Patents

Literature

205 results about "Decalin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decalin (decahydronaphthalene, also known as bicyclo[4.4.0]decane and sometimes decaline), a bicyclic organic compound, is an industrial solvent. A colorless liquid with an aromatic odor, it is used as a solvent for many resins or fuel additives. It is the saturated analog of naphthalene and can be prepared from it by hydrogenation in the presence of a catalyst. Decahydronaphthalene easily forms explosive organic peroxides upon storage in the presence of air.

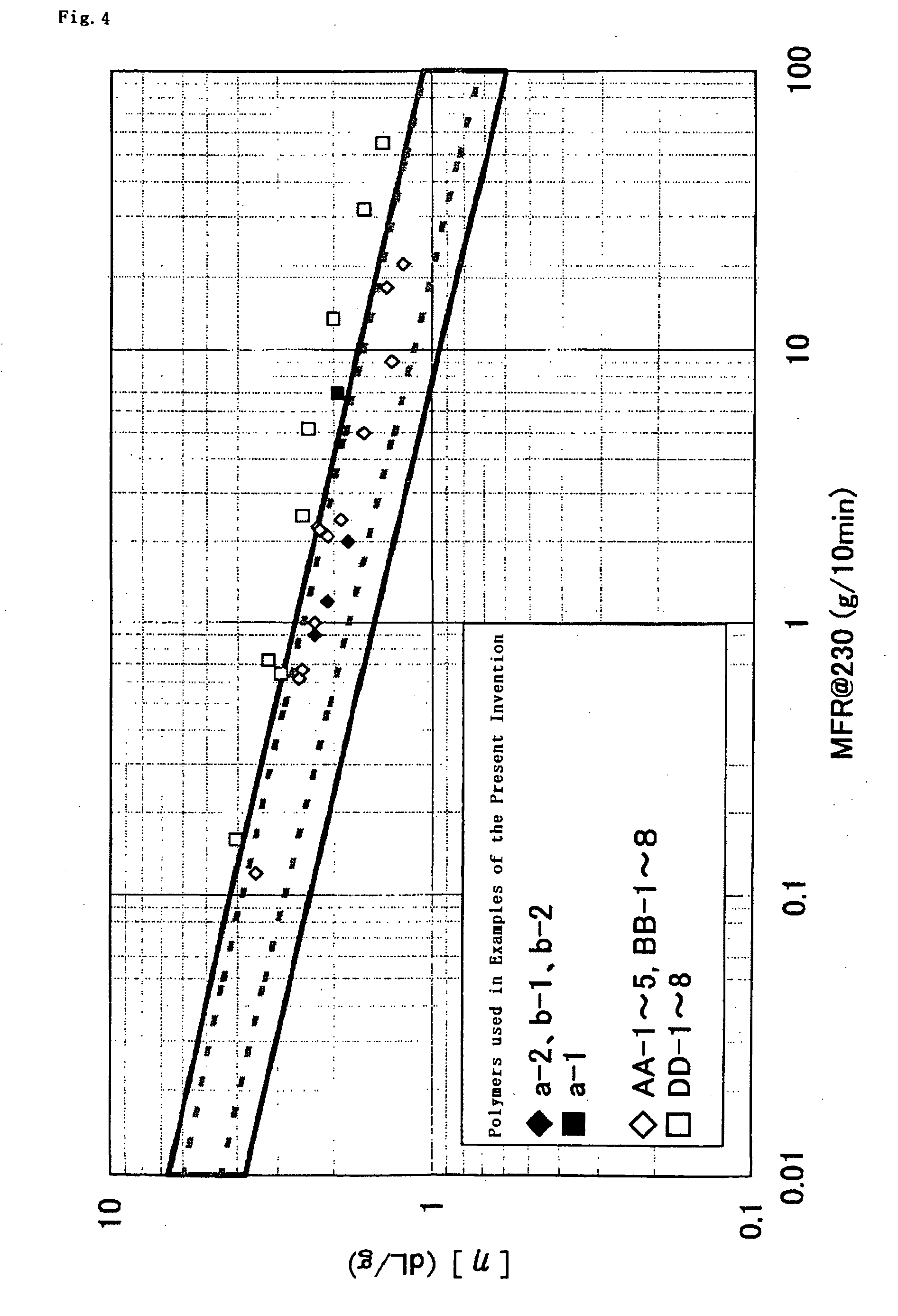

Polypropylene resin composition and use thereof

A polypropylene resin composition exibiting a high melt tension and superior moldability, which can be molded efficiently by a high-speed molding into scarcely deformable larger molded articles of better appearance with high stiffness and which comprises polypropylene as a main component and has the following characteristic features 1) to 4), namely,1) that a melt flow rate (MFR, determined at 230° C. under a load of 2.16 kg) is in the range of 0.01 to 5 g / 10 min.,2) that a content of a high molecular weight polypropylene exhibiting an intrinsic viscosity [eta], determined at 135° C. in decalin, of 8-13 dl / g is in the range of 15 to 50% by weight,3) that a gel areal density in number is 3,000 / 450 cm2 or less and4) that a molecular weight distribution determined by gel permeation chromatography (GPC) is 6-20, as expressed by Mw / Mn, and is 3.5 or higher, as expressed by Mz / Mw.

Owner:PRIME POLYMER CO LTD

Polypropylene resin composition and injection-molded article thereof

A polypropylene resin composition, which is light weighing, has very high values for the stiffness and heat resistance and is superior in the scratch-proof property with better moldability upon molding and which can be injection-molded into formed articles without occurrence of cracking, comprising 5-25% by weight of a higher molecular weight polypropylene (A) having an intrinsic viscosity [eta], determined in decalin at 135° C., in the range from 6 to 11 dl / g and 95-75% by weight of a lower molecular weight polypropylene (B) having an intrinsic viscosity [eta], determined in decalin at 135° C., in the range from 0.6 to 1.6 dl / g, wherein the said resin composition has the following charactristic features <<1>> and <<2>>, namely,<<1>> an isotactic pentad fraction (mmmm-fraction), determined by 13C-NMR, of at least 96.5% and<<2>> a molecular weight distribution value expressed by Mw / Mn (weight-average molecular weight / number-average molecular weight), determined by gel permeation chromatography (GPC), of at least 8.

Owner:PRIME POLYMER CO LTD

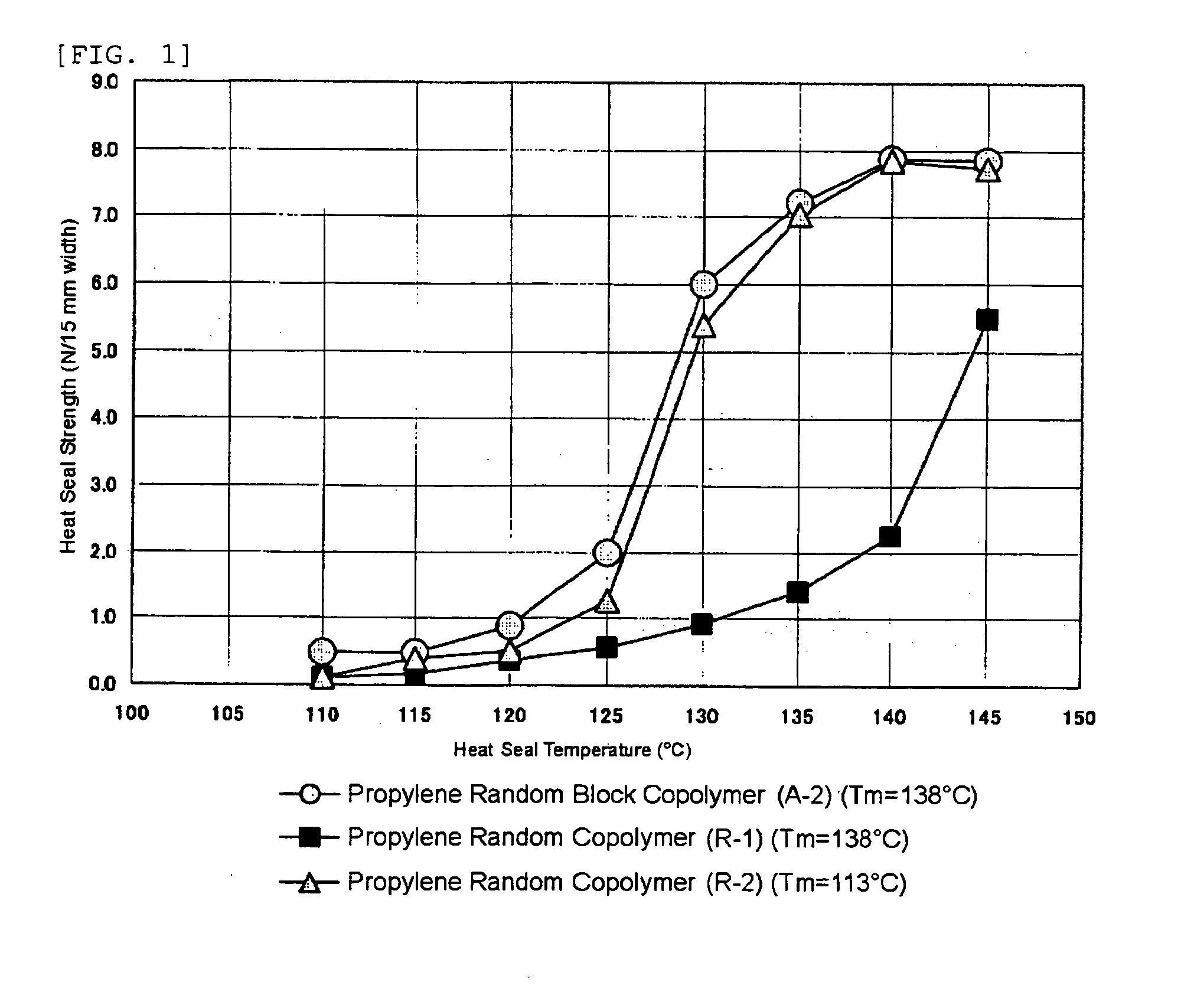

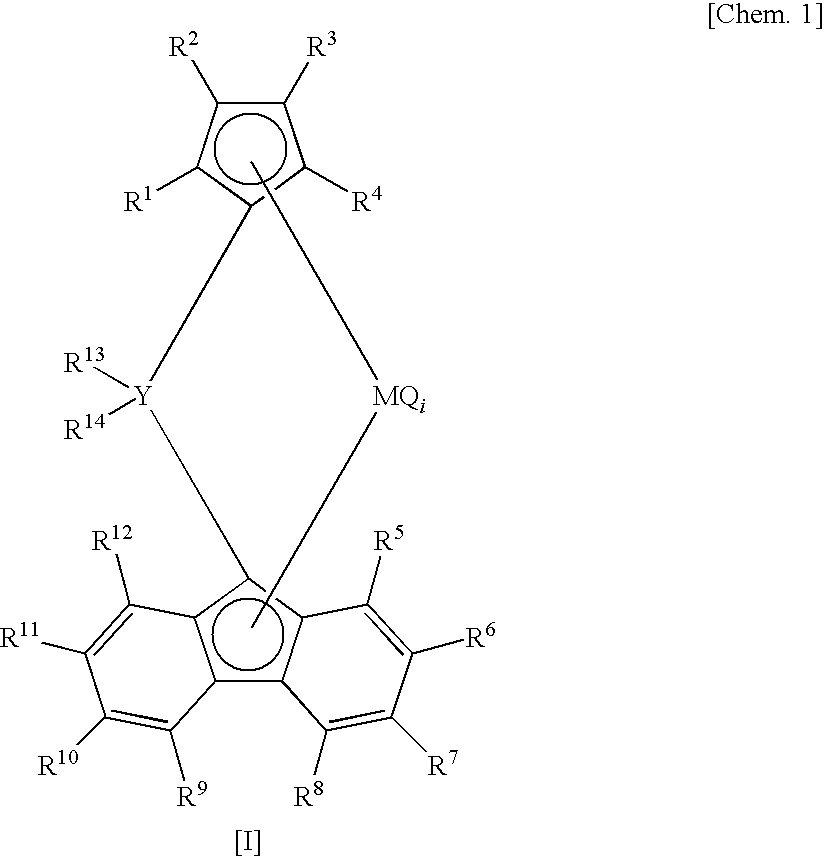

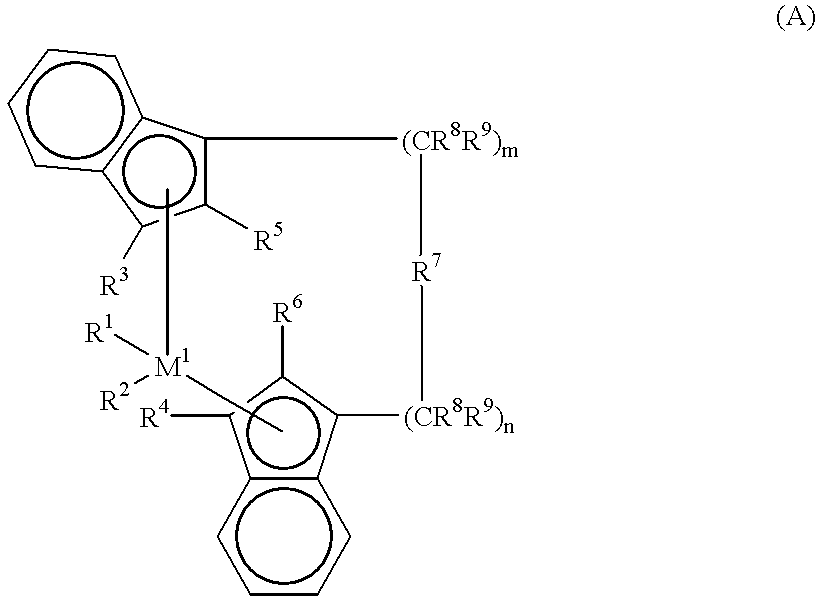

Propylene Random Block Copolymer, Resin Composition Containing the Copolymer and Molded Article Made Thereof

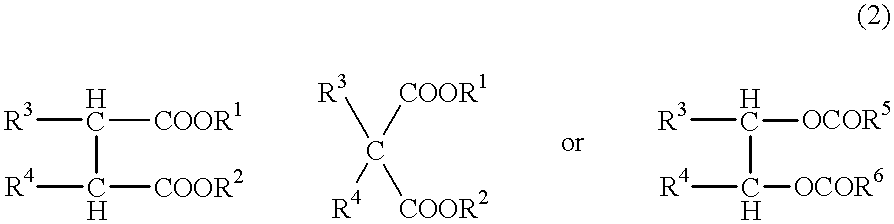

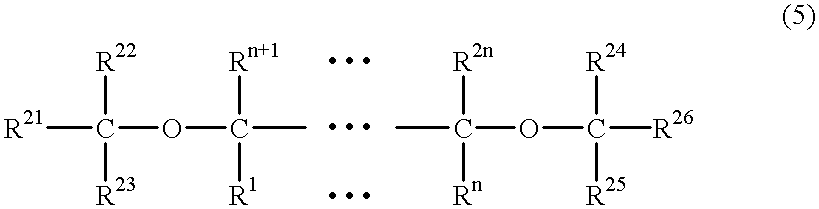

The invention provides a propylene random block copolymer (A) that has a melt flow rate from 0.1 to 100 g / 10 min and a melting point from 100 to 155° C. and includes 90 to 60% by weight of a portion insoluble (Dinsol) in n-decane at room temperature and 10 to 40% by weight of a portion soluble (Dsol) in n-decane at room temperature, wherein the Dinsol satisfies the following requirements (1) through (3) and the Dsol satisfies the following requirements (4) through (6). The invention further provides molded articles such as sheets, films, injection molded articles, hollow molded articles, injection blow molded articles and fibers, which are formed of the propylene random block copolymer (A) or a propylene resin composition containing the propylene random block copolymer (A). (1) The molecular weight distribution (Mw / Mn) obtained by GPC of the Dinsol is from 1.0 to 3.5, (2) the content of skeletons derived from ethylene in the Dinsol is from 0.5 to 13% by mole, (3) the total amount of 2,1- and 1,3-propylene units in the Dinsol is 0.2% by mole or less, (4) the molecular weight distribution (Mw / Mn) obtained by GPC of the Dsol is from 1.0 to 3.5, (5) the intrinsic viscosity [η] in decalin at 135° C. of the Dsol is from 1.5 to 4 dl / g and (6) the content of skeletons derived from ethylene in the Dsol is from 15 to 35% by mole.

