Patents

Literature

352 results about "Heat analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adaptive analysis methods

InactiveUS20070244676A1Analogue computers for electric apparatusComputation using non-denominational number representationIntegrated circuitFrequency domain

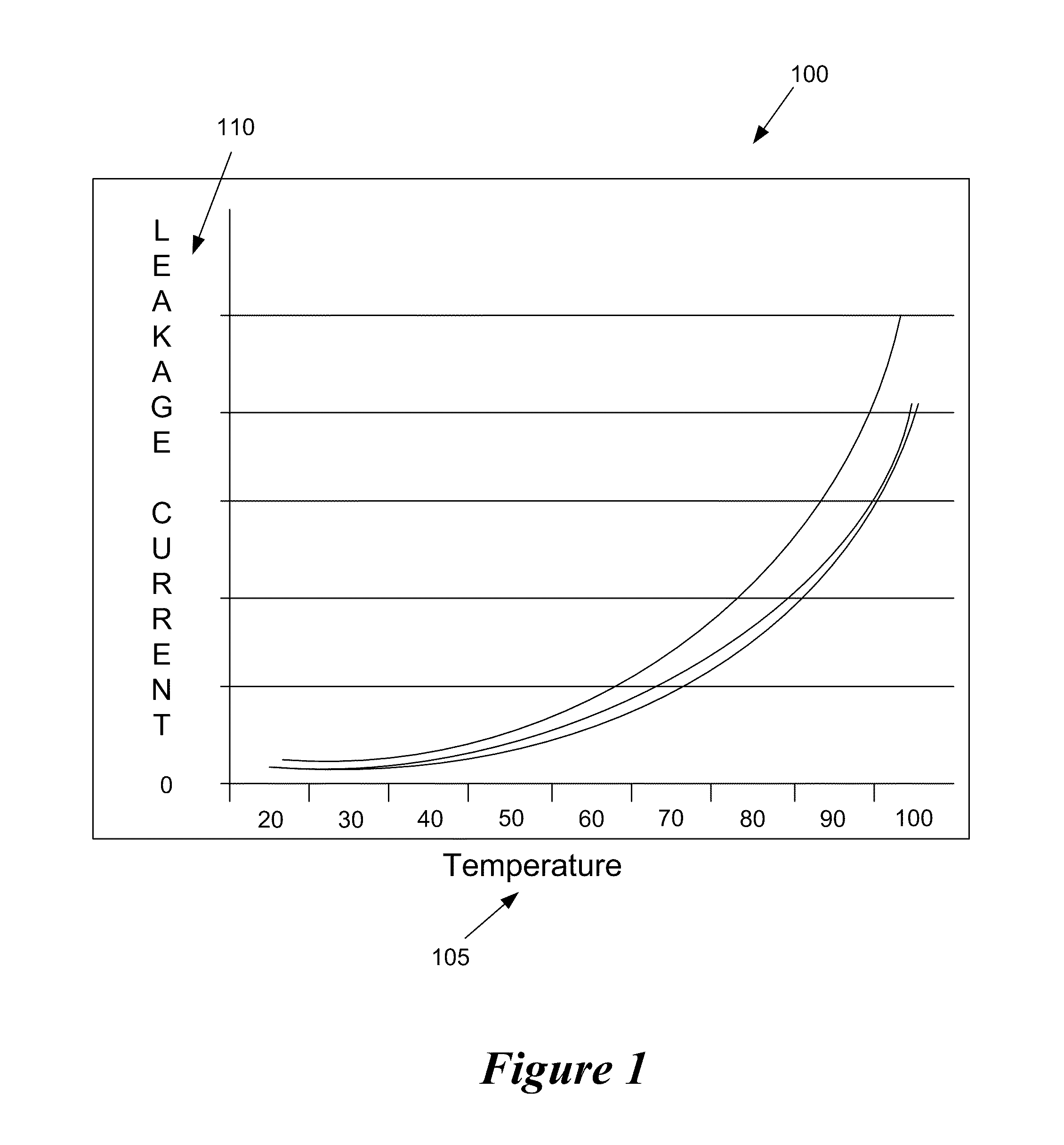

This invention relates to a comprehensive method of analyzing dynamic and steady-state properties of a system. Steady state (static), short time scale dynamic, and long time scale dynamic properties of the system are described by a plurality of elements. The method unifies spatial, temporal, and frequency-domain techniques to minimize analysis time while maintaining accuracy during both steady state, short time scale, and long time scale analysis. The method dynamically adapts spatial and temporal modeling granularity to achieve high efficiency while maintaining accuracy. The method is applicable to properties of a system that diffuse through space and / or time, such as temperature, concentration, density, etc., in fields such as biomedical modeling, molecular dynamics, meteorology, astrophysics, financial analysis, engineering, etc., and in particular, to thermal analysis of electronic devices such as integrated circuits.

Owner:NORTHWESTERN UNIV +1

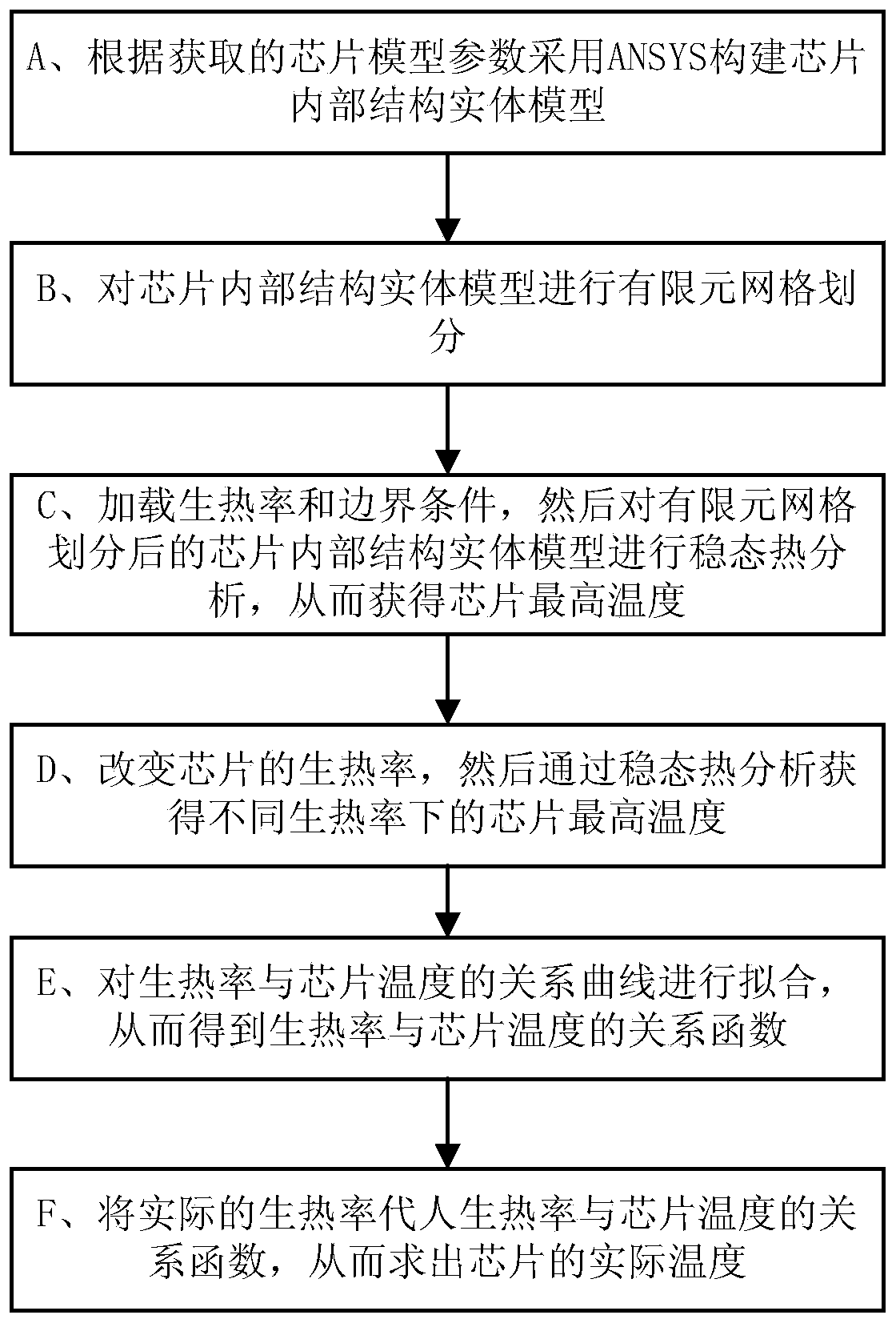

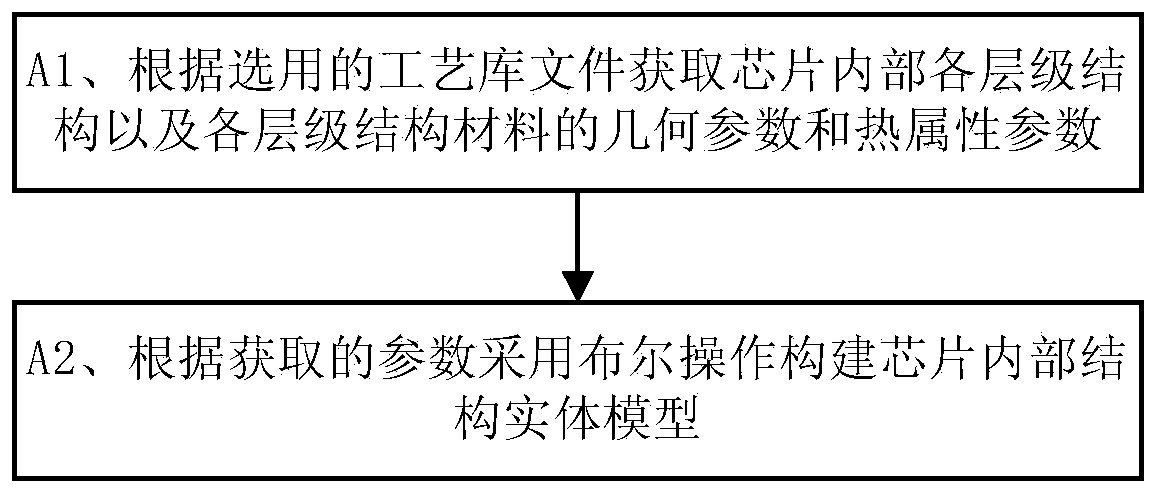

Chip temperature predicating method based on ANSYS finite element heat analysis

ActiveCN104182568ALow costEasy to operateSpecial data processing applicationsGeneration rateHeat analysis

The invention discloses a chip temperature predicating method based on ANSYS finite element heat analysis. The chip temperature predicating method comprise steps as follows: a chip interior structure solid model is established by ANSYS according to acquired chip model parameters; the chip interior structure solid model is subjected to finite element mesh generation; the heat generation rate and the boundary conditions are loaded, then, the chip interior structure solid model after finite element mesh generation is subjected to steady-state heat analysis, and the maximum temperature of a chip is obtained; the heat generation rate of the chip is changed, and the maximum temperature of the chip under different heat generation rates is acquired through steady-state heat analysis; the relation curve of the heat generation rate and the chip temperature is fitted, and a relation function of the heat generation rate and the chip temperature is obtained; and the actual heat generation rate is substituted into the relation function of the heat generation rate and the chip temperature, and the actual temperature of the chip is obtained. According to the method, the temperature predication is placed at the physical design stage of the chip, the cost is reduced and the operation is simple and convenient; and the method can be widely applied to the technical field of semiconductors.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

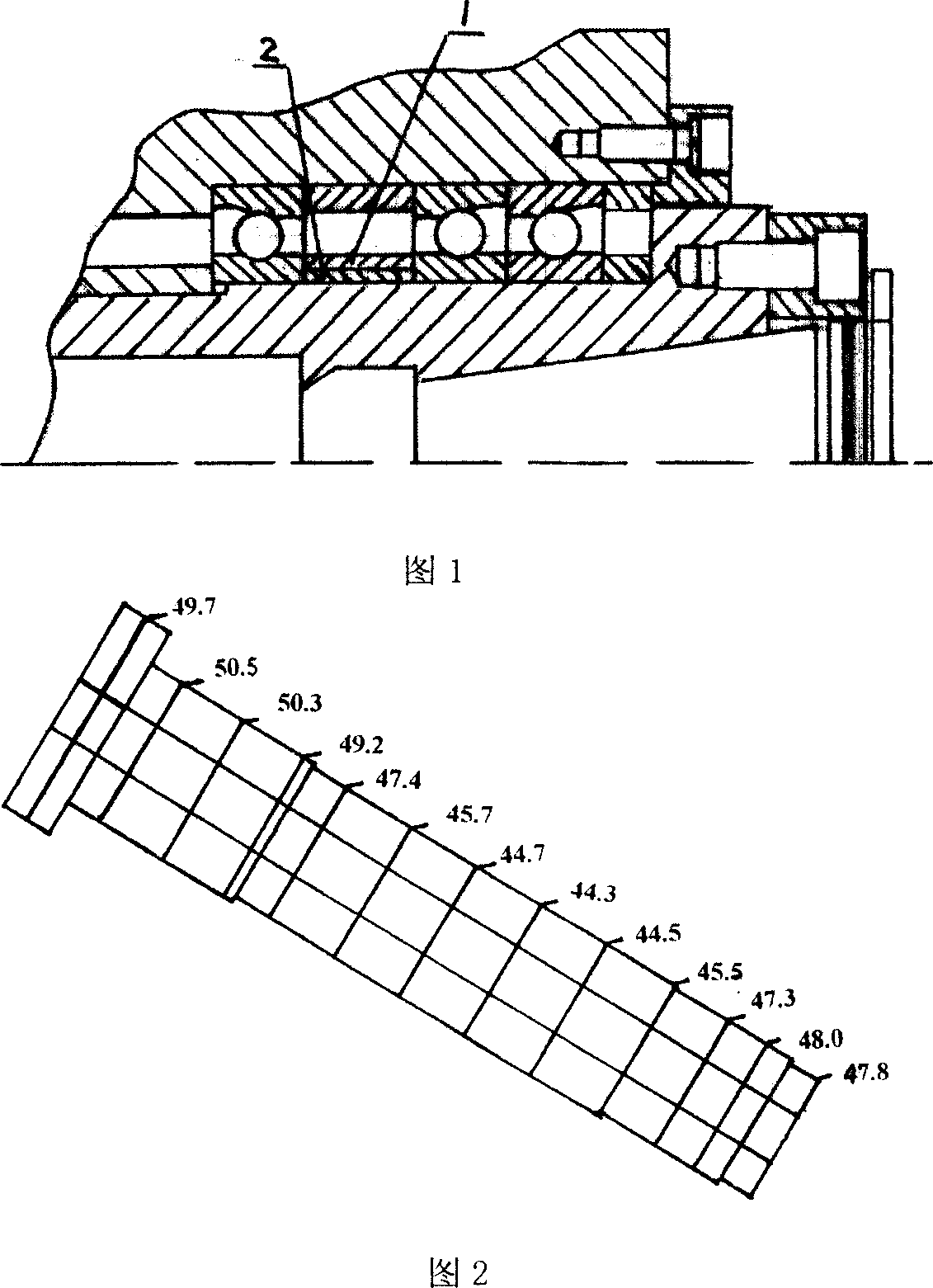

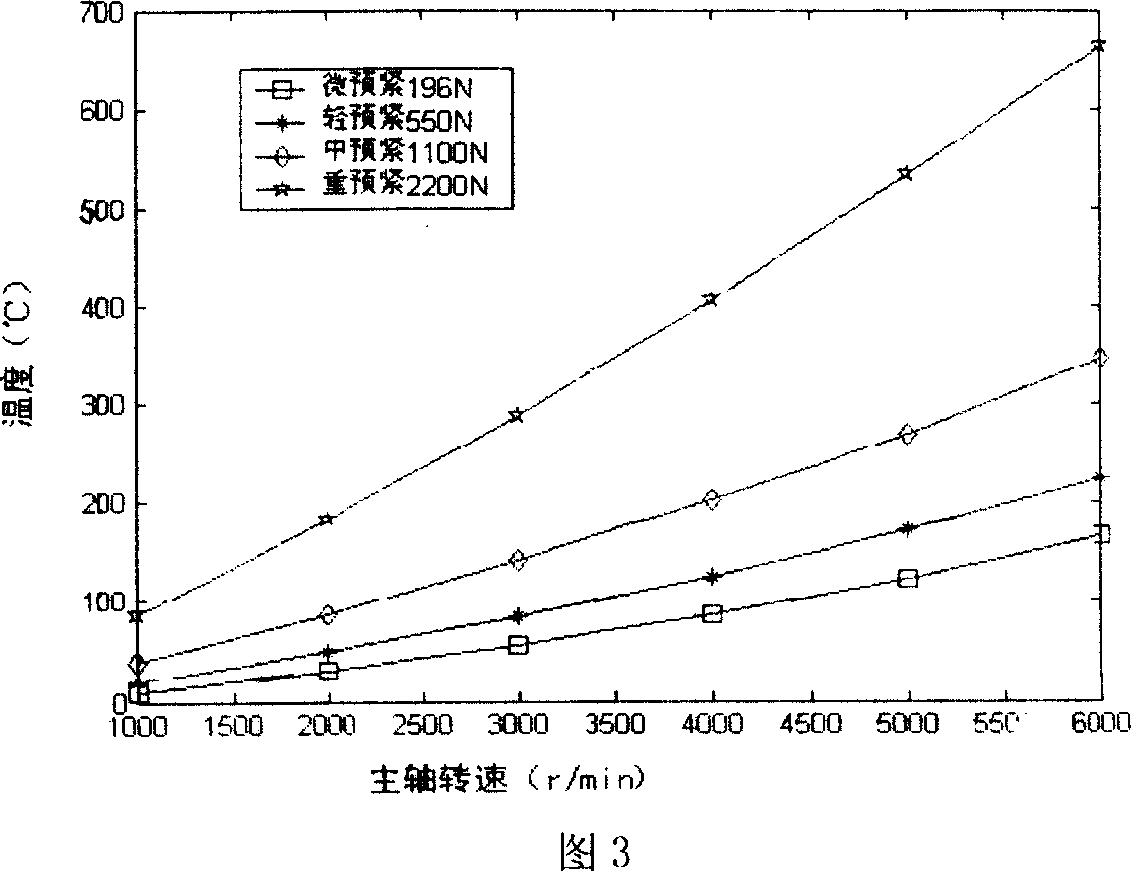

Method of regulating bearing pretightening force using heat characteristics of metal material and its device

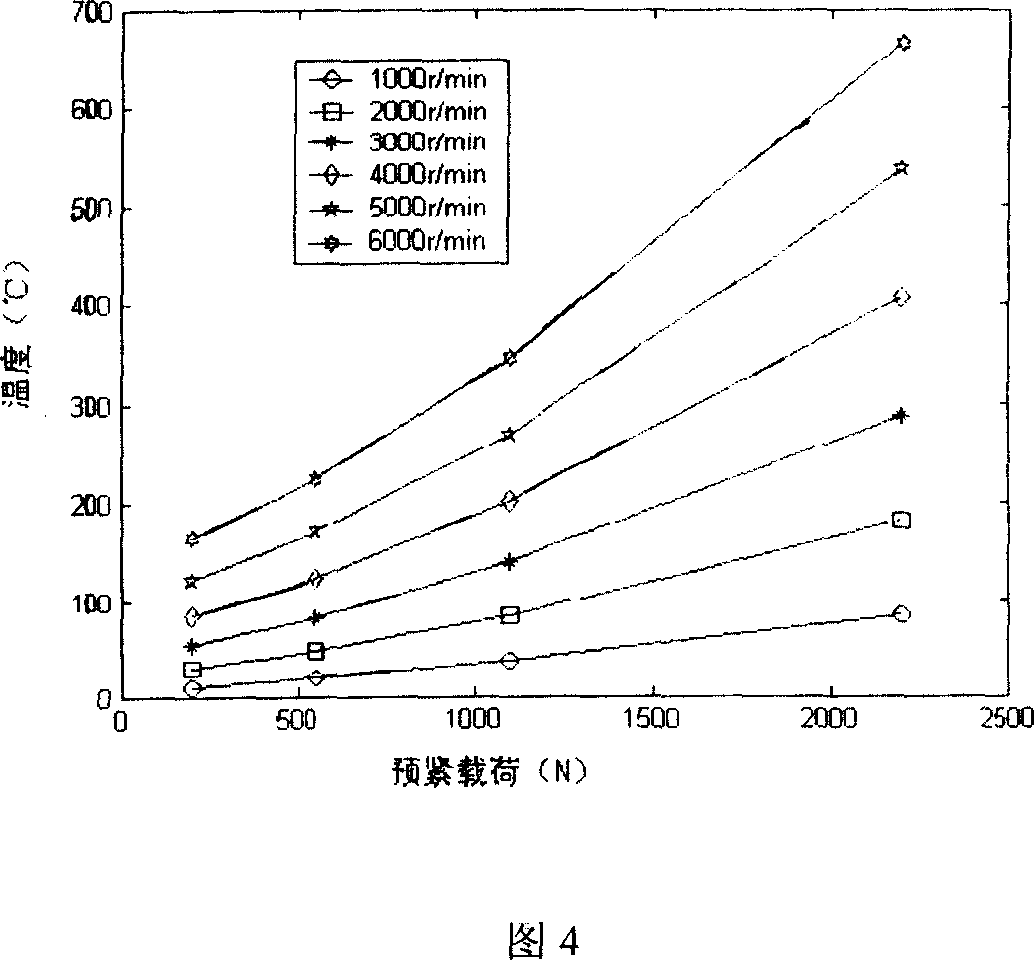

InactiveCN1948775AAdjust the preloadEffective adjustment of preloadMilling equipment detailsBearing unit rigid supportMetallic materialsEngineering

The inventive method consists in: modeling for thermal analysis of heating and temperature rise of the main shaft, using a cylindrical-coordinate system for the temperature distribution of the axially symmetric structure and determining the boundary condition; calculating friction heat and power loss of front and back bearings of main shaft in a state of different speeds and different pretightening forces; determining the relation of axial shifting of the bearing with the pretightening forces; according to the above calculated data, choosing material for making double-layer bushing and making length different double-layer bushing size of the sleeve because the extension volume of the bushing heat expansion depends on the length of the sleeve.

Owner:北京机械工业学院

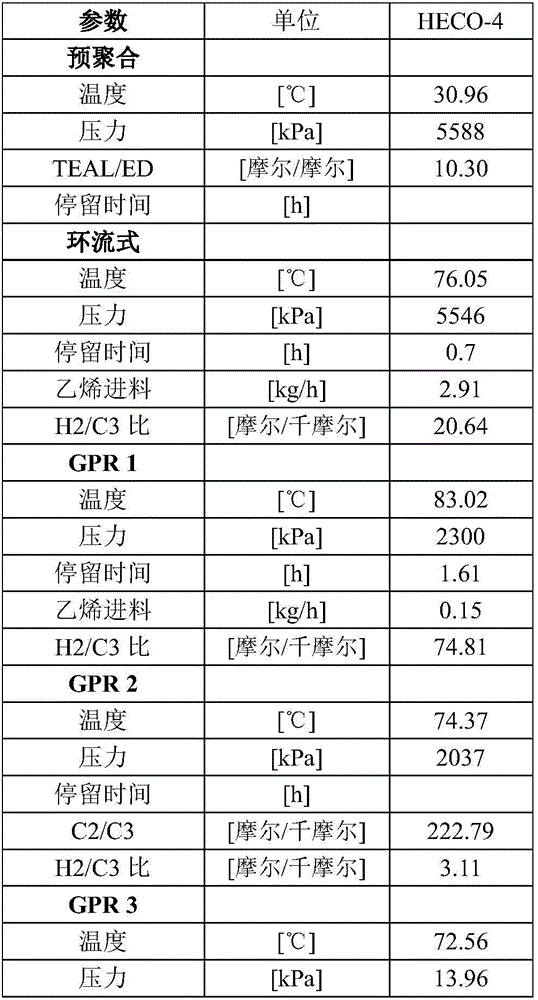

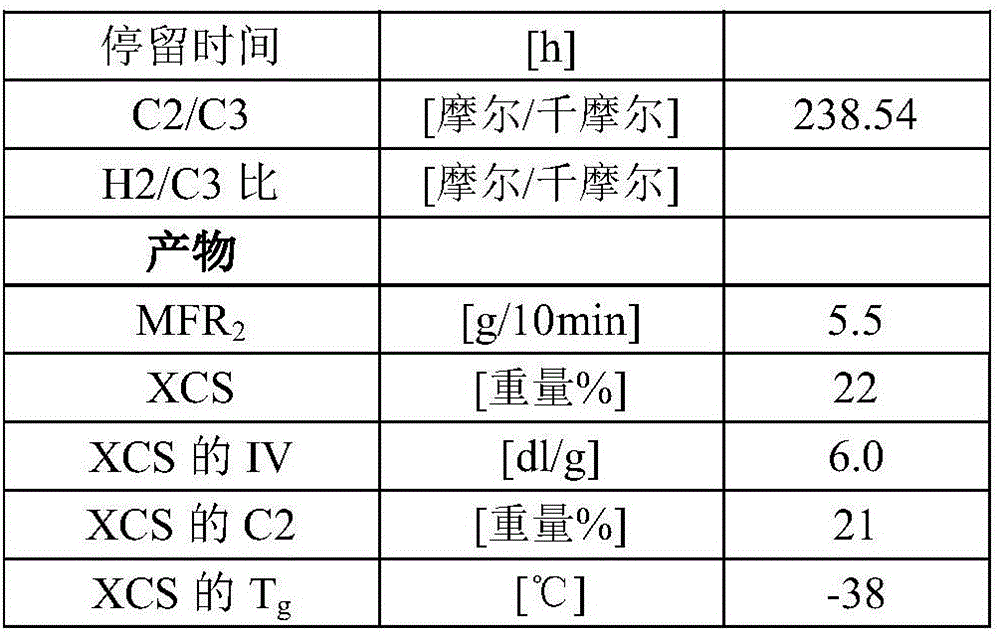

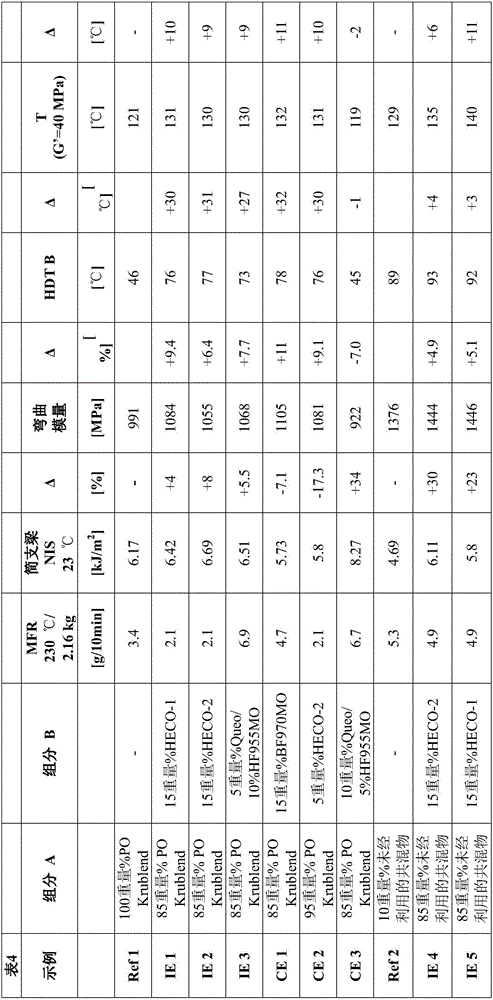

Polypropylene - polyethylene blends with improved properties

Owner:BOREALIS AG

Smart Body Temperature Screening System at Controlled Area

InactiveUS20200146557A1Minimize impactImprove accuracyImage enhancementTelevision system detailsColor imageHeat analysis

