Method for preparing amino alcohol from dihydric alcohol and/or polyhydric alcohol

A technology of dihydric alcohol and polyhydric alcohol, applied in the field of preparing amino alcohol, can solve the problems of high toxicity of amino alcohol raw material, unreasonable resource utilization, difficulty in product separation, etc., achieves reduction of one-time investment and production cost, and easy long-term operation , the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

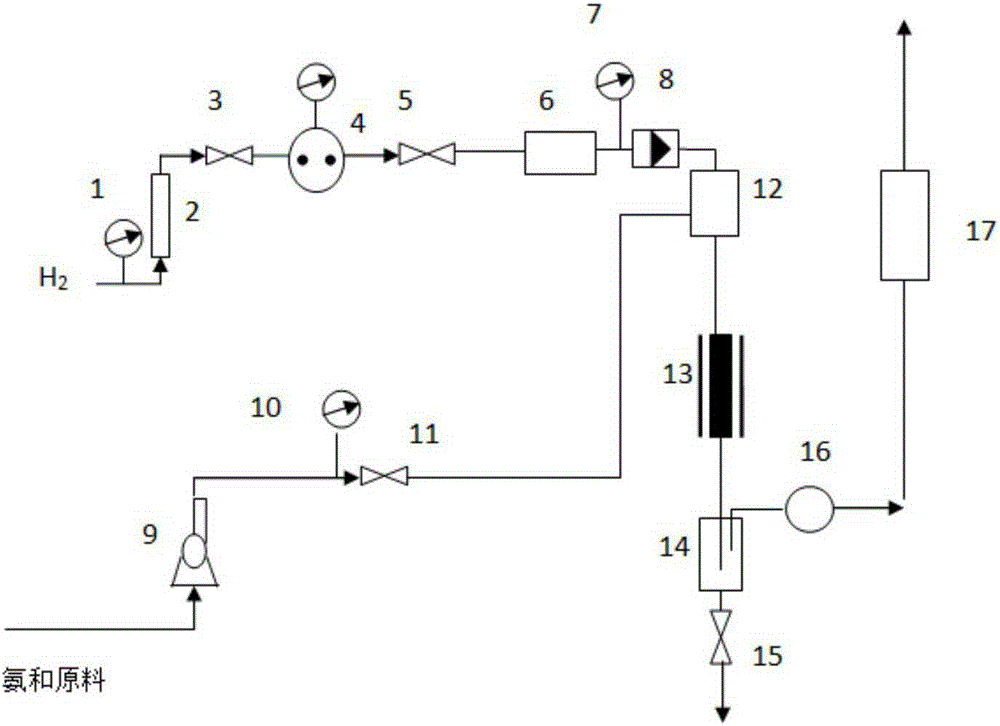

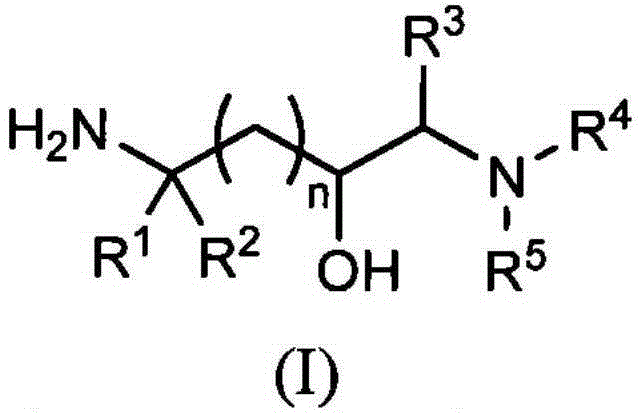

[0015] The invention provides a method for preparing aminoalcohol with dihydric alcohol and / or polyhydric alcohol and ammonia as raw materials. Dibasic alcohol and / or polyhydric alcohol and liquid ammonia are mixed in a certain proportion, pumped into the reactor, and the catalyst and The reaction is carried out in the presence of hydrogen, the product is mainly amino alcohol, and the by-products include imine, diamine, polyamine and so on.

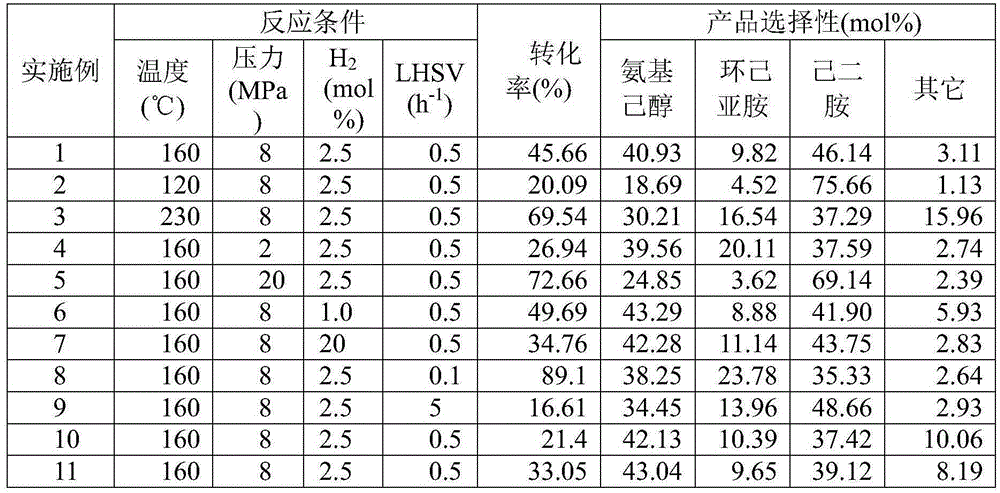

[0016] The product is analyzed by Agilent7890N, SE-30 capillary column, FID detector, and isobutanol is used as internal standard for quantitative analysis.

[0017] The catalyst used is 15%Ni-1.6%Re-1.2%B / Al 2 o 3 Catalyst, preparation method is to take by weighing 7.432 grams of Ni (NO 3 ) 2 ·6H 2 O, 0.231 g NH 4 ReO 4 and 0.686 g H 3 BO 3 Dissolve in 12ml deionized water. half of this aqueous solution was then impregnated to 10 g of Al 2 o 3 (20-40 mesh) carrier, air-dried, then dried at 120°C for 4 hours, and then calcined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com