Owner:MITSUI CHEM INC +1

Thermoplastic elastomer composition

A thermoplastic elastomer composition prepared by dynamically treating with heat (a) an oil-extended ethylene-based copolymer rubber which comprises an ethylene-based copolymer rubber with an intrisic viscosity [ eta ] in the range from 4.3 to 6.8 dl / g when measured at 135 DEG C. in decalin and a mineral oil softening agent and (b) an olefin-based resin, in the presence of a crosslinking agent. The composition exhibits well-balanced and excellent elasticity recoverability and moldability, and can produce molded articles with superior appearance.

Owner:JSR CORPORATIOON

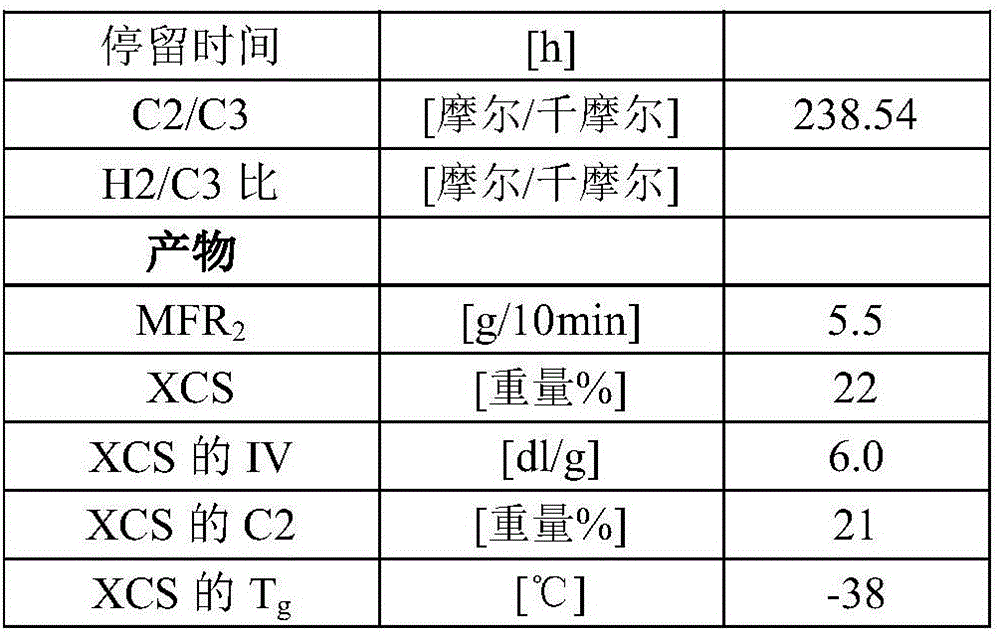

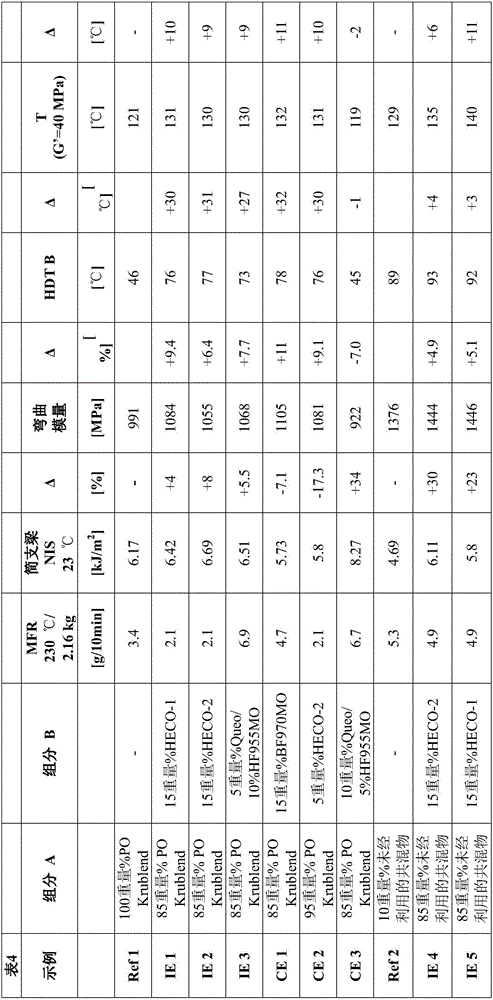

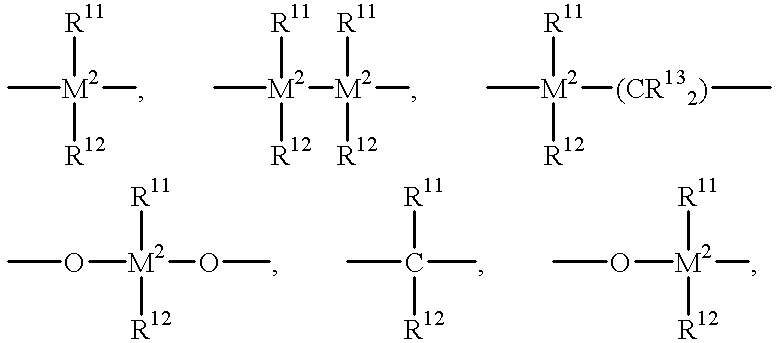

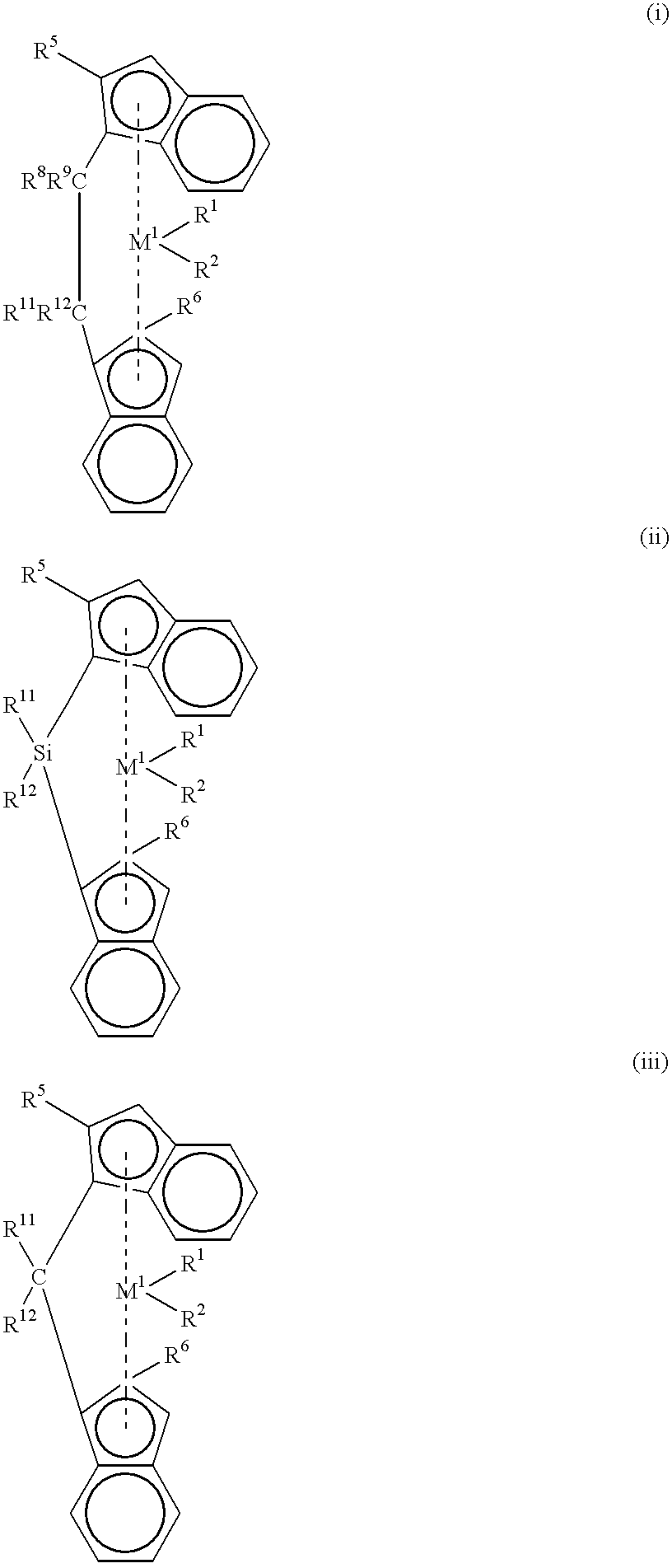

Thermoplastic polyolefins with high flowability and excellent surface quality produced by a multistage process

InactiveUS20110086970A1Improve liquidityImprove surface qualityOrganic-compounds/hydrides/coordination-complexes catalystsMixingElastomerPolymer science

