Resealable Leak-Resistant Containers Having A Pressed Pulp Tray With A Thermoformed Plastic Lid

a thermoformed plastic and leak-resistant technology, which is applied in the direction of lids, lids, packaging, etc., can solve the problems of small “draft angle” of the pulp container, difficult to manufacture a pulp container with leak-resistant properties, and uneven distribution of fibers in the produced par

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

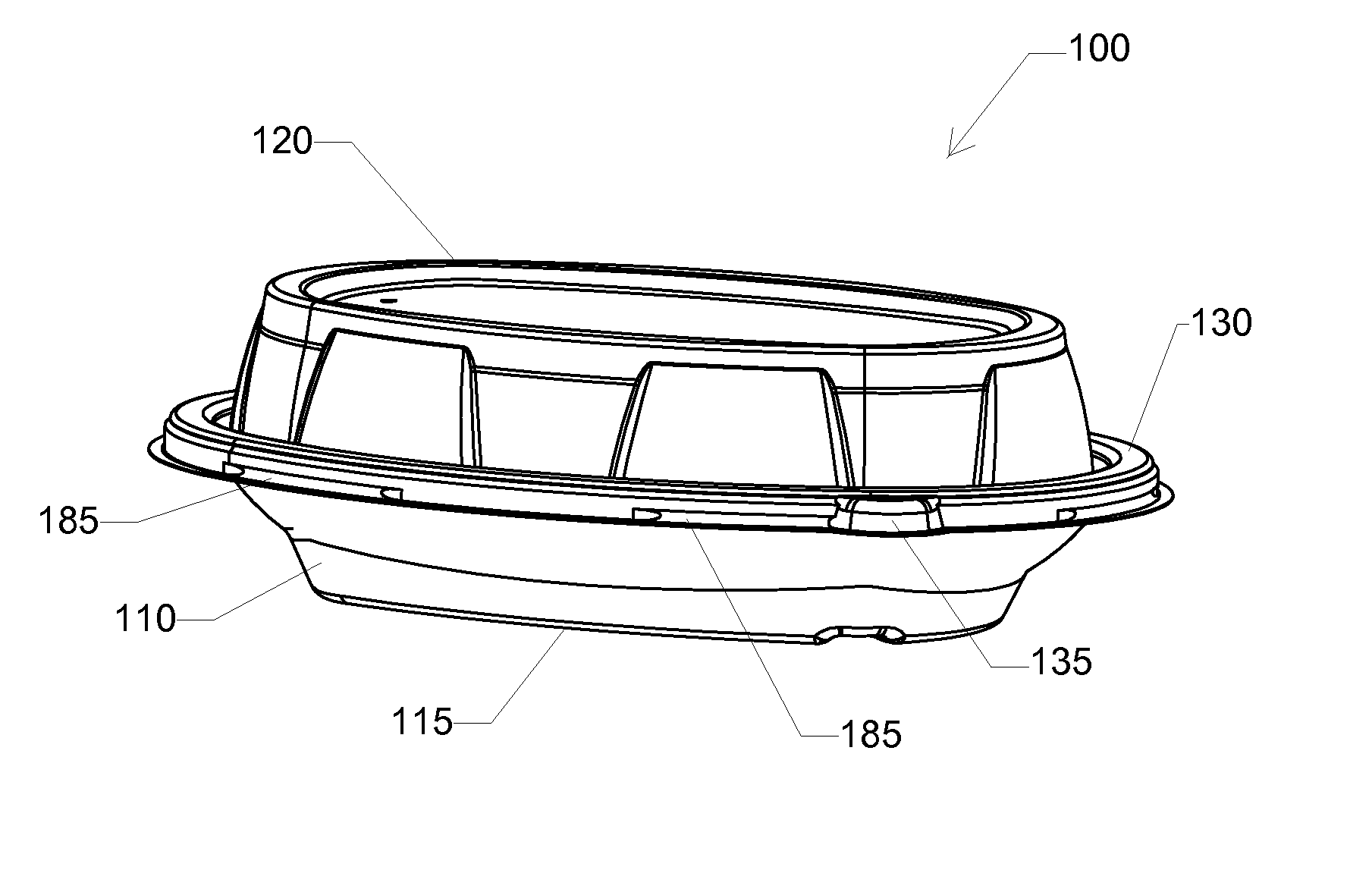

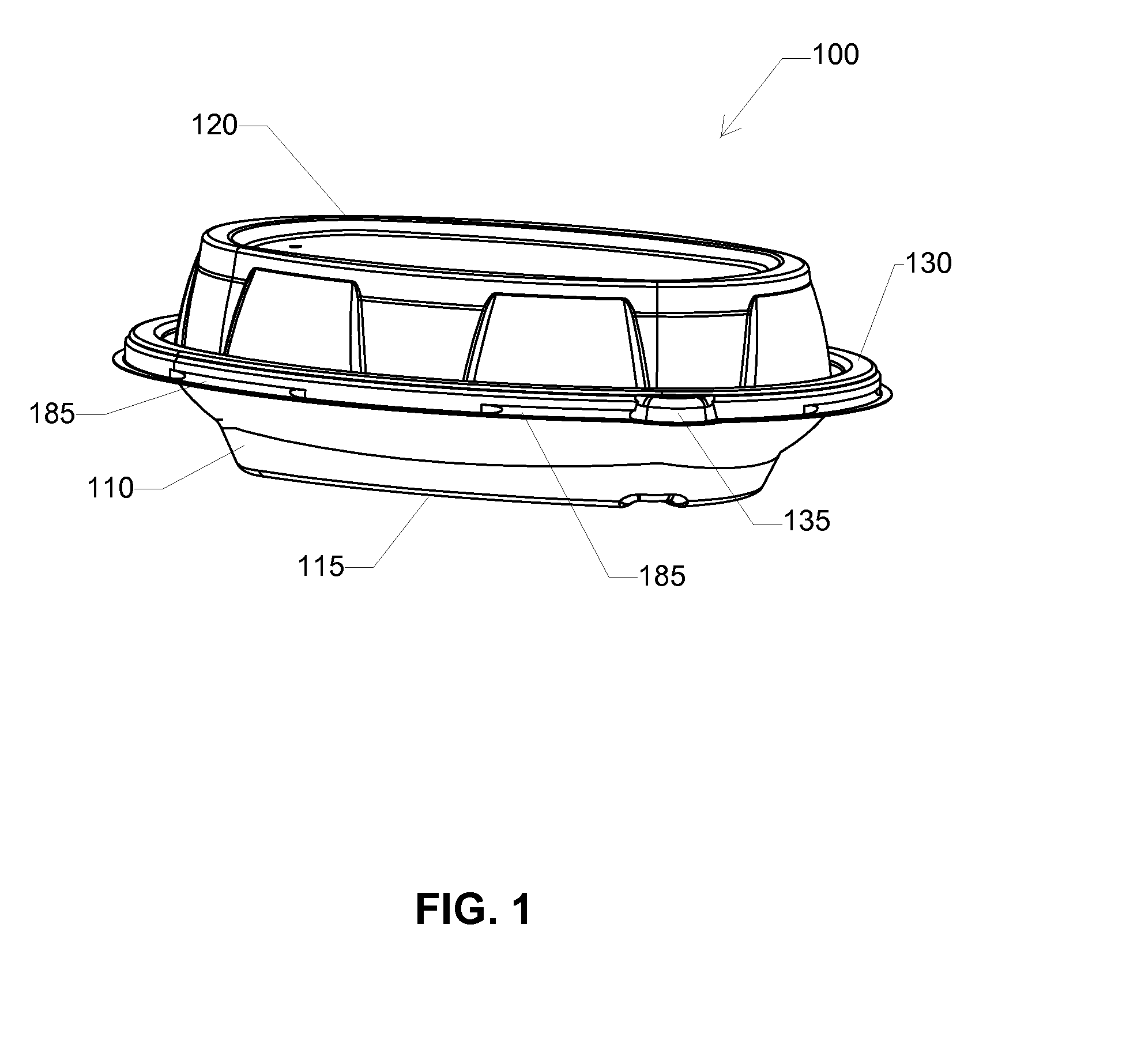

