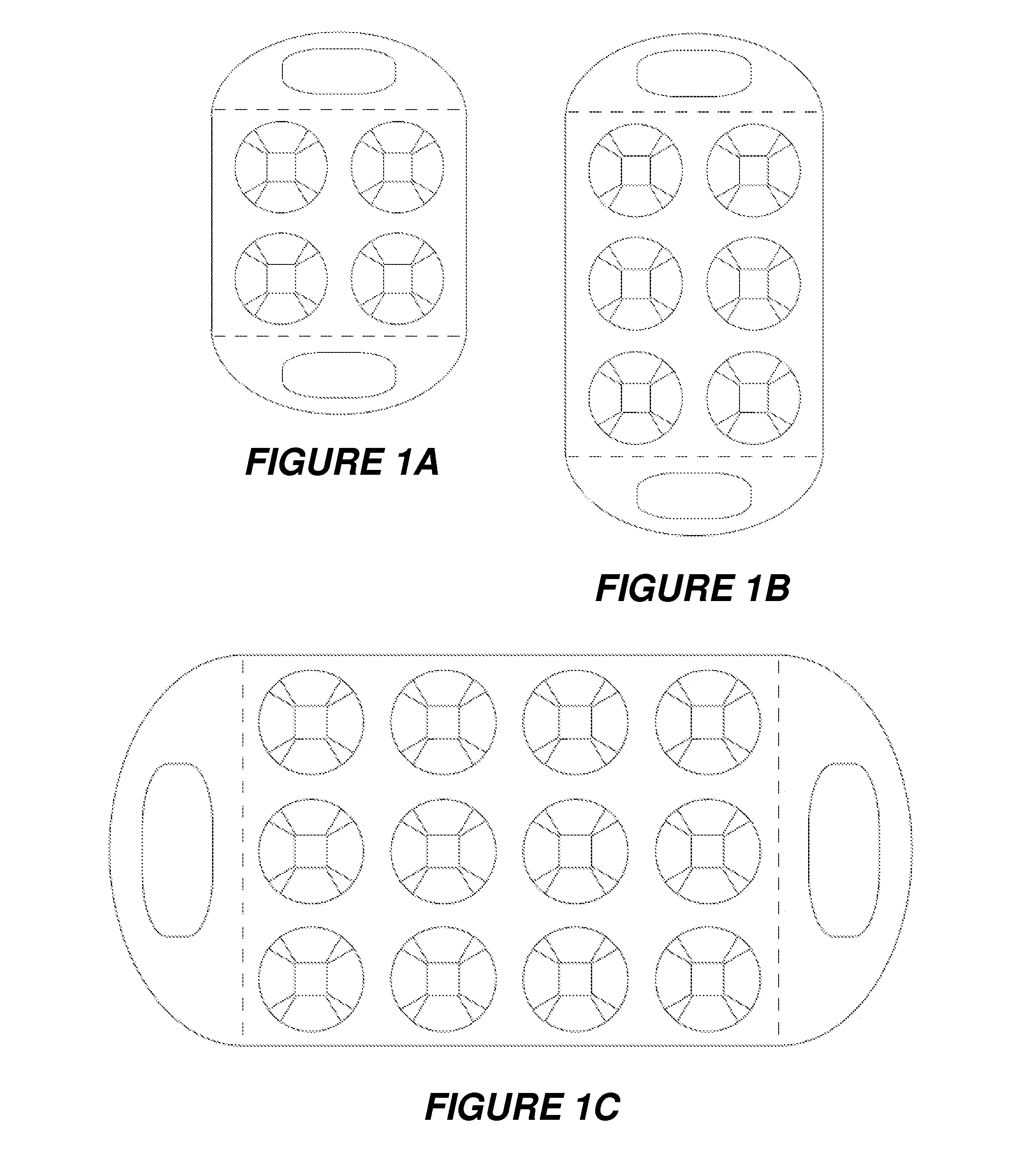

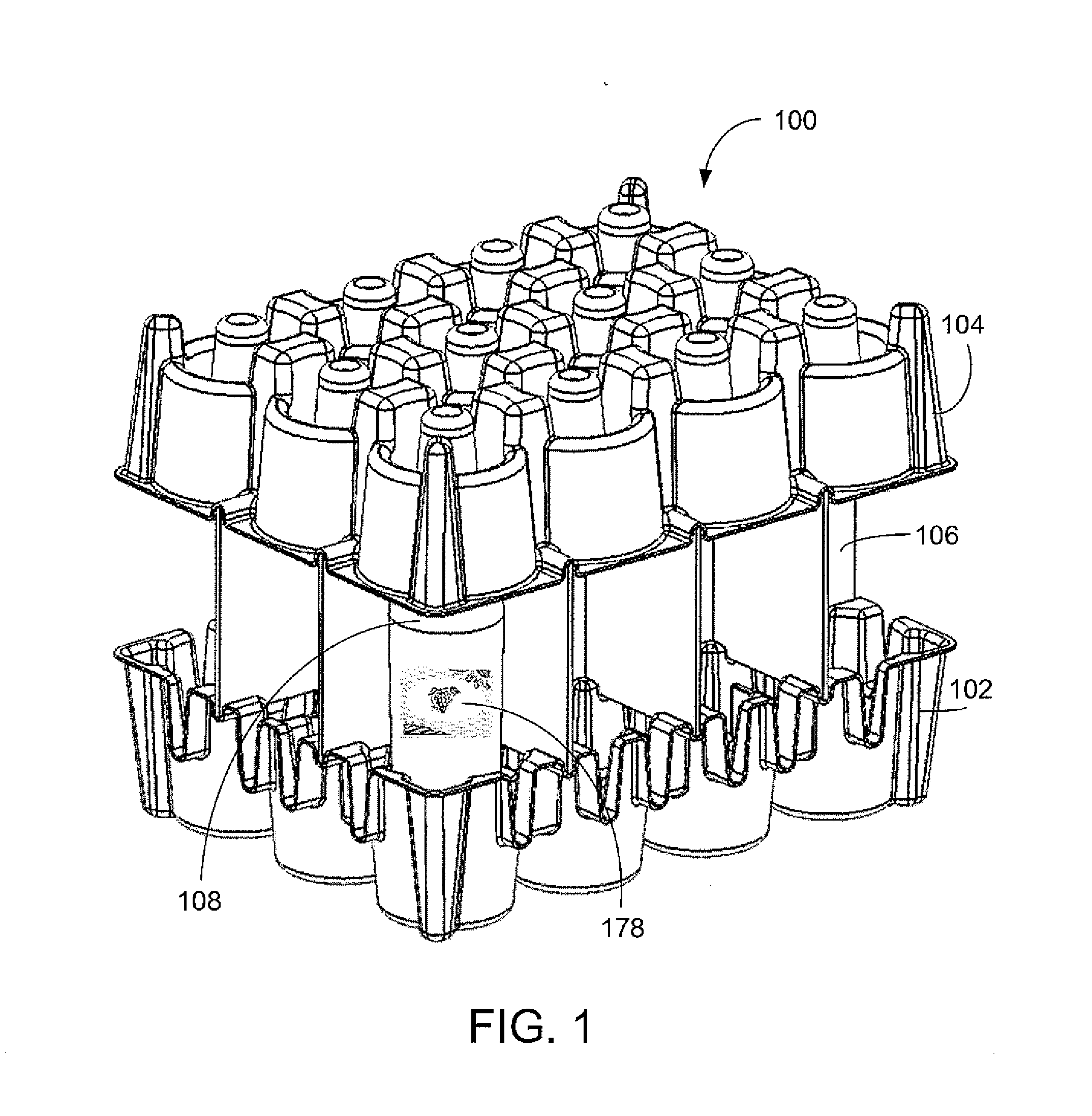

Biodegradable beverage carrier

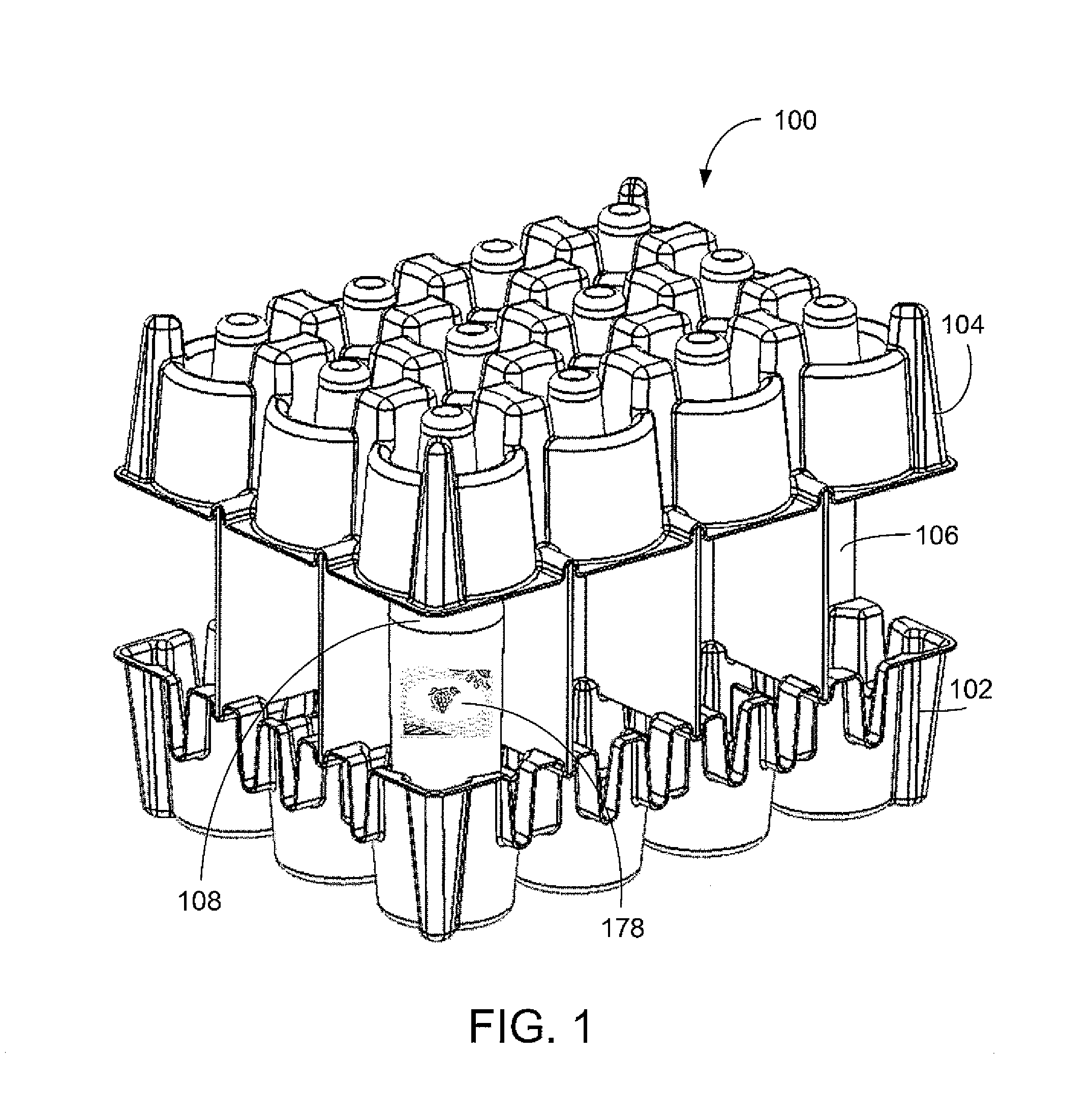

A biodegradable liquid container carrier is made from molded pulp or fiber and is designed to grasp liquid containers at the top portion thereof. As a result, less material is used in the manufacture of the carrier. This is made possible by a combination of a wet end treatment with a fatty acid modified PET during processing of the pulp mass before forming the pulp mass into a liquid container carrier. A base coat that is 10-80% clay or pigment, 20-90% styrene-butadiene latex and 0-15% fatty acid modified PET and a top coat that is 75-100% fatty acid modified PET and 0-25% clay mixture onto the base coat are then applied to the molded liquid container carrier. These treatments greatly enhance the strength, rigidity and water-resistance of the carrier. However, the carrier is still biodegradable and will biodegrade in 90 days under composting conditions.