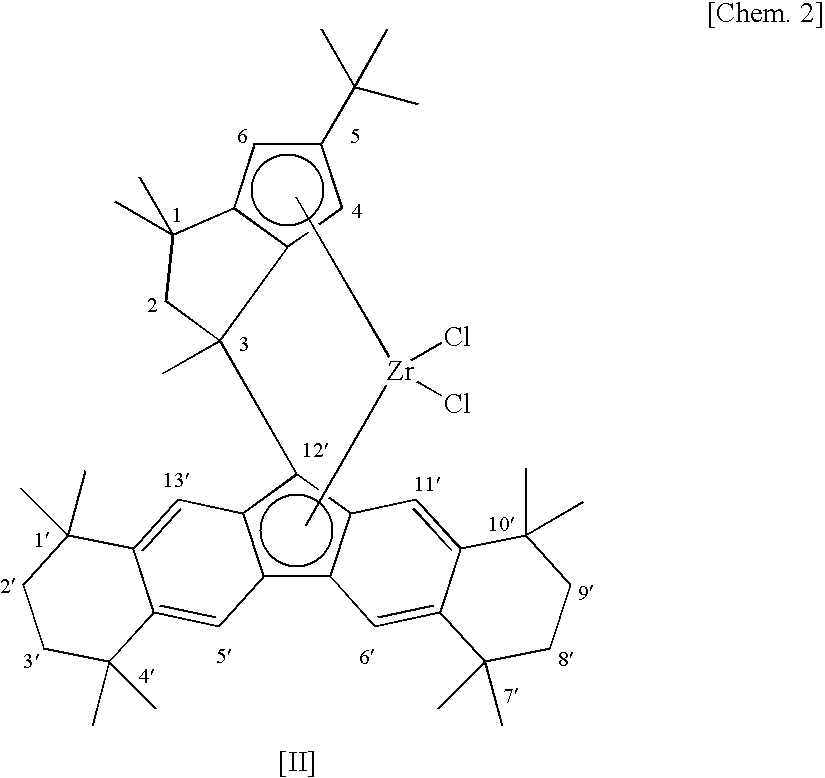

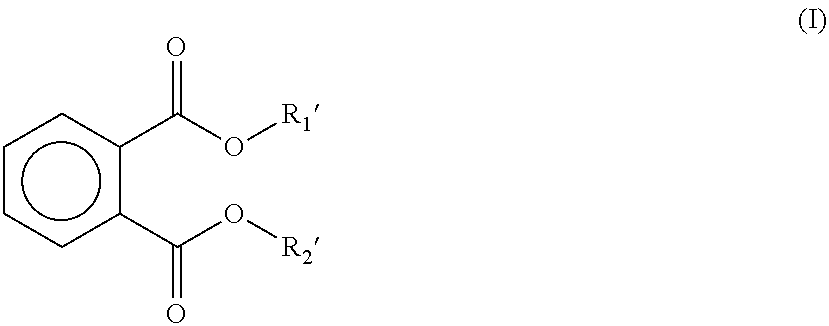

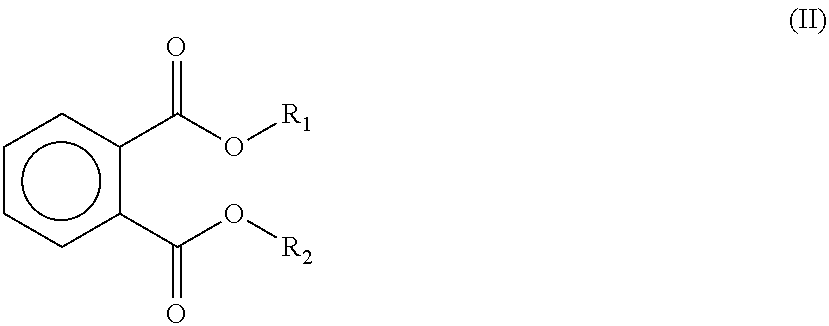

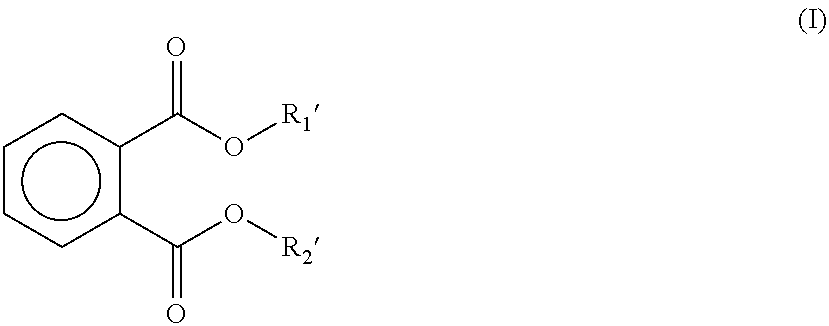

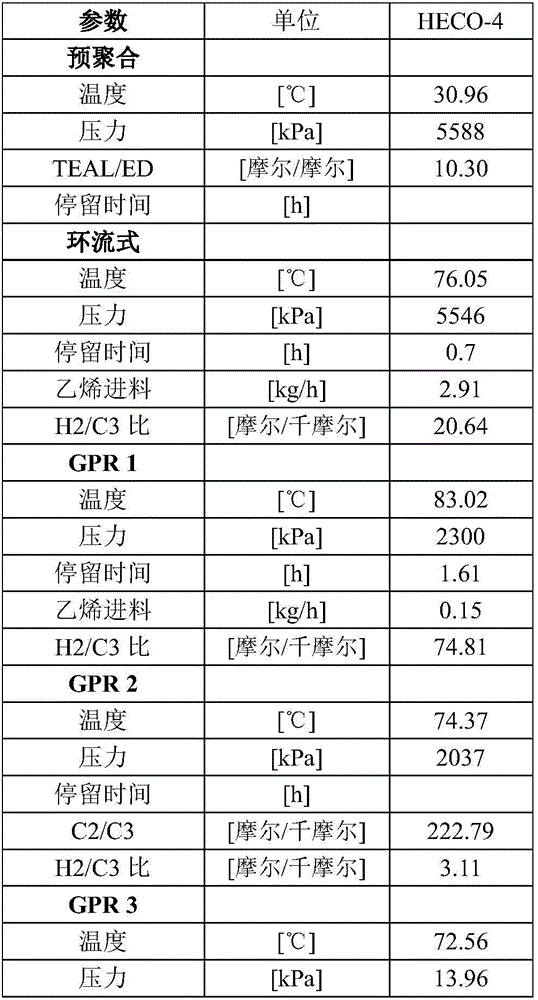

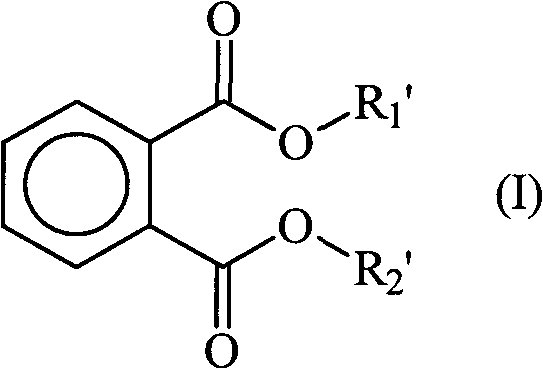

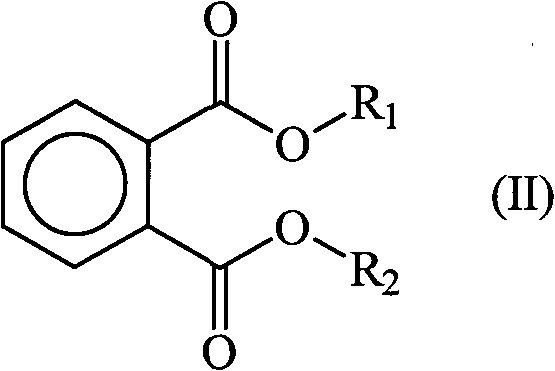

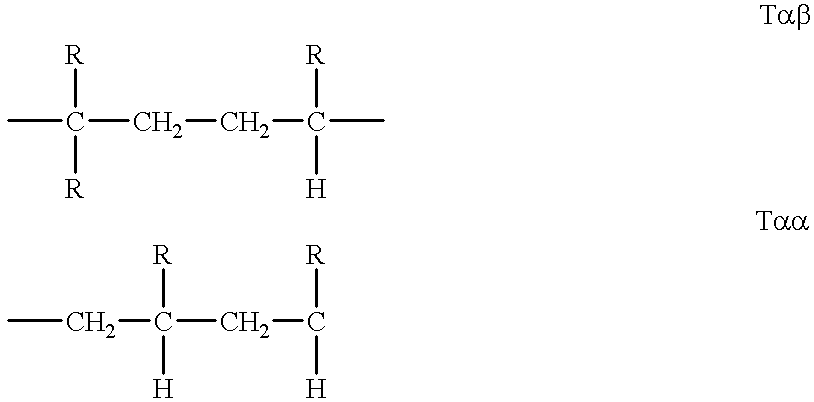

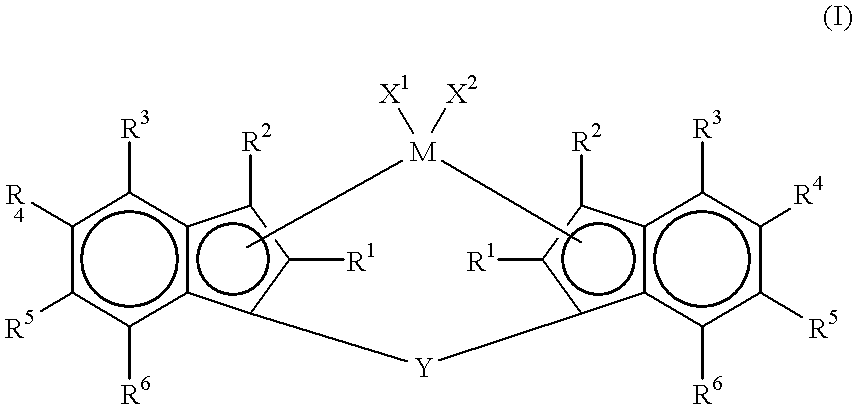

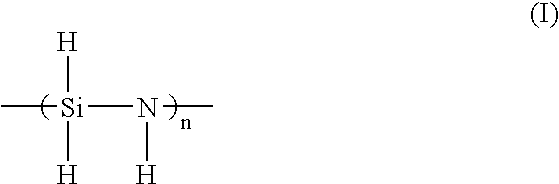

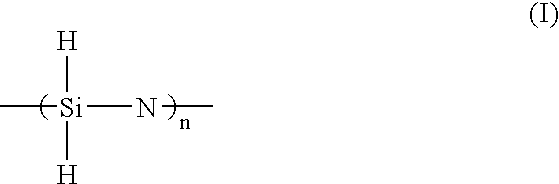

Reactor grade thermoplastic polyolefins with high flowability and excellent surface quality comprising (A) 40-90 wt % of a propylene homo- or copolymer matrix with an MFR in accordance with ISO 1 133 (230° C., 2.16 kg load) of >200 g / 10 min and (B) 2-30 wt % of an elastomeric ethylene-propylene copolymer having an intrinsic viscosity IV (according to ISO 1628 with decalin as solvent) of ≦2.8 dl / g and an ethylene content of >50 to 80 wt % and (C) 8-30 wt % of an elastomeric ethylene-propylene copolymer having an intrinsic viscosity IV (according to ISO 1628 with decalin as solvent) of 3.0-6.5 dl / g and an propylene content of 50 to 80 wt %, the reactor grade thermoplastic polyolefins being obtainable by a multistage polymerization process with at least 3 polymerization steps in the presence of a catalyst system comprising (i) a Ziegler-Natta procatalyst which contains a trans-esterification product of a lower alcohol and a phthalic ester and (ii) an organometallic cocatalyst and (iii) external donor represented by formula (I) Si(OCH2CH3)3(NR1R2) wherein R1 and R2 can be the same or different a represent a hydrocarbon group having 1 to 12 carbon atoms, as well as the use of these reactor grade thermoplastic polyolefins and molded articles produced from them.

Owner:BOREALIS AG

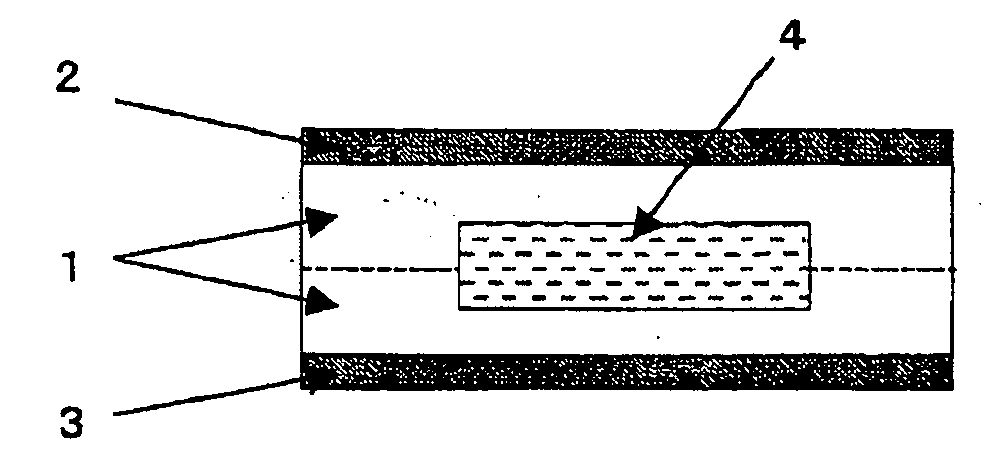

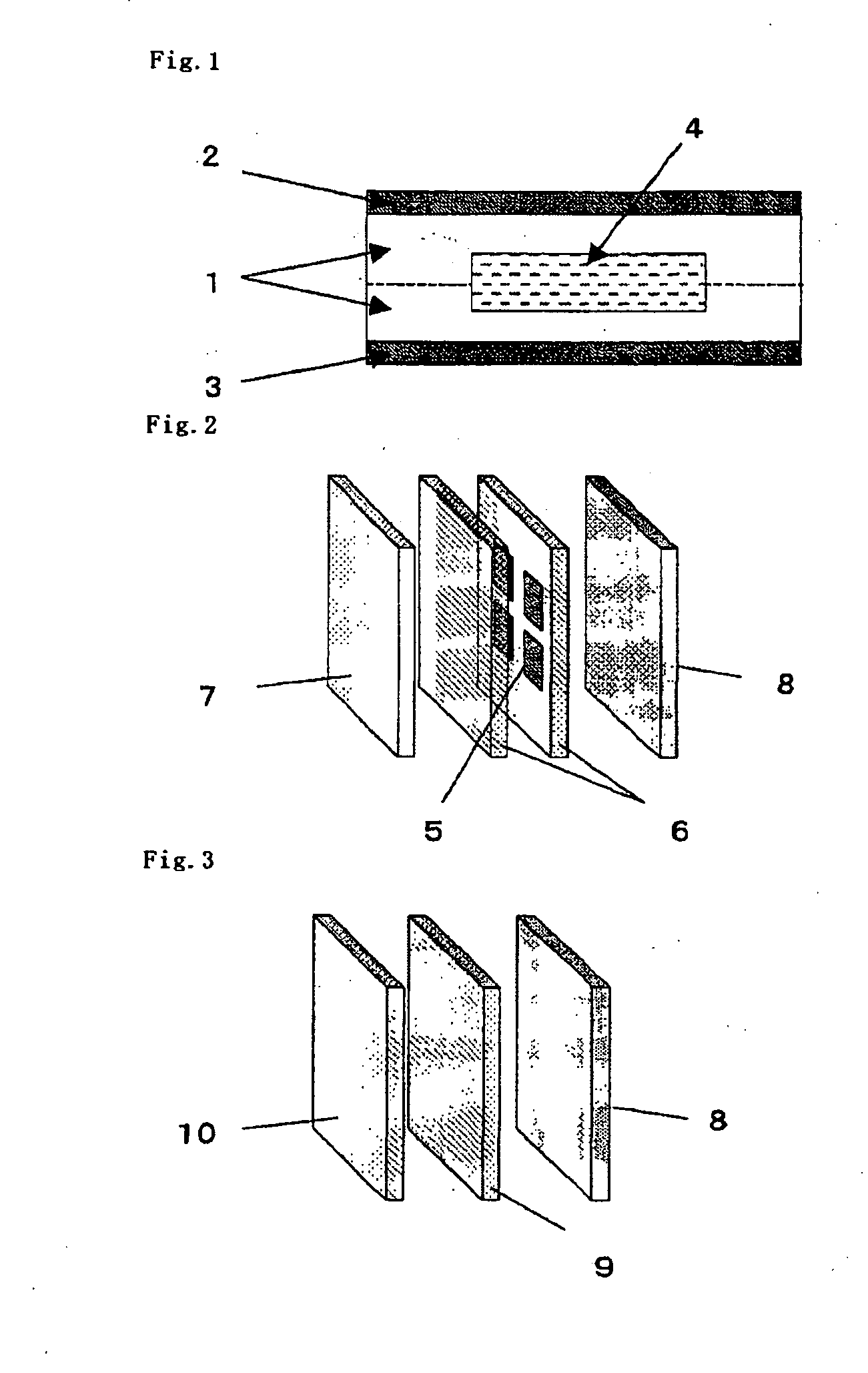

Method of preparing cathode containing Iron disulfide for a lithium cell

ActiveUS20090291366A1Improve discharge efficiencyUseful electrical energyFinal product manufactureOrganic electrolyte cellsPrimary cellAlloy

