Patents

Literature

363results about How to "Adapt to market demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of electromagnetic shielding conductive fabric

InactiveCN101876140ALess investmentSmall plating resistancePhysical treatmentSuperimposed coating processPolyesterCopper plating

The invention discloses a preparation method of an electromagnetic shielding conductive fabric. In the preparation method, the electromagnetic shielding conductive fabric is prepared by sequentially carrying out pretreating, vacuum nickel plating, copper electroplating and nickel electroplating on a full polyester fabric, and then the obtained electromagnetic shielding conductive fabric is cured, wherein plasma glow discharge treatment is carried out in the pretreating step, a magnetron sputtering technology is adopted in the vacuum nickel plating step, and a vertical placement mode is adopted among conductive rods in the processes of copper electroplating and nickel electroplating. By adopting the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating, the defects of high cost and difficult treatment of electroplating wastewater, caused by the adoption of an electroless copper and nickel plating technology in the traditional preparation method of the electromagnetic shielding conductive fabric, are avoided; and compared with the traditional preparation method of the electromagnetic shielding conductive fabric, which adopts a full vacuum copper and nickel plating technology, the method of the invention which adopts the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating has smaller equipment investment and plating resistance, is more suitable for large-scale production, and can better adapt to market demands.

Owner:昆山市同福电子材料厂

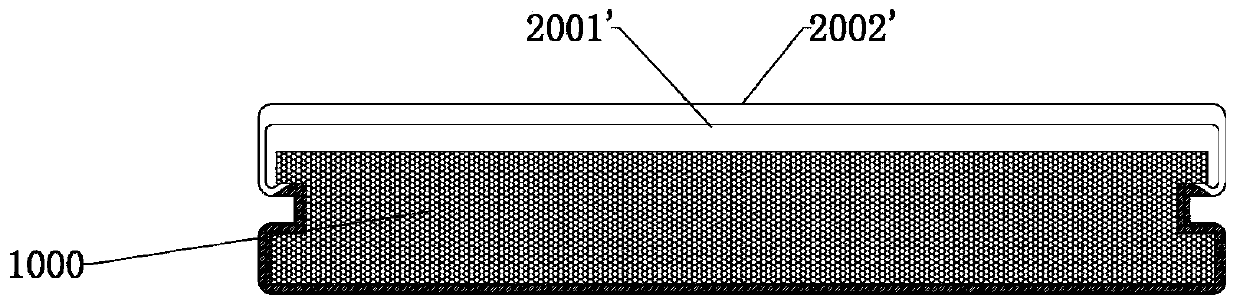

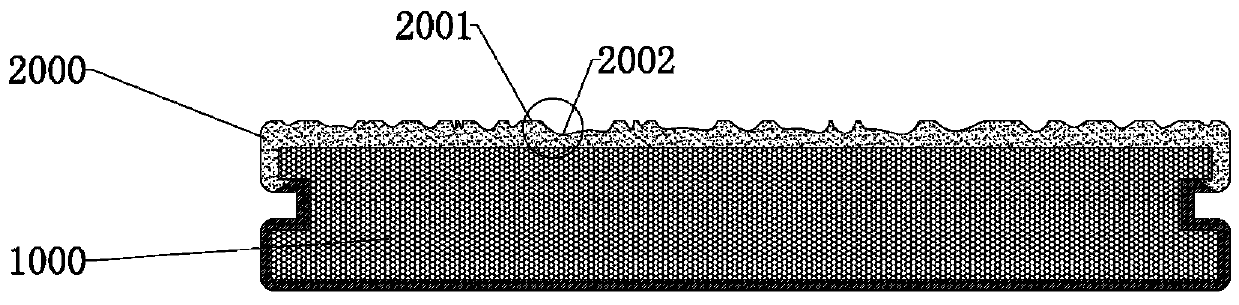

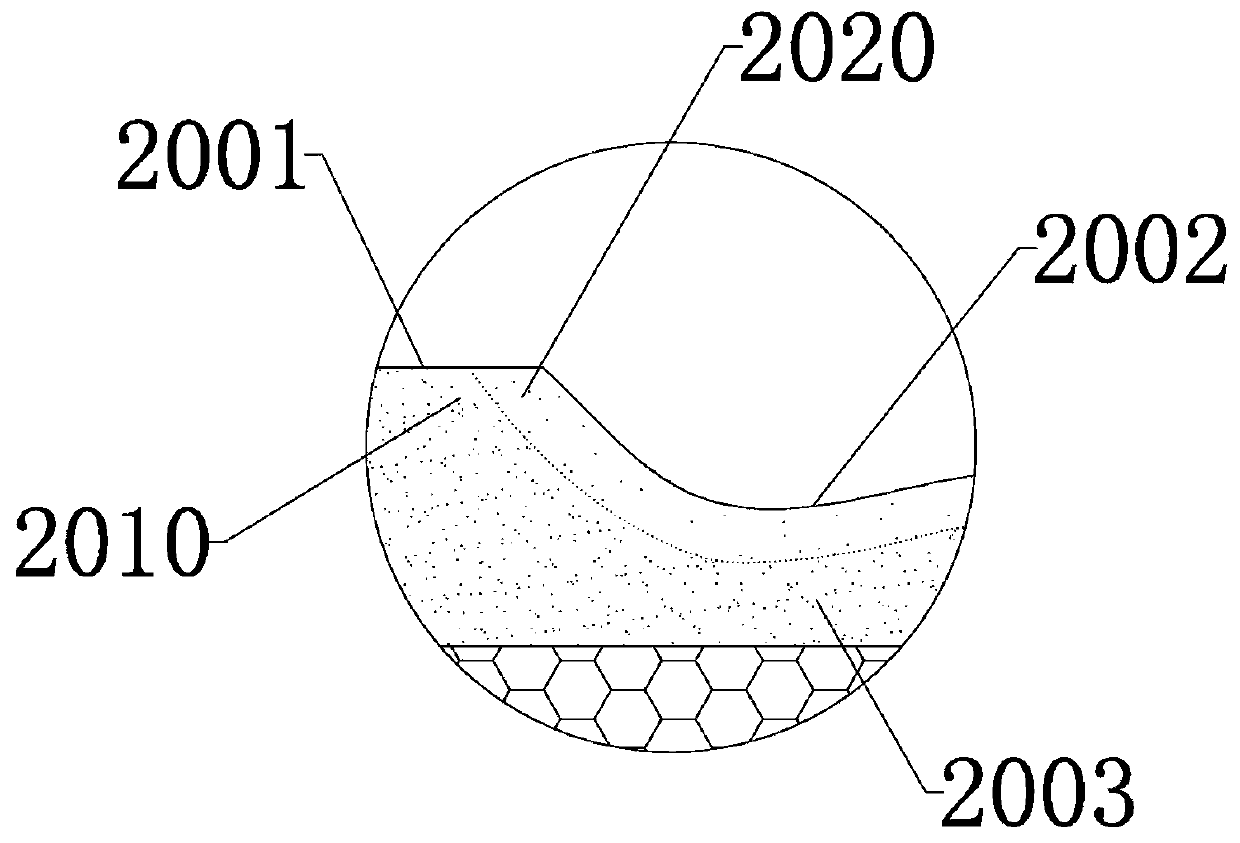

Green tyre in composite structure between wheel track of polyurethane and tyre core of rubber, and fabricating method

ActiveCN1539628AReduce rolling resistanceImprove comfortOther chemical processesPolyureas/polyurethane adhesivesPolymer scienceSurface layer

A composite type composed of polyurethane surface layer and main body of rubber is prepared through treating the surface of main body, synthesizing and modifying the prepolymer of polyurethane, and casting the surface layer. Its advantages are high elasticity and antiwear nature, and low rolling resistance.

Owner:BESTIRE XINXING NEW MATERIAL TECH CO LTD

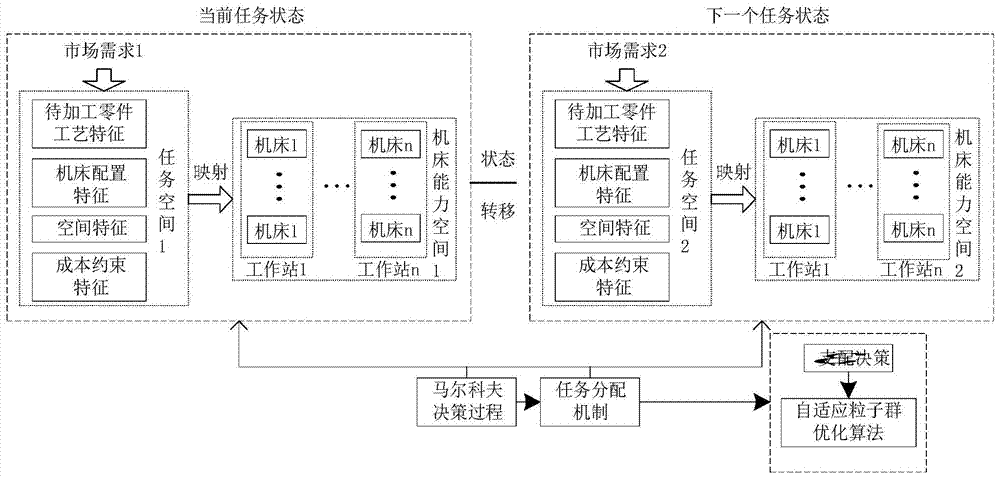

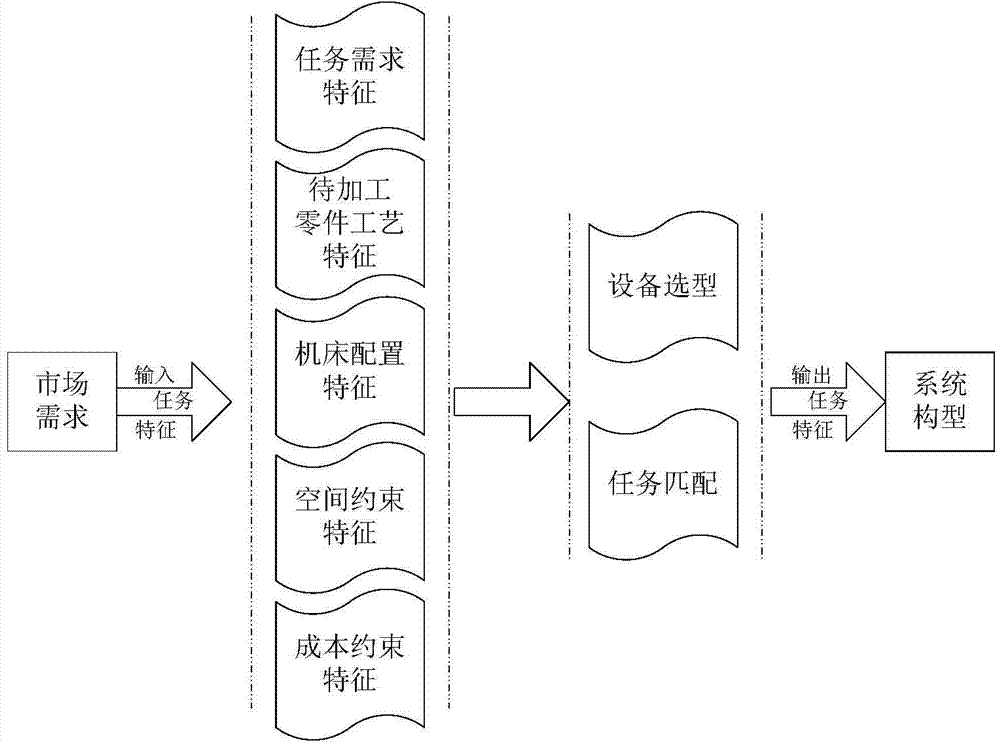

Reconfigurable manufacturing system polymorphic configuration optimization method based on tasks

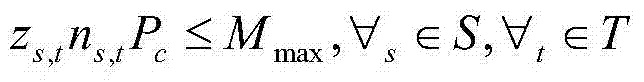

InactiveCN103942610AFlexible handlingAdapt to market demandForecastingResourcesParticle swarm optimizationSystem configuration

The invention discloses a reconfigurable manufacturing system polymorphic configuration optimization method based on tasks. The reconfigurable manufacturing system polymorphic configuration optimization method comprises the following steps that firstly, according to changes in market requirements, feature information of the dynamic tasks is obtained, process features of a part to be machined are analyzed, and the priority levels of the tasks are determined; secondly, a dynamic space model used for describing the state change process of the tasks and a machine tool capacity space model used for describing the number of machine tools are established; thirdly, a mapping relation from dynamic task space to machine tool capacity space is established, and reasonable station operation is distributed to the dynamic tasks through the Markov decision process on the basis of the mapping relation; fourthly, a task distribution mechanism which enables the machine tool capacity to be optimized is established according to machining capacity information of the machine tools; fifthly, a system queue model used for describing the task state input and output process is established according to the task distribution mechanism and a system optimization objective, and multi-objective optimization analysis is conducted on the system configuration through epsilon-dominated adaptive particle swarm optimization.

Owner:TONGJI UNIV

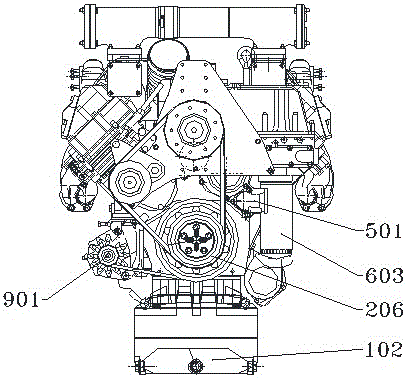

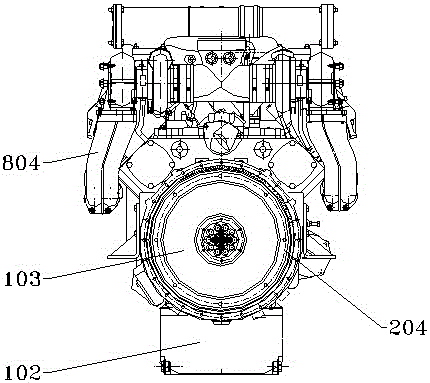

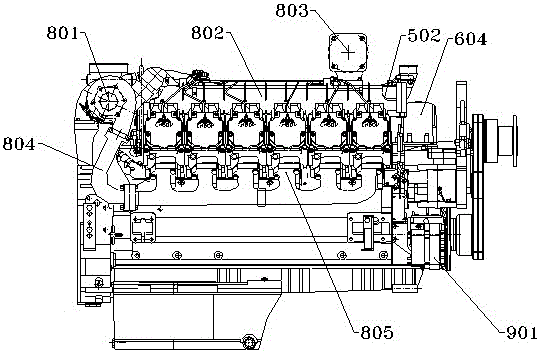

12-cylinder water cooling diesel engine

The invention discloses a 12-cylinder water cooling diesel engine. The engine comprises a crank connecting rod mechanism arranged on a fixed part, a gas distribution mechanism, a transmission mechanism, a cooling system, a lubricating system, a fuel supply system, an intake / exhaust system, an electric system and a starting mechanism. The water cooling engine widens the power range, increases the power from traditional 195-499 kW to 780 kW, preferably exerts the characteristics of high power, small size, compact structure and low fuel consumption of the series of diesel engines, adapts to the market demands, satisfies the use requirements of users, is better in market competitiveness, can be applied to such fields as engineering machinery and generator sets, and widens the application field of 132-series engines.

Owner:HEBEI HUABEI DIESEL ENGINE

Environment-friendly strengthened flexible waterproof paint and preparation method thereof

The invention discloses environment-friendly strengthened flexible waterproof paint and a preparation method thereof, belonging to the technical field of paint applications. The environment-friendly strengthened flexible waterproof paint is used for solving the problems in the prior art that waterproof paint is low in strength and cannot cover fine cracks. The environment-friendly strengthened flexible waterproof paint is characterized by being prepared from an ingredient A and an ingredient B, wherein the ingredient A is prepared from pure acrylic acid emulsion, a defoaming agent, environment-friendly bactericide and water, the ingredient B is prepared from silicate cement 42.5, quartz sand 70-140, quartz sand 200 and a water reducing agent, and the weight ratio of the ingredient A to the ingredient B is 1: (1.5-2.0). The invention further provides the preparation method of the waterproof paint. The waterproof paint disclosed by the invention is not only high in strength, but also can cover the fine cracks, so that the phenomenon of water leakage during construction caused due to the fact that the strength is not enough and the fine cracks cannot be covered is effectively prevented.

Owner:NIPPON PAINT CHENGDU

Traditional Chinese medicines prescription for enhancing physical strength and immunity and adjusting sub-health

InactiveCN103142850AThe production process is simpleLow costAntinoxious agentsImmunological disordersCordyceps militarisTraditional medicine

The invention relates to a traditional Chinese medicine prescription for enhancing the physical strength and the immunity and adjusting the sub-health, which comprises the components by weight: 2-9g of ginseng, 5-15g of cordyceps militaris, 5-15g of rhizoma polygonati, 5-15g of medlar, 9-15g of arillus longan, 5-15g of mulberry, 5-15g of tuckahoe and 10-30g of yam. A preparation method comprises the following specific preparation steps of: adding water into the medicines, soaking for 2 hours, then decocting for 0.5 hour and pouring out the liquid medicine; adding water, carrying out secondary decoction for 0.5 hour, mixing the liquid medicine decocted for twice, filtering, concentrating to the moderate amount to form a traditional Chinese medicine for enhancing the physical strength and the immunity and adjusting the sub-health. The traditional Chinese medicine prescription has the beneficial effects that power, granules, tablets, capsules or pills can be prepared as required; the ginseng in the prescription not only has the effects of reinforcing the vital energy, tonifying the spleen and strengthening the middle warmer, but also has the effects of nourishing both yin and yang and supporting the healthy energy in combination with the cordyceps militaris; the rhizoma polygonati has the effects of nourishing the kidney, moistening the lung, tonifying the spleen and tonifying qi; and the traditional Chinese medicine prescription has the advantages of simple preparation process and low cost and adapts to the market demands.