Owner:RAYMOND TACCOLINI

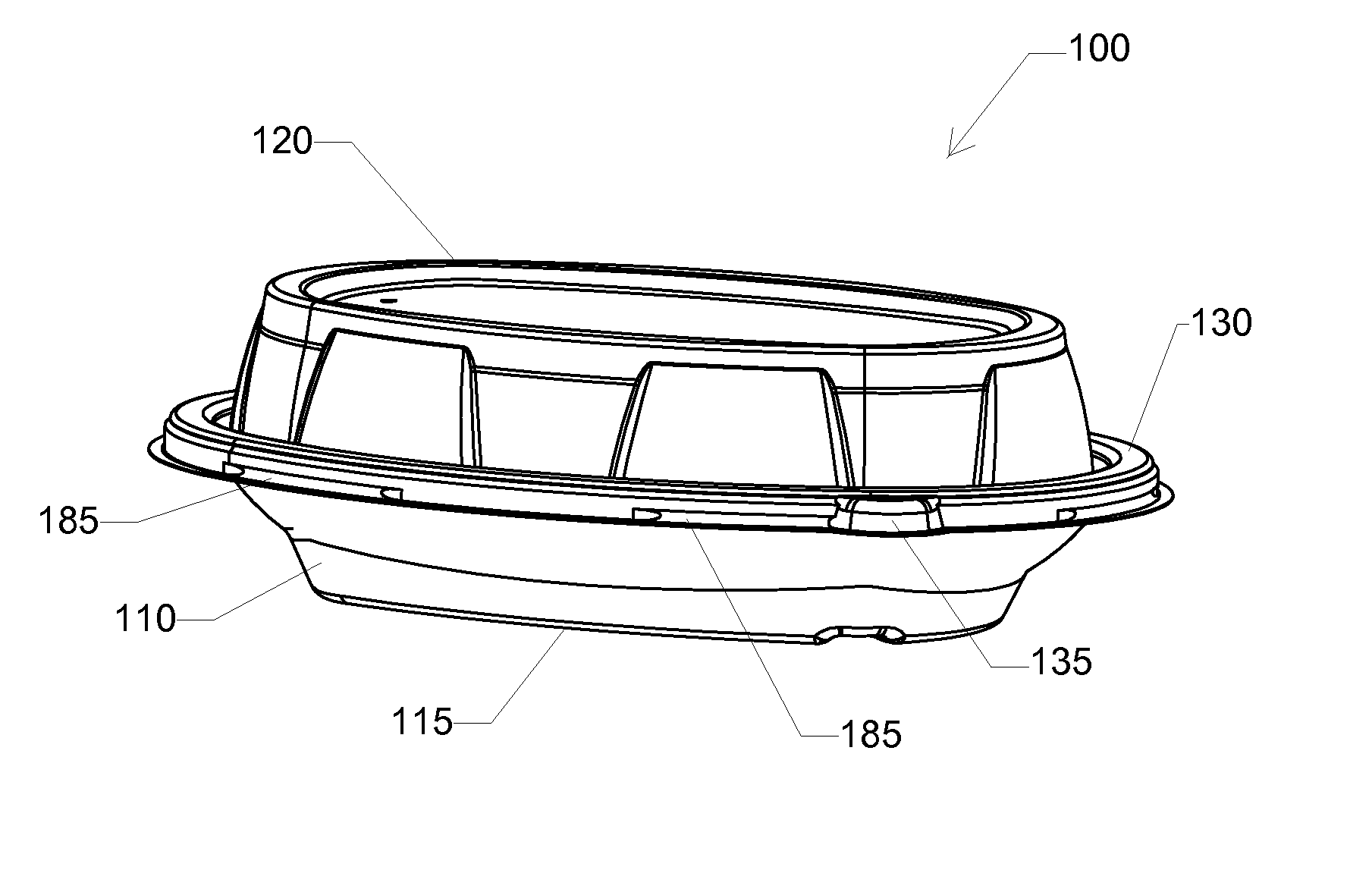

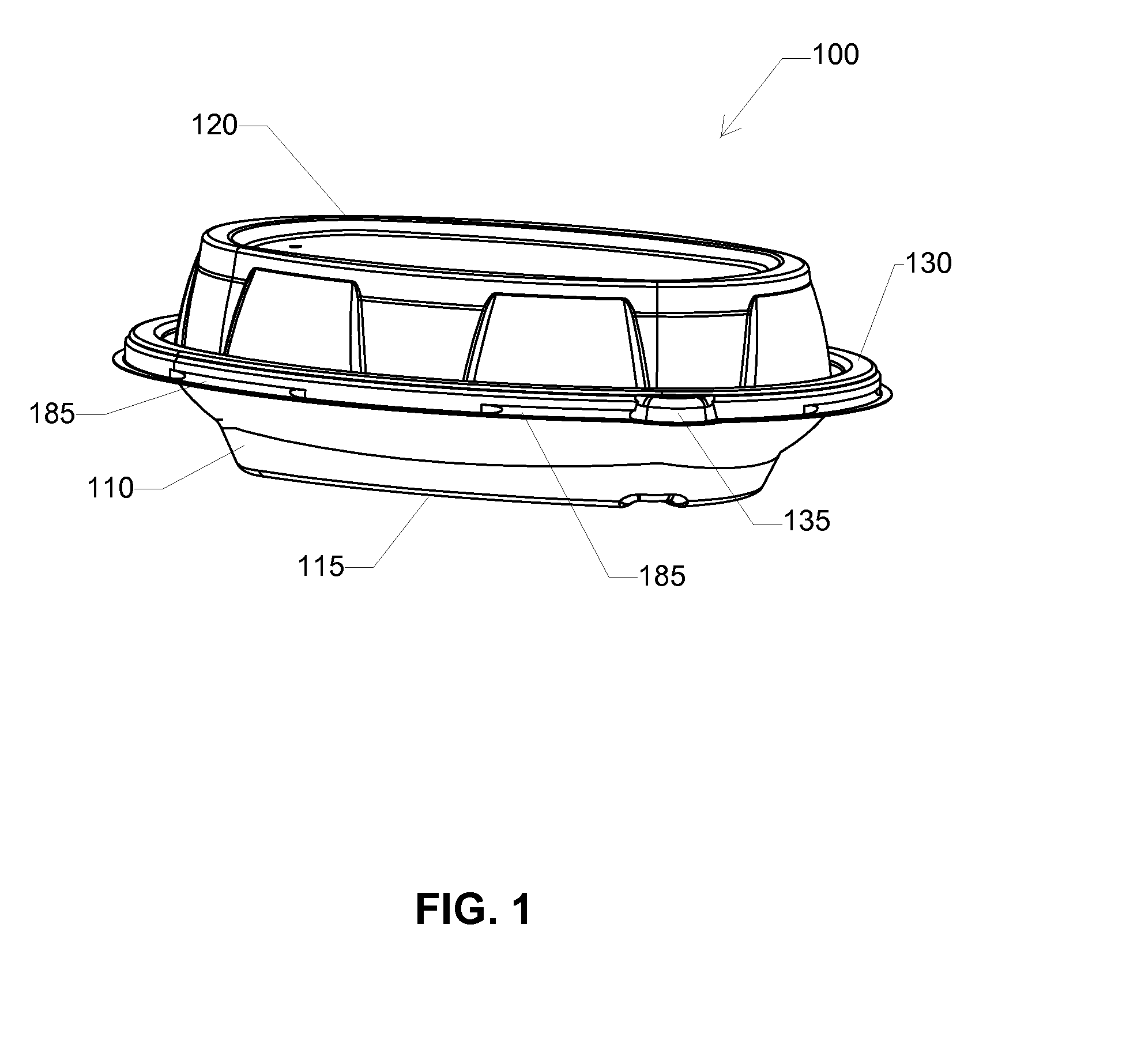

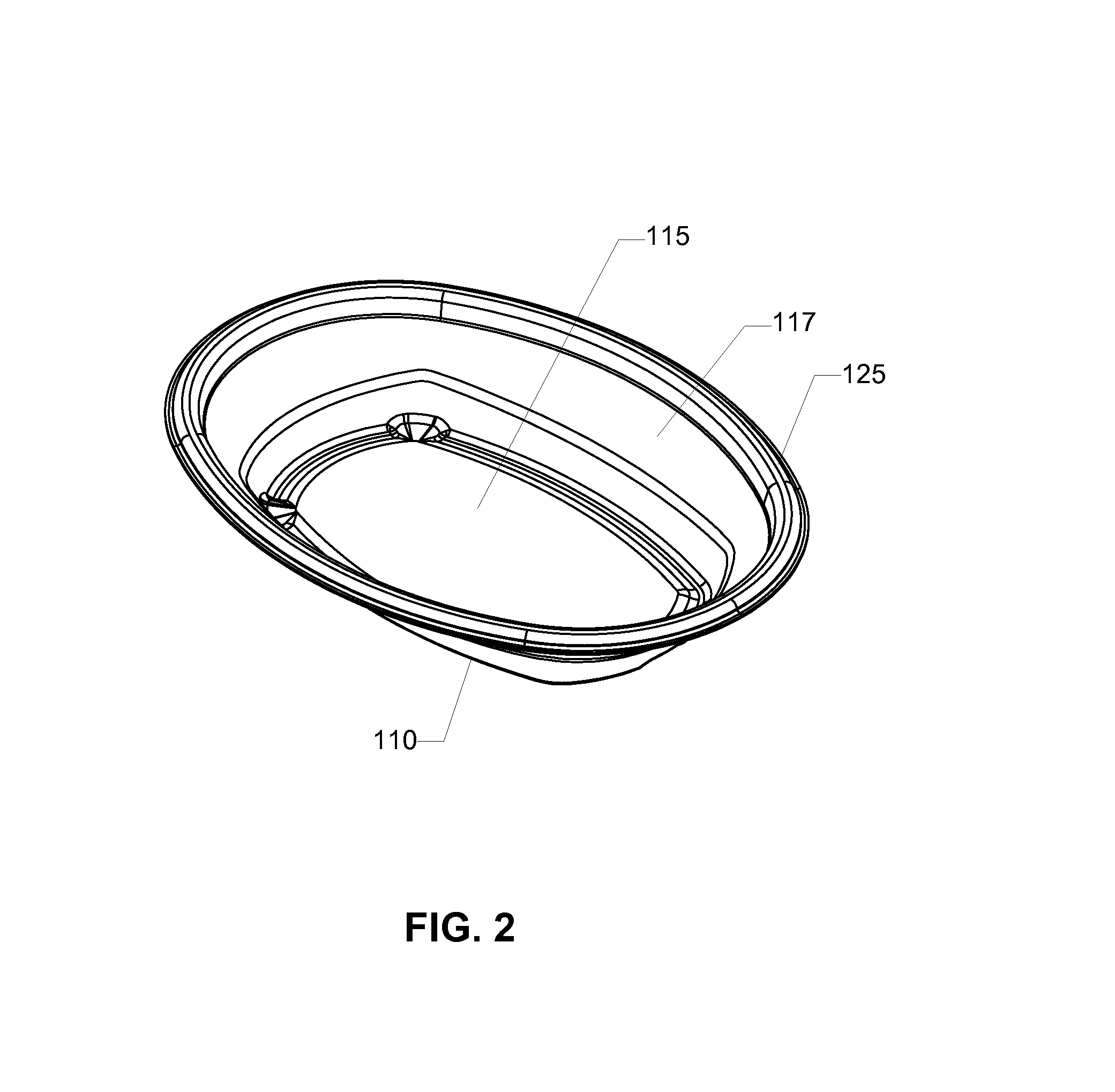

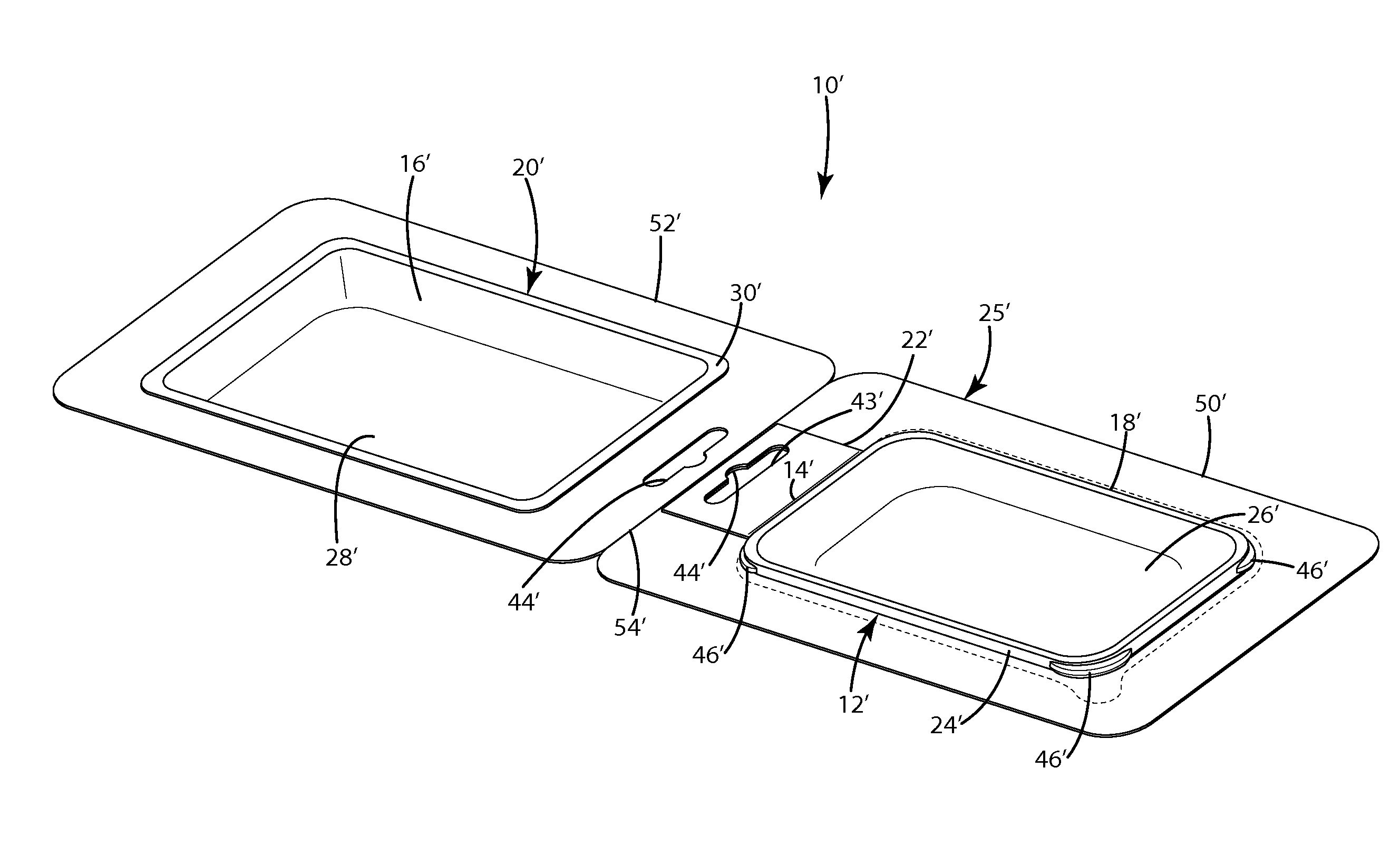

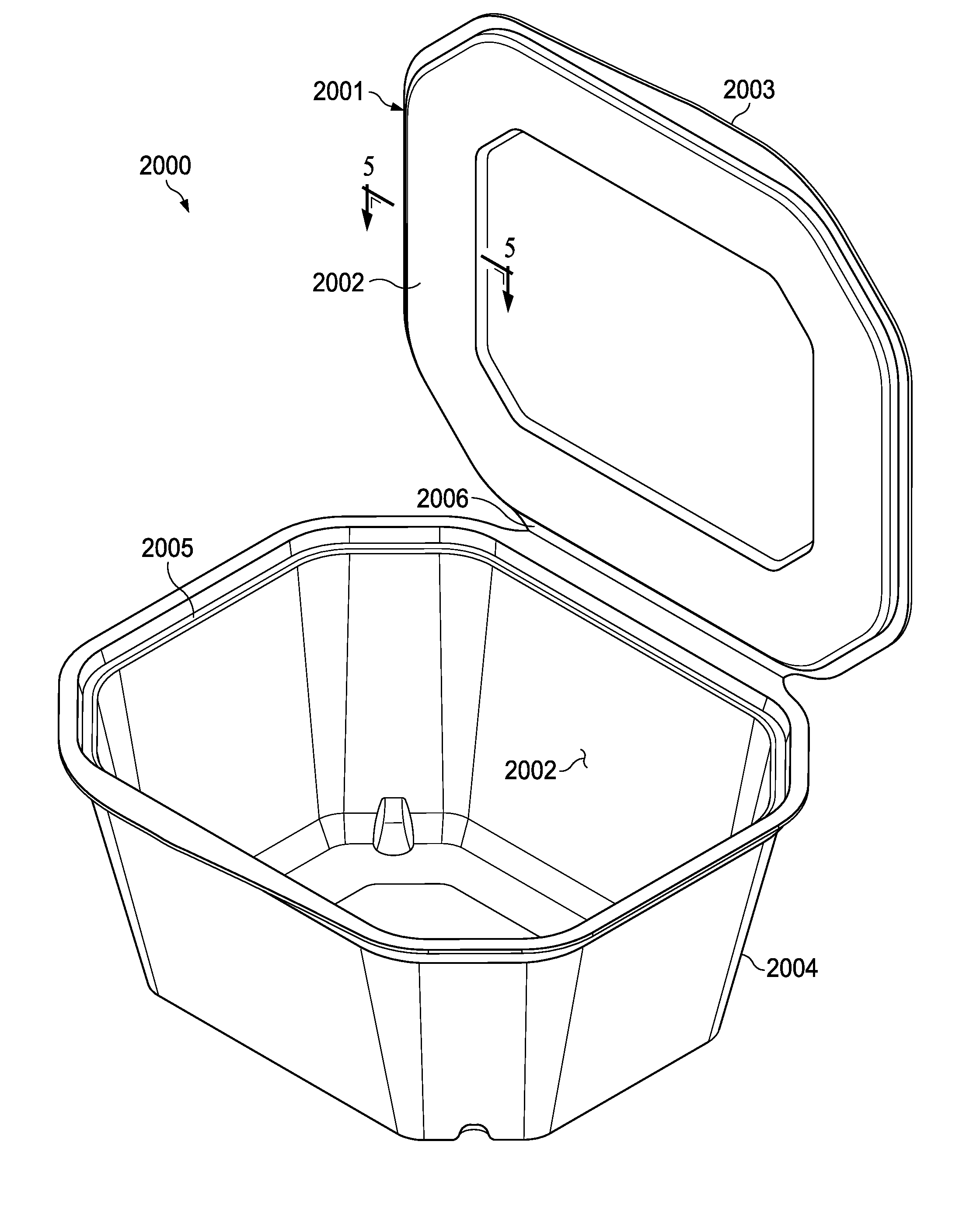

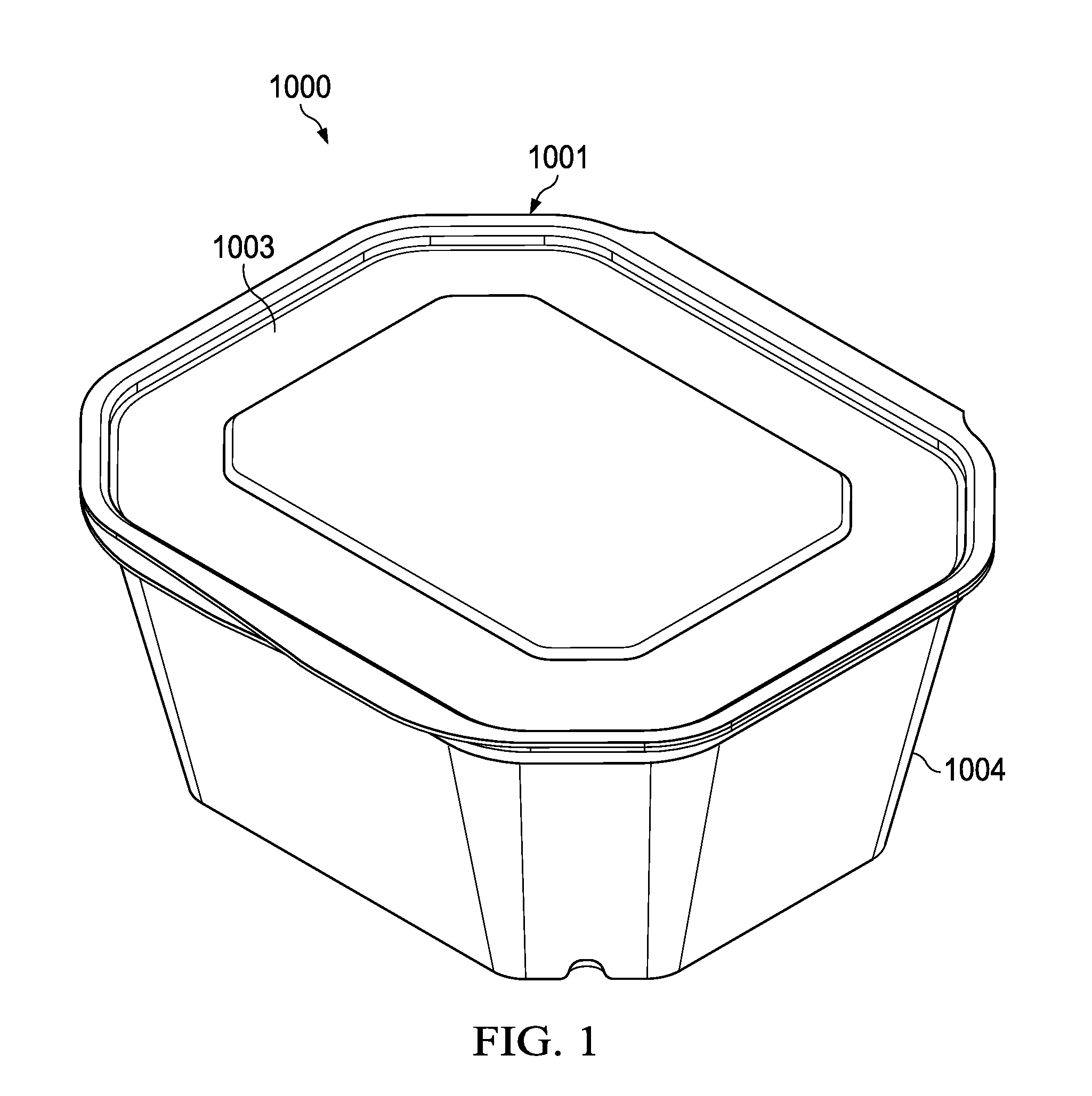

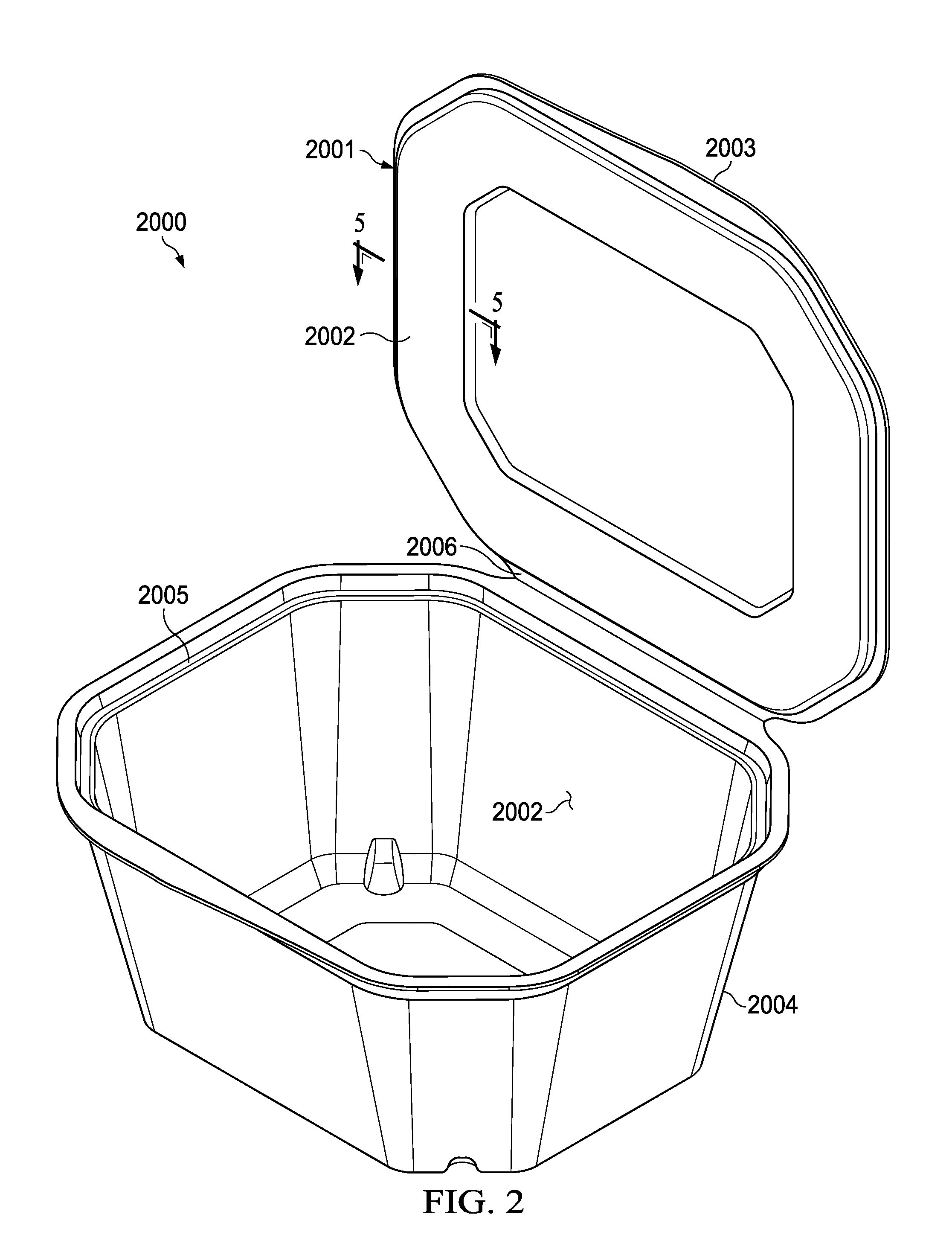

Resealable Leak-Resistant Containers Having A Pressed Pulp Tray With A Thermoformed Plastic Lid

A leak-resistant pulp container with a plastic lid is disclosed, including a tray formed of molded pulp and having a boom and a sidewall forming an interior volume. The tray has an edge extending peripherally outward from an upper edge of the sidewall, and the tray edge has an outer portion. The container further includes a plastic lid having an edge extending peripherally outward therefrom, and the lid edge having an outer portion.

Owner:SABERT CORP

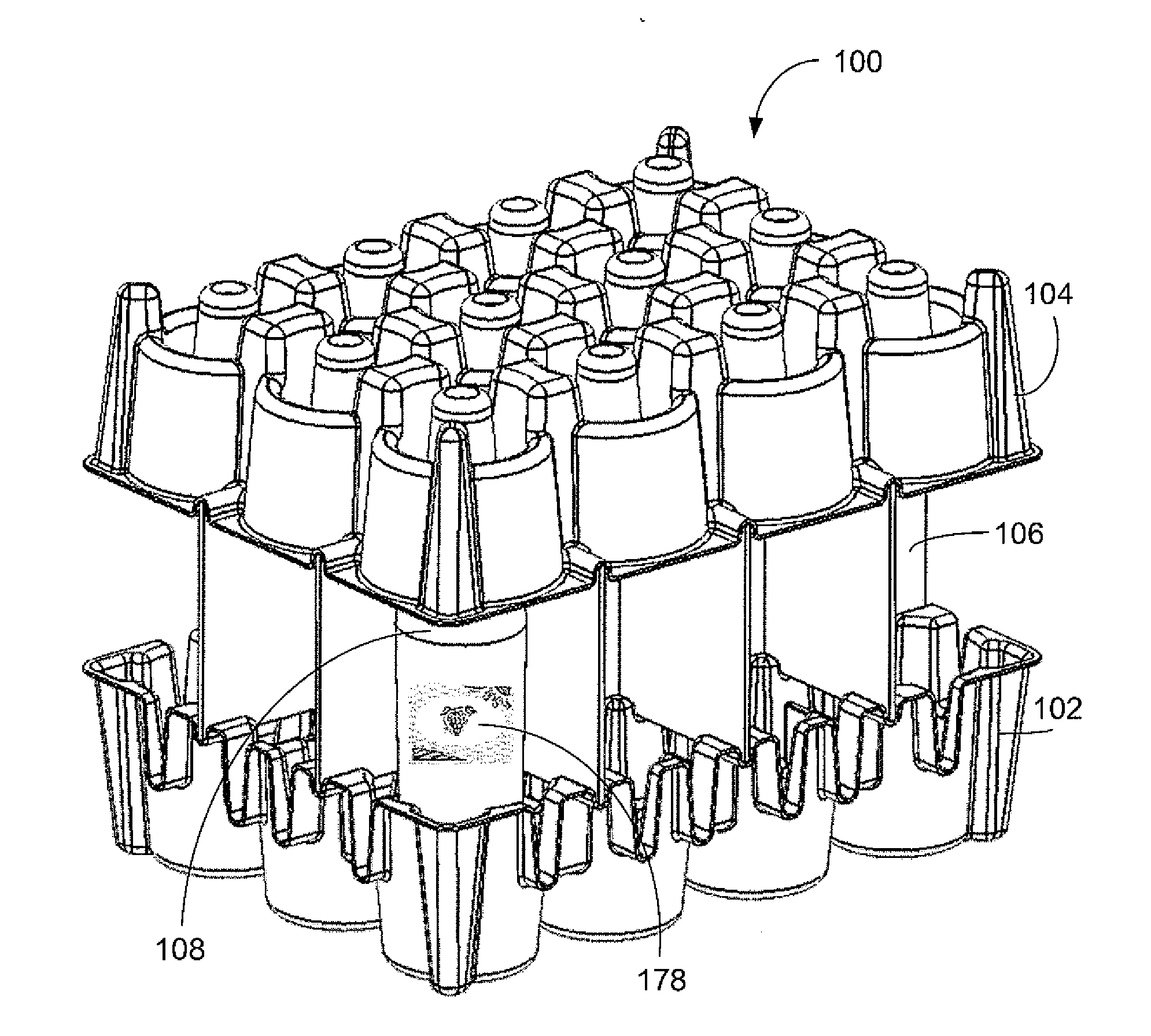

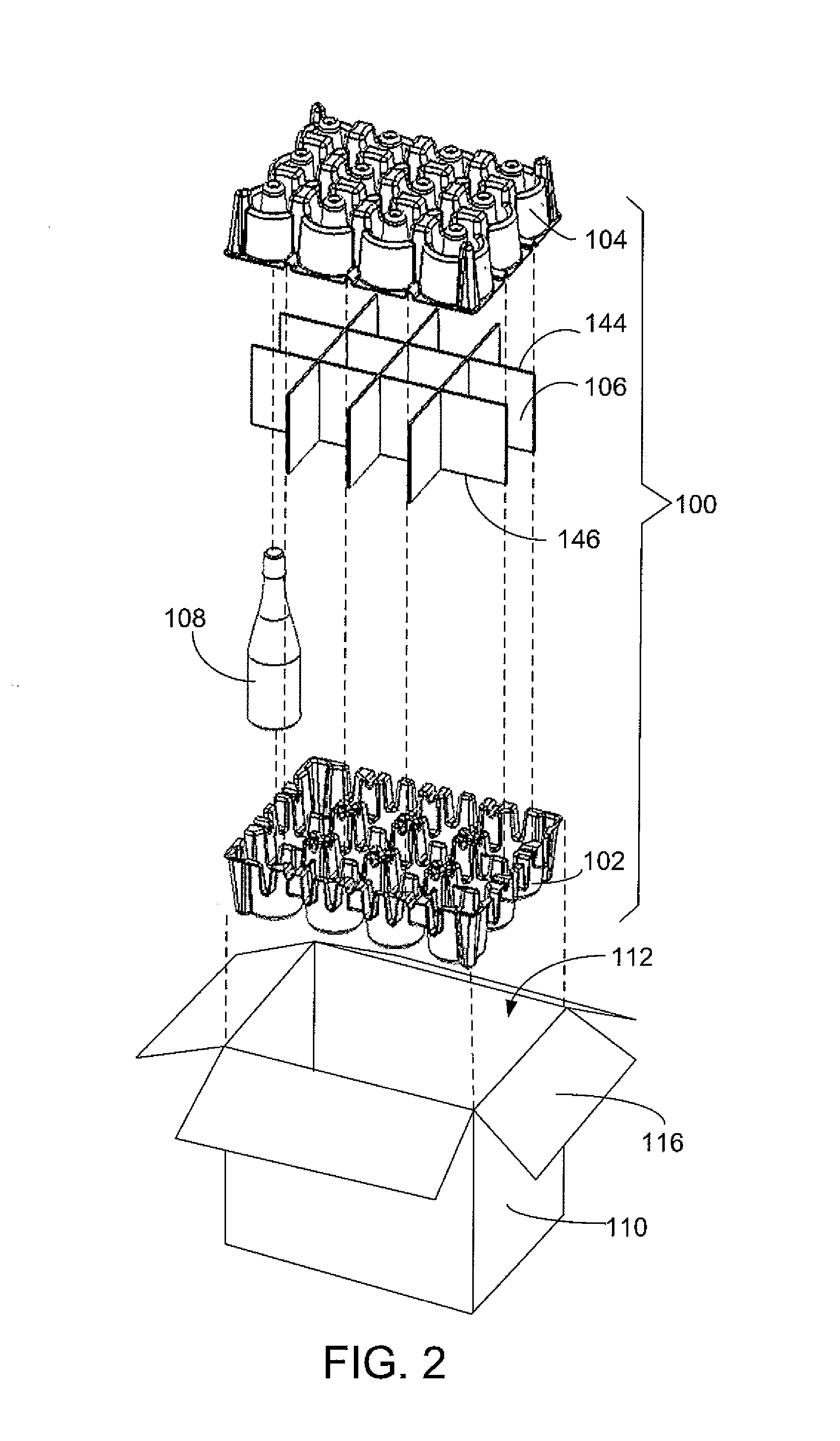

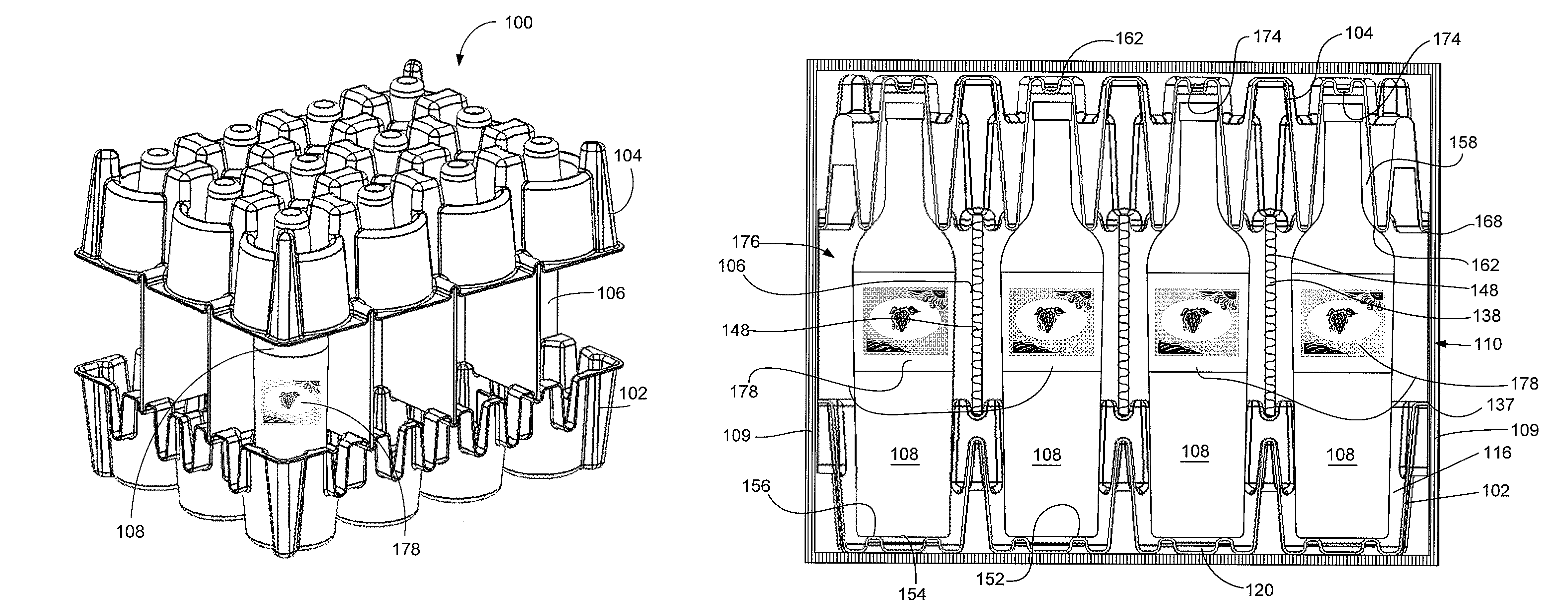

Bottle shipment packaging and method

ActiveUS20120037529A1Maintain integrityPreserving aesthetic labelingWrappersSolid materialCardboardMolded pulp

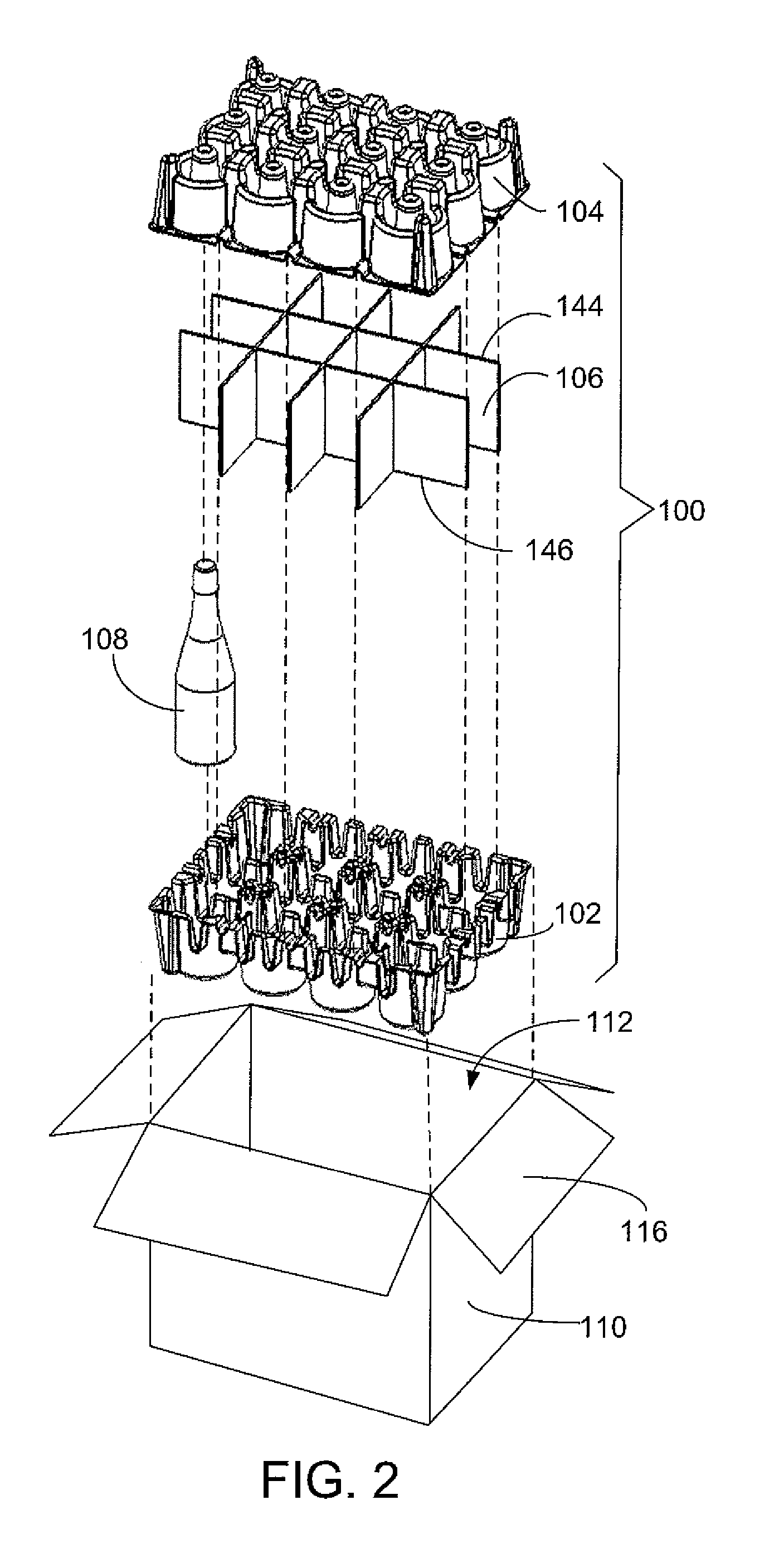

A bottle packaging for shipment includes a bottom tray, and a top tray made of molded pulp fiber, such as newspaper pulp, and a cardboard partition support structure disposed between the trays. Cavities formed in the bottom and top trays are arranged to engage both ends of a bottle and include crushable elements that can axially engage each bottle. The support partition may be made of corrugated cardboard material and be arranged such that the cardboard flutes provide support for loads imparted to the sides of the carton when the carton is laying on its side. The partition forms a void surrounding each bottle in the area of its labels. In this way, structural support and cushioning can be provided to the packaged bottles from all directions.

