Polypropylene - polyethylene blends with improved properties

A blend, polypropylene technology, used in the field of recycled blends

Active Publication Date: 2016-12-14

BOREALIS AG

View PDF12 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This objective has not been add

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

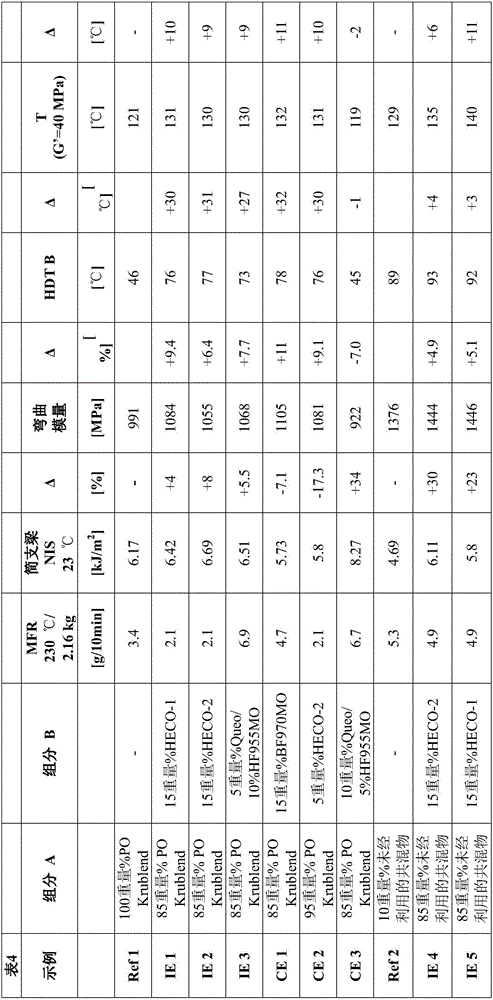

Polypropylene-Polyethylene blends comprising A) 75 to 90wt% of a blend of A-l) polypropylene and A-2) polyethylene and B) 10 to 25wt% of a compatibilizer being a heterophasic polyolefin composition comprising B-l) a polypropylene with an MFR2 between 1.0 and 300 g/10 min (according to ISO 1133 at 230 DEG C at a load of 2.16 kg) and B-2) a copolymer of ethylene and propylene or C4 to C10 alpha olefin with a Tg (measured with dynamic-mechanical thermal analysis, DMTA, according to ISO 6721-7) of below -25DEG C and an intrinsic viscosity (measured in decalin according to DIN ISO 1628/1 at 135DEG C) of at least 3.0 dl/g, whereby the blend has simultaneously increased Charpy Notched Impact Strength (according to ISO 179-leA, measured at 23DEG C), Flexural Modulus (according to ISO 178) as well as heat deflection resistance (determined with DMTA according to ISO 6721-7).