Owner:王波

Graphene-modified waterborne anticorrosive coating

ActiveCN106590401AImprove mechanical propertiesStrong mechanical propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsAcid anhydride formationMechanical property

The invention relates to a grapheme-modified waterborne anticorrosive coating. The grapheme-modified waterborne anticorrosive coating is composed of a grapheme-modified waterborne alkyd resin, pigment and filler, a cosolvent, a leveling agent, a dispersing agent, a wetting agent, a defoaming agent, a thickening and anti-settling agent, a flash rust inhibitor, a pH value regulator and deionized water, wherein the graphene polyurethane-modified waterborne alkyd resin is prepared from vegetable oil or fatty acid, organic acid anhydride, dimethylolpropionic acid, polyol, grapheme, polyisocyanate and deionized water through a reaction. The prepared grapheme-modified waterborne anticorrosive coating integrates the advantages of grapheme and polyurethane, has properties like high hardness, good adhesion, good chemical resistance, antistatic performance, corrosion resistance, aging resistance and good mechanical properties, and is endowed with excellent corrosion resistance, aging resistance, excellent mechanical properties and antistatic performance.

Owner:广东科迪新材料科技有限公司 +1

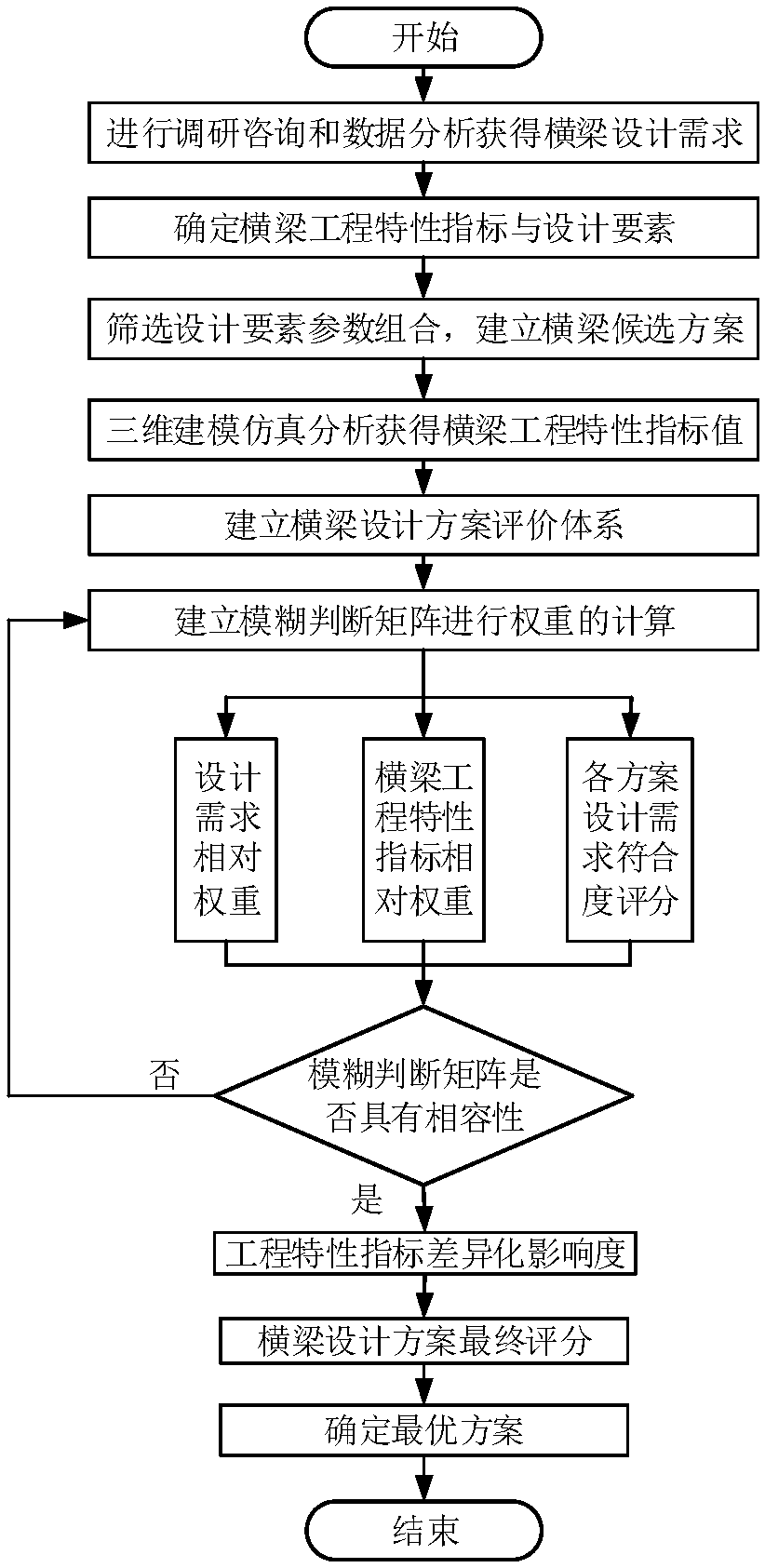

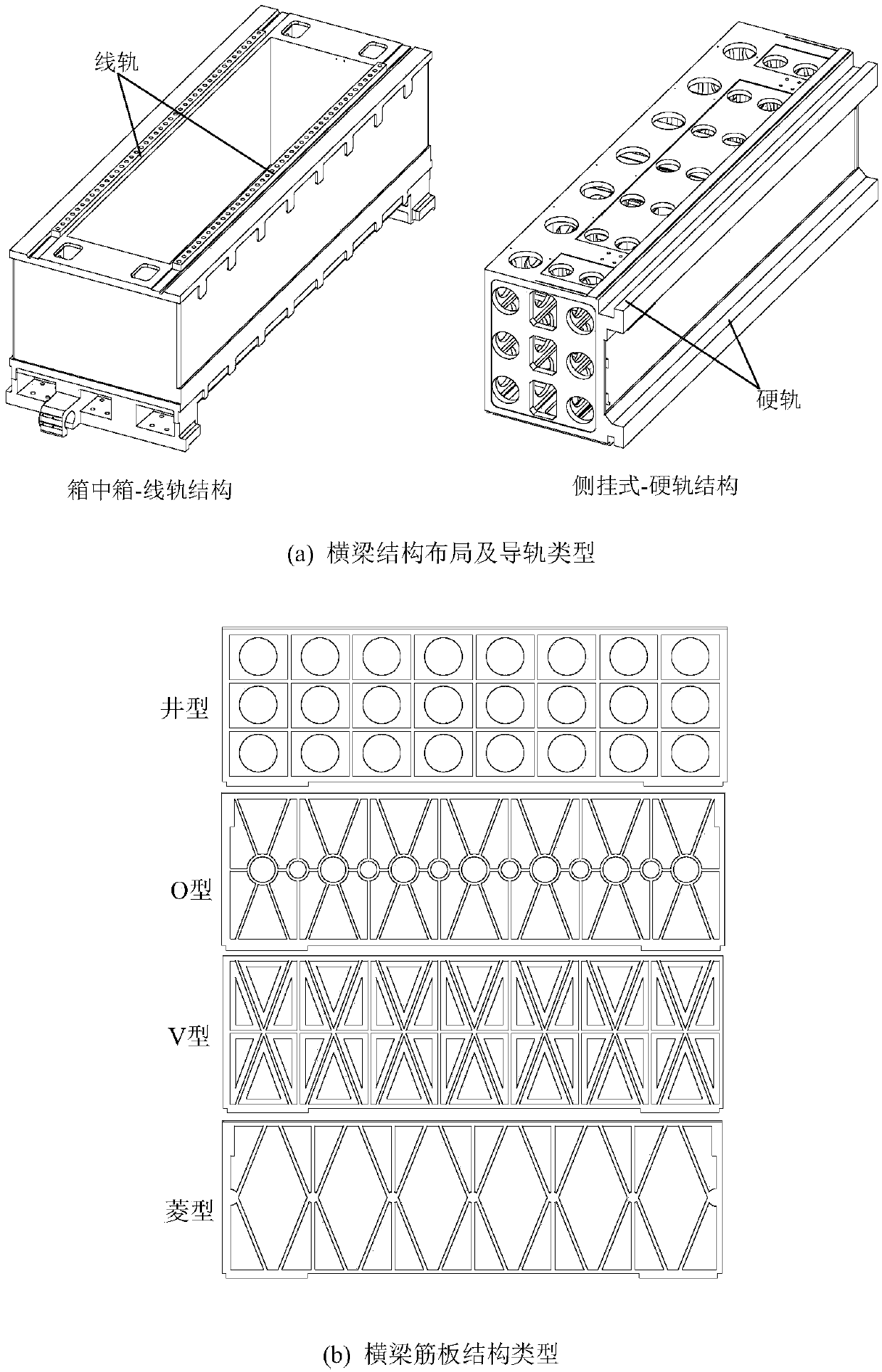

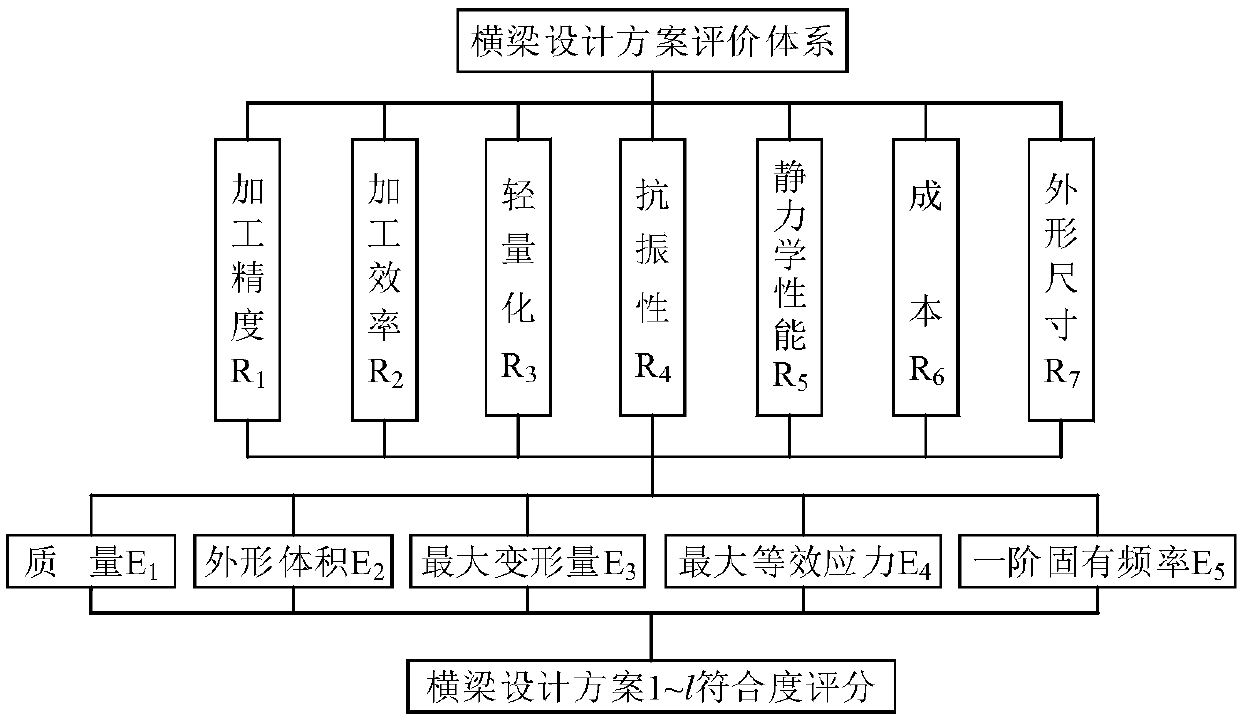

Evaluation method for machine beam design scheme by using fuzzy analytic hierarchy process

ActiveCN108399287ASolve the comprehensive evaluation problemEasy programmingGeometric CADDesign optimisation/simulationDimensional modelingFuzzy analytic hierarchy process

The present invention discloses an evaluation method for a machine beam design scheme by using the fuzzy analytic hierarchy process. The method comprises the following steps: determining a beam designrequirement through investigation and consultation, mapping the beam design requirement to a beam engineering characteristic index, and converting the beam design requirement into a beam design element; screening a design element parameter combination to formulate the beam candidate scheme, and carrying out the three-dimensional modeling to obtain a beam engineering characteristic simulation value; and establishing a beam design scheme evaluation system, using the fuzzy analytic hierarchy analysis process to establish a fuzzy judgment matrix for the relative weight calculation, and solving the differentiation influence degree of the beam engineering characteristic index on each scheme so as to obtain the final score of the beam design scheme and to determine the optimal scheme. Accordingto the method disclosed by the present invention, the customer demand is emphasized, the weights of the factor indexes which affect the beam design scheme evaluation is comprehensively considered, theproblem of multi-level and fuzzy beam design scheme comprehensive evaluation is solved, and the method has the characteristics of flexibility, conciseness, easy program-programming, and the like.