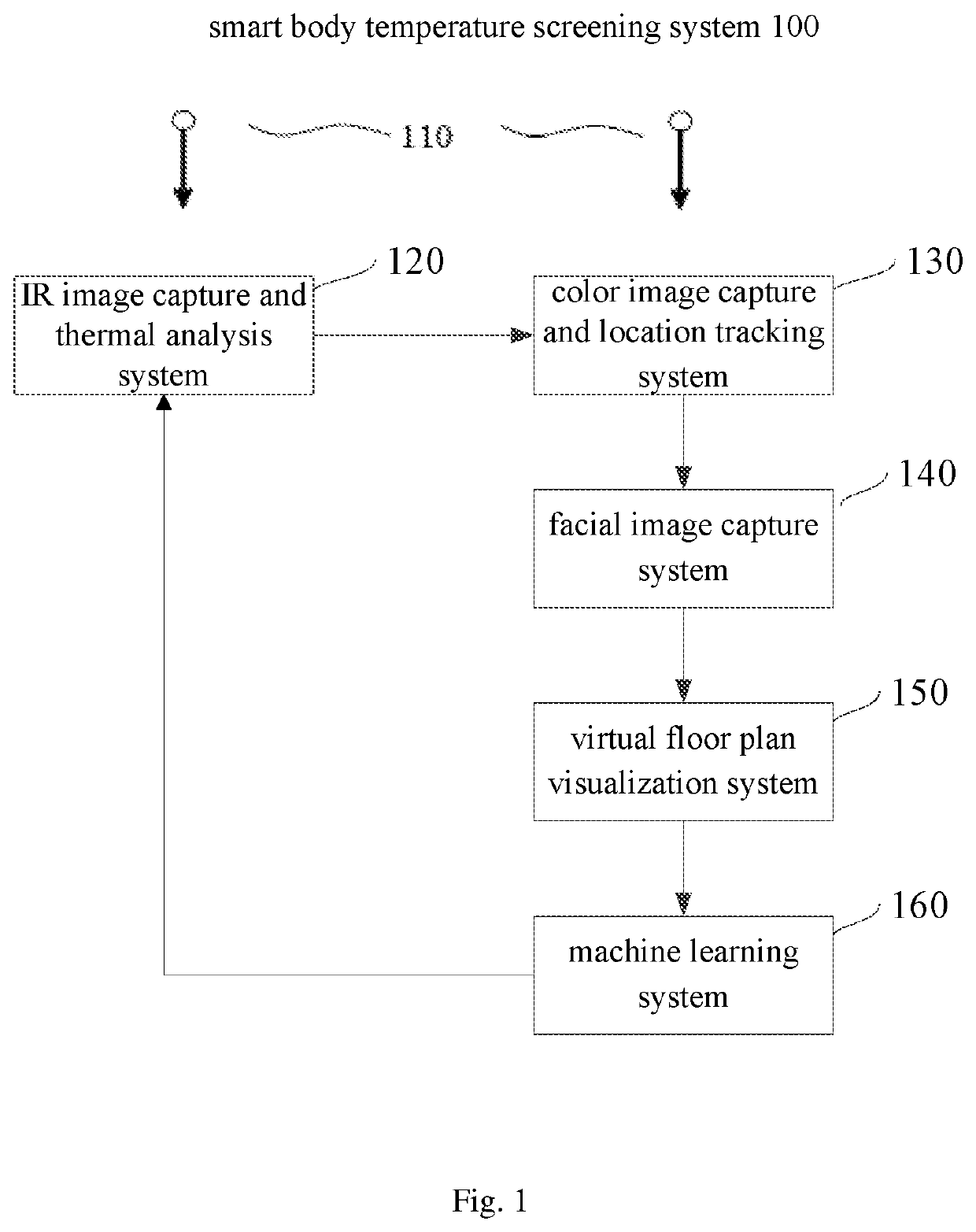

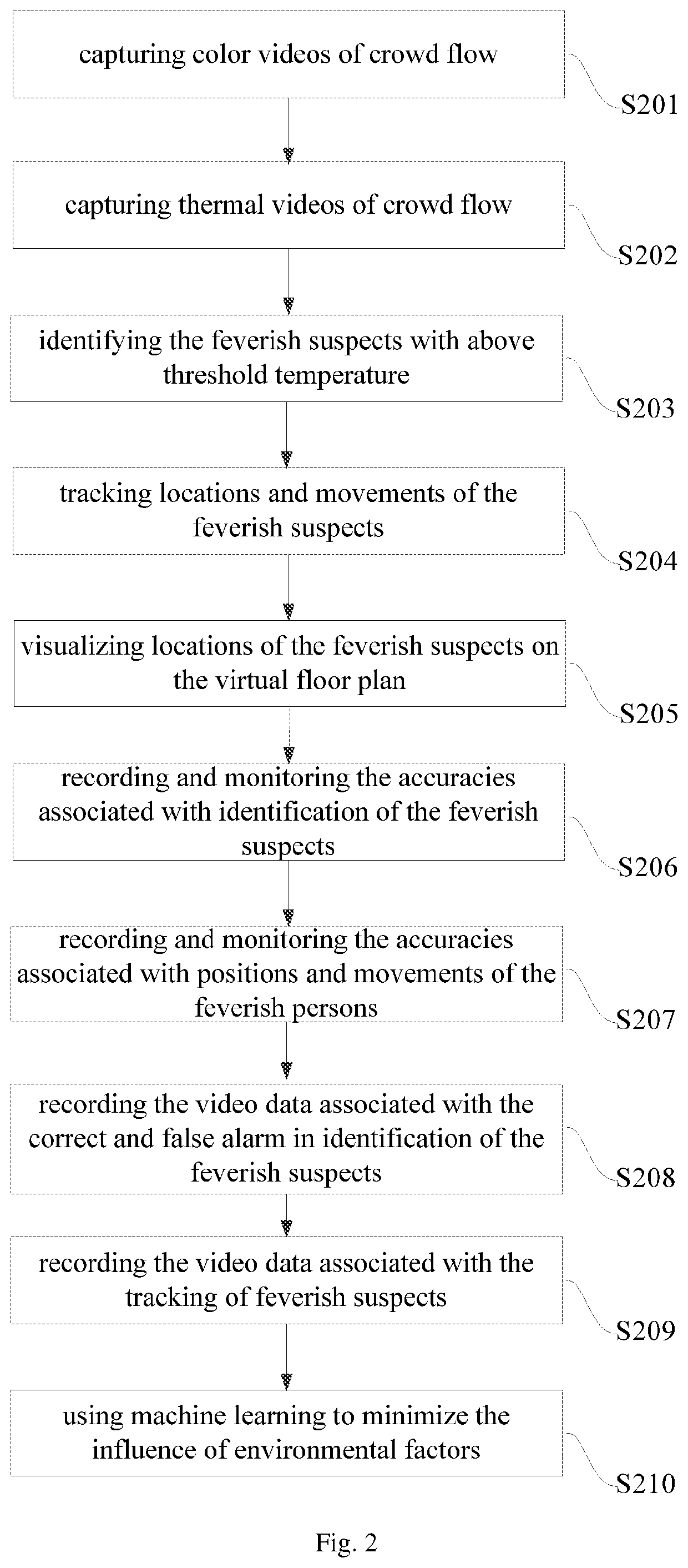

The present invention provides a smart body temperature screening system (100) at controlled area and includes: images of controlled area (110); an IR image capturing and thermal analysis system (120) configured to take in digitized IR images sequences and determine the pixel coordinates with temperature higher than pre-determined thresholds; a color image capturing and location tracking system (130) configured to capture the color image sequence and determine the pixel coordinates of human, combine the pixel coordinates from the IR image capturing and thermal analysis system with the pixel coordinates of human to identify the pixel coordinates of feverish suspects with above threshold temperature; a facial image capturing system (140) configured to capture the pictures of the feverish suspects according to the pixel coordinates of feverish suspects and the original color images from the color image capturing and location tracking system; a virtual floor plan visualization system (150) configured to map the pixel coordinates of feverish suspects on to a virtual floor plan; a machine learning system (160) configured to use machine learning to minimize the influence of environmental factors and improve the accuracy for detecting the feverish persons from the feverish suspects. The present invention can smartly identify and locate fever suspects without locking the fever suspects in a specific area.

Owner:ELECTRICAL & MECHANICAL SERVICES DEPT THE GOVERNMENT OF THE HONG KONG SPECIAL ADMINISTATIVE REGION

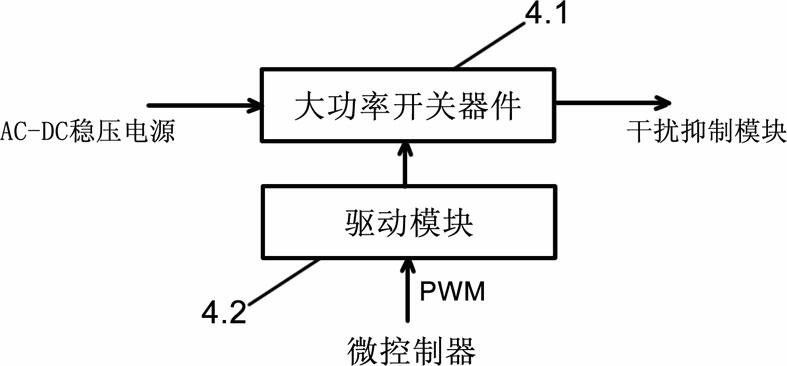

High-frequency PWM (pulse width modulation) temperature control device and control method for thermal analyzer

InactiveCN102109861AHigh resolution power controlPrecise temperature controlTemperatue controlMaterial thermal analysisMicrocontrollerJunction temperature

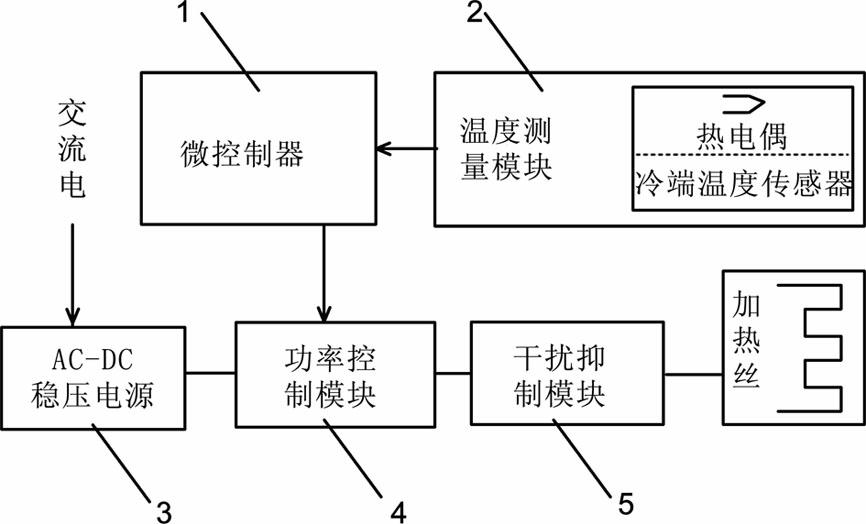

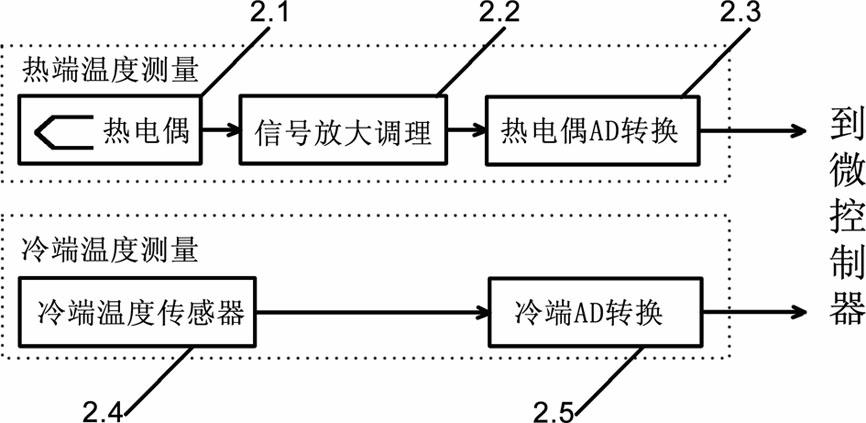

The invention belongs to the technical field of thermoanalysis, in particular to a high-frequency PWM temperature control device and a control method for a thermal analyzer. The temperature control device includes a microcontroller module, a power control module and a temperature measurement module connected with a microcontroller respectively, an AC-DC voltage stabilization module and an interference rejection module connected with the power control module, and a heating wire connected with the interference rejection module; and the temperature measurement module further includes a thermocouple voltage measurement module and a cold junction compensation module. The AC-DC voltage stabilization module is used for converting AC to stable DC, and the power control module is used for receiving high-frequency PWM signals output by the microcontroller; and the microcontroller detects the thermocouple voltage and the cold junction temperature, obtains the actual temperature, and dynamically regulates the duty factor of the PWM signals output by the microcontroller. The invention further provides the control method suitable for the temperature control device, and can realize the high-precision temperature control required by the thermal analyzer.

Owner:FUDAN UNIV

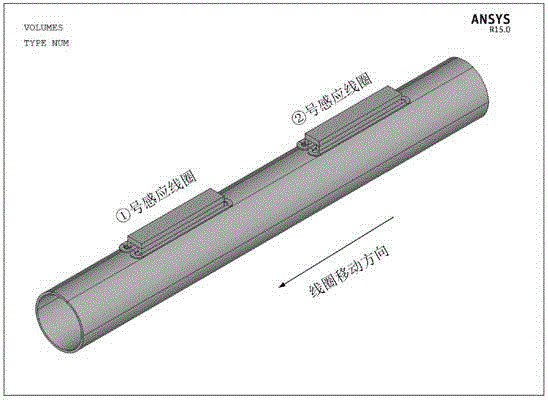

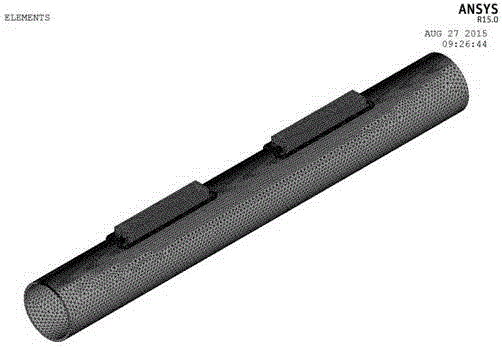

Method for dynamically simulating intermediate-frequency heat treatment process of longitudinal welded pipes

ActiveCN105740536AAchieve relative motionEasy to masterDesign optimisation/simulationSpecial data processing applicationsIntermediate frequencyHeat analysis

The invention discloses a method for dynamically simulating intermediate-frequency heat treatment process of longitudinal welded pipes. According to the method, the movement of welded pipes in practical production is replaced by the movement of induction coils, an ANSYS APDL language-based macro document library, and the macro document library comprises a control library, a parameter library, an environment library and a computation library, wherein the control library is used for controlling the execution sequences of macro documents in the parameter library; the parameter library comprises modeling parameters and load parameters when the coils are at different positions; the environment library is used for establishing geometric models, meshing, load application and solving types required by two physical environments: electromagnetic analysis and heat analysis; and the computation library is used for carrying out electromagnetic-thermal coupling computation on the induction heating process by adopting DO circulation and storing the solving result into a database. Compared with the prior art, the method is capable of dynamically simulating the intermediate-frequency heat treatment process of the longitudinal welded pipes, and the simulation is closer to the reality; through modifying the parameters, various production processes of the factories can be simulated; and the whole simulation process takes ANSYS software as a platform, so that the operation is automatic, the operation is simple and the factory technicians can grasp and use the method conveniently.