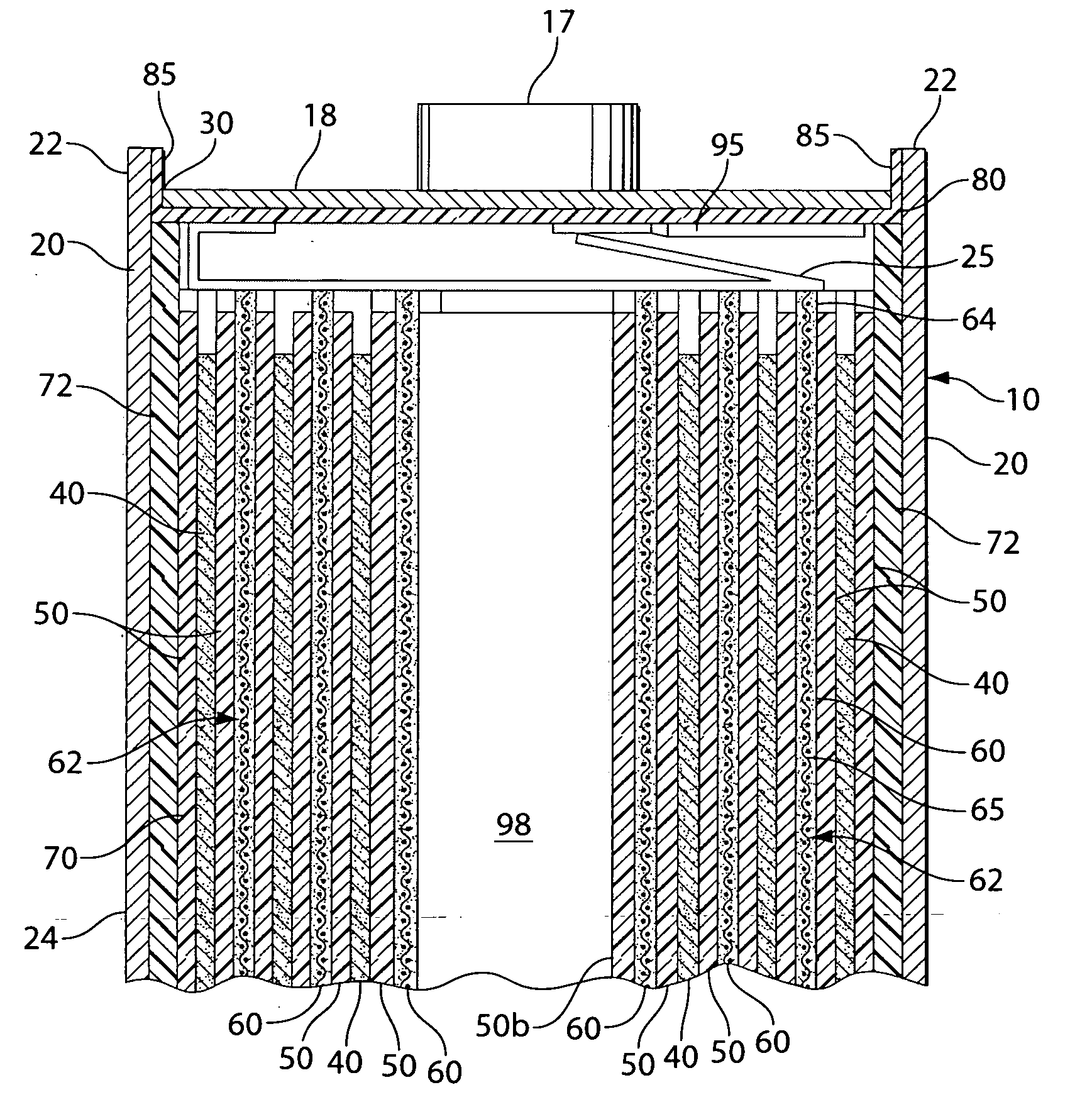

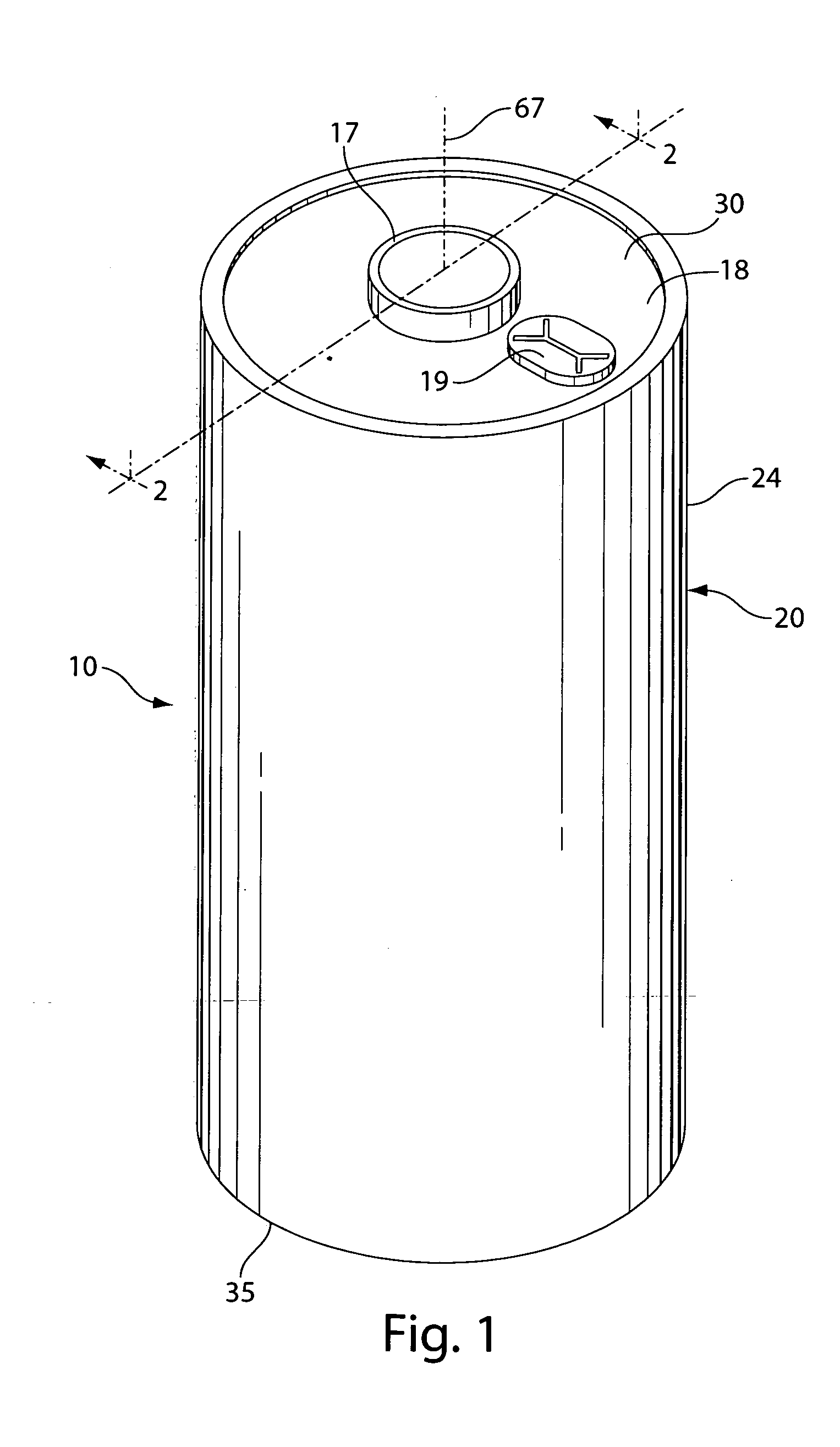

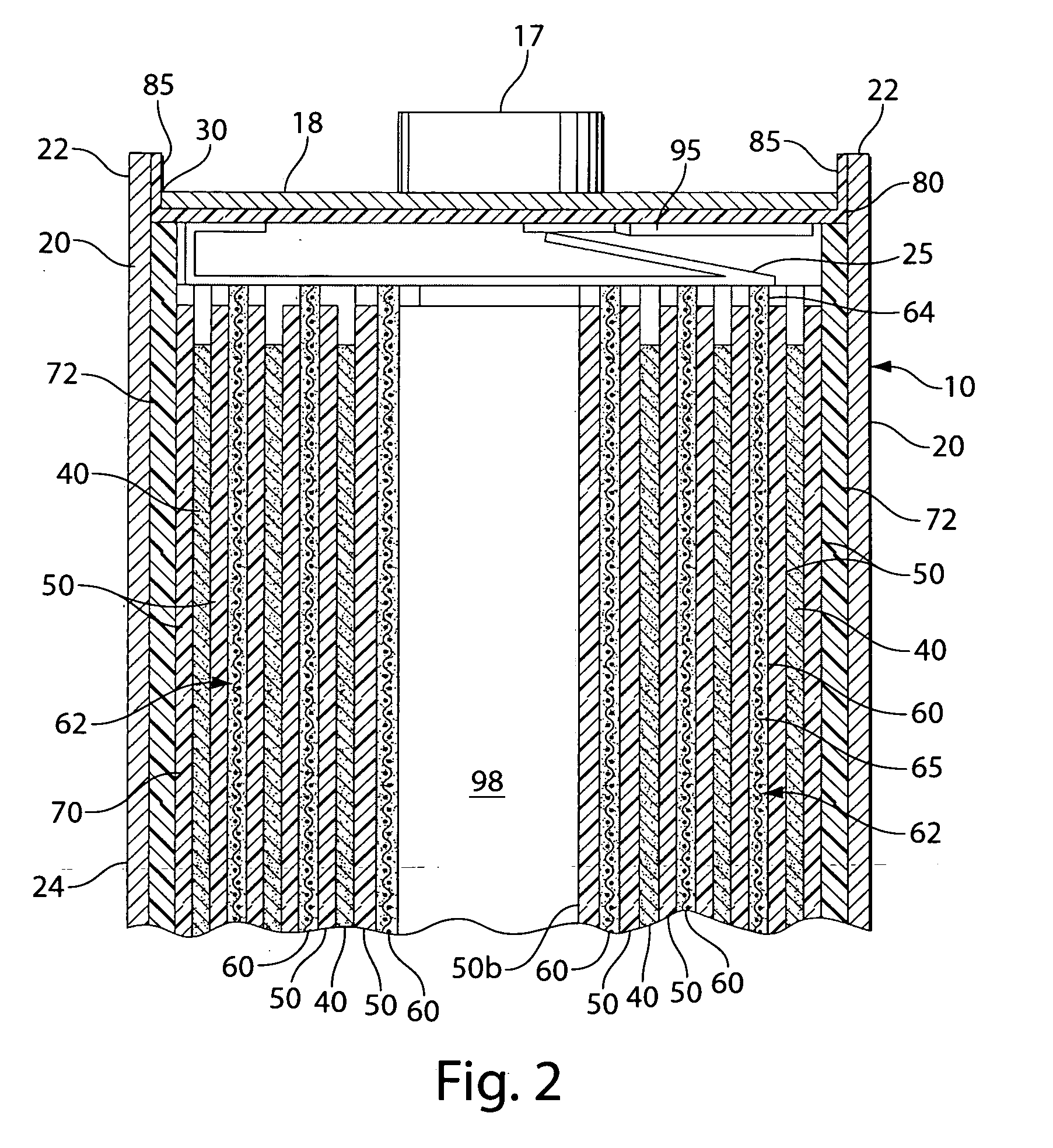

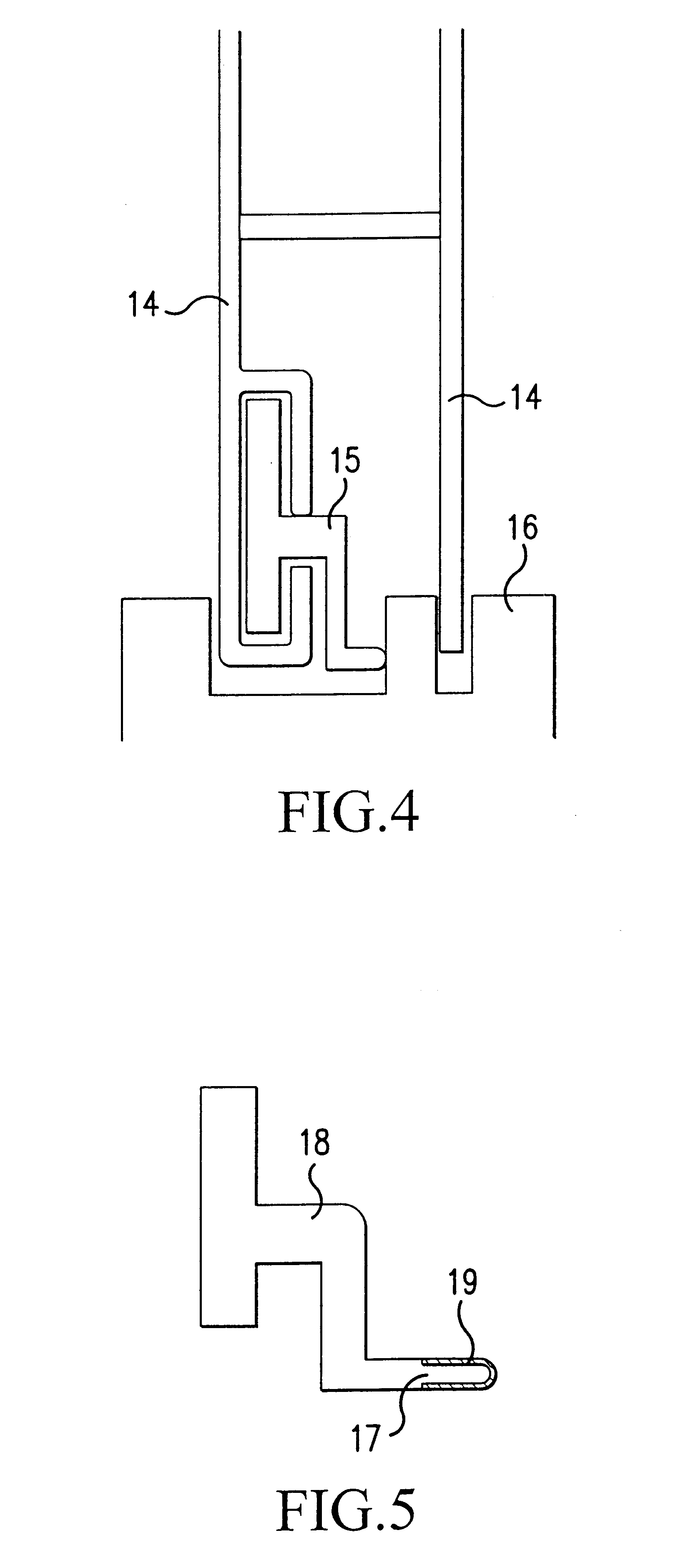

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) or a mixture of iron disulfide (FeS2) and iron sulfide (FeS) and conductive carbon particles. A cathode slurry is prepared comprising the FeS2 or FeS2 plus FeS powder, conductive carbon, binder, and a solvent. The binder is preferably a styrene-ethylene / butylene-styrene (SEBS) block copolymer. There is an advantage discovered in utilizing a hydronaphthalene solvent to form the cathode slurry. The preferred solvent is 1,2,3,4-tetrahydronaphthalene or decahydronaphthalene and mixtures thereof. The slurry mixture is coated onto a conductive substrate and the solvent evaporated leaving a dry cathode coating on the substrate. Higher drying temperature may be used resulting in a dry cathode coating which resists cracking. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

Polypropylene - polyethylene blends with improved properties

Owner:BOREALIS AG

Heterophasic polypropylene copolymer composition

Heterophasic polypropylene composition comprising (A) 45 to 70 wt% of a propylene homo- or copolymer matrix with an MFR2 in accordance with ISO 1133 (230 DEG C, 2.16 kg load) of => 80 g / 10 min and (B) 25 to 40 wt% of an elastomeric propylene-ethylene copolymer, having an intrinsic viscosity IV (ISO 1628, with decalin as solvent) of => 3.3 dl / g and an ethylene content of 20 to 50 wt%, (C) 0-15 wt% of an elastomeric ethylene / alpha-olefin random copolymer (D) 3 - 25 parts per weight of inorganic filler, the heterophasic polypropylene compositions having a total MFR2 (230 DEG C / 2.16 kg) in accordance with ISO 1133 of => 5 g / 10 min, a Charpy notched impact strength according to ISO 179 / 1eA at +23 DEG C of => 15.0 kJ / m2, preferably => 25.0 kJ / m2, a minimum value for the Charpy notched impact strength according to ISO 179 / 1eA at -200C of => 7.0 kJ / m2, preferably => 10.0 kJ / m2 and a tensile modulus according to ISO 527-3 of =>1200 MPa; their preparation and use for producing injection moulded articles being free of flow marks.

Owner:BOREALIS AG

Olefinic thermoplastic elastomer composition and method for producing the same

The present invention relates to an olefinic thermoplastic elastomer composition which comprises a crystalline polyolefin resin (A), an ethylene-alpha-olefin-non-conjugated polyene copolymer rubber (B) and at least on rubber (C) selected from polyisobutylene, butyl rubber and a propylene-ethylene copolymer rubber having a propylene content of 50 mol % or more or an ethylene-alpha-olefin copolymer (D) having a density of 0.870 to 0.940 (g / cm<3>) and an ethylene content of 85 mol % or more, said ethylene-alpha-olefin-non-conjugated polyene copolymer rubber (B) being crosslinked thermoplastic elastomer composition, being obtained by random copolymerization of ethylene, and alpha-olefin having 3 to 20 carbon atoms and a non-conjugated polyene in the presence of a metallocene catalyst, (1) containing the unit (a) derived from the ethylene and the unit (b) derived from the alpha-olefin in a molar ratio of 40 / 60 to 95 / 5 [(a) / (b)], (2) having an iodine value of 1 to 50 and (3) having an intrinsic viscosity [eta] measured in decalin at 135° C. of 1.0 to 10 dl / g; and relates to a method for manufacturing the same.

Owner:MITSUI CHEM INC

Method for synthesizing decalin

InactiveCN101602644AReduce metal contentImprove conversion rateHydrocarbon by hydrogenationCatalyst activation/preparationReaction temperatureActive phase

The invention provides a method for synthesizing decalin, and relates to a method for synthesizing a compound. The invention provides the method for synthesizing the decalin from naphthalene in one step by using a load type catalyst taking nano metal with low content and small size as an active phase and under the conditions of low reaction temperature and pressure. The method comprises the following steps of: mixing the naphthalene and cyclohexane, and placing the mixture in a high pressure autoclave; adding a catalyst in the high pressure autoclave; and discharging air in the high pressure autoclave, stabilizing the pressure of hydrogen gas in the high pressure autoclave to between 2 and 5MPa for reaction, and obtaining the decalin. The conversion rate of the naphthalene is 100 percent, and the maximum yield of the decalin is 99 percent. The method for preparing the catalyst of Ni / gamma-Al2O3 comprises the following steps of: dissolving metallic salt of nickel in water, adding gamma-Al2O3 in the mixed solution, pouring clear solution out, and drying the clear solution to obtain a precursor of the catalyst; and reducing the precursor of the catalyst.