Owner:NANTONG UNIVERSITY

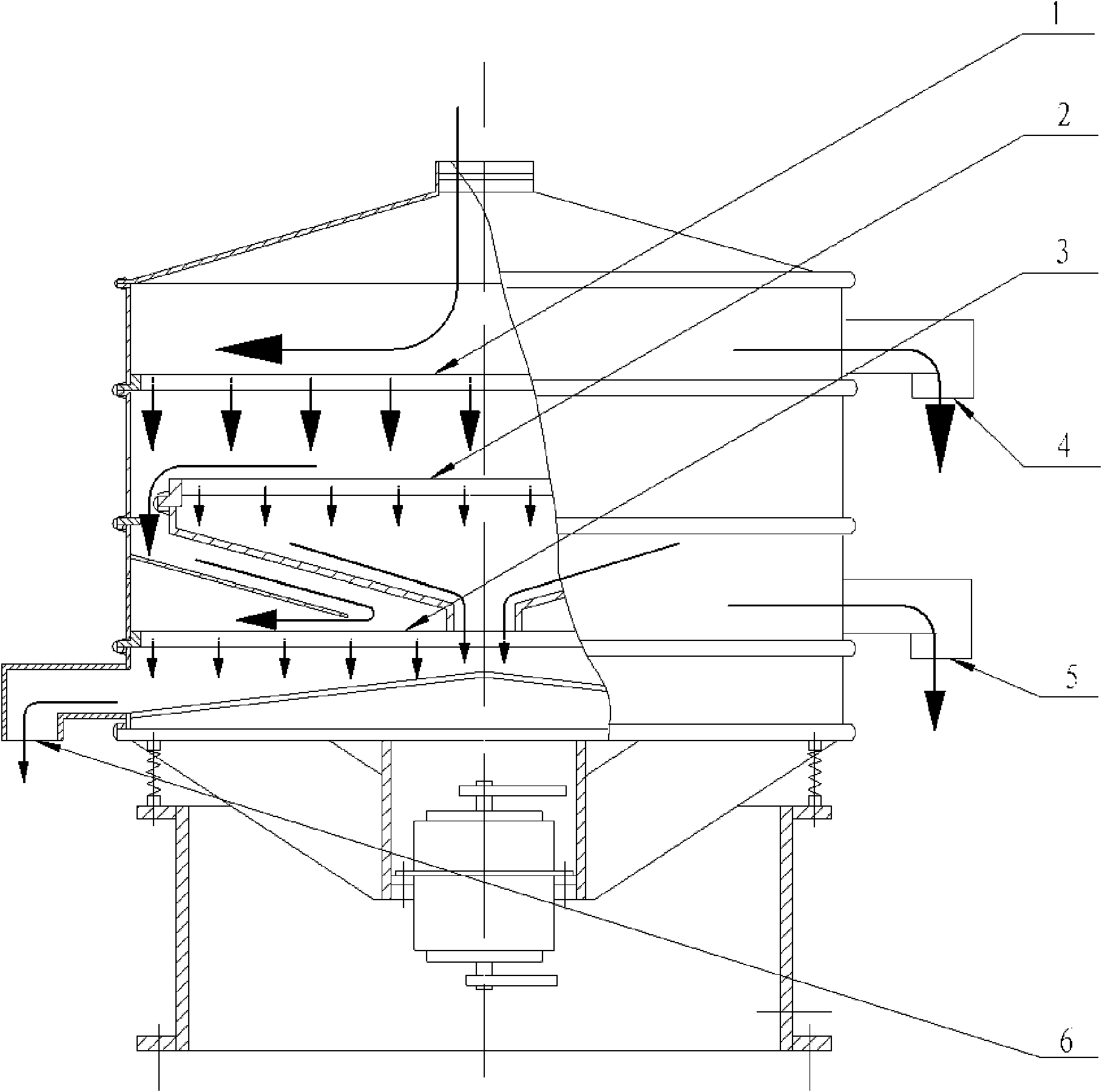

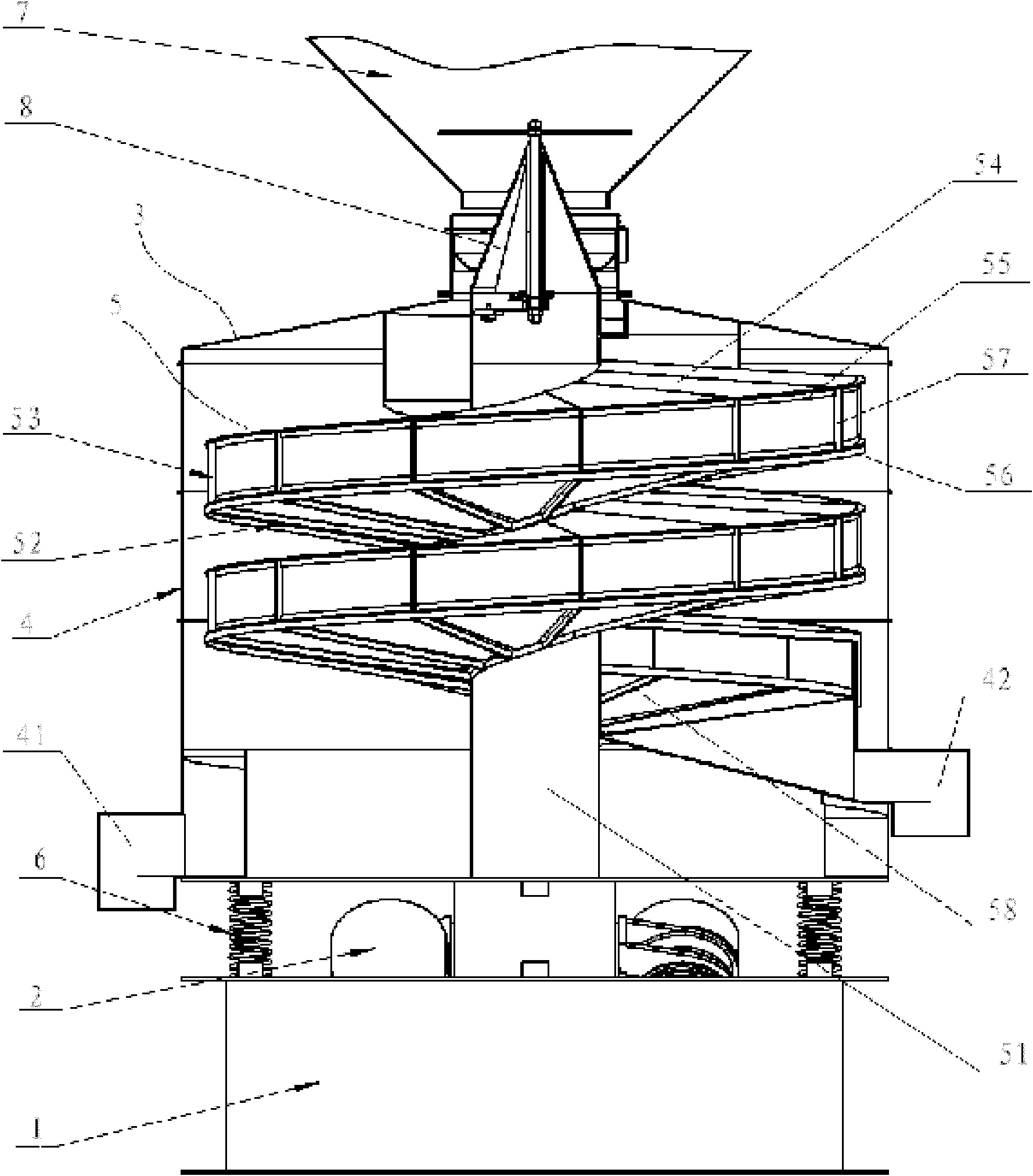

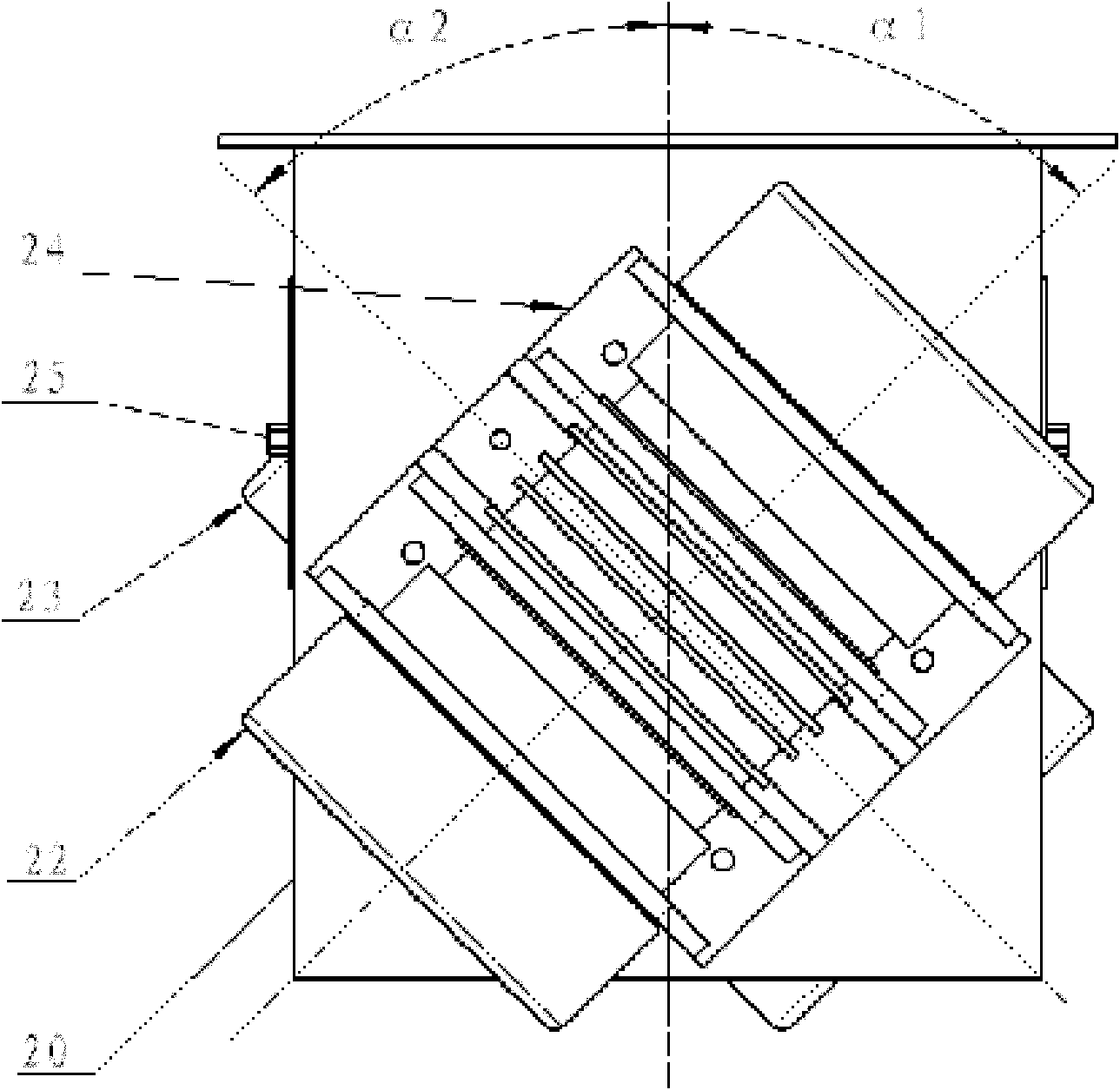

Vertical spiral vibrating screen

InactiveCN102371246AImproved resistance to fatigue vibrationIncrease the range of motionSievingScreeningEngineeringFine powder

The invention discloses a vertical spiral vibrating screen capable of greatly increasing the area of a screen and lengthening the movement stroke of powder. The vertical spiral vibrating screen comprises a base, a screen arranged on the base through a plurality of supporting springs, a vibrating device connected with the lower end of the screen and positioned in the base, a bin arranged at the upper end of the screen and a feeding valve arranged in the bin. The screen comprises a shell, a middle upright post and a screen net. The shell is a cylinder provided with a cover plate and a bottom plate, and the lower part of the shell is provided with a fine powder feeding hole and a coarse powder feeding hole; the middle upright post is vertical to the center of the shell; and the screen net comprises a bottom screen net, a lateral screen net and a top plate, wherein the inner edge of the bottom screen net is fixed on the middle upright post and is downwards spiral around the middle upright post, the lateral screen net is arranged coaxial with the middle upright post and is downwards spiral around the middle upright post, the lower end of the lateral screen net is connected with the outer edge of the bottom screen net, and the inner edge of the top plate is fixed on the middle upright post and is downwards spiral around the middle upright post.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

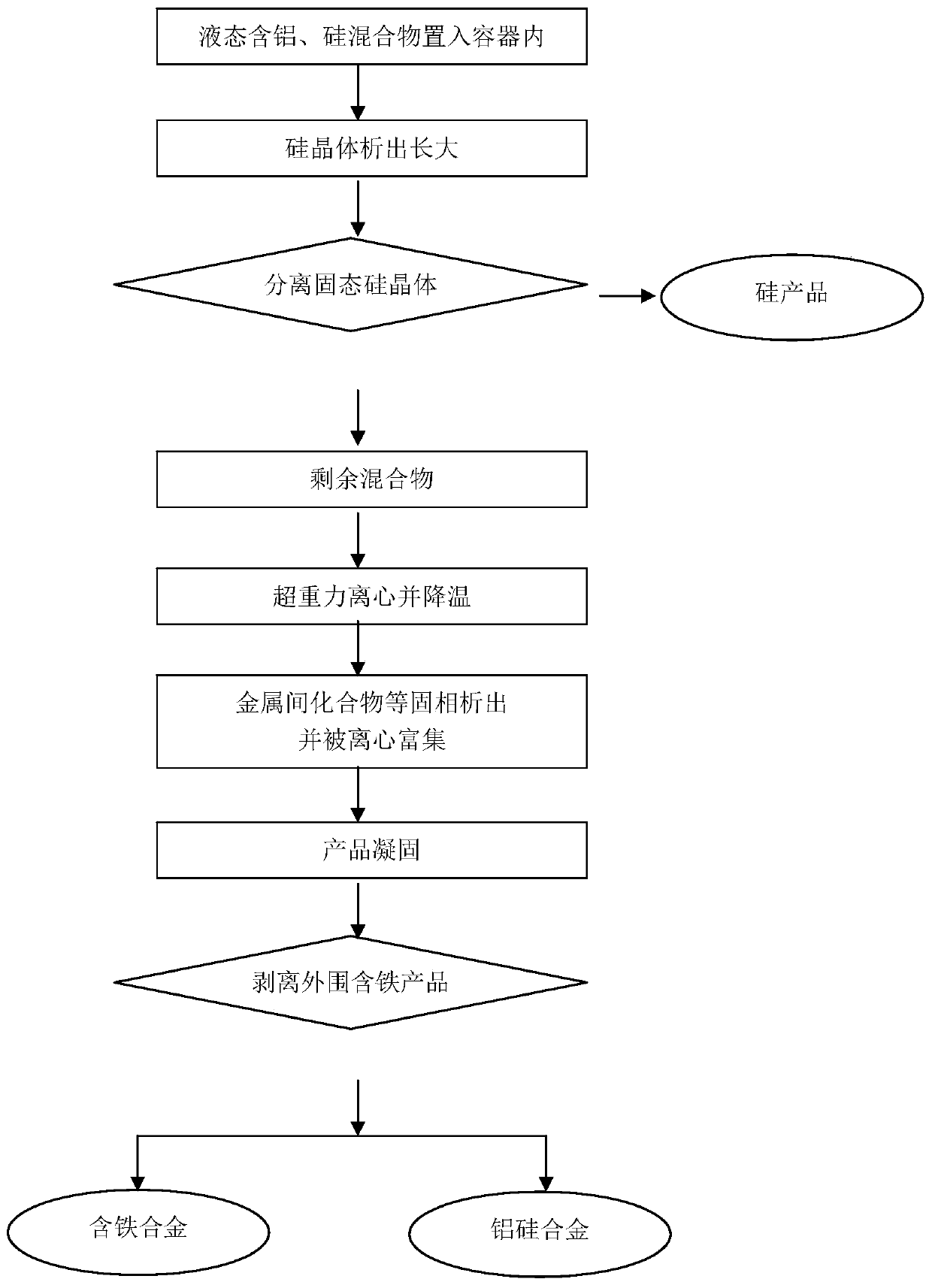

Method for filtering and centrifugally separating mixture containing aluminum, silicon, iron and the like, removing impurities and carrying out purification

InactiveCN110846513ALow costImprove profit marginsProcess efficiency improvementSilicon compoundsSilicon alloyLiquid state

The invention relates to a method for filtering and centrifugally separating a mixture containing aluminum, silicon, iron and the like, removing impurities and carrying out purification. The method includes the steps that (1), the liquid-state mixture containing the aluminum and the silicon is put in an insulated bag container; (2), the temperature operation interval of the mixture is controlled,and pure silicon crystals are precipitated and grow; (3), intermetallic compounds and other impurities are enriched and settle on the outer layer under the effect of centrifugal supergravity or pressurization, aluminum-silicon alloys on an interlayer are purified, and silicon solid phases are collected in a filtering and filtering and centrifuging manner; (4), the remaining liquid-state mixture issubjected to supergravity centrifuging and gradually cooled and solidified; and (5), solidified products are stripped in a mechanical or manual manner, and the multiple high-grade products are obtained at low cost.

Owner:刘旭

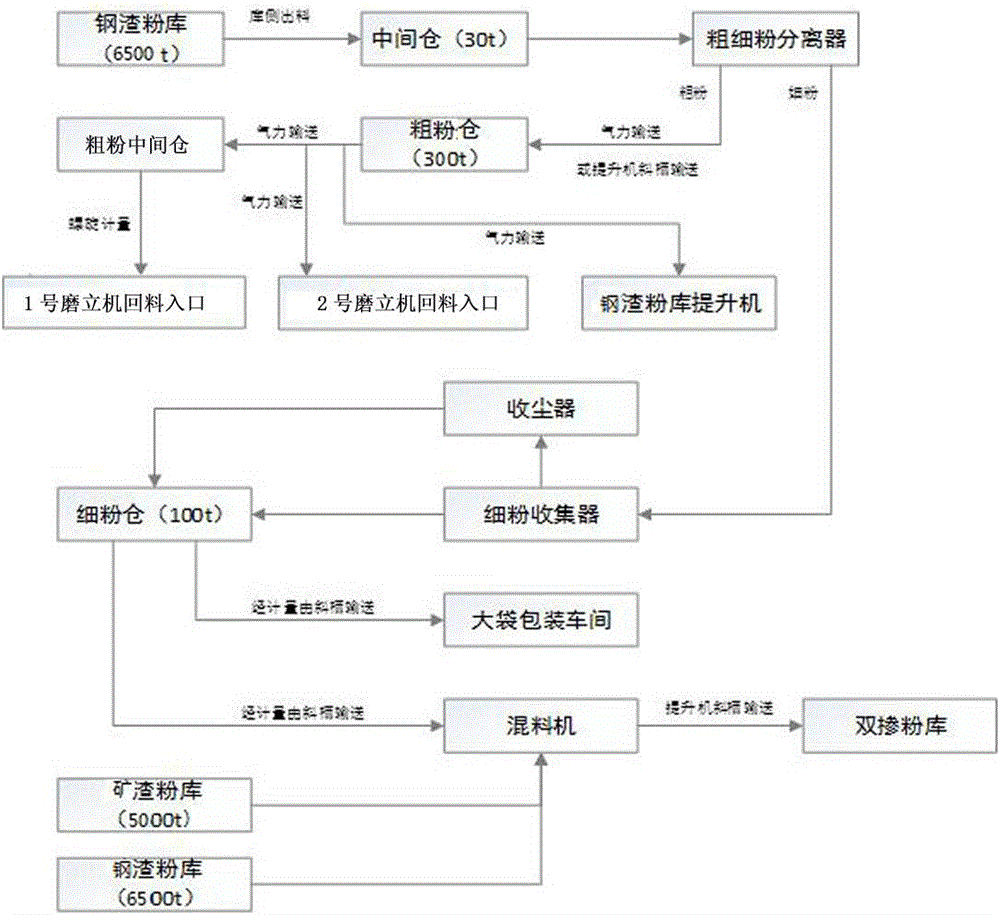

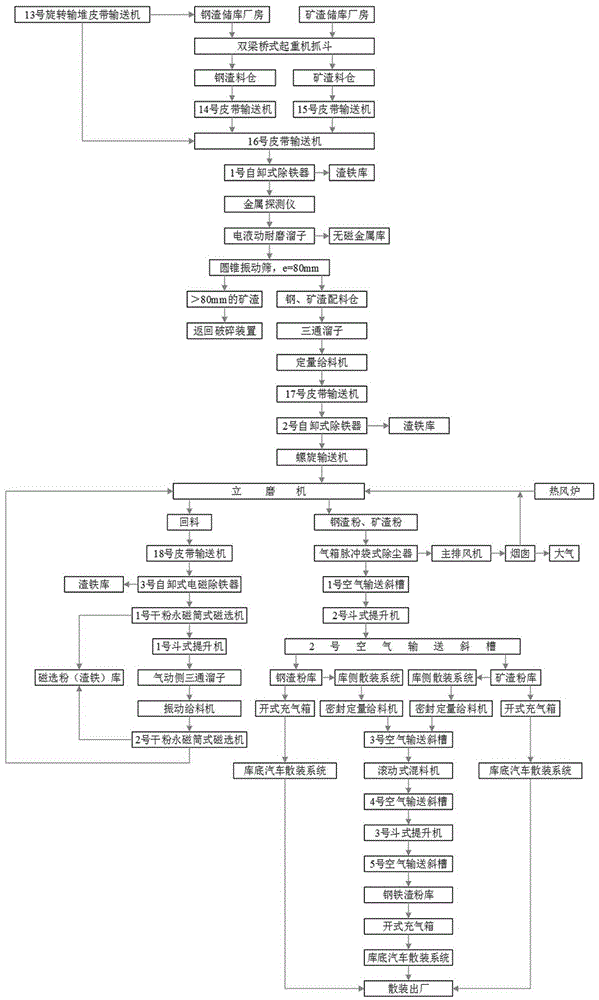

Production method for superfine steel slag micro powder

InactiveCN106076575AReduce milling loadReduce energy consumptionGrain treatmentsSlagEnergy consumption

The invention relates to a production method for superfine steel slag micro powder. The production method is characterized by comprising the following specific steps: a steel slag processing metal recovery processing step; and an independent steel slag powder grinding step by a vertical mill: a steel slag powder collecting step and a superfine steel slag micro powder separating step, thereby preparing superfine steel slag micro powder with a specific surface area being 600-1000 m<2> / kg. The production method has the advantages that: steel slag powder is separated after being grinded by the vertical mill, superfine steel slag micro powder is extracted, process operation parameters are optimized, and powder producing load of the superfine steel slag micro powder is reduced by properly increasing fineness of the steel slag powder grinded by the vertical mill, so that a steel slag powder grinding production process and a superfine steel slag micro powder grinding production process are formed, and therefore, the production method is small in energy consumption and is high in feasibility in comparison with a mode of directly grinding the steel slag micro powder by the vertical mill.

