Method for repairing cyanide-polluted soil by physical heat analysis technology

A technology for polluted soil and cyanide, applied in the field of soil remediation, can solve problems such as difficult large-scale engineering applications, changing soil physical and chemical properties, and increasing remediation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The cyanide-contaminated soil of a certain site has been tested to have a volatile cyanide content of 560mg / kg, and it is required to restore it to below 8.0mg / kg (Class B of the "Soil Environmental Quality Evaluation Standard for Exhibition Sites").

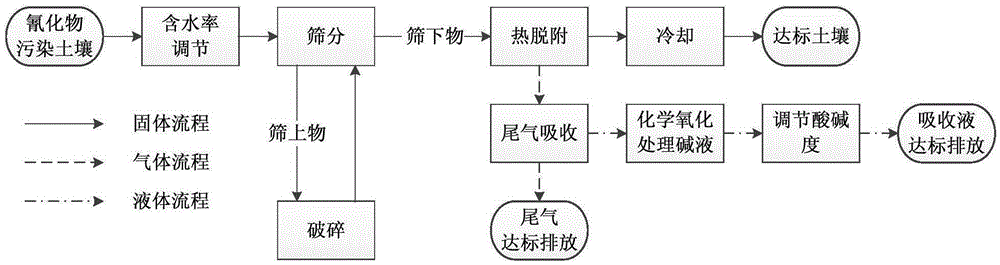

[0023] Method flow chart as figure 1 As shown, the specific operation steps are as follows:

[0024] (1) The moisture content of the cyanide-contaminated soil at the site by physical means θ m Control is 13%;

[0025] (2) Mechanically crush the cyanide-contaminated soil until the diameter of the aggregate is less than 2cm, and carry out quality control through a hanging vibrating screen, and the oversize can be mechanically crushed again by physical means before screening;

[0026] (3) Put the cyanide-contaminated soil in batches for roasting in a tube furnace. The roasting temperature is selected to be 300-600° C., and the roasting time is 10-20 minutes. After the soil physical thermal analysis is completed, it is cool...

Embodiment 2

[0031] The cyanide-contaminated soil of a certain site was tested to have a total cyanide content of 157.2 mg / kg, which needs to be restored to below 0.90 mg / kg (Class A of the "Soil Environmental Quality Evaluation Standard for Exhibition Sites").

[0032] Method flow chart as figure 1 As shown, the specific operation steps are as follows:

[0033] (1) The moisture content of the cyanide-contaminated soil at the site by physical means θ m Control is 18%;

[0034] (2) Mechanically crush the cyanide-contaminated soil until the diameter of the aggregate is less than 2cm, and carry out quality control through a hanging vibrating screen, and the oversize can be mechanically crushed again by physical means before screening;

[0035] (3) Put the cyanide-contaminated soil in batches for roasting in a tube furnace. The roasting temperature is selected to be 300-600° C., and the roasting time is 10-20 minutes. After the soil physical thermal analysis is completed, it is cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com