Thermoplastic polyolefins with high flowability and excellent surface quality produced by a multistage process

a multi-stage process and polyolefin technology, applied in the field of thermoplastic polyolefins, can solve the problems of tigerstripes or flow marks, common surface quality problems, and inability to completely prevent marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Base Resin According to the Invention

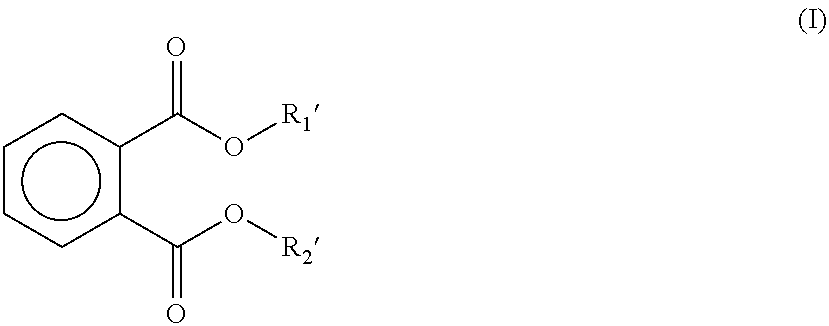

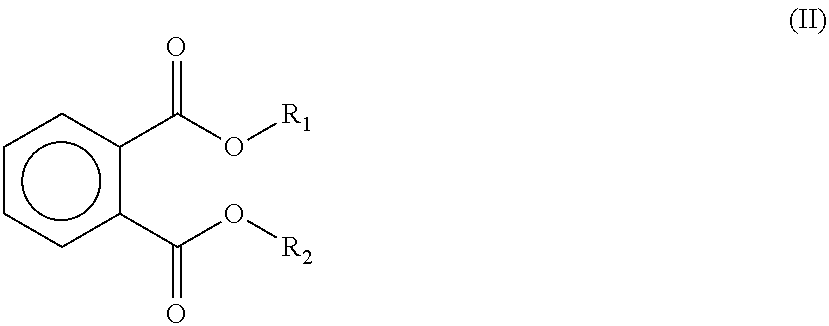

The base resin was produced in a plant having a prepolymerization reactor, a loop reactor and two fluid bed gas-reactors connected in series. The catalyst used in the polymerization was prepared according to WO 92 / 19653 with DOP as dialkylphthalat of the formula (I) and ethanol as alcohol, the cocatalyst was Triethylaluminium (TEA) and as an external donor (D) diethylamino triethoxy silane was used.

After a first pre-polymerisation step the catalyst system was fed to the slurry reactor, where the polymerisation of the polypropylene homopolymer matrix phase was performed. The slurry phase loop reactor was then followed by a first gas phase reactor in series, in which a first elastomeric rubber disperse phase was produced by copolymerisation of propylene with ethylene comonomer. The polymerisation temperature in the slurry phase loop reactor was 62° C., whereas the temperature in the first gas phase reactor was 80° C. After transfer t...

example 2

In order to show the advantageousness of the catalyst system used according to inventive Example 1 in comparison to the catalyst system used according to EP 1 600 480 (ZN104 (commercially available from LyondellBasell), triethylaluminium as cocatalyst and dicyclopentyldimethoxysilane as external donor) regarding fines produced during production of the polypropylene matrix, several polypropylene matrices with different MFR were produced in the above described plant set up and the amount of fines produced in the loop reactor were determined by sieving the polymer powder obtained from the loop reactor.

The powder passing a 0.180 mm screen was considered as fines.

TABLE 1wt % of finesMFRpp-matrixCat. of Example 1 / [g / 10 min]ZN104 / DCDMSDEATES502.5 wt %0.9 wt %1005.4 wt %1.2 wt %250n.a.1.4 wt %DCDMS dicyclopentyl dimethoxy silaneDEATES diethylamino triethoxy silanen.a. not applicable

With the combination of ZN104 / DCDMS it was not possible to produce a polypropylene matrix with an MFR of above...

example 3

Testing of the Base Resin

The base resin (RTPO) was initially obtained in powder form.

The resin together with 10 wt % Tital15 (talc from Ankerport) and 0.1% NA11 as well as 10 wt % of EG8200 (elastomer Engage®8200 from DuPont Dow Elastomers) were pelletized by feeding the blend to a Prism 24twin-screw extruder (Prism Ltd., Staffordshire, UK). The polymer was extruded through a strand die, cooled and chopped to form pellets.

TABLE 2Properties of compounded RTPOMFR 230° C. / 2.16 kg[g / 10′]29.2Flexural Modulus [MPa]1281Tensile Modulus [MPa]1229Impact - Charpy NIS(23° C.) [kJ / m2]17.5Impact - Charpy NIS(0° C.) [kJ / m2]8.2Impact - Charpy NIS(−20° C.) [kJ / m2]5.5Shrinkage longitudinal [%]0.58Shrinkage lateral [%]0.9

Surface Quality (Tigerskin)

Plaques of a dimension of 210×189×3 mm3, grained with VW grain K50, were produced under following conditions:

Melt temperature: 240° C.

Mold temperature: 30° C.

Dynamic pressure: 10 bar hydraulic

The filmgate over the whole width had a thickness of 1.4 mm.

With t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| intrinsic viscosity IV | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com