Patents

Literature

350 results about "Trimethyl benzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethyl Benzene is a colorless liquid with a distinct odor. It is used in making dyes, pharmaceuticals and antioxidants, and as a solvent. REASON FOR CITATION. * Trimethyl Benzene is on the Hazardous Substance List because it is cited by ACGIH, DOT, NIOSH, DEP and NFPA.

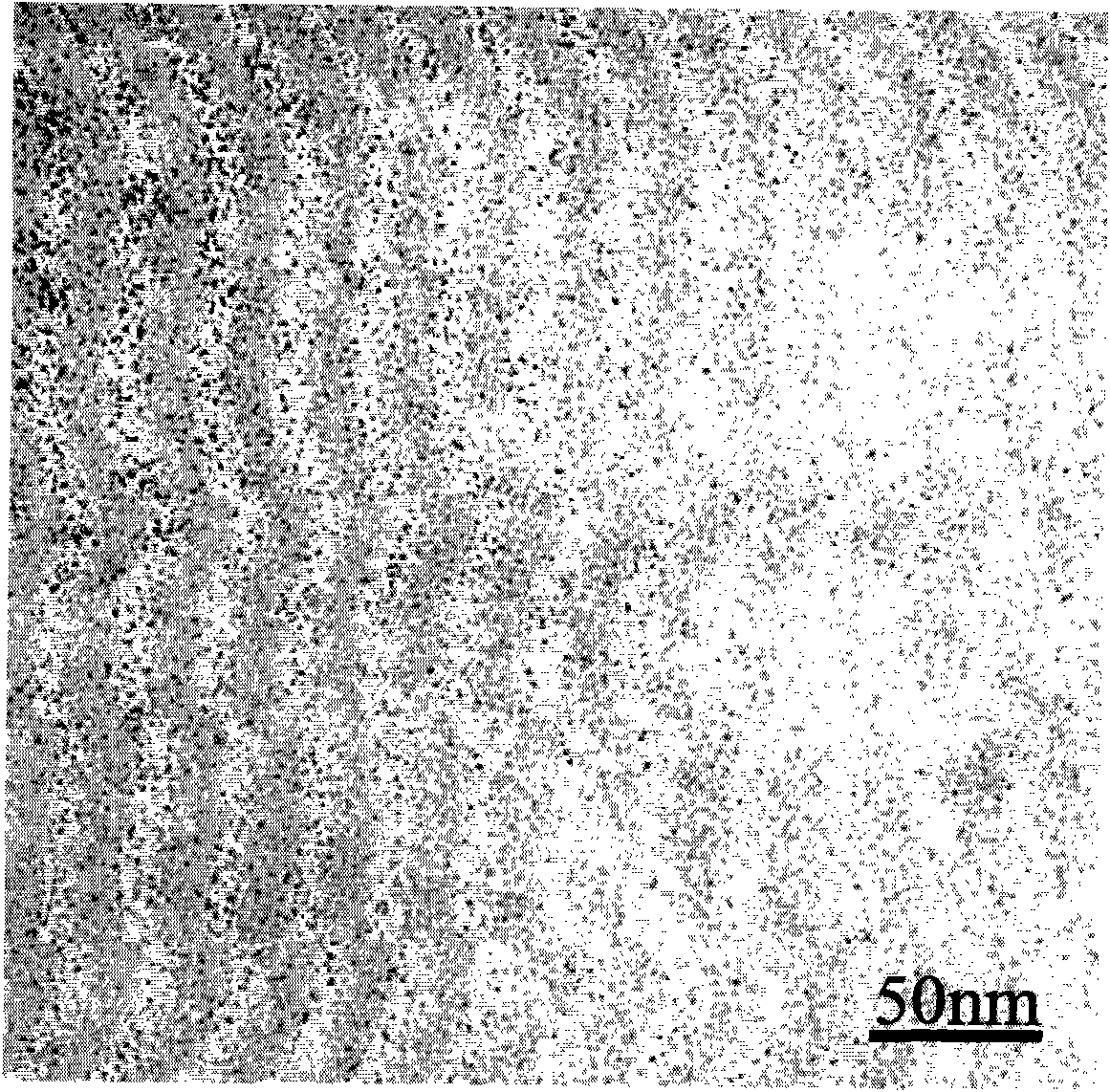

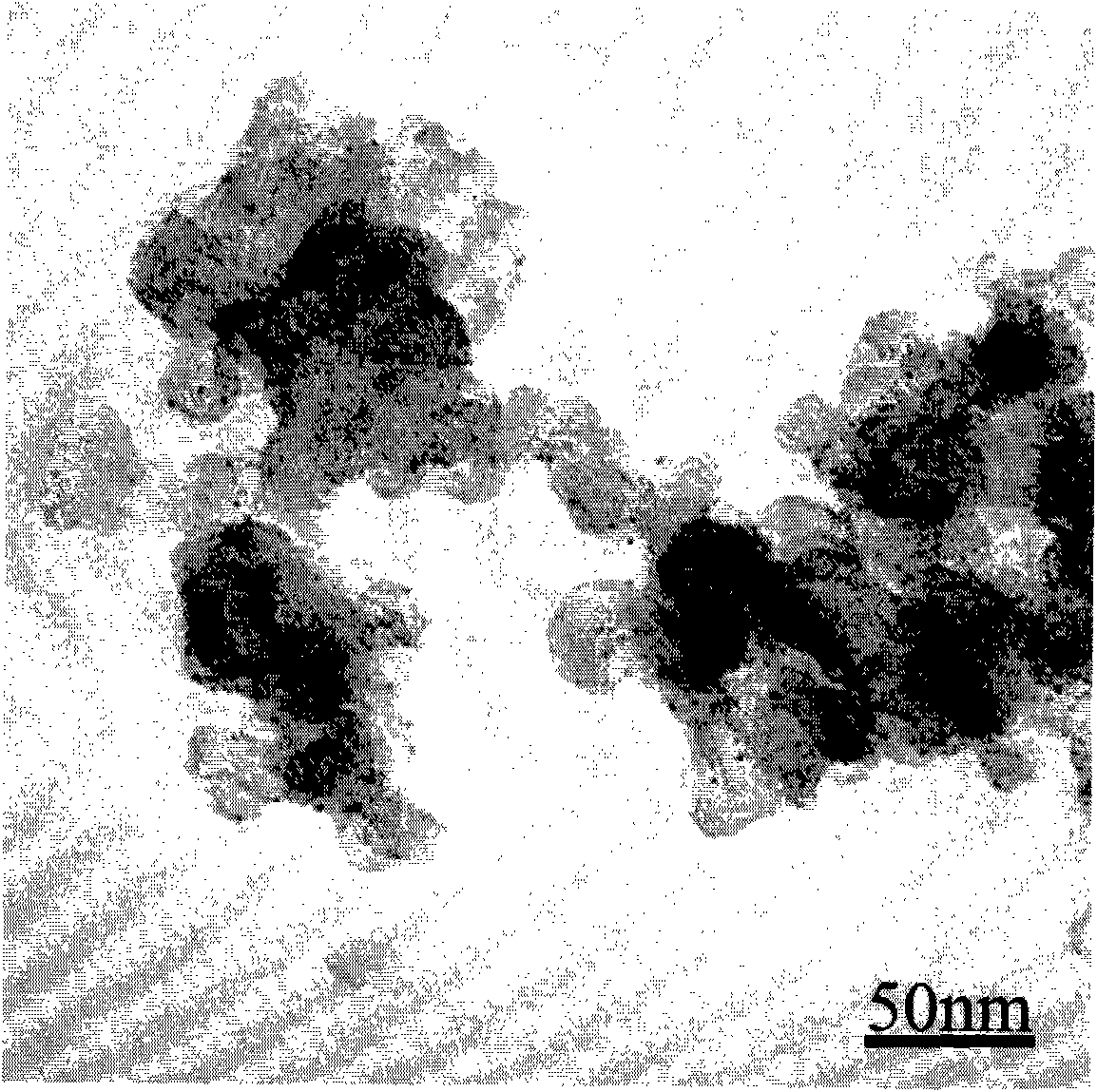

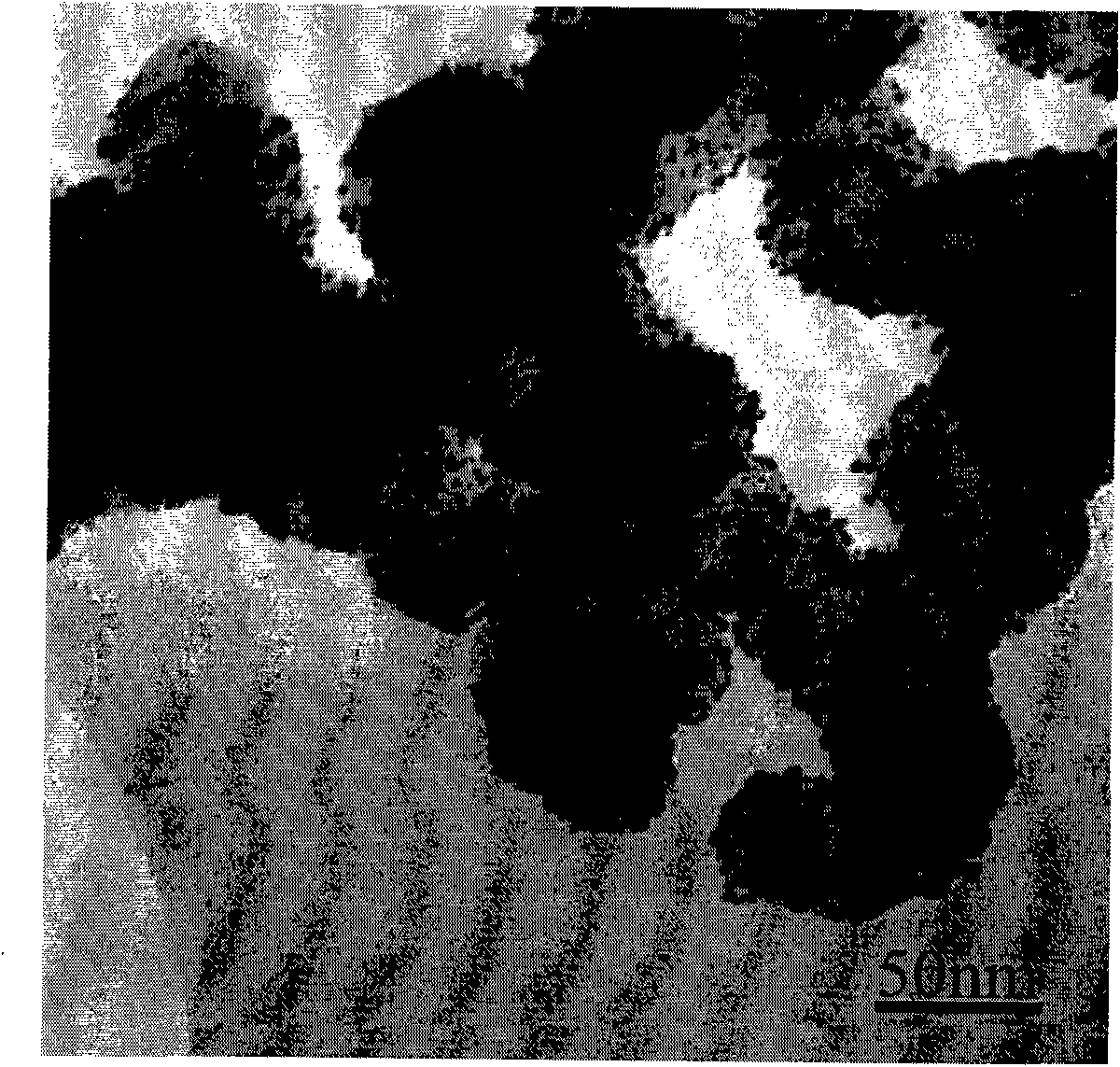

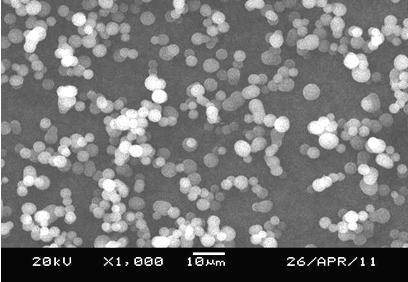

Supported transition metal or transition metal alloy nanocluster catalyst and preparation method and application thereof

InactiveCN101670286AImprove availabilityImprove adsorption capacityOrganic compound preparationHydroxy compound preparationIonSolvent

The invention discloses a transition metal or an alloy nanocluster catalyst and preparation method and application thereof. The invention prepares a supported transition metal or an alloy nanoclustercatalyst by a new method in which a transition metal or an alloy nanocluster which is synthesized by an alkali-polyol method and stabilized by solvent and simple ions is supported on a carbon or oxidecarrier. The content of the transition metal or alloy nanocluster in the catalyst is 0.1-50wt%, and the particle size is 0.7-5nm. The transition metal or alloy nanocluster in the catalyst is distributed on the outer surface or in mesopores and macropores of the carrier material, and the atoms on the surface of the metal or alloy nanocluster have high availability. The catalyst has good catalyticperformance on the hydrogenation of 2,3,5-trimethylquinone, and the catalytic activity of the prepared Pt / Al2O3 and Pt / C supported metal nanocluster catalyst on the hydrogenation of the 2,3,5-trimethylquinone is much higher than that of the corresponding commercially available catalysts.