Owner:GRAFCOR PACKAGING

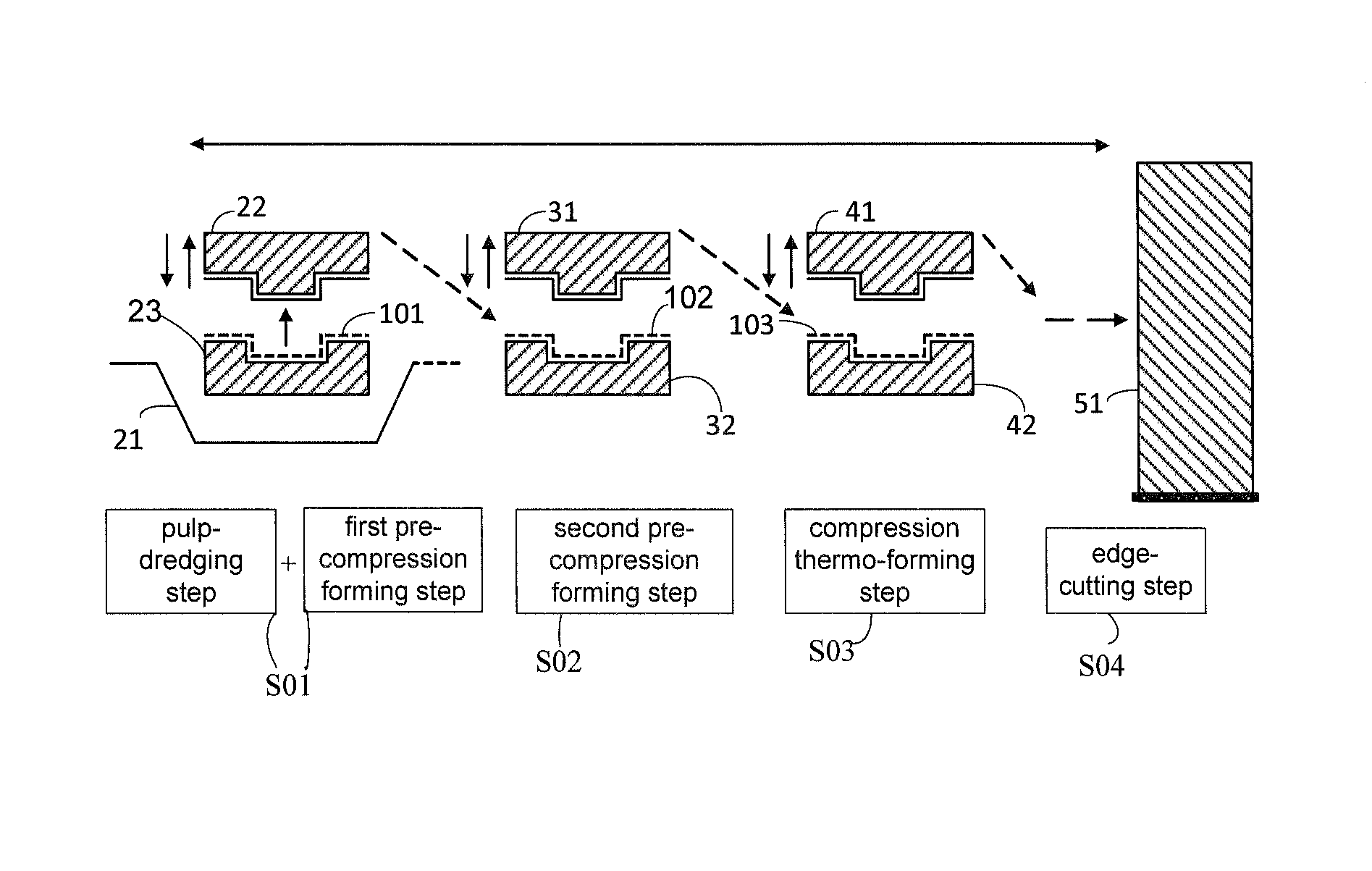

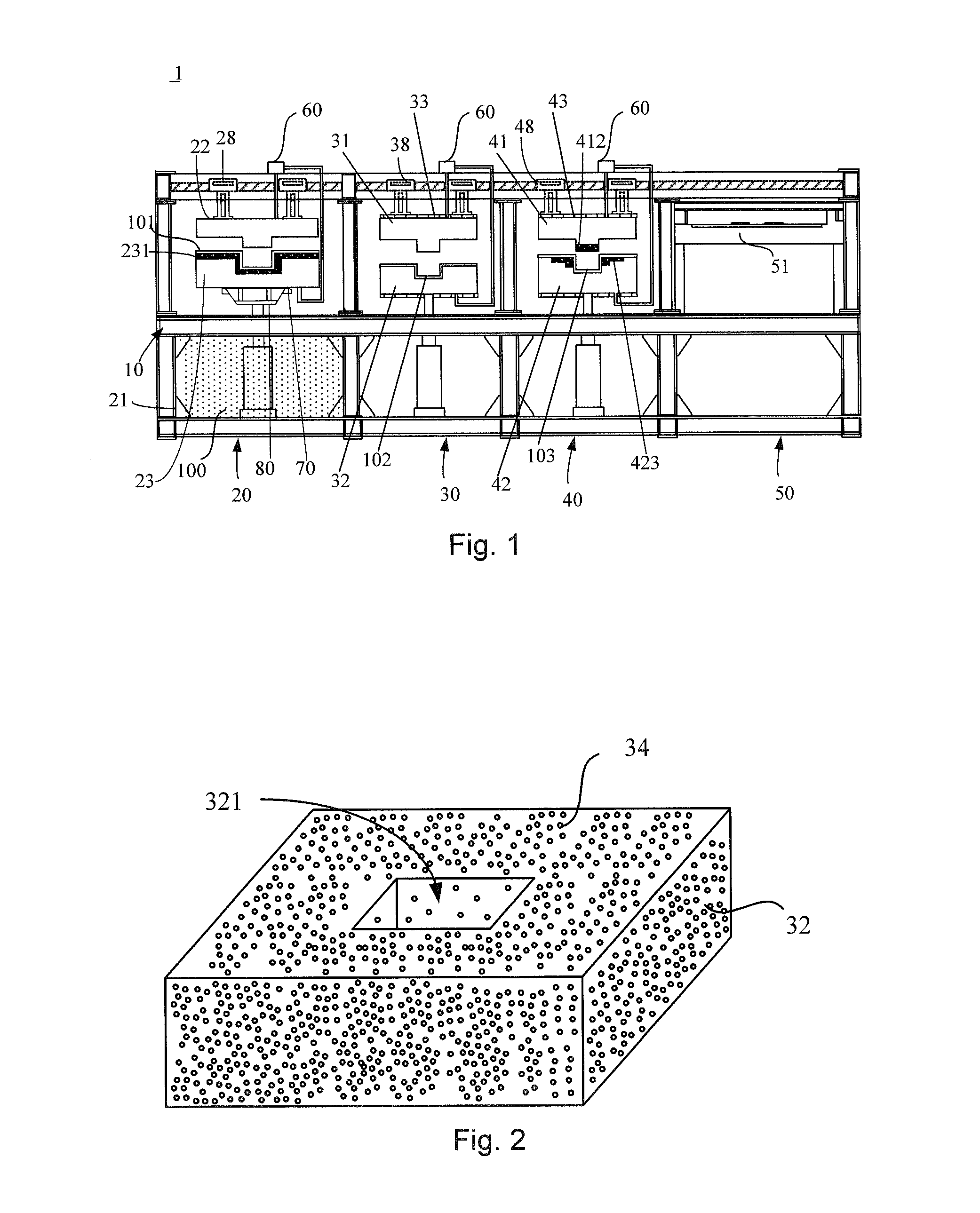

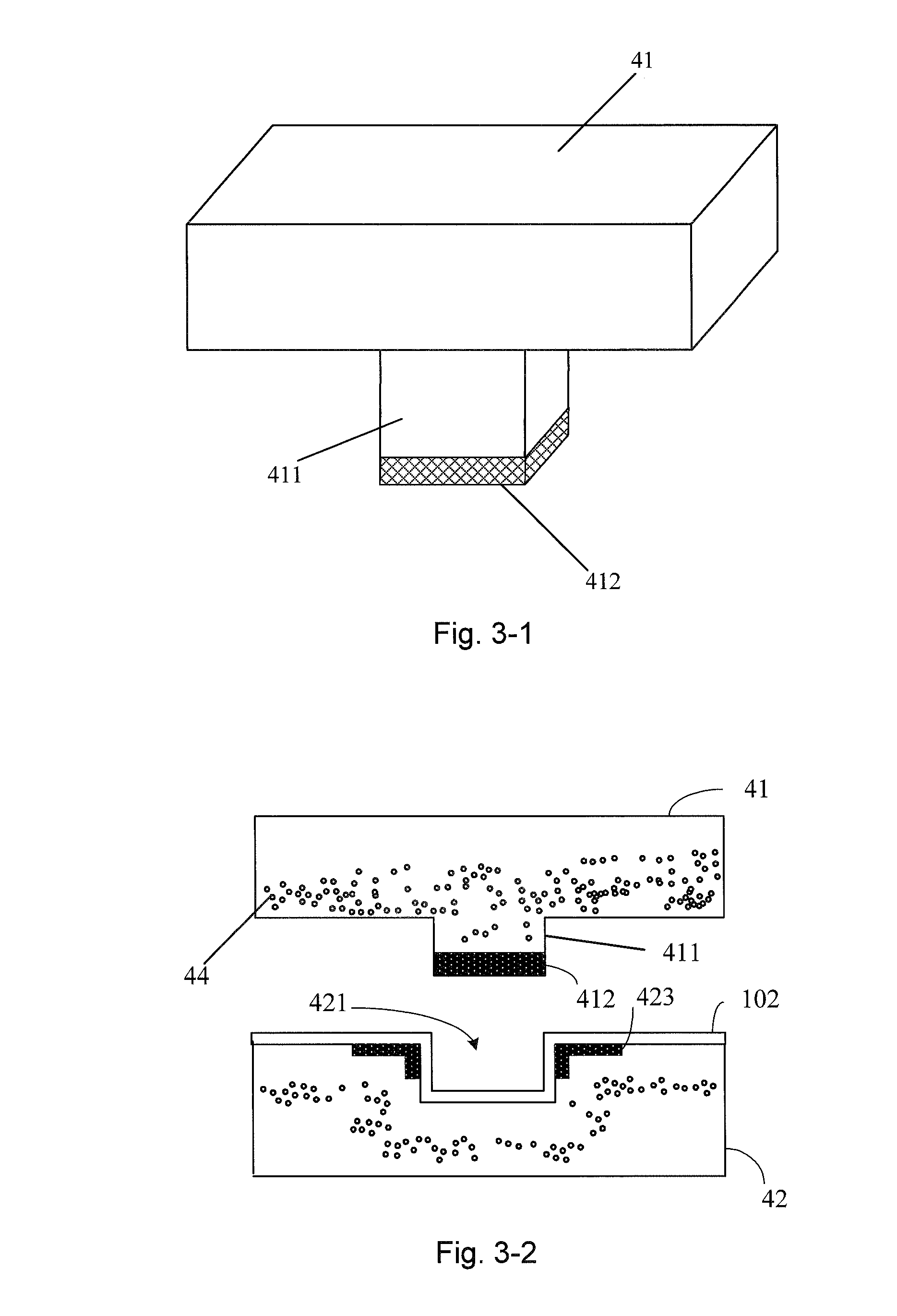

Pulp molding machine, pulp molding process and paper-shaped article made thereby

ActiveUS20160168801A1Shorten production timeReduce contentFibreboardPaper-making machinesMolding machineShell molding

A pulp molding machine, a pulp molding process and a paper-shaped article made thereby are provided. The pulp molding machine comprises a pulp-dredging stage, a first pre-compression forming sub-stage, a second pre-compression stage, a compression thermo-forming stage and an edge-cutting stage. The pulp molding process comprises the steps of a pulp-dredging step, a first pre-compression forming step, a second pre-compression forming step, a compression thermo-forming step and an edge-cutting step. The pulp molding machine the pulp molding process can drain off water or vapor from a wet pulp more efficiently and shorten the cycle time of the pulp molding process due to the extra pre-compression sub-stage. The paper-shaped article made thereby has a greater smoothness and structural strength than conventional paper-shaped product.