Owner:江苏金诺炉辊有限公司

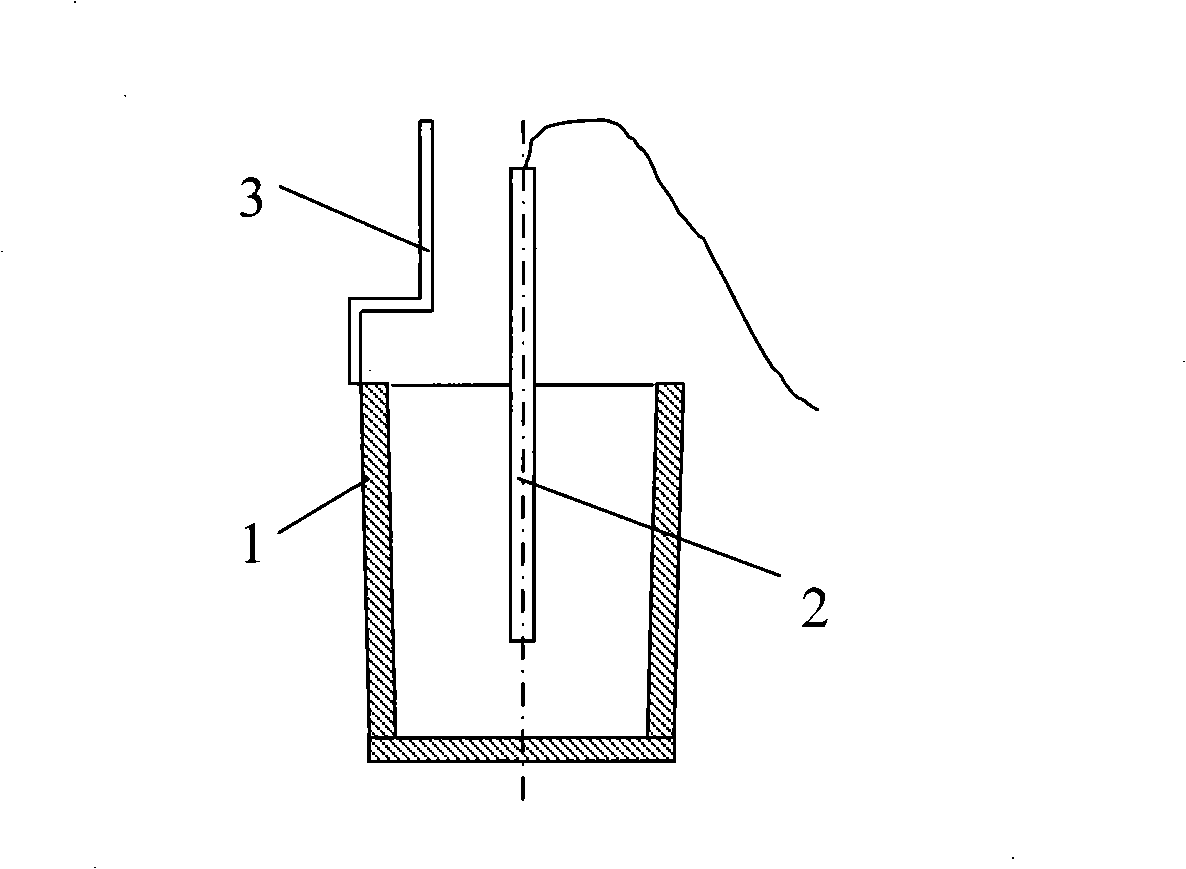

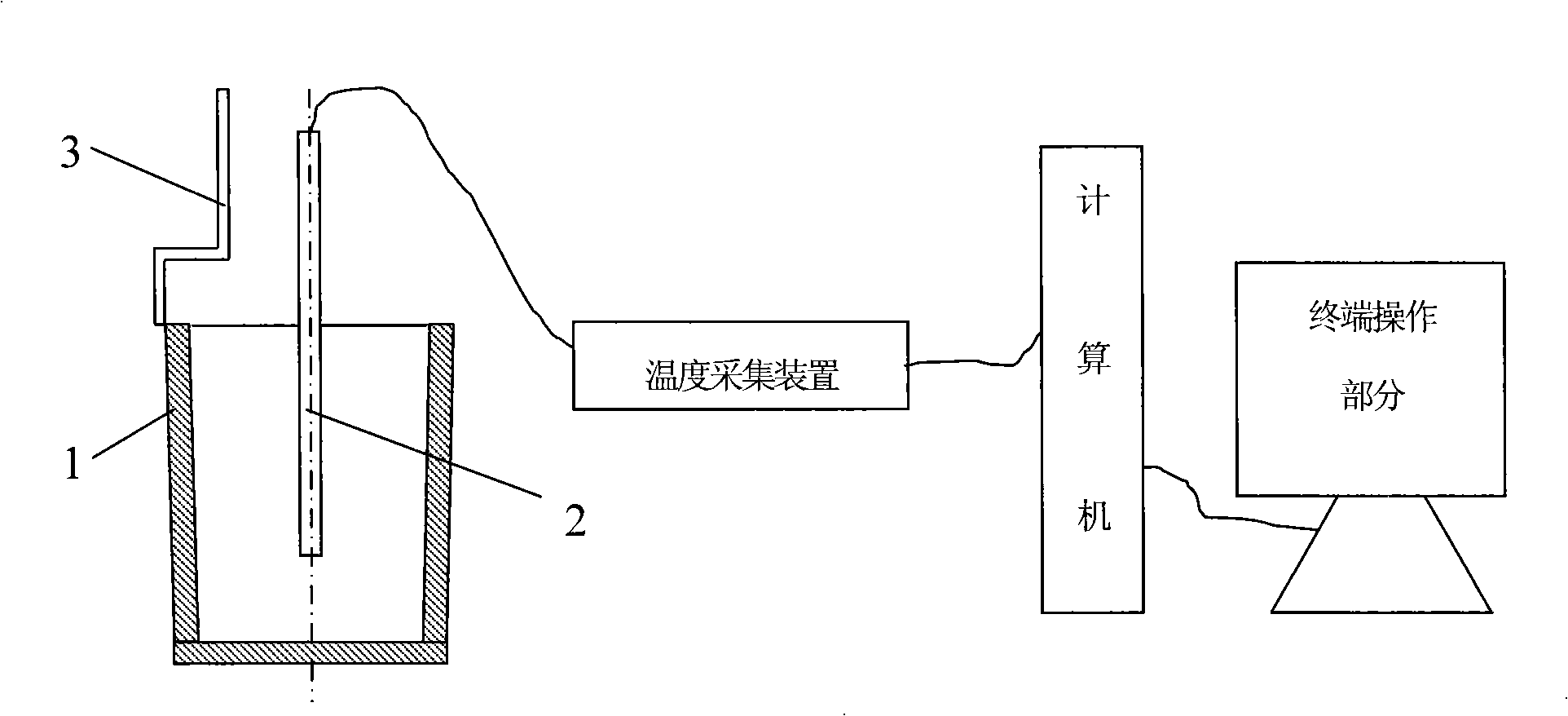

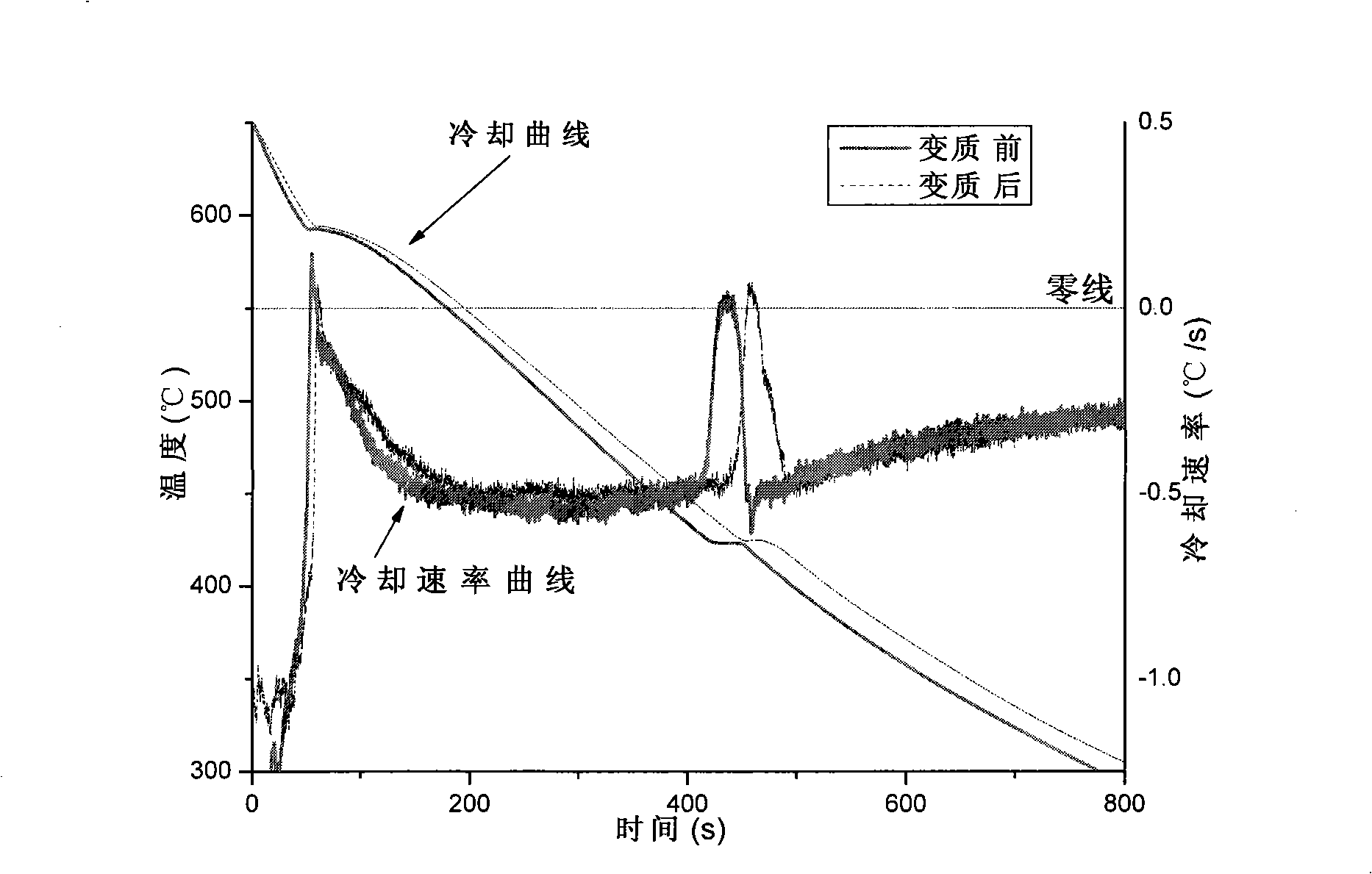

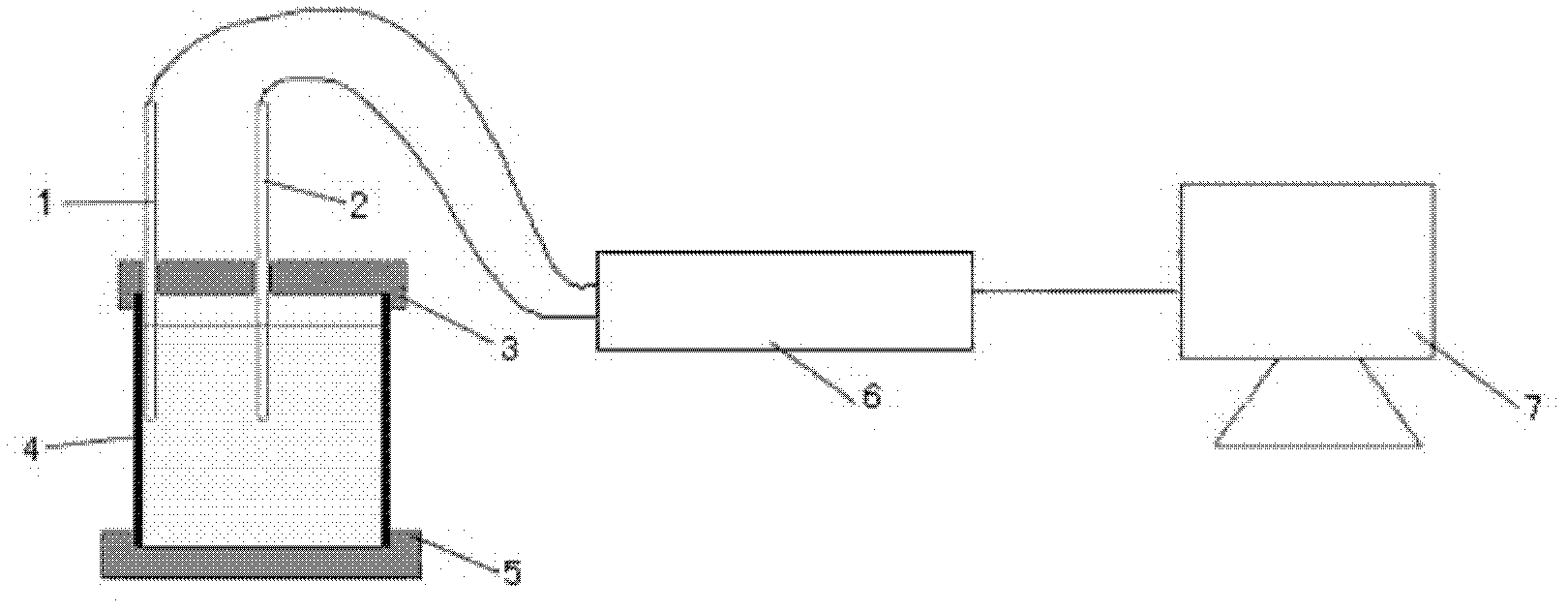

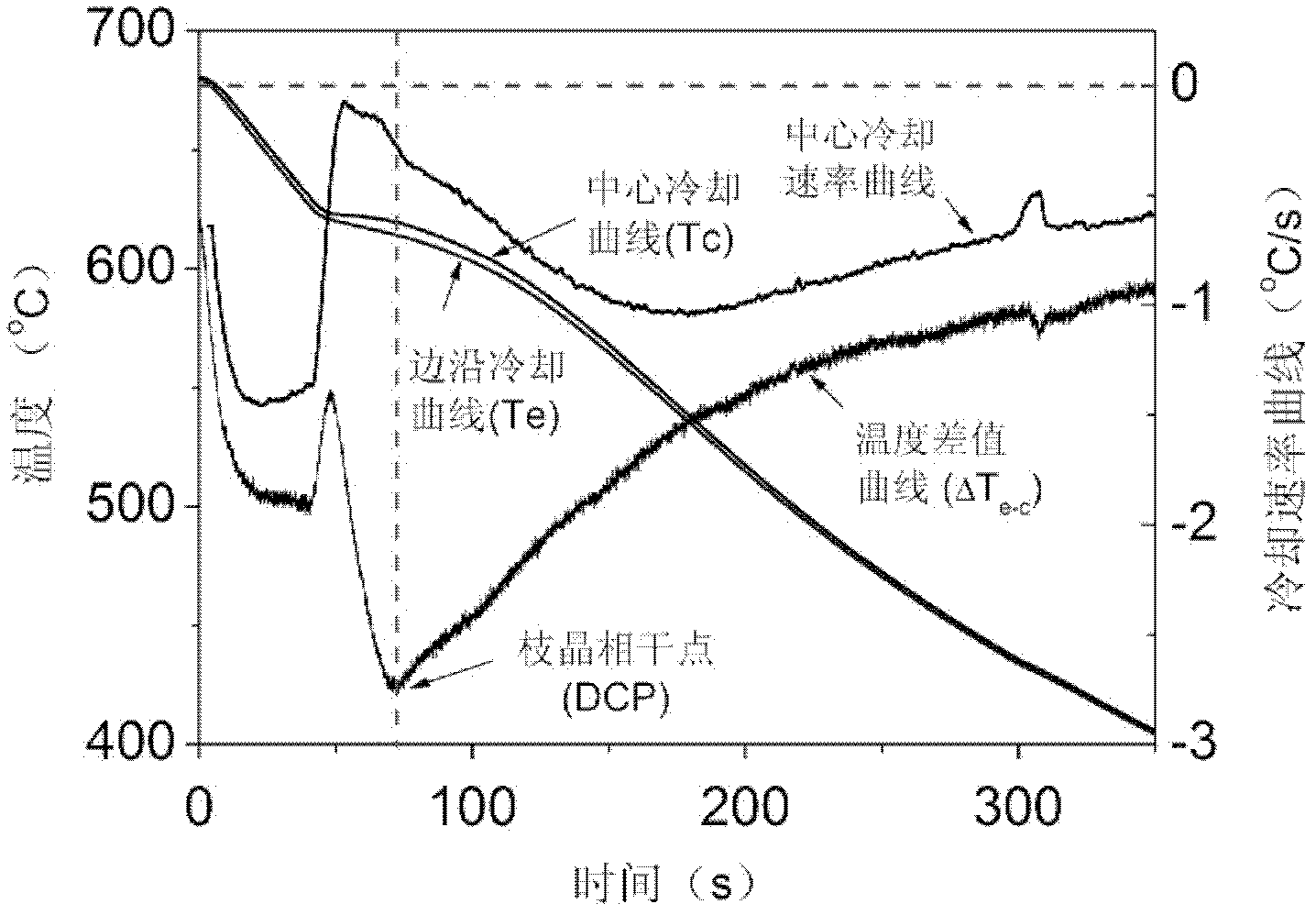

Thermal analysis test method and apparatus of magnesium and magnesium alloy deteriorative processing tissue thinning effect

InactiveCN101303319AObservation of reglow phenomenonRe-glow phenomenon recordsMaterial thermal analysisComputer-aidedComputer aid

The invention relates to a thermal analysis testing method of magnesium and magnesium alloy deteriorate process organizing thinning effect, which specifically uses the correlation between the deteriorate effect and the characteristic parameter on the cooling rate curve when a fused mass is solidified, establishes a thermal analysis testing technique, and develops a corresponding thermal analysis apparatus based on the thermal analysis testing technique. The thermal analysis testing technique of the invention has the following steps: 1, establishing a thermal analysis cooling curve (T -t); 2, derivation to the cooling curve to obtain a cooling rate curve (dT / dt -t); 3, respectively calculating the recalescence exothermic peak areas of the fused mass fore and after the deterioration; 4, defining the deterioration degree to judge the deterioration effect. The thermal analysis process includes data capture, computer analysis of the cooling curve, quantization of the exothermic peak areas, and result comparison; the process is realized by the computer and data analysis software, which are configured to a computer aided thermal analysis detecting device. The thermal analysis testing method and testing apparatus of the invention can be used in the smelting field of magnesium and magnesium alloy, as a ladle analysis approach to control and improve the metallurgy quality.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

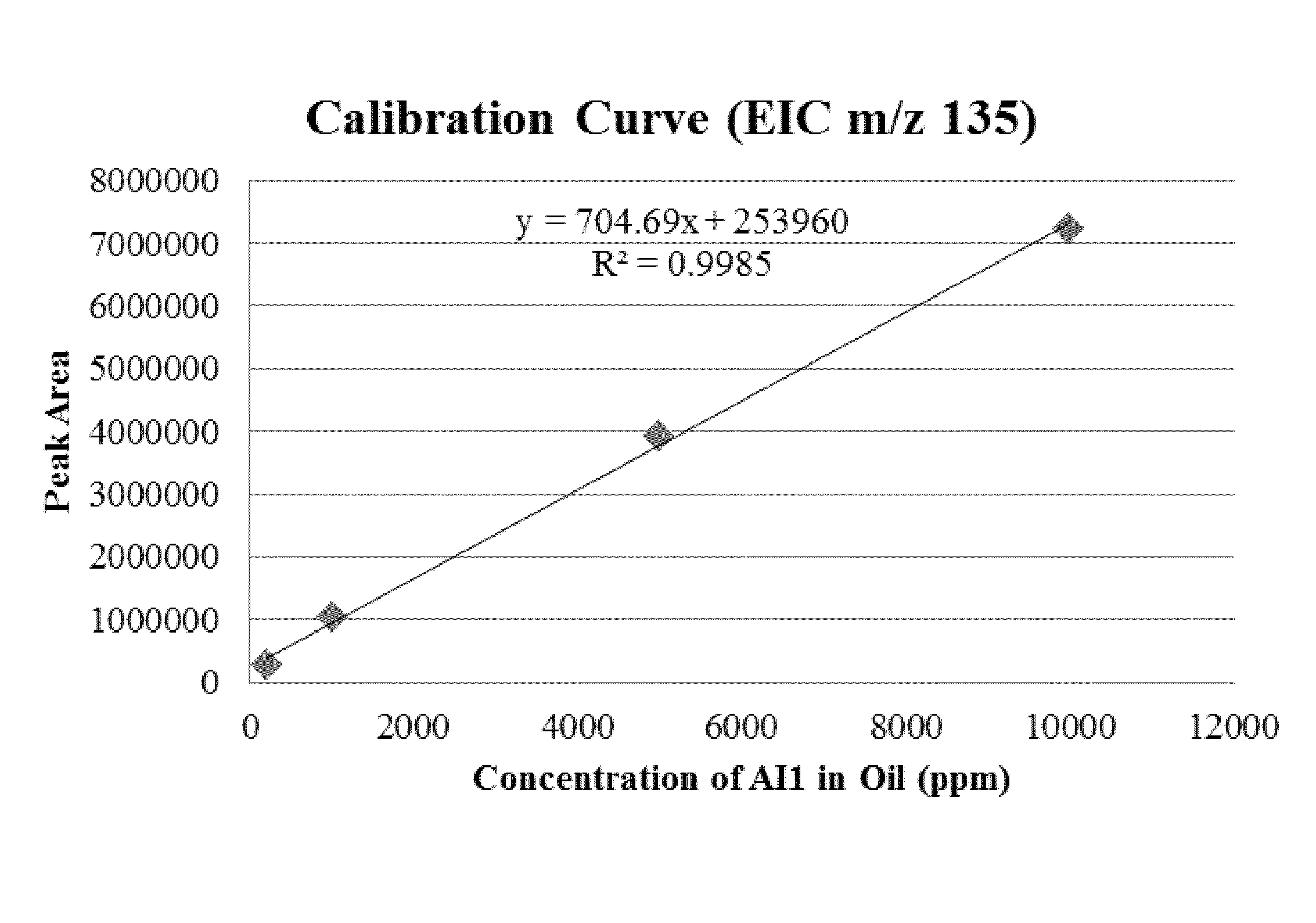

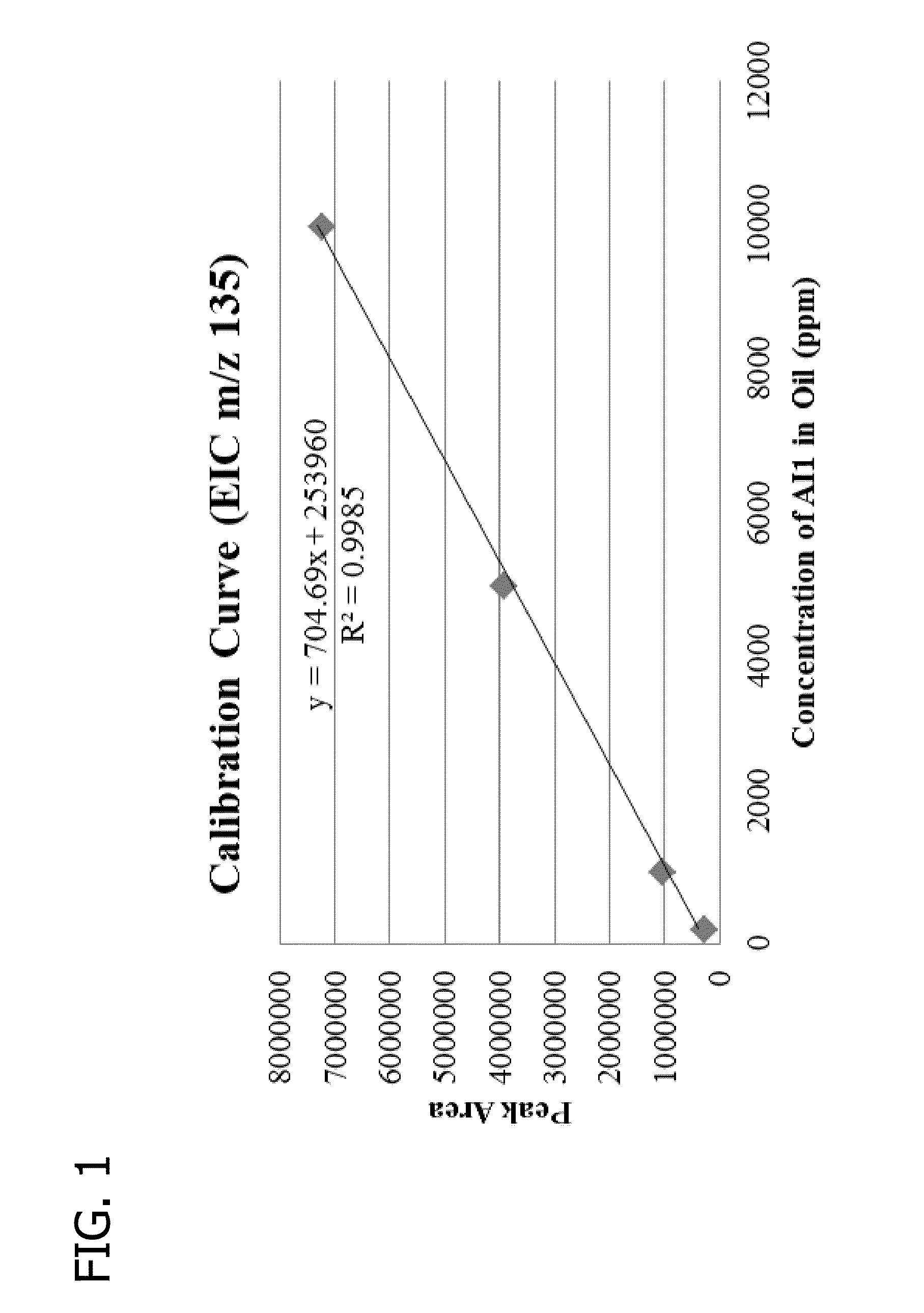

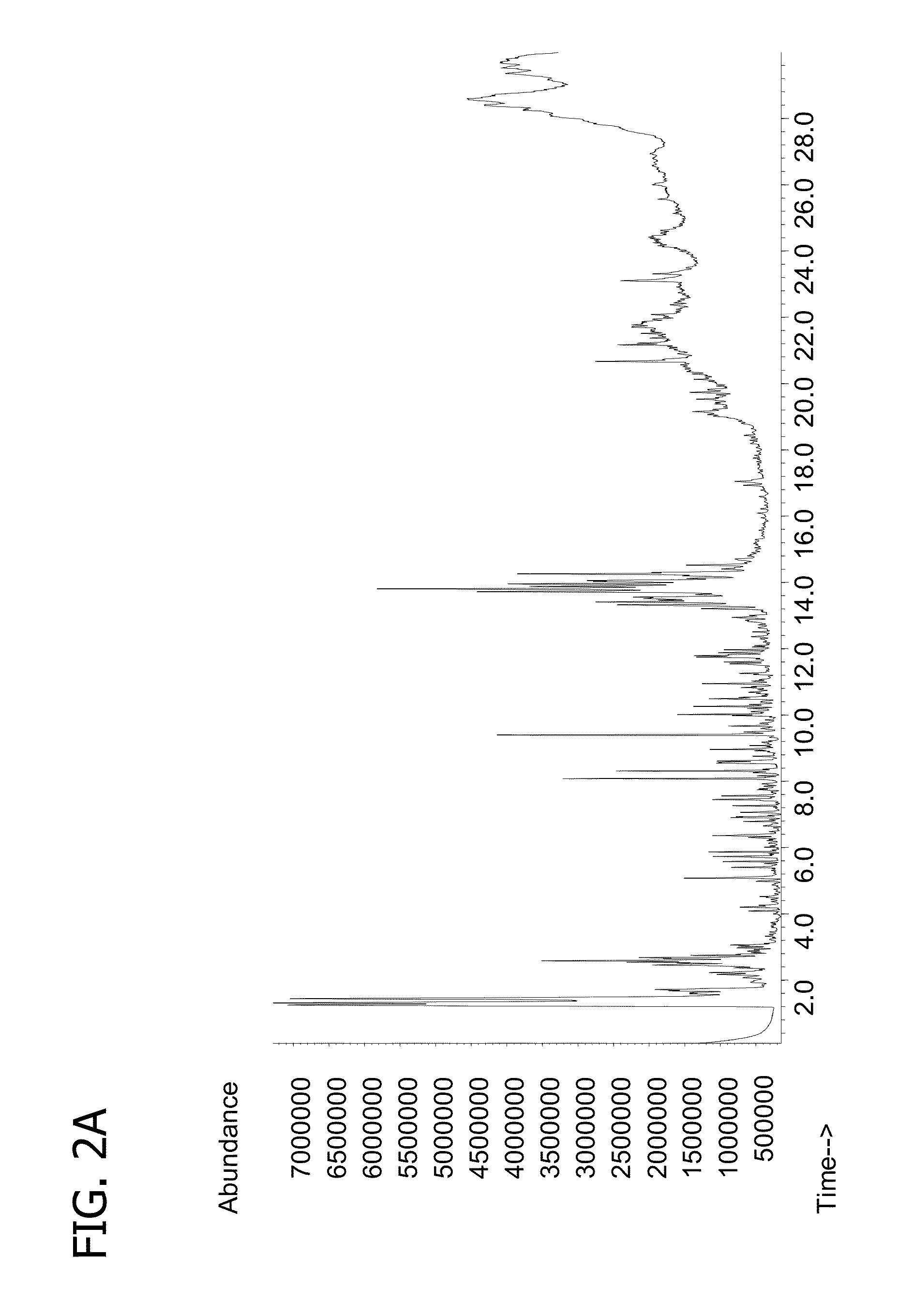

Quantification of asphaltene inhibitors in crude oil using thermal analysis coupled with mass spectrometry

ActiveUS20160061790A1Component separationMaterial testing goodsMass Spectrometry-Mass SpectrometryMass spectrometry imaging

The present invention generally relates to a novel method for the characterization and quantification of involatile macromolecules in hydrocarbon samples of crude oil. More particularly, the method utilizes pyrolysis / gas chromatography / mass spectrometry (PY / GC / MS, PY / GC / MS / MS or PY / GC / triple quad MS) to detect and quantify polymeric asphaltene inhibitors in crude oil.

Owner:CHAMPIONX USA INC

Thermal analysis and detection method and device for solidification grain size of magnesium alloy melt

ActiveCN102998324ALow costMetamorphic effect in timeParticle size analysisMaterial thermal analysisSolid phasesAlloy element

The invention provides a thermal analysis and detection method and device for solidification grain size of a magnesium alloy melt and belongs to the fields of magnesium alloy melt treatment and casting solidification. The thermal analysis and detection method provided by the invention comprises that certain amounts of magnesium and magnesium alloy melt are poured into a sampling cup to be cooled, two thermocouples are adopted for respectively determining temperatures at the center and the edge of the melt in a solidification process in a magnesium alloy melt cooling process, a temperature acquisition device is used for acquiring temperature data, a computer program is used for recording variation of the temperatures at the center and the edge of the melt in the solidification process along with time, then dendritic crystal coherence point solid phase fractional number is determined by virtue of a thermal analysis and detection method, and the dendritic crystal coherence point solid phase fractional number is compared with a standard value to judge a refining or roughening effect on the grain size of a magnesium alloy by modification, grain refining or alloying element addition. According to the thermal analysis and detection method and device provided by the invention, recalescence is not required in a thermal analysis cooling curve of the solidification process, the thermal analysis and detection method and device provided by the invention are especially applicable to the magnesium alloy with lower solidification latent heat release, a modification effect can be represented within a wider solidification speed range, and solidification grain size can be predicted.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

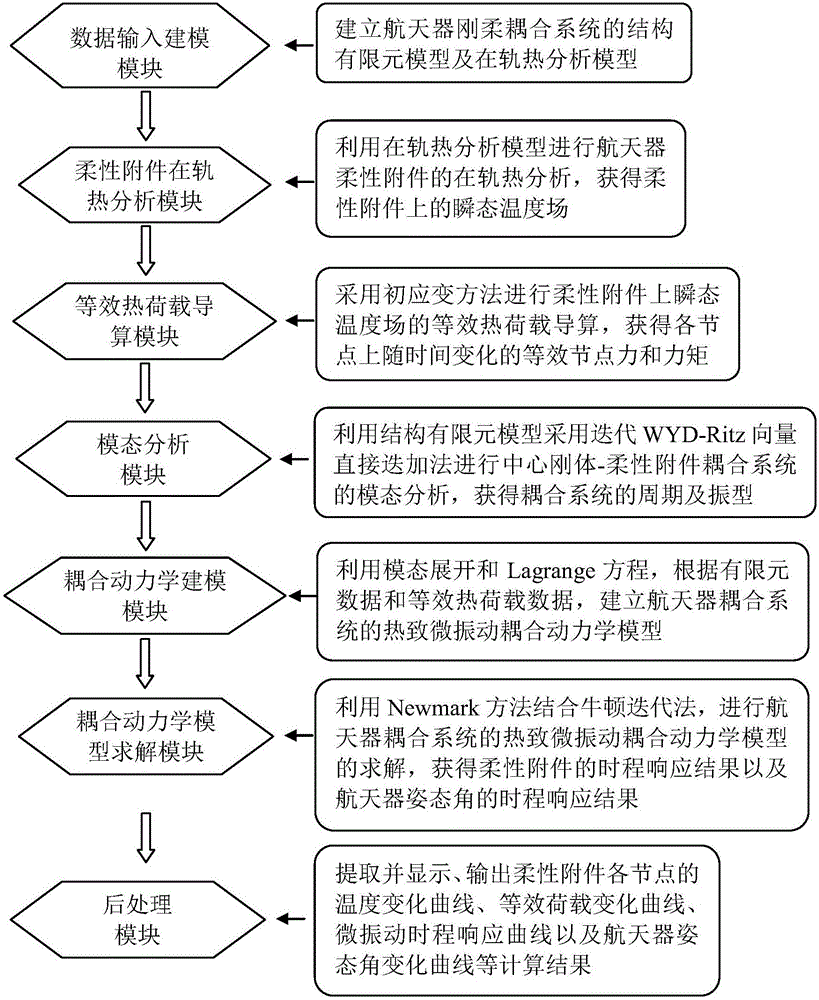

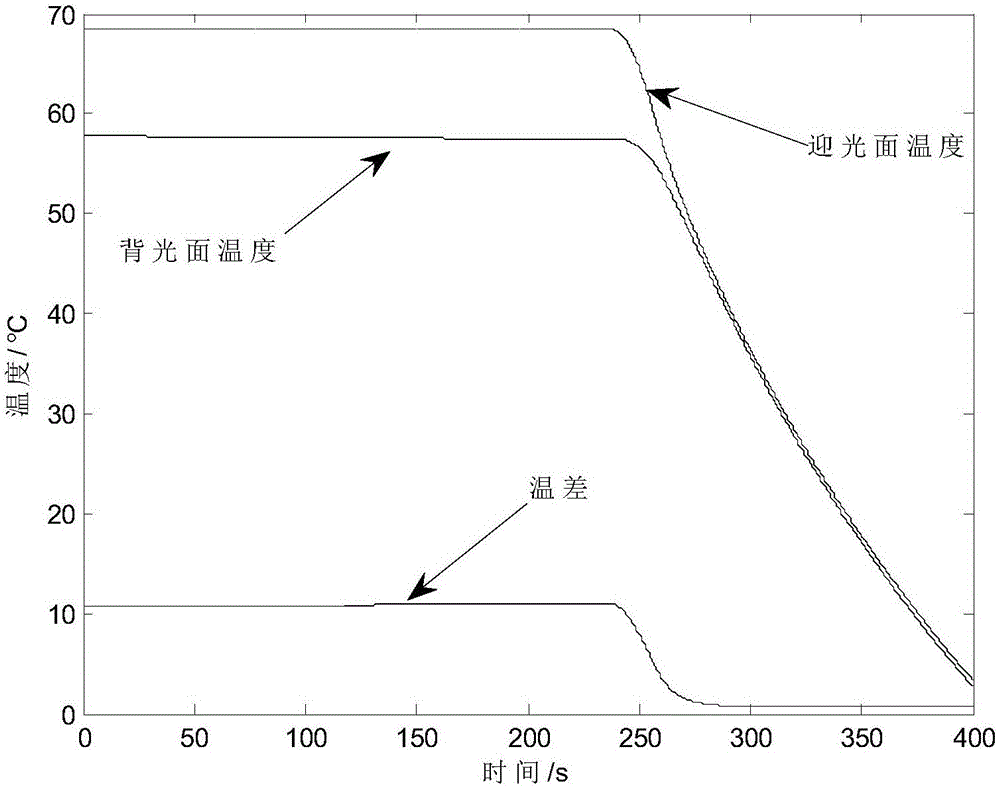

Simulated analysis platform for thermal disturbance responses of spacecraft

ActiveCN106407588ADesign optimisation/simulationSpecial data processing applicationsDynamic modelsEngineering

The invention belongs to the technical field of design, and dynamics simulation and control of high-precision spacecraft, and in particular relates to a simulated analysis platform for thermal disturbance responses of the spacecraft. The platform comprises a data input modeling module, a flexible attachment on-orbit thermal analysis module, an equivalent thermal load derivation module, a modal analysis module, a coupling dynamics modeling module, a coupling dynamics model solution module and a post-processing module in sequence; the simulated analysis platform builds a coupling dynamics model of large flexible satellite-borne attachments and stars, and provides a special simulated analysis platform for coupling responses of the large flexible satellite-borne attachments and the stars. The simulated analysis platform can be used for solving posture variations of the spacecraft with complex flexible attachments caused by thermally induced dynamic deformations of the flexible attachments, can provide a simple and effective model, method and tool for forecast and assessment of thermally induced vibration responses of the spacecraft with the flexible attachments under actual conditions, and can serve as a reference for a satellite design process.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY +1