Owner:XIAMEN UNIV

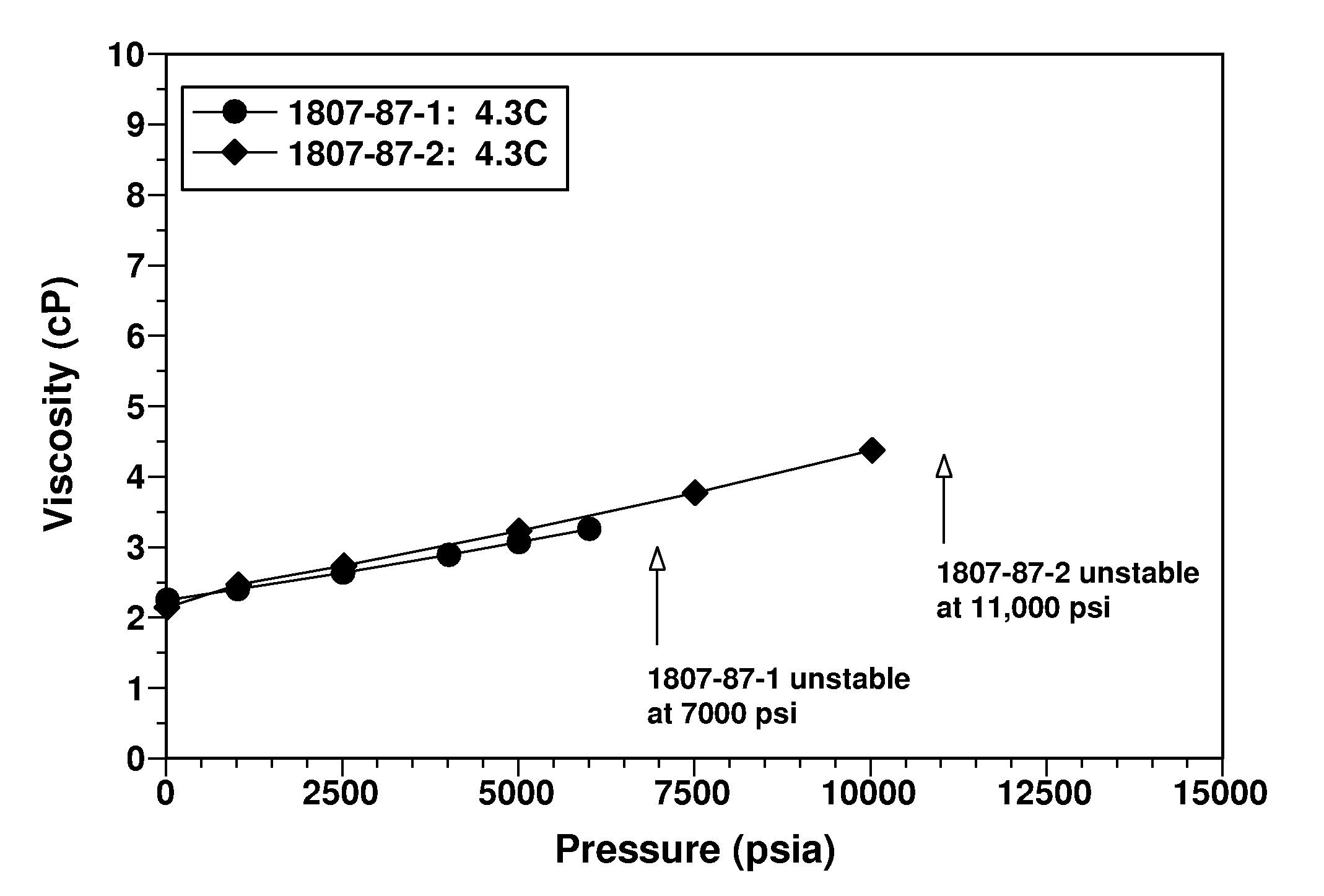

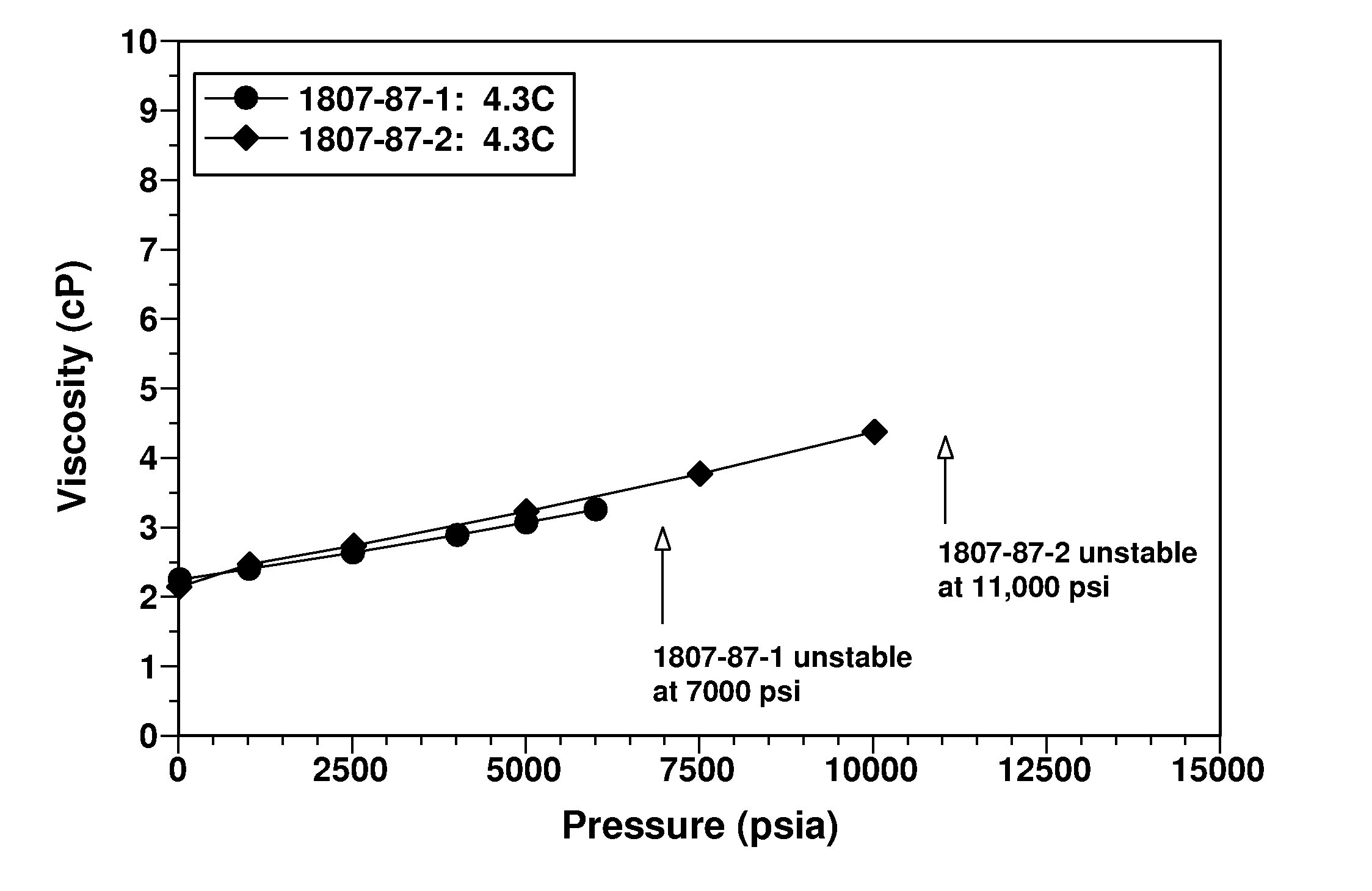

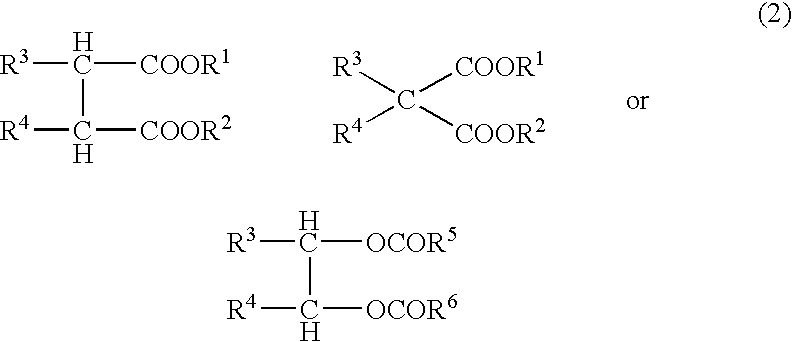

Paraffin inhibitor compositions and their use in oil and gas production

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

Paraffin Inhibitor Compositions and Their Use in Oil and Gas Production

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

Method of preparing exo-dicyclopentadiene from endo-dicyclopentadiene or cyclopentadiene

InactiveCN1907927ALiquid phase reaction conditions are mildHigh yieldHydrocarbon by isomerisationBENZYL ALCOHOL/WATERHeptane

The invention discloses a preparation method for exo-dicyclopentadiene from bridge-type dicyclopentadiene or cyclopentadiene, belonging to the exo-dicyclopentadiene preparation technology. The method includes preparing a solution composed of bridge-type dicyclopentadiene or cyclopentadiene, and benzene, or toluene, or benzyl alcohol, or decalin, or cyclohexane, or heptane, or hexane at a certain quality ratio, adding p-tert-butylcatechol, or 2, 5-di-tert-butylhydroquinone, or 2,6-di-tertbutyl-4-methylphenol, or hydroquinone, or 2-methyl-1,4-dihydroxybenzene, or o-hydroquinone inhibitor and carrying out reaction at a certain temperature and pressure, distilling and separating to obtain the exo-dicyclopentadiene. The invention has the advantages of one-step synthesis without catalyst, mild reaction conditions and high yield, and is suitable for industrial production.