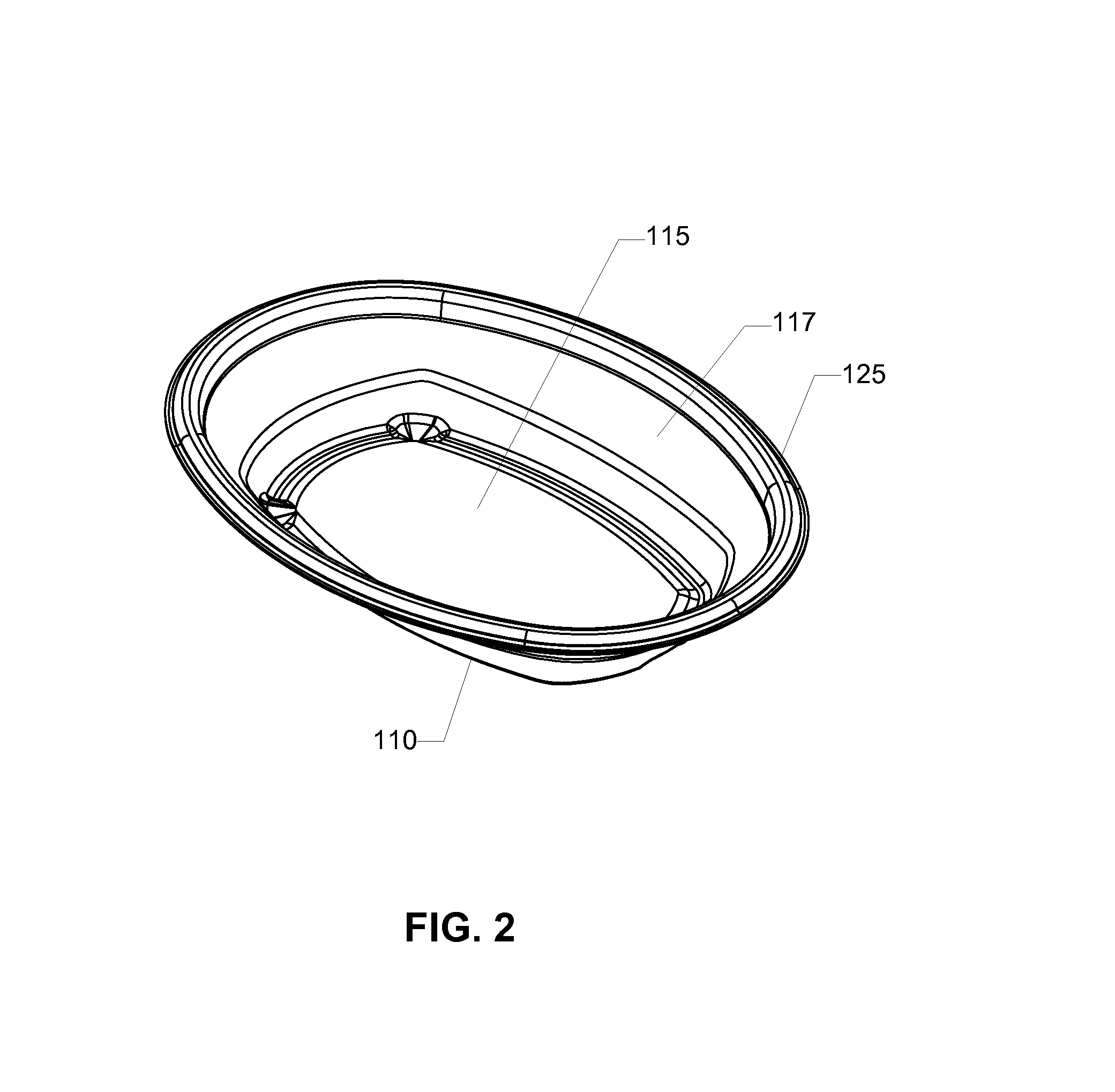

[0029]FIGS. 1-3 show an embodiment of a resealable leak-resistant container 100 having a molded pulp tray 110 with a plastic lid 120. The tray 110 has a bottom 115 and a sidewall 117 forming an interior volume (see, e.g., FIG. 2). The tray 110 has an edge 125 extending peripherally outward from an upper edge of the sidewall 117. The tray 110 and the lid 120 each has a substantially oval shape (see, e.g., FIG. 3). Although, other shapes are also possible, such as square (see FIG. 4) or round (see FIG. 5). A tab 135 may extend from the lid edge 130 and beyond the tray edge 125. The inward facing lip portions 185 are described below in the discussion of FIG. 7.

[0030]The lid 120 of the leak-resistant pulp container 100 may be formed of any of the following plastic materials: high density polyethylene (HDPE), polyethylene terephthalate (PET), polypropylene (PP), polystyrene (PS), and polylactic acid (PLA). The plastic lid can be formed by various processes, including, for example, thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com