Owner:JIANGSU RONGDA NEW MATERIAL

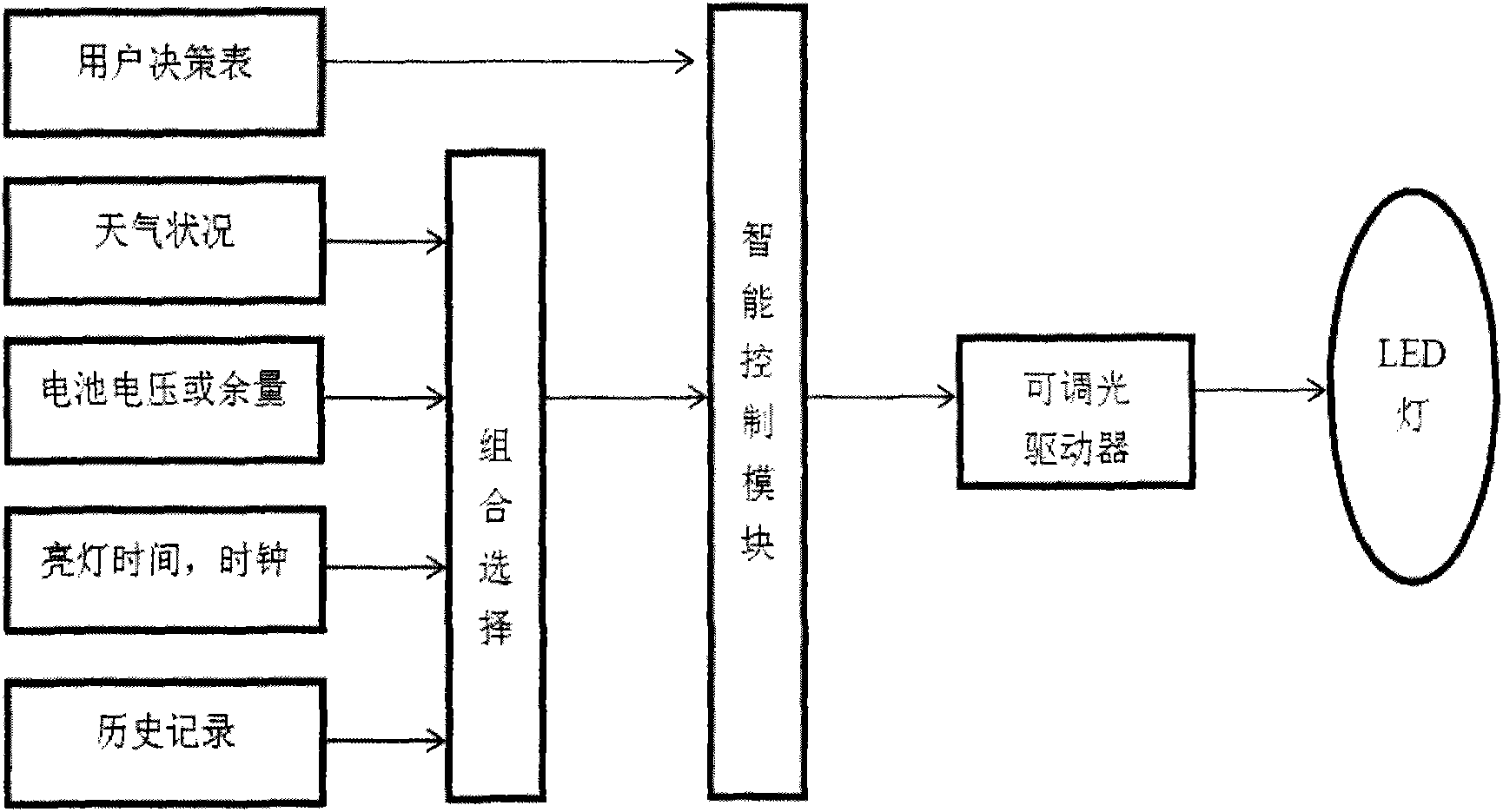

Solar LED street lamp control method

InactiveCN103415104AReduce usageReduce brightnessElectric light circuit arrangementEnergy saving control techniquesElectric energyEngineering

The invention relates to the road lighting technology, in particular relates to a solar LED street lamp control method. Specifically, a street lamp intelligent control module carries out intelligent computing according to such parameters as a battery voltage or residual energy, weather conditions, historical records and lighting time, and then controls brightness of the LED street lamp based on a user decision. Optimal configuration of a photovoltaic battery, a storage battery and road lighting is realized, and the utilization rate of collected solar energy is improved, so that the lighting need of the people is met and also the electric energy can be saved to the maximum; the photovoltaic battery panel area and the capacity of the storage battery are reduced; and thus, the cost is reduced and the need of the market is met.

Owner:ANHUI LONG VOLT ENERGY CO LTD

Transmission shaft set assembling technology

ActiveCN101380893AEliminate error accumulationGuarantee the quality of dynamic balanceControl devicesUniversal jointDynamic balance

The invention relates to an assembling process of a drive shaft assembly. The process comprises the following steps: the first step: the assembling of part A: an extruder and a working platform device are adopted to arrange a universal joint on a flange fork and a universal joint fork on the universal joint; the second step: the assembling of part B: an extruder and a working platform device are adopted to arrange a universal joint on a flange fork and a spline shaft fork and a spline hub sub-assembly or a sliding fork and a rear shaft head sub-assembly on the universal joint; the third step: an extruder and a universal clip extrudes and assembles components of part A, components of part B and a shaft tube into a drive shaft assembly; the fourth step: a welding machine and a universal clip are adopted for alignment and welding of the drive shaft assembly; and the fifth step: a dynamic balancer and a universal clip are adopted for the dynamic balance of the drive shaft assembly. Therefore, the invention can increase the assembling precision and product quality of the drive shaft assembly, eliminates the part processing error, improves the labor efficiency, shortens the production period and decreases the production cost and labor intensity.

Owner:XUCHANG YUANDONG DRIVE SHAFT

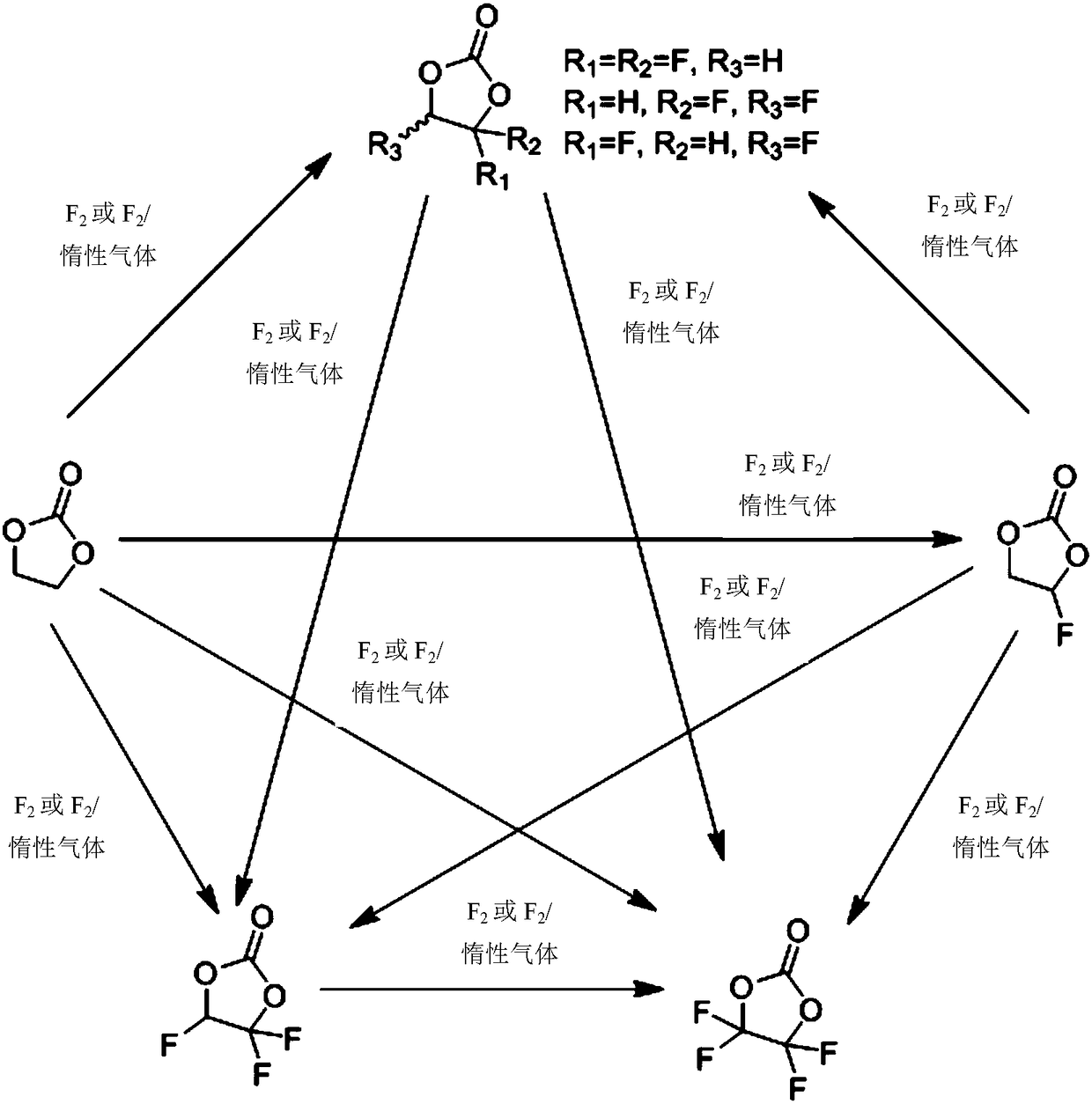

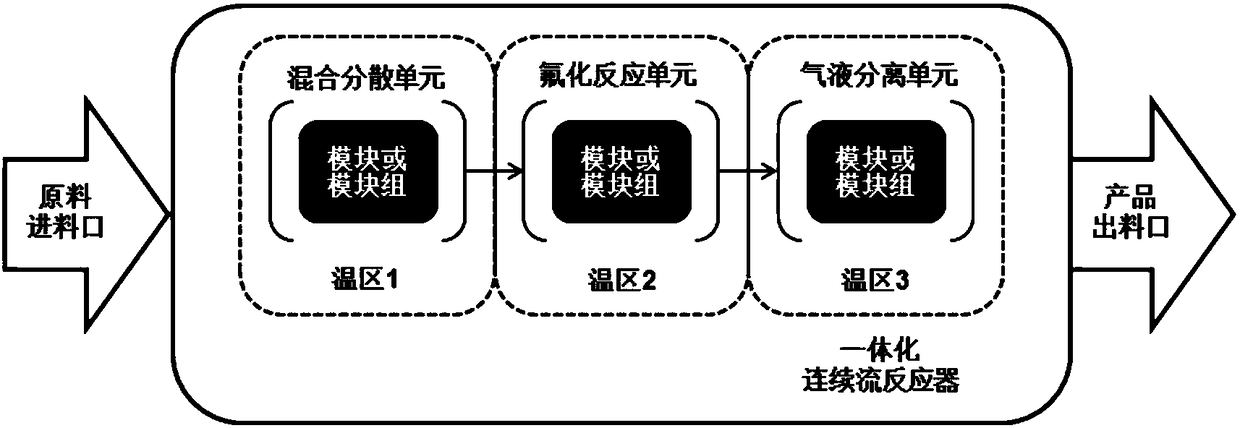

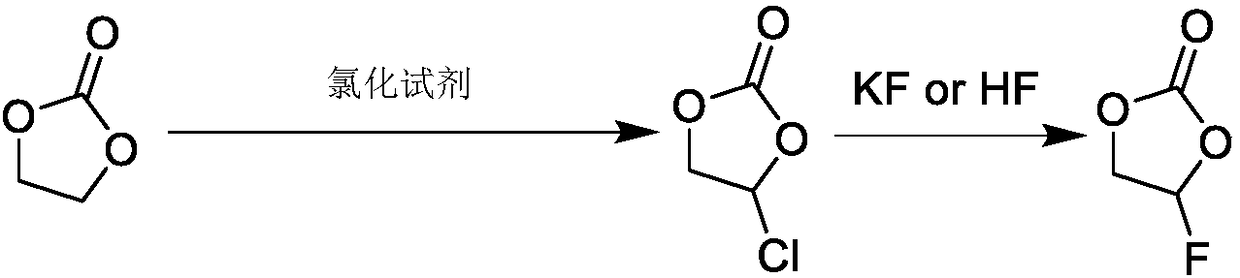

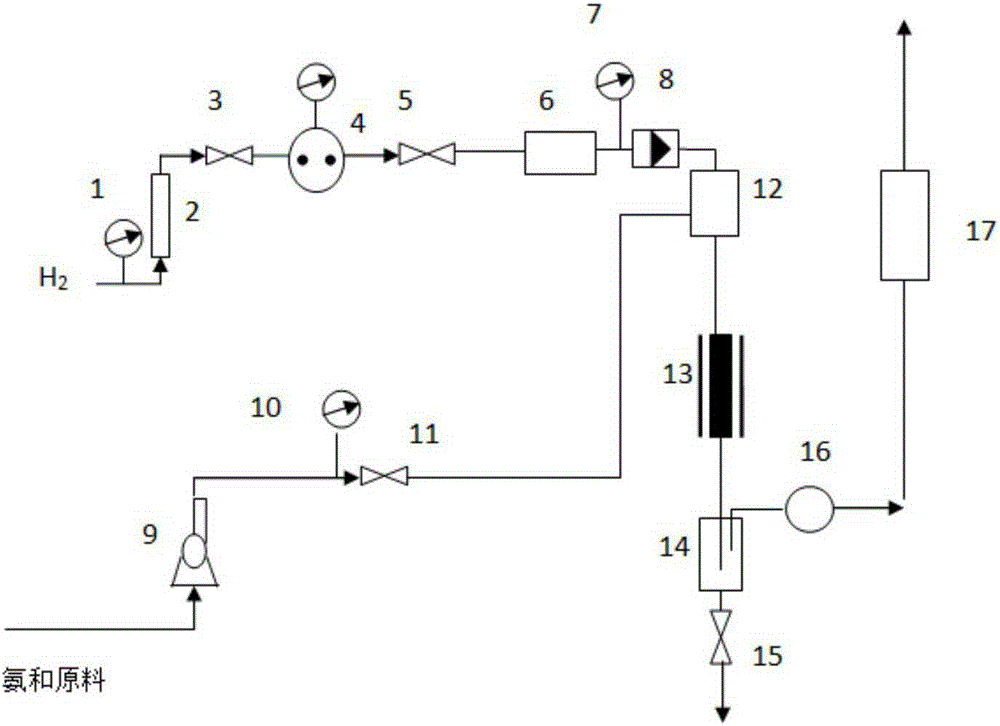

Rapid continuous flow synthesis process of fluoroethylene carbonate

InactiveCN108250176AOvercoming the defect of amplification effectNo effect on yieldOrganic chemistryContinuous flowCarbonate

The invention relates to a rapid continuous flow synthesis process of fluoroethylene carbonate and an integrated continuous flow reactor for realizing the process. The continuous flow synthesis process is characterized in that a raw material to be fluorinated and fluorine gas are used as reactants, and are continuously and successively subjected to steps of mixed dispersion, fluorination reaction,gas-liquid separation, so as to obtain the fluoroethylene carbonate; and the synthesis process is carried out in the integrated continuous flow reactor, the raw material to be fluorinated and the fluorine gas are continuously added to a feed inlet of the integrated continuous flow reactor, and the fluoroethylene carbonate is continuously obtained from a discharge port of the integrated continuousflow reactor with the reaction time equal to or less than 600 s. The process is a rapid, safe, efficient, highly versatile and easy for mass production continuous synthesis process of the fluoroethylene carbonate.

Owner:SHANGHAI HYBRID CHEM TECH

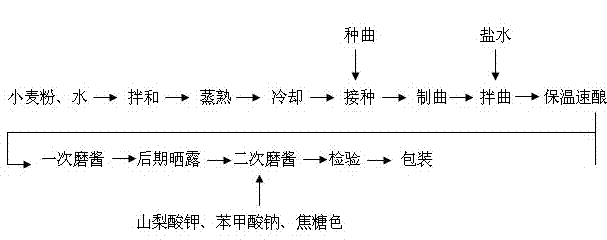

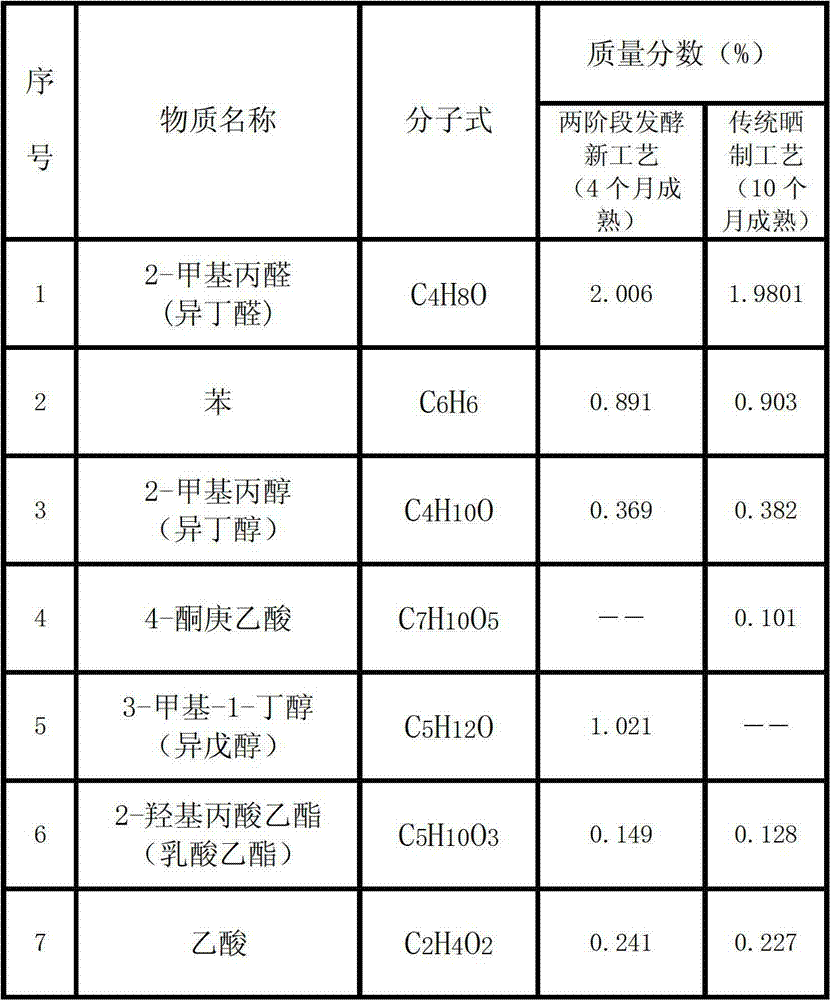

Production process for flour paste

The invention provides a production process for flour paste. The process comprises the following steps: 1, material steaming: a step of adding water into the raw material flour, steaming the flour with vapor, delivering steamed flour to a koji-making pool and spreading the flour so as to cool the steamed flour; 2, inoculation: a step of adding a starter into the steamed flour and carrying out inoculation; 3, koji making: a step of putting a koji material into a koji material tank, heating the koji material after static culture, then carrying out ventilation to prepare koji, carrying out culture for 15 to 17 h and then taking the prepared koji out when the koji material is full of mycelia and generates yellowish green spores; 4, insulated speedy brewing after mixing of the koji: a step of transferring the fermented koji material into an insulated fermenting tank, adding a saline solution, allowing the koji material to be uniformly soaked by the saline solution, using steam to heat a water bath tank and turning the fermented flour over once a week; 5, primary grinding; 6, drying in the open air; and 7 secondary grinding. The production process provided by the invention adds the stepof insulated speedy brewing; compared with a later open-air drying step which lasts for 9 to 10 months in traditional methods, the insulated speedy brewing step which lasts for 1 month and the open-air drying step which lasts for 3 months in the invention enables the whole process to be decreased by 6 months, and therefore, occupation of the fermenting tank and capital is reduced while product quality is guaranteed.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