Owner:GOLDEN ARROW PRINTING

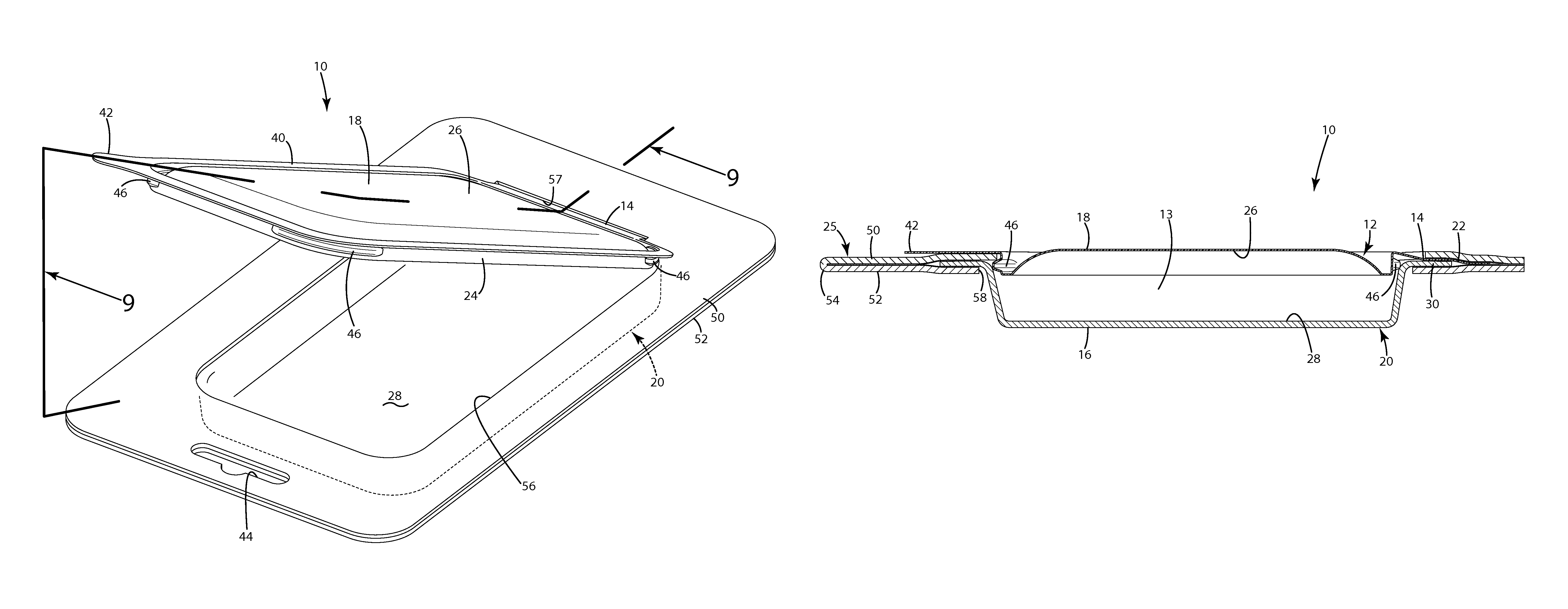

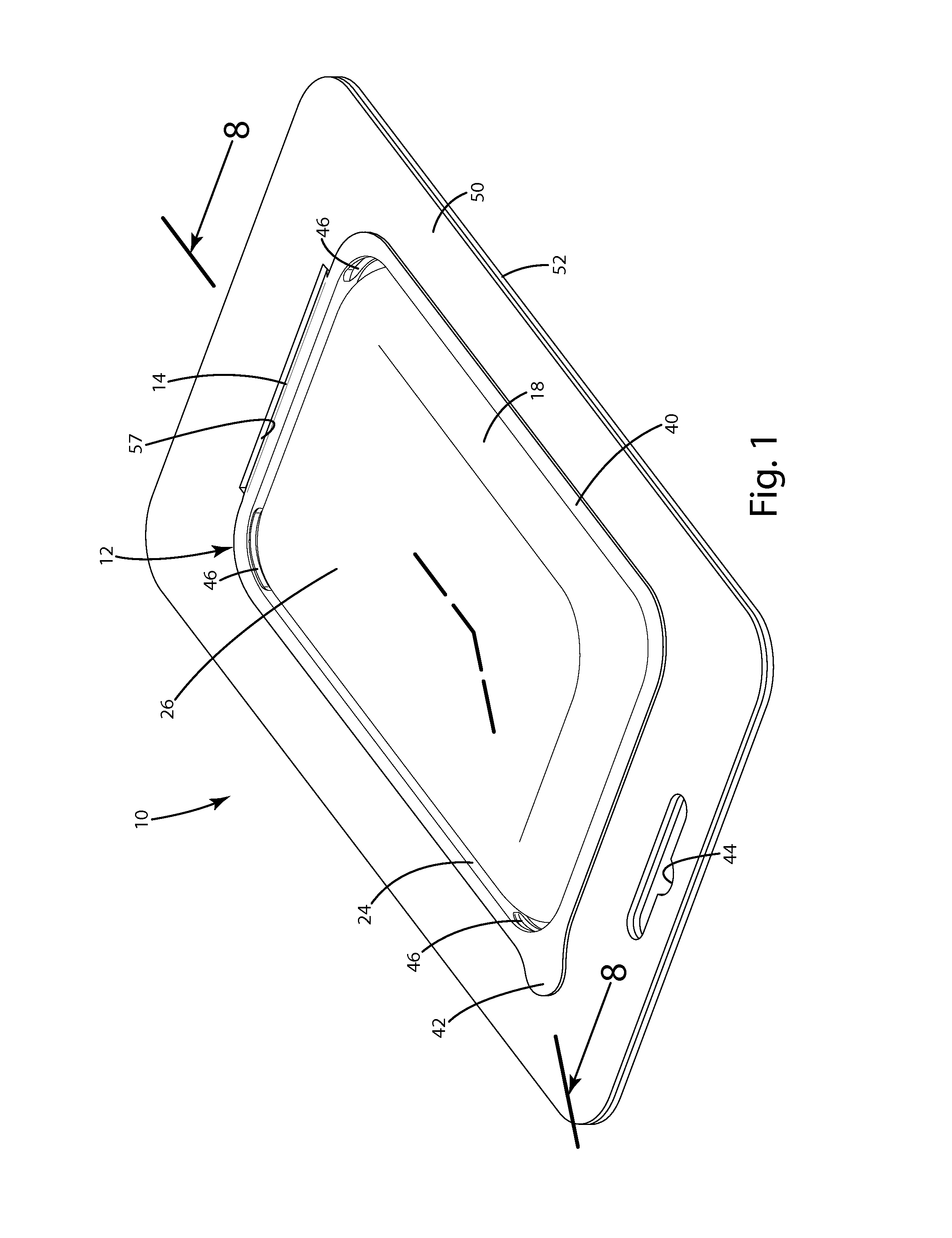

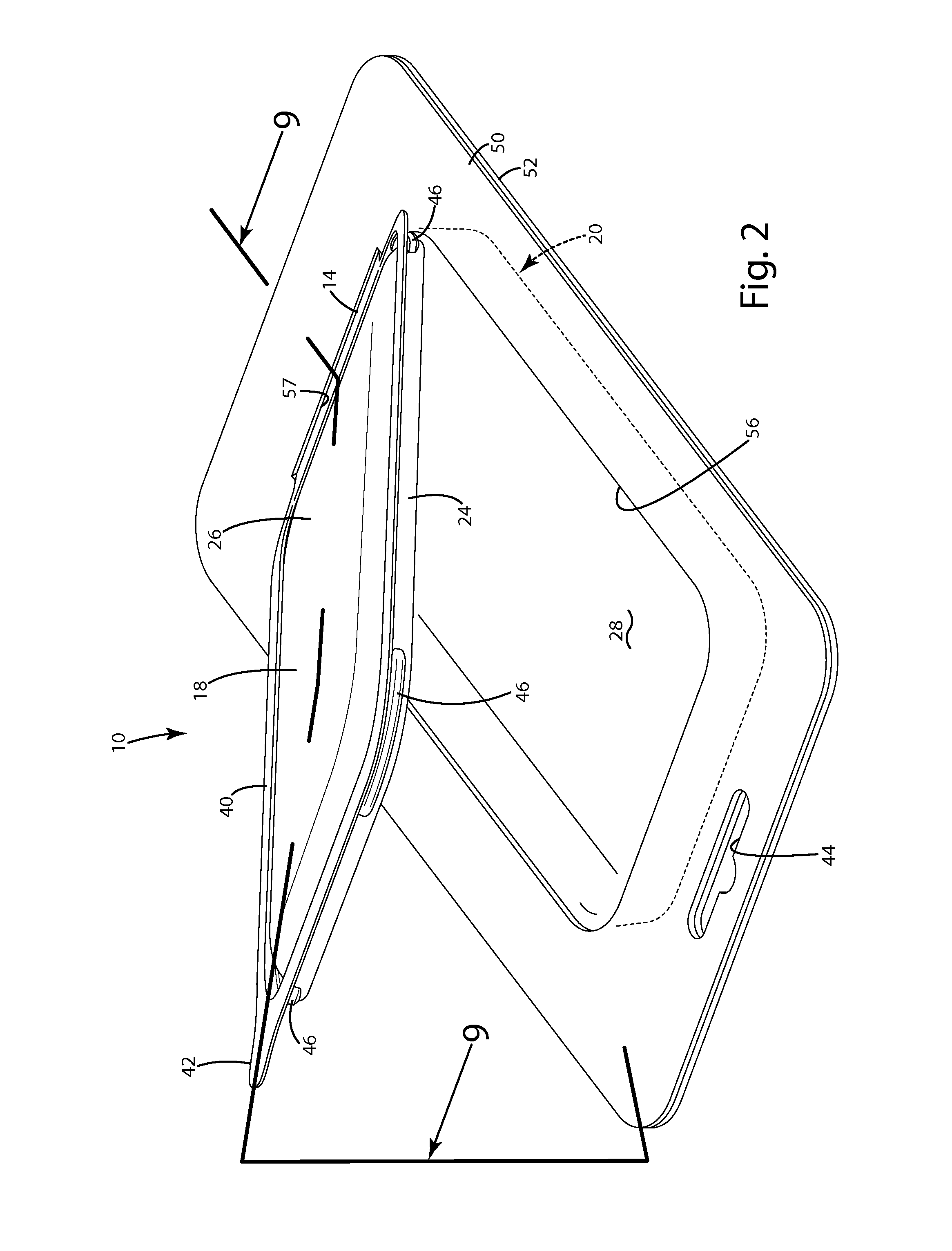

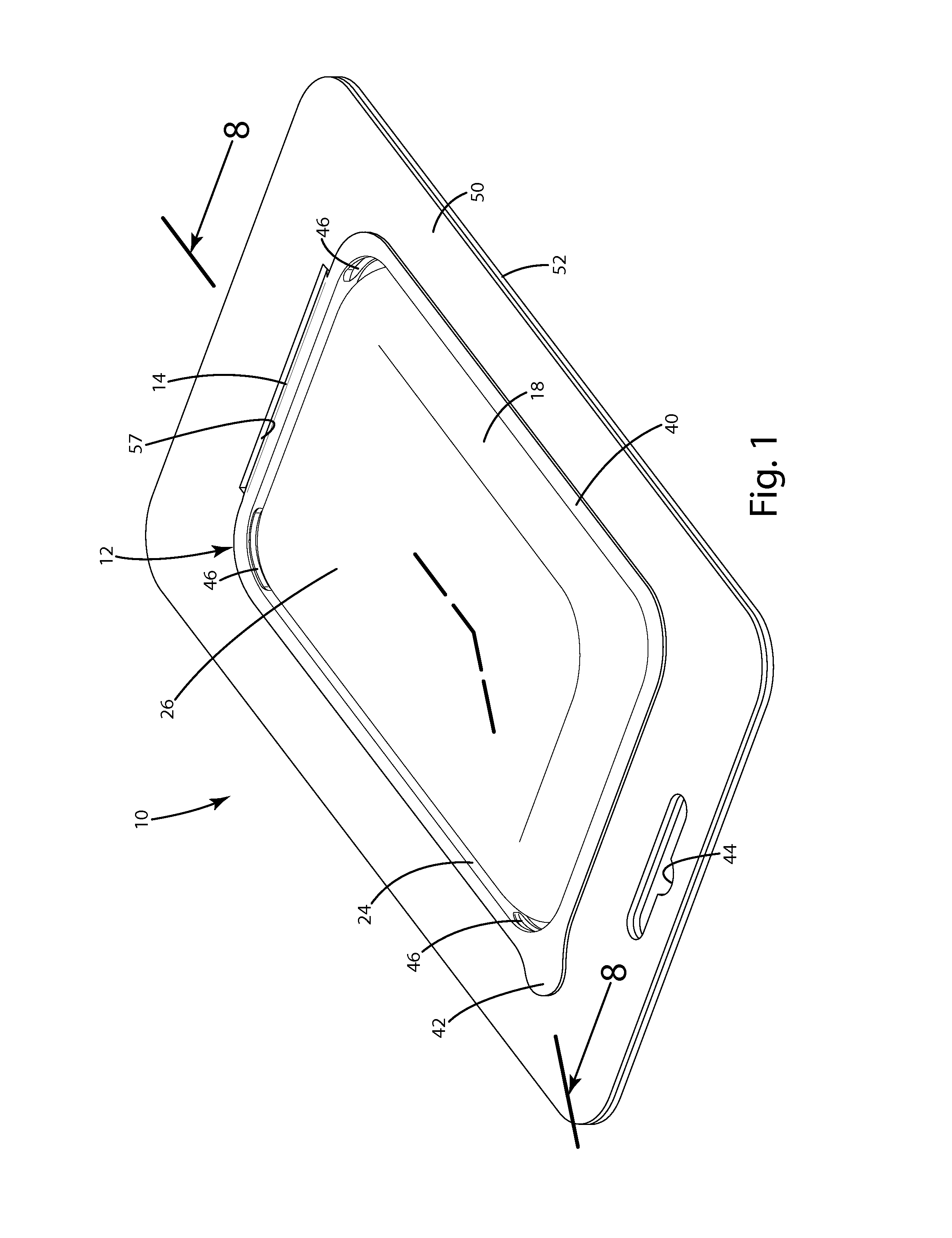

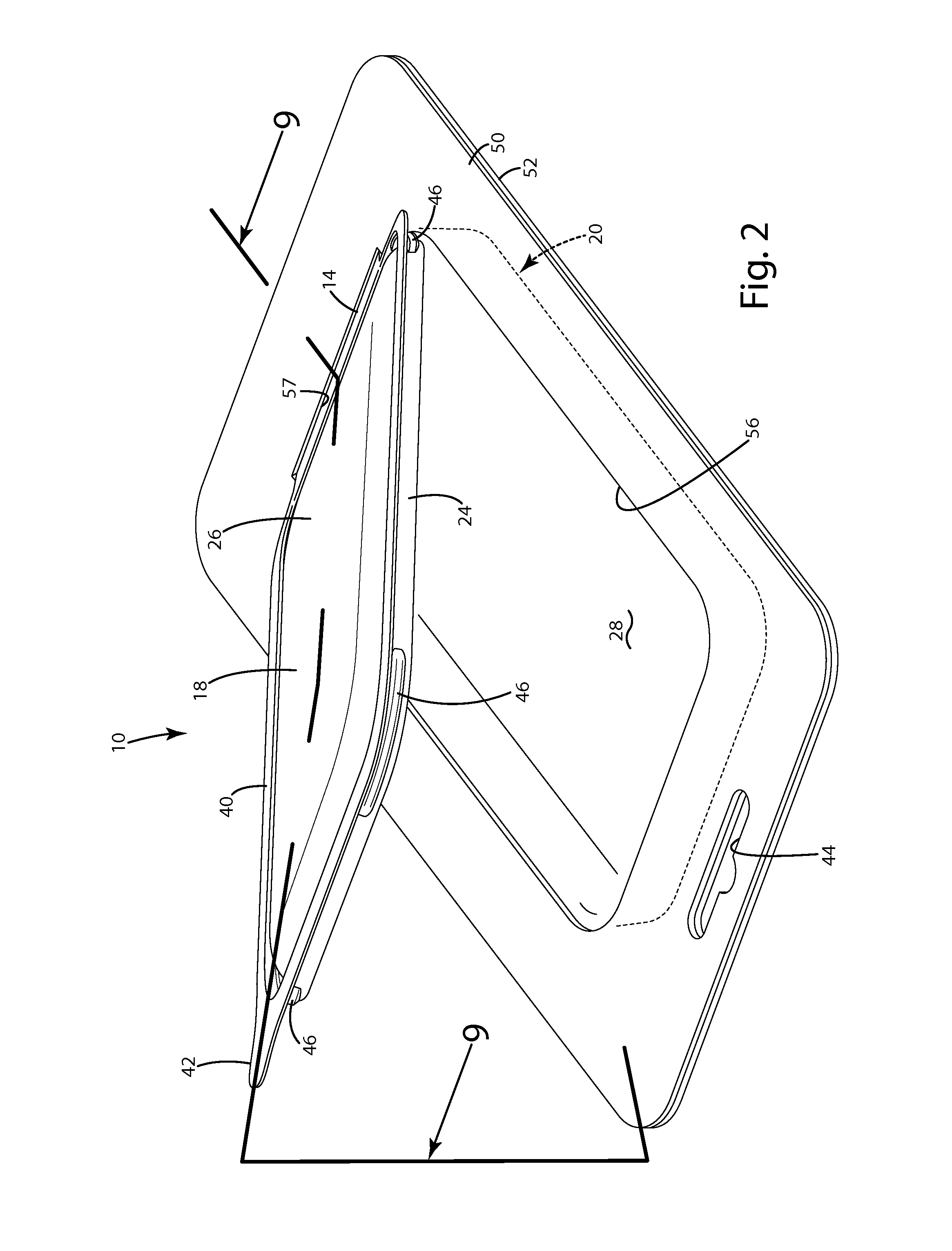

Reclosable display package and method of use

InactiveUS8616373B2Avoid hard activationEasy to masterCapsBoxes/cartons making machineryMolded pulpInterference fit

A reclosable package for packaging an article is provided with a plastic door component and a separate tray that cooperate to form an article containing cavity. The tray may be manufactured from a paper pulp material, such as molded pulp. The door component and tray may be installed between a pair of panels. The door component may include a door portion and a flange portion joined along a hinge. The flange portion may be sandwiched between the panels to hold the door component in place. The door portion may be movable about the hinge to allow the package to be opened and closed. The door portion may interface with the door panel in a way that resists movement of the door portion between the open position and the closed position. The door portion may include snap elements configured to have an interference fit with the door panel.

Owner:DISPLAY PACK

Manufacture process of disposable bowl cover and bowl cover made by same

InactiveCN101637982AReduce energy consumptionImprove waterproof performanceWater-repelling agents additionPaper/cardboard articlesMolded pulpHigh pressure

The invention provides a manufacture process of disposable bowl cover with high strength, strong stability and good water proof performance. The process includes the concrete steps of raw material beating-batching-compression molding-side shearing and punching-making back-off slot by pressing; wherein the material beating includes that: the used raw material is mainly bagasse paddle board accounting for 80-90% of total mass and supported by a small amount of wood pulp and bamboo pulp accounting for 10-20%, water dissociation beating is carried out by a beating engine, and the beating concentration is 4-6%; the compression molding includes: wet blank with water content of 65-75% is directly transferred into an aluminium or steel compression molding mold for high temperature high pressure dehydration, so that the water content of product can reach 5-7%, and the pressure thereof is 15-20x10<3>kgf, the temperature is 150+ / -10 DEG C, and the compression time is 45+ / -5 seconds. Compared withthe existing molded pulp process, the invention saves energy consumption; and the water proof performance, the strength and the stability of the product are greatly improved.

Owner:佛山浩博环保制品有限公司

Three-dimensional pulp moulding decorating plate as well as manufacturing method and application thereof

ActiveCN102691388APromote environmental protectionFlame retardantCovering/liningsThree-dimensional effectsPulp and paper industryMolded pulp

The invention relates to a three-dimensional pulp moulding decorating plate as well as a manufacturing method thereof by using a common pulp moulding device and a practical application thereof in the field of decoration. The height of the three-dimensional protruding part of the three-dimensional pulp moulding decorating plate ranges from 5mm to 150mm and the ordinary wallpaper is not as high as the protruding part. The three-dimensional pulp moulding decorating plate can be spliced and cut, and the wallpaper with the same specification and different patterns can be spliced into more patterns.

Owner:BEIJING TONGLANHAI TECH CO LTD

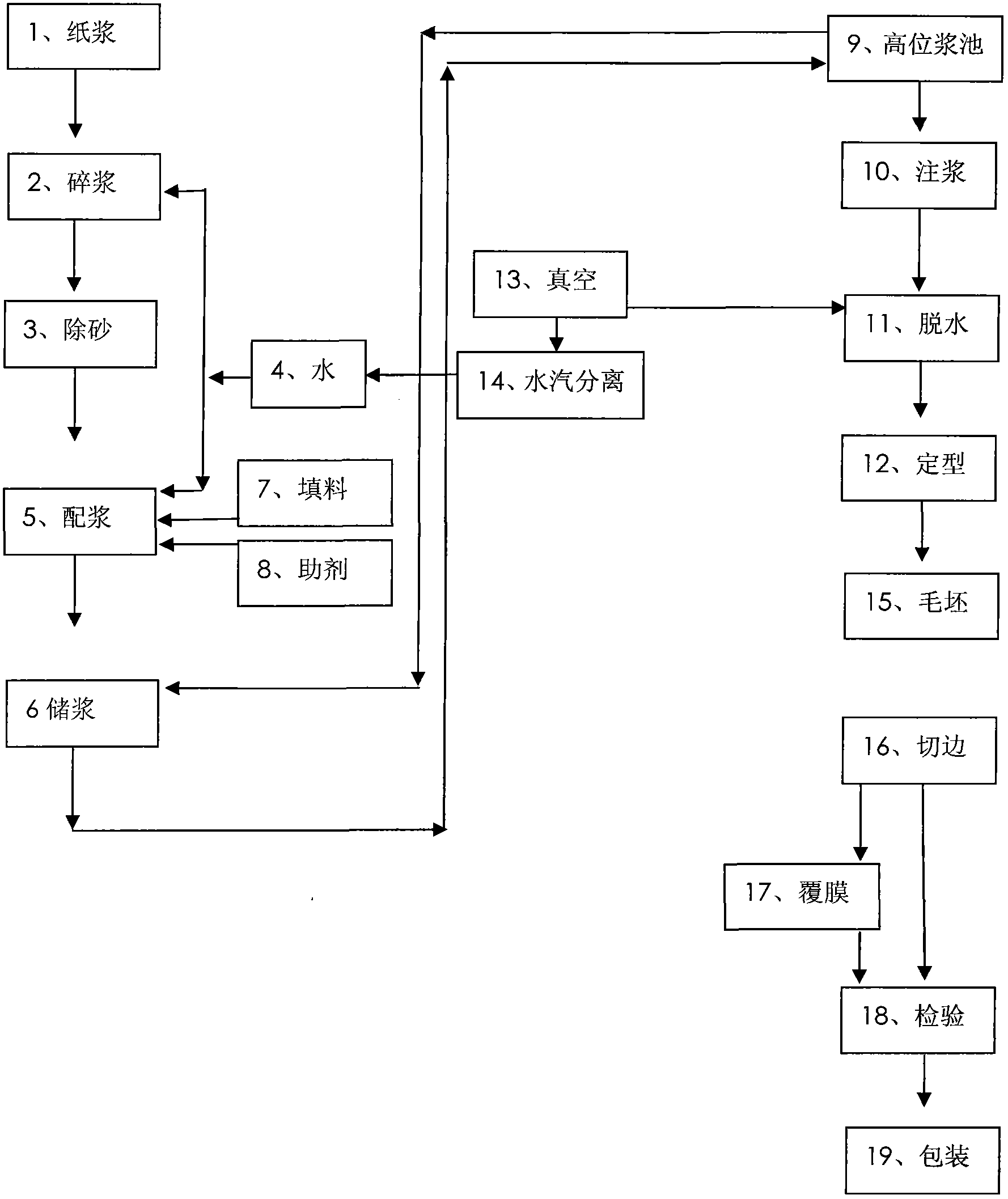

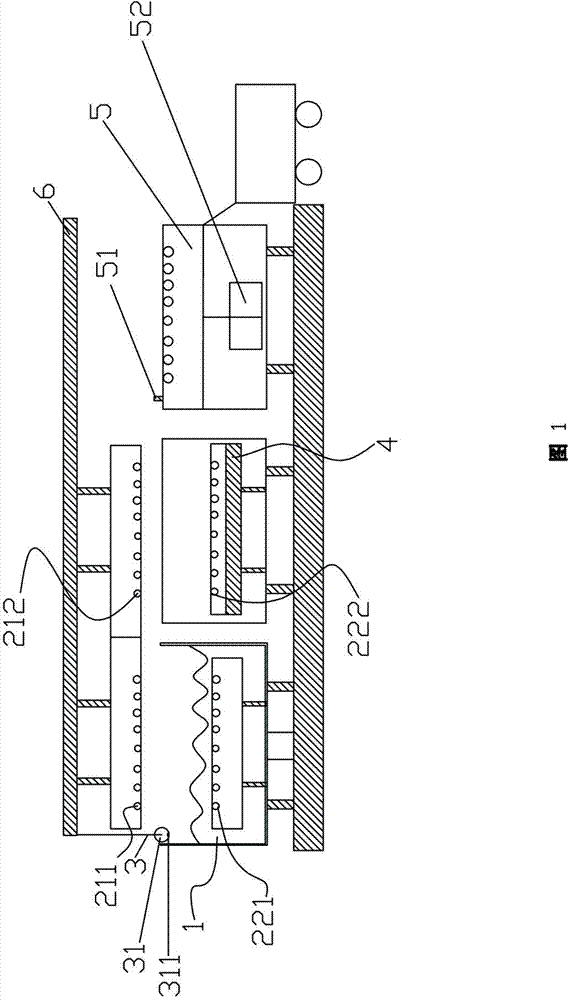

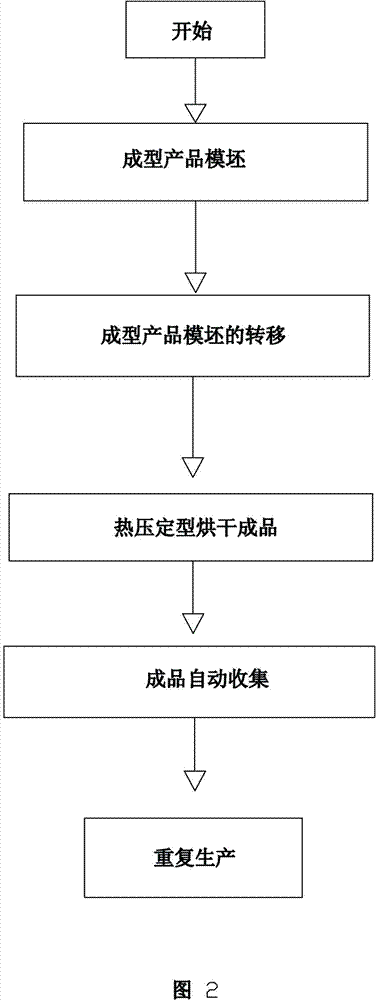

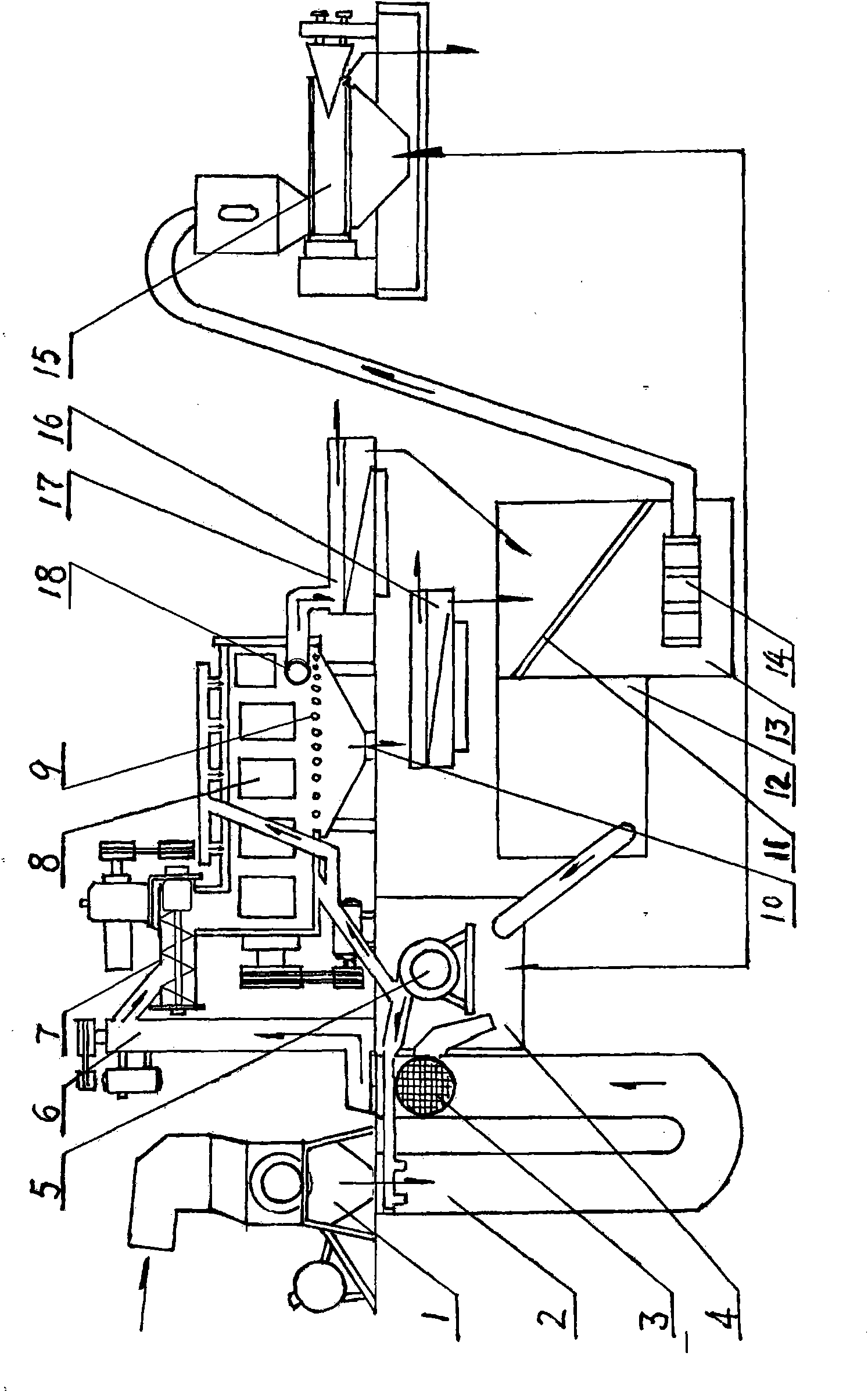

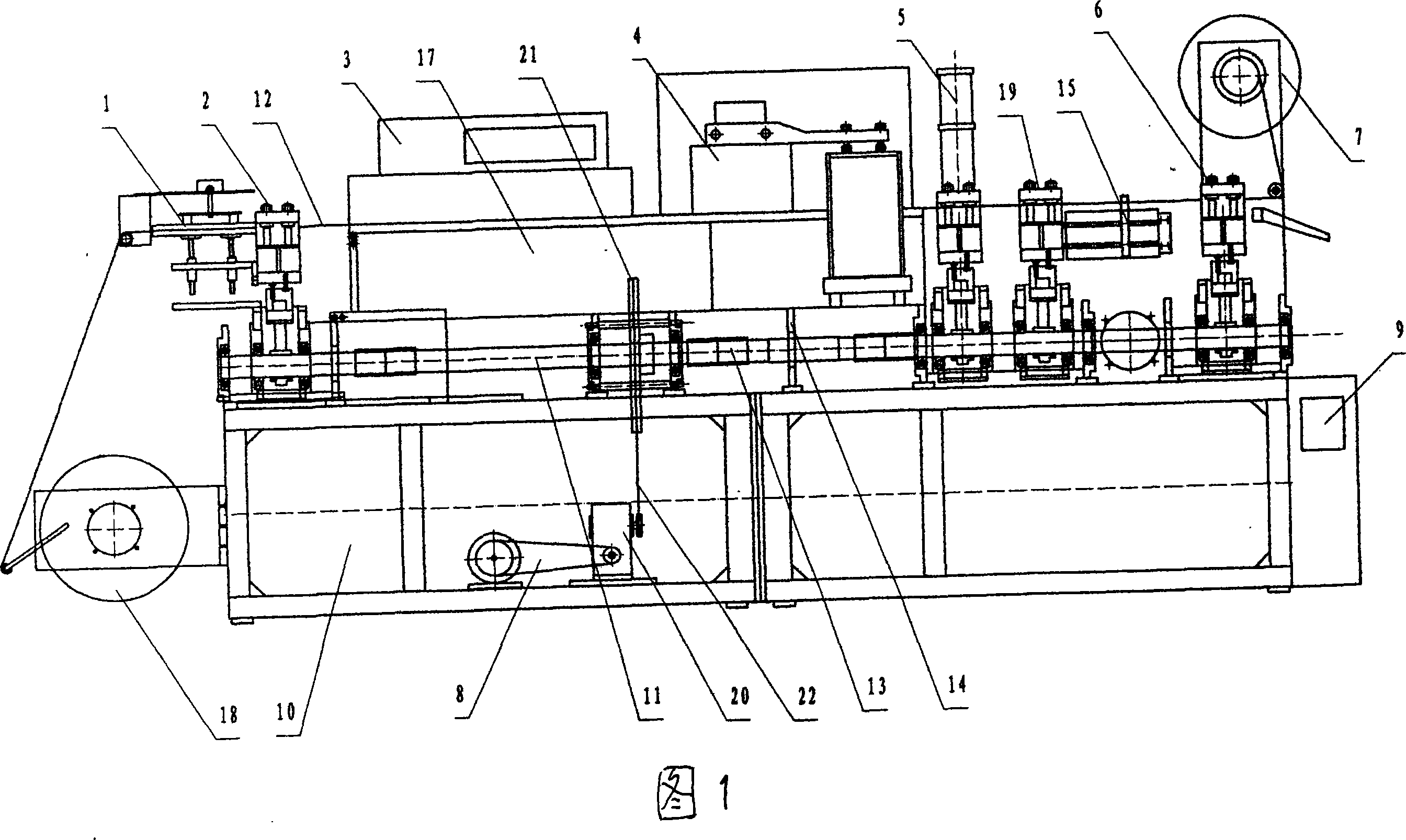

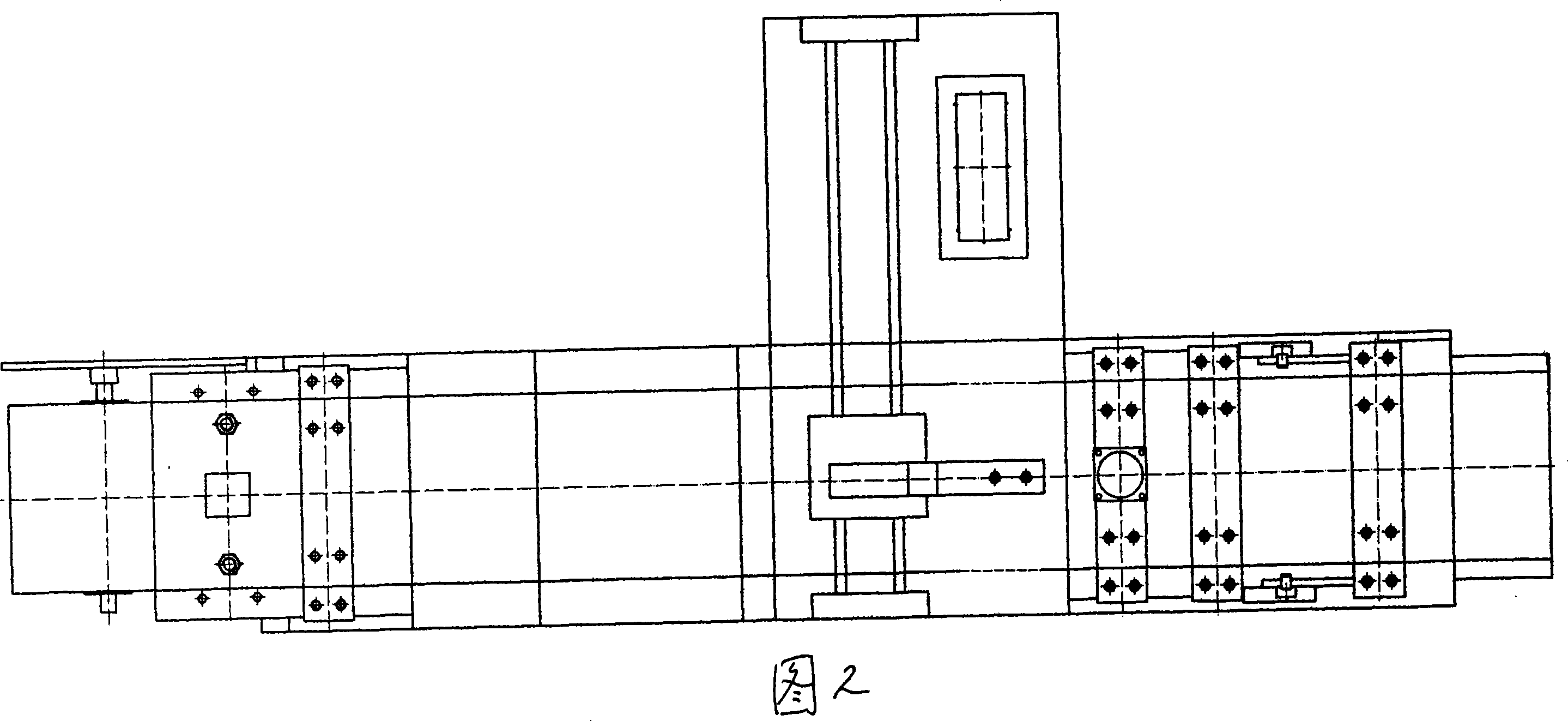

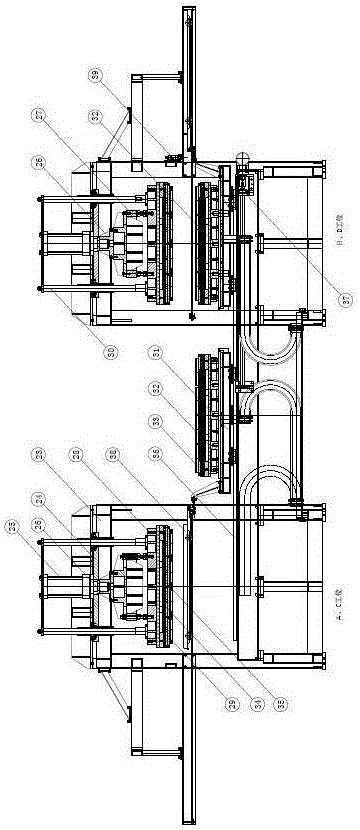

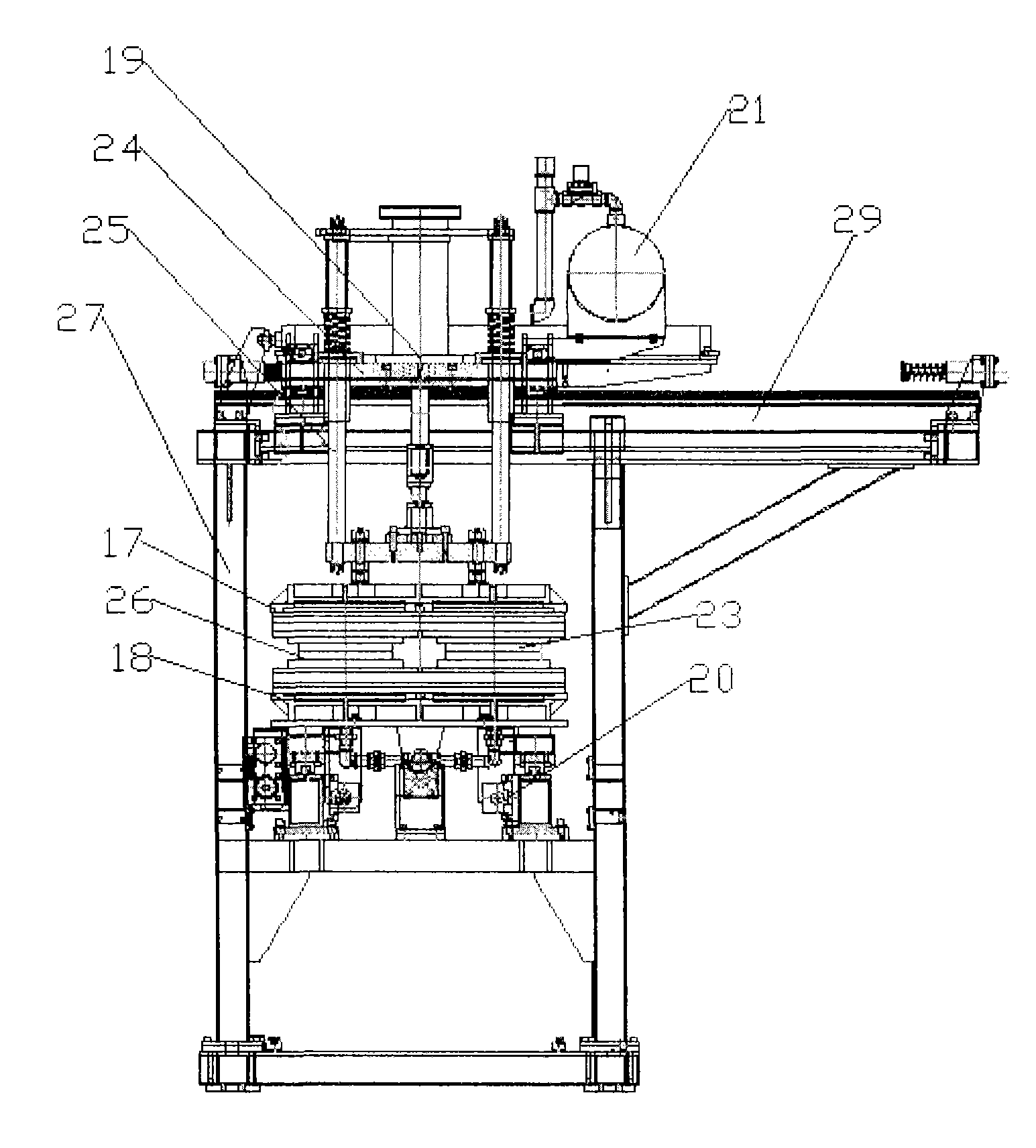

Automatic paper pulp molding and shaping one-piece combined machine and process adopted by same