Description

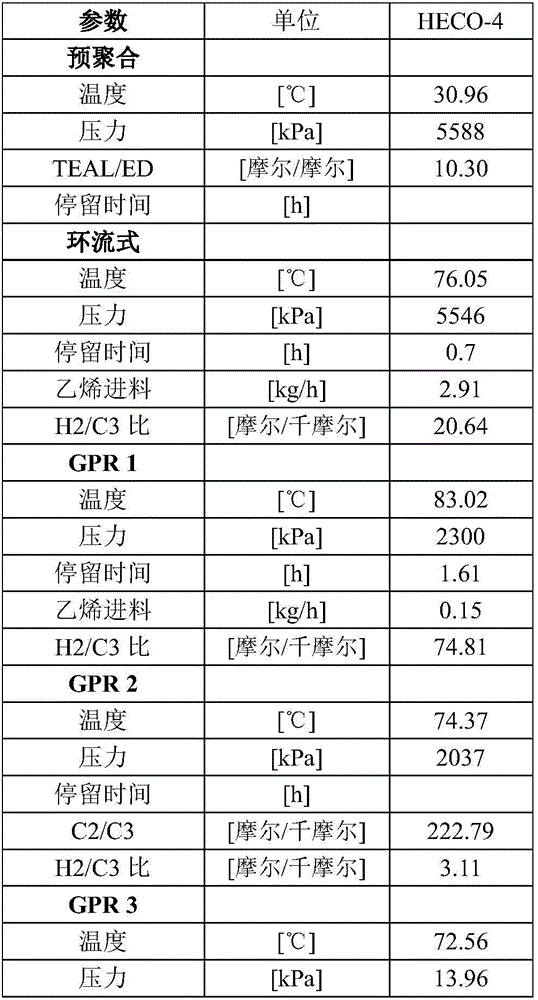

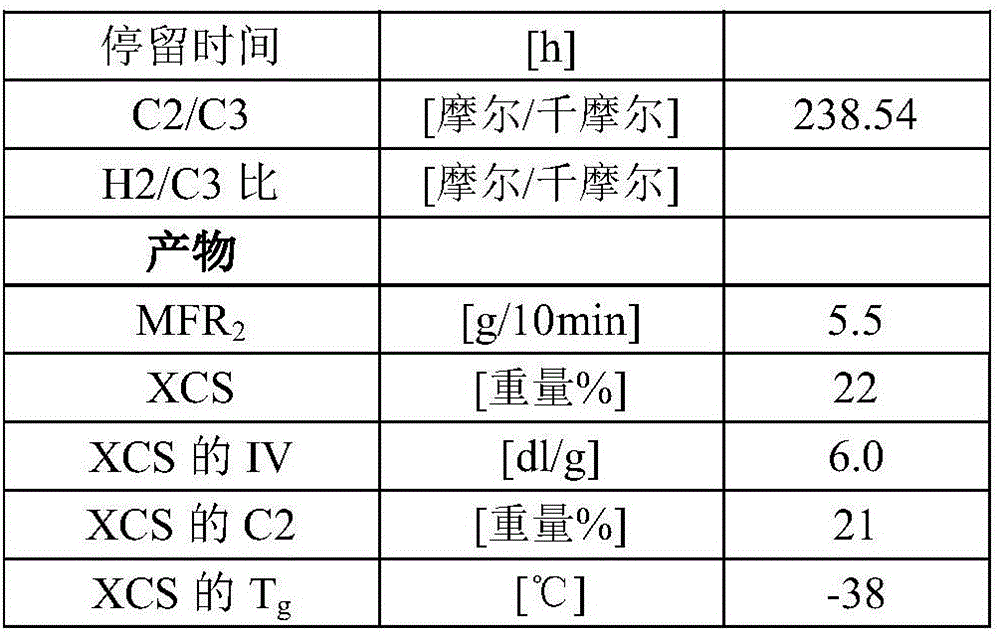

technical field [0001] The present invention relates to blends of polypropylene and polyethylene comprising a specific class of compatibilizers. Due to the addition of specific compatibilizers, rigidity, impact strength and heat deformation resistance are simultaneously increased. Furthermore, the present invention also relates to recycled blends of polypropylene and polyethylene containing specific types of compatibilizers. Background technique [0002] Polyolefins like polypropylene and polyethylene are typical commercial polymers with many fields of application and a significant growth rate. The reason for this is not only their favorable price / performance ratio, but also the versatility of this class of materials and their very wide range of possible modifications, which allow a wide range of end-use properties to be tuned. [0003] Chemical modification, copolymerization, blending, stretching, heat treatment and combinations of these techniques can convert common grad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/06C08L23/16

CPCC08L23/06C08L23/12C08L2205/08C08L2205/035C08L2205/025C08K2201/003C08L2207/062C08L23/16C08L2205/02C08L2207/20C08F210/06C08F4/6492C08F2/001C08F210/16C08F2500/12C08F2500/17C08F2500/27C08F2500/35C08F2500/32C08F2500/30C08F2500/31C08L2207/02

Inventor 苏珊娜·卡伦马库斯·加莱特纳卡尔-古斯塔夫·伊克巴哈阿尼·库尔施莱施塔诺伯特·赖歇尔赫尔诺特·鲍姆加特

Owner BOREALIS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com