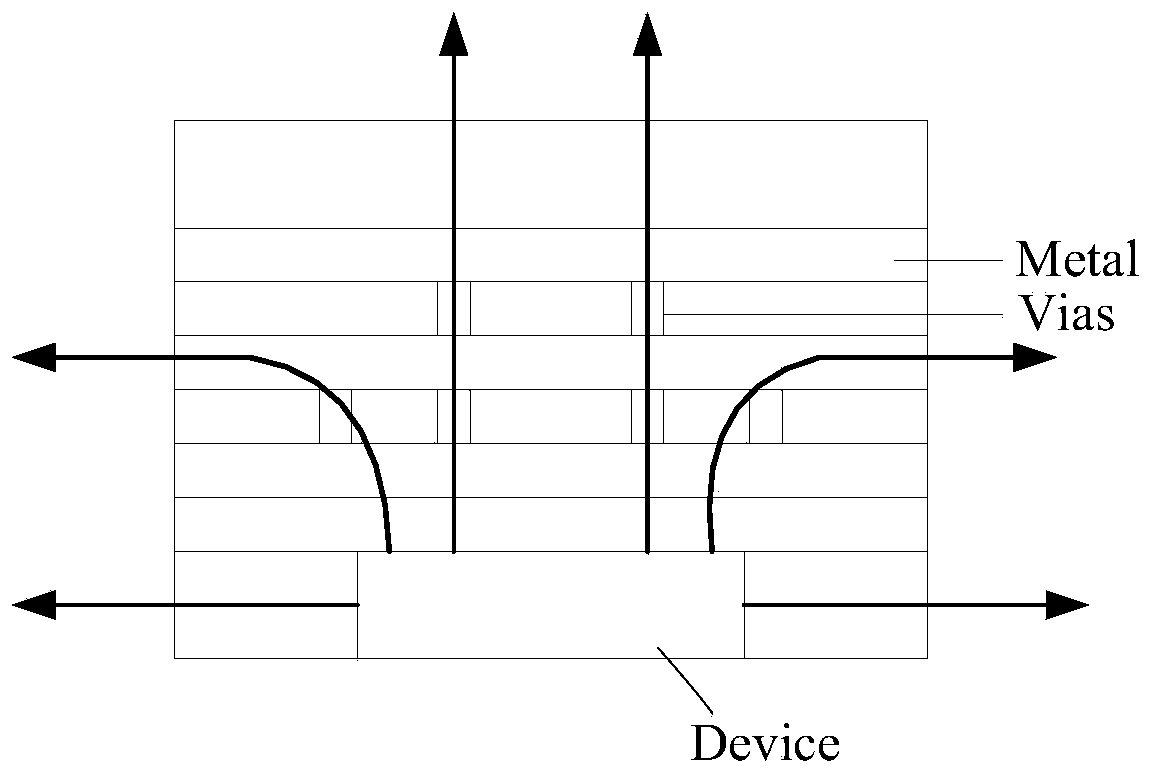

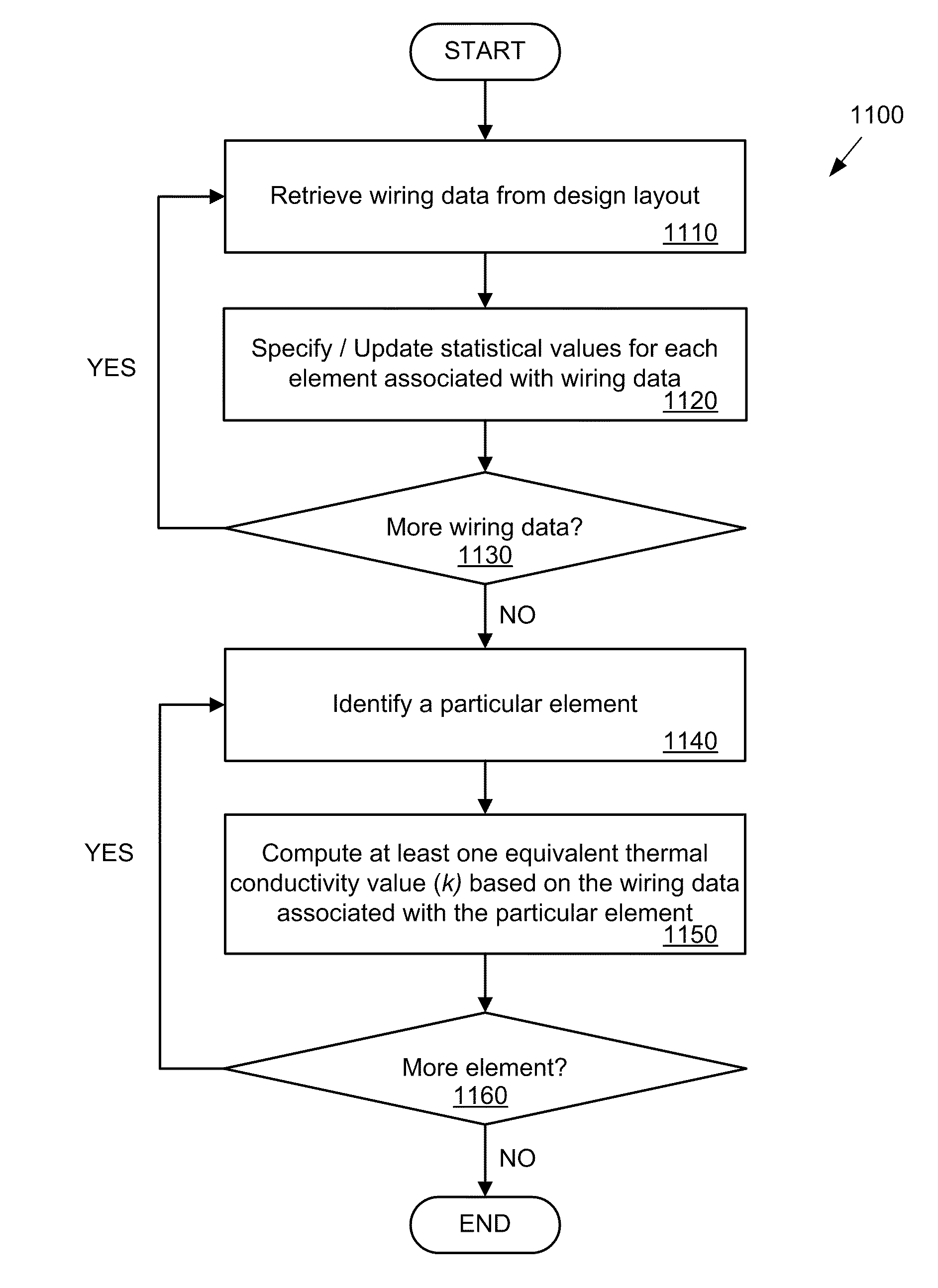

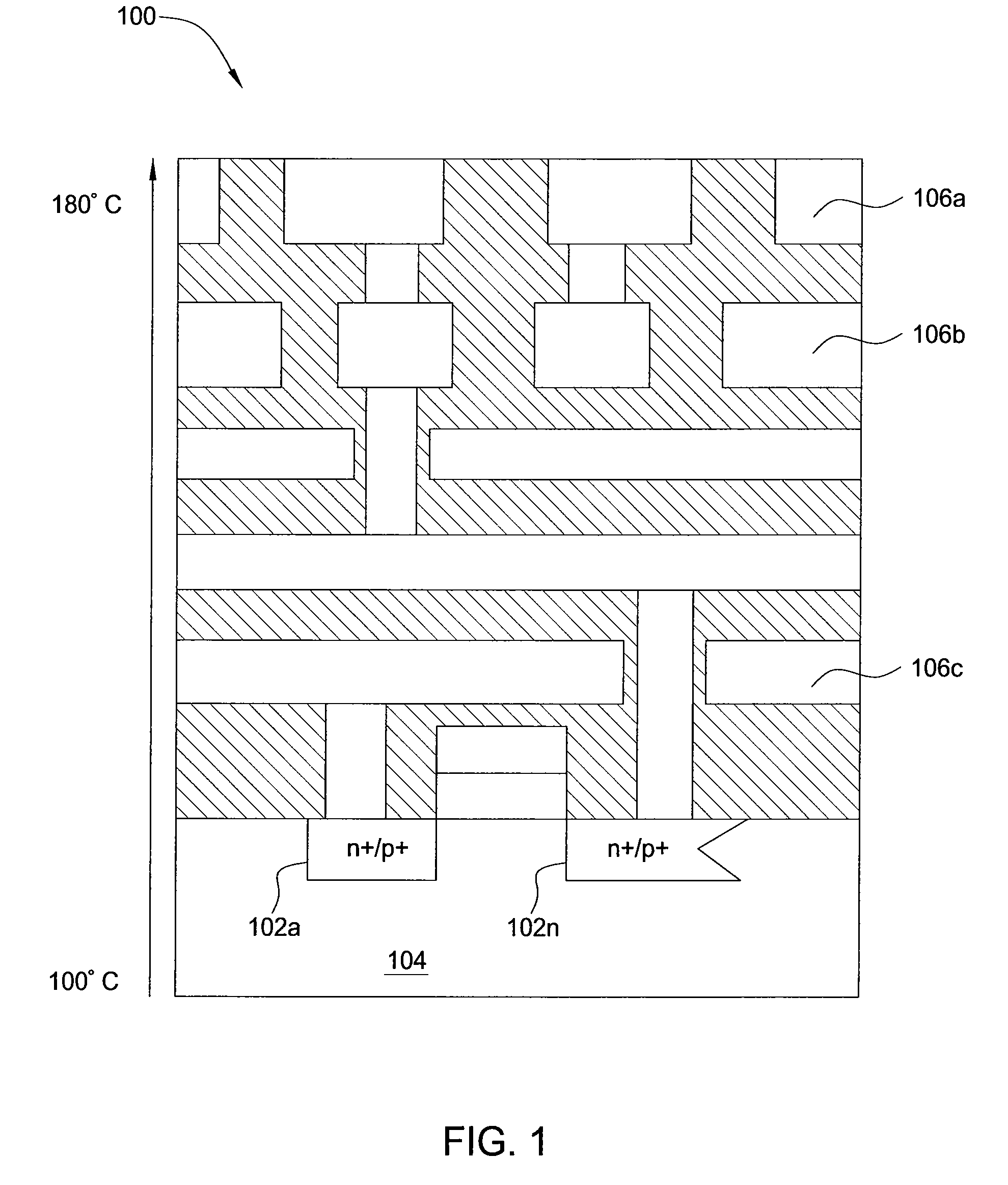

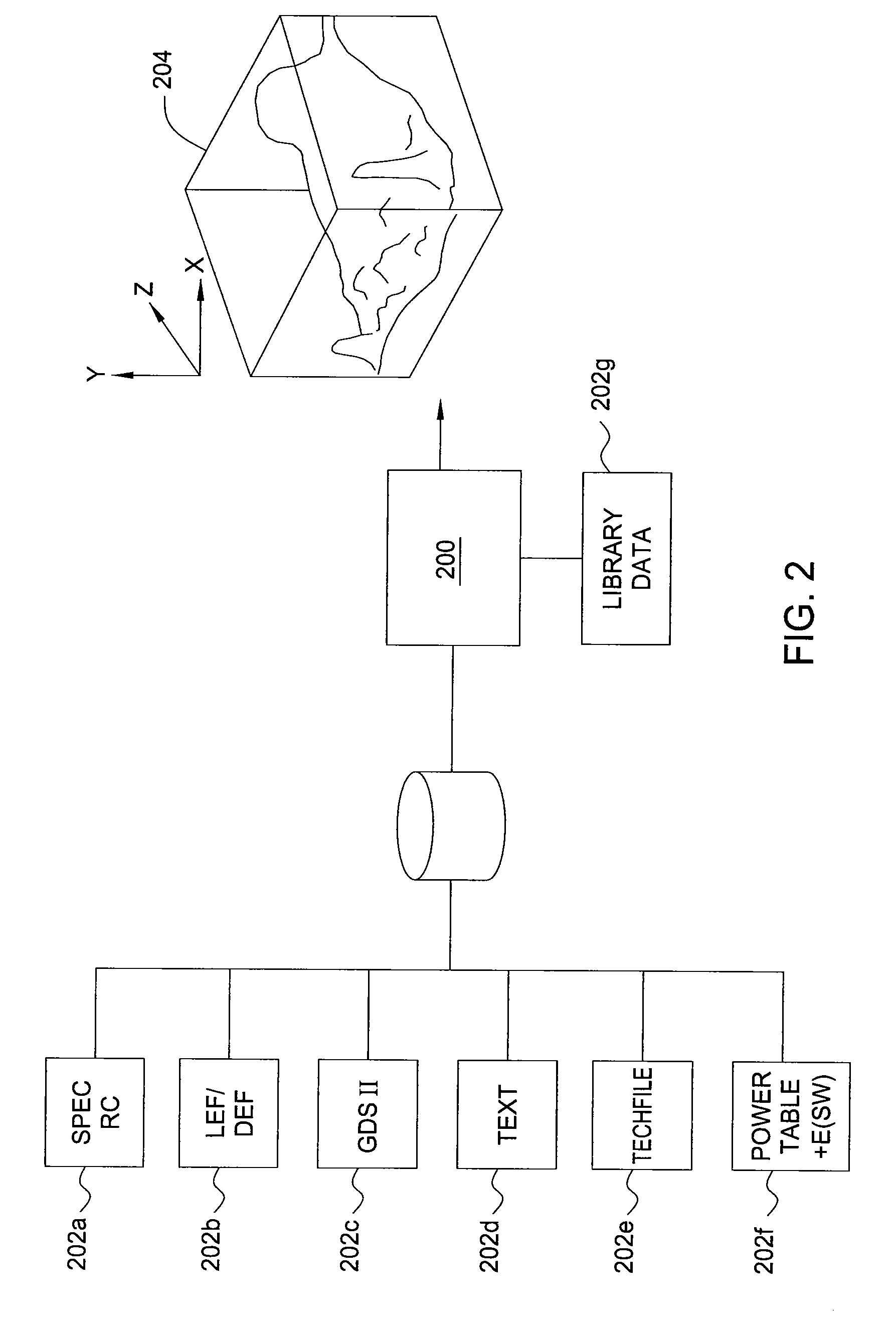

Method and apparatus for thermal analysis of through-silicon via (TSV)

Some embodiments of the invention provide a method for performing thermal analysis of an integrated circuit (“IC”) design layout. The IC design layout includes several wiring layers in some embodiments. The IC design layout includes a substrate that has at least one through-silicon via (“TSV”). The method divides the IC design layout into a set of elements. The method identifies a temperature distribution for the IC design layout by using the set of elements. In some embodiments, at least one element includes a metal component and a non-metal component. The non-metal component is silicon in some embodiments, and a dielectric in other embodiments.

Owner:CADENCE DESIGN SYST INC

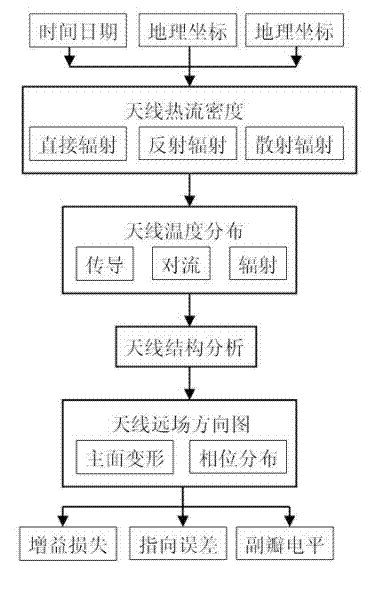

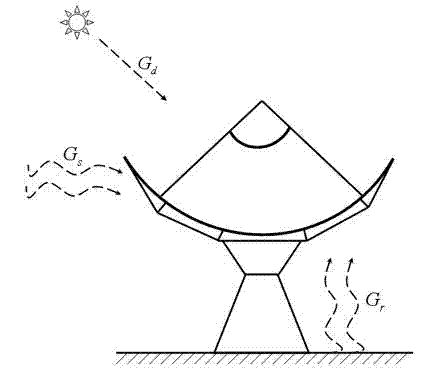

Electric coupling analysis method of temperature loader of large-scale foundation surface antenna

InactiveCN102243276ARealize the effect of electrical performanceSpecial data processing applicationsAntenna radiation diagramsElement modelHeat flow

The invention relates to an analysis method of a large-scale foundation surface antenna, in particular to an electric coupling analysis method of a temperature loader of a large-scale foundation surface antenna. The method is characterized by comprising the following steps of: 1) determining time, geographical position and gesture of the antenna; 2) calculating the density of heat flow from the sun to the antenna; 3) performing thermal analysis on the antenna by using the density of the heat flow as a load to obtain temperature distribution; 4) adding the temperature distribution serving as atemperature load into a finite element model of the antenna, and performing structural analysis to obtain antenna deformation data; 5) extracting the main surface deformation data of the antenna, andcalculating a far-field pattern of the antenna; and 6) giving a gain loss, a directional error and a minor lobe level. The invention provides the electric coupling analysis method of the temperature loader of the large-scale foundation surface antenna. By the method, influence on the electric performance can be analyzed when the antenna which faces upwards deforms due to the influence of environment, solar radiation and temperature.

Owner:XIDIAN UNIV

Method for producing molded parts, especially for use in automobile manufacture, and corresponding appropriate films comprising a coating

InactiveUS20090061215A1Sufficient cross-linkingSufficient scratch resistanceSynthetic resin layered productsRecord information storageCar manufacturingLiquid polymer

A process for producing moldings, in which a pigmented coating composition (P) and a free-radically crosslinkable coating composition (K), which after crosslinking to completion produces a transparent coating (KE) are applied to a support sheet a dried but as yet not completely crosslinked coating (KT) is produced from the coating composition (K), the coated support sheet is shaped and is injection backmolded or foam-backed with a liquid polymeric material, and the coating (KT)—if this has not already taken place—is cured or aftercured; the crosslinkable coating composition (K) comprising a free-radically crosslinkable component (KK) which contains hydrogen bond forming structural elements in an amount such that1. a coating (MT) produced from the mixture (M) of component (KK) with additives, but as yet not crosslinked to completion, has a ratio of storage modulus G(MT)′ to loss modulus G(MT)″ of from 5 to 200, G(MT)′ and G(MT)″ having been determined at 20° C. by means of rheological oscillation measurements, and2. a coating (ME) produced from the mixture (M) of component (KK) with additives and crosslinked to completion has a storage modulus E(ME)″ of from 1.0*107.0 to 8.0*107.0 Pa, E(ME)′ having been measured in the rubber-elastic range by dynamic mechanical thermal analysis.

Owner:BASF COATINGS GMBH

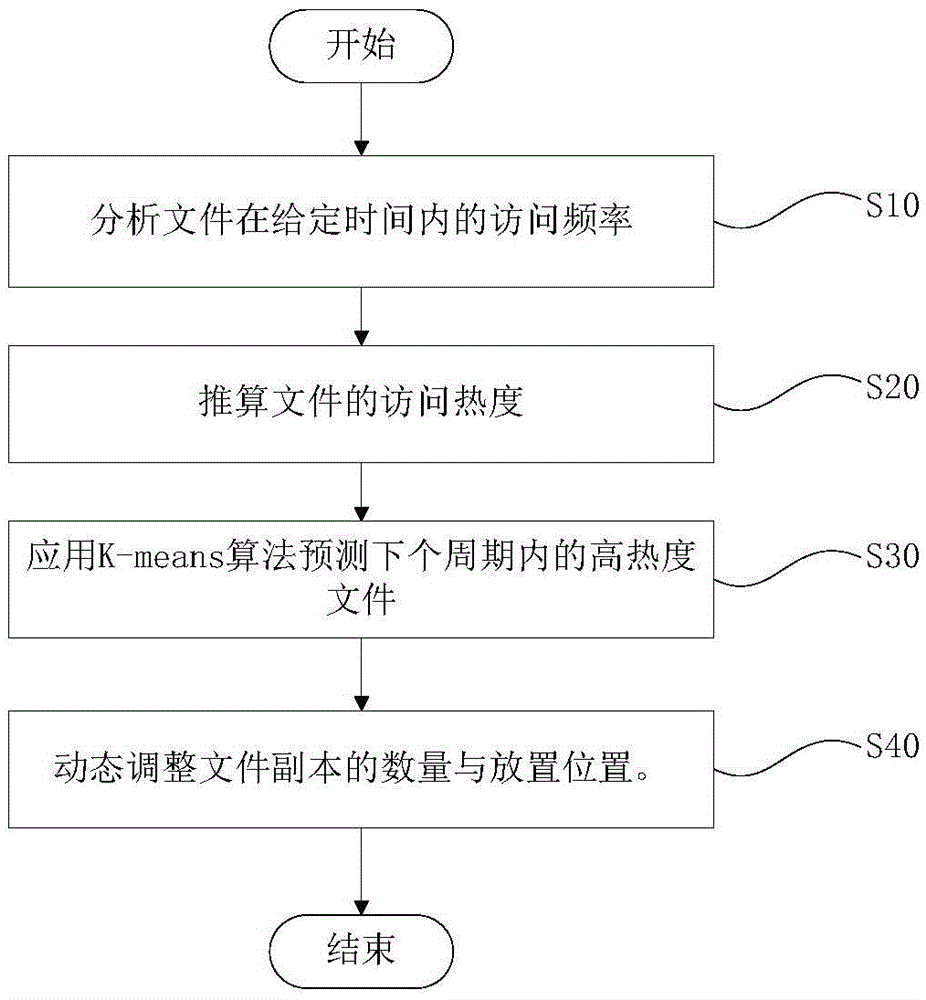

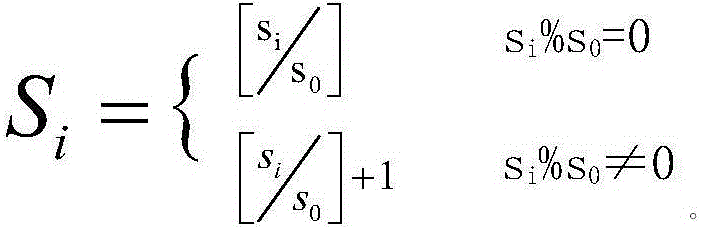

Transcript placement method based on file heat analysis and K-means

InactiveCN105574153AAchieve reasonable placementImprove rationalitySpecial data processing applicationsHeat analysisAccess frequency

The invention provides a transcript placement method based on file heat analysis and K-means. At first, The access frequency of a file in a given period of time is analyzed to calculate the access heat of the file. A possible file with high access heat is predicated by the access heat of the file, in combination with the K-means algorithm, and the number and placement positions of file transcripts are dynamically adjusted on demand by comprehensively considering a statistical cycle, a file size, a working environment and other factors. The transcript placement method provided by the invention can be used for effectively shortening the average response time of file access and improving the data service performance.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

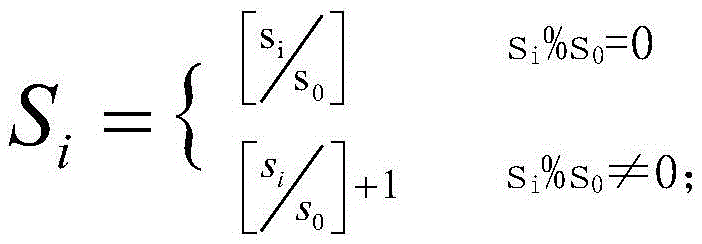

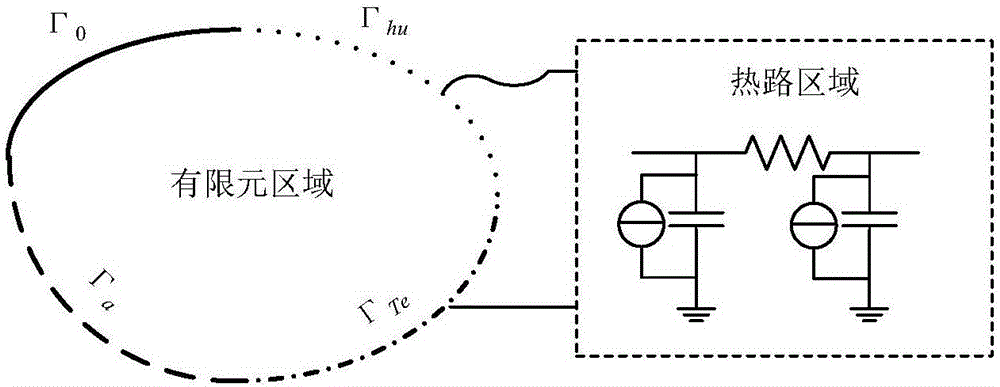

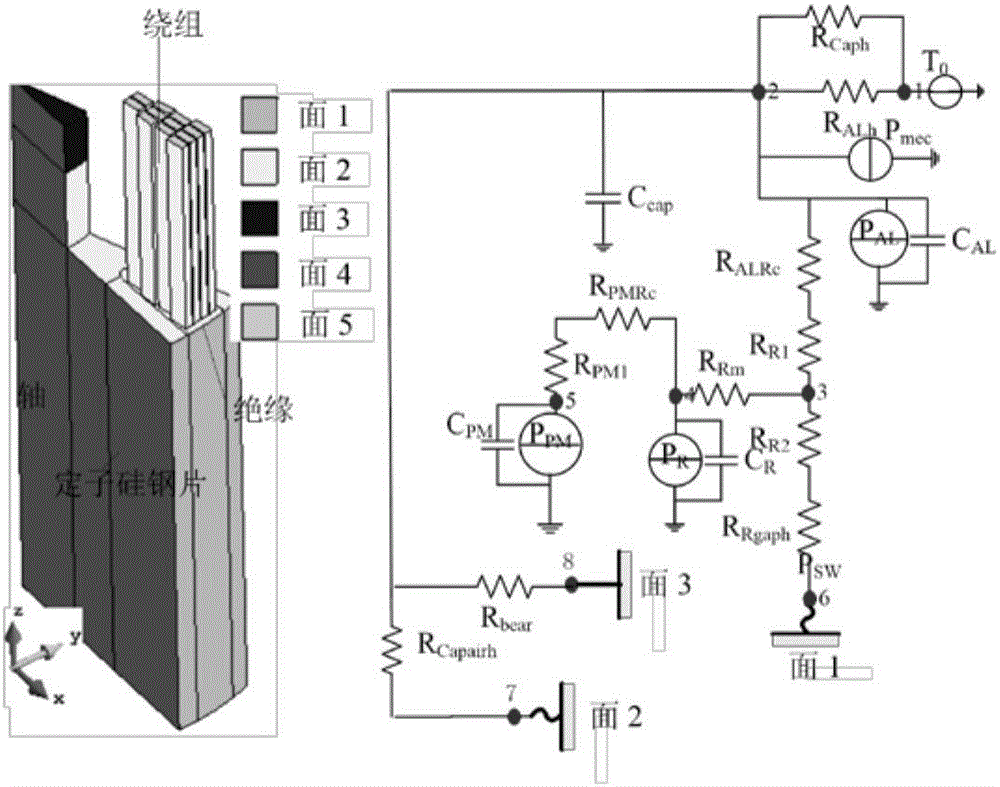

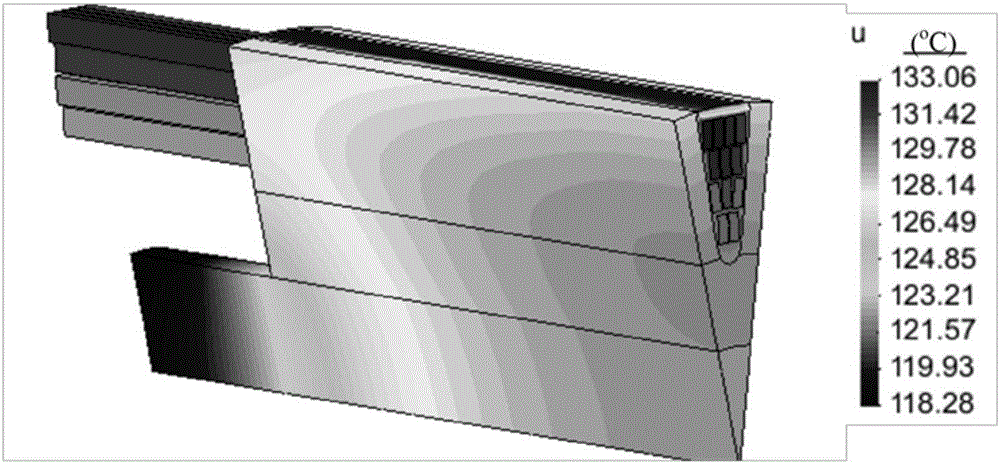

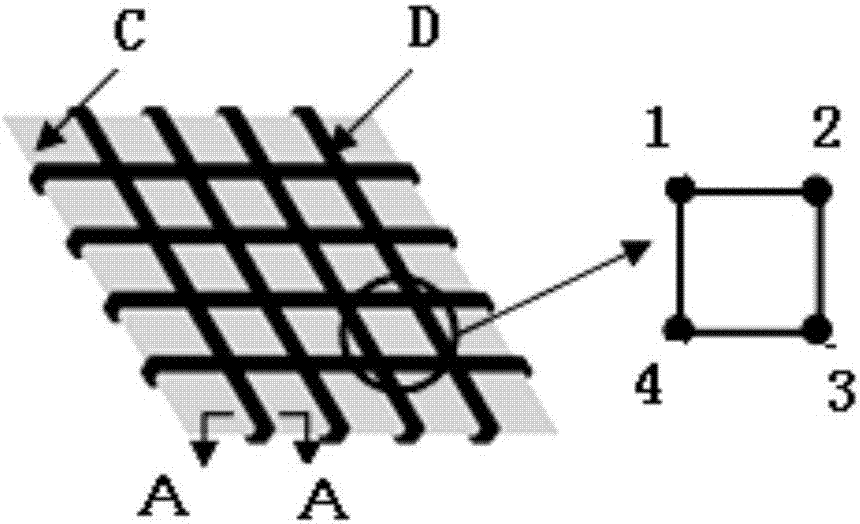

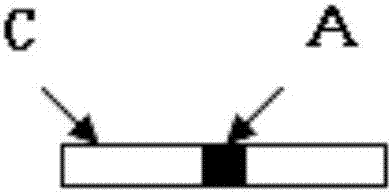

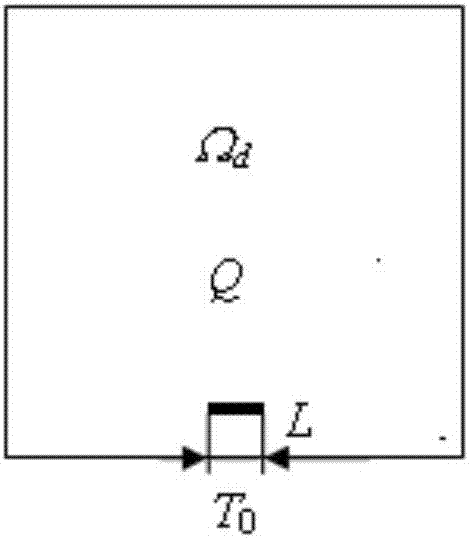

Temperature field-thermal circuit direct coupling-based motor heat analysis method

ActiveCN106446364AGood for convective heat transferGeometric CADDesign optimisation/simulationUnit loadDirect coupling

The invention discloses a temperature field and thermal circuit direct coupling-based motor heat analysis method. Part of parts of a motor are modeled by adopting a finite element method, and other parts are modeled by adopting a thermal circuit method. A temperature field is related to a thermal circuit through an equivalent temperature boundary and an equivalent convection boundary. During solving, a thermal circuit part is regarded to consist of one-dimensional finite element units, and two connected boundaries are regarded as two boundary units. Finally a unit stiffness matrix, a unit load matrix, a unit mass matrix and the like corresponding to the one-dimensional finite element units and the boundary units are superposed to a global stiffness matrix, a global load matrix and a global mass matrix, and the temperature field and the temperature distribution in the thermal circuit are worked out at the same time through a method for solving a global linear equation set. According to the method, the advantages of the finite element method and the thermal circuit method in the motor heat analysis are combined, so that sufficient calculation precision can be ensured and the calculation speed can be remarkably increased.

