Automatic paper pulp molding and shaping one-piece combined machine and process adopted by same

A pulp molding and combined machine technology, applied in textiles and papermaking, etc., can solve the problems of low output, many operators, high labor intensity, etc., and achieve the effect of huge pulp volume, improved production efficiency, and accelerated drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

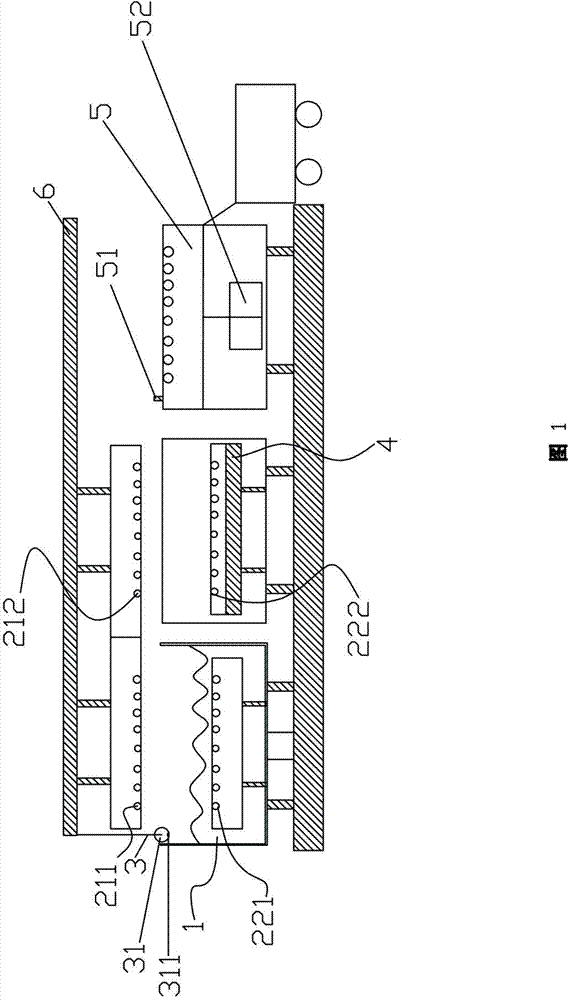

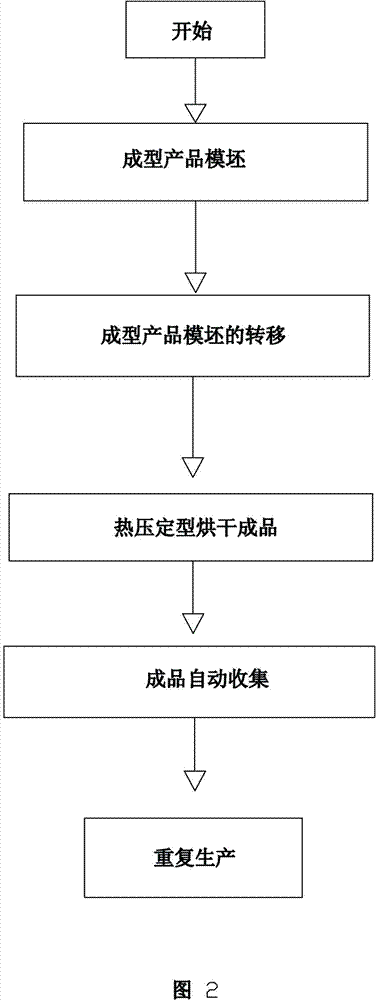

[0023] refer to figure 1 As shown in the figure, an automatic pulp molding and shaping combined machine includes a forming pulp tank 1 equipped with an overflow device (not shown in the figure), two sets of moulds, a pressure spraying edge trimming device 3, a connecting There is a heat-pressing and shaping drying device 4 with heat-conducting oil and an automatic product collection device 5. The two sets of molds include: a forming mold and a shaping mold. The pressure spraying and trimming-free device 3 can be installed in the forming above the slurry tank 1; the two groups of molds all include an upper mold and a lower mold, and the lower mold 221 of the forming mold can be moved up and down in the forming slurry tank 1, and the lower mold 222 of the shaping mold is arranged on the hot-pressed drying hydraulic pressure In the device 4 , the upper mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com