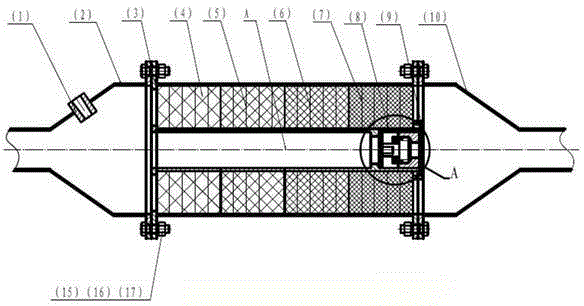

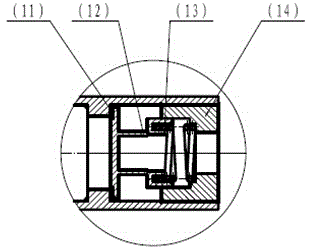

Efficient tail gas particle purification system of mining rubber-tyred vehicle

ActiveCN104594981ALow costImprove purification effectExhaust apparatusSilencing apparatusExhaust pipeMetal foam

The invention belongs to the technical field of tail gas emission of transportation equipment of mining rubber-tyred vehicles for underground coal mines and particularly relates to an efficient tail gas particle purification system of a mining rubber-tyred vehicle. The efficient tail gas particle purification system solves the problem that in the running process of existing mining rubber-tyred vehicles for underground coal mines, tail gas particle emission performance exceeds standards seriously. The efficient tail gas particle purification system of the mining rubber-tyred vehicle comprises an exhaust pipe and an exhaust tail pipe and further comprises a tail gas particle purification device and a display and warning system, the tail gas particle purification device comprises an exhaust safety device and a tail gas particle catcher arranged between the exhaust pipe and the exhaust tail pipe, the tail gas particle catcher comprises multiple levels of catcher bodies arranged in a shell in sequence, the catcher body of each level is formed by stacking a plurality of metal foam sheets, the metal foam sheets are made of Fe-Cr-Al in a firing mode, have different hole diameters and have the thicknesses of 3 mm-5 mm, and the hole diameters of the metal foam sheets in the levels of catcher bodies gradually decrease.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

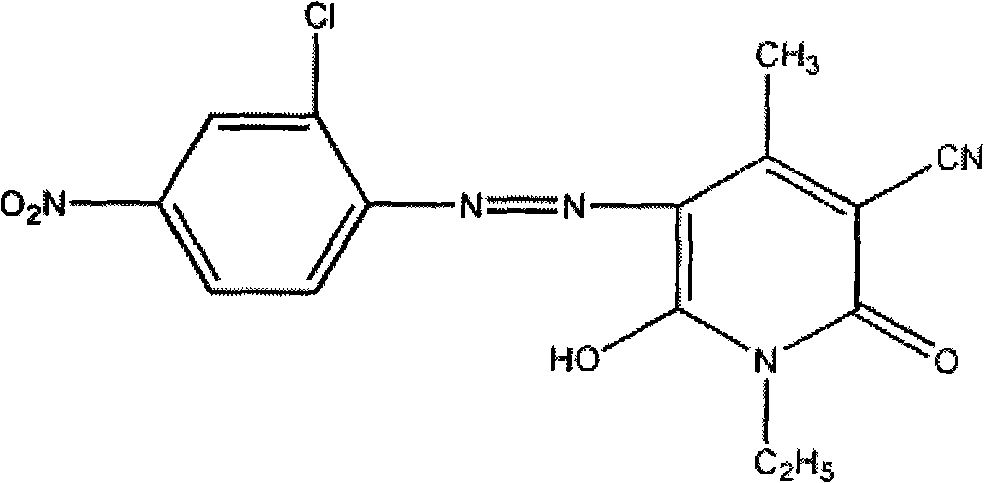

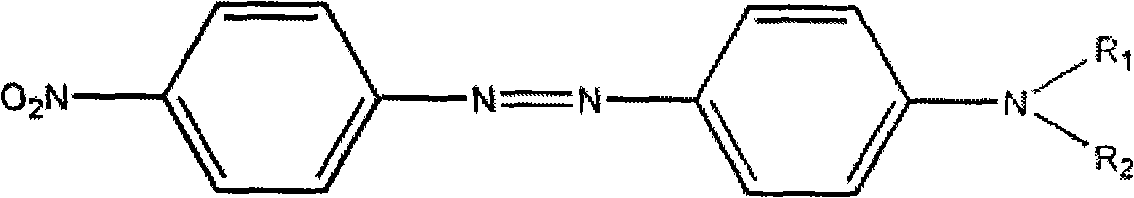

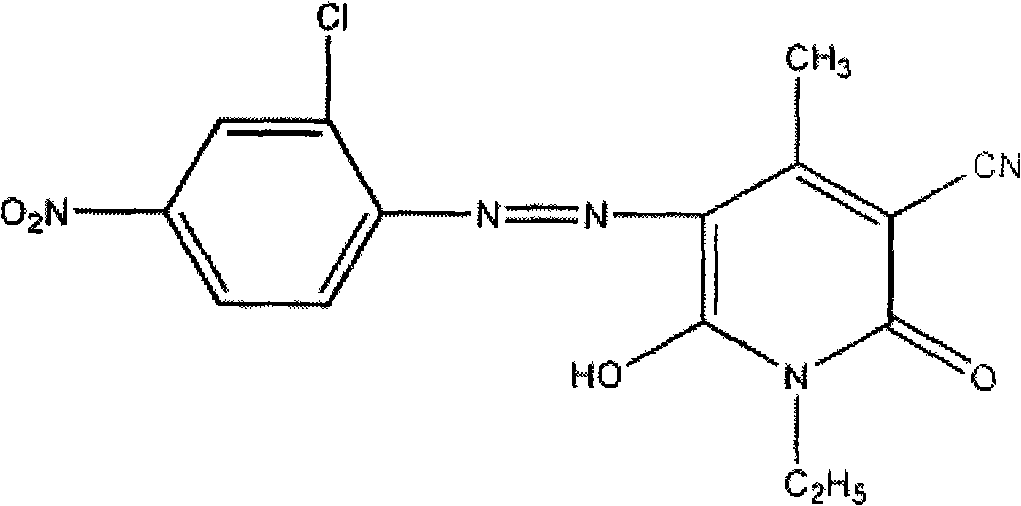

Monoazo type composition dye

The invention relates to a disperse yellow dye, in particular to a monoazo type composition dye which is suitable for dyeing and printing polyester fabrics and blended fabrics thereof. The dye comprises a component I which is 2-chloro-4-nitrophenylazo-N'-ethyl-3'-cyano -4'-methyl-6'-hydroxy-2'-pyridone and a component II, wherein the component II can be a component II-1 which is 4-nitrophenylazo-N'-ethyl-N'-cyanoethylaniline or a component II-2 which is 4-nitrophenylazo-N'-cyanoethyl-N'-ethyoxyl formylaniline; the ratio of the component I and the component II in percentages by weight is preferably 60-95% : 40-5% and 30-95% : 70-5%, thus a wider yellow spectrum space can be provided. In addition, the invention also contains a diffusant which is preferably MF or sodium lignin sulfonate. Theinvention has the advantages of high migration ability, high intensity, and the like and can better substitute for disperse golden yellow E-3RL (disperse yellow 23) which is forbidden at present.

Owner:董源

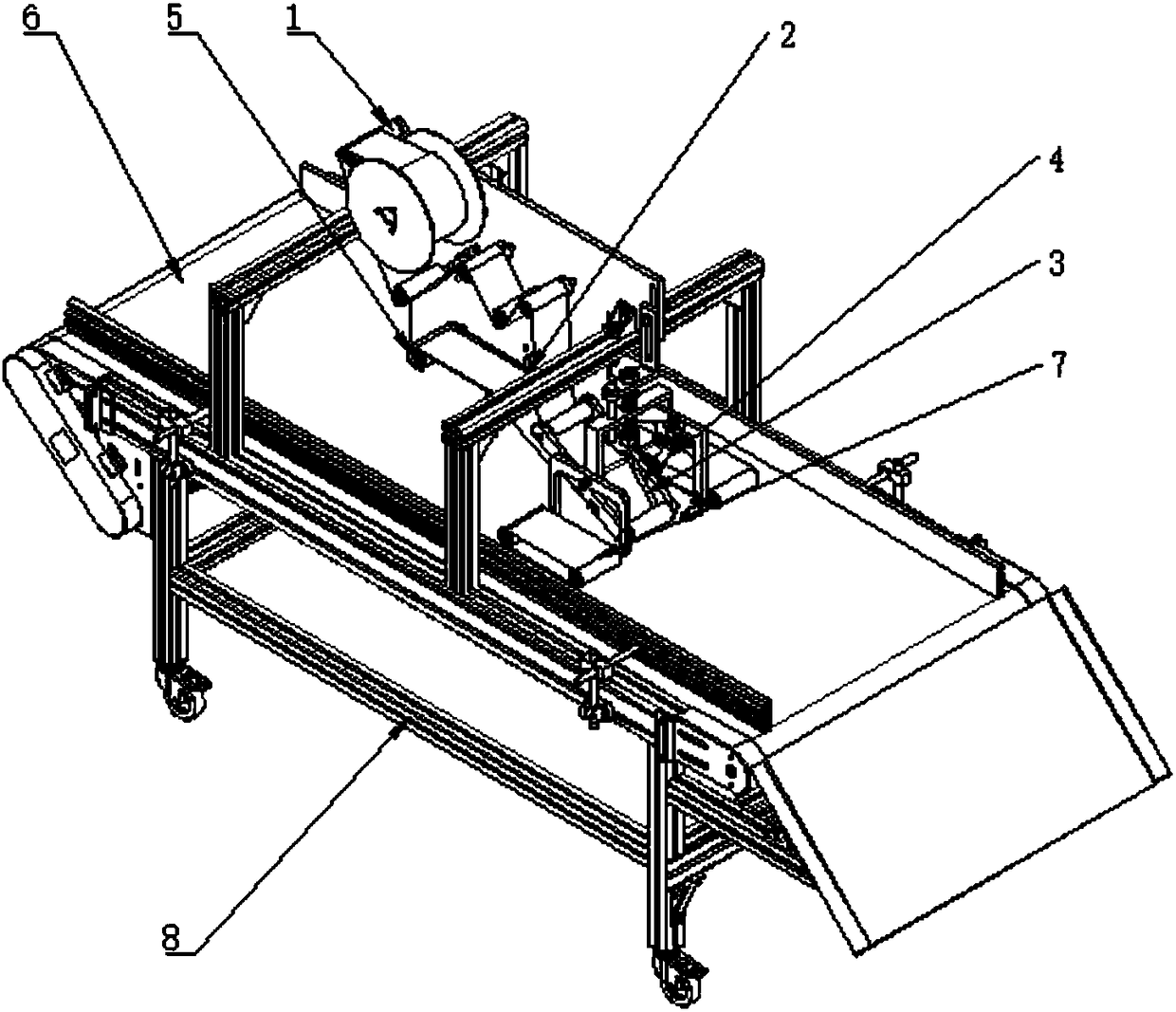

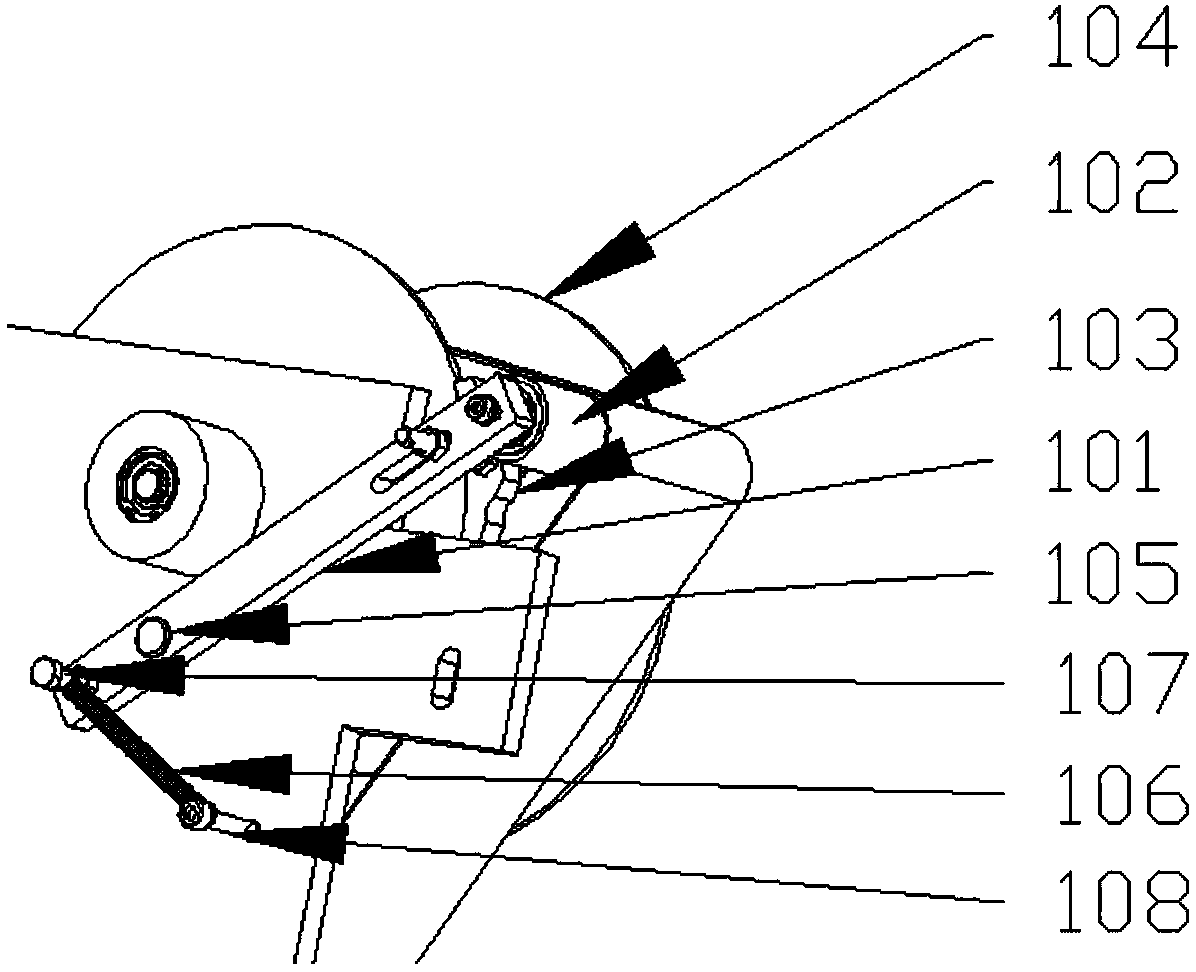

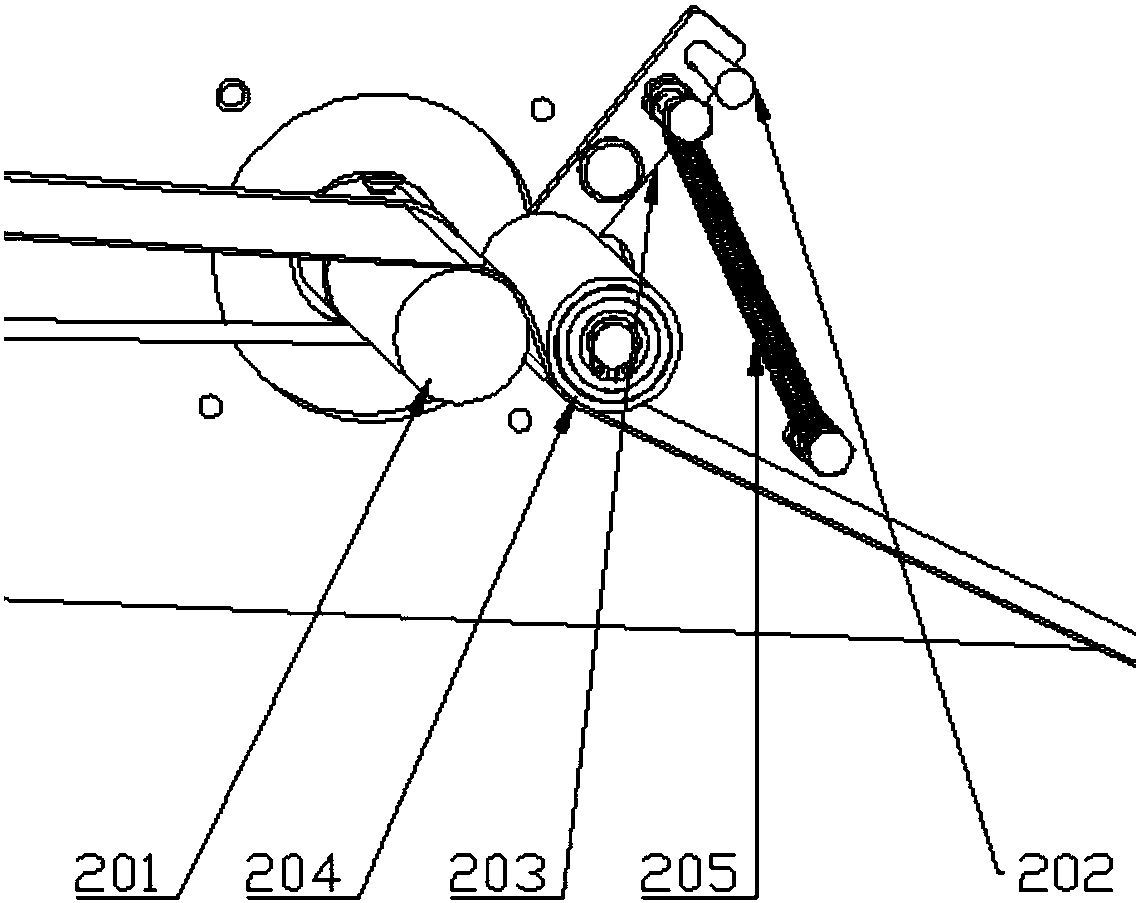

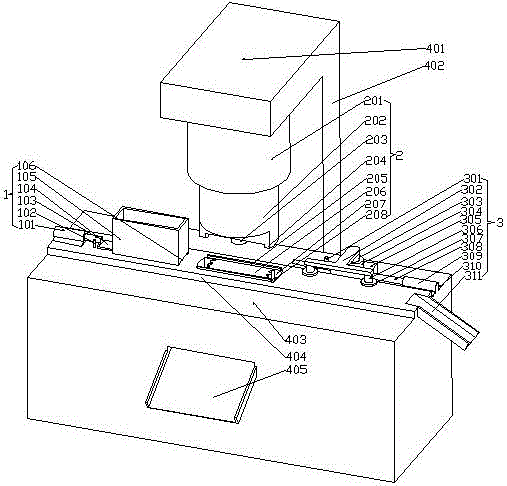

Souvenir bag labeling machine

ActiveCN108190164AAdapt to market demandEasy to installLabelling machinesWebs handlingPaper recyclingEngineering

