Vacuum extrusion low-temperature drying process and equipment for pulp molding

A pulp molding and vacuum extrusion technology, applied in the dryer section, papermaking, papermaking and other directions, can solve the problems of macular plugging and other problems, and achieve the effect of avoiding macular macula, reducing thermal energy consumption, creating conditions, and reducing thermal energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

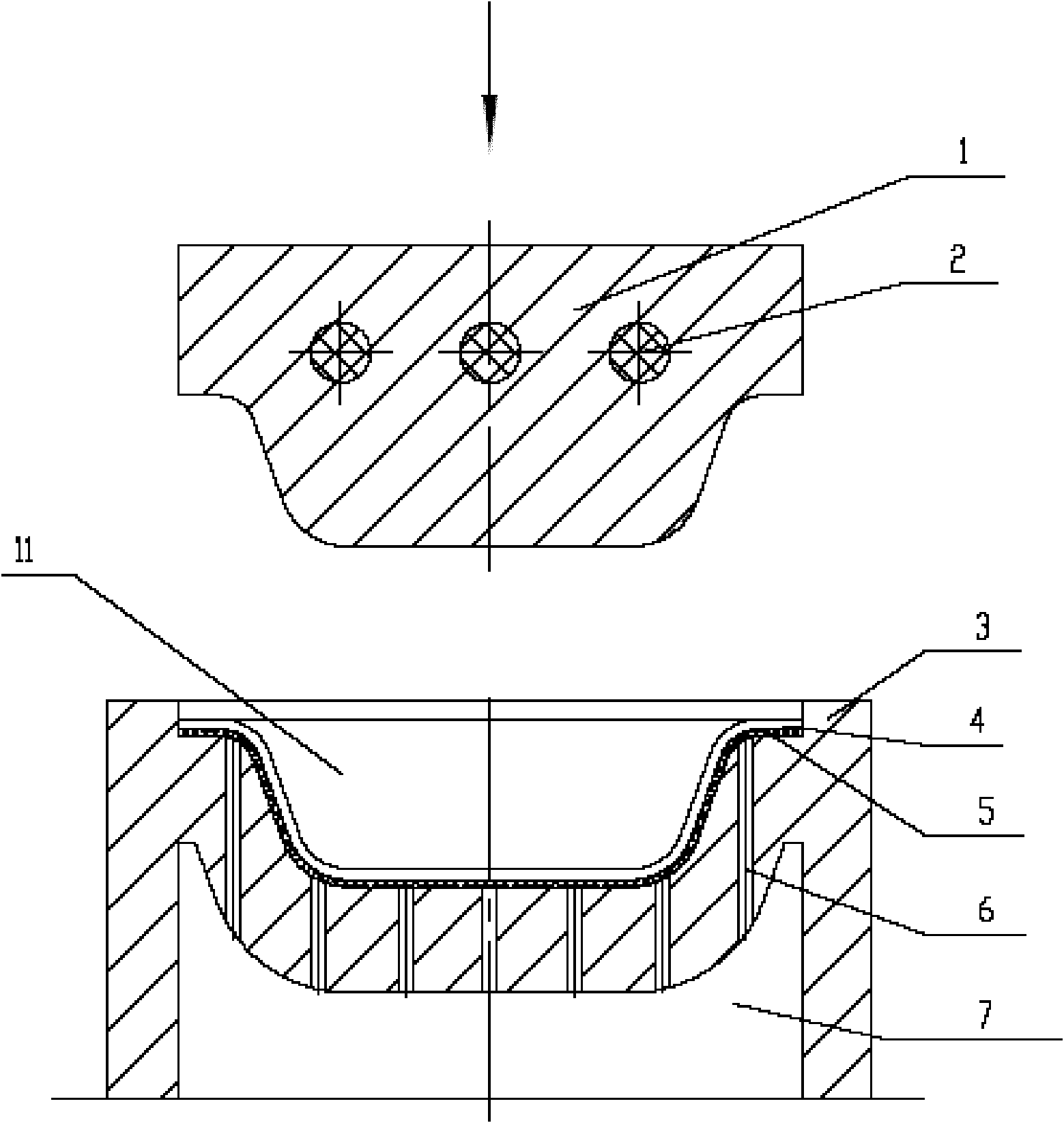

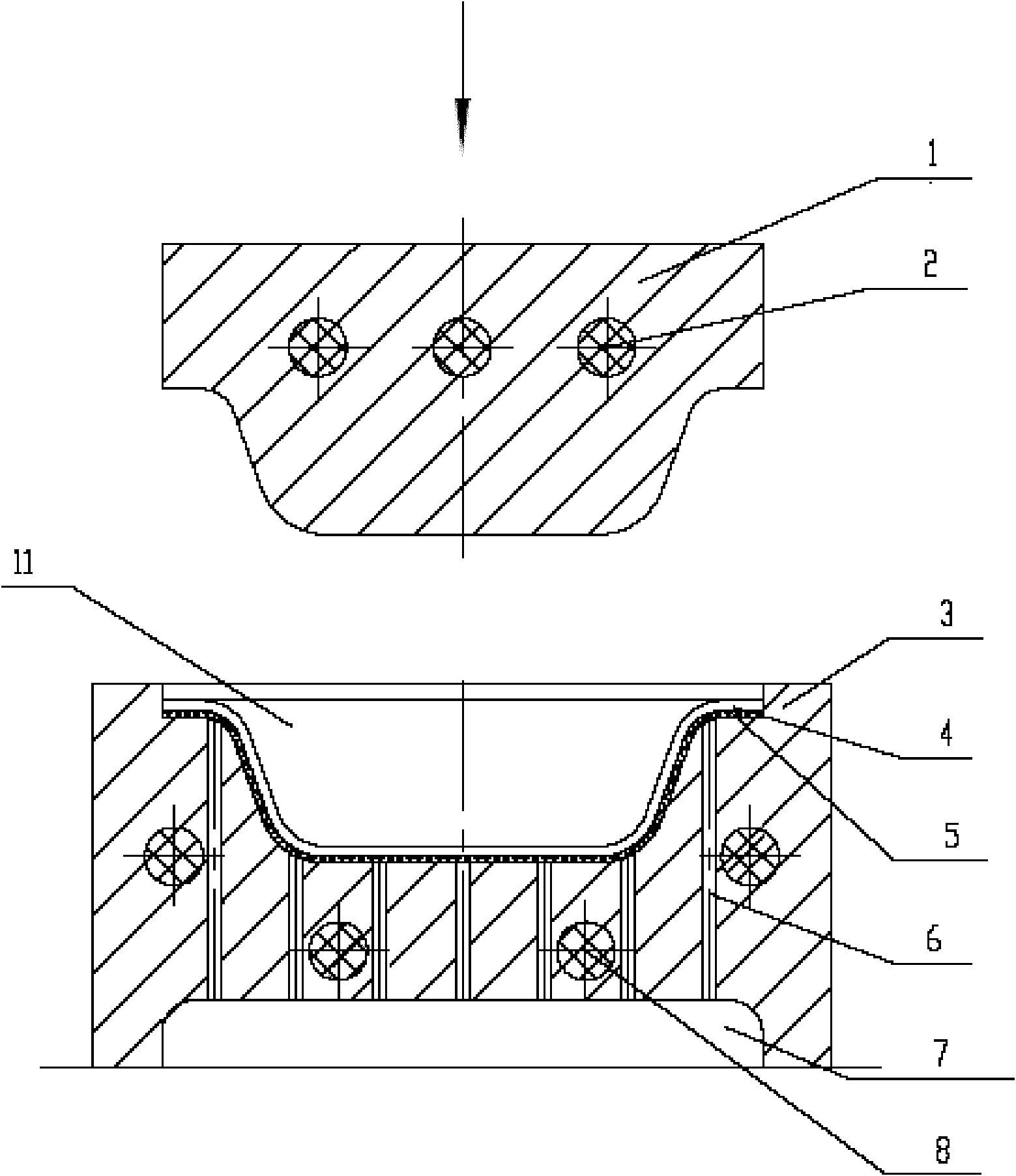

