Method for filtering and centrifugally separating mixture containing aluminum, silicon, iron and the like, removing impurities and carrying out purification

A technology of centrifugal separation and mixture, which is applied in the field of metallurgy, can solve the problems of high cost, strict requirements on raw material purity or impurity content, low efficiency, etc., and achieve the effect of high value, increasing value and profit, and increasing profit margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

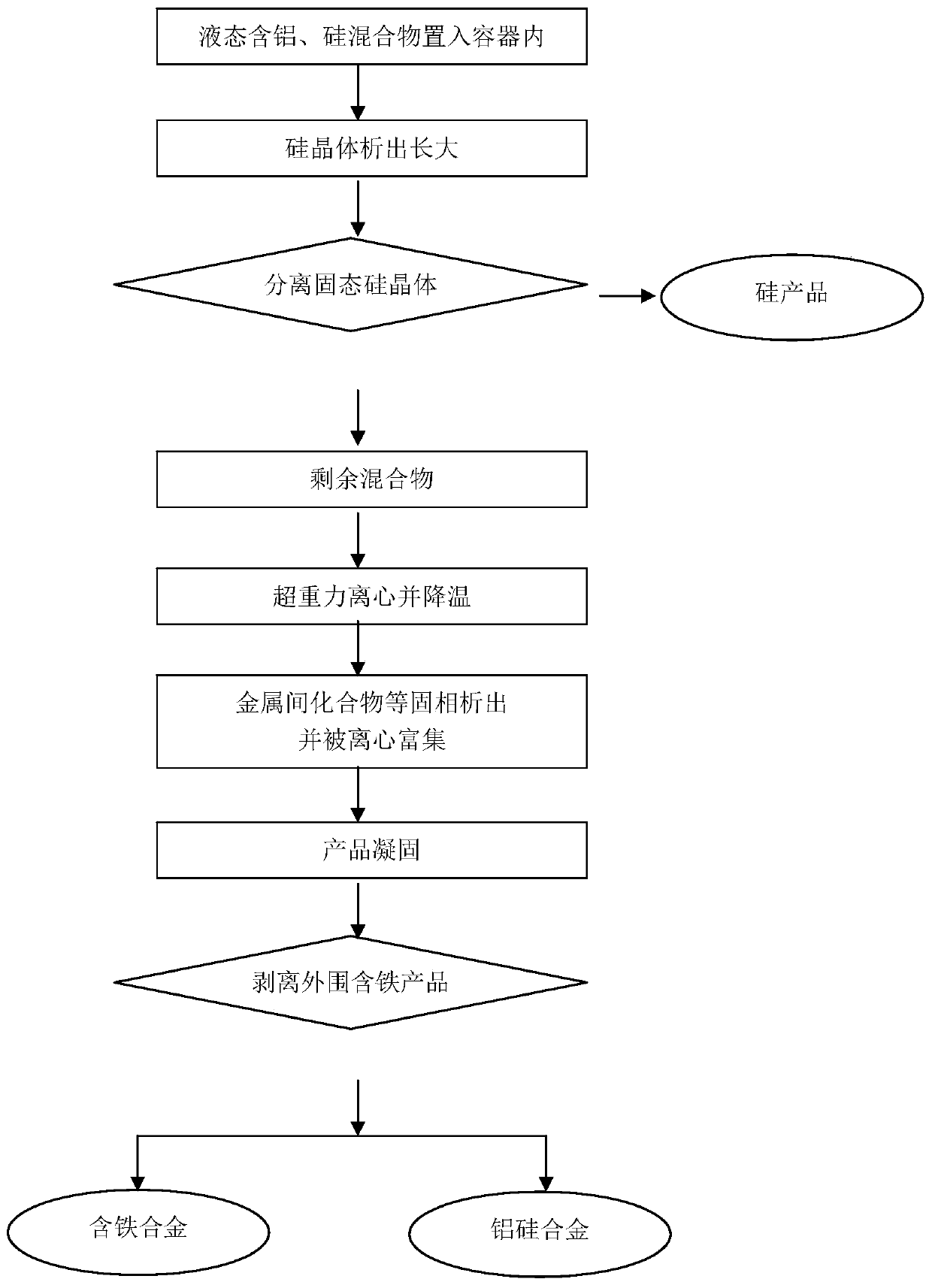

Image

Examples

Embodiment 1

[0029] A method for filtering and centrifuging a mixture containing aluminum silicon ferrosilicon and the like and removing impurities and purifying, the steps are:

[0030] (1) Put a total of 200 kg of liquid aluminum-silicon mixture at 1600°C into the heat preservation container. Said mixed metals are reduced by metallurgical processes such as electrothermal smelting (or submerged arc furnace method, electric arc furnace method, fire method, etc.), or are melted from recycled materials containing metal elements such as waste aluminum, Or it is obtained by blending and melting, or other methods. The mixed metal is a mixture containing aluminum, silicon, iron and other metal elements. The content range of related elements is as follows: aluminum: 9%-90%, silicon: 9%-90%, iron: 0.1%-18%, titanium: 0%-10%, Calcium: 0%-10%, Carbon: 0%-10%, Oxygen: 0%-20%, Others: 0%-7%.

[0031] In this step, the mixture contains 45% aluminum, 45% silicon, 7% iron, and 2% titanium, and the othe...

Embodiment 2

[0042] A method for filtering and centrifuging a mixture containing aluminum silicon ferrosilicon and the like and removing impurities and purifying, the steps are:

[0043] (1) Put a total of 300 kg of liquid aluminum-silicon mixture at 2000°C into an insulated container, in which the mixture contains 57% aluminum, 38% silicon, 2.3% iron, and 1% titanium. Slag impurities, the inner wall of the heat preservation bag is made of ceramic heat insulation material.

[0044] (2) Control the cooling rate of the mixture to 30°C / min, and use the principle of segregation purification in the molten aluminum-silicon environment to allow purer silicon crystals to precipitate and grow.

[0045] (3) Collect the solid silicon product by filtering and centrifuging to obtain 61 kg of silicon product with a purity of 99.3%.

[0046] (4) The remaining liquid mixture is subjected to supergravity centrifugation, and gradually cooled and solidified. During the cooling process, solid phases such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com