The invention relates to a souvenir bag labeling machine. A souvenir bag conveying device is mounted on a rack and provided with a photoelectric sensor. A braking mechanism is mounted on the souvenirbag conveying device, and a drawing mechanism is mounted blow the front portion of the braking mechanism. A label peeling mechanism and a pneumatic label covering mechanism are mounted below the frontportion of the drawing mechanism, and a label flattening roller is mounted at the front end of the pneumatic label covering mechanism. A souvenir bag compressing device is mounted between the label peeling mechanism and the souvenir bag conveying device, and a wax paper recycling mechanism is mounted below the drawing mechanism. Wax paper separated from a label is recycled and wound around a label rolling device of the wax paper recycling mechanism through a drawing shaft and a pressing roll of the drawing mechanism. According to the souvenir bag labeling machine, the labeling work of souvenir bags can be automatically completed, and a synchronous contact pasting method of a brush-pasting method is adopted for achieving the aim of reliable and efficient labeling; and the whole mechanism is high in movement speed, simple in structure and convenient to operate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

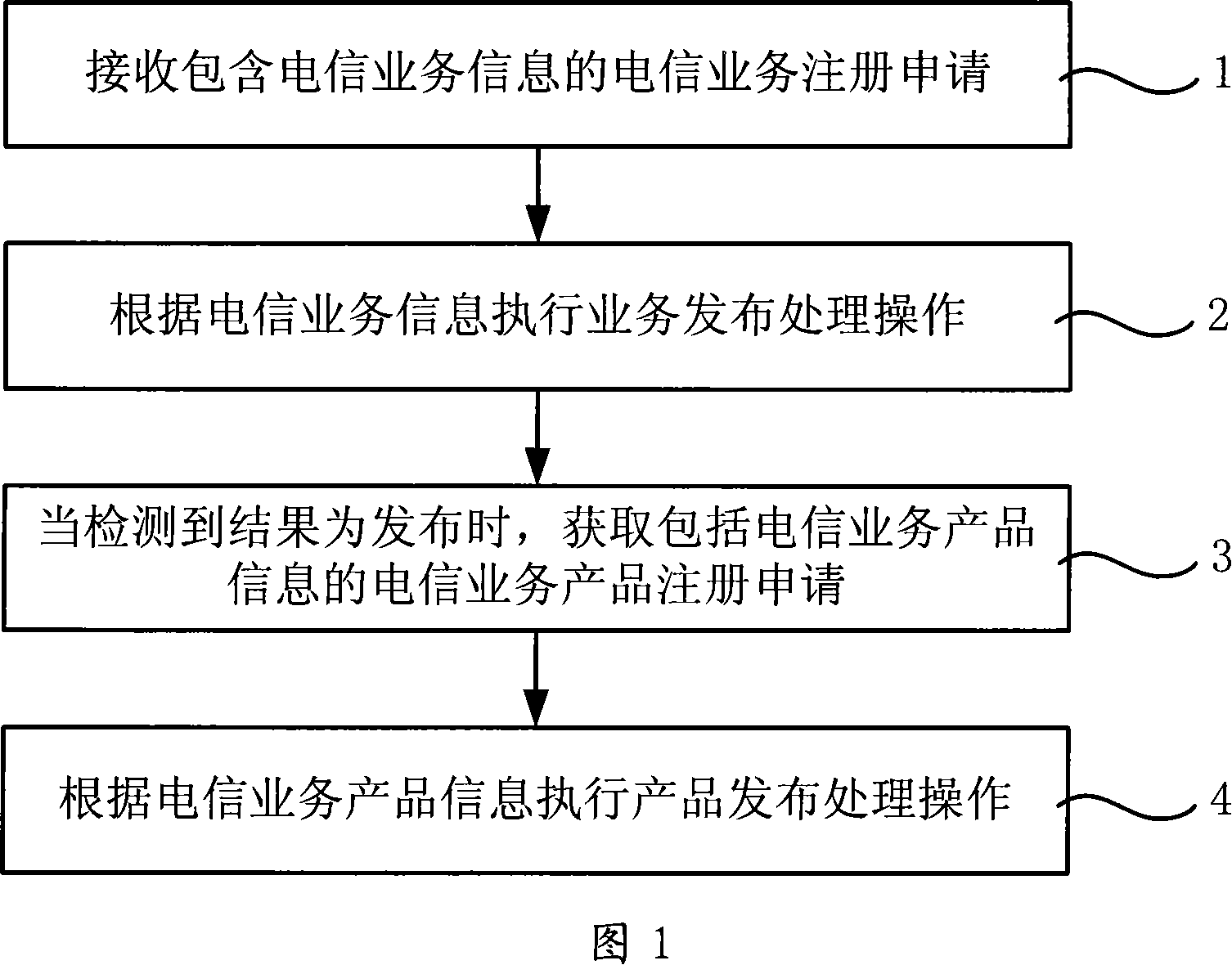

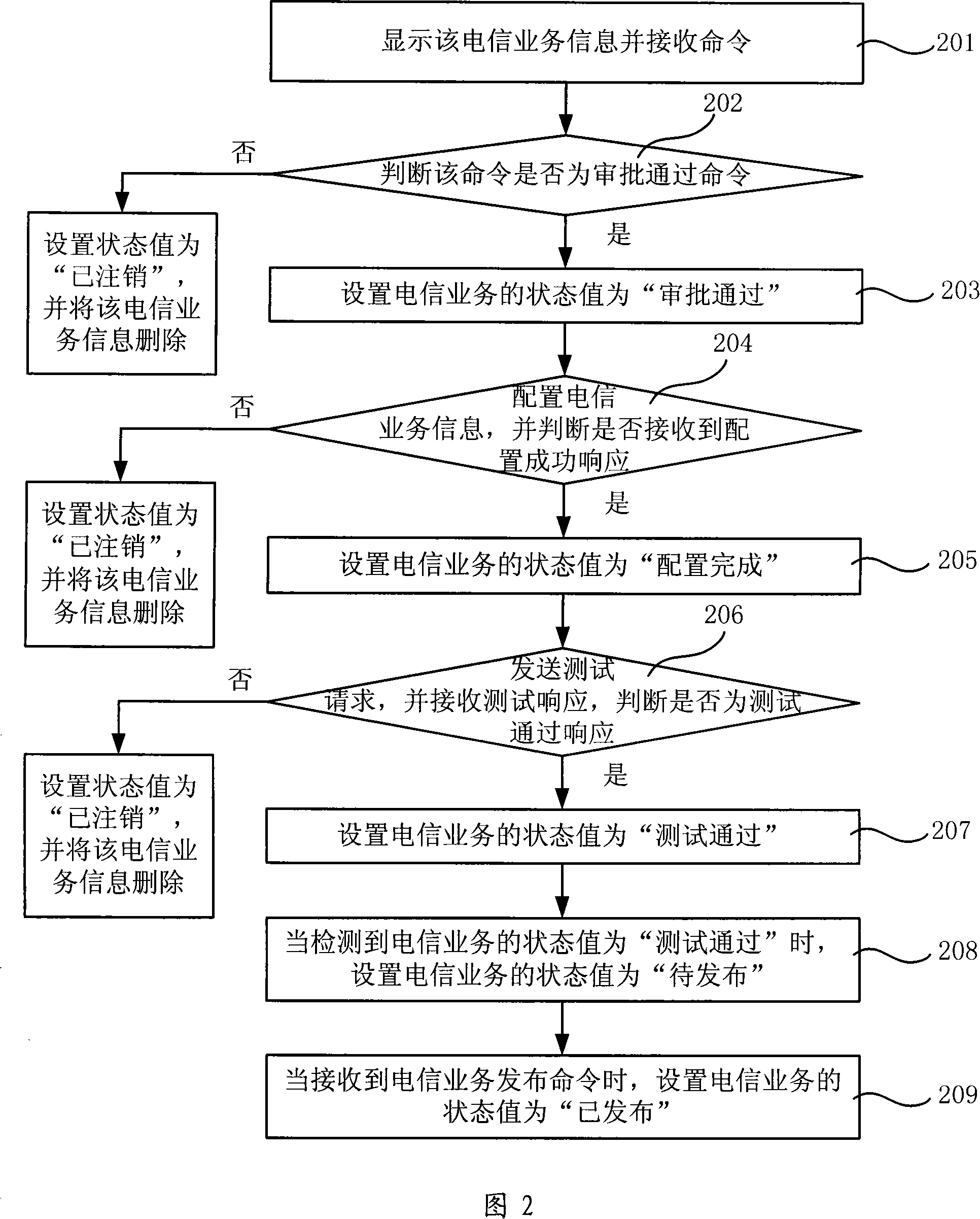

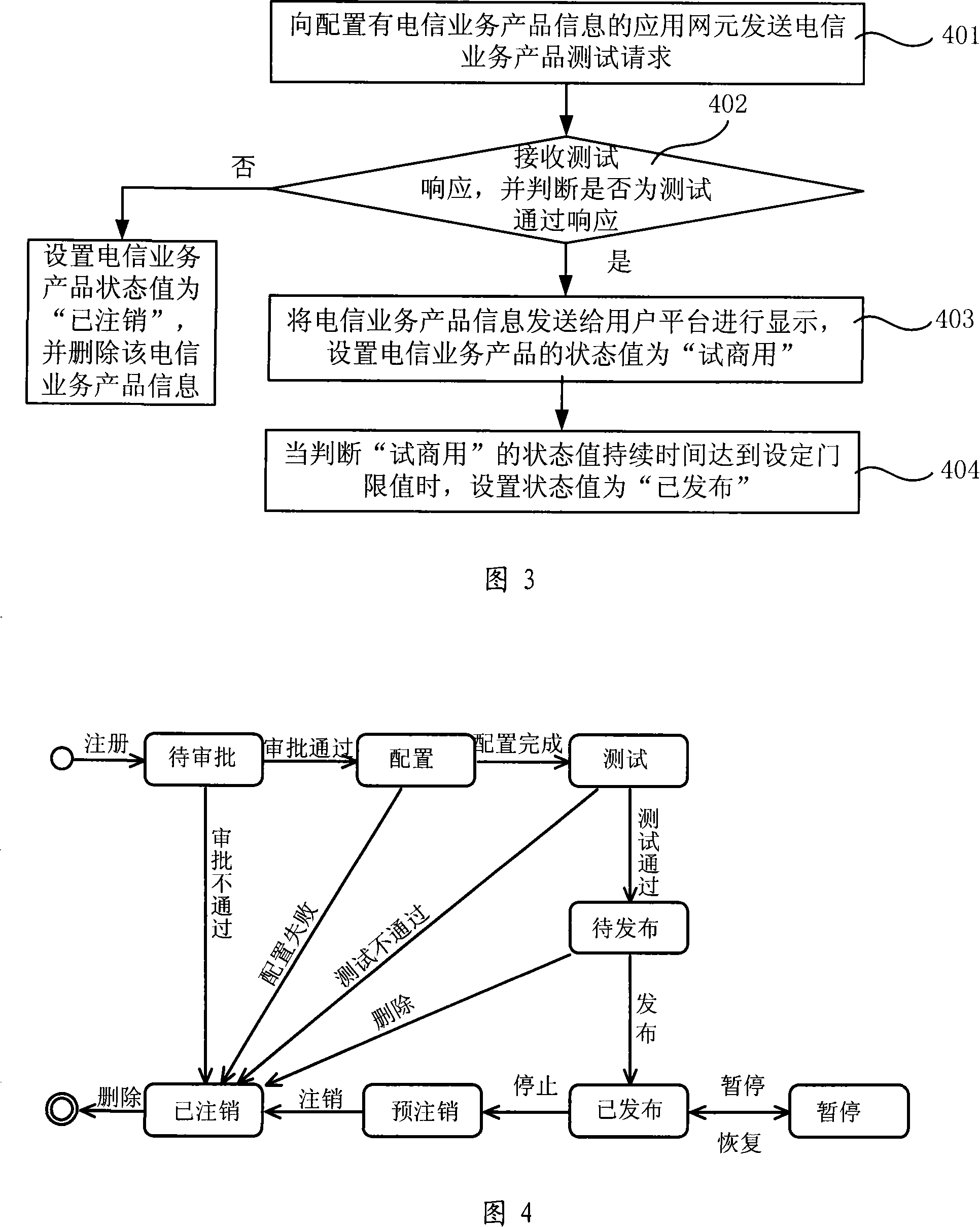

Method, device and system of telecommunication service information processing

ActiveCN101202958AImprove flexibilityClear relationshipSpecial service for subscribersRadio/inductive link selection arrangementsInformation processingService provision

The invention relates to a method of telecommunication service information processing and a device and a system thereof. The method comprises that the register application of the telecommunication service is received; the service publishing and processing operation is performed to the telecommunication service; when the publishing of the telecommunication service is tested, the register application of the telecommunication service product is obtained; the product publishing and processing operation is performed to the telecommunication service product. A telecommunication service information processing device comprises a service register module, a service publishing module, a product register module and a product publishing module which perform the steps of the telecommunication service information processing method. The other telecommunication service information processing device comprises a service application module, a service state record module, a product generation module, a product application module and a product state record module. The telecommunication service information processing system comprises an operation business platform and a service provider platform. The invention is the two-stage information processing of the telecommunication service / telecommunication service product and can flexibly and roundly manage the present telecommunication service product.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

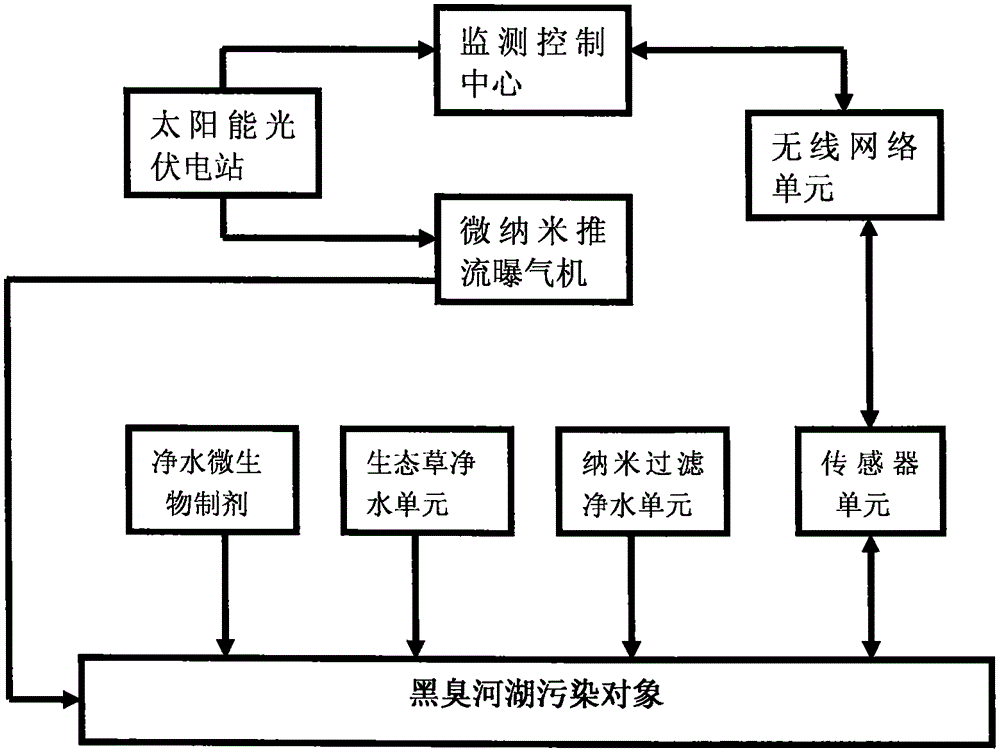

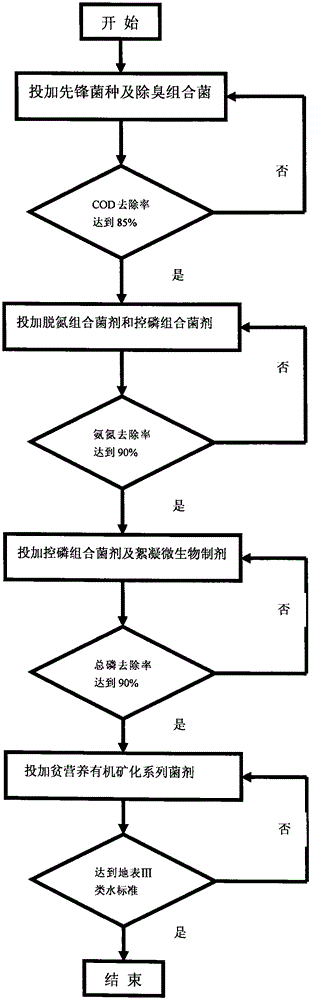

In-situ ecological restoration technology integration system for black and odorous rivers and lakes and control method thereof

InactiveCN105481206ARestore self-purification abilityAccelerate decomposition and conversionWater treatment parameter controlWater contaminantsMicro nanoFiltration

The invention discloses an in-situ ecological restoration technology integration system for black and odorous rivers and lakes. The system comprises a water purification microbial preparation, a micro-nano plug flow aerator, a stirrer, an ecological grass water purification unit, a nano-filtration water purification unit, a monitoring and controlling center, a sensor unit, a wireless network unit and a solar photovoltaic power station. The water purification microbial preparation is used for absorbing and mineralizing organic carbon and organic nitrogen, chelating heavy metal and immobilizing soluble phosphate. The micro-nano plug flow aerator is used for carrying out water body oxygenation, aeration and plug flow formation and putting the water purification microbial preparation to achieve nanocrystallization of bubbles. The monitoring and controlling center is used for monitoring water quality indexes on line and automatically correcting control commands according to water quality changes. By means of the system, the concept of only treating water in traditional pollution treatment is broken, a breakthrough is obtained, the self-purification capability of rivers, lakes and shallow seas can be rapidly recovered in a short time, a biologic chain system can be activated, a water ecological benign cycle can be formed, and the purpose of treating wastewater fundamentally can be achieved. The invention further discloses a control method based on the in-situ ecological restoration technology integration system for black and odorous rivers and lakes.