Owner:HANGZHOU EASITECH

Thermoelectric module with bi-tapered thermoelectric pins

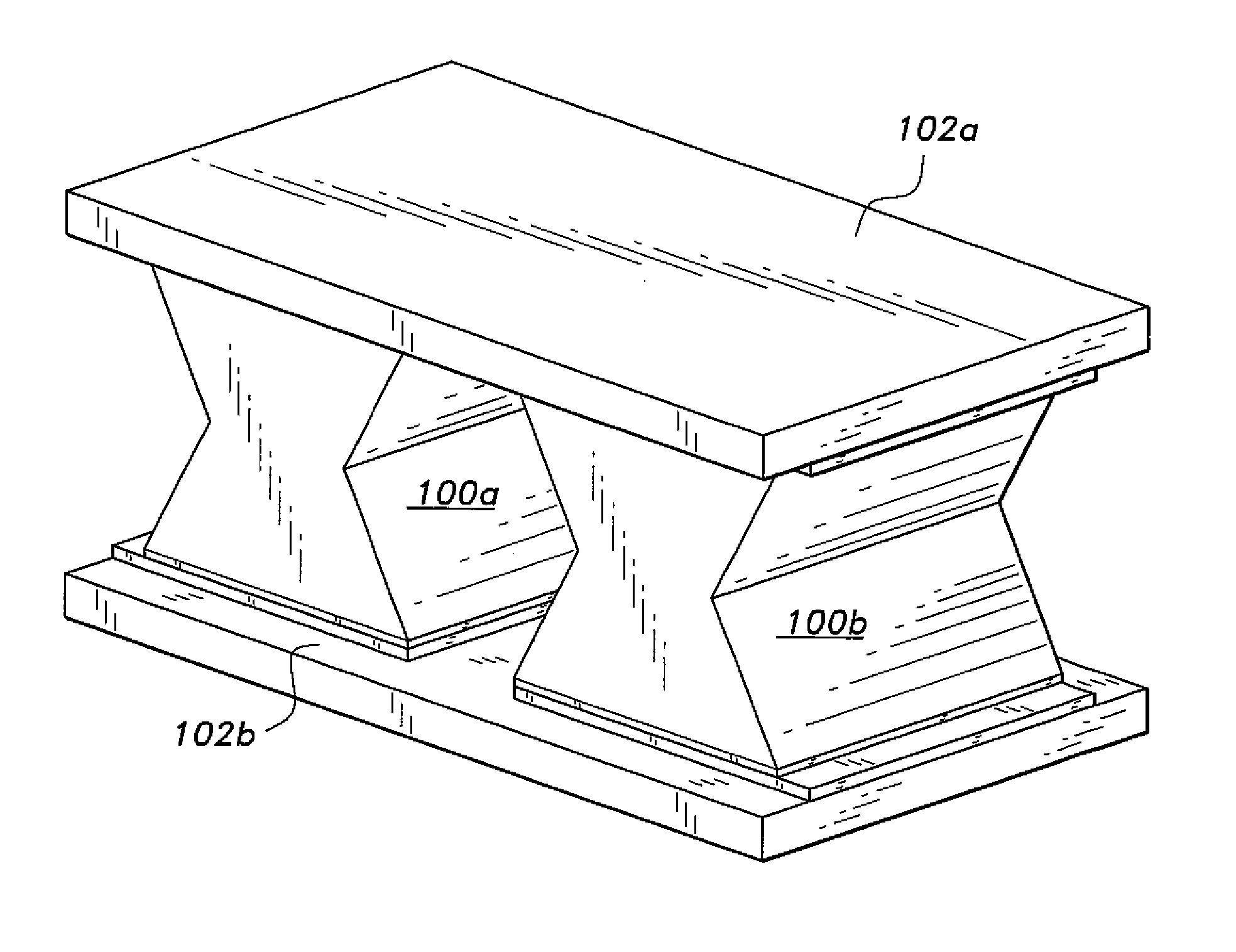

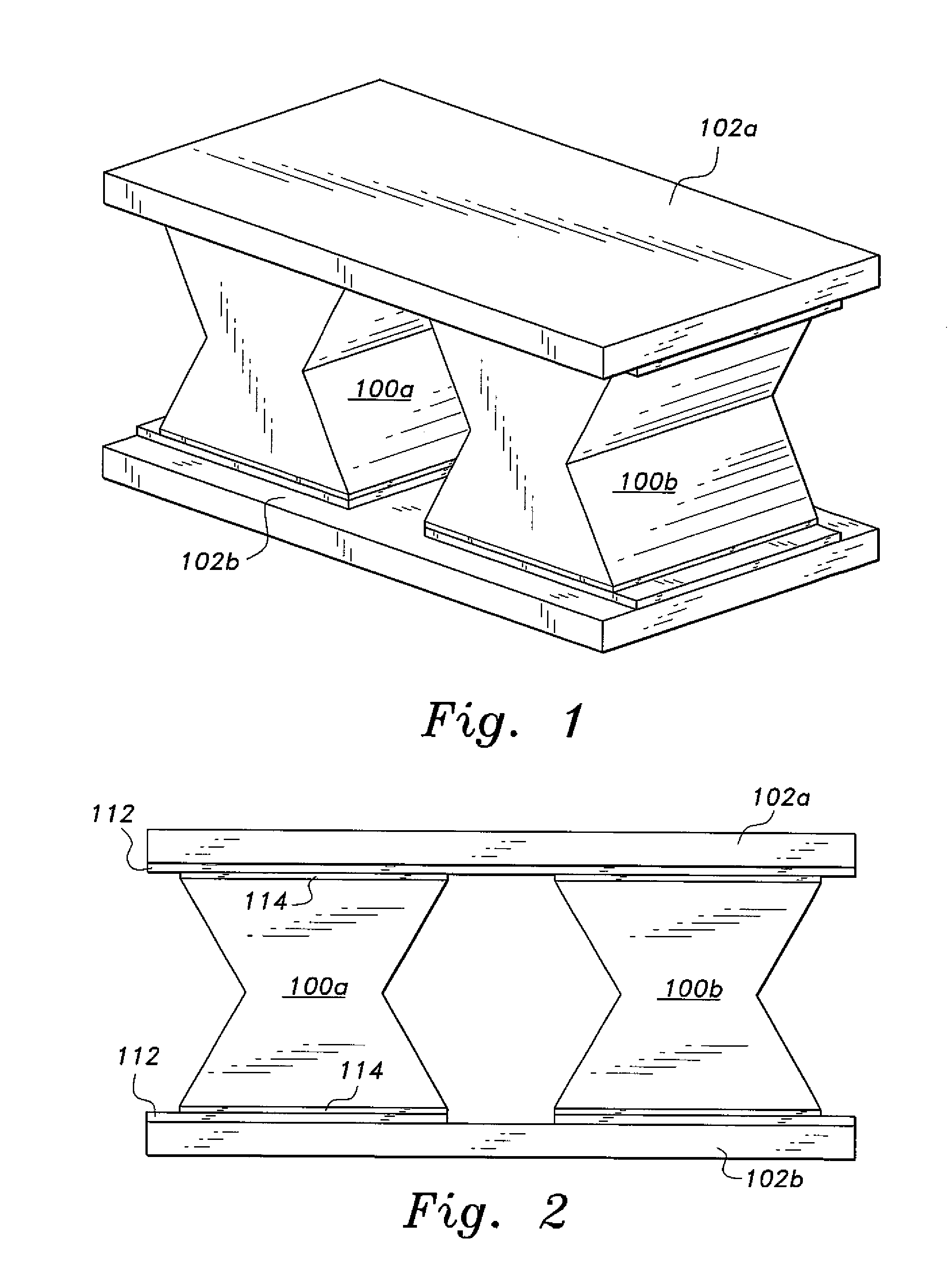

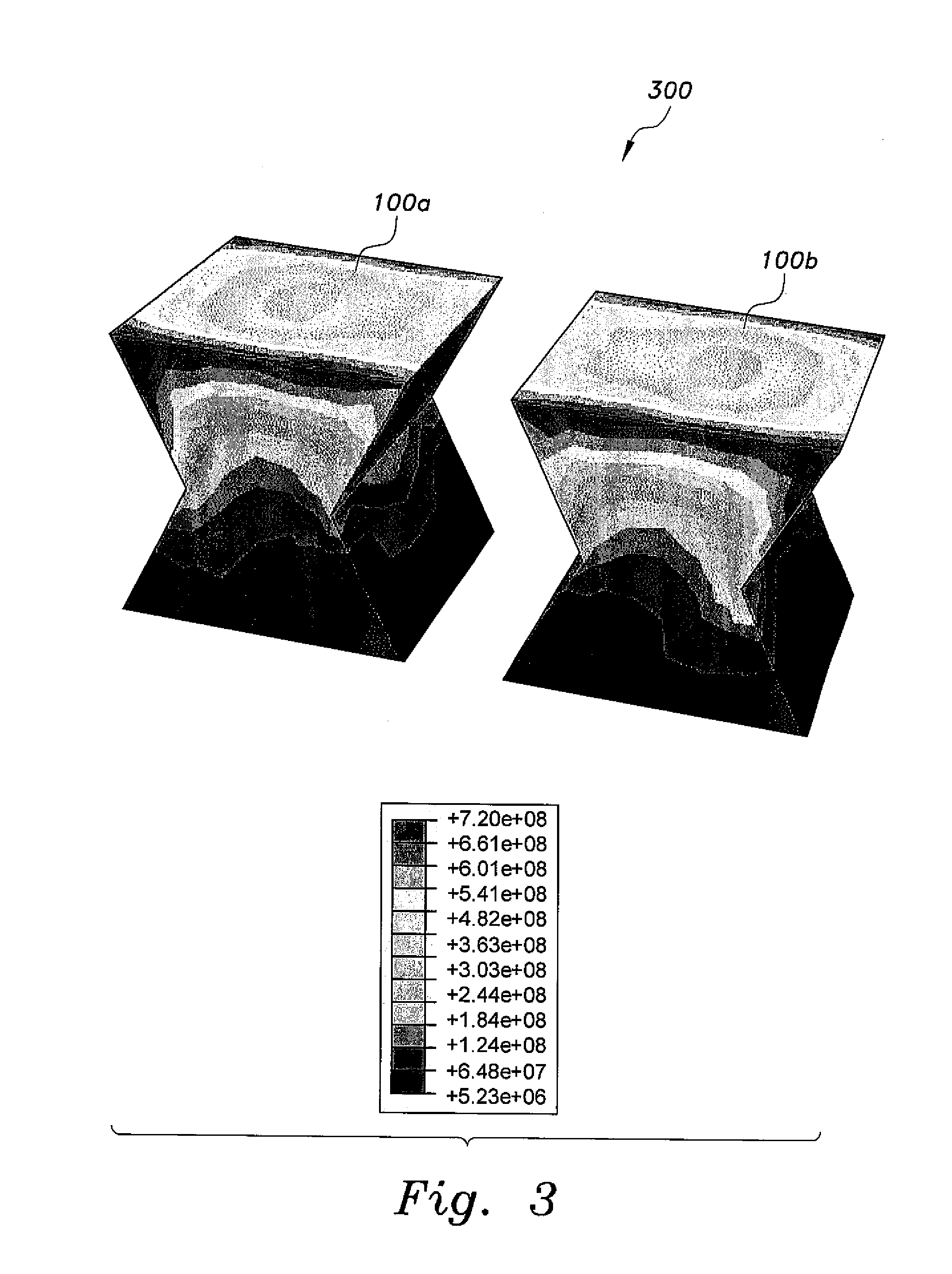

InactiveUS20140137917A1MaintenanceReduce thermal stressThermoelectric device with peltier/seeback effectThermoelectric device junction materialsBismuth tellurideDevice material

The thermoelectric module with bi-tapered thermoelectric pins is a semiconductor device configured as a thermoelectric power generator that has pins made of Bismuth Telluride that attach to a ceramic hot plate and a ceramic cold plate to form a thermoelectric module (TEM). The pins will include at least one N-doped pin and one P-doped pin. The bi-tapered pin structure of the TE pins exhibits low maximum thermal stress as predicted by thermal analysis, thereby maintaining thermal, electrical, and mechanical integrity of the TEM device.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

