Production method for superfine steel slag micro powder

A technology of ultra-fine steel slag powder and production method, which is applied in the direction of grain processing, etc., can solve the problems of poor feasibility and high energy consumption, and achieve the effect of high feasibility, low energy consumption, and rational use of original resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

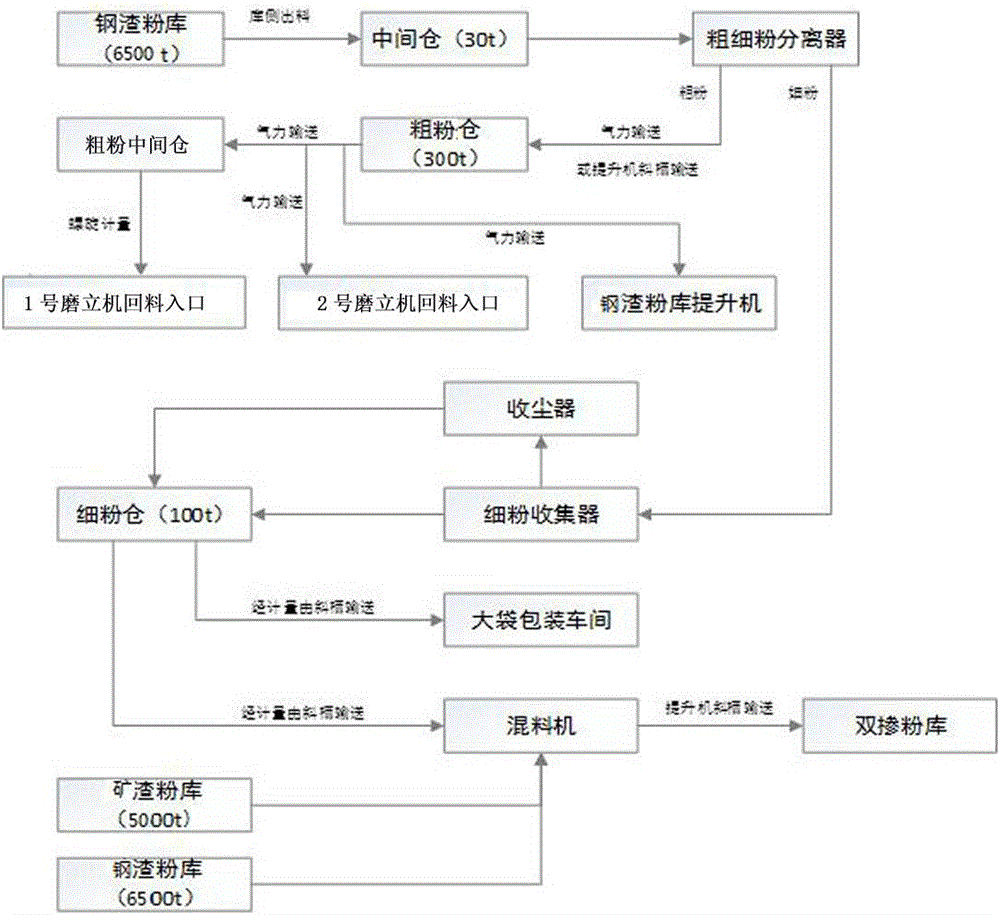

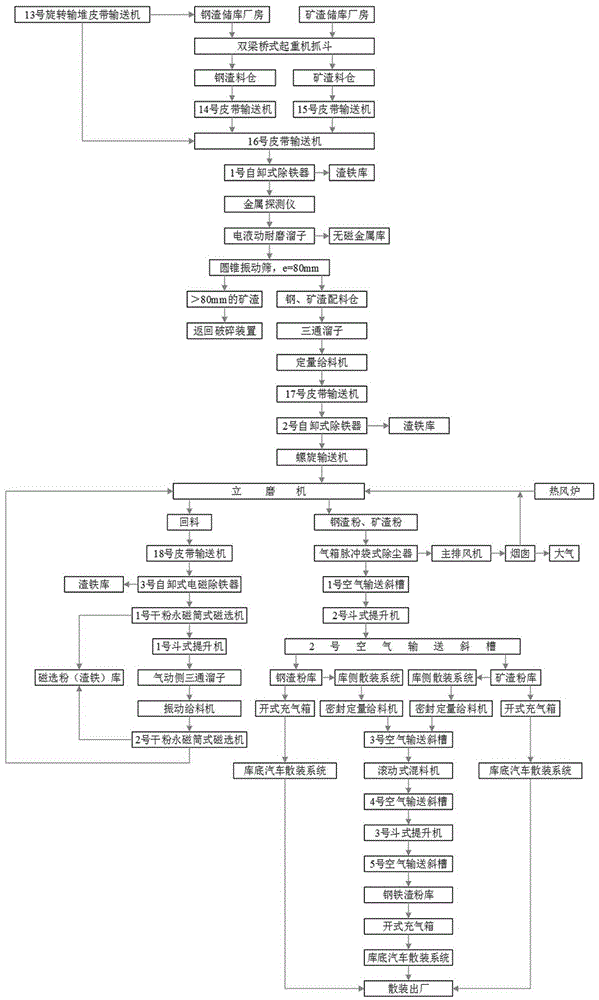

[0021] Ultrafine steel slag micropowder production method step of the present invention is specifically as follows:

[0022] (1) Firstly, the raw material steel slag tailings are subjected to steel slag processing metal recovery treatment steps, which include steel slag crushing, iron removal pretreatment closed-circuit cycle process, steel slag pre-grinding, magnetic separation iron removal closed-circuit cycle process, and magnetic separation iron removal process again .

[0023] In the steel slag crushing and metal removal pretreatment closed-circuit circulation process, the sieve hole diameter of the hydraulic tilting screen is 200mm, and the steel slag with a particle size ≤ 200mm is screened out into the feeding bin, weighed by the quantitative feeder, and stably transported to the No. 1 belt On the conveyor, it is sent to the hydraulic jaw crusher for crushing through the No. 2 belt conveyor, and the output particle size is controlled to be ≤40mm. The crushed steel slag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com