Owner:YUANRUN BEIJING ENVIRONMENTAL PROTECTION TECH

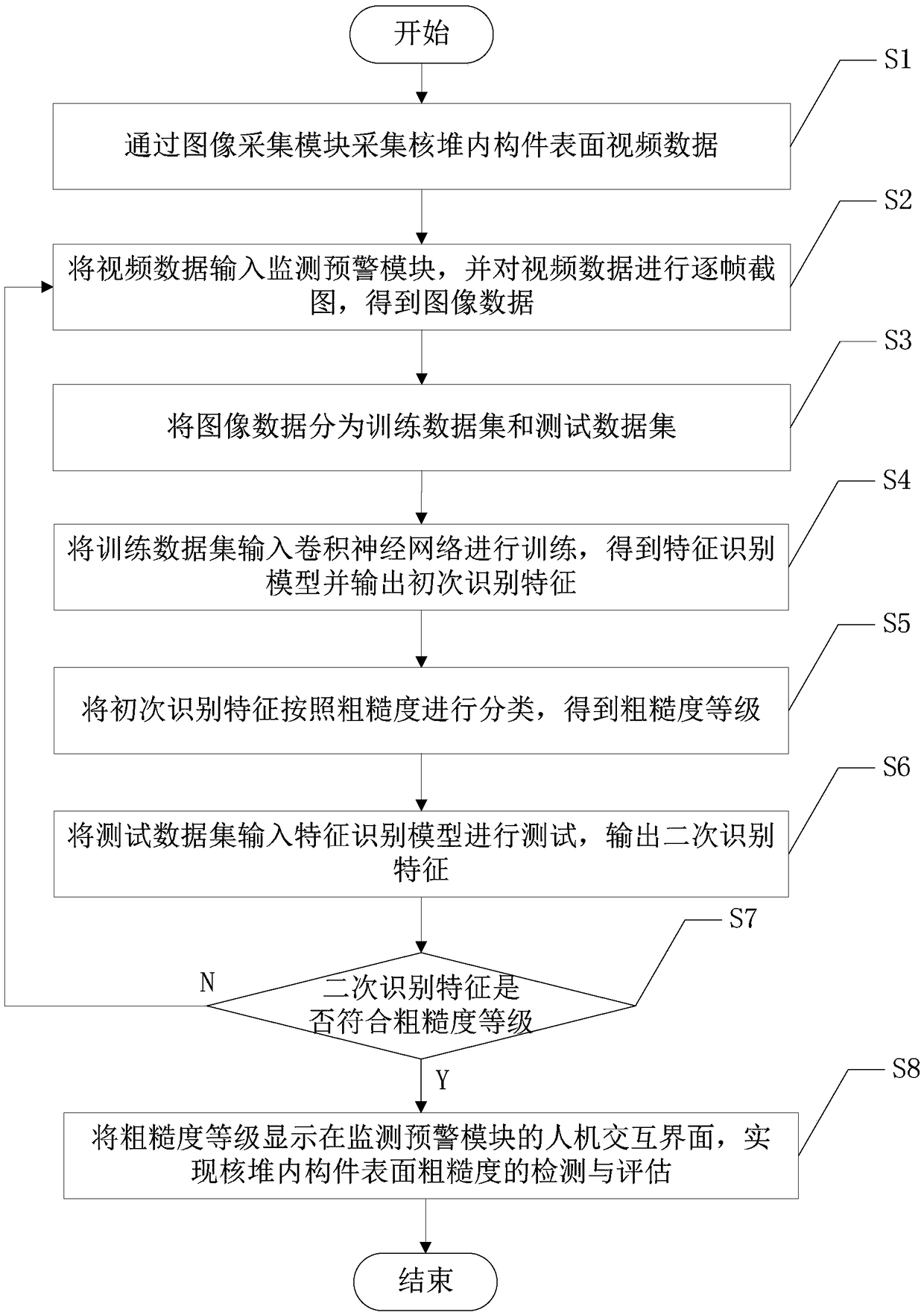

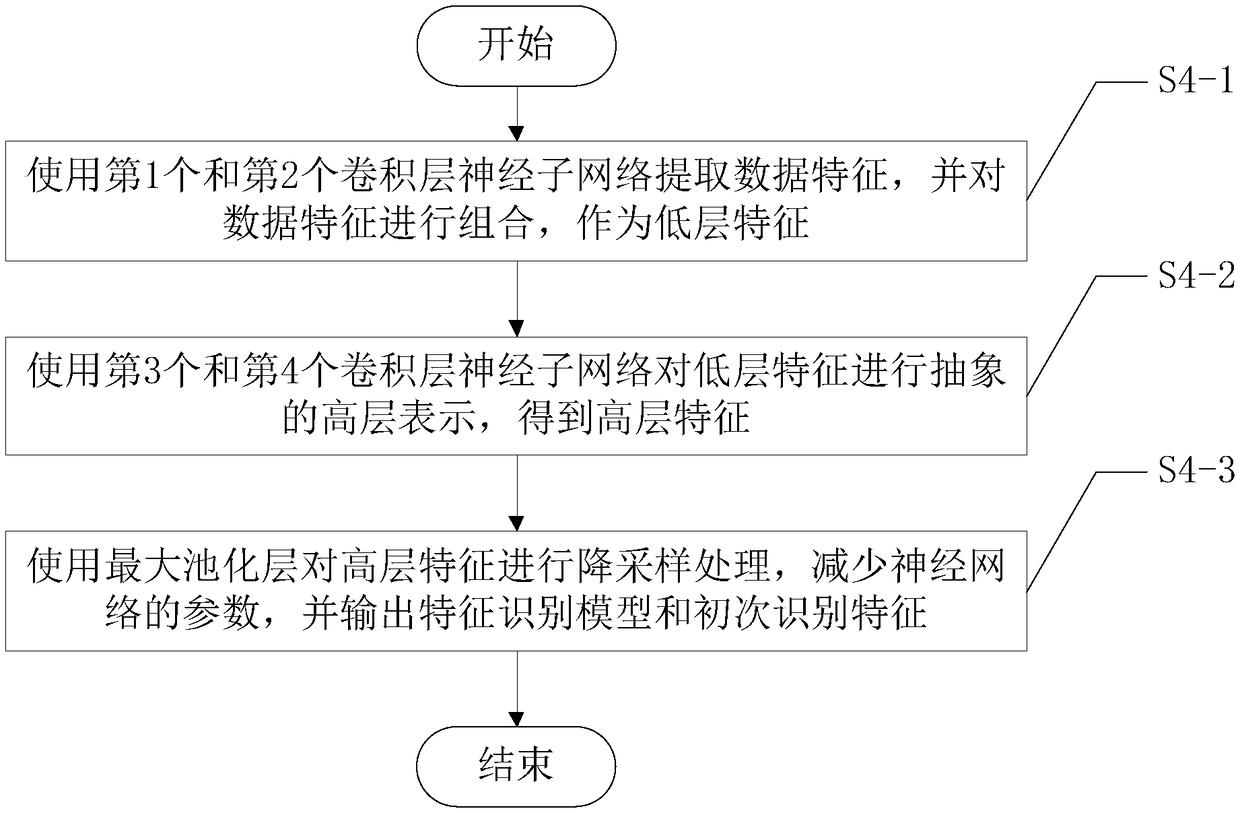

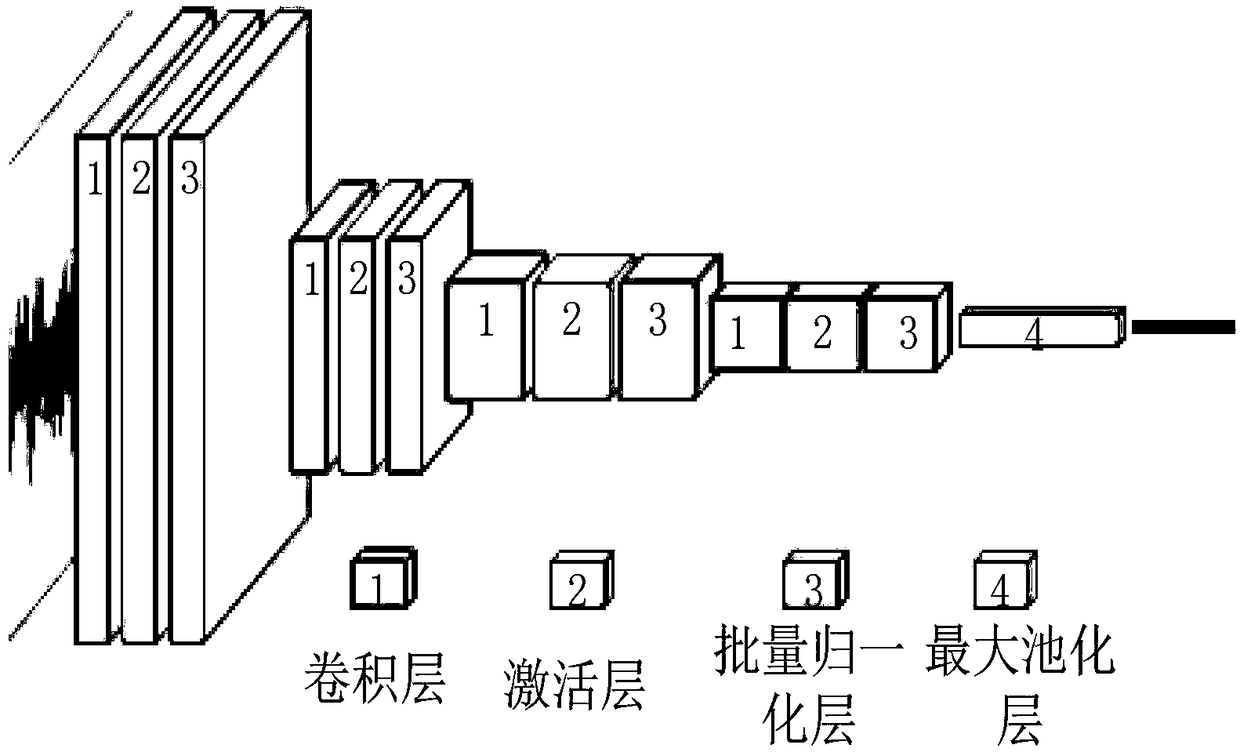

Nuclear reactor internal component surface roughness assessment method based on convolutional neural network

InactiveCN108734142AImprove efficiencyReduce human inputCharacter and pattern recognitionNeural architecturesTraining data setsAssessment methods

The invention discloses a nuclear reactor internal component surface roughness assessment method based on a convolutional neural network. The method comprises the following steps of S1, collecting video data; S2, obtaining image data; S3, dividing the image data into a training data set and a test data set; S4, inputting the training data set into the convolutional neural network for training, obtaining a feature identification model and outputting initial identification features; S5, classifying the initial identification features according to roughness, thereby obtaining roughness levels; S6, inputting the test data set into the feature identification model for test, and outputting secondary identification features; S7, judging whether the secondary identification features are consistentwith the roughness levels or not; and S8, displaying the roughness levels on a human-computer interaction interface. According to the method, the problem that in the prior art, the manpower investment is high and the efficiency is low due to artificial detection and assessment, and the material surface roughness detection and assessment timeliness and continuity requirements cannot be ensured issolved.

Owner:SOUTHWEST JIAOTONG UNIV +1

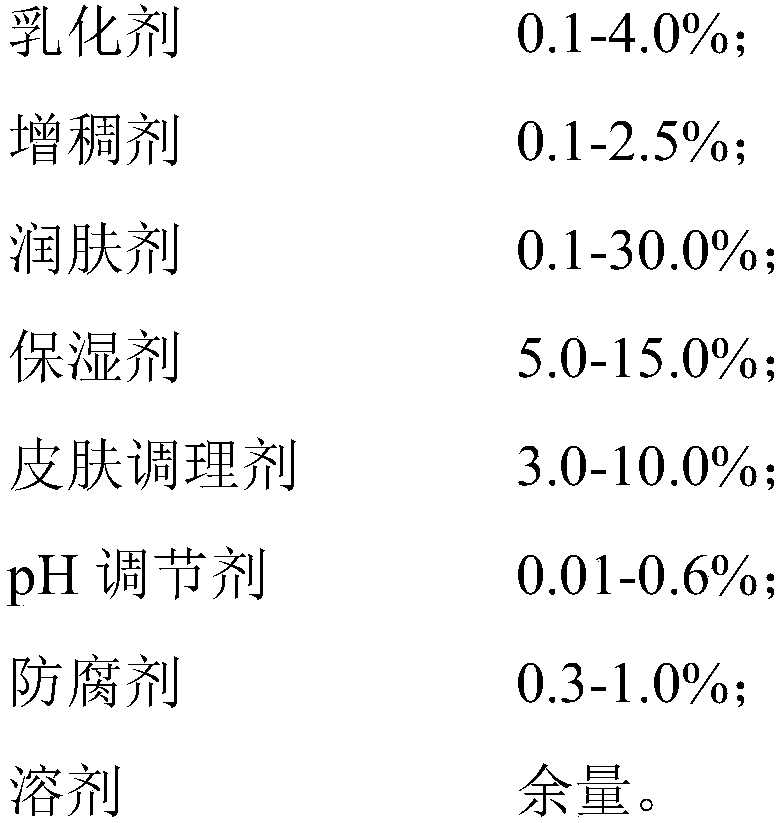

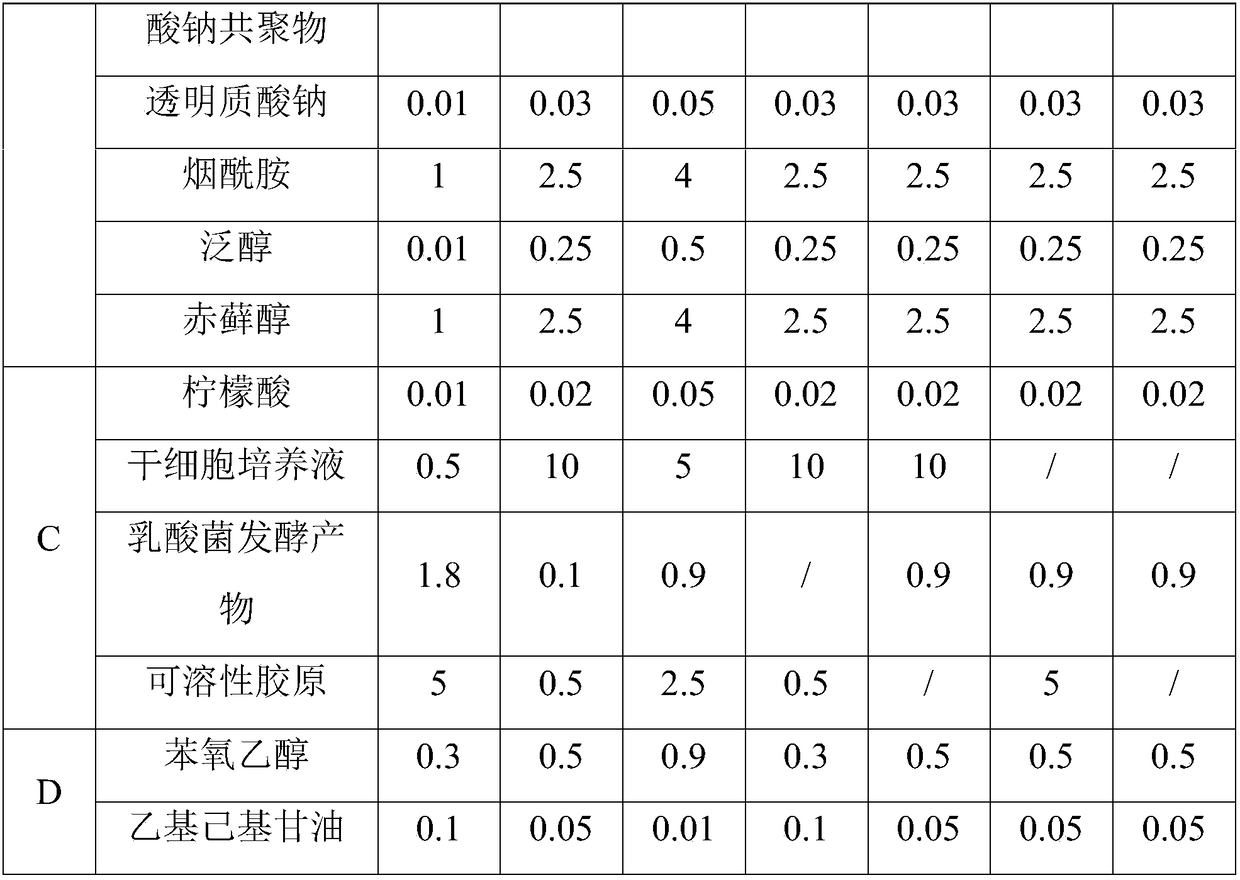

Composition and cosmetic product to soothe and repair skin and their preparation methods

InactiveCN108553405APromote proliferationIncrease vitalityCosmetic preparationsToilet preparationsBiotechnologyNormal cell

The invention provides a composition to soothe and repair skin, comprising, by weight, 0.5-5 parts of soluble collagens and 0.5-10 parts of a stem cell culture liquid. The composition to soothe and repair skin is prepared by reasonably matching the soluble collagens and the stem cell culture liquid in a certain ratio; the soluble collagens cooperate with oligopeptides in the stem cell culture liquid to reconstruct skin structure, thus forming normal cell structures and maintaining and adjusting cellular physiological functionality and metabolic activity such that the skin is soothed and repaired.