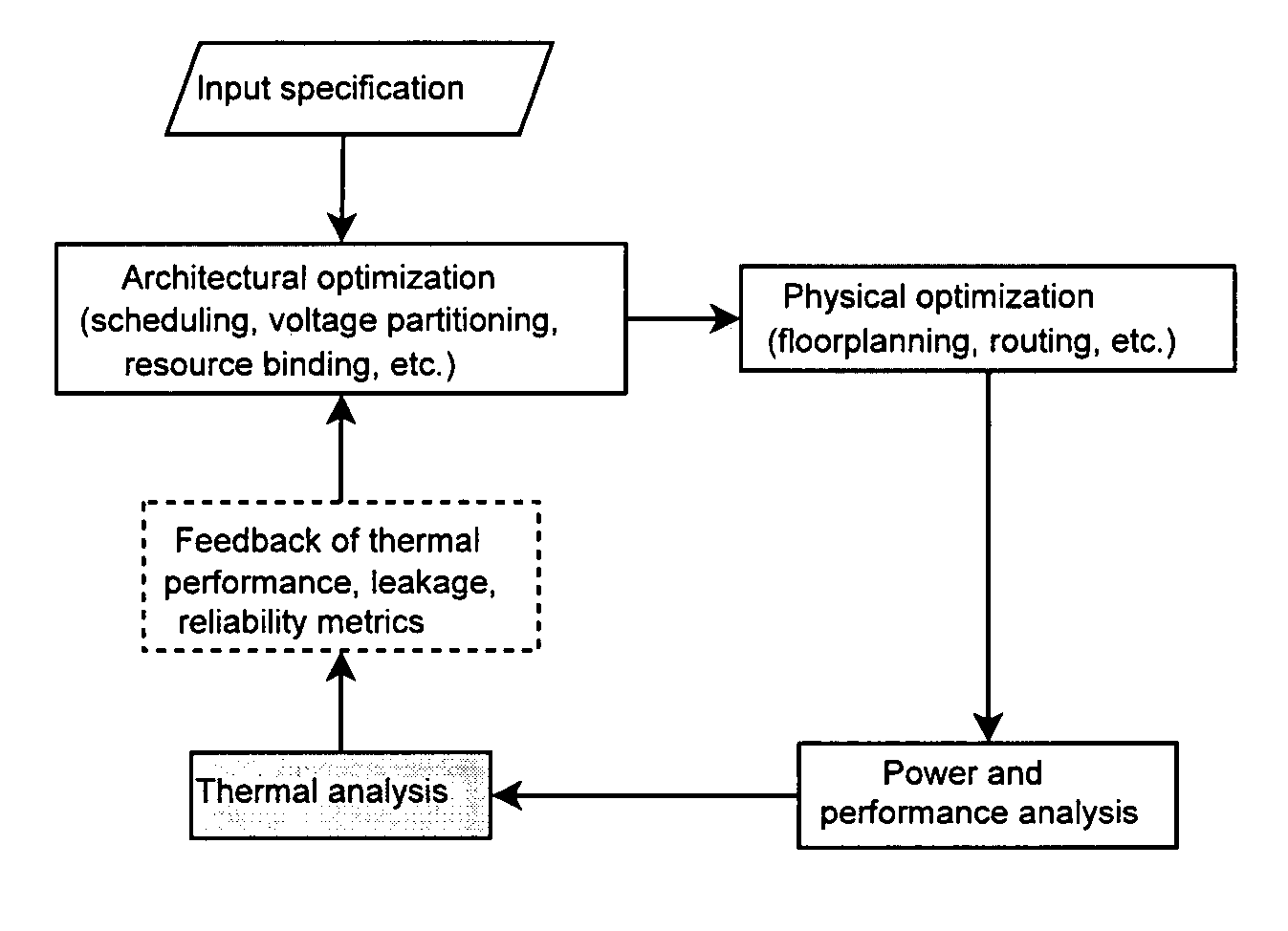

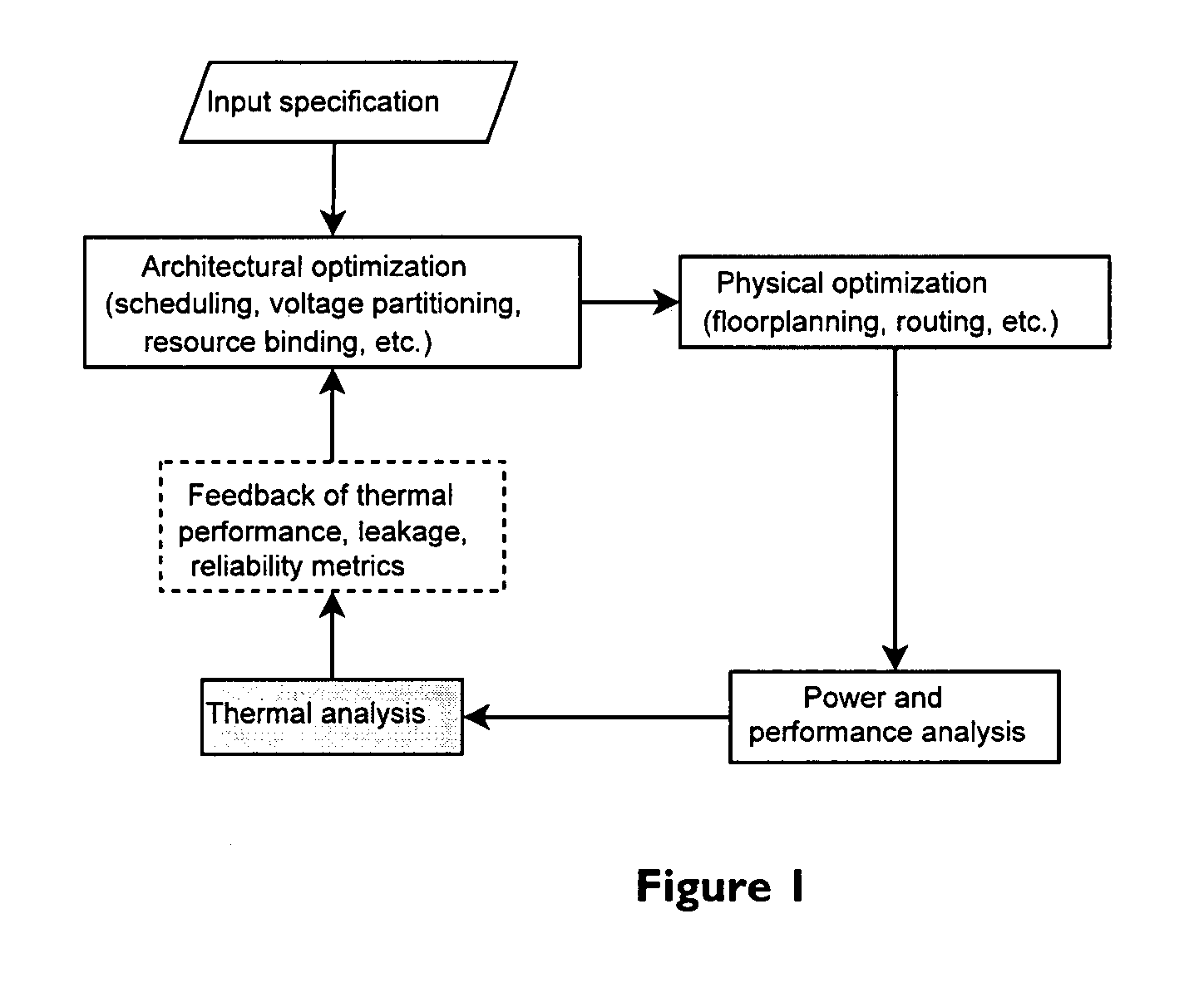

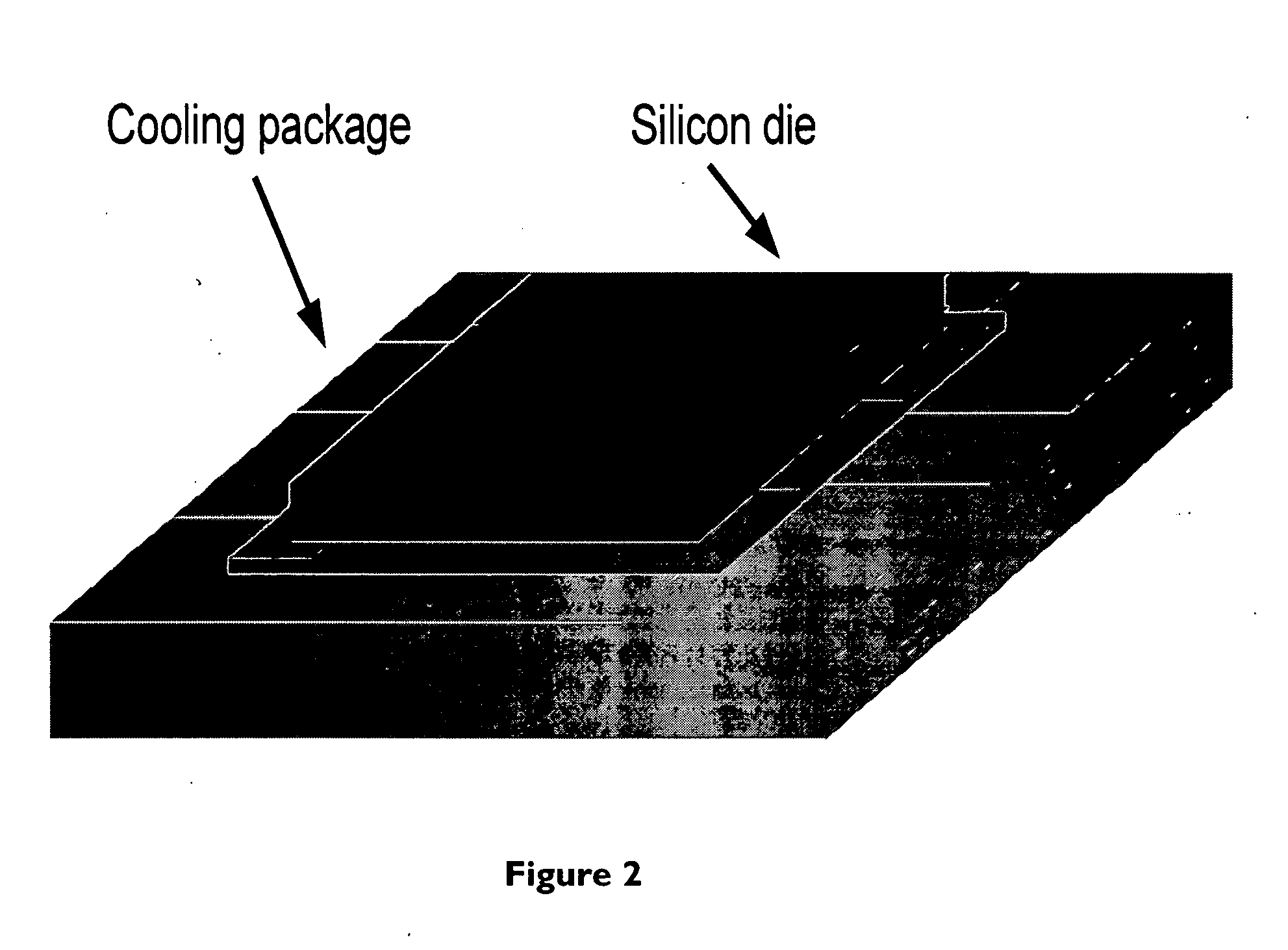

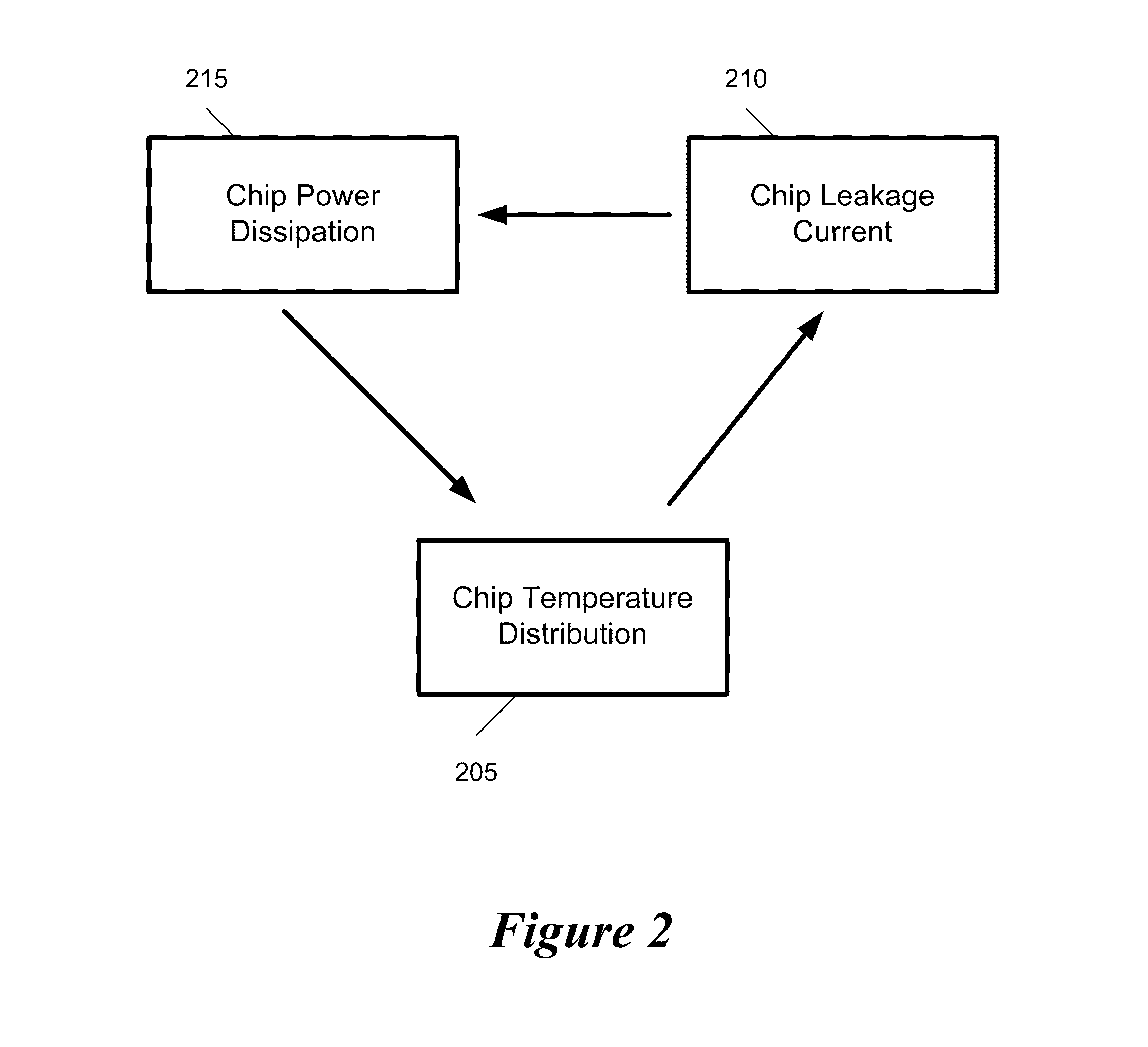

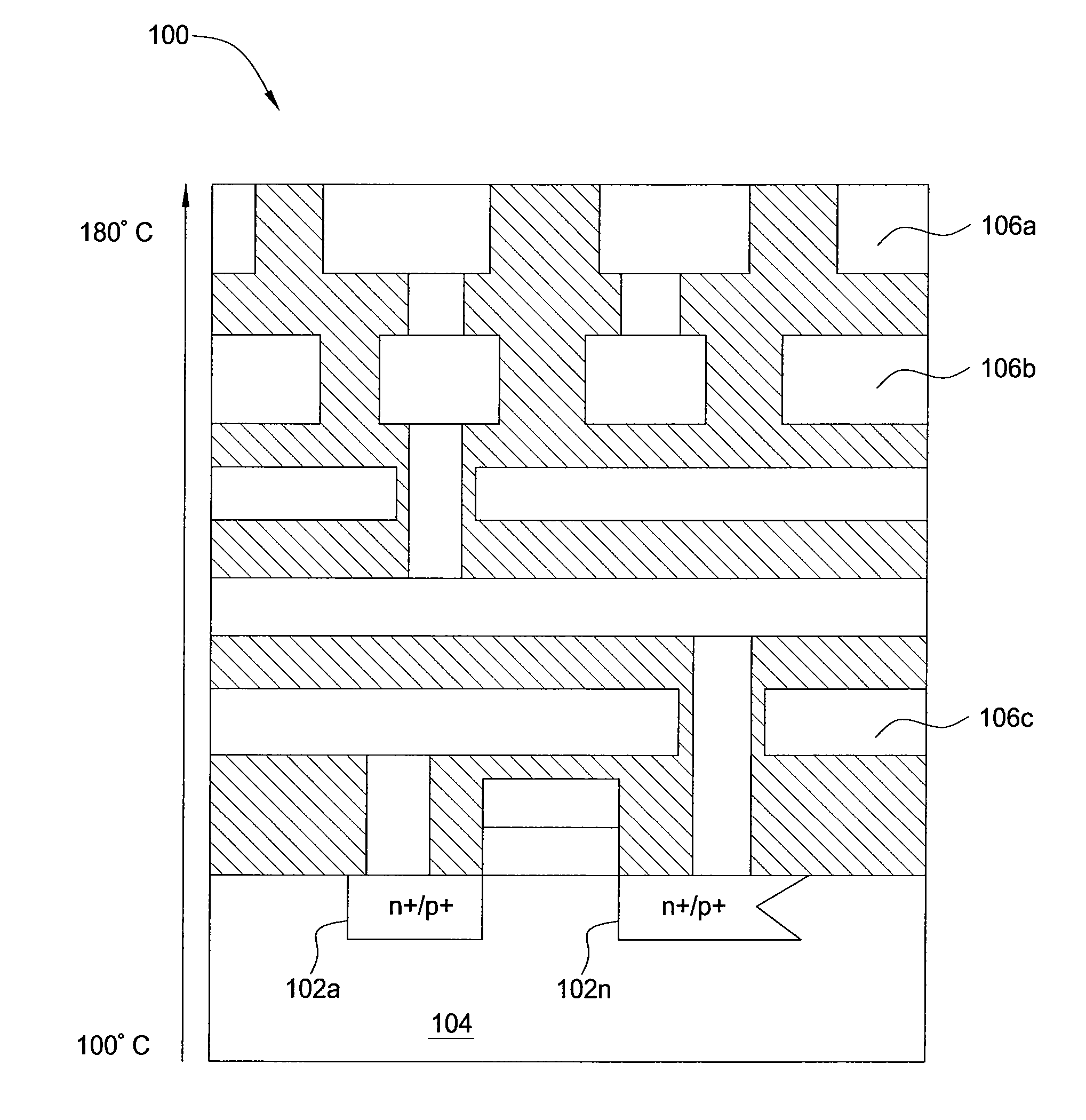

Method and apparatus for full-chip thermal analysis of semiconductor chip designs

ActiveUS20070120239A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor chipHeat analysis

A method and apparatus for full-chip thermal analysis of semiconductor chip designs is provided. One embodiment of a novel method for performing thermal analysis of a semiconductor chip design comprises receiving at least one input relating to a semiconductor chip design to be analyzed. The input is then processed to produce a three-dimensional thermal model of the semiconductor chip design. In another embodiment, thermal analysis of the semiconductor chip design is performed by calculating power dissipated by transistors and interconnects included in the semiconductor chip design and distributing power dissipated by the interconnects.

Owner:KEYSIGHT TECH

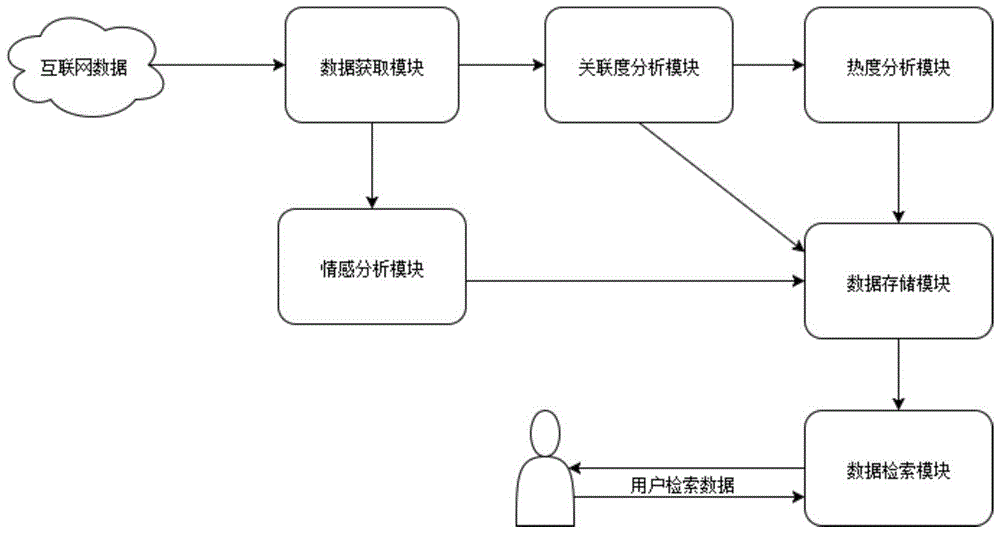

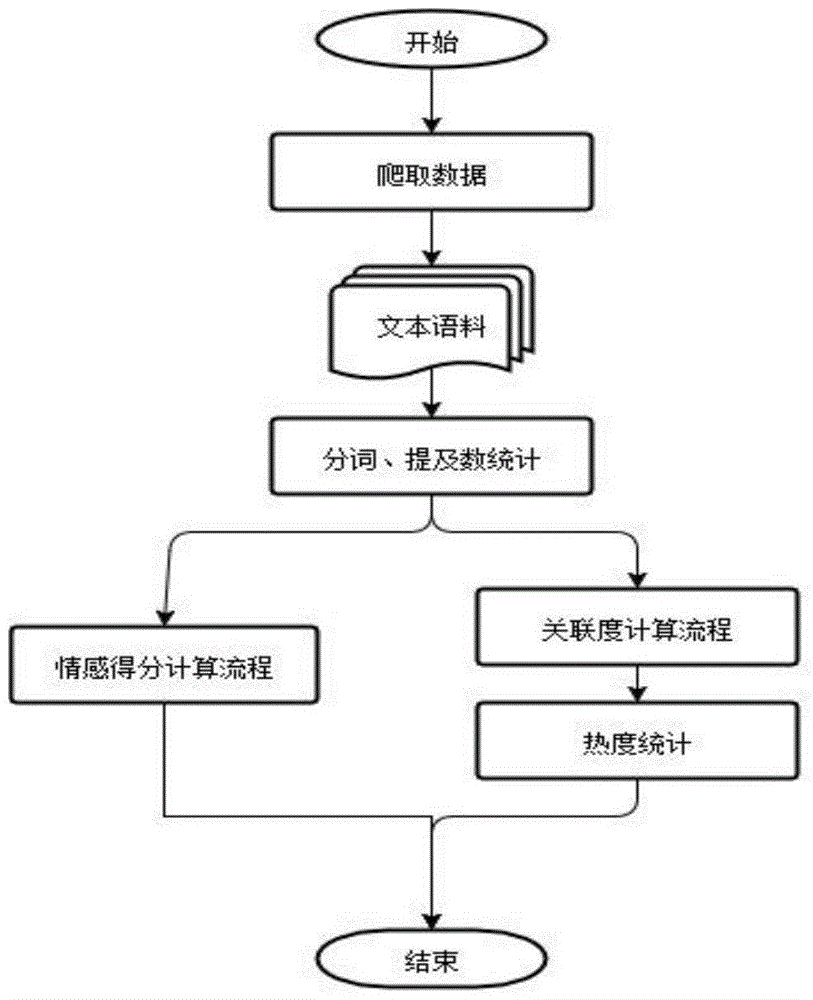

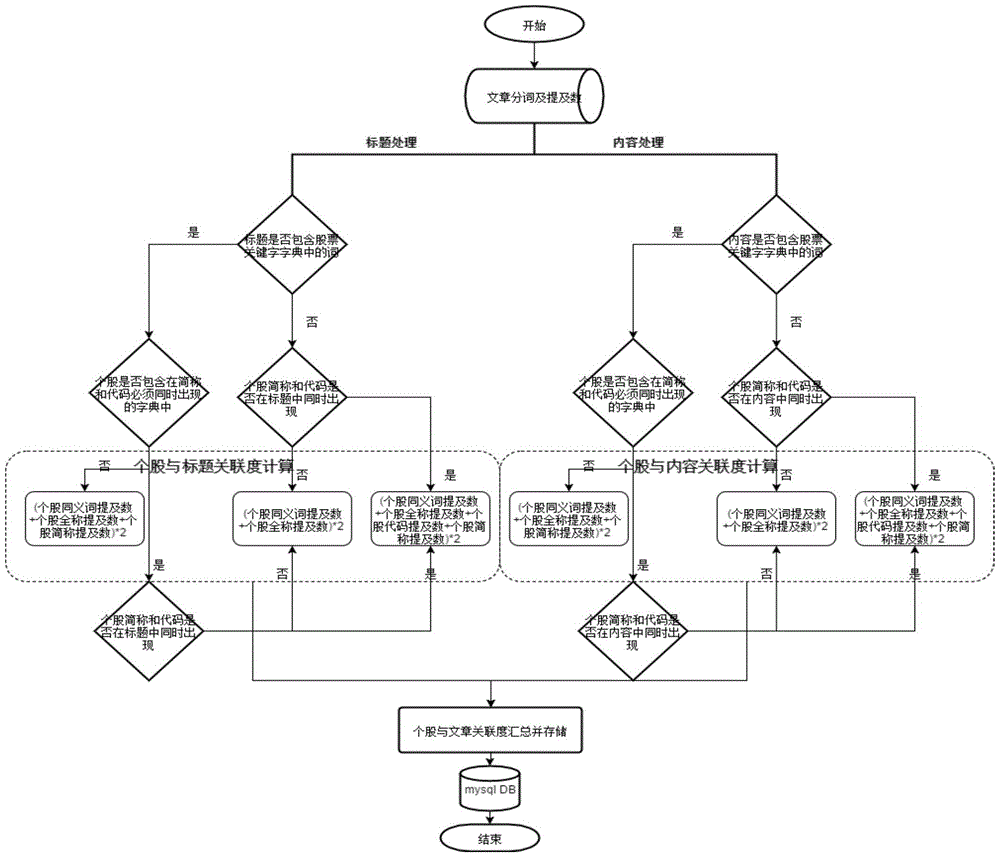

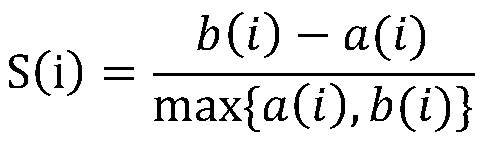

Calculation method and system for relevance degree of individual share and article

InactiveCN105740353AEfficient searchFast and efficient search engine retrievalNatural language data processingSpecial data processing applicationsData retrievalHeat analysis

The present invention discloses a calculation method and system for relevance degree of an individual share and an article. The system comprises a data acquisition module, a relevance degree analysis module, an emotion analysis module, a heat analysis module, a data storage module and a data retrieval module. The method comprises: acquiring massive financial news corpus every day; performing text data mining; analyzing a relevance between an individual share and an article among the corpus that is acquired in real time; analyzing individual share emotion in the corpus that is acquired in real time; summarizing the relevance between the individual share and the article, i.e. heat of the individual share daily; enabling an investor to retrieve market condition news of a share that draws the attention of the investor, and providing the relevance degree with the article, and historical heat indicators of the emotion and share for reference, so that the method and system become an excellent retrieval tool of the investor for individual share market condition news.

Owner:NAT UNIV OF DEFENSE TECH

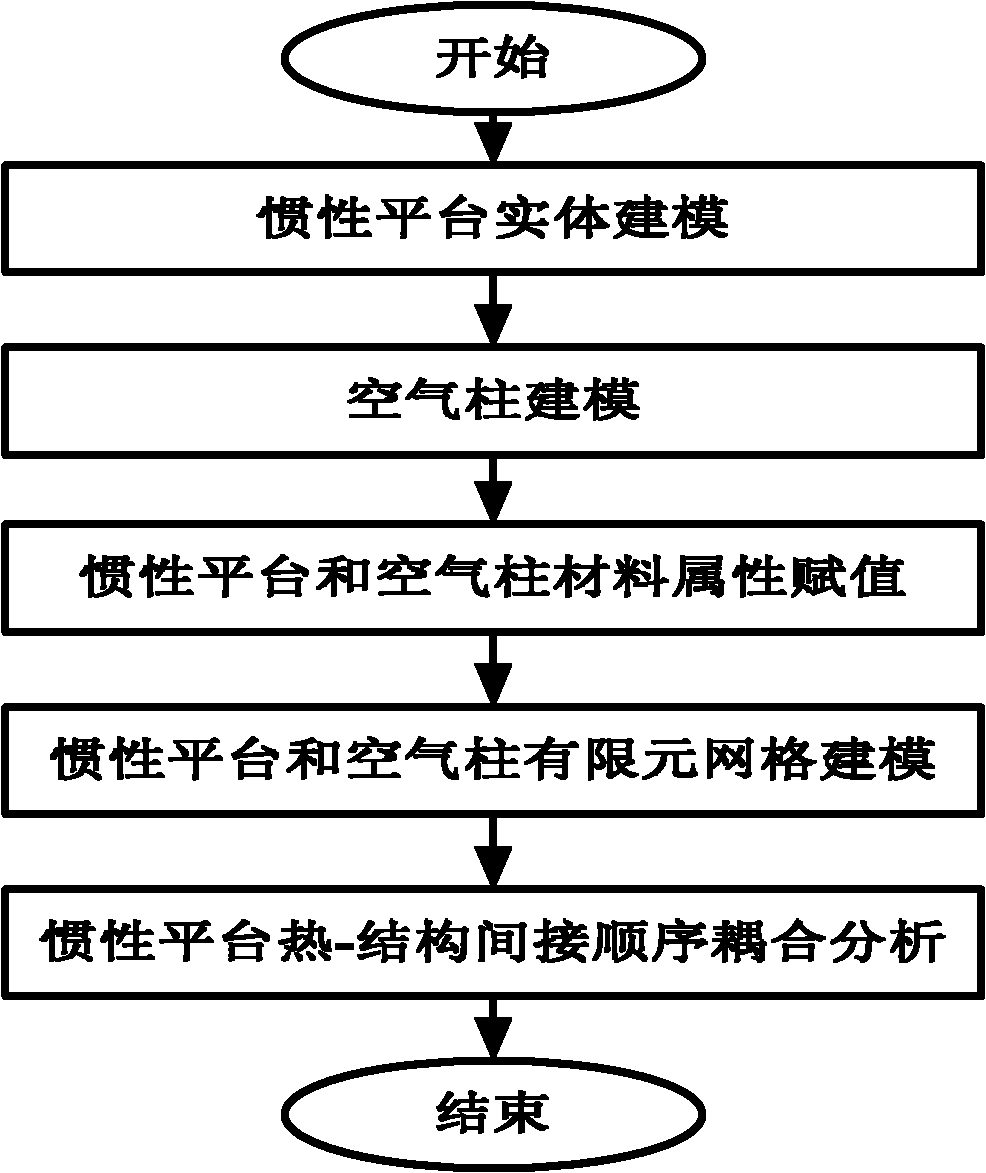

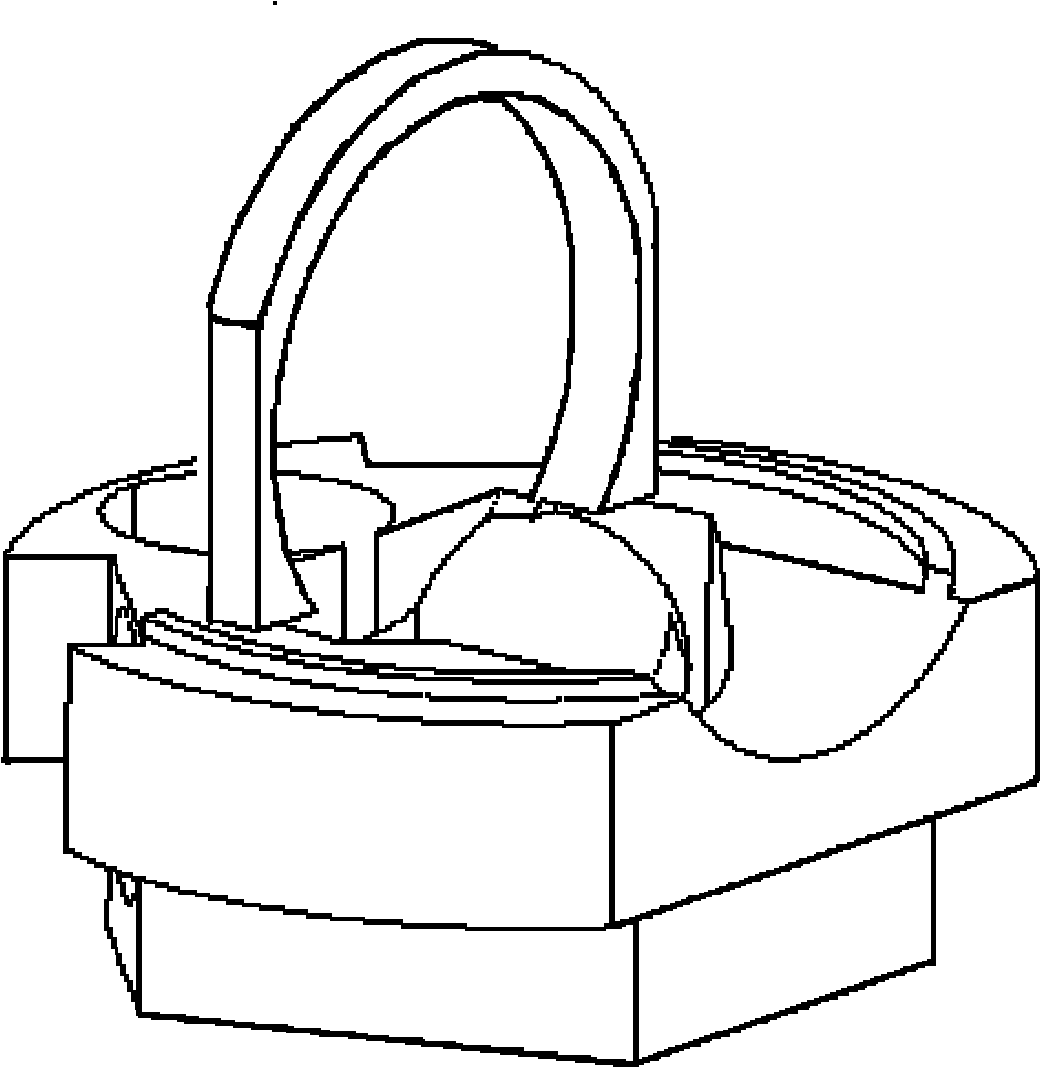

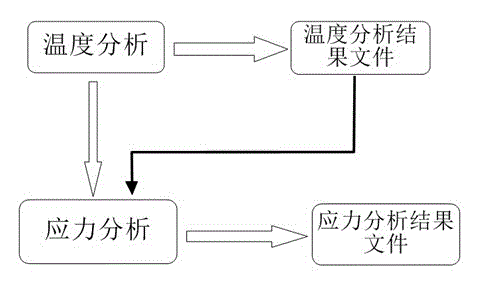

Inertial platform residual stress release simulating method based on finite element

InactiveCN102063539ADrawn preciselyApply to achieveSpecial data processing applicationsHeat analysisStructural analysis

The invention discloses an inertial platform residual stress release simulating method based on a finite element, which comprises the steps of: 1, modeling an initial platform entity, integrally obtaining an initial platform entity model by applying entity drawing software, then guiding the initial platform entity model into finite element simulating software; 2, modeling an air column, establishing initial platform peripheral air into an air column model; 3, assigning initial platform and air column material attributes, inputting the initial platform and air column material attributes according to the requirement on the finite element simulating software; 4, modeling an initial platform and an air column finite element grid, wherein two procedures of selecting a unit type and dividing the grid are included; and 5, coupling and analyzing an initial platform heat-structure, wherein two procedures of transient heat analysis and structure analysis are included: the transient heat analysis is as follows: a temperature cycle stress is loaded on the outer surface of the air column so as to provide heat conditions for the inertial platform residual stress release simulating analysis, andthe structure analysis is as follows: an initial platform transient heat analysis result is loaded to the heat-structure coupling analysis to obtain a rule of releasing the inertial platform residualstress with the temperature cycle stress.

Owner:BEIHANG UNIV

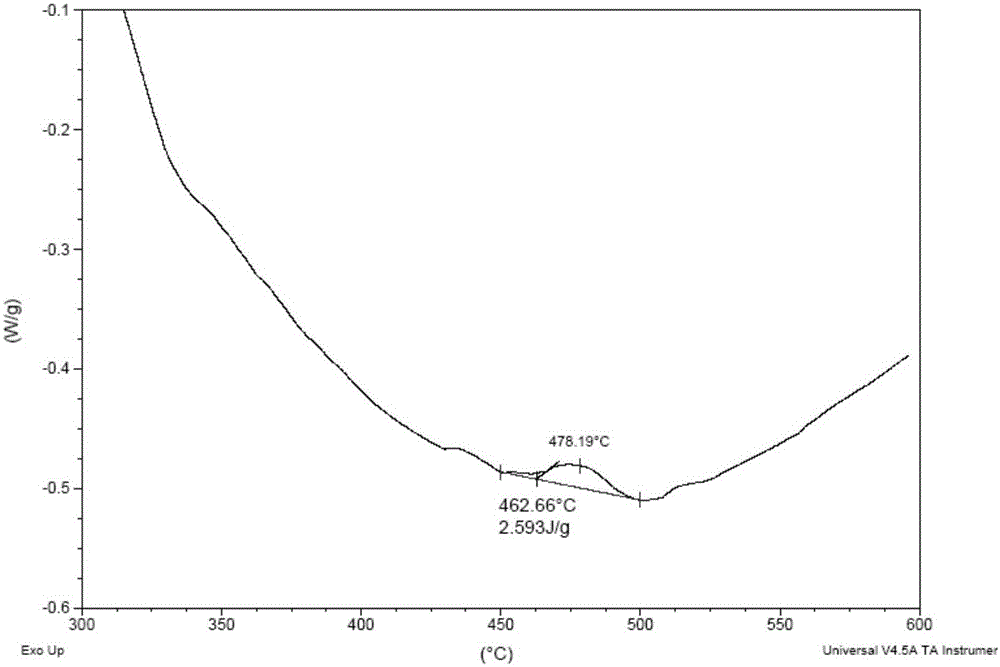

Thermal analysis determination method for plant biomass lignin content

InactiveCN105203579AReduce usageReduce pollutionPreparing sample for investigationMaterial thermal analysisOrganic matterThermal index

The invention discloses a thermal analysis determination method for the plant biomass lignin content. The method comprises the following steps that 1, plant biomass samples are prepared; 2, the characterization parameter standard of slow pyrolysis of standard organic matter on the anaerobic condition is determined; 3, the characterization parameter standard of slow pyrolysis of natural plant biomass on the anaerobic condition is determined; 4, a DSC scanning experiment of the plant biomass samples is performed to obtain DSC thermograms of the characterization parameter standard of slow pyrolysis of the natural plant biomass on the anaerobic condition; 5, the DSC thermograms are interpreted to obtain thermal indexes; 6, the lignin content is calculated. According to the thermal analysis determination method for the plant biomass lignin content, a large number of the experimental steps are omitted, the experimental time is effectively shortened, the usage of acidized agentia is avoided, and environmental pollution is reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

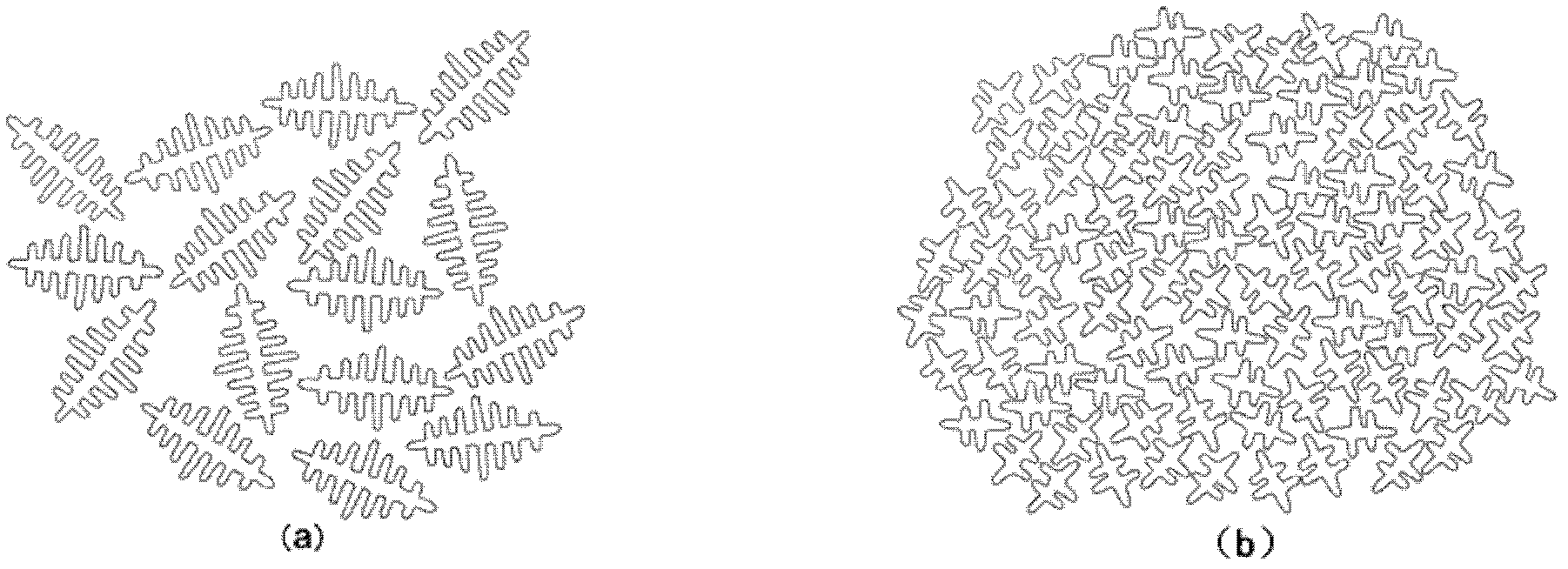

Bionic principle-based structure cooling channel layout optimization design method