ActiveCN102733268ALabor savingRealize fully automated operation managementTextiles and paperProduction rateAutomatic control

The invention relates to an automatic paper pulp molding and shaping one-piece combined machine. The machine comprises a molding pulp tank, two groups of molds, a pressure spraying trimming-free device, a hot press shaping drying device connected with heat conduction oil, and a product automatic collecting device, wherein each mold comprises a molding mold and a shaping mold; the pressure spraying trimming-free device is arranged above the molding pulp tank in a mode of moving forwards and backwards; a lower die of the molding mold is arranged in the molding pulp tank; a lower die of the shaping mold is arranged in the hot press shaping drying device; and upper dies of the two groups of molds are arranged on a horizontal guide rail in a linkage mode. A process adopted by the automatic paper pulp molding and shaping one-piece combined machine comprises the steps of preparing a molding product die blank, transferring the product die blank, performing hot press shaping and drying to obtain a finished product, and performing automatic transferring, collecting and stacking of the finished product. The whole process flow adopts fully-computerized digital programming programmed automatic control operation, so that 3 / 4 manpower is saved, energy resources are saved, the production rate is improved, and the production cost is reduced.

Owner:泉州中乾机械有限公司

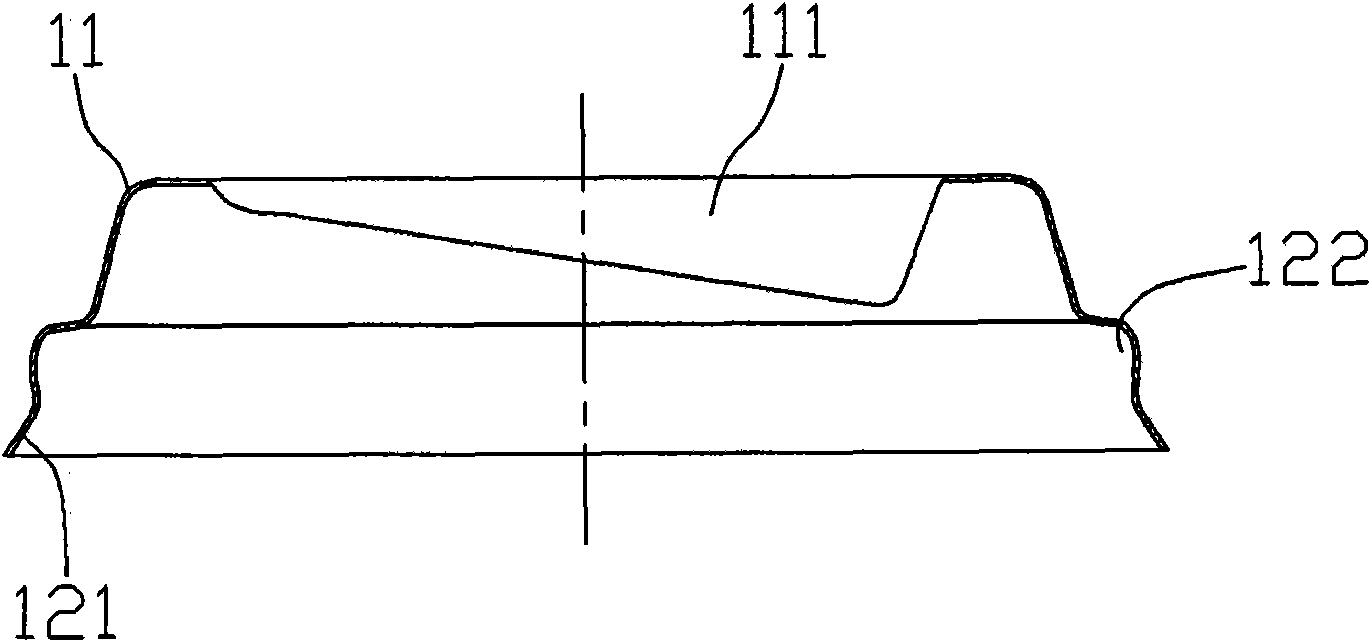

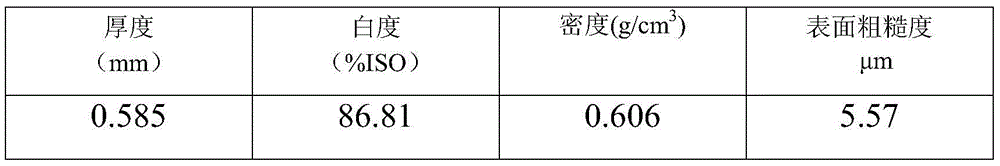

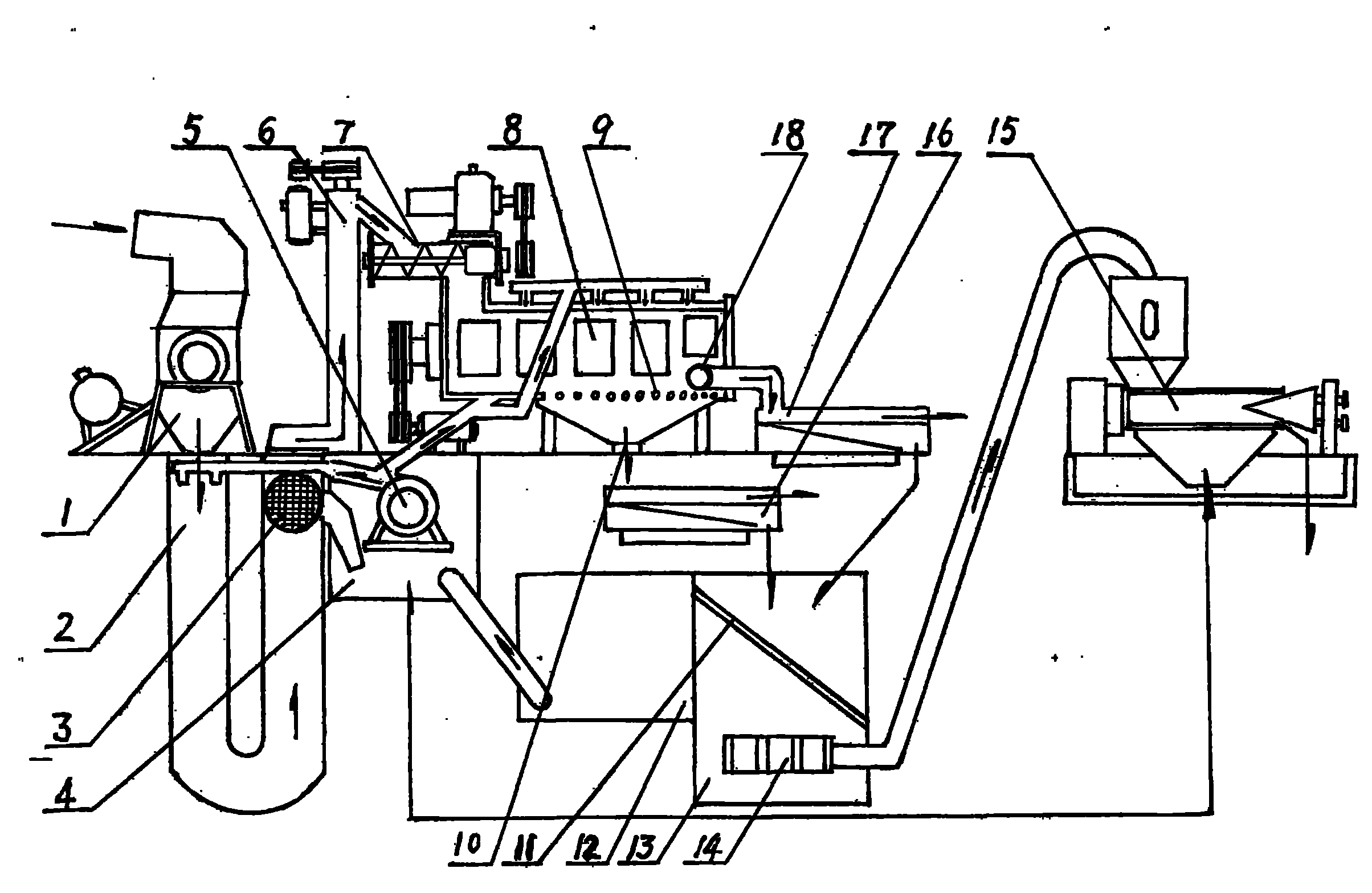

Method for producing 20 tons of molded pulp products per day

InactiveCN105568777AEasy to degradeNo pollution in the processWater-repelling agents additionReinforcing agents additionMolded pulpFiber

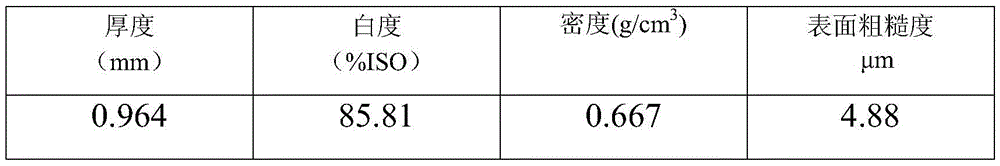

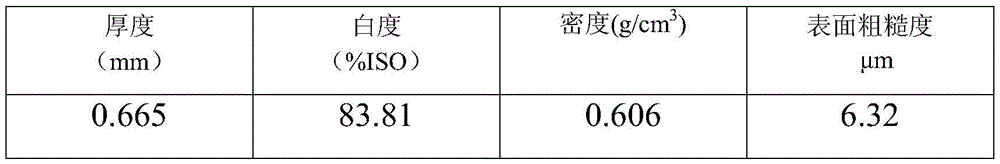

The invention belongs to the technical field of molded pulp packaging materials and particularly relates to a method for producing 20 tons of molded pulp products per day. The method adopts plant fiber materials as raw materials; with adoption of the method, wood pulp, bamboo pulp and bagasse pulp can be mixed and pulped on the premise of control of lower production cost, the beating degree is about 20-25 degrees SR, then a waterproof agent and a reinforcing agent are added to the mixed pulp, then an easy-to-degrade paper high-end packaging material is prepared from the mixed pulp through a molded pulp molding machine, and finished products of the molded pulp products are obtained finally through die cutting. The whiteness of the finished products is as high as 84%-86% ISO, and the surface roughness is 4-6 mu m. The prepared molded pulp products belong to green packaging, and wood pulp is not used in the raw materials, so that good environmental protection effect is realized; the produced materials are easy to degrade, are free of environmental pollution, have good durability and sufficiently meet the ideas of environmental protection and sustainable development.

Owner:SOUTH CHINA UNIV OF TECH

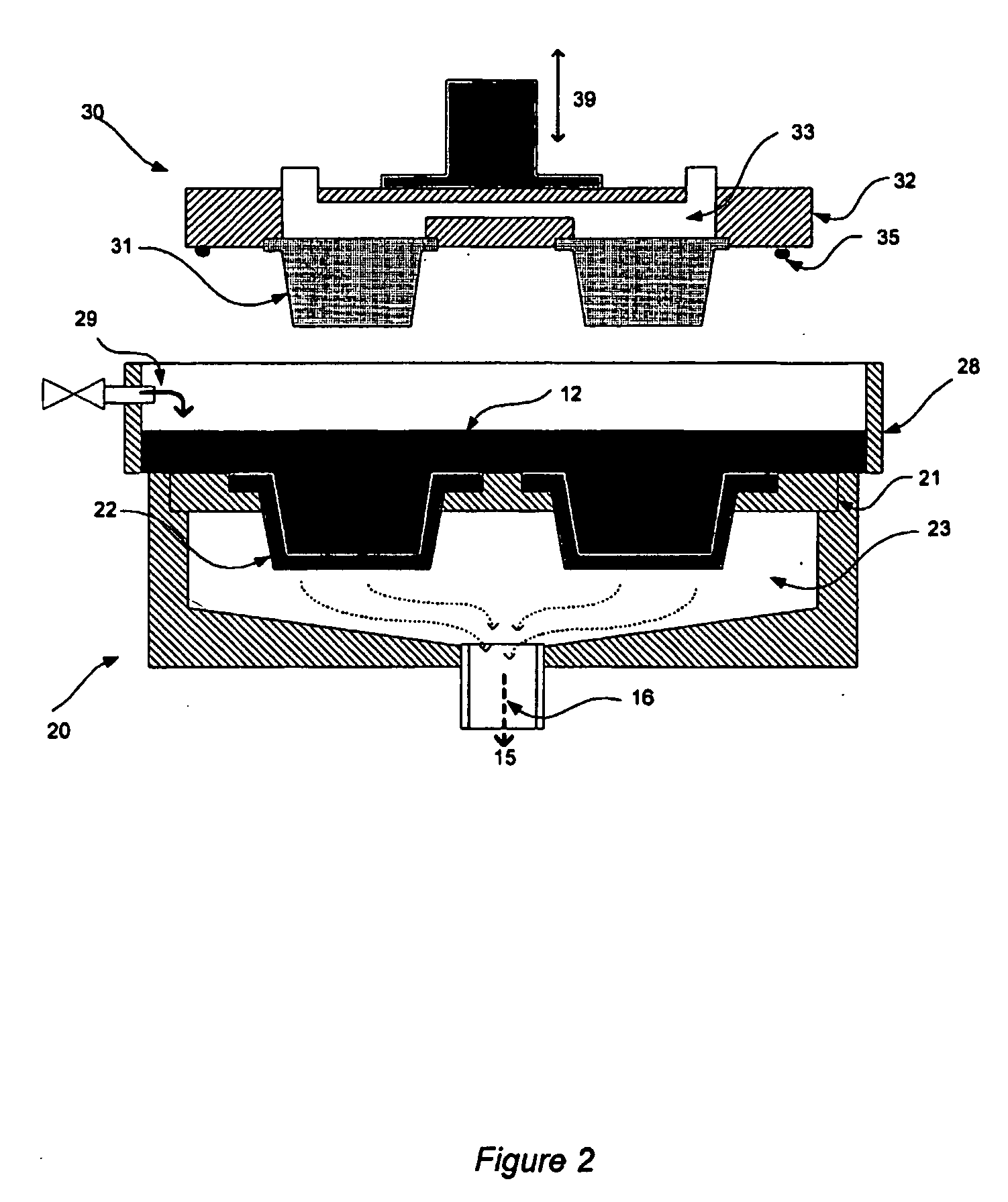

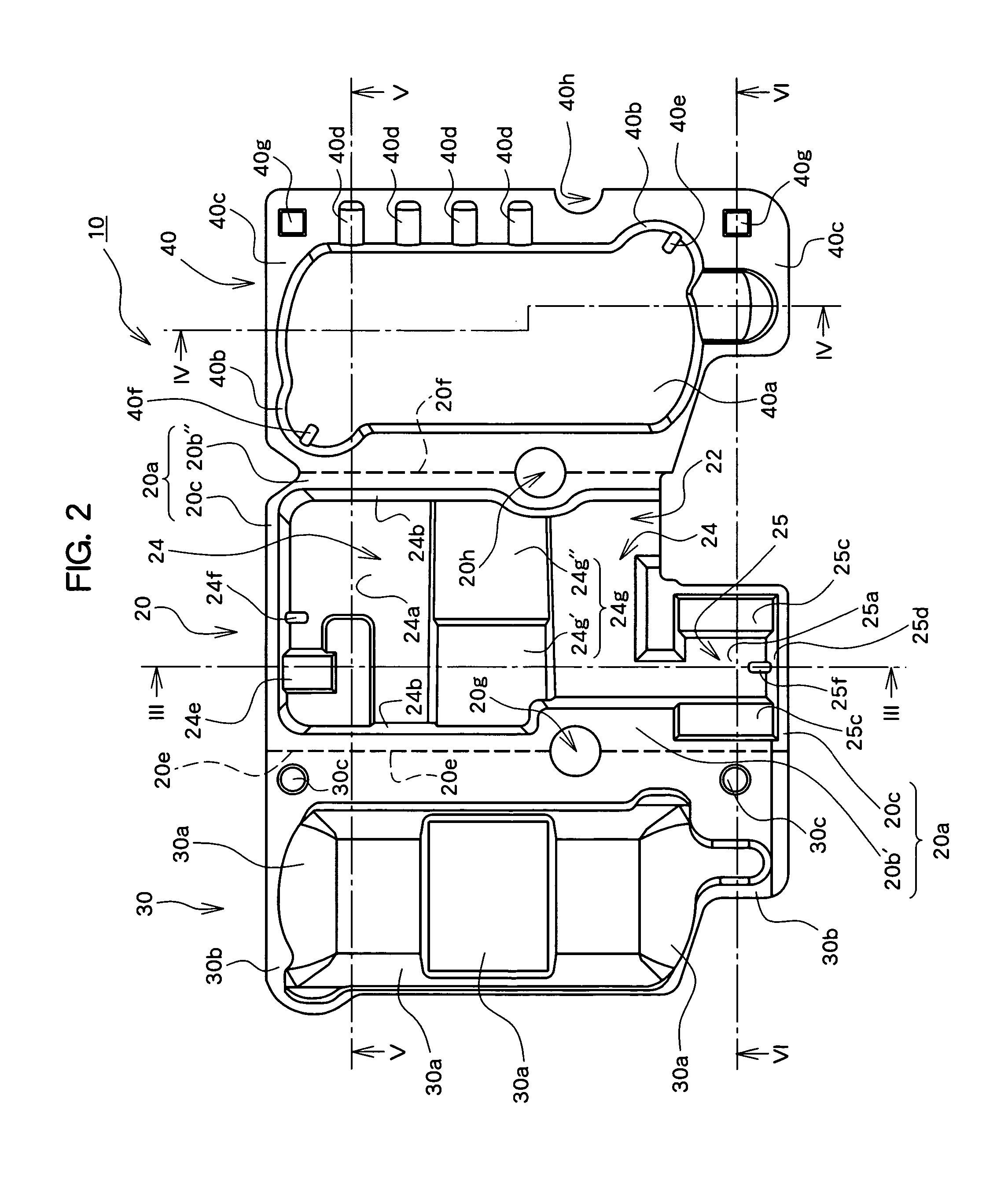

Molded pulp container

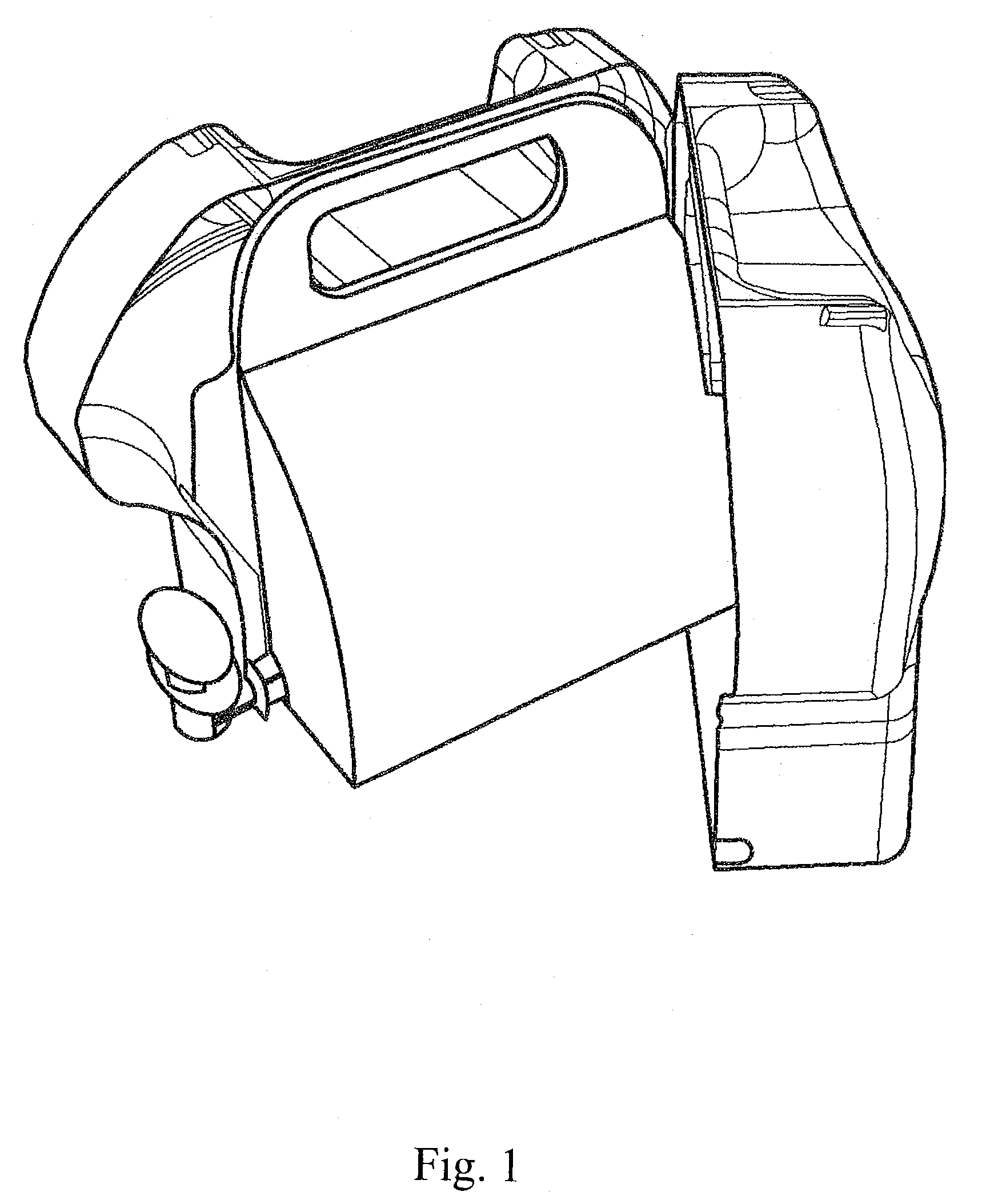

ActiveUS20060289665A1Easy to operateAir-treating devicesOther heat production devicesMolded pulpEngineering