Owner:BEIHAO STEM CELL & REGENERATIVE MEDICINE RES INST CO LTD

Bearing bush blank manufacturing method

ActiveCN105149402ANo pollution in the processRealize automated productionMetal-working feeding devicesStripping-off devicesMechanical engineeringEngineering

The invention discloses a bearing bush blank manufacturing method. The manufacturing method is characterized in that a raw bearing bush blank is arranged in a blank storing tank of a feeding mechanism, a feeding travel switch is operated, and an air cylinder of the feeding mechanism can drive a push plate to send the blank to a stamping mechanism to be stamped; a stamping travel switch is operated, a hydraulic driving device of the stamping mechanism drives a stamping cutter to stamp the blank, and cuttings can flow out from a cutting flowing out opening of a supporting mechanism; a discharging travel switch is operated, a stamped formed bearing bush blank is taken to a discharging slide bench by a sucker of a sucking air cylinder, and the discharging slide bench moves along a guide rail on a work plate to send the bearing bush blank to a discharging opening in the tail portion of the work plate of the supporting mechanism; and the blank is manufactured. According to the manufacturing method, automatic production is achieved, the manual labor is reduced, and the modern large-scale production is facilitated. Furthermore, the manufacturing method adapts to market requirements and is convenient to popularize.

Owner:犍为星辉陶瓷有限责任公司

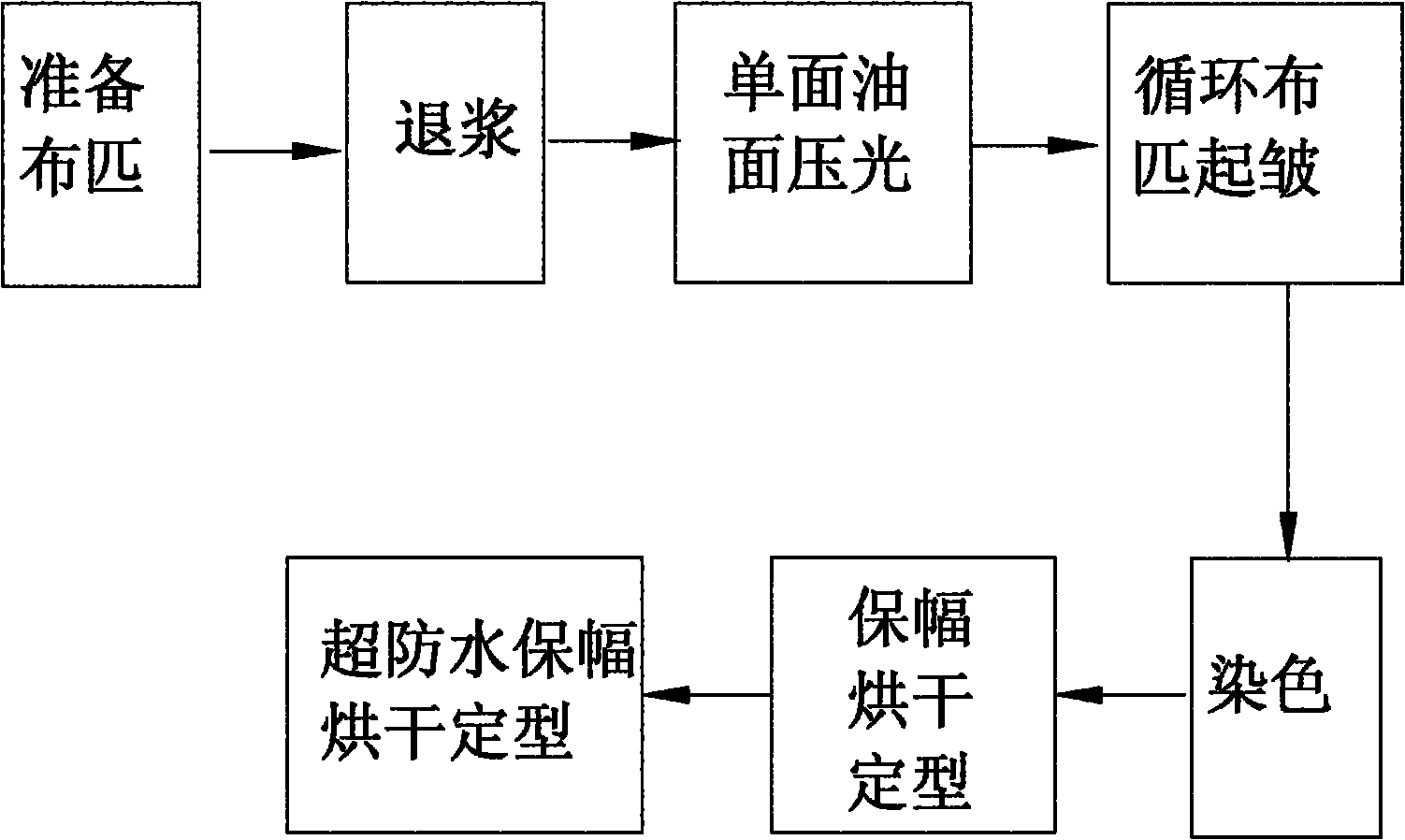

Plain creased fabric and manufacturing method thereof

ActiveCN102094316AIncrease pattern changeBionic effectPattern makingLiquid/gas/vapor textile treatmentEngineeringSizing

The invention discloses a plain creased fabric and a manufacturing method thereof. The manufacturing method comprises the steps of desizing, single oil surface calendering, cloth creasing by means of circular hot and cold water alternatiion, dyeing and width-keeping drying and sizing. The dyeing is carried out by stages in a temperature rise way. In the preparation method disclosed by the invention, because calendering and creasing processing are carried out on a fabric before dyeing after desizing, the dyed cloth creases in a fish-scale shape and has good creasing effect. Two surfaces of the plain creased fabric disclosed by the invention are interwoven from warp yarns and weft yarns; one surface of the fabric is a bright surface, and the other surface is a dark surface; the creases are of a fish scale shape; and the plain creased fabric disclosed by the invention has natural simulated creases because two surfaces of the fabric present different effect, i.e. a bright effect and a dark effect, can be worn in both sides and improves the fashion performance of clothes.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Foamed floor with wood textures

ActiveCN110670839APlay a protective effectAct as a constraintNatural patternsDecorative surface effectsOrganic chemistryMaterials science

The invention relates to a foamed floor with wood textures, and belongs to the technical field of co-extrusion foamed plates. The foamed floor comprises a foamed substrate and hard surface layers; andthe hard surface layers comprise (a) and (b), wherein (a) is provided with a first exposed surface formed by a first color resin, a connecting substrate and a base layer, (b) is provided with a second exposed surface formed by a second color resin and a connecting substrate, the first exposed surface is composed of a plurality of exposed units, the second exposed surface is composed of a plurality of sunken units, the plurality of exposed units and the plurality of sunken units are arranged in a staggered manner, a connecting unit is arranged between each exposed unit and the adjacent sunkenunit, and the connecting units are composed of the connecting substrates and connecting surface materials. According to the floor, the resins are taken as materials, the realistic effect of the wood textures is realized based on the performance manipulation in multiple aspects such as three dimensions (depth of the wood textures), color difference, and brightness and darkness and based on the twosurface layers; and in addition, the various wood textures can be obtained by adjusting the three dimensions, the color difference, and the brightness and darkness.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

Stewed duck head in soy sauce for children

InactiveCN103719891AModerate tasteDoes not damage the shapeFood preparationPreservation methodsSoya sauce

The invention discloses a stewed duck head in soy sauce for children. A manufacturing method comprises the following steps: 1, raw materials selection and processing; 2, spices stewing; 3, pickling; 4, air-curing; 5, frying; 6, boiling and slaking; 7, soaking in thick spices; 8, cooling and packaging; 9, vacuum sealing; 10, sterilization; 11, splat cooling; 12 outer packing. According to the method adopting the steps, the product quality and favor can be stabilized through pickling and air-curing; through the mixing of the spices and coordination of the steps, the food is healthy and safe as no preservative agent is used. The duck head is good in appearance color, stable in quality and more suitable for children tasting after subjected to two-time marinating. The duck head more adapts to market demands according to different fresh-preservation methods; double-layered packaging is adopted, so that the bagging is tidy and attractive and the quality is more stable; the shape of the duck head is not damaged during the whole process; duck head subjected to marinating is the same as that subjected to manual marinating.

Owner:安徽兴程食品有限责任公司

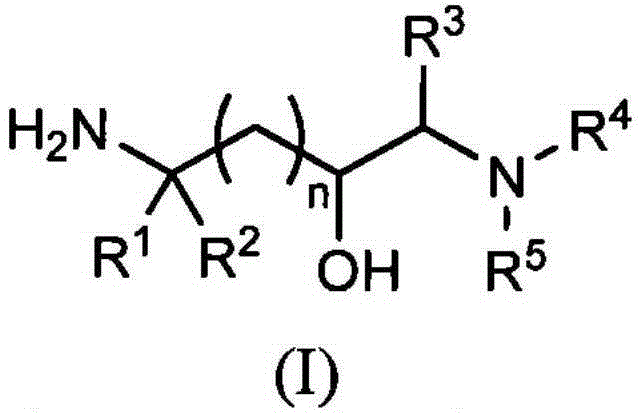

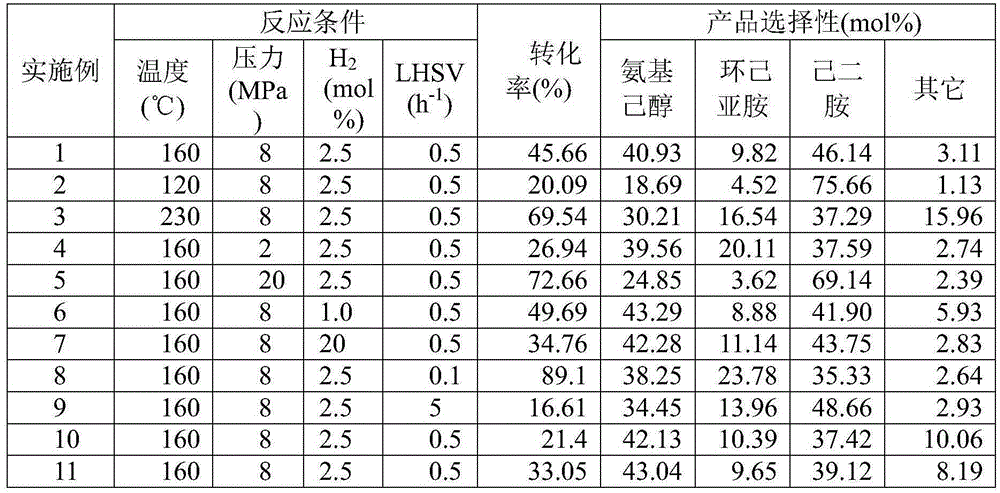

Method for preparing amino alcohol from dihydric alcohol and/or polyhydric alcohol

InactiveCN106810459AImprove performanceHigh selectivityOrganic compound preparationAmino-hyroxy compound preparationAlcoholHydrogen

The invention relates to a method for preparing amino alcohol from dihydric alcohol and / or polyhydric alcohol. The method comprises the following steps: mixing dihydric alcohol and / or polyhydric alcohol with liquid ammonia in a certain ratio, pumping into a reactor, and performing reaction in the presence of a catalyst and hydrogen. Due to adoption of a novel catalyst, the method is excellent in catalysis property and easy in long-time operation. As an alkamine product is produced from dihydric alcohol and / or polyhydric alcohol through hydroforming amination, the method can be achieved under relatively low reaction pressure, and the constitution of the product can be flexibly adjusted and varied by adjusting and changing reaction conditions, so that the selectivity of a target product can be improved, the reaction procedures are simple, the reaction process is environmental-friendly, and the one-time investment and production cost of a production device can be lowered; and a reaction product can be easily separated from the catalyst, so that large-scale continuous industrial production can be easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

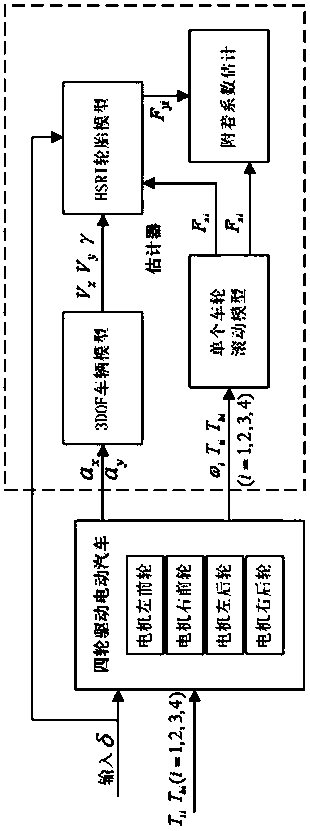

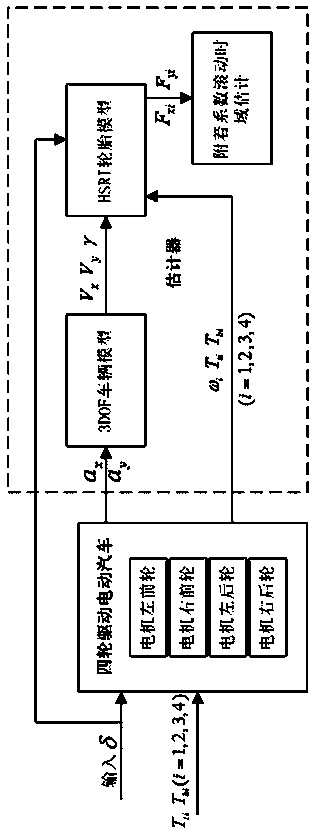

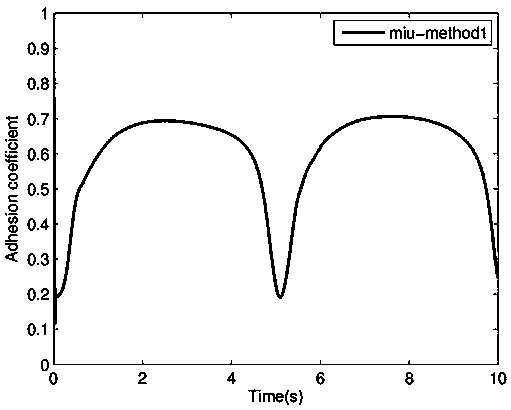

Method for estimating road adhesion coefficient of four-wheel-drive electric automobile

InactiveCN109515442AAdapt to market demandReduce installation costsAdhesion coefficientEstimation methods

The invention provides a method for estimating a road adhesion coefficient of a four-wheel-drive electric automobile and belongs to the technical field of control. The invention aims at providing themethod for estimating the road adhesion coefficient of the four-wheel-drive electric automobile, which comprises the steps of providing two estimation strategies first, designing a final estimator tointegrate the two estimation strategies, obtaining a method I to utilize points with adhesion coefficients above a mean value and substituting into a method II to obtain accurate and effective road adhesion coefficient estimation information. The method for estimating the road adhesion coefficient of the four-wheel-drive electric automobile comprises the steps of pavement adhesion coefficient estimation based on a formula method, pavement adhesion coefficient estimation based on formula deformation and algorithm fusion. According to the method for estimating the road adhesion coefficient of the four-wheel-drive electric automobile, the estimation method can be more suitable for complicated and changeable working conditions, the adaptability is higher, and the adhesion coefficient estimation value is more effective and accurate.

Owner:JILIN UNIV

Grouping method of square battery module

ActiveCN105742685ASimple operation processReduce manufacturing costAssembling battery machinesFinal product manufactureGroup methodEngineering

The invention discloses a grouping method of a square battery module. The grouping method comprises the following steps of sequentially and vertically laminating battery cores into groups according to a thickness direction after positive electrodes and negative electrodes of the battery cores are arranged in the same direction; fixing the battery cores by a thermoplastic film; separately welding the positive electrodes of all battery cores with a pole plate to be connected in parallel, and welding the negative electrodes of all battery cores with another pole plate to be connected in parallel to form standard battery core modules; arranging and combining at least two standard battery core modules in series or in series and in parallel to form standard battery core modules with determined voltage and capacity; and compacting, packaging and welding the stand battery core modules to obtain the square battery module. According to the grouping method, 3-5 parallel standard battery core modules are taken as a basis, more than three arbitrary battery modules in parallel required by market are combined in series or in series and in parallel, the type number of the standard battery core modules is remarkably reduced to only three types from several types in the past, the standard grouping of the battery module is achieved, the production efficiency is improved, and the production cost is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

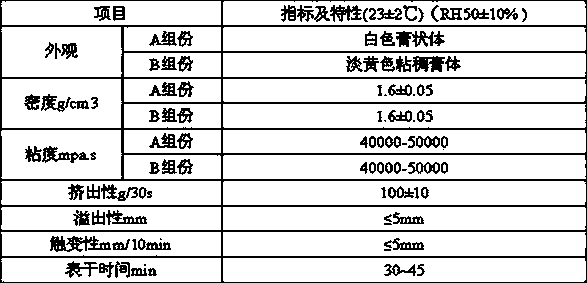

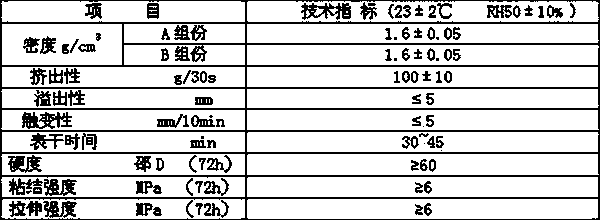

Environment-friendly polyurethane two-component corner-crimping glue

ActiveCN104327790AHigh hardnessImprove toughnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAlcoholPolyol

The invention discloses environment-friendly polyurethane two-component corner-crimping glue. The corner-crimping glue consists of a component I and a component II, wherein a weight ratio of the component I to the component II is 10:1 to 1:10, the component I comprises the following components: 41-52 percent of polyhydric alcohol A, 30-40 percent of filler A, 8-15 percent of filler B, 6-12 percent of modifier, 0.05-0.1 percent of catalyst, 1-2 percent of surfactant A, 2-5 percent of plasticizer A and 5-10 percent of plasticizer B; and the component II comprises the following components: 50-60 percent of isocyanate, 15-25 percent of MDI prepolymer, 10-16 percent of filler C, 2-6 percent of polyhydric alcohol B, 1-2 percent of surfactant B and 10-15 percent of plasticizer C. The comprehensive strength of the corner-crimping glue is greatly superior to that of polyurethane single-component corner-crimping glue, and the corner-crimping glue is high in stability and high in curing speed; and the corner-crimping glue has excellent joint filling capacity and is suitable for corner-crimping insertion of aluminum alloy doors and windows and curtain walls and overall corner cementing adhesion-sealing.

Owner:大连固瑞聚氨酯股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com