Owner:TIANJIN UNIV

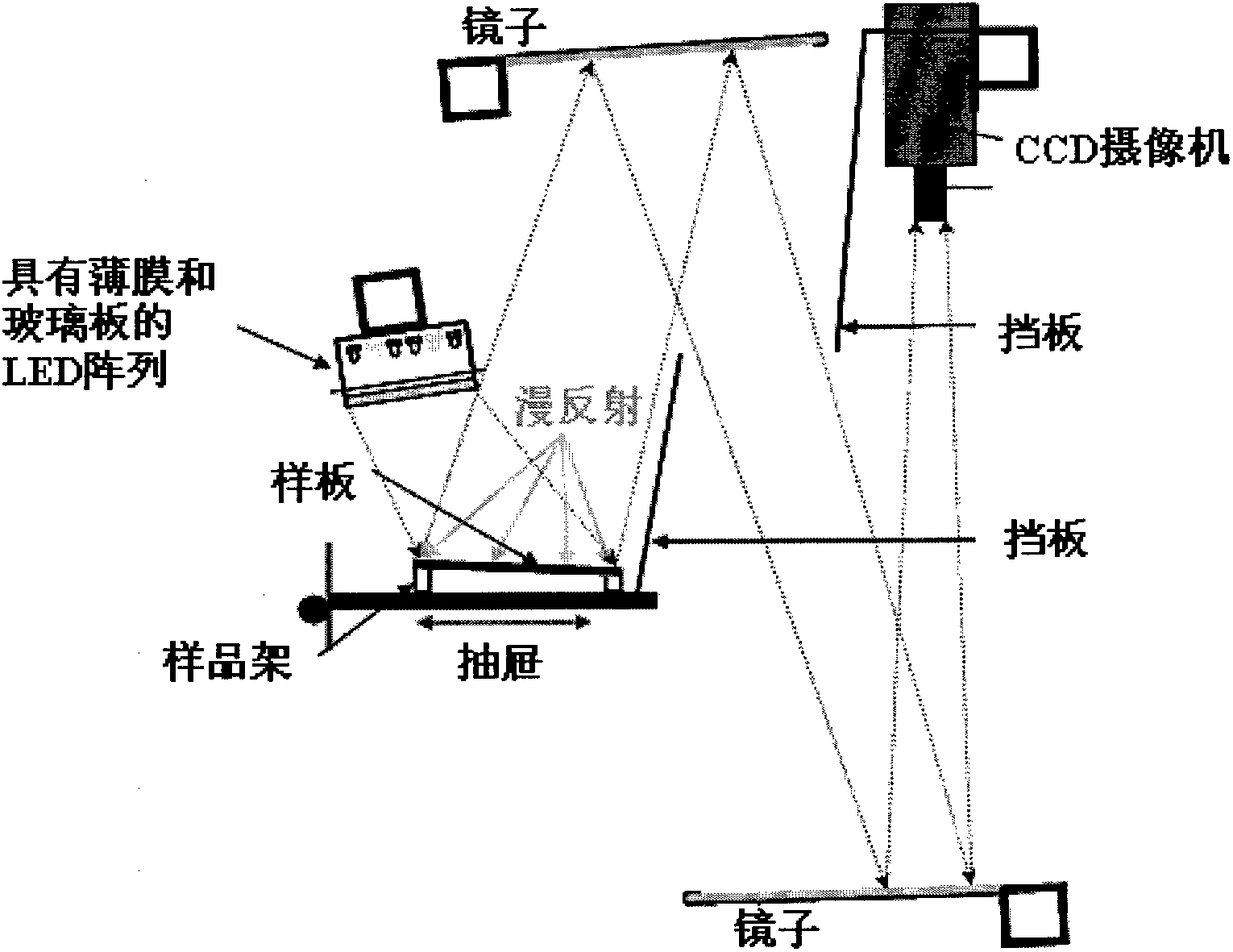

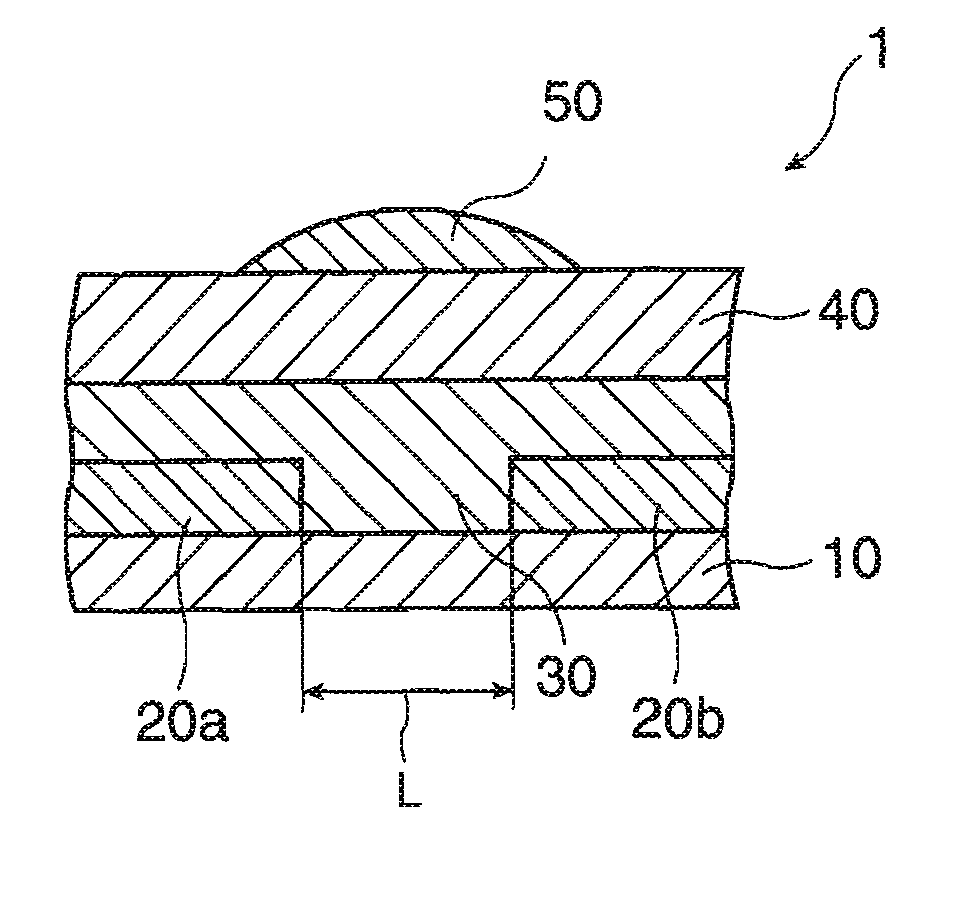

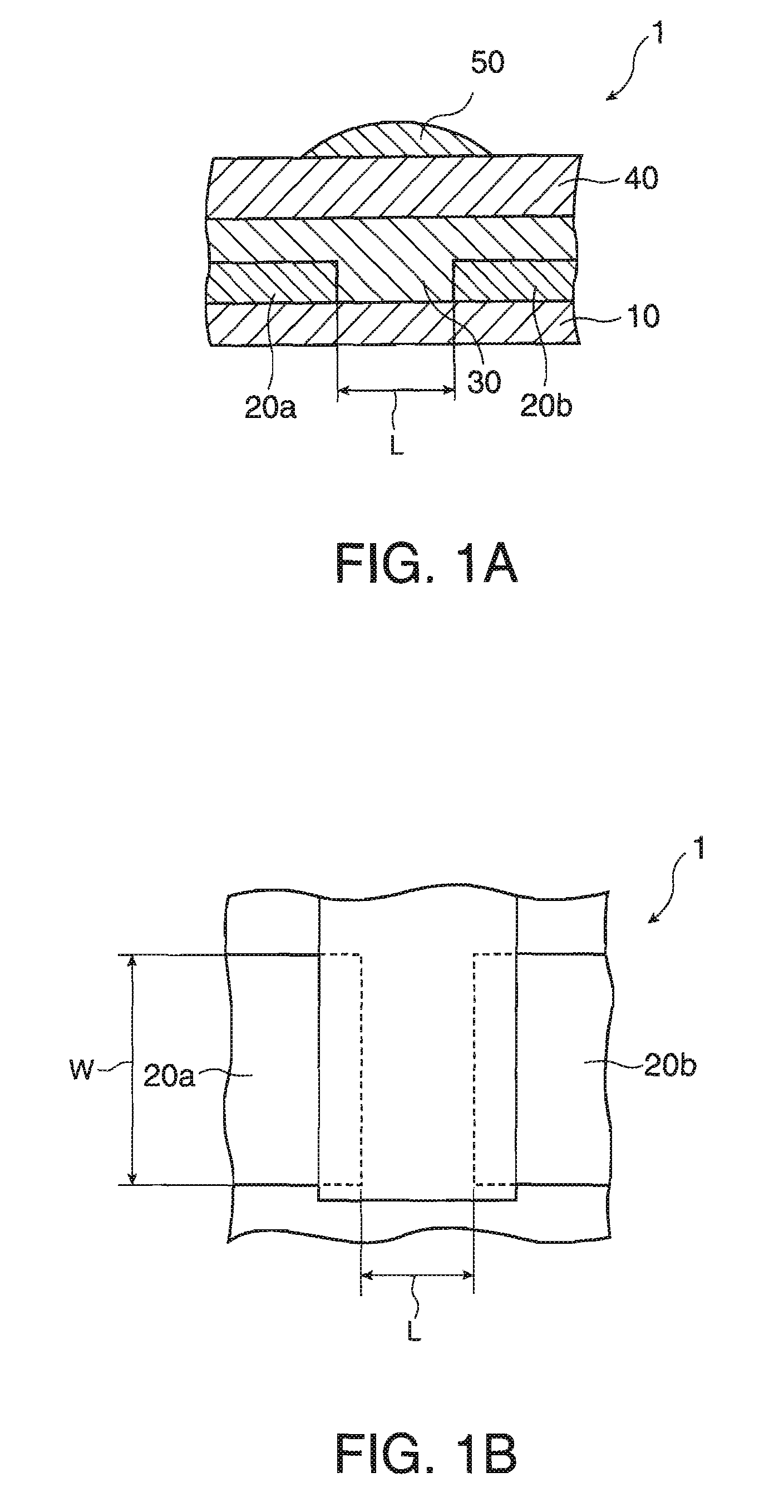

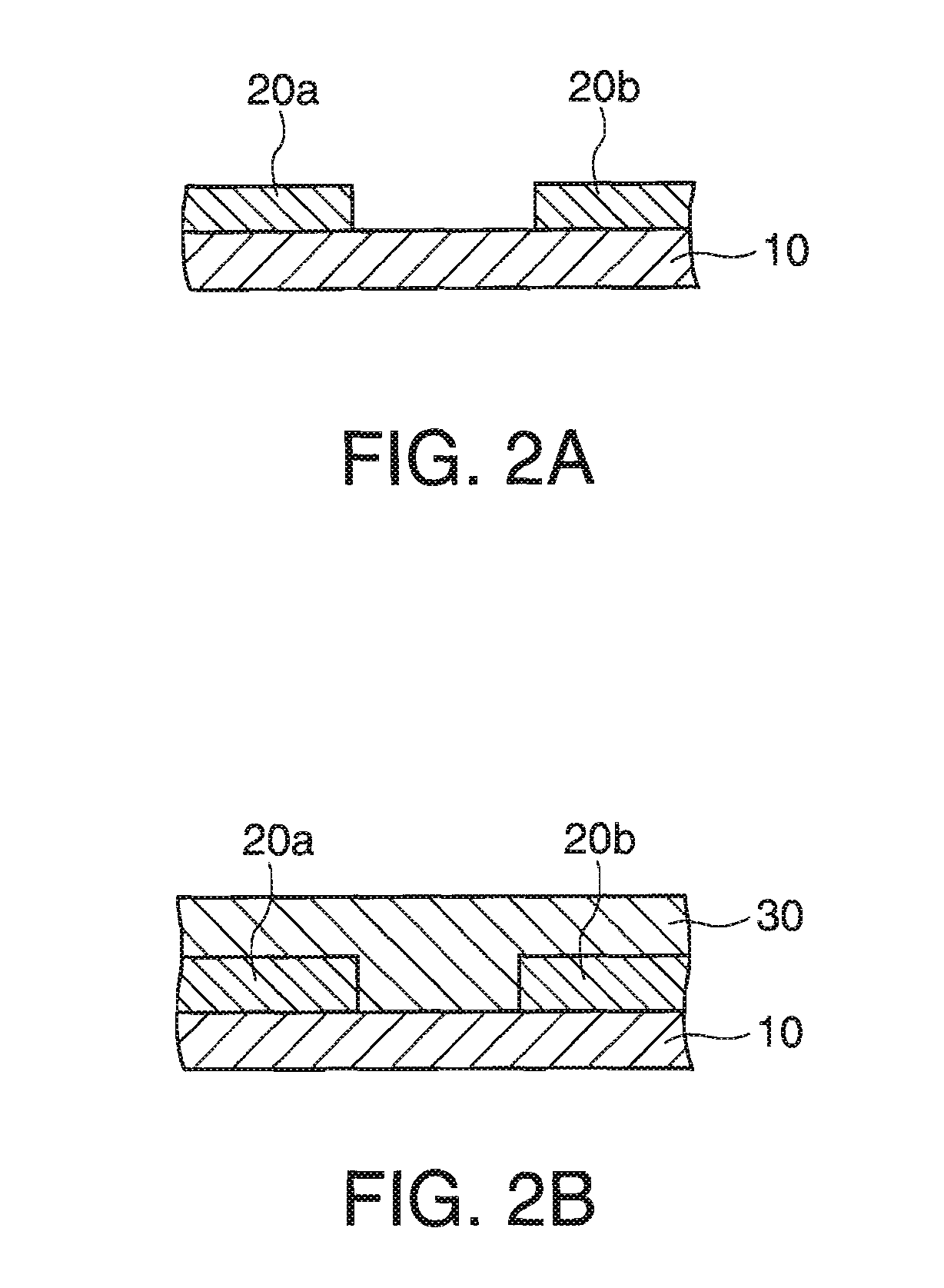

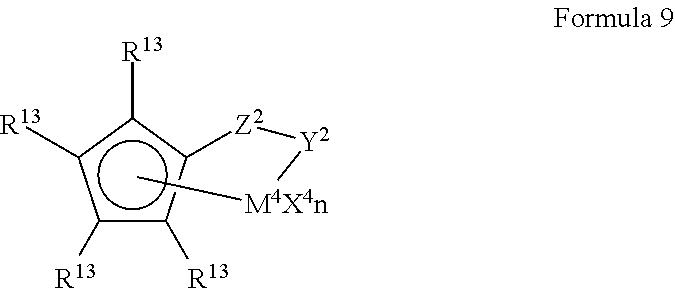

Method for manufacturing organic semiconductor composition and transistor, method for manufacturing active matrix device, method for manufacturing electro optical device, and method for manufacturing electronic apparatus

ActiveUS20070145324A1Improve stabilityImprove featuresSolid-state devicesBuilding constructionsOrganic solventActive matrix

An organic semiconductor composition comprises: an organic semiconductor material having a structural unit including at least one thiophene ring as a repeating unit; and an organic solvent including cis-decalin.

Owner:E INK CORPORATION

Paraffin inhibitor compositions and their use in oil and gas production

InactiveUS20040058827A1Desirable utilityReciprocating drilling machinesOther chemical processesSolubilityParaffin wax

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone.

Owner:BAKER HUGHES INC

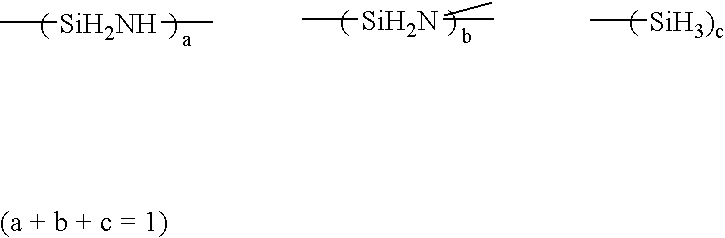

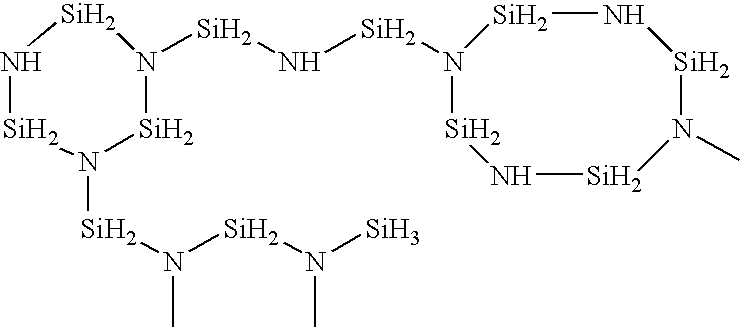

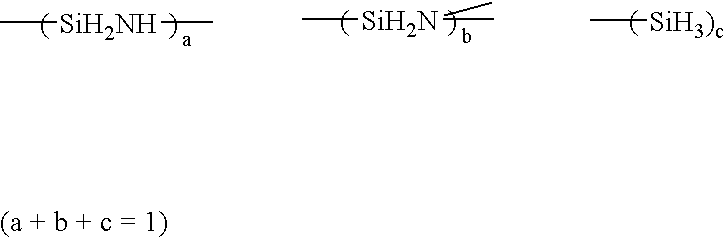

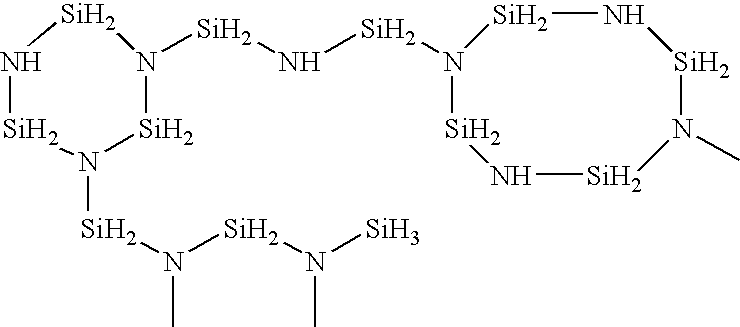

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS7344603B2Improve abilitiesAvoid adversely affecting the properties of a groundSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

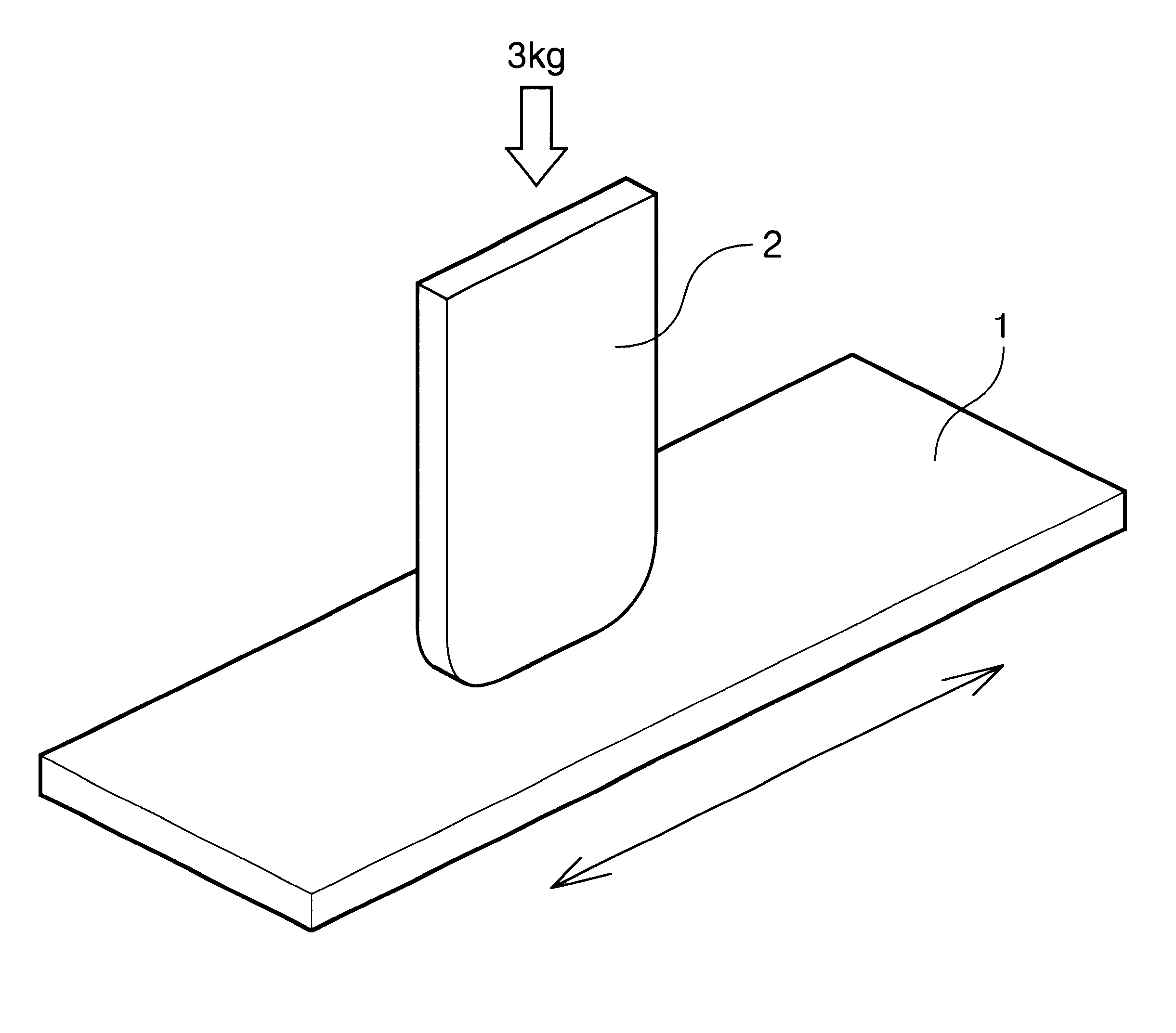

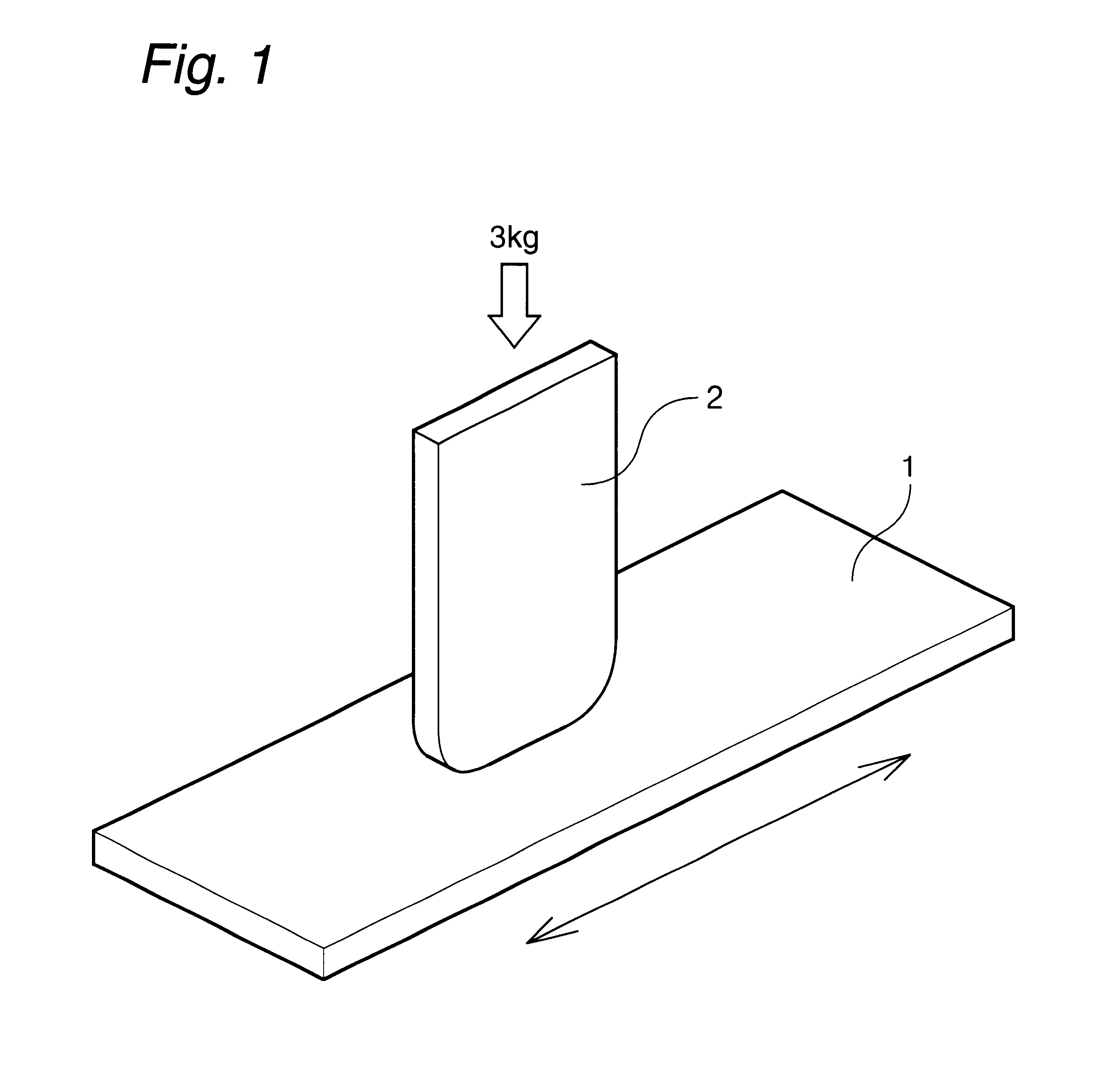

High lubricity, multi-layer polyolefin laminate

InactiveUS6706385B1Easy to slideImprove wear resistanceEngine sealsSynthetic resin layered productsPolymer sciencePolyolefin

The laminate of the invention comprises a sliding member of a resin composition and a Substrate layer of a thermoplastic olefin elastomer (A), and is obtained by co-extruding: the resin composition which is obtained by melt kneading a thermoplastic olefin elastomer (A), an ultra-high-molecular weight polyolefin (except a powder thereof having a particle diameter of 1 to 100 mum) having an intrinsic viscosity, as measured in a decalin solvent at 135° C., of 1 to 40 dl / g, an inorganic or organic filler powder, and optionally, a polyolefin resin, an organopolysiloxane, a fatty acid amide and a fluororubber in a twin-screw extruder, and the thermoplastic olefin elastomer (A). The laminate has excellent sliding properties with window glass and excellent abrasion resistance. Moreover, the laminate can be produced by a simple process because it requires no adhesive, and the laminate has great bonding strength between the substrate layer and the sliding member layer.