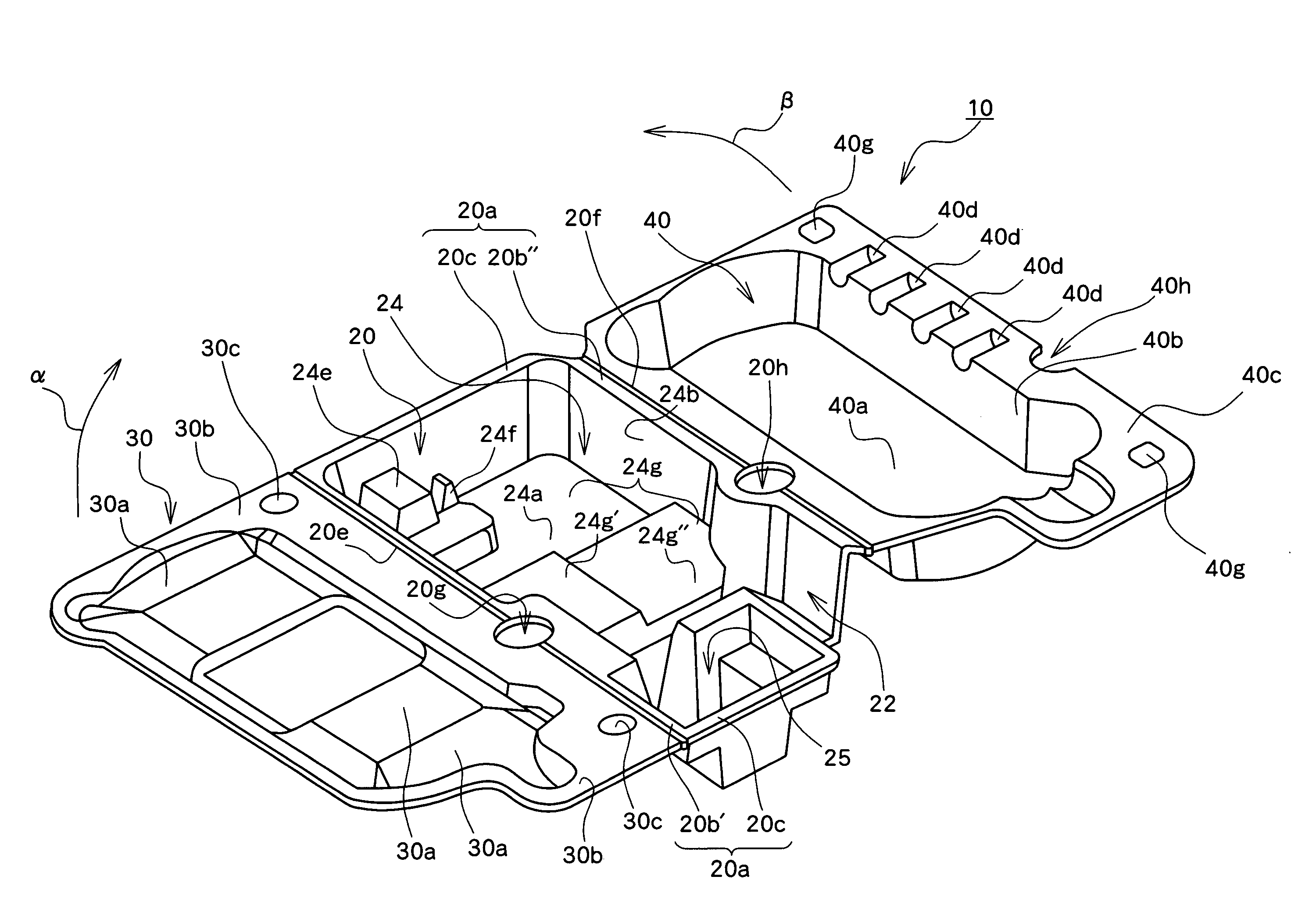

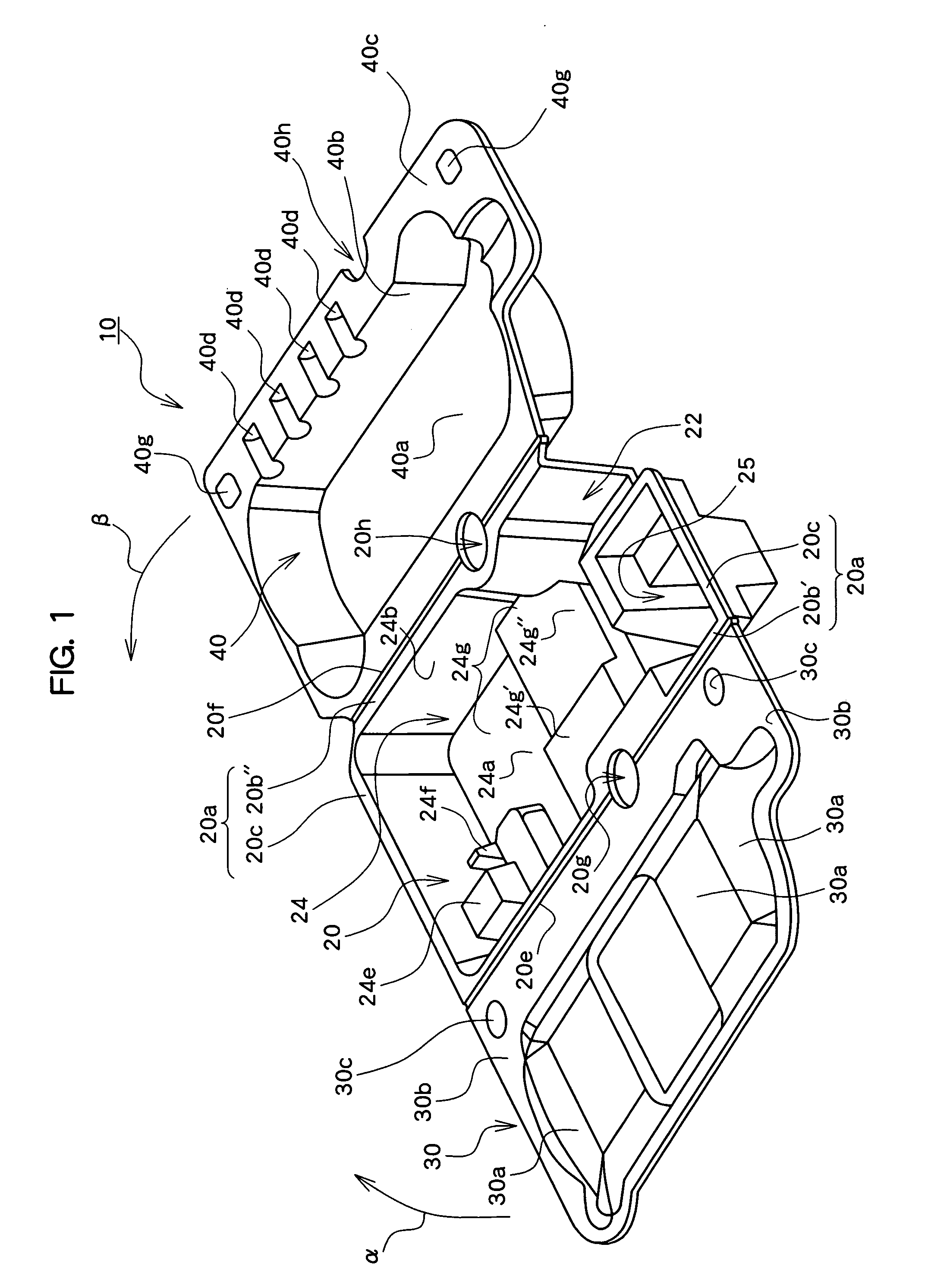

The invention provides a container which can store a product which is constituted of a plurality of devices therein integrally and in a compact manner, and can also facilitate the packing of the product. A molded pulp container includes a storing recessed portion which has an opening at an upper surface thereof and is molded in conformity with a shape of a first material to be stored, a partition portion which is connected to the brim portion of the opening of the storing recessed portion and is foldable toward the storing recessed portion side to be placed on at least a portion of the brim portion of the storing recessed portion and, at the same time, forms a base on which a second material to be stored is placed, and a lid portion which is molded in conformity with a shape of the second material to be stored and is connected to the brim portion formed on the storing recessed portion and is folded to the storing recessed portion side to cover the partition portion from above.

Owner:SONY COMPUTER ENTERTAINMENT INC

Single-component polyurethane hot-melt adhesive for paper-plastic lamination and preparation method thereof

The invention specifically relates to a single-component polyurethane hot-melt adhesive for paper-plastic lamination and a preparation method thereof, belonging to the technical field of polyurethane. The hot-melt adhesive is prepared by reacting crystalline polyester polyol, amorphous polyester polyol, polyether polyol and a chain extender with isocyanate. The moisture-cured type single-component polyurethane hot-melt adhesive has high initial bonding strength, good finished-product friction coefficient and excellent temperature toleration and is applicable to flow line production; and the hot-melt adhesive has excellent environmental protection performance and is applicable to lamination of a variety of paper and plastic films.

Owner:南通恒华粘合材料科技有限公司

Production process for separating and recycling paper-plastic composites

InactiveCN102091714AScientific and reasonable processHigh recovery rateSolid waste disposalPlastic recyclingMolded pulpEconomic benefits

The invention discloses a production process for separating and recycling paper-plastic composites, which relates to the production process for separating and recycling the paper-plastic composites and is characterized by comprising the steps of: crushing the paper-plastic composite materials by a crusher, hydrothermally degrading the composite materials in a soaking and cleaning tank, removing paper by a paper removing machine so as to separate paper from plastic, mixing the separated paper with water to obtain pulp, filtering and dehydrating the pulp to obtain finished pulp, and preparing the separated plastic into plastic products by a plastic extruding machine. The production process has the following benefits: 1. the process is scientific and reasonable, the paper-plastic composites can be separated and recycled without adding any chemical material or heating, therefore, the process saves time and labor and is safe and efficient; 2. the paper-plastic composites can be separated thoroughly with the recycle rate, paper and plastic can be totally separated and recycled, and the economic benefit is good; 3. water can be recycled completely, and precious water resources can be saved; and 4. the process does not pollute environment.

Owner:巨锋

Reclosable display package and method of use

InactiveUS20130062342A1Easy to closeEasy to openCapsBoxes/cartons making machineryMolded pulpInterference fit

A reclosable package for packaging an article is provided with a plastic door component and a separate tray that cooperate to form an article containing cavity. The tray may be manufactured from a paper pulp material, such as molded pulp. The door component and tray may be installed between a pair of panels. The door component may include a door portion and a flange portion joined along a hinge. The flange portion may be sandwiched between the panels to hold the door component in place. The door portion may be movable about the hinge to allow the package to be opened and closed. The door portion may interface with the door panel in a way that resists movement of the door portion between the open position and the closed position. The door portion may include snap elements configured to have an interference fit with the door panel.

Owner:DISPLAY PACK

Fully-automatic thermal-formation paper-plastic package technology and packing machine

An auto heat formed paper model packing process: first to use the rolling device to roll the plastic material and form the plastic sheet which is transformed to the heating and module device to make it module; then it is filled with the need material by the filling device and cover with the paper sheet by the sealing device and sealed in the sealing device; last to form the paper plastic packing product by the blanking device. The transform of the packing material and the collect of the waste edge material are controlled by the pushing device and the waste material collecting device. The automatic heat form paper plastic packing machine: the above devices are installed on the frame which is connected with the board by the transmission shaft which is connected with the power transport unit; the above devices which are all connected with the micro computer controlling device. The process of rolling, heat forming, fill and sealing, blanking are finished automatically, so it can decrease the human power and the cost.

Owner:潘震州

Water-emulsion type paper-plastic composite adhesive and method for preparing same

InactiveCN101338175AGood adhesionImprove moisture resistanceRosin adhesivesMolded pulpDispersed media

The invention discloses a water emulsion paper plastic composite adhesive which comprises the compositions with the weight portions of 2-8 portions of SBS resin, 2-8 portions of EVA resin, 2-12 portions of mixed solvent, 15-25 portions of tackifying resin, 1-25 portions of polyvinyl alcohol, 1-3 portions of composite emulsifier and 20-30 portions of water. After the mutual solution of the SBS resin, the EVA resin, the mixed solvent and the tackifying resin in the compositions and the emulsification of water phase solution prepared from the composite emulsifier, water and the polyvinyl alcohol, the latex adhesive with the viscosity of 500-2500MPa.s and less than 0.6 percent of the water absorption rate is obtained. The adhesive takes water as dispersing medium and has the characteristics of environmental friendly performance of water emulsion laminating adhesive, transporting and storing safety, high adhering strength and good humidity resistance of solvent laminating adhesive, etc. The deficiencies of present solvent laminating adhesive and acrylic water emulsion laminating adhesive are solved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Grass fiber bio-separation compound preparation and application method thereof

The invention discloses a grass fiber bio-separation compound preparation and an application method thereof. The grass fiber bio-separation compound preparation comprises bacteria components and enzyme components, wherein the bacteria components comprise white rot fungi and zymogeneous bacteria, and the enzyme components comprise cellulose, xylanase, laccase, protease, thermostable amylase, ligninase and pectinase. According to the grass fiber bio-separation compound preparation, straw serving as the raw material is treated with a biological method, a biological cycle liquid and a waste cooking liquid produced in the treatment process can be recycled without drainage, and lignin can be extracted; and besides, according to the method, straw does not require cutting and dust removal, and the cooking does not require high temperature and high pressure, so that a large quantity of manpower and electric charges is omitted, and the preparation and the method are suitable for a plurality of raw materials such as wheat straw, straw, cotton stalks, reeds and the like, can be used for producing a paddle board, molded pulp, various types packaging paper, office paper and household paper and have the advantages of low cost and environment protection.

Owner:北京秸大环保科技有限公司

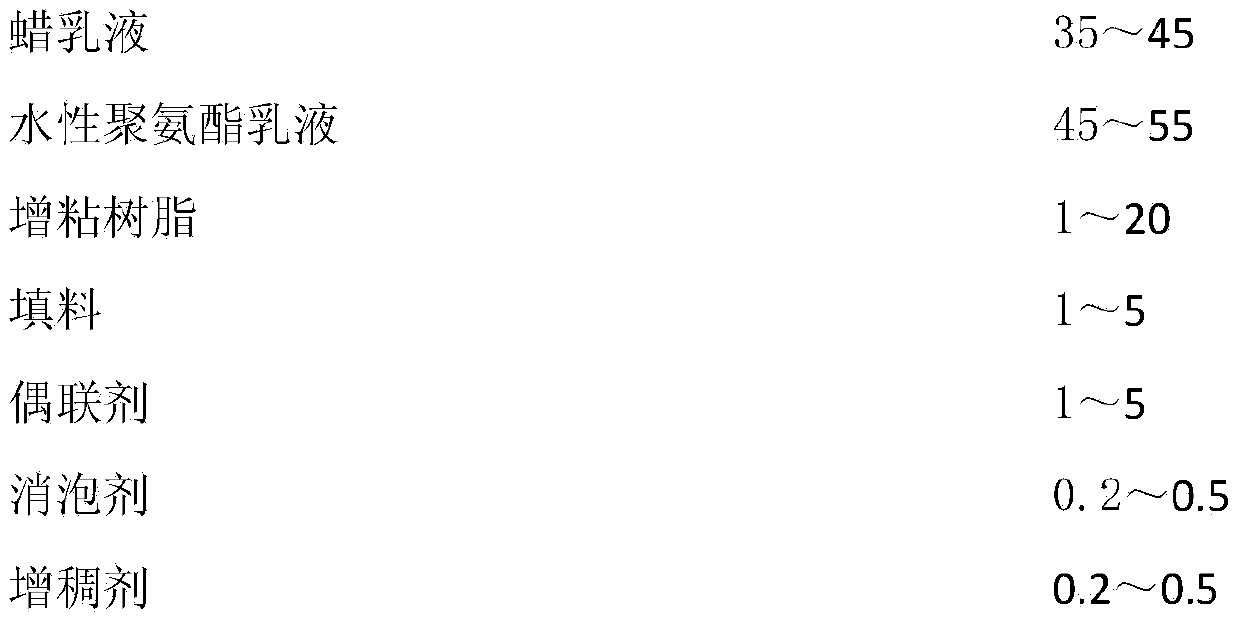

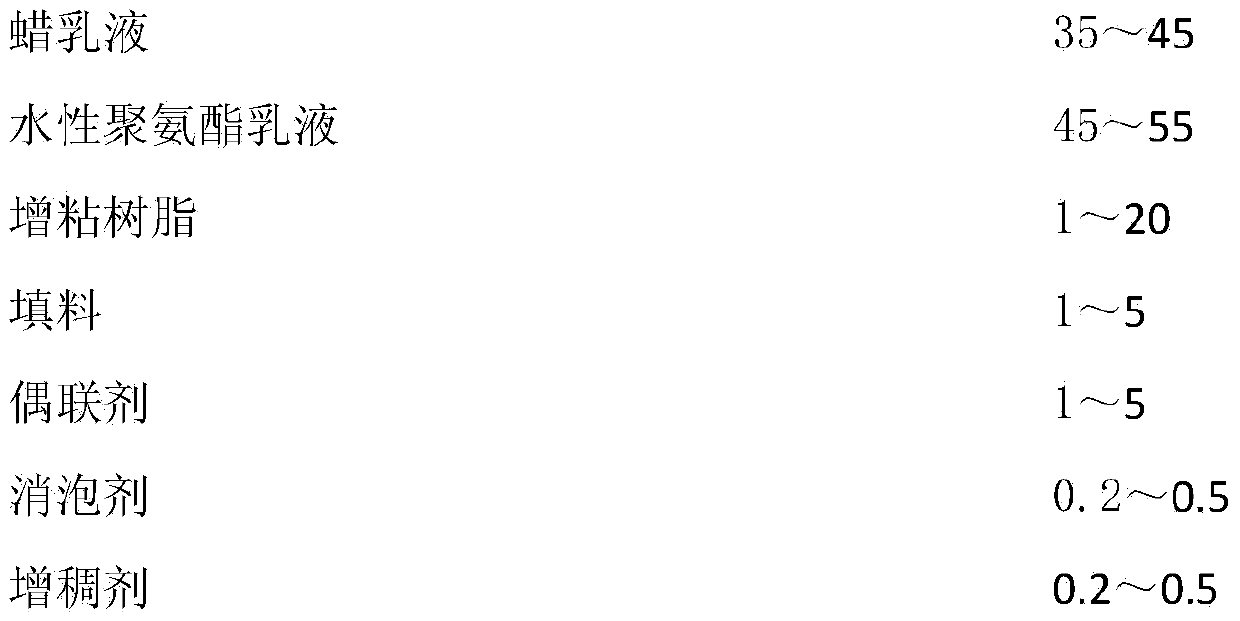

Water-based paper and plastic laminating/peelable adhesive and method for manufacturing same

InactiveCN103421461AGood adhesionAdhesivelyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWaxWater based

The invention discloses water-based paper and plastic laminating / peelable adhesive and a method for manufacturing the same. The water-based paper and plastic laminating / peelable adhesive comprises, by mass, 35-45 parts of wax emulsion, 45-55 parts of water-based polyurethane emulsion, 1-20 parts of tackifying resin, 1-5 parts of additives, 1-5 parts of coupling agents, 0.2-0.5 part of defoamers and 0.2-0.5 part of thickeners. The water-based paper and plastic laminating / peelable adhesive and the method have the advantages that the wax emulsion, the water-based polyurethane emulsion, the additives, the tackifying resin, the coupling agents, the thickeners and the defoamers are compounded with one another to finally manufacture the water-based paper and plastic laminating / peelable adhesive, the water-based paper and plastic laminating / peelable adhesive is high-temperature-resistant and is high in initial adhesion, permanent adhesion and peel strength when used for laminating paper and plastics, the paper cannot be torn by an adhesion surface of a film when separated from the plastics, and is prevented from being damaged, and the adhesion surface is not sticky after the paper is separated from the plastics.

Owner:SOUTH CHINA UNIV OF TECH

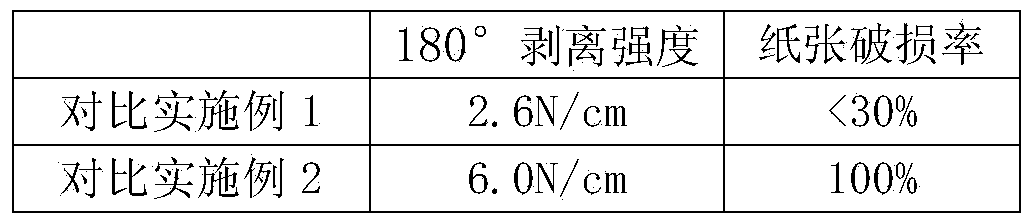

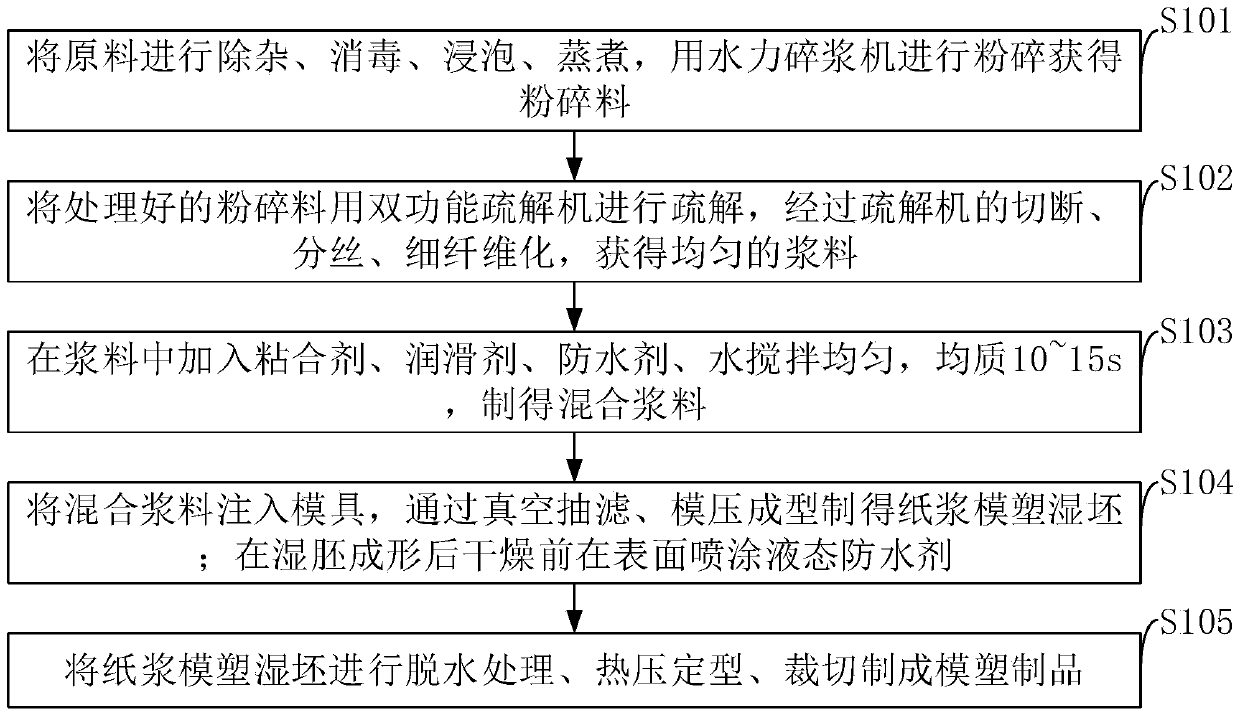

Environment-friendly molded pulp formation method and product

InactiveCN109797604ANo environmental pressureReduce dosageWater-repelling agents additionNon-woody plant/crop pulpMolded pulpShell molding

The invention discloses an environment-friendly molded pulp formation method. The method comprises the steps that raw materials are subjected to impurity removal, sterilization, soaking and boiling, and a hydrapulper is used for conducting smashing to obtain a smashed material; the treated smashed material is defibered for obtaining an even pulp; the mixed pulp is prepared; a molded pulp wet blankis made; after the wet blank is formed, before the wet blank is dried, the surface of the wet blank is sprayed with a liquid-state waterproof agent; the molded pulp wet blank is dewatered, subjectedto hot press formation and cut to a molding product. The product made through the environment-friendly molded pulp formation method is an environment-friendly degradable material, and after being wasted, the material can be directly discarded and naturally degraded into soil for planting or smashed and reduced into the soil for planting for reuse or discarding; according to the method, the application quantity of chemical products is greatly lowered, and plain boiled water can also be more clean. The surface of the product is coated with the material, no chemical product exists in the product,the production cost is reduced, and the environment-friendly performance is better.