ActiveCN106971022AReasonable designReasonable layoutGeometric CADDigital data processing detailsDesign by analogyHeat analysis

Owner:UNIV OF SHANGHAI FOR SCI & TECH

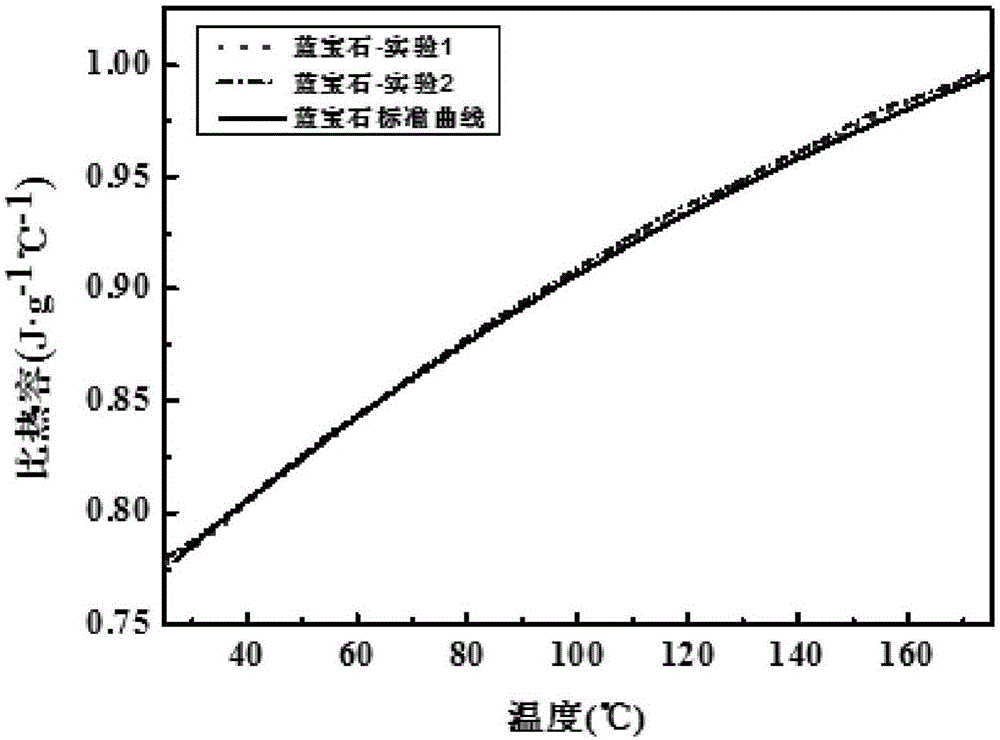

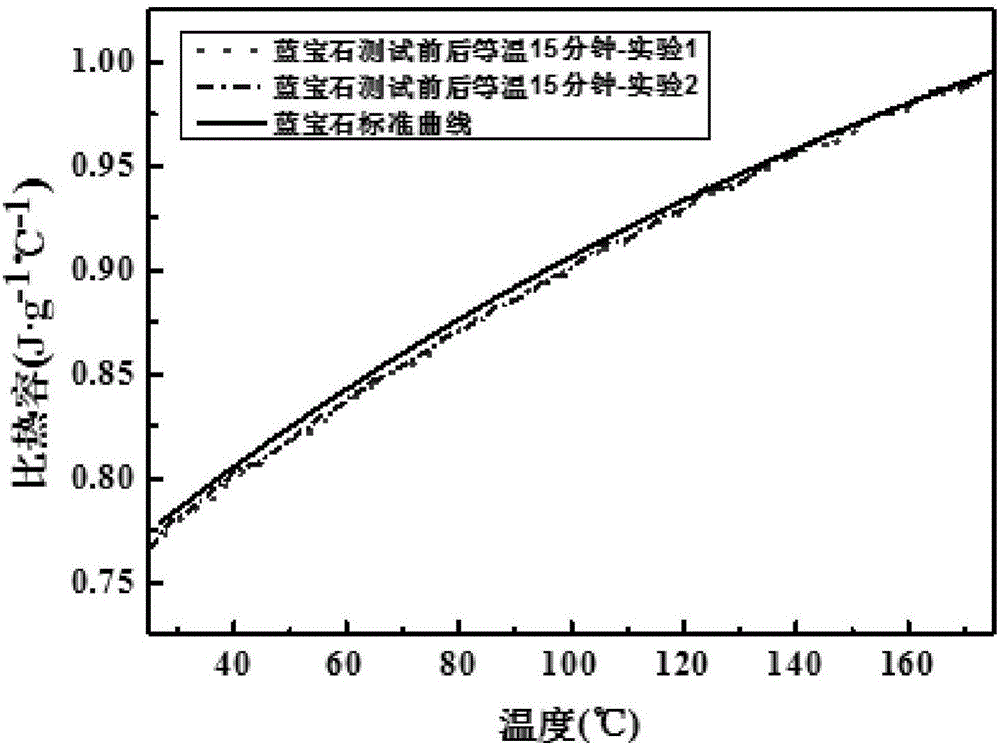

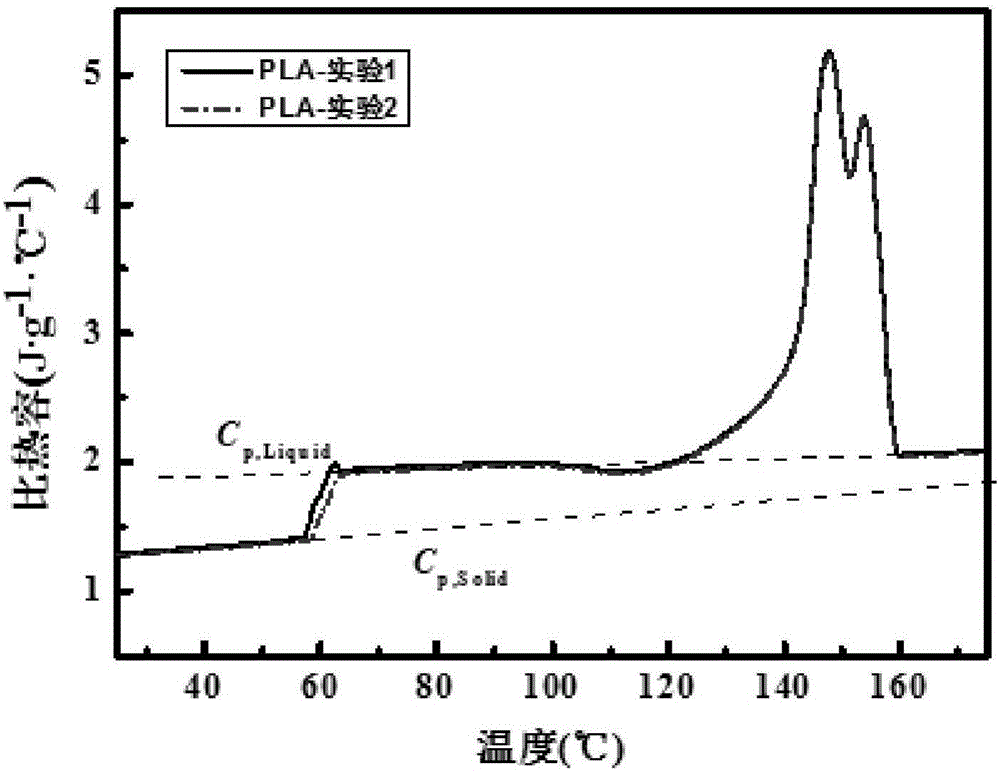

Thermal analysis method for determining content of each phase state ingredient of half crystallization high molecular material

InactiveCN106770427AAccurate and reversible specific heat capacityAccurate Glass Transition TemperatureSpecific heat investigationInvestigating phase/state changeChemistryPhase state

The invention provides a thermal analysis method for determining the content of each phase state ingredient of a half crystallization high molecular material. According to the method, conventional and step type temperature rise modes are respectively used for heating a sample; a StepScan DSC curve is resolved into a reversible specific heat capacity curve and an irreversible specific heat capacity curve; the glass transition position is determined through the discontinuous mutation of the specific heat capacity on the reversible specific heat capacity curve; then, the content of different phase state ingredients of half crystallization molecules is determined according to the specific heat capacity increase and the melting enthalpy on the DSC curve. Through an SSDSC technology, the glass transition is separated out from a dynamic process to obtain the parameters such as the reversible specific heat capacity, the glass transition temperature and the melting enthalpy in the test sample temperature rise process; the glass transition temperature of the half crystallization high molecular material can be obtained; the reversible specific heat capacity corresponding to different temperatures can be accurately obtained; meanwhile, the content of different phase states such as the crystallization state, the flowing amorphous state and the hard amorphous state in the half crystallization high molecular test sample can be calculated according to the specific heat capacity and the melting enthalpy.

Owner:NANJING NORMAL UNIVERSITY

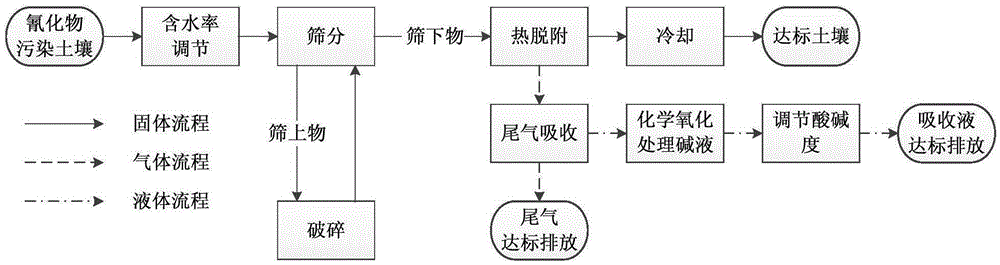

Method for repairing cyanide-polluted soil by physical heat analysis technology

InactiveCN105414162AAvoiding Dehydration ConundrumsEnsure safetyContaminated soil reclamationHigh concentrationSoil science

The invention discloses a method for repairing cyanide-polluted soil by a physical heat analysis technology. The method comprises such steps as control of a water content theta m of the cyanide-polluted soil below 20%, smashing of the soil to reach an aggregate diameter below 2 cm, feeding of the soil into a physical heat analysis kiln for repairing and tail gas treatment. The method is adopted to repair the cyanide-polluted soil, so that the high-concentration cyanide-polluted soil can be treated, the problem that the soil physicochemical properties are largely changed by a chemical oxidation method is solved, the soil dehydration difficulty in actual engineering operation is prevented, and the repair rate can reach above 99%.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

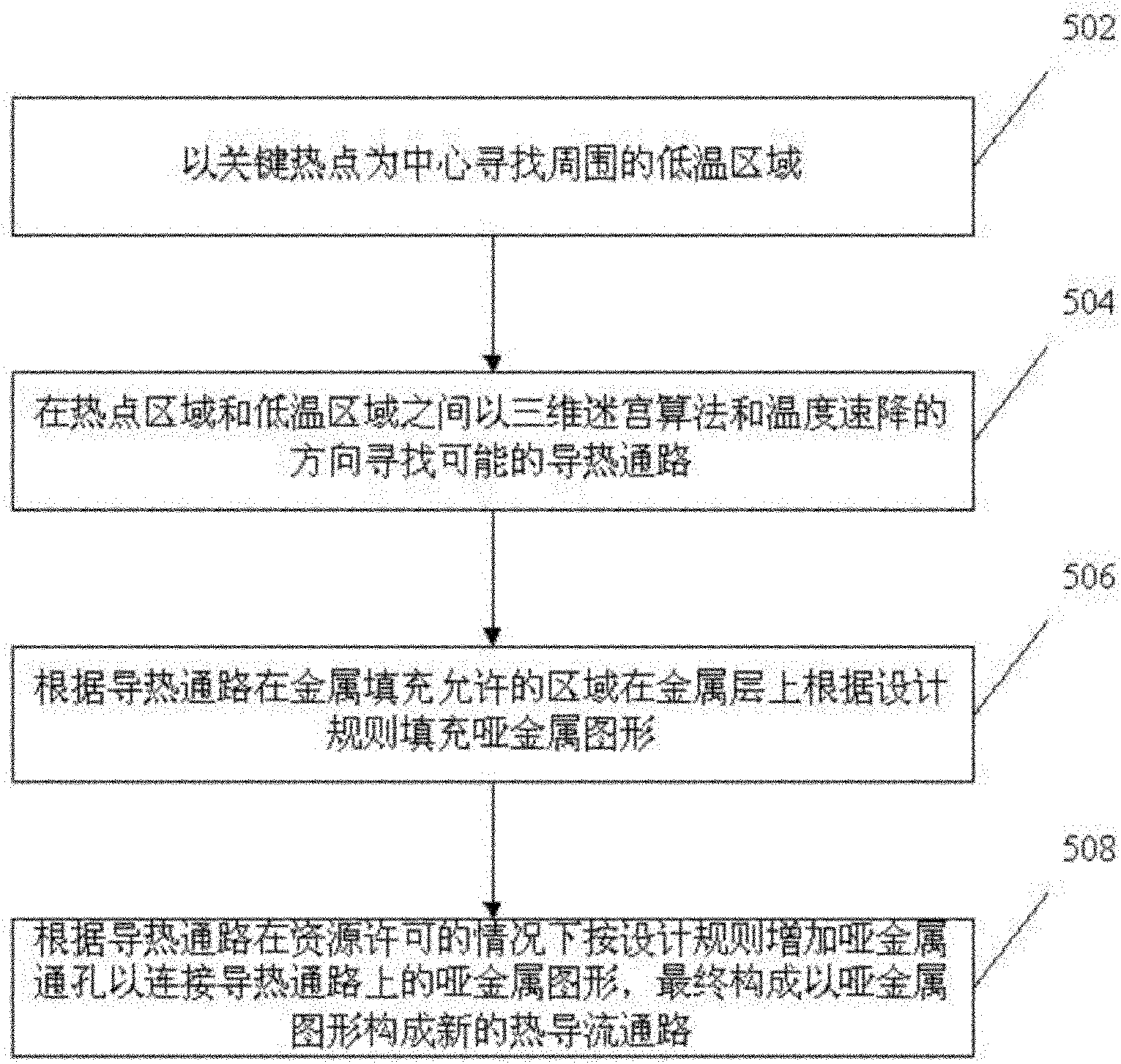

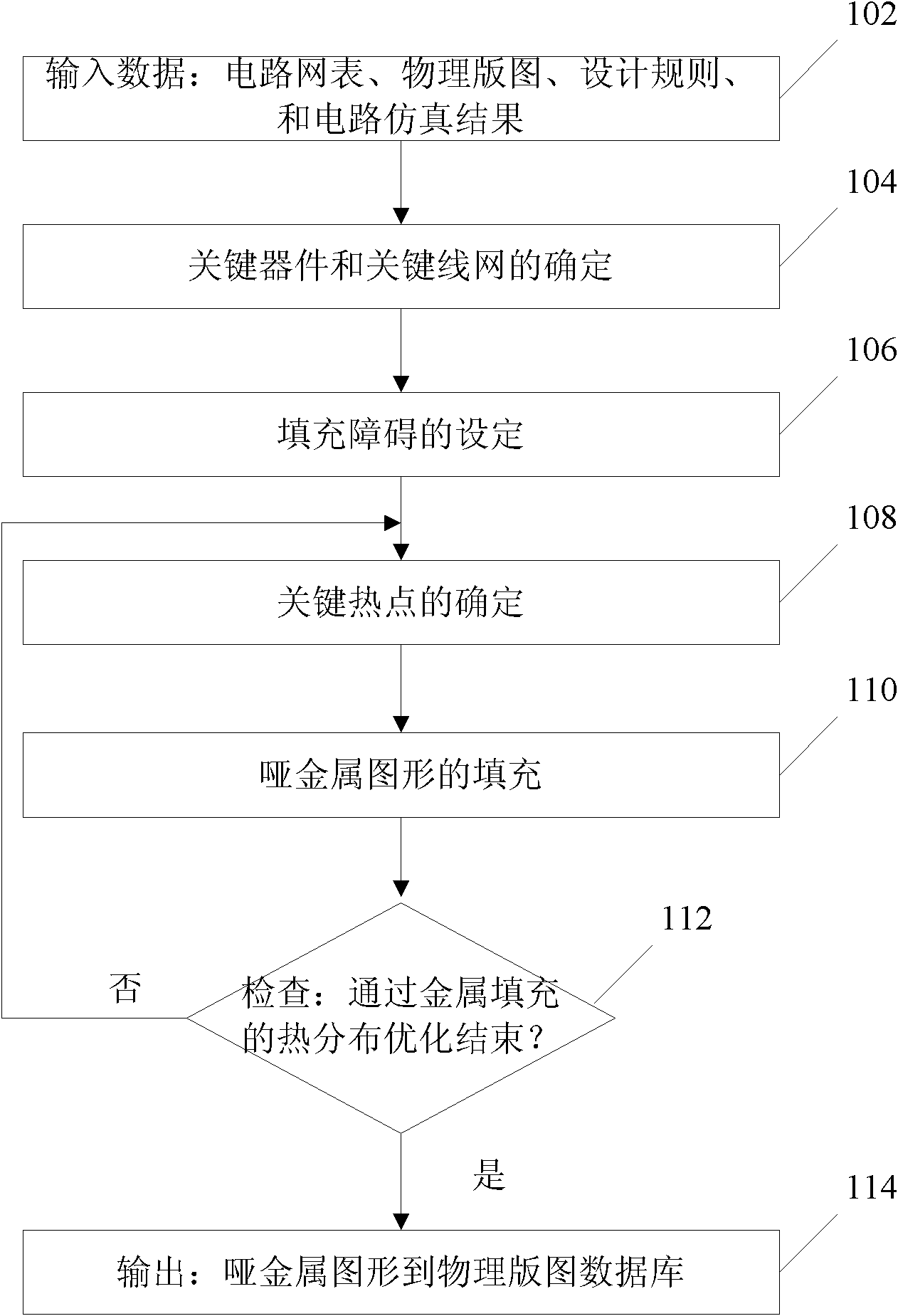

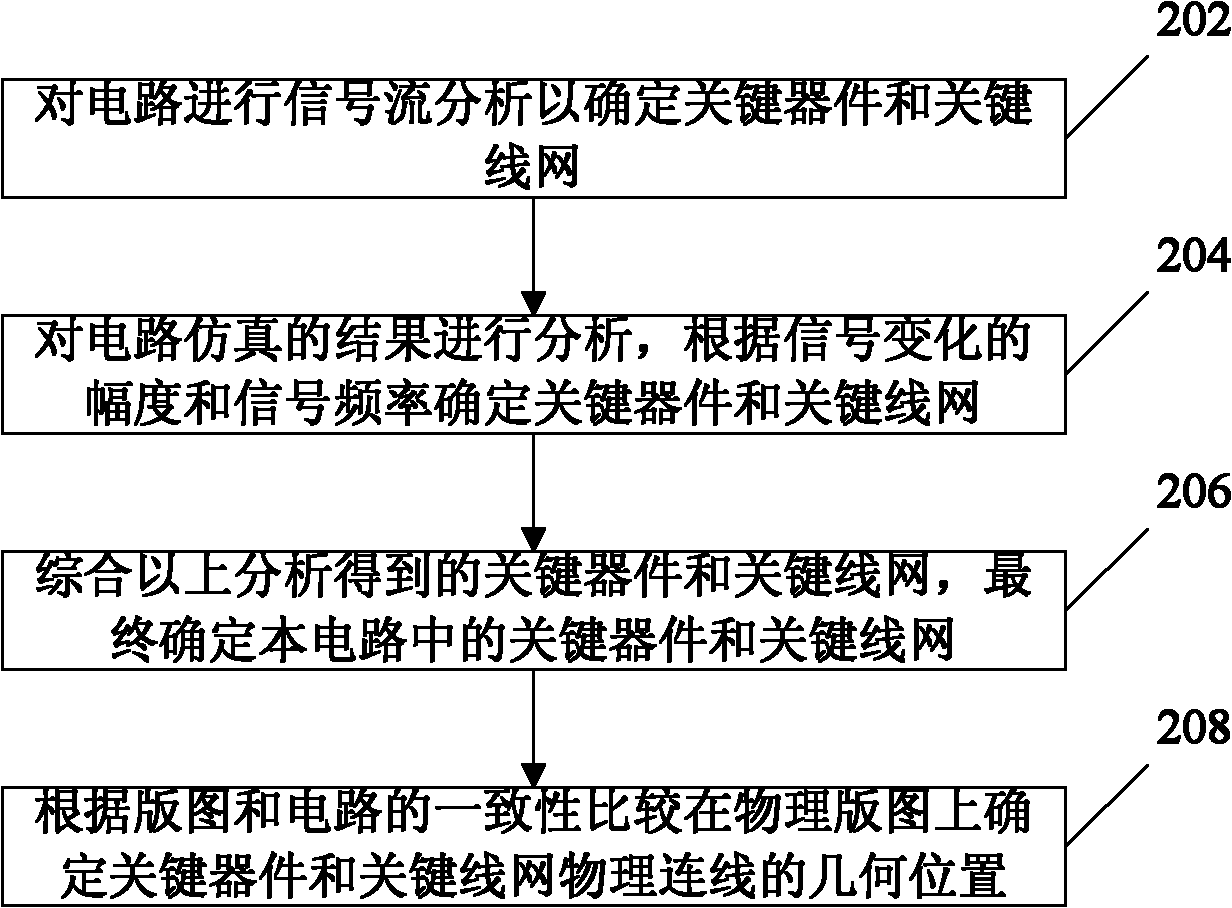

Method for optimizing integrated circuit layout heat distribution

ActiveCN102314526AWork lessImprove reliabilitySpecial data processing applicationsGraphicsHeat analysis

The invention relates to a method for optimizing integrated circuit layout heat distribution, which belongs to the field of integrated circuit design automation. The method comprises the following steps of: inputting a circuit netlist, a circuit simulation result, a physical layout of a circuit and a physical design rule of the circuit; performing circuit analysis to determine a key apparatus anda key net in the circuit; setting a filling barrier on the physical layout of the circuit according to the physical design rule of the circuit; performing heat analysis to determine a key heat point on the physical layout of the circuit; adding a heat-conduction passage for the key heat point, filling dumb metal patterns on a metal layer according to the heat-conduction passage and the physical design rule of the circuit, and additionally forming dumb metal through holes according to the heat-conduction passage and the physical design rule so as to connect the dumb metal patterns on the heat-conduction passage until the physical layout heat distribution of the circuit cannot be optimized through new dumb metal filling; and outputting the filled metal patterns to a physical layout database. The heat distribution of the integrated circuit physical layout can be effectively optimized through dumb metal filling.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

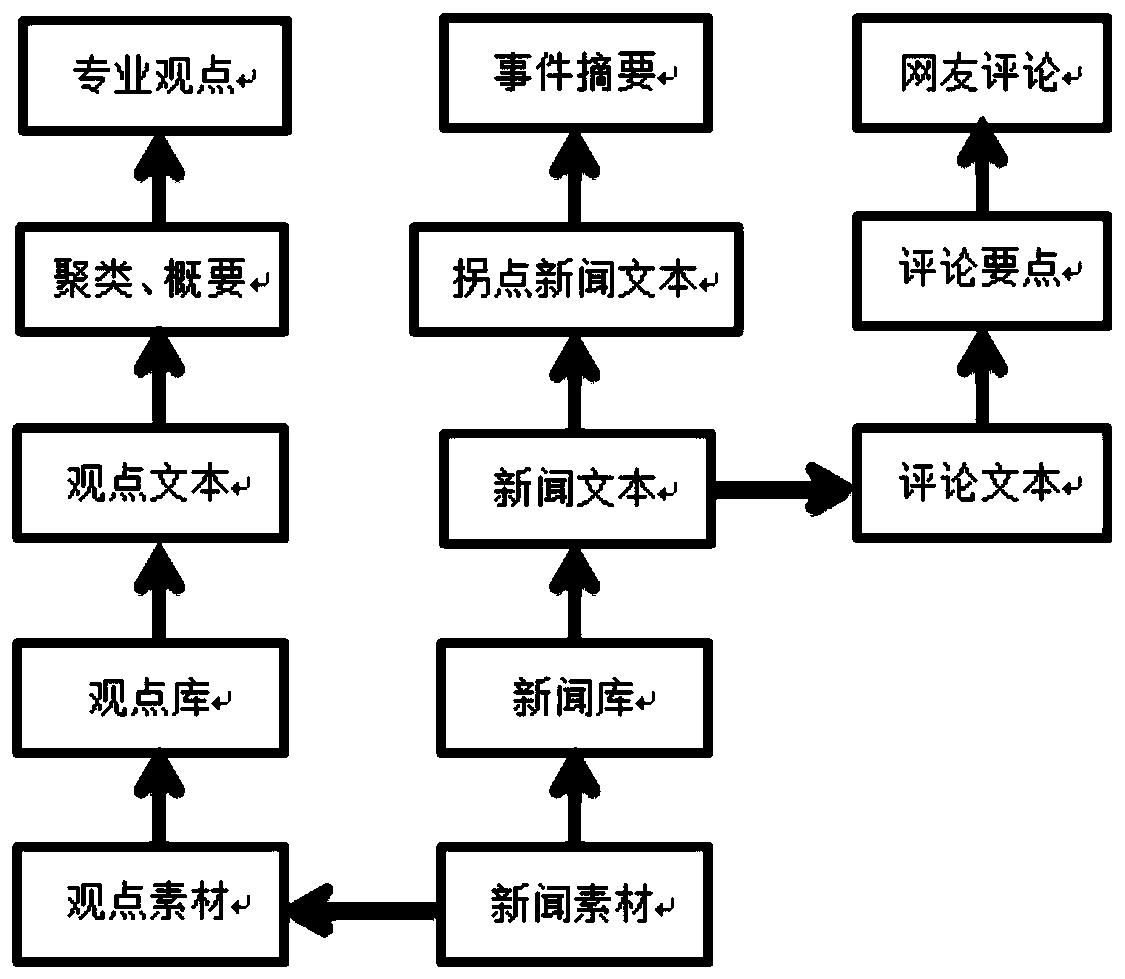

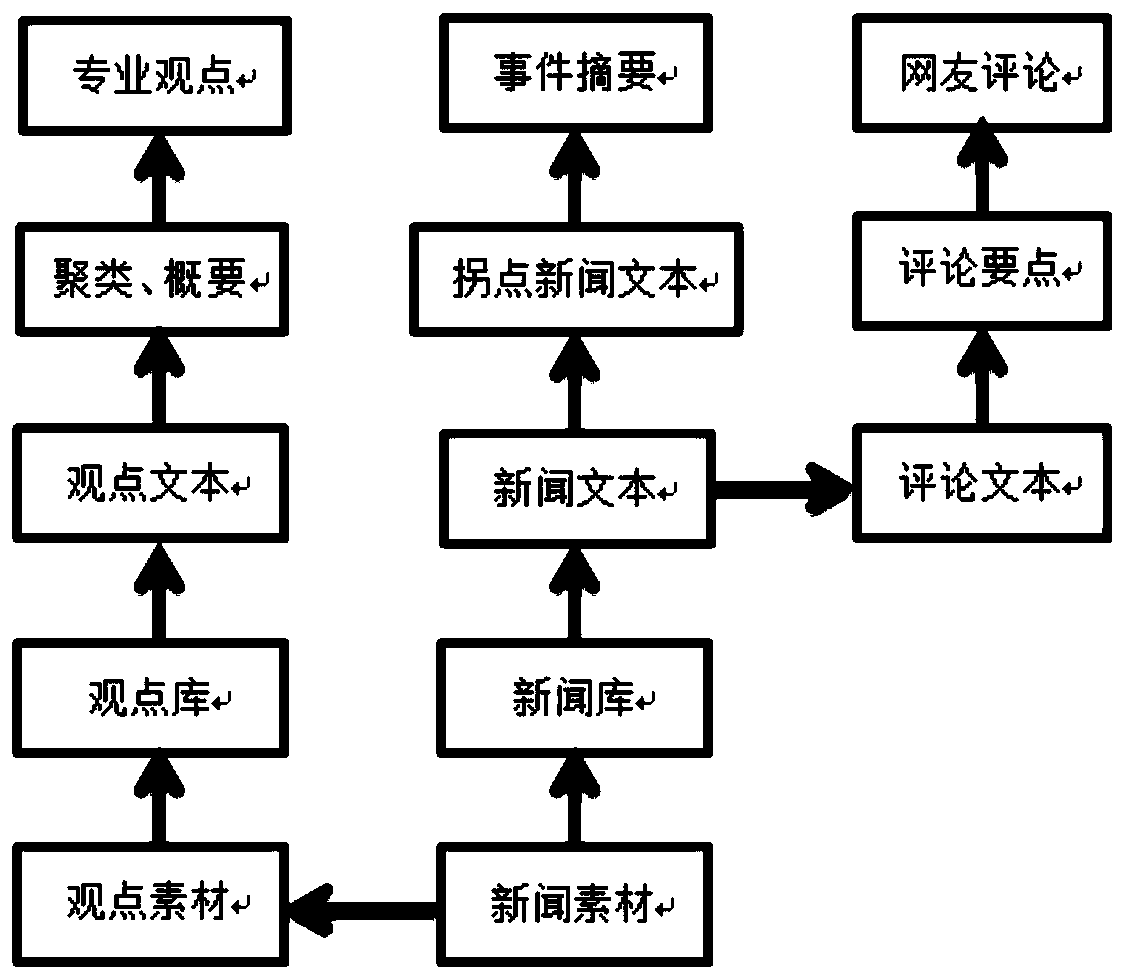

News event information induction method

ActiveCN109960756AAccurately reflect the development trendReflect the development trendNatural language data processingSpecial data processing applicationsTemporal changeHeat analysis

The invention discloses a news event information induction method, which comprises the following steps: collecting news materials, and creating a news library; obtaining all news texts of the target event from a news library, carrying out heat analysis, obtaining an inflection point news text, extracting event information in the inflection point news text, and storing the event information; the method for obtaining the news text of the inflection point comprises the following steps: obtaining the news text of the inflection point, counting the hot values of all the news texts, sorting according to the time sequence of news text release, constructing a curve graph of the hot values changing along with time, taking the news texts corresponding to all the maximum points of the curve graph, namely the inflection point news text, and enabling the hot values to be the sum of the page view of the news and the independent visitor volume of the website. According to the method disclosed by theinvention, the development situation of the news event is accurately reflected by selecting the news text, namely the inflection point news text, when the target news event is at the key node for abstract analysis and processing.