Owner:PEKING UNIV

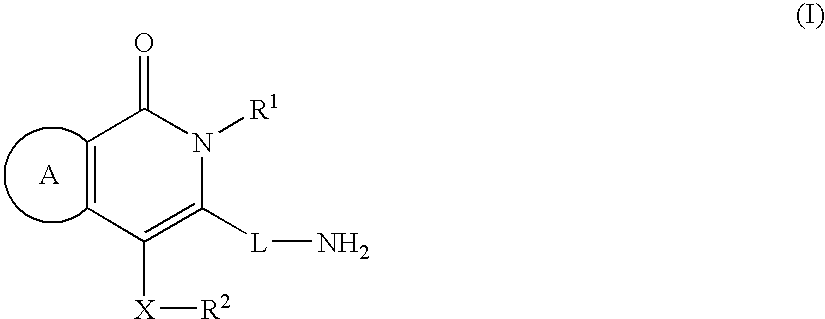

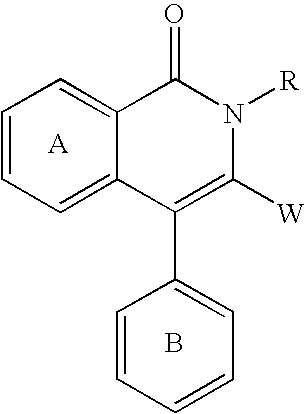

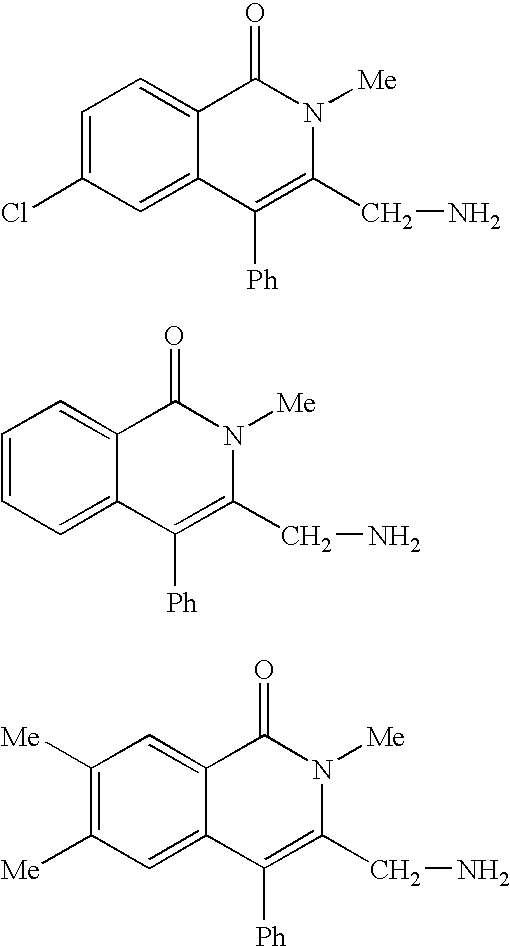

Fused heterocyclic compounds

The present invention provides a compound of the formula: wherein ring A is an optionally substituted 5 to 10-membered aromatic ring; R1 and R2 are the same or different and each is an optionally substituted hydrocarbon group or an optionally substituted heterocyclic group; X is a bond and the like; and L is a divalent hydrocarbon group, and a salt thereof, except 3-(aminomethyl)-2,6,7-trimethyl-4-phenyl-1(2H)-isoquinolinone, 3-(aminomethyl)-2-methyl-4-phenyl-1(2H)-isoquinolinone, 3-(aminomethyl)-6-chloro-2-methyl-4-phenyl-1(2H)-isoquinolinone and 3-(aminomethyl)-2-isopropyl-4-phenyl-1(2H)-isoquinolinone. The compound shows a superior peptidase-inhibitory activity and is useful as an agent for the prophylaxis or treatment of diabetes and the like.