Owner:杭州西红柿环保科技有限公司

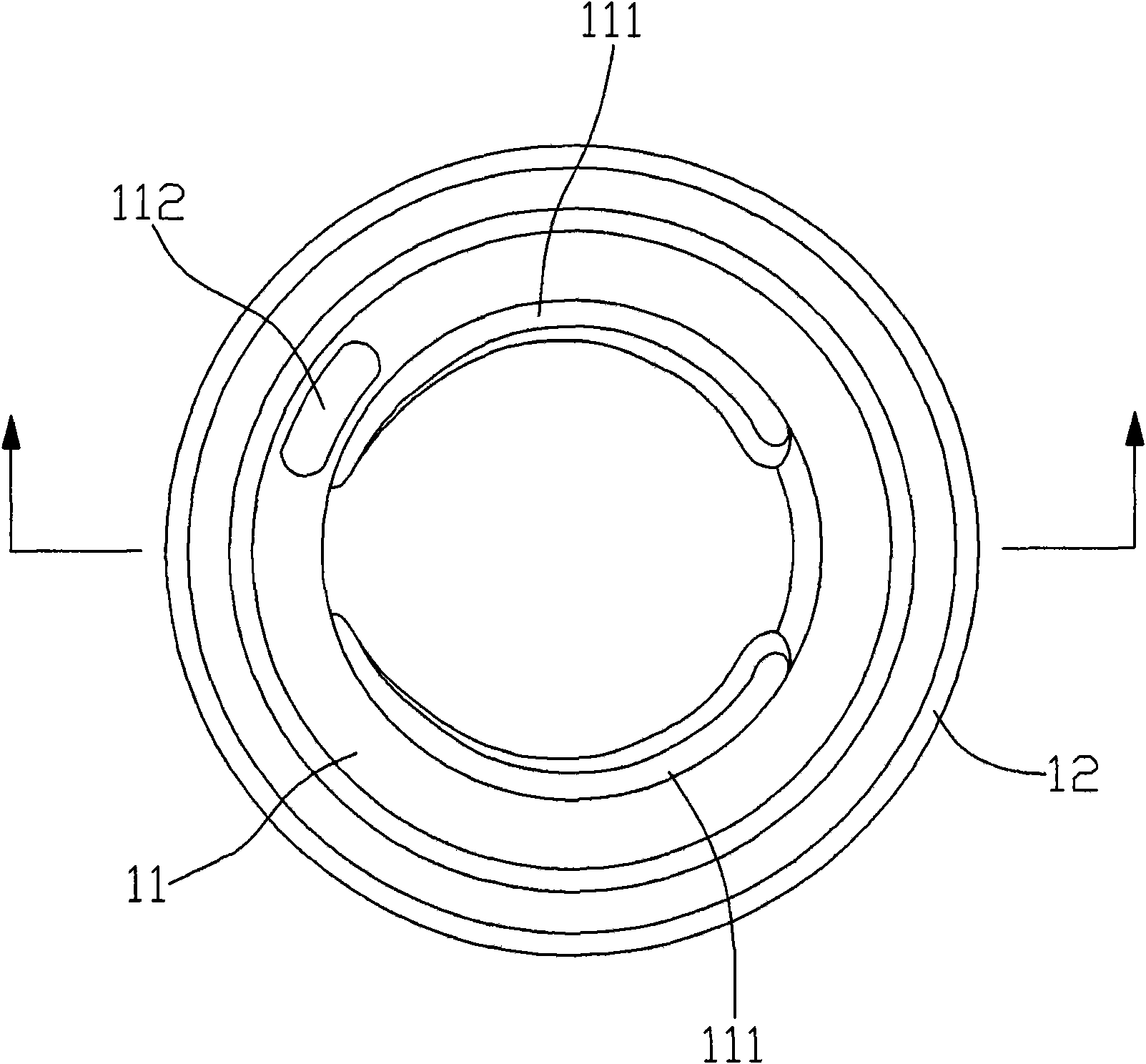

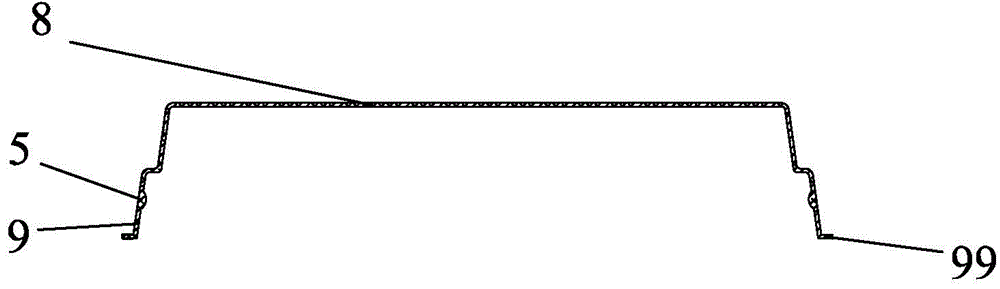

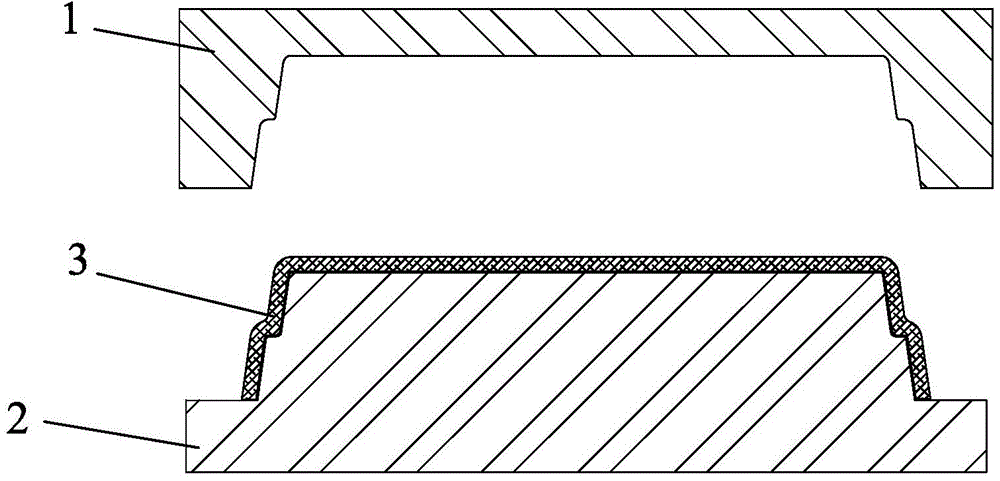

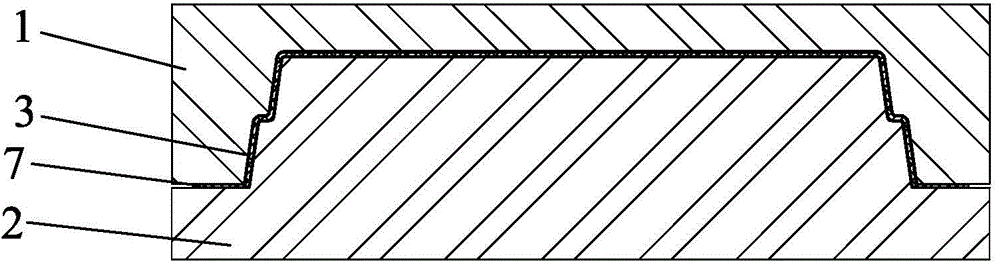

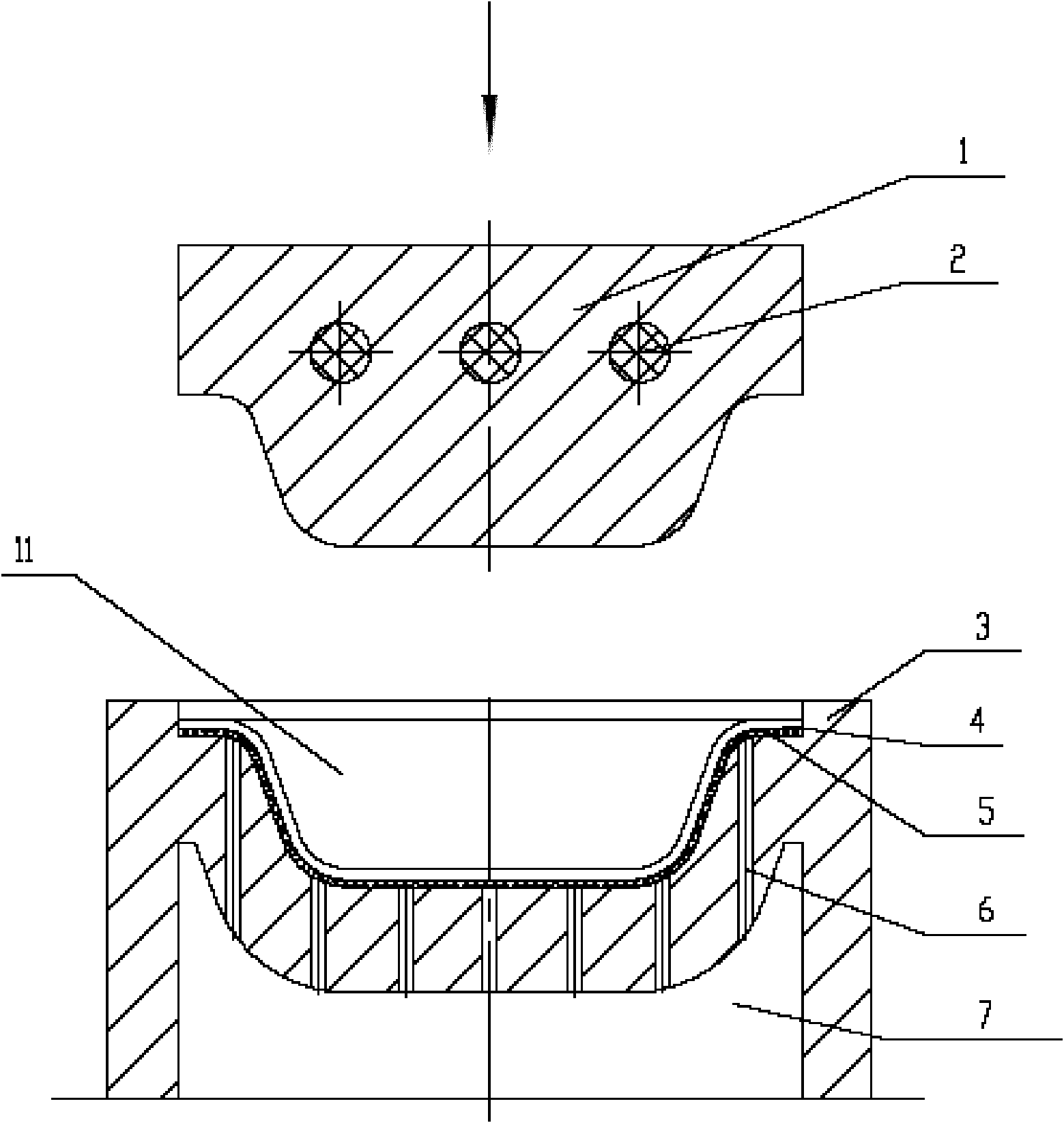

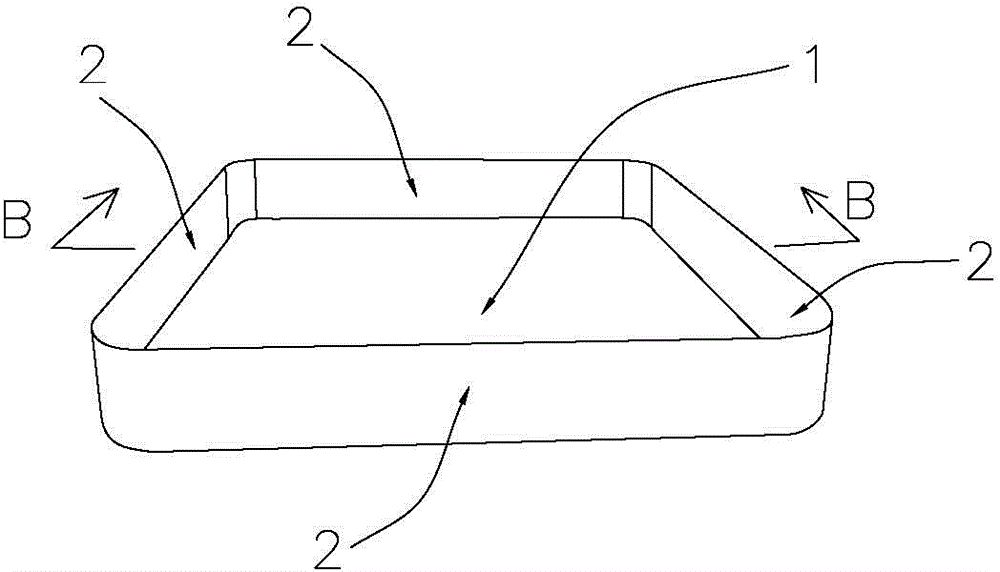

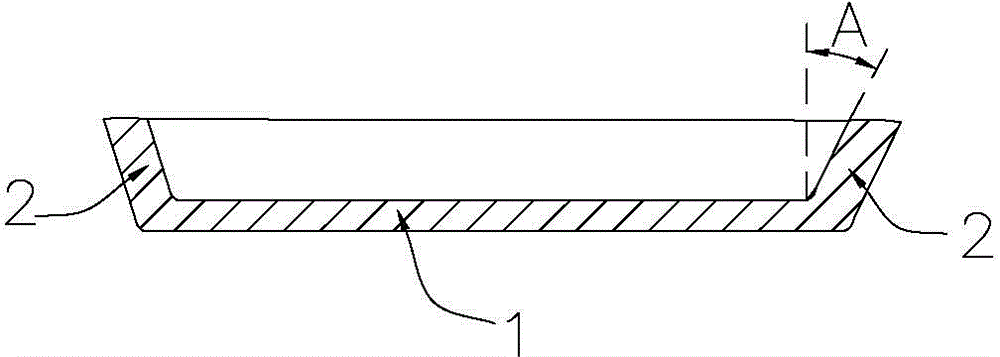

Molded pulp container cover with clamping tenon, mold for manufacturing container cover and manufacturing method

ActiveCN103603234ADoes not affect normal opening and closingIncreasing the thicknessRemovable lids/coversTextiles and paperMolded pulpShell molding

The invention discloses a molded pulp container cover with a clamping tenon. The molded pulp container cover comprises a middle cover top and a downward-inclining cover opening (9) externally arranged around the cover top, wherein the middle of the inner side of the cover opening (9) is provided with an inward-protruding clamping tenon (5) in the peripheral direction. The clamping tenon (5) is solid. The protruding height of the clamping tenon is larger than the thickness of a cover opening body for 0<h<=1mm. The invention further provides a mold for manufacturing the container cover. The middle of the side of a male mold is provided with an arc-shaped groove (4) in the peripheral direction, and the depth of the arc-shaped groove is 0<h<=1mm. In the hot-pressing shaping process, the solid clamping tenon is directly manufactured by utilizing an increased gap between the male mold and a female male while wet paper blank hot-pressing shaping. The manufactured molded pulp container cover has the advantages of being low in manufacture cost and high in strength.

Owner:江峰

Bottle shipment packaging and method

ActiveUS8434620B2Preserving aesthetic labelingMaintaining the integrity of the bottleWrappersSolid materialCardboardFiber

A bottle packaging for shipment includes a bottom tray, and a top tray made of molded pulp fiber, such as newspaper pulp, and a cardboard partition support structure disposed between the trays. Cavities formed in the bottom and top trays are arranged to engage both ends of a bottle and include crushable elements that can axially engage each bottle. The support partition may be made of corrugated cardboard material and be arranged such that the cardboard flutes provide support for loads imparted to the sides of the carton when the carton is laying on its side. The partition forms a void surrounding each bottle in the area of its labels. In this way, structural support and cushioning can be provided to the packaged bottles from all directions.

Owner:GRAFCOR PACKAGING

Heat-able On-the-Go Food Products Apparatus and Method

A molded pulp base container sprayed with a barrier and a sealant layer, used as a heatable package for on-the-go (OTG) food products is disclosed. The container by itself, in one embodiment, is used for microwave / oven heating the food contents in the container, eliminating the need for a separate susceptor or an additional package for heating. The inside surface of the container is spray coated with a food safe poly layer to create a moisture / oxygen barrier for shelf life stability. A sealant layer is directly applied on top of the barrier layer to provide hermesicity for the container. Adding a brine solution and a percentage of sodium to the finished package formulation, selectively heats the food contents of the package while keeping the package itself cool enough to handle. In another system embodiment, a condiment package is fitted to a formed top of the container.

Owner:FRITO LAY NORTH AMERICA INC

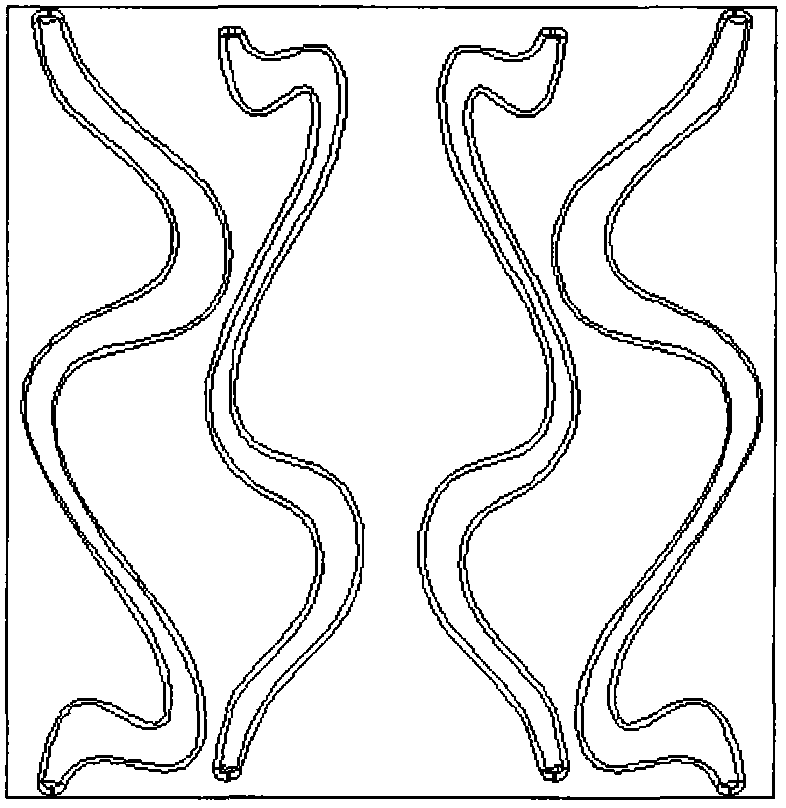

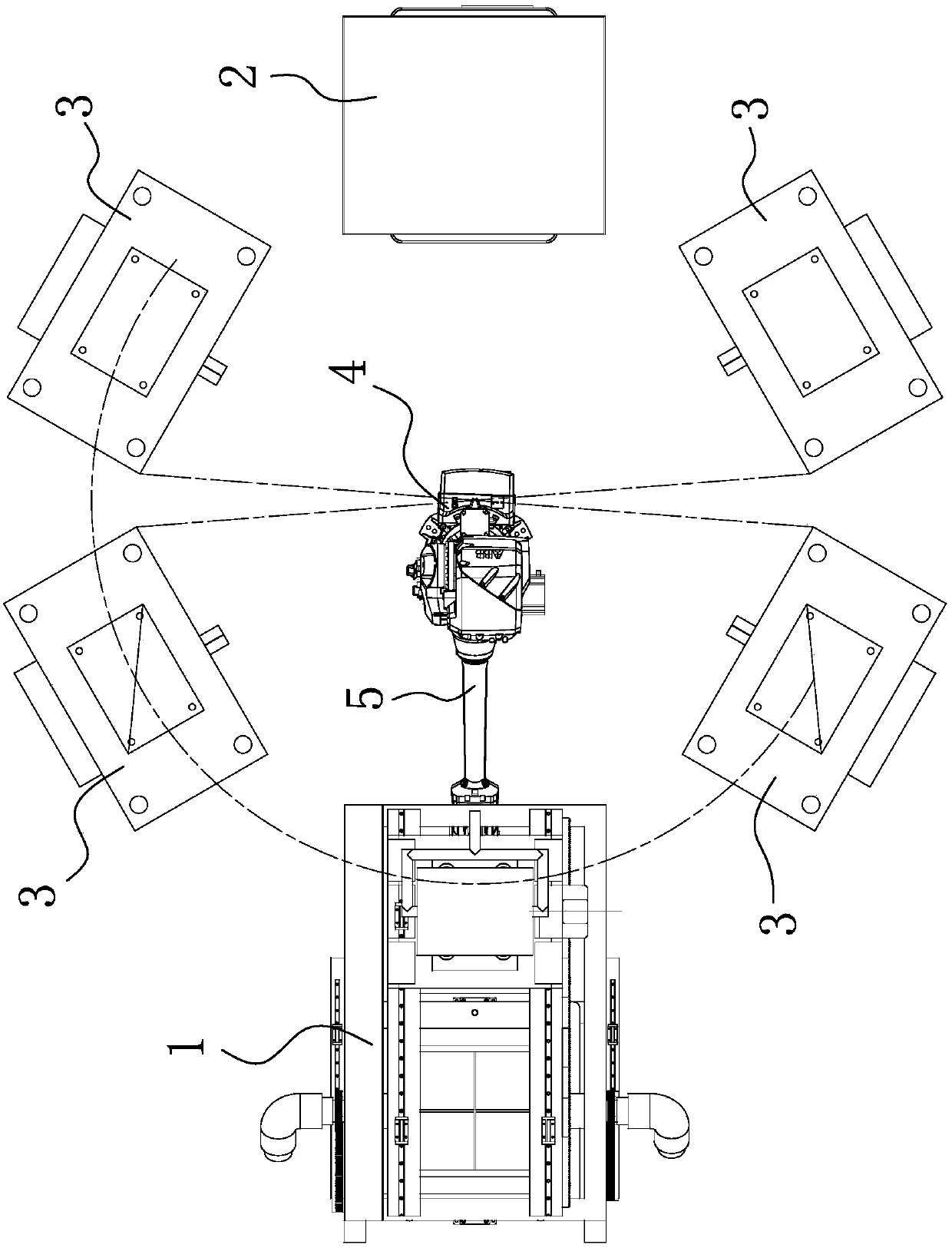

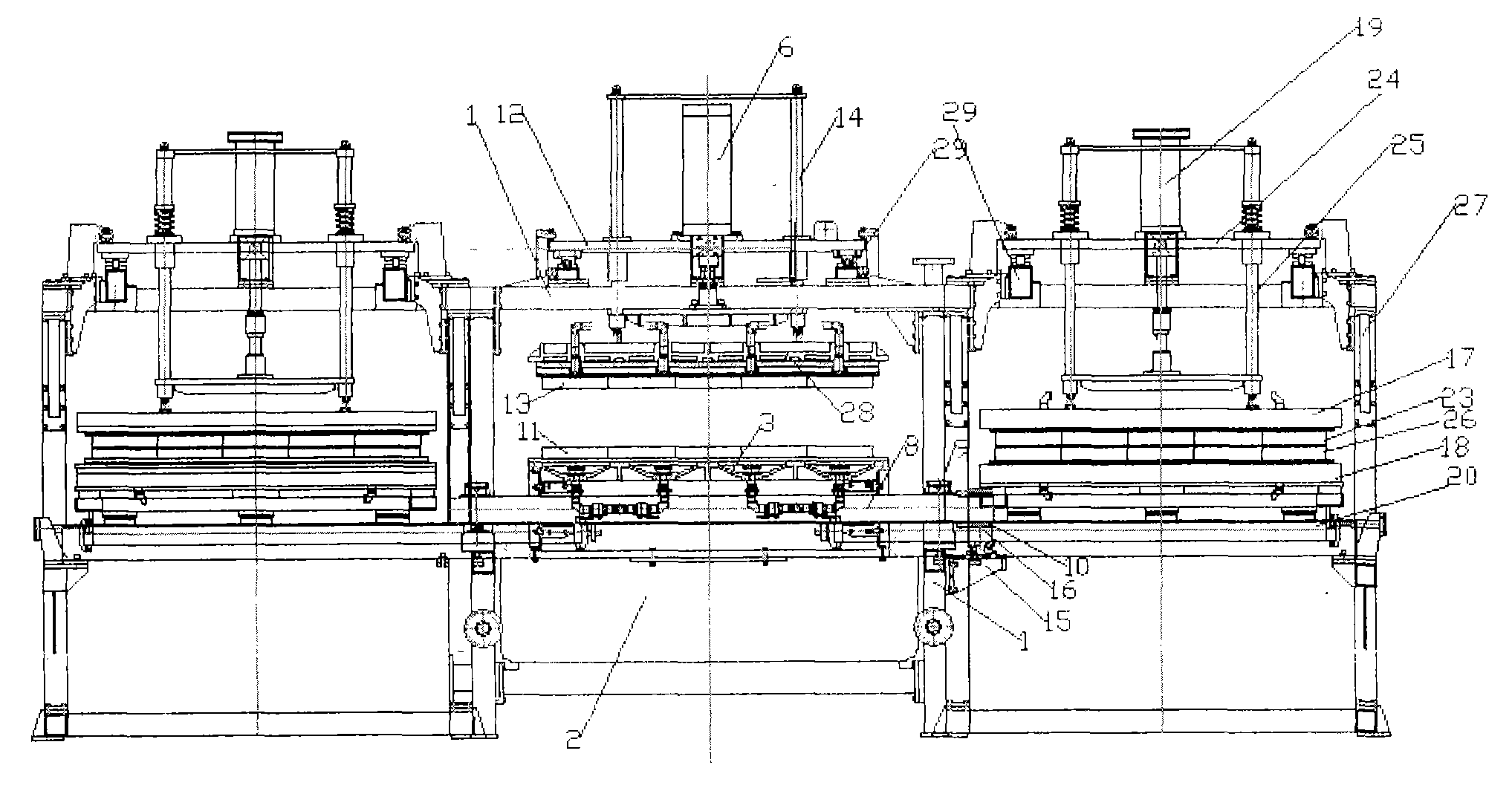

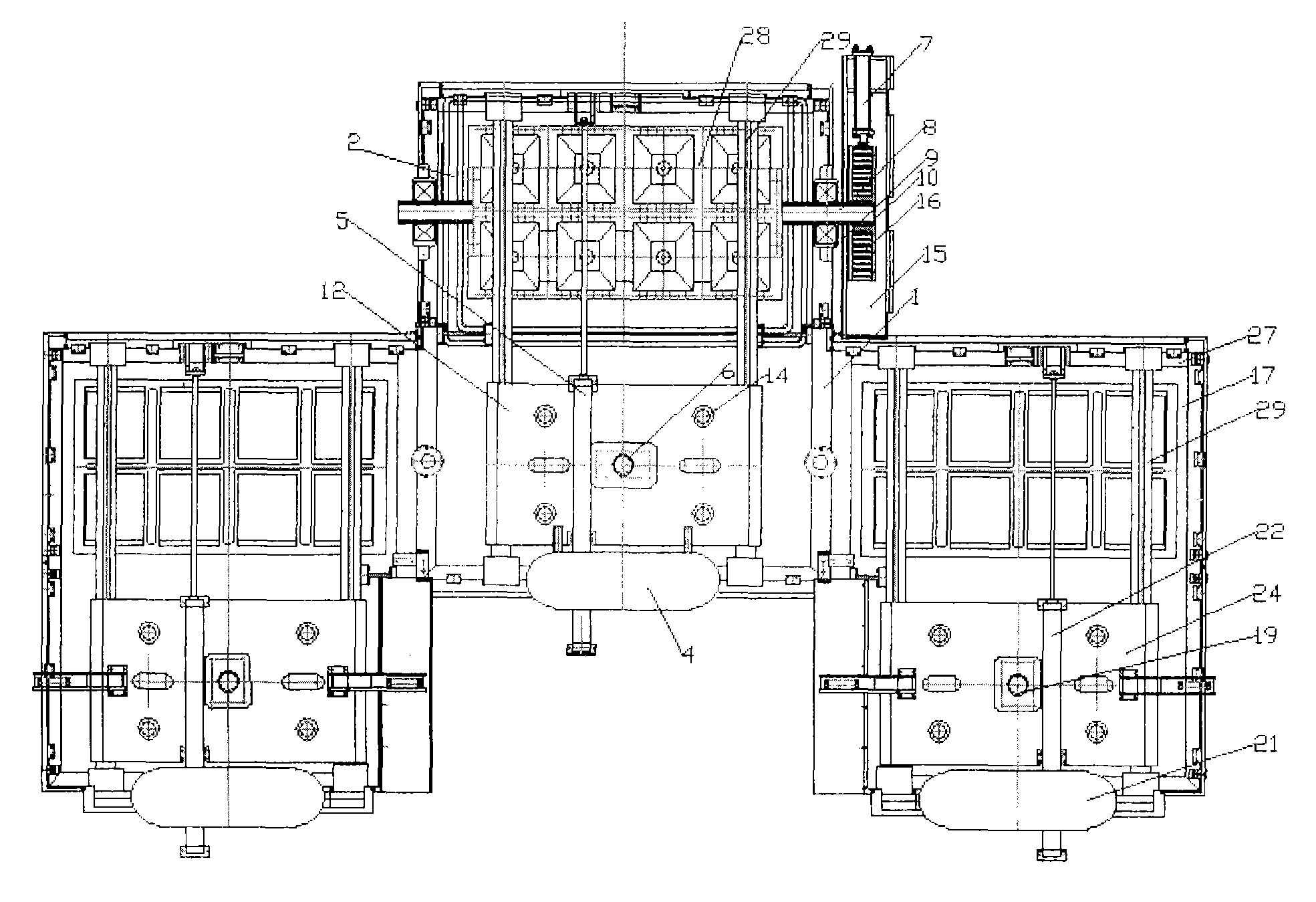

Flexible production line for producing paper pulp molded products

PendingCN107915044ASimple structureEasy to manufactureStacking articlesTextiles and paperMolded pulpProcess engineering

The invention belongs to the technical field of machines and particularly relates to a flexible production line for producing paper pulp molded products. Through the flexible production line, the problems that design is not reasonable and the like in the prior art are solved. The flexible production line for producing the paper pulp molded products comprises at least one product molding device, atleast one product stacking device and a plurality of hot-pressing sizing devices. The production line further comprises a transfer device. A mechanical arm is connected to the transfer device. At least one suction cup is connected to the mechanical arm; the mechanical arm drives the suction cups to transfer paper pulp molded products molded by the product molding device every time to the productstacking device one by one; the product stacking device stacks the paper pulp molded products received every time. The flexible production line has the advantages that the production efficiency can beimproved, and the cost is lower.