Owner:MITSUI CHEM INC

Thermoplastic resin composition for sealing solar cell, sheet for sealing solar cell and solar cell

InactiveUS20100000600A1Improve heat resistanceIncrease flexibilityPhotovoltaic energy generationSemiconductor devicesCross-linkSolar cell

An object of the present invention is to provide a material used for producing a sheet for sealing a solar cell which is excellent in mechanical strength, solar cell sealing property and transparency if the material is not cross-linked.The thermoplastic resin composition of the present invention for sealing a solar cell is characterized by comprising:(A) 0 to 70 parts by weight of a propylene-based polymer having a melting point of 100° C. or higher and(B) 30 to 100 parts by weight of a propylene-based copolymer satisfying the following requisite (b);(b): MFR (230° C., load: 2.16 kg) falls in a range of 0.01 to 100 g / 10 minutes, and at least one of the following requisites (b-1) and (b-2) is satisfied;(b-1): an rr fraction is 60% or more and(b-2): a structural unit derived from propylene is contained in an amount of 55 to 90 mole %, and a structural unit derived from α-olefin having 2 to 20 carbon atoms (excluding propylene) is contained in an amount of 10 to 45 mole %; and an intrinsic viscosity [η] (dL / g) measured in decalin at 135° C. and MFR described above satisfy a specific relational equation.

Owner:MITSUI CHEM INC

Polyethylene Powder for Fiber, Fiber, and Article

ActiveUS20150299903A1Increase resistanceSpeed up drawingWarp knittingKnotting netsFiberPolymer science

An object of the present invention is to provide a polyethylene powder for a fiber which is excellent in the color tone of an obtained article and allows an obtained fiber to be highly drawn, and a fiber and an article made of the polyethylene powder for a fiber. The present invention provides a polyethylene powder for a fiber, wherein the intrinsic viscosity measured at 135° C. in decalin is 10 dL / g or higher and 40 dL / g or lower, the total amount of Al, Mg, Ti, Zr, and Hf is 1.0 ppm or higher and lower than 15 ppm, the amount of a particle having a particle size exceeding 355 μm is 2.0% by mass or lower, and the amount of a particle having a particle size of 75 μm or smaller is 3.0% by mass or higher and 50.0% by mass or lower.

Owner:ASAHI KASEI CHEM CORP

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS20050027089A1Excellent propertyImprove trimming effectSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

Olefin copolymer shrink film

InactiveUS6194501B1High transparencyLow temperature shrinkabilityWrappers shrinkageFilm/foil adhesivesAlpha-olefinIntrinsic viscosity

Disclosed herein is an olefin copolymer shrink film comprising an alpha-olefin / aromatic vinyl compound random copolymer. This alpha-olefin / aromatic vinyl compound random copolymer comprises 99.9 to 58 mol % of structural units derived from ethylene, 0 to 30 mol % of structural units derived from an alpha-olefin having 3 to 20 carbon atoms (provided that the total of the structural units derived from ethylene and the structural units derived from an alpha-olefin having 3 to 20 carbon atoms ranges from 99.9 to 88 mol %), and 0.1 to 12 mol % of structural units derived from an aromatic vinyl compound. The alpha-olefin / aromatic vinyl compound random copolymer has an intrinsic viscosity [eta], as measured in decalin at 135° C., of 0.1 to 10 dl / g and has a melting point, as measured by a differential scanning calorimeter, of 60 to 125° C. The olefin copolymer shrink film is oriented in at least one direction. The olefin copolymer shrink film has excellent low-temperature shrinkability and transparency.

Owner:MITSUI CHEM INC

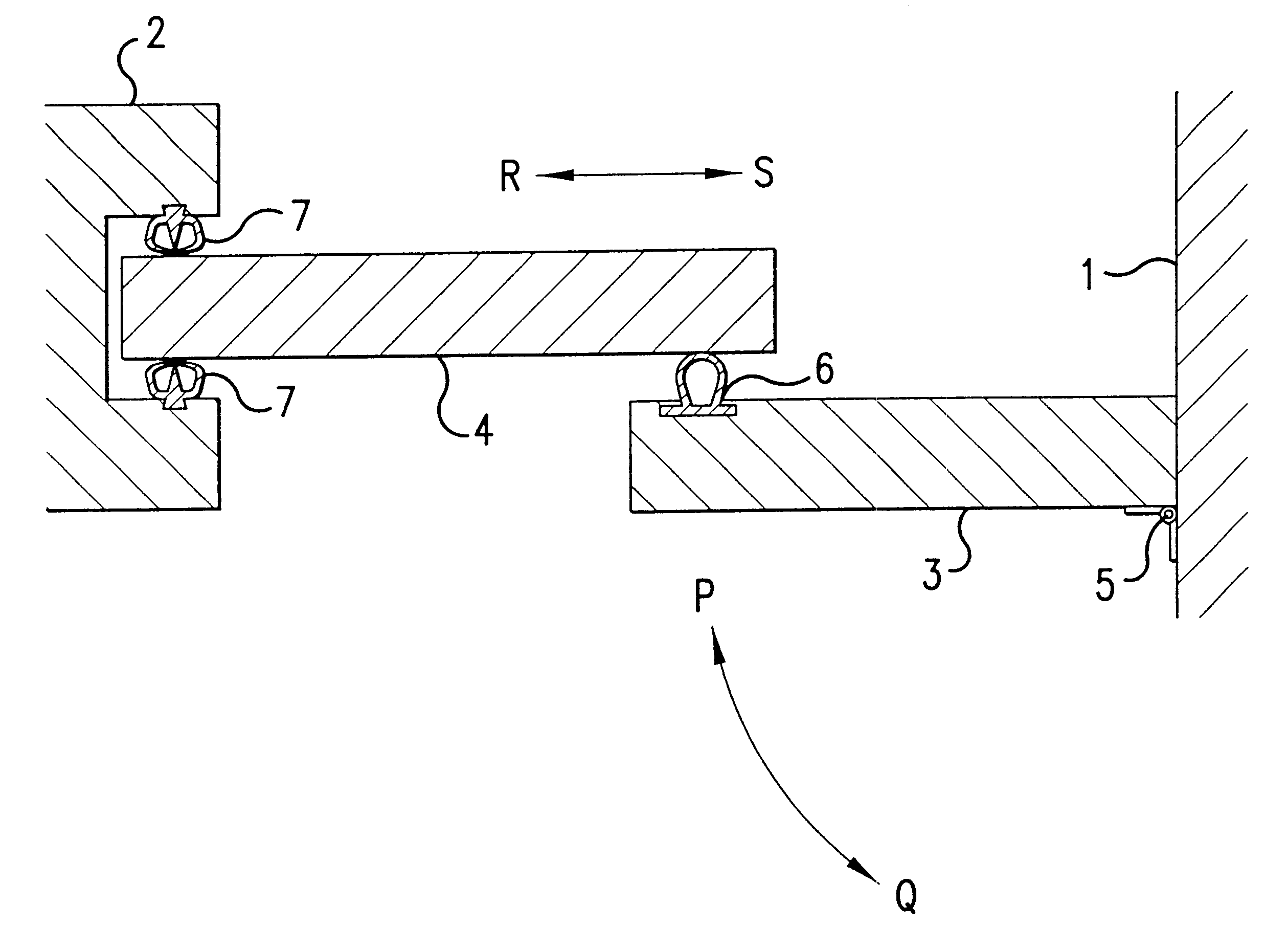

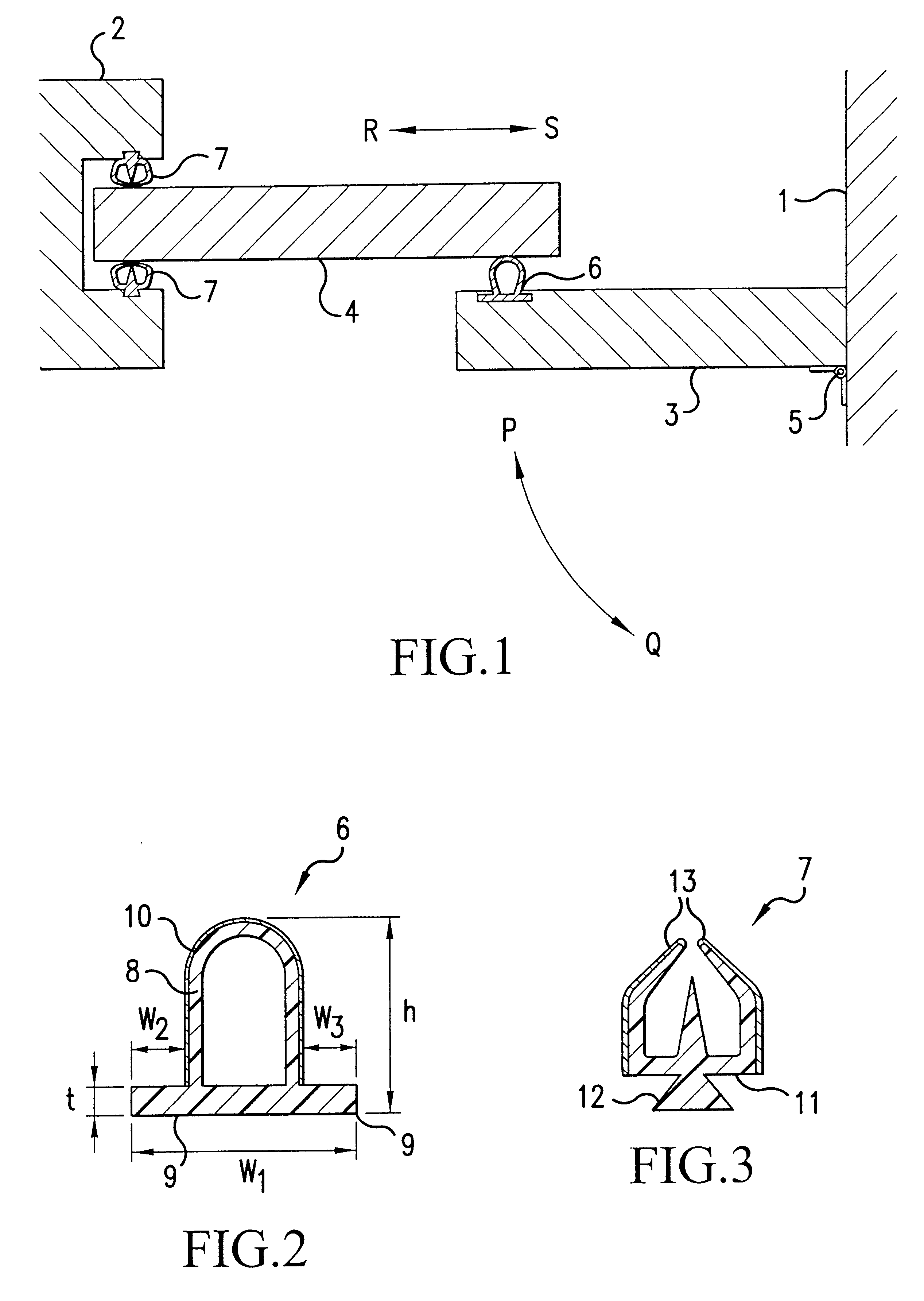

Laminated products of olefinic thermoplastic elastomer and constructional gaskets

InactiveUS6589664B1Increased durabilityMaintain good propertiesEngine sealsDomestic sealsPolyolefinThermoplastic elastomer

The present invention relates to a laminate comprising an olefinic thermoplastic elastomer which comprises:(a) a substratum layer comprising an olefinic thermoplastic elastomer composition (A) having the following characteristics {circle around (1 to {circle around (3:{circle around (1 wherein X denotes the JIS A-hardness value (a dimensionless value) of the olefinic thermoplastic elastomer composition determined according to the prescription of JIS K6301 and Y represents the compression set value (expressed by %) of the olefinic thermoplastic elastomer composition determined according to the prescription of JIS K6301 under a condition of 70° C. and 22 hours,{circle around (2 a tensile strength value in the range from 5 to 30 MPa determined according to the prescription of JIS K6301 and{circle around (3 an elongation set value of 18% or less determined according to the prescription of JIS K6301, and(b) a surface skin layer comprising an ultra high molecular weight polyolefin composition (B) having an intrinsic viscosity [eta] measured in decalin at 135° C. in the range from 3.5 to 8.3 dl / g; and a constructional gasket comprising the olefinic thermoplastic elastomer composition (A).

Owner:MITSUI CHEM INC

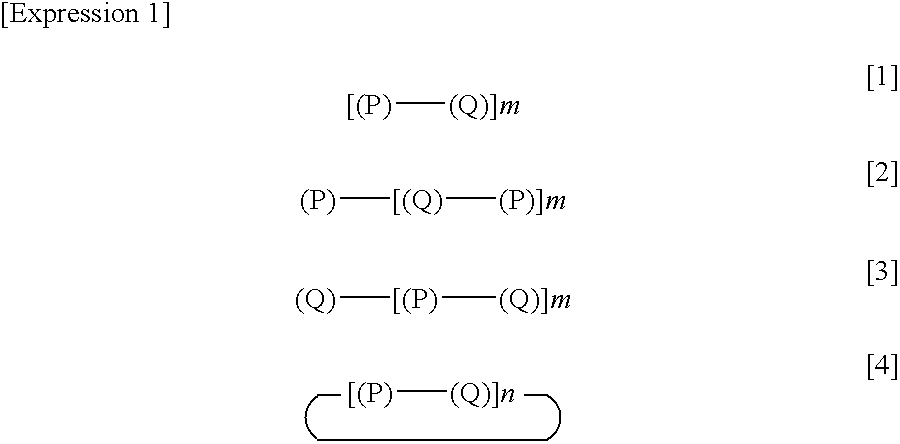

Polyolefin polymer containing vinyl groups at both ends and composition thereof

ActiveUS20100004393A1Excellent mechanical propertiesSynthetic resin layered productsMedical devicesCompression moldingPolymer science

The present invention is a polyolefin polymer containing vinyl groups at both ends thereof, and a composition and a molded product containing the polymer, wherein the polymer contains a constitutional unit derived from at least one selected from the group consisting of ethylene (a), an α-olefin (b) having 3 to 20 carbon atoms, and a cyclic olefin (c), and(1) a ratio of terminal vinylation is 70% or more relative to all of both ends of molecular chains, and(2) an intrinsic viscosity [η] is in the range of 0.01 to 10 dl / g as measured in a decalin solution at 135° C.The polymer of the present invention may be molded by a LIM molding, an injection molding, a transfer molding, a compression molding, and the like, and is excellent in acid resistance, gas permeation resistance, hydrolysis resistance, and dynamic fatigue resistance. From the polymer, a thermoplastic resin composition and a crosslinkable resin composition, and a crosslinked composition having excellent mechanical characteristics are obtained.

Owner:MITSUI CHEM INC

Resin composition based on crystalline polypropylene

InactiveUS20020058741A1High crystallinityGood molding effectFilm/foil adhesivesMixingFlexural modulusIntrinsic viscosity

Present invention provides a resin composition bases on crystalline polypropylene which does not suffer from occurrence of flow mark and rashes caused from polymer gel upon molding and, thus, can produce molded articles exhibiting superior appearance and having excellent mechanical strength, such as flexural modulus and so on, together with better flowability upon the molding and which can be obtained at a lower cost by choosing starting materials of high productivity. The resin composition based on crystalline polypropylene according to the present invention comprises (a) 3-65% by weight of a component soluble in paraxylene of 23° C. (b) 35-97% by weight of a component soluble in paraxylene of 135° C. and insoluble in paraxylene of 23° C. and (c) 0-30% by weight of a component insoluble in paraxylene of 135° C., wherein the component (a) soluble in paraxylene of 23° C. is composed substantially of an elastomeric constituent (a1) having a content of styrene or its derivative in the range of 0-35% by weight and an intrinsic viscosity [eta] determined in decalin at 135° C. in the range of 0.1-5 dl / g, the component (b) soluble in paraxylene of 135° C. and insoluble in paraxylene of 23° C. is composed substantially of a crystalline polypropylene constituent (b1) having an isotactic pentad proportion (mmmm) of 97% or higher, a molecular weight distribution expressed by weight-average molecular weight / number-average molecular weight (Mw / Mn), determined by gel permeation chromatography (GPC), of 6 or higher and a molecular weight distribution expressed by z-average molecular weight / weight-average molecular weight (Mz / Mw) of 6 or higher and the component (c) insoluble in paraxylene of 135° C. is composed substantially of a filler (c1).