Owner:TAKEDA PHARMA CO LTD

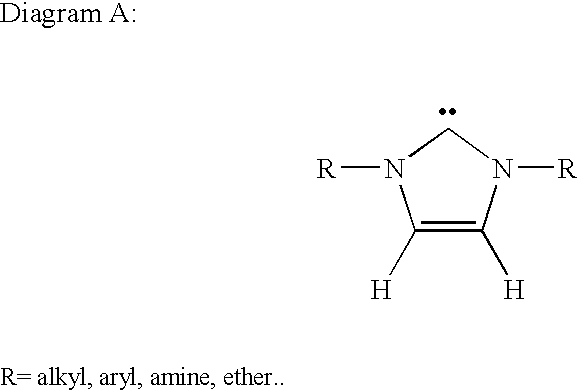

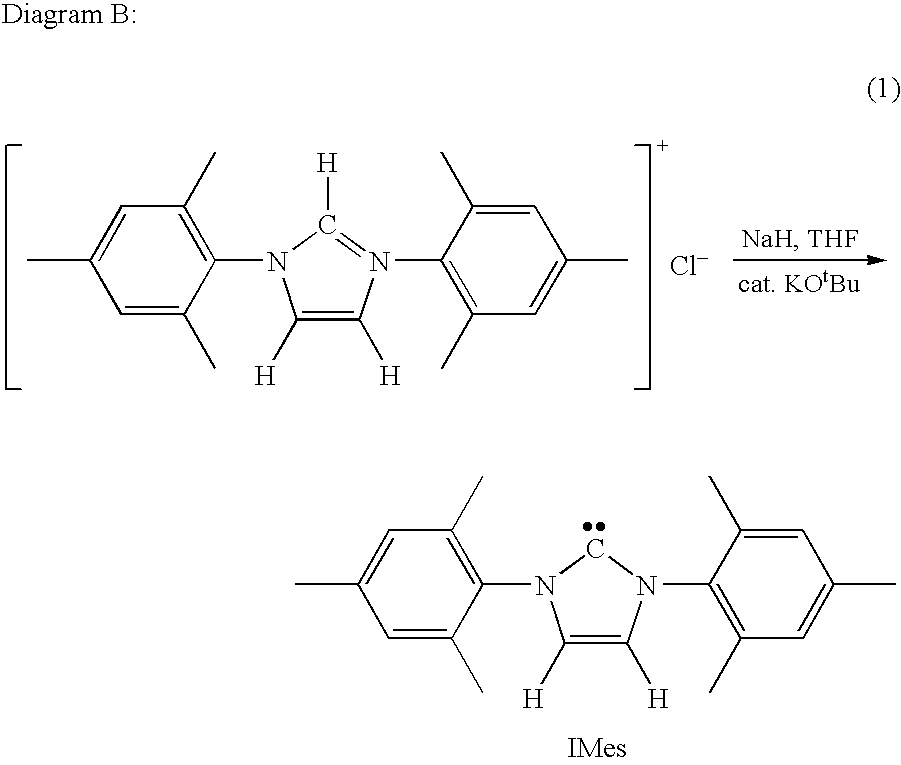

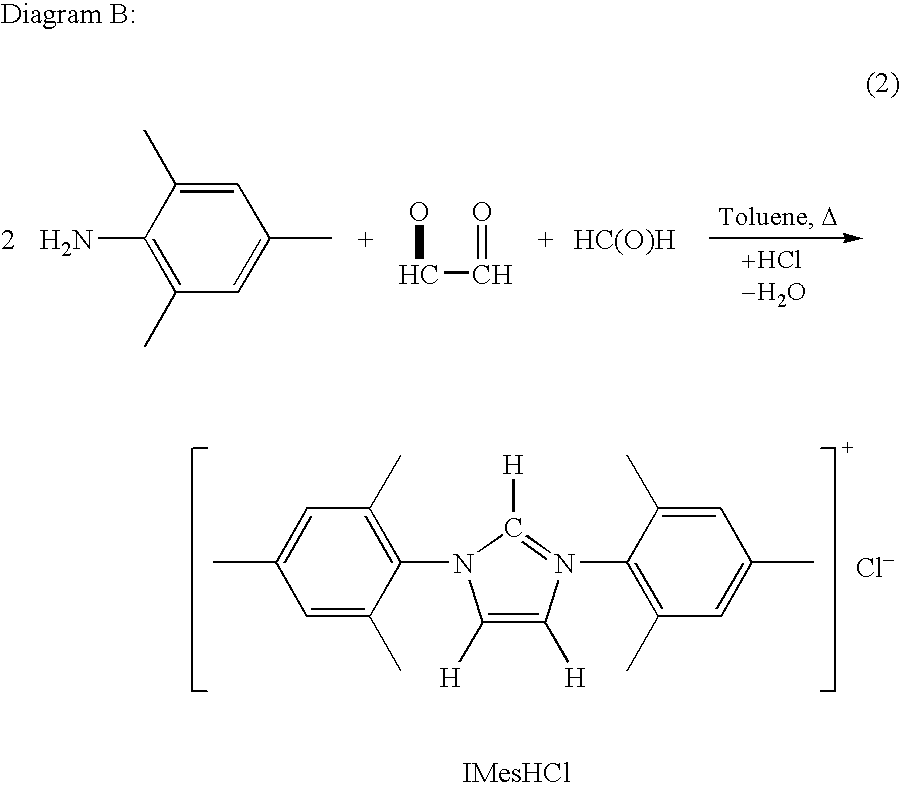

Synthesis of 1,3 distributed imidazolium salts

Imidazolium salts are the immediate precursors to N-heterocyclic carbenes (NHC) yet a simple, general synthetic route to a wide variety of imidazolium salts is not yet available. Such a straightforward route is described for two specific members of this family of ligand precursor: 1,3-Bis(2,4,6-trimethylphenyl)imidazolium chloride (IMes.HCl) and 1,3-Bis(2,6-diispropylphenyl)imidazolium chloride (IPr.HCl). The procedure appears general and similar protocols can be used to isolate various imidazolium salts.

Owner:UNIV OF NEW ORLEANS RES & TECH FOUND INC A NON PROFIT LOUISIANA

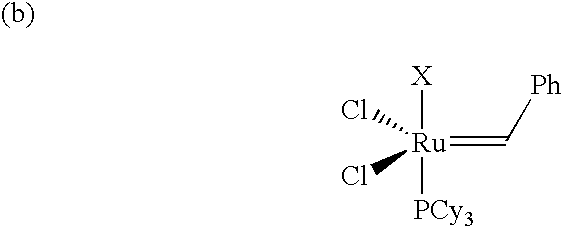

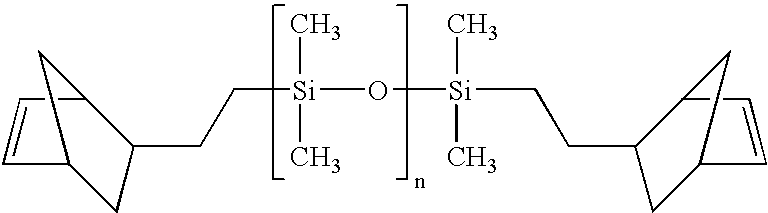

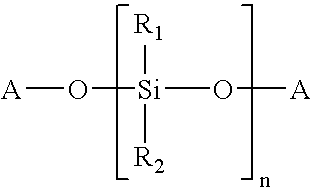

Composition curable by metathesis reaction

InactiveUS6844409B2Increase alkalinityImpression capsGroup 8/9/10/18 element organic compoundsEndcappingOligomer

A composition curable by a metathesis reaction and comprising an olefin-containing resin system and metathesis catalyst. The resin system comprises siloxane-based oligomers or polymers end-capped and / or tethered with olefin functional groups that are capable of undergoing a metathesis reaction. The composition also includes a ruthenium carbene complex catalyst, whereby the catalyst initiates the metathesis reaction of the composition. The oligomer or polymer may be, for example, one or a combination of a telechelic polydimethylsiloxane end-capped with norbornenylethyl groups, a polydimethylsiloxane tethered and end-capped with norbornenylethyl groups, a tri-functional polydimethylsiloxane end-capped with norbornenylethyl groups, or a quadri-functional polydimethylsiloxane end-capped with norbornenylethyl groups. The catalyst may be, for example, a ruthenium carbene complex, such as 1,3-bis-(2,4,6-trimethylphenyl)-2-(imidazolidinylidene) dichloro(o-isopropoxyphenylmethylene) ruthenium.