Owner:ZHEJIANG SHURCON MFG

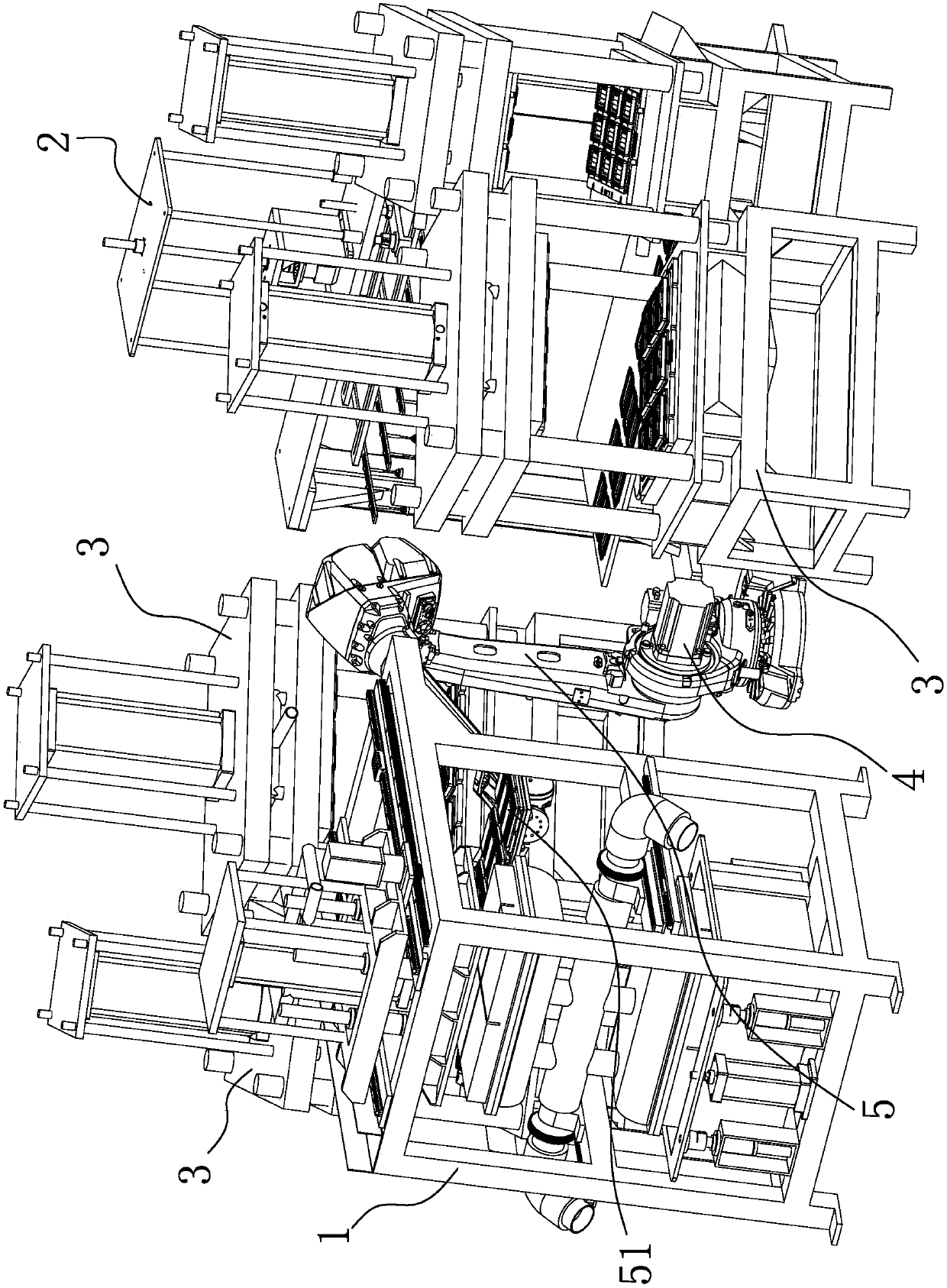

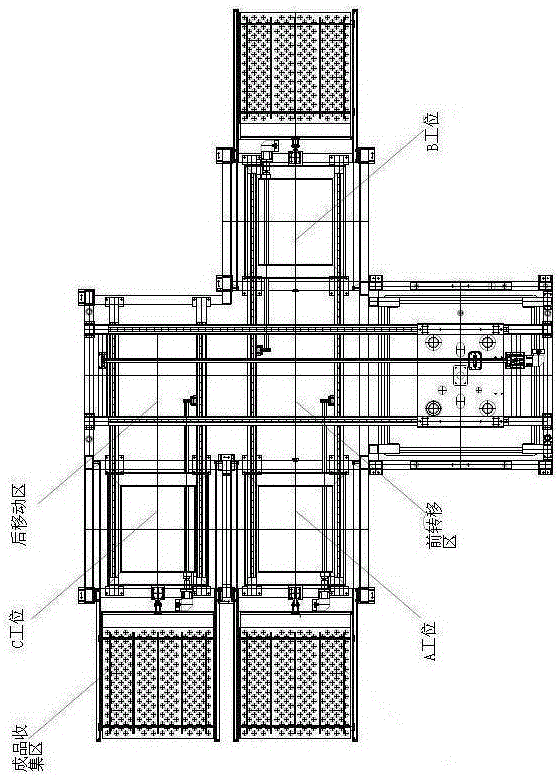

Full-automatic multi-station integrated pulp molding equipment and production technology

ActiveCN106638164AQuality improvementUniform slurryTextiles and paperShell moldingPulp and paper industry

The invention belongs to the field of pulp molding product production equipment in a papermaking technique. Full-automatic multi-station integrated pulp molding equipment comprises an electric-heat conduction oil universal heating device, a steam heating device, a pulp chest homogenizing device, an adsorptive molding device, hot-press sizing devices, a first kind product collection device not needing stacking and a second kind product collection device capable of automatically conducting stacking; a groove is formed in a molding template of the molding device, an airflow dispersion cover plate is installed over the groove, an airflow main pipeline is vertically installed, a deckle edge spraying and template cleaning device is independently installed, heating plates of the molding devices are fixed to an upper molding template and a lower molding template through heat insulation plates, the upper molding template achieves multi-point pressurizing through a pressure stabilizing frame, the lower molding template is fixed to a transverse tackle, and heat deformation of the heating plates is effectively controlled by the molding templates. The equipment is suitable for large-scale production of pulp molding products, few molds are used, and the molds are unified and easy to replace.

Owner:许洪涛 +1

Vacuum extrusion low-temperature drying process and equipment for pulp molding

ActiveCN101967767AReduce consumptionReduce consumption and create conditionsDryer sectionThermal energyMolded pulp

The invention relates to a vacuum extrusion low-temperature drying process and vacuum extrusion low-temperature drying equipment for pulp molding. The process comprises the following steps of: vacuum low-temperature extrusion deep dehydration at a blank forming stage during the pulp forming, and vacuum low-temperature extrusion drying and shaping at subsequent hot pressing, drying and shaping stages. The process is characterized in that: the step of vacuum low-temperature extrusion deep dehydration at the blank forming stage during the pulp molding can ensure that a wet green body at a forming stage is dehydrated under the condition of vacuum suction and in a low-temperature extrusion environment, and generates a small amount of low-temperature vapor to further remove water in the wet green body and around the wet green body so as to fulfill the aim of deep dehydration and create conditions for efficiently avoiding yellow spots generated on molded pulp products and plugged holes on a forming die body and greatly reducing heat consumption during drying and shaping at the subsequent molding process stages; and the step of vacuum low-temperature extrusion drying and shaping at the subsequent hot pressing, drying and shaping stages can ensure that the products are dried and shaped by hot pressing under the condition of vacuum suction and in a lower temperature environment, so thatthe thermal energy consumption is reduced, and the production efficiency is improved.

Owner:上海英正辉环保设备有限公司

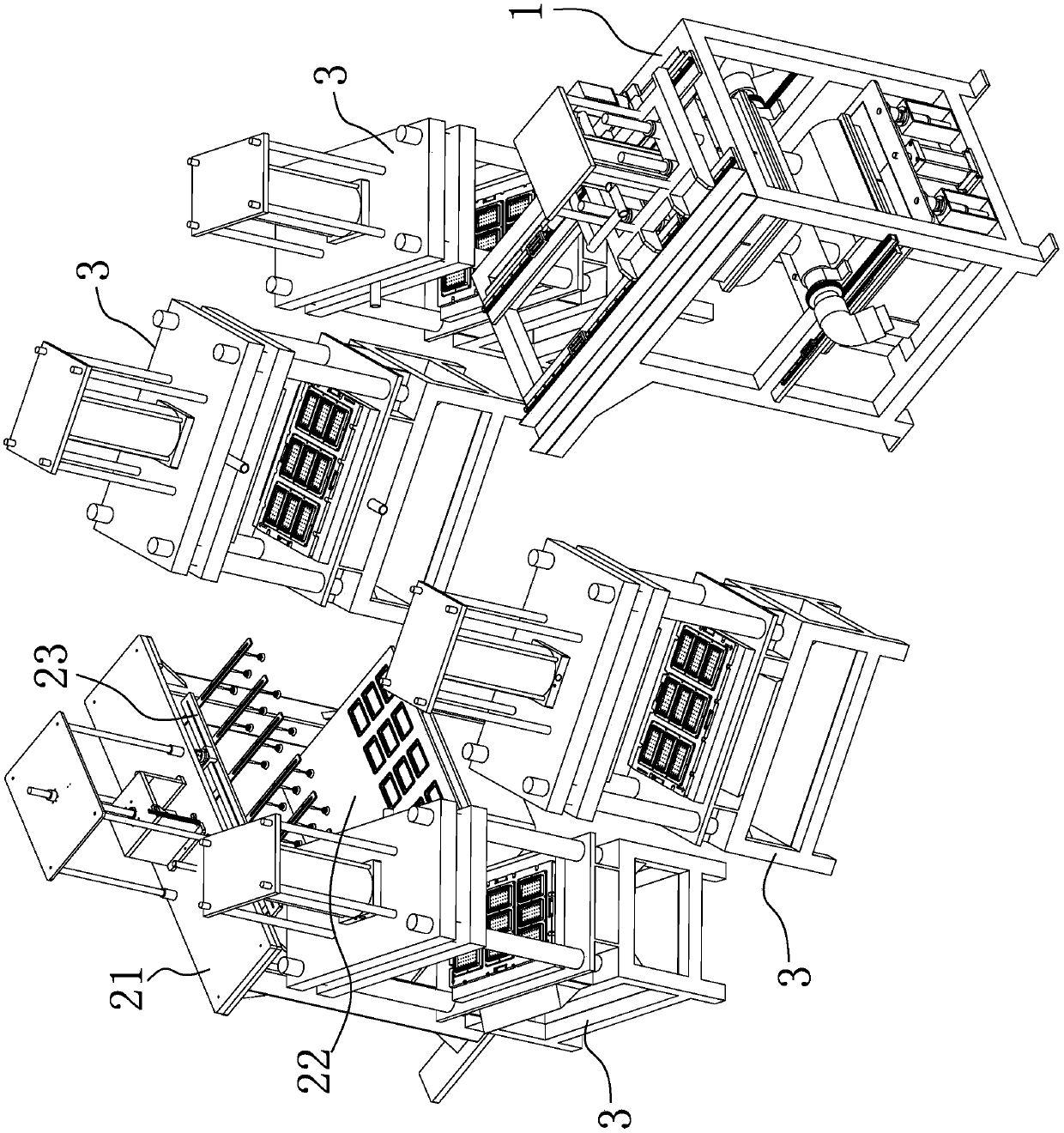

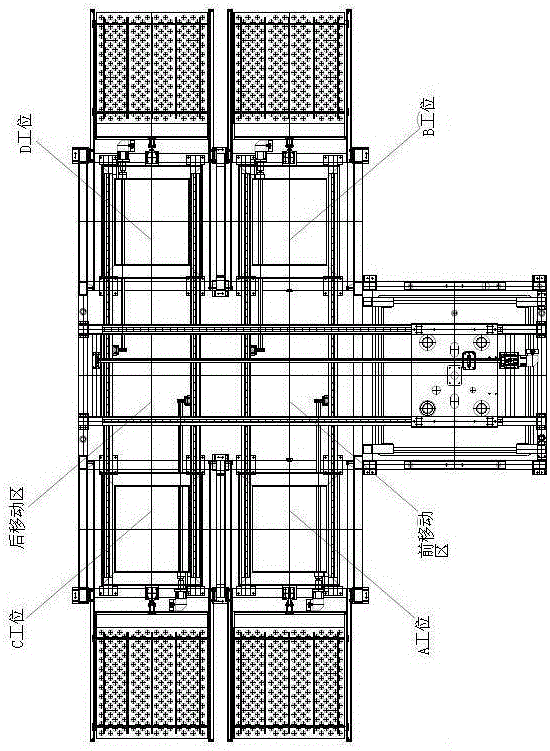

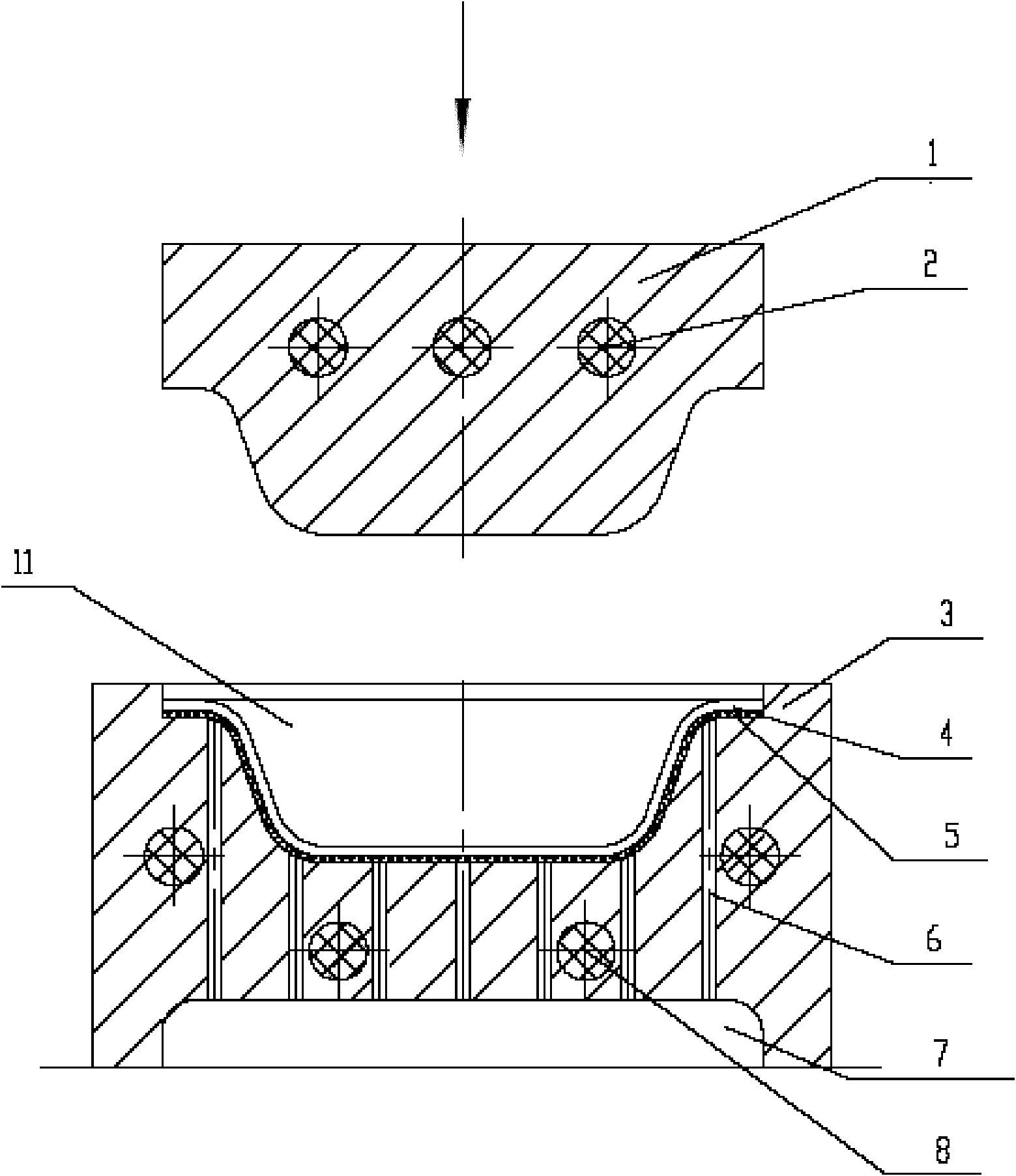

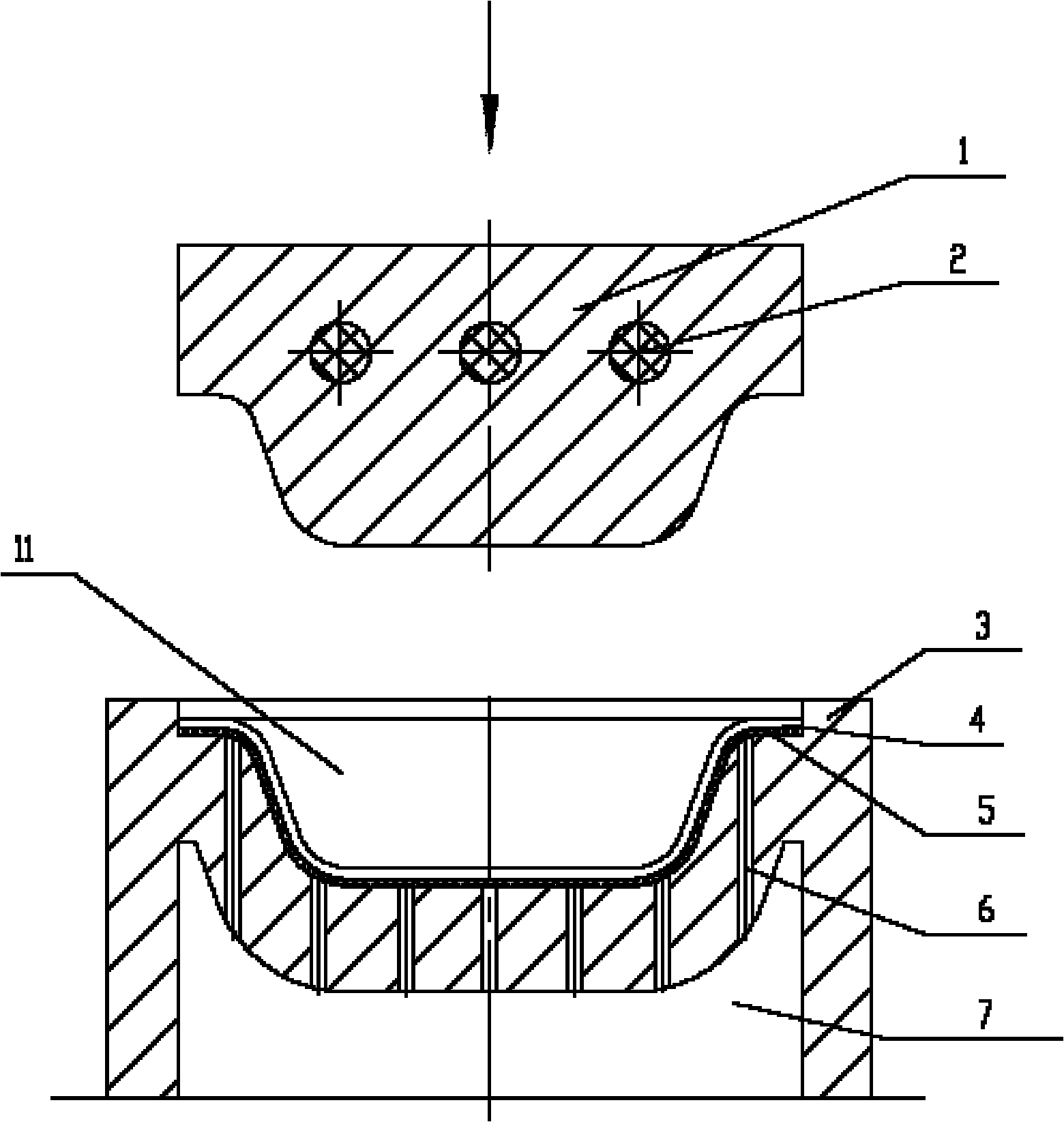

Full-automatic molded pulp two-station integrated device and production process thereof

Disclosed are a full-automatic molded pulp two-station integrated device and a production process of the full-automatic molded pulp two-station integrated device. The full-automatic molded pulp two-station integrated device comprises a suction filtration molding device and two hot-pressing shaping devices. The suction filtration molding device comprises a molding rack, a pulp tank, a molding mould plate, a transfer mould plate, a molding transfer mould air storage tank, a molding transfer mould supporting plate moving air cylinder, a transfer air cylinder, an overturn oil cylinder and an overturn main shaft. The two hot-pressing shaping devices are matched with the suction filtration molding device. Each hot-pressing shaping device comprises an upper mould plate, a lower mould plate, an upper mould pressurizing air cylinder, a lower mould moving air cylinder, a shaping transfer mould air storage tank and a shaping transfer mould supporting plate moving air cylinder. The transfer air cylinder is installed on a transfer mould supporting plate. A transfer mould is fixed to a transfer mould plate. The transfer mould plate is guided through a mould plate guide shaft and driven by the transfer air cylinder to move vertically along the mould plate guide shaft. The full-automatic molded pulp two-station integrated device and the production process of the full-automatic molded pulp two-station integrated device improve the utilization ratio of a mould and also improve product quality and labor productivity.

Owner:张宝华

Pulp-molding packaging product and manufacturing method thereof

ActiveCN103556547AReduce moisture contentImprove structural strengthTextiles and paperRigid containersShell moldingUltimate tensile strength

The invention relates to the technical field of pulp-molding packaging products, particularly to a pulp-molding packaging product and a manufacturing method thereof. The manufacturing method comprises the steps as follows: pulping, molding (pulp sucking and dewatering), demolding, hot-pressing shaping and the like; and the structural strength of a pulp-molding wet blank is enhanced, the tearing phenomenon occurring easily during demolding is eliminated, the difficulty of demolding is reduced, on one hand, the production difficulty is greatly reduced, improvement of the yield is facilitated, on the other hand, the inclination degree of the tapered structure of the manufactured product is further reduced, minimum inclination angles formed by side edges and bottom edges of the pulp-molding packaging product can be 1.5 degrees, the size of an internal empty space of the pulp-molding packaging product during packaging is greatly reduced, and the capacity for protecting a packaged product is improved. The pulp-molding packaging product is made of bagasse, waste paper and the like, has the advantages of capacity for reducing consumption of forest resources, low environmental pollution, high quality and low price and is broad in development and application prospect.

Owner:广东省汇林包装科技集团有限公司

Solventless polyurethane adhesive and method for paper plastic packaging

InactiveCN103131378AImprove adaptabilityNo pollution in the processNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMolded pulpPolyurethane adhesive

The invention relates to the technical field of polyurethane adhesives, particularly a solventless polyurethane adhesive for a paper plastic packaging precoating technique, which is composed of 95-99 wt% of polyurethane prepolymer with isocyanate-terminated main chain and 1-5 wt% of additive. The coating weight of the adhesive is 2-8 g / m<2>. The polyurethane solventless adhesive provided by the invention has favorable bonding force for paper, films, aluminum foils and the like, has the advantages of no pollution and easy coating in construction, saves the cost, has high curing speed after precoating, and has strong adaptability to presswork; and after the adhesive is coated on the presswork, the presswork does not fade or form a film, and can resist deflection. The invention is widely used for paper plastic packaging.

Owner:SHANGHAI CHAOSU NEW MATERIAL TECH CO LTD

Method for recycling waste paper-plastic or paper-aluminum package material

The invention discloses a method for recycling a waste paper-plastic or paper-aluminum package material. The method comprises the following steps: (1) cutting a waste package material into small pieces, washing to remove impurities, and drying; (2) putting the small material pieces into a water-soluble alkali solution, stirring under the constant temperature condition of 50-100 DEG C, so as to enable the alkali solution to dissolve the paper-plastic or paper-aluminum package material of the waste package material into paper pulp fiber and plastic or aluminum foil, thereby obtaining a separation mixture; (3) feeding the separation mixture into a high-frequency defibering machine so as to disperse and defiber the paper pulp fiber, thereby obtaining a defibering mixture; putting the defibering mixture into a slag cleaner, treating to respectively obtain paper pulp fiber and a plastic or aluminum foil material, subsequently drying the paper pulp fiber and the plastic or aluminum foil material so as to obtain a recycled paper pulp, plastic or aluminum foil material. The method has the excellent effects that paper pulp, plastic and aluminum foil are separated and recycled from the waste paper composite package material, and the method is simple in process, controllable in cost, resource-saving and beneficial for ecologic environment.

Owner:青岛福创环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com