Heterophasic polypropylene copolymer composition

A technology of heterogeneous polypropylene and propylene copolymers, applied in the direction of coating, etc., can solve the problems that wave flow marks cannot be completely prevented, and the physical properties of polymer compositions are not satisfactory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

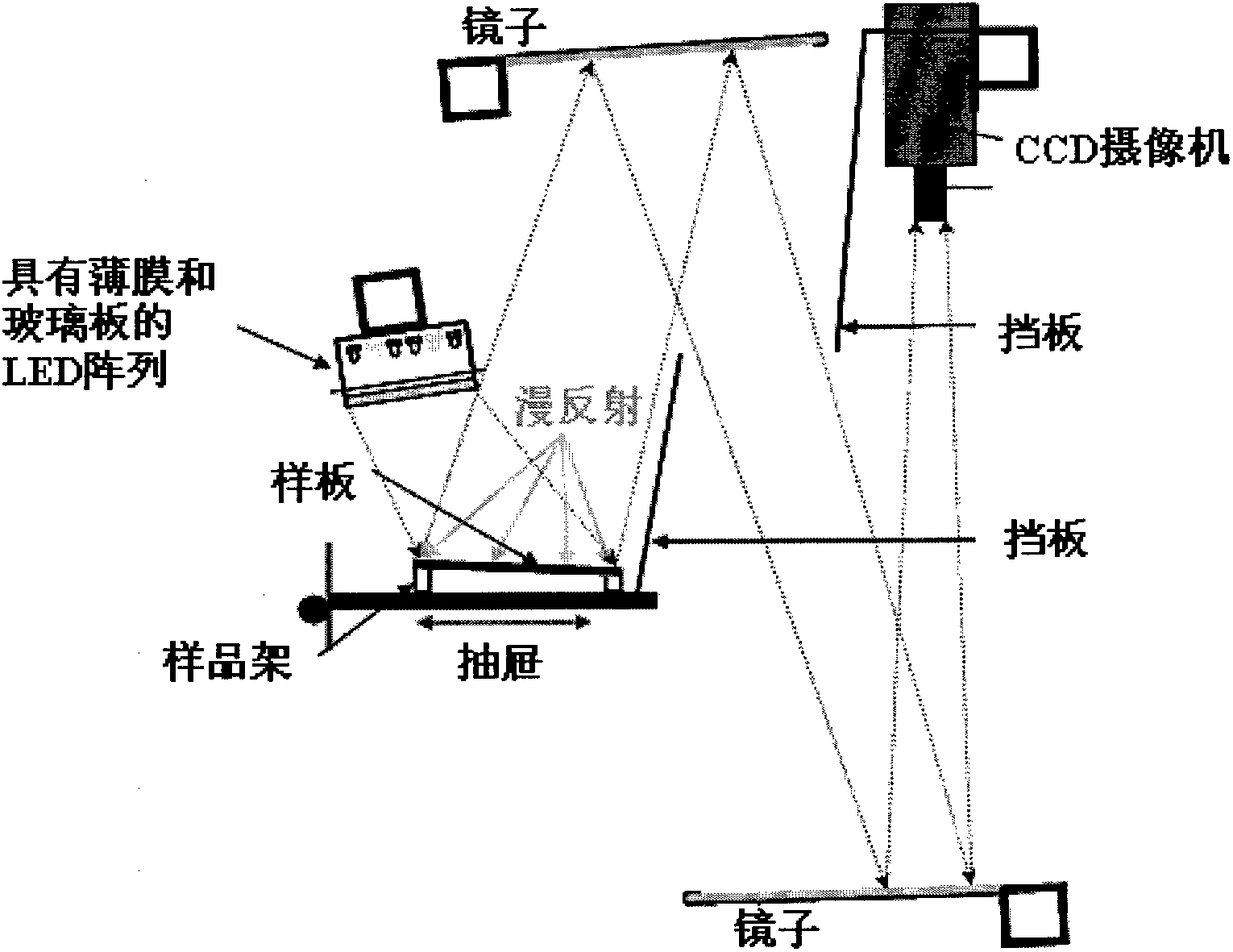

Image

Examples

Embodiment

[0161] Hereinafter, the present invention will be further illustrated by examples.

[0162] method:

[0163] a) Melt flow rate:

[0164] Melt flow rate is the MFR of polypropylene measured according to ISO 1133 (230°C, 2.16 kg load) unless otherwise stated 2 , and take g / 10min as the unit. MFR is an indication of the flowability and processability of a polymer. The higher the melt flow rate, the lower the viscosity of the polymer.

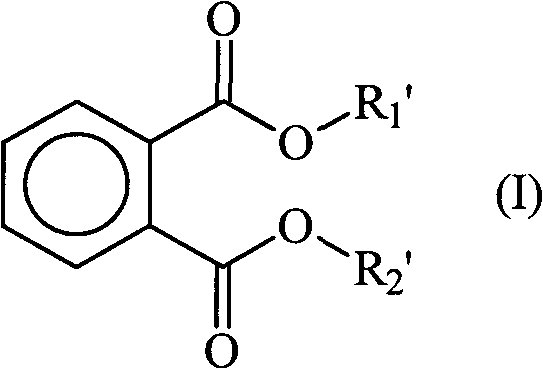

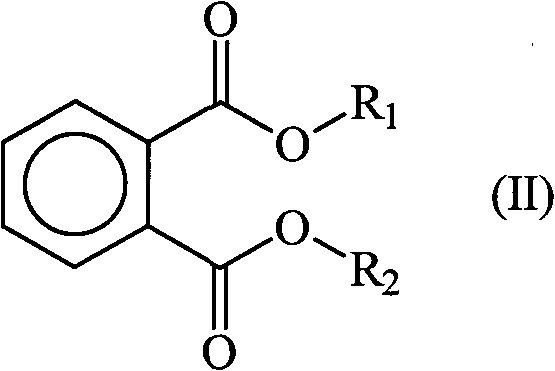

[0165] b) Comonomer content:

[0166] The comonomer content depends on the 13 C-NMR calibrated Fourier transform infrared spectroscopy (FTIR) was measured. When determining the ethylene content in polypropylene, film samples (thickness about 250 mm) were prepared by hot pressing. -CH2 - Absorption peak (800-650cm -1 ) area was measured with a Perkin Elmer FTIR 1600 spectrometer. The method by 13 The ethylene content data determined by C-NMR were calibrated.

[0167] c) Flexural modulus

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com