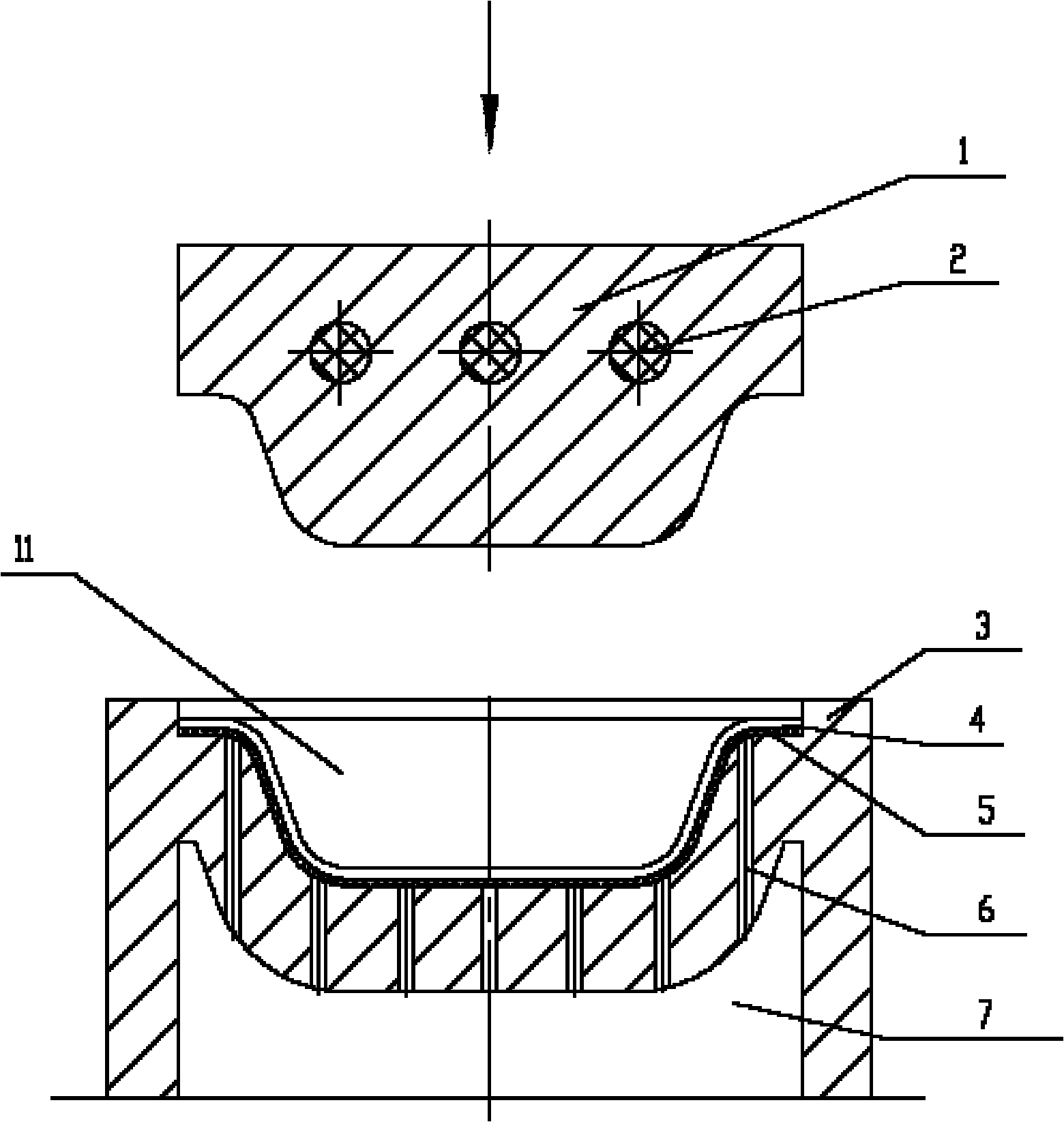

[0015] figure 1 with figure 2 The structural schematic diagrams of the implementation of the two parts of the blank forming part and the hot pressing drying and shaping part are respectively shown. Such as figure 1 with figure 2 As shown, both the first mold body 1 and the second mold body 3 are included in the implementation schematic diagram of the paper-making part of the pulp molding and the heat-pressing drying and shaping part. The first mold body is provided with a heating element 2, the second mold body 3 is provided with a mold cavity 11, and the entire inner wall of the mold cavity 11 of the second mold body 3 is provided with drainage holes that can pass through the vacuum negative pressure mold cavity 7 6. A wire mesh layer 5 is laid on the cavity 11 . Also shown in the figure is the parison 4 that is covered on the top of the wire mesh 5 and that has been sheet-formed. exist figure 2 A heating element 8 is also arranged on the second mold body 3 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com