Owner:NAT COMP NETWORK & INFORMATION SECURITY MANAGEMENT CENT +1

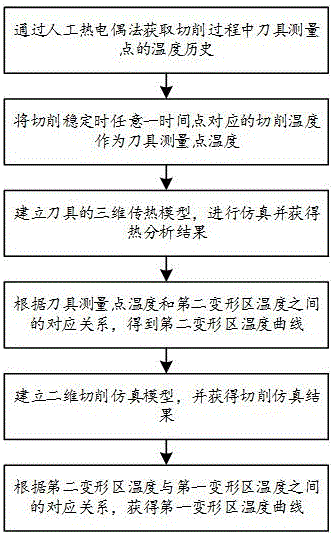

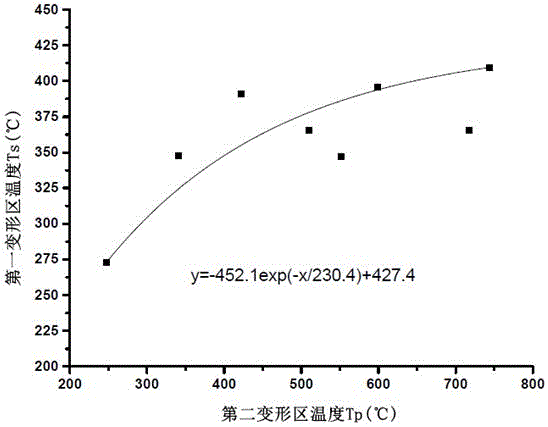

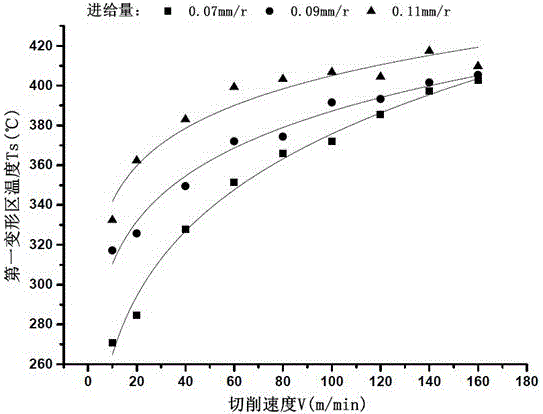

Method for acquiring temperature of first deformation area and second deformation area in high-speed cutting

ActiveCN105930558ASolve the problem of difficult temperature acquisitionIncrease the amount of informationComputer aided designSpecial data processing applicationsStable stateTemperature curve

The invention relates to the technical field of high-speed cutting, and discloses a method for acquiring the temperature of a first deformation area and a second deformation area in high-speed cutting. The method includes: firstly, acquiring a temperature history of a tool measurement point during cutting through a manual thermocouple method; using the cutting temperature corresponding to any time point as the temperature of the tool measurement point and obtaining a temperature curve of the measurement point in a corresponding time duration in the condition of a stable cutting temperature according the temperature history; establishing a three-dimensional heat transfer model of a tool, and performing simulation and obtaining a heat analysis result; obtaining the temperature of the tool measurement point and the temperature of the second deformation area through analysis, acquiring a corresponding relationship between the temperature of the tool measurement point and the temperature of the second deformation area, and acquiring a temperature curve of the second deformation area according to the temperature curve of the measurement point; establishing a two-dimensional cutting simulation model, and acquiring a cutting simulation result; and acquiring a corresponding relationship between the temperature of the first deformation area and the temperature of the second deformation area in the condition of the stable cutting temperature through analysis, and then acquiring a temperature curve of the first deformation area. The method is simple, reliable, and is wide in application.

Owner:BEIJING FORESTRY UNIVERSITY

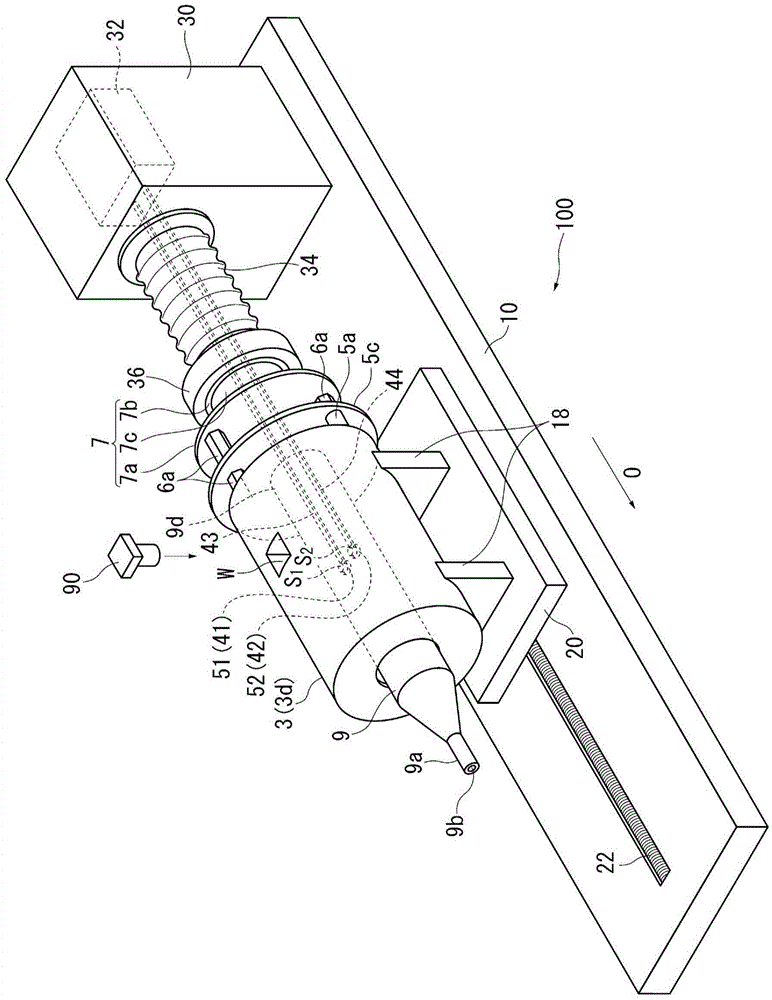

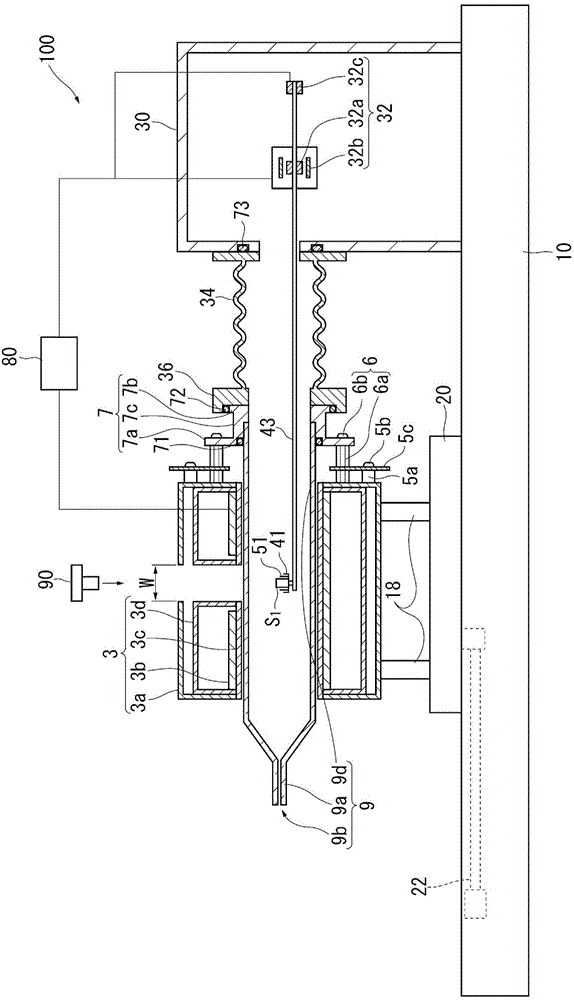

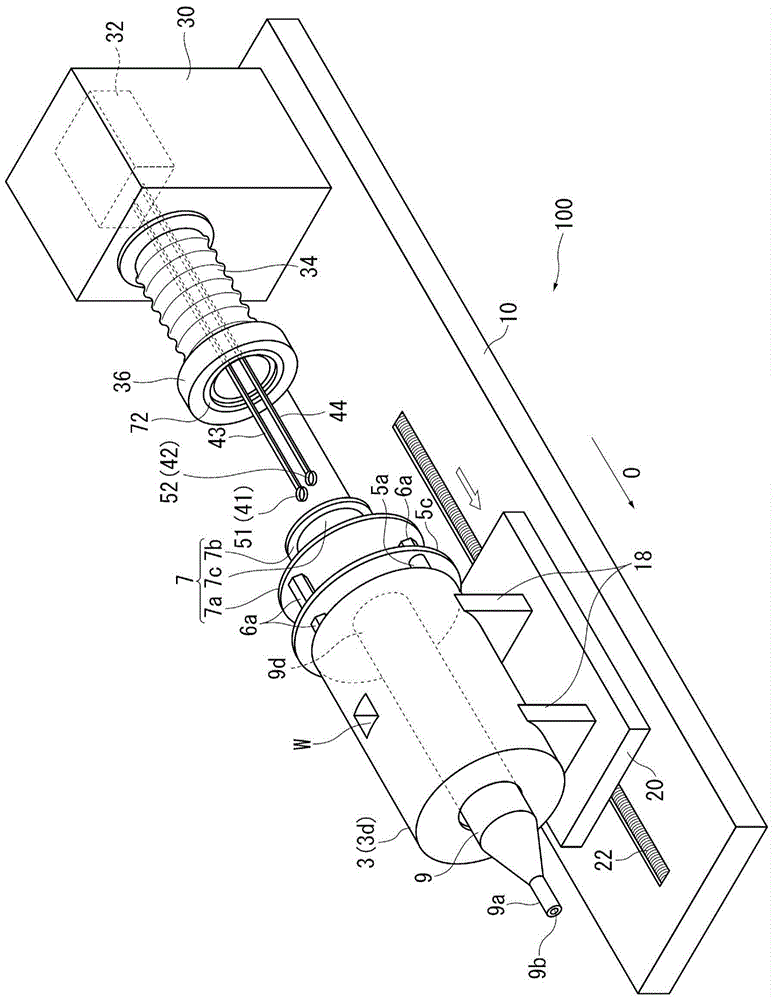

Thermal Analyzer

A thermal analyzer is provided with: a furnace tube; a sample holder; a heating furnace; a measurement chamber; and a measurement unit. The heating furnace comprises a fixing section to be fixed to the furnace tube. The furnace tube is configured to be attachable to and detachable from the heating furnace and provided with an engagement portion that is configured to be engaged with the fixing section at a variable position in the radial direction. A is configured to be detachable from the heating furnace and the furnace tube after inserting the furnace tube into the heating furnace and engaging the engagement portion of the furnace tube with the fixing section while the gap jig is interposed between the heating furnace and the furnace tube to maintain the gap between the heating furnace and the furnace tube in the radial direction to be in the predetermined distance.

Owner:HITACHI HIGH TECH SCI CORP

Pipeline steel welding residual stress prediction method based on ANSYS

InactiveCN103605861ASave human effortSave moneySpecial data processing applicationsStructure analysisWelding residual stress

The invention discloses a pipeline steel welding residual stress prediction method based on ANSYS. The method is characterized by sequentially comprising the following steps that (1) welding piece welding conditions are determined; (2) a solid model of a welding piece is established, an SOLID70 unit dividing scanning net is defined, solving constraint and loading on a welding temperature field are exerted according to practical working conditions; (3) a heat analysis unit SOLID70 is converted into a structure analysis unit SOLID45, the elasticity modulus, the linear expansion coefficient, the Poisson ratio, the yield stress and the elasticity modulus after yield under different temperatures of the welding piece are defined; (4) node temperatures obtained by temperature field analysis are used as loading to be exerted on the structure model, how the constraint conditions are exerted is determined according to model specific situations, and then residual stress distribution is solved. The method is high in analysis efficiency and high in accuracy.

Owner:HOHAI UNIV CHANGZHOU

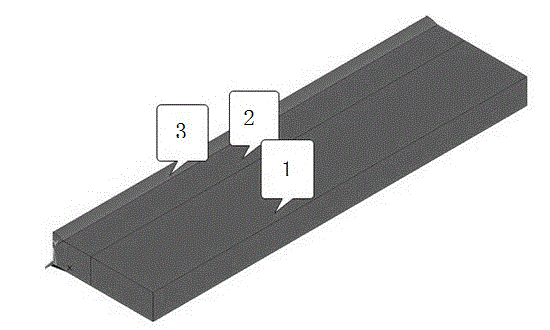

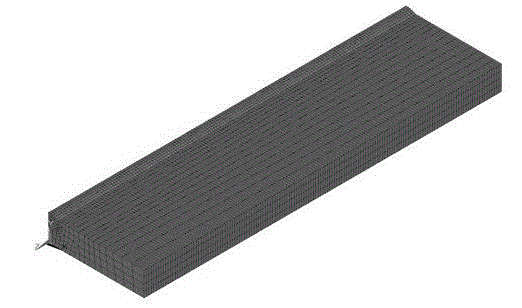

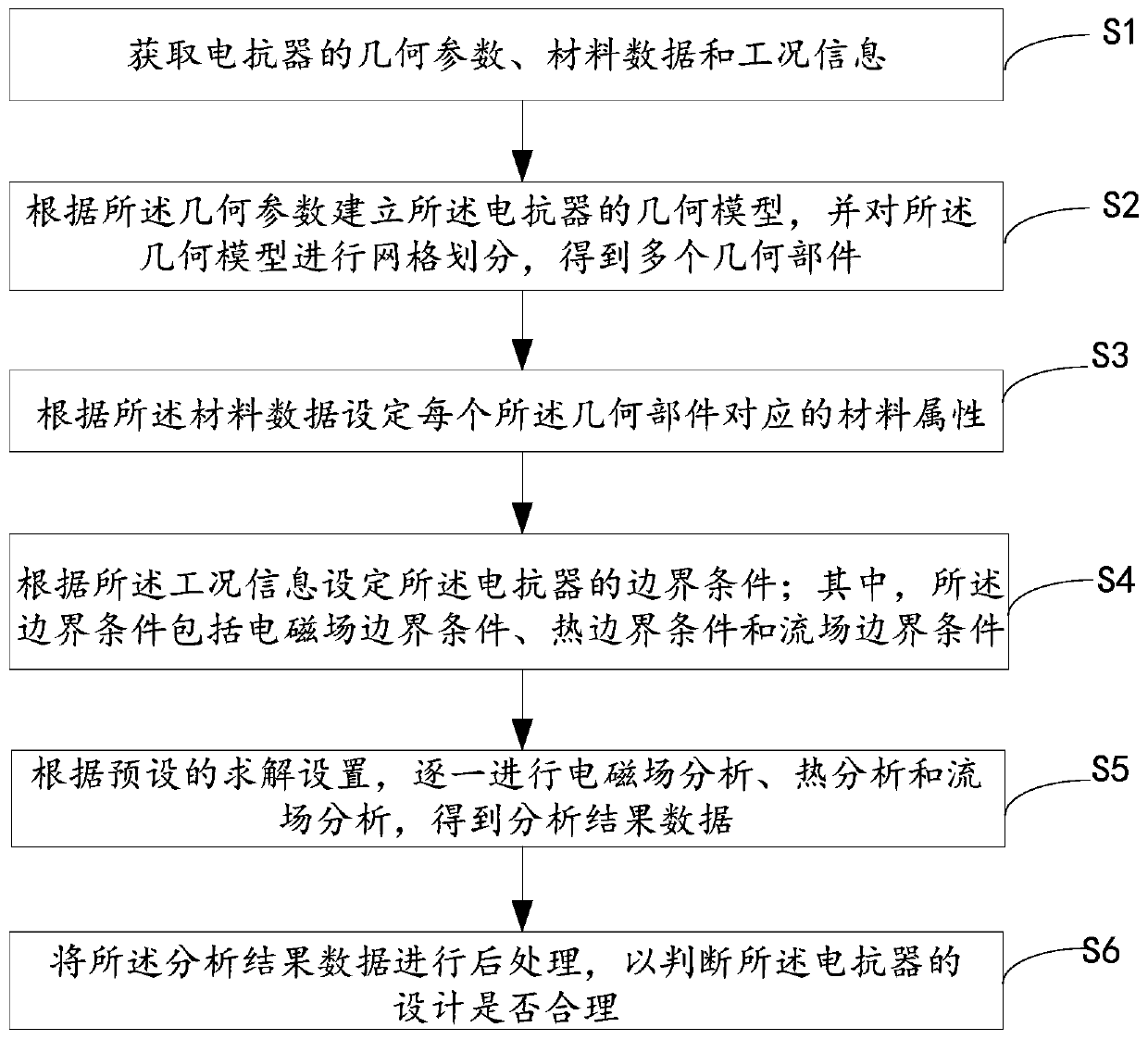

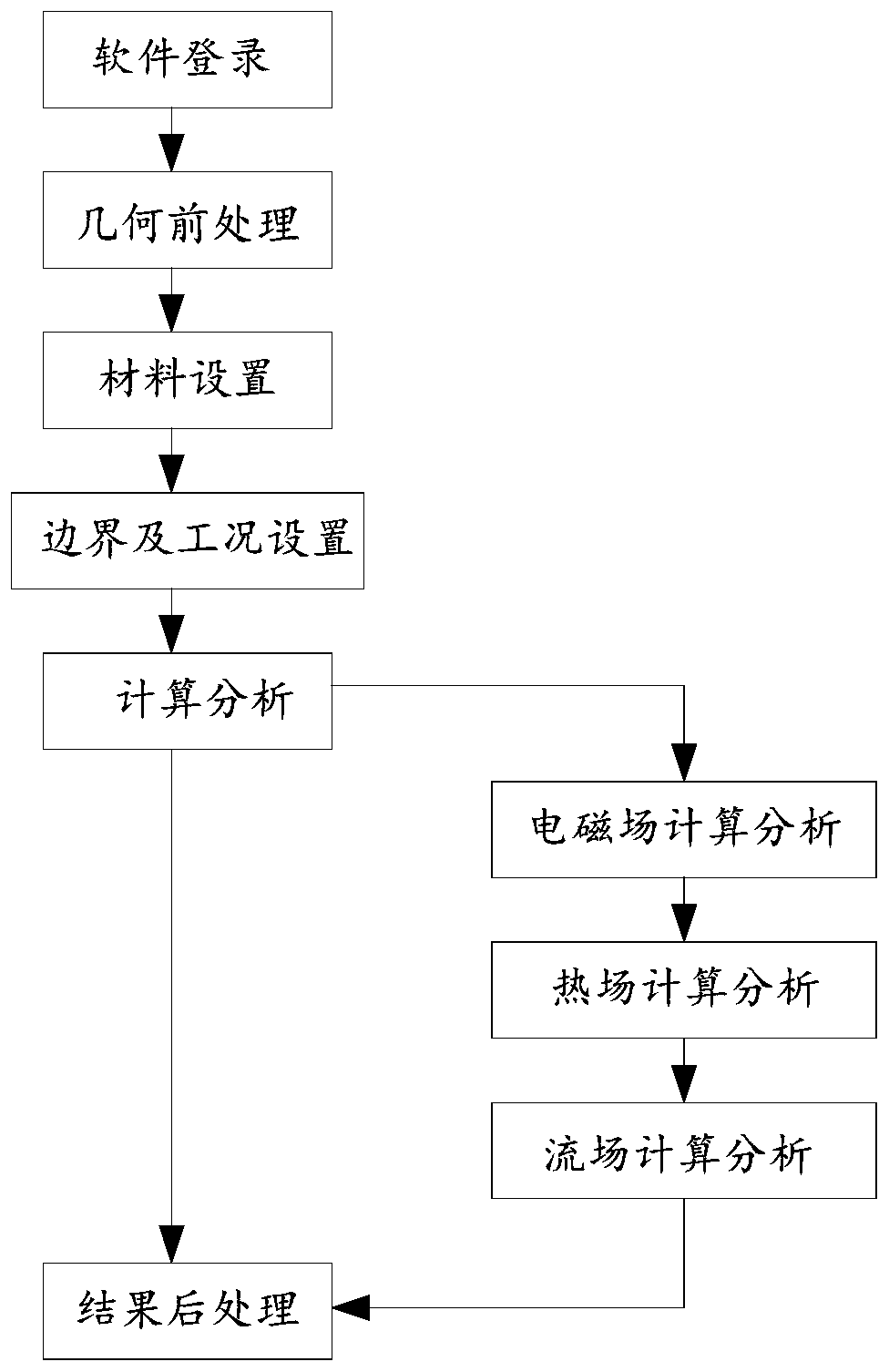

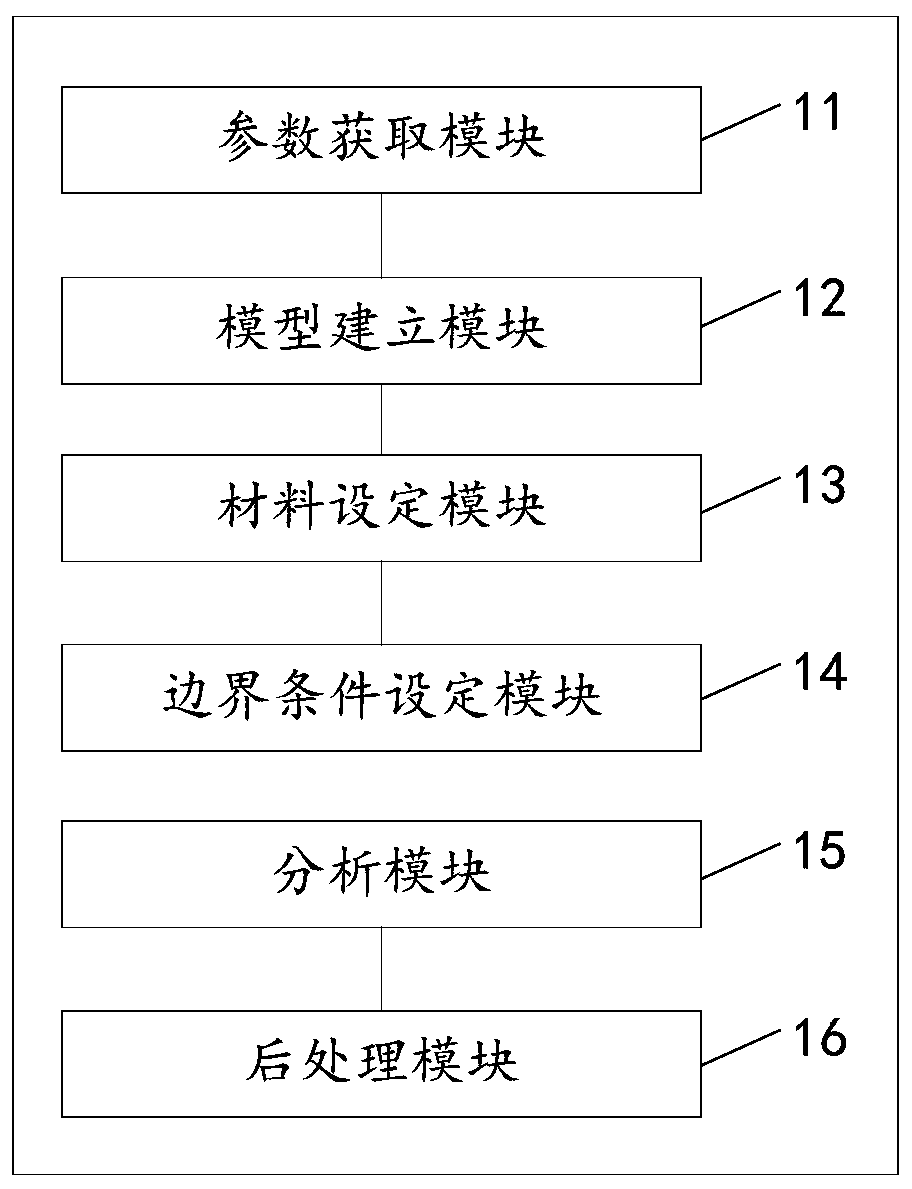

Simulation method and device for multi-physical-field coupling of electric reactor and storage medium

PendingCN110765685ASimple designQuality improvementDesign optimisation/simulation3D modellingHeat analysisField analysis

The invention discloses a simulation method and device for multi-physical-field coupling of an electric reactor and a storage medium. The method comprises the steps of acquiring geometrical parameters, material data and working condition information of an electric reactor; establishing a geometric model of the reactor according to the geometric parameters, and performing mesh generation on the geometric model to obtain a plurality of geometric components; setting a material attribute corresponding to each geometric component according to the material data; setting boundary conditions of the reactor according to the working condition information; wherein the boundary conditions comprise an electromagnetic field boundary condition, a thermal boundary condition and a flow field boundary condition; according to preset solving settings, electromagnetic field analysis, making thermal and flow field analysis one by one to obtain analysis result data; and carrying out post-processing on the analysis result data to judge whether the design of the reactor is reasonable or not. According to the invention, electric-magnetic-thermal-fluid coupling field analysis of the electric reactor can be realized, and the design of the electric reactor is optimized, so that the electric reactor can operate more stably.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com