Thermal Analyzer

一种热分析装置、加热炉的技术,应用在材料热分析、测量装置、分析材料等方向,能够解决无法可视地观察热分析试样变化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

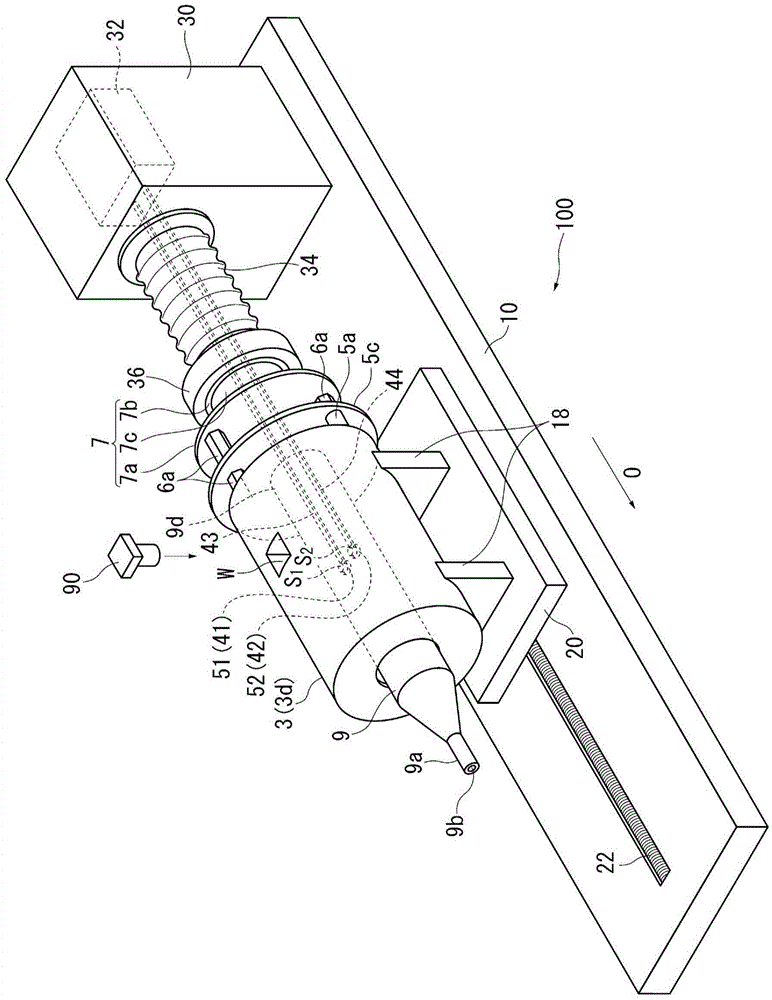

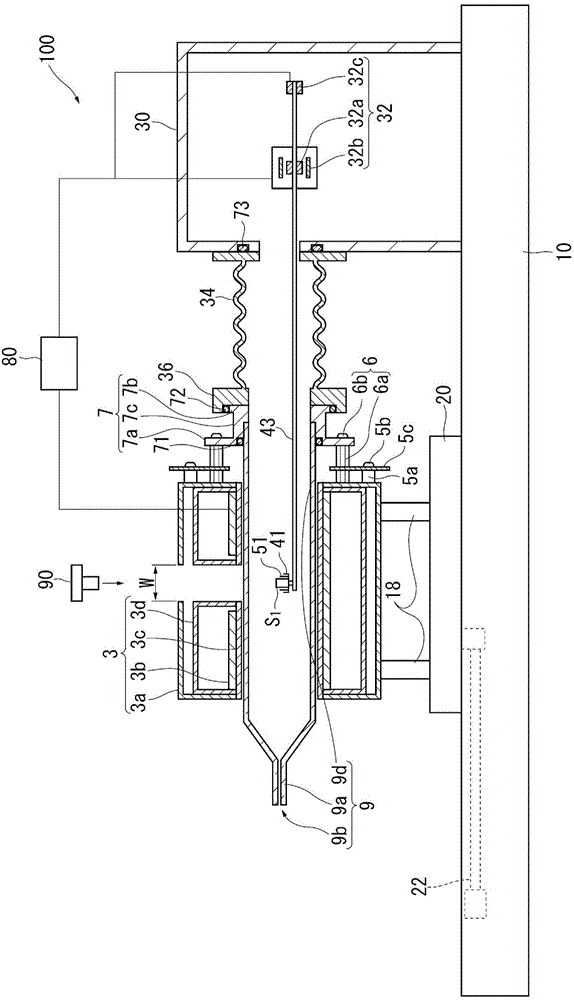

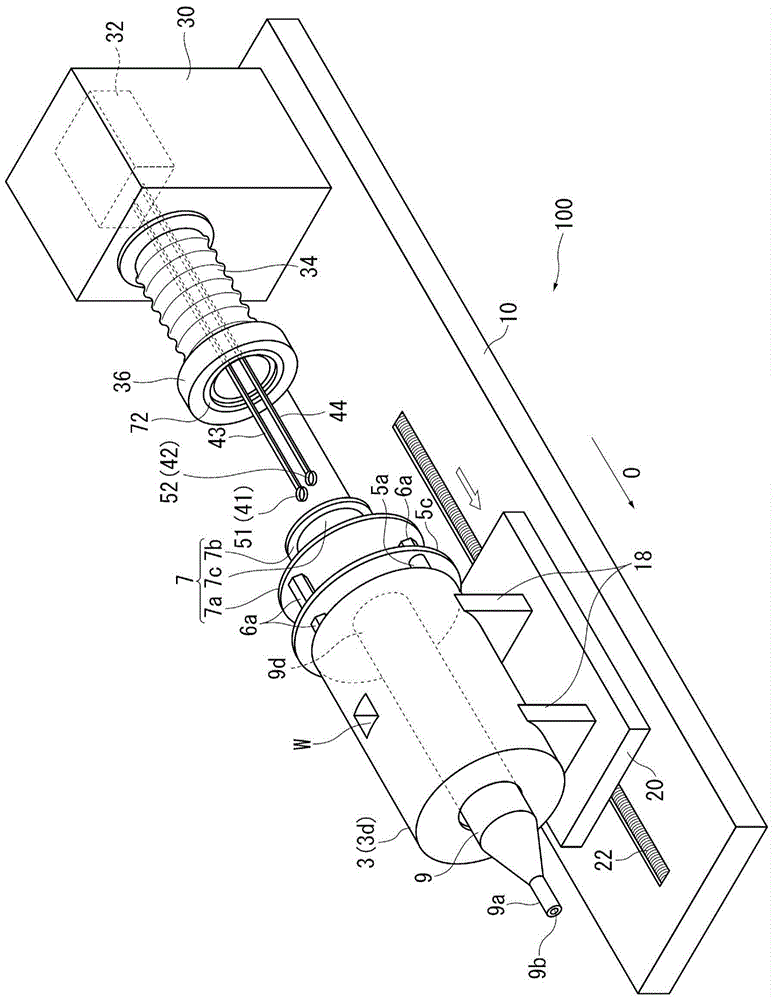

[0066] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, along the axial direction O, the side of the front end portion 9a of the furnace tube 9 is referred to as a "front end (side)", and the opposite side is referred to as a "rear end (side)". In addition, the surface facing the front end side in the axial direction O is referred to as a "front end facing surface", and the surface facing the rear end side is referred to as a "rear end facing surface".

[0067] figure 1 is a perspective view showing the configuration of the thermal analysis device 100 according to the first embodiment of the present invention, figure 2 is a cross-sectional view along the axial direction of the thermal analysis device 100 . image 3 It is a diagram showing a state in which a sample is placed or replaced in the thermal analysis device 100 . Figure 4 It is an exploded perspective view of the thermal analysis device 100 . also,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com