Owner:MITSUI CHEM INC

Method for synthesizing decalin

InactiveCN102320913AReasonable useEfficient use ofHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogenOrganic solvent

The invention relates to a method for synthesizing decalin, which comprises the following specific steps: naphthalene is dissolved in an organic solvent to be prepared into a reaction raw material, then a prepared catalyst Pd / gamma-Al2O3 is arranged in a reaction tube of a fixed bed reactor, the upper part and the lower part of the reaction tube are filled with quartz sand, the raw material enters the fixed bed reactor through a high-pressure infusion pump for reaction so as to obtain the decalin, wherein the reaction temperature is controlled to be 100-280 DEG C, the reaction pressure is 1.5-4.0Mpa, the liquid hour mass space velocity is 0.5-2.0h-1, and the hydrogen oil ratio is 80-1000. The maximum conversion rate of the naphthalene reaches 99.92%, and the yield of the decalin reaches 99.36%.

Owner:NANJING UNIV OF TECH

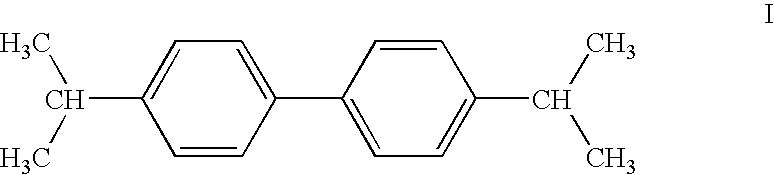

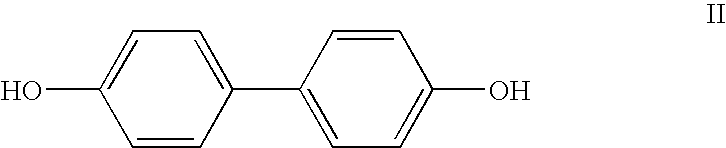

Continuous preparation of 4,4'-diisopropylbiphenyl

A continuous flow process has been discovered for the highly selective isopropylation of biphenyl to 4,4′-diisopropylbiphenyl. Thus biphenyl and propene in decalin are passed through a solid zeolite catalyst bed contained in a flow reactor at moderate temperature (220° C.) and pressure (10-30 atm) together with a continuous stream of nitrogen. Surprisingly, catalyst performance is improved by the continuous introduction of the nitrogen into the reactor along with the reactants and solvent. Thus, improved performance as measured by higher percent conversion to products, higher yields of diisopropylated products and lower yields of undesired triisopropylated products are observed when a diluent gas such as nitrogen is employed. The alkylation process is selective for 4,4′-diisopropylbiphenyl using a zeolite catalyst, preferably a dealuminated mordenite in which the molar ratio of SiO2 to Al2O3 moieties is in a range between about 10 to 1 and about 500 to 1.

Owner:GENERAL ELECTRIC CO

Composition of polyamide and acid or anhydride-grafted ethylene/C6-C20 alpha -olefin copolymer

The polyamide resin composition of the invention comprises 100 parts by weight of a polyamide resin (A) and from 5-200 parts by weight of a graft-modified ethylene / alpha -olefin random copolymer (B) which is obtained by graft-modifying an ethylene / alpha -olefin random copolymer of ethylene and an alpha -olefin of 6 to 20 carbon atoms with an unsaturated carboxylic acid or its derivative and has a graft quantity of 0.01 to 10% by weight. The graft-modified ethylene / alpha -olefin random copolymer (B) is a graft-modified product of an ethylene / alpha -olefin random copolymer having an alpha -olefin content of from 6 to 25% by mole and an intrinsic viscosity of from 0.5 to 5.0 dl / g measured in decalin at 135 DEG C.

Owner:MITSUI CHEM INC

Highly pure, terminal-unsaturated olefin polymer and process for production thereof

Provided are a highly-pure, terminal-unsaturated olefin polymer which is produced through homopolymerization or copolymerization of one or more α-olefins having from 3 to 28 carbon atoms, or copolymerization of at least one α-olefin having from 3 to 28 carbon atoms and ethylene, in the presence of a catalyst, and which satisfies the following (1) to (4); and a method of efficiently producing the olefin polymer having a high degree of terminal unsaturation degree and containing little catalyst residue.(1) The content of the transition metal derived from the catalyst is at most 10 ppm by mass, the content of aluminium is at most 300 ppm by mass, and the content of boron is at most 10 ppm by mass;(2) The polymer has from 0.5 to 1.0 vinylidene group / molecule as the terminal unsaturated group;(3) The polymer has an intrinsic viscosity [η], as measured in decalin at 135° C., of from 0.01 to 2.5 dl / g;(4) The polymer has a molecular weight distribution (Mw / Mn) of at most 4.

Owner:IDEMITSU KOSAN CO LTD

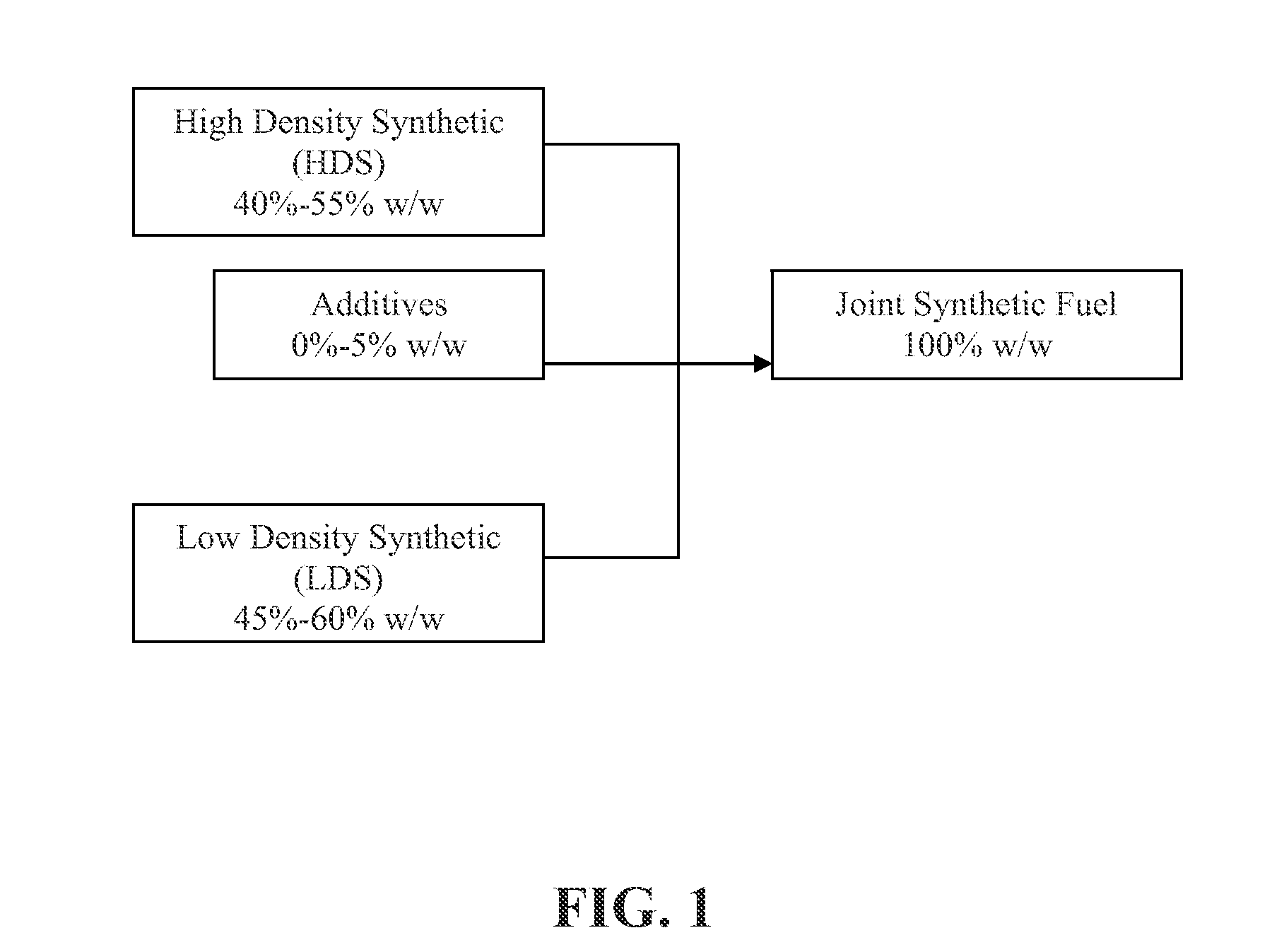

Fomula for Joint Synthetic Jet, Rocket, And Diesel Fuel

A synthetic fuel formula using a blend of High Density Synthetic (HDS) (e.g. Decalin and Tetralin), and Low Density Synthetic (LDS) (e.g. Synthetic Paraffinic Kerosene—SPK) is disclosed. This HDS and LDS blend has been shown to be useful as a jet, rocket and diesel fuel of standard density, and under low temperature conditions. The inventions described herein relate to 100% synthetic hydrocarbon fuels derived from various carbonaceous materials such as, but not limited to, biomass, municipal waste, natural gas, and coal. This 100% synthetic fuel can be universally used for both jet and diesel fuels. It meets Joint Battlefield Use Fuel of the Future (J-BUFF), or Single Battlefield Fuel (SBF) strategic requirements. The commercial advantage of the present invention is that it can be prepared from commercial available fuel stocks or co-processed using currently available chemical processes.

Owner:KNIGHT ROY CAMERON +3

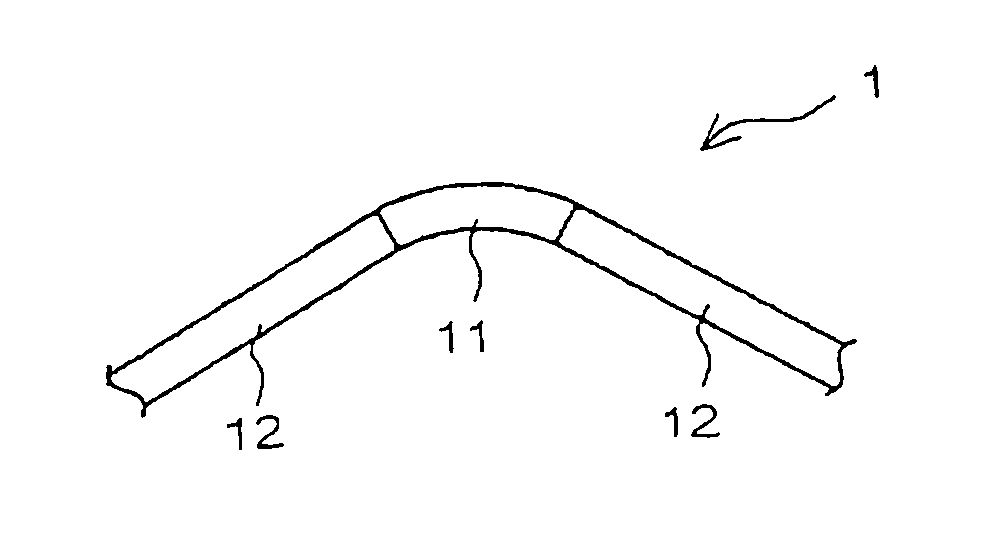

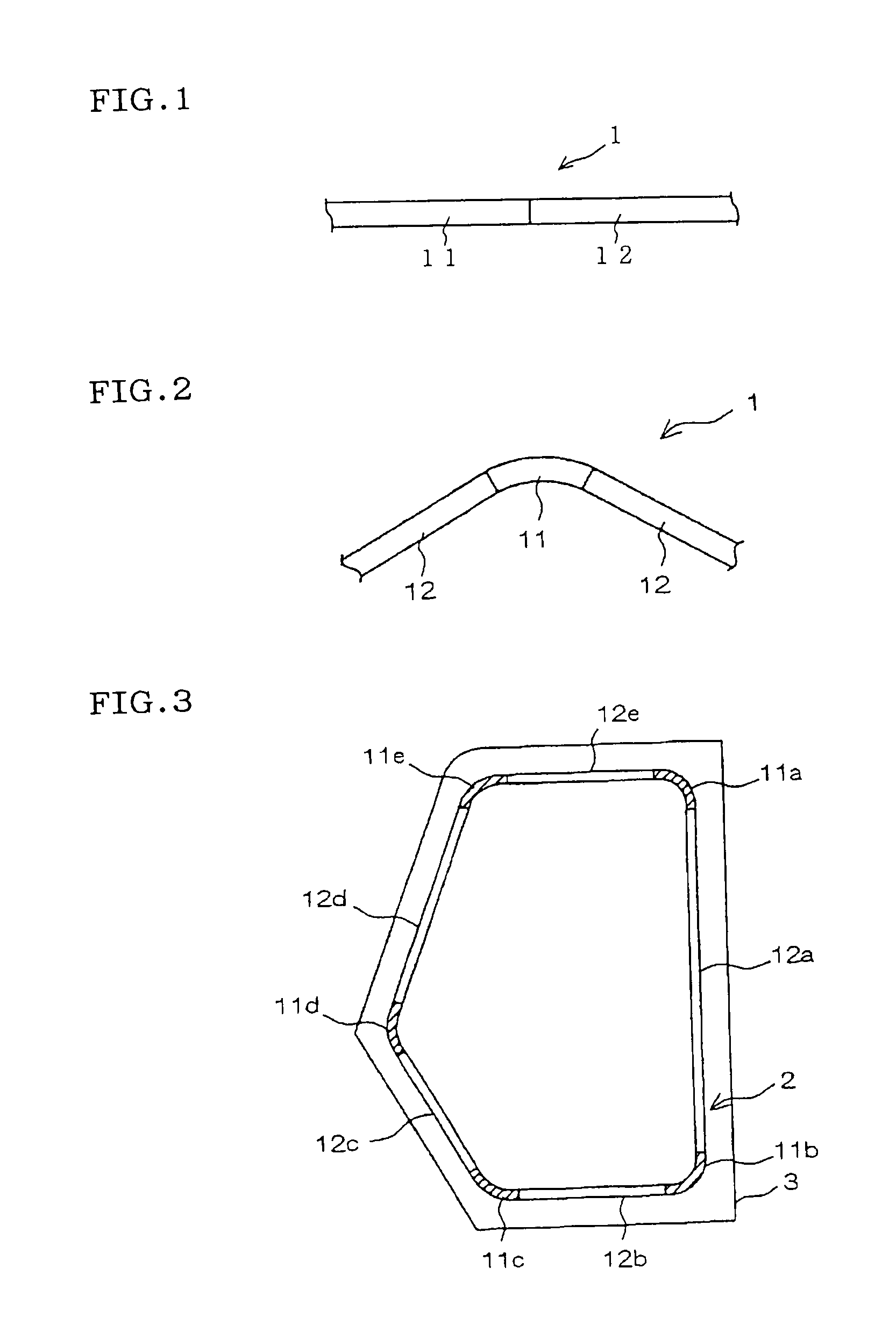

Molded Composite Material and Process for Production Thereof

InactiveUS20090176045A1Improved compression setGood adhesivenessMouldsSynthetic resin layered productsPolyolefinPolymer science

A molded composite comprising a first molded part 11 and a second molded part 12 which is bonded to the surface and / or a cross-sectional surface of the first molded part 11 is disclosed. The first molded part 11 is obtained by extrusion foam molding of an olefin thermoplastic elastomer composition, comprising (A) an ethylene-α-olefin copolymer rubber having an intrinsic viscosity [η] of 3.5 to 6.8 dl / g as measured at 135° C. in a decalin solvent, (B) a polyolefin resin, and (C) a mineral oil-based softener in a predetermined proportion and obtained by dynamically heat-treating a mixture of at least (A) the ethylene-α-olefin copolymer rubber and (B) the polyolefin resin in the presence of a cross-linking agent, at an expansion ratio of 1.2 times or more and the second molded part 12 is obtained by injection molding of the olefin thermoplastic elastomer composition and / or another thermoplastic elastomer composition and bonded to the surface and / or a cross-sectional surface of the first molded part 11.

Owner:JSR CORPORATIOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com