Owner:THE KERR

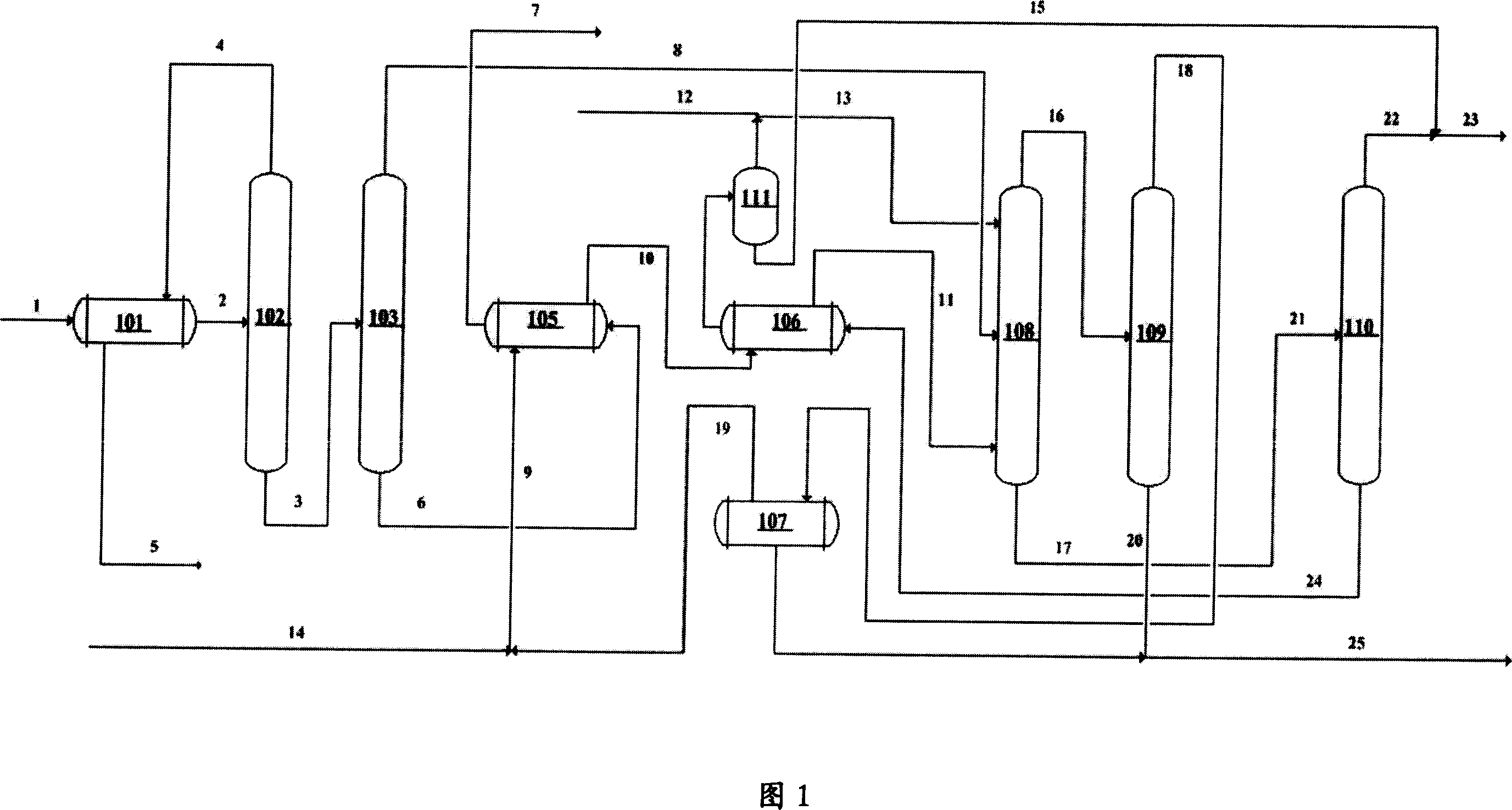

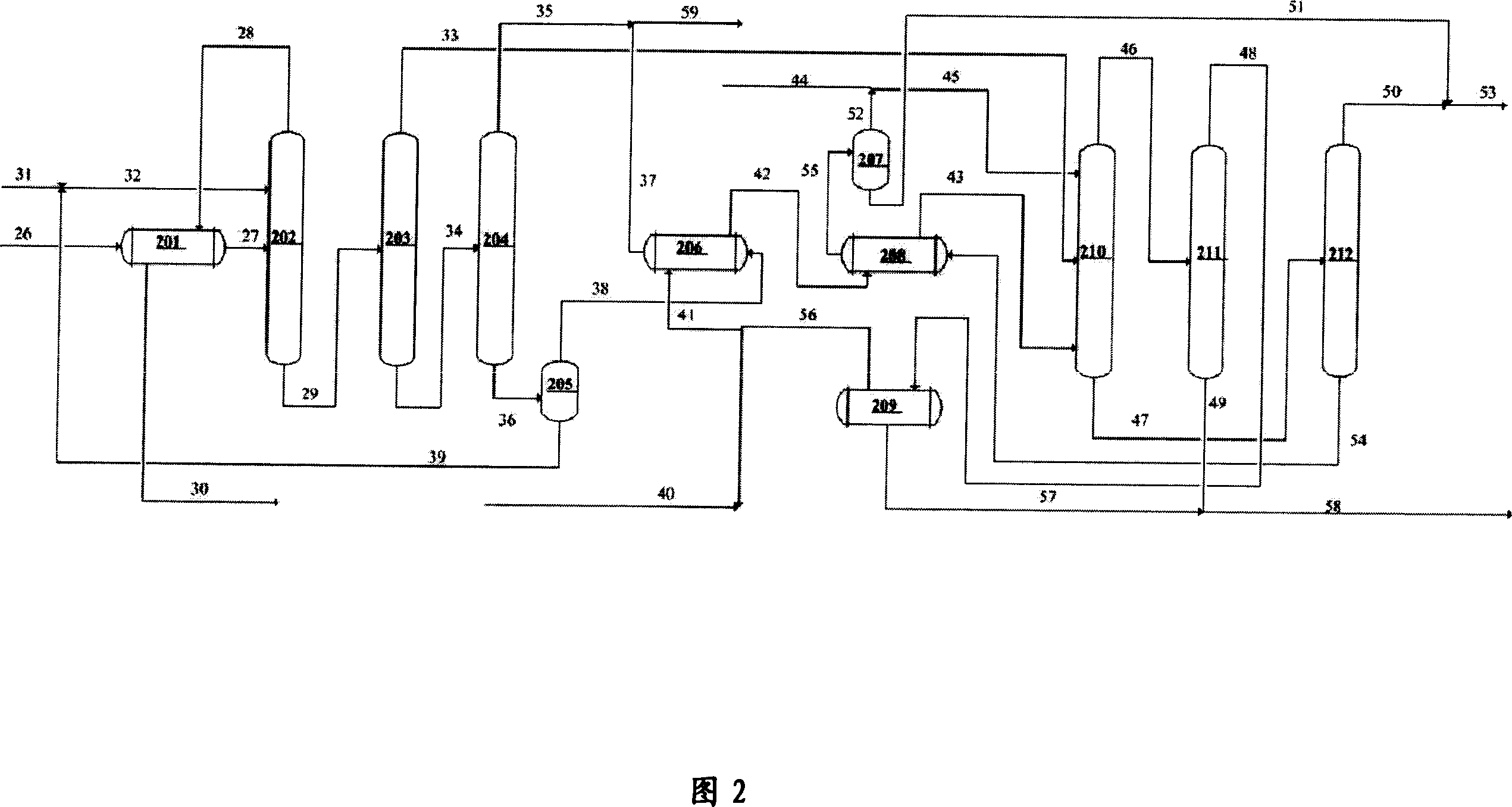

Method of double solvents, benzene substitutive rectification for separating c9 aromatics

This invention discloses a method for separating C9 aromatic hydrocarbons by double-solvent extraction and rectification. The method comprises: (1) pre-fractionating C9 aromatic hydrocarbon mixture, and collecting the rich fraction containing mesitylene and o-methyl ethyl benzene; (2) introducing the rich fraction into the middle of a double-solvent extraction-rectification column, introducing high-boiling-point solvent from the top of the column and low-boiling-point solvent from the bottom of the column, and extracting to obtain mixed fractions containing mesitylene and the low-boiling-point solvent at the top of the column and mixed fractions containing o-methyl ethyl benzene and the high-boiling-point solvent at the bottom of the column; (3) separating the mixed fractions in a solvent recovery column to obtain mesitylene and o-methyl ethyl benzene products, discharging, and recycling the solvents. The method significantly expands the relative volatility between trimethyl benzene and o-methyl ethyl benzene by using high-boiling-point and low-boiling-point solvents.

Owner:CHINA PETROLEUM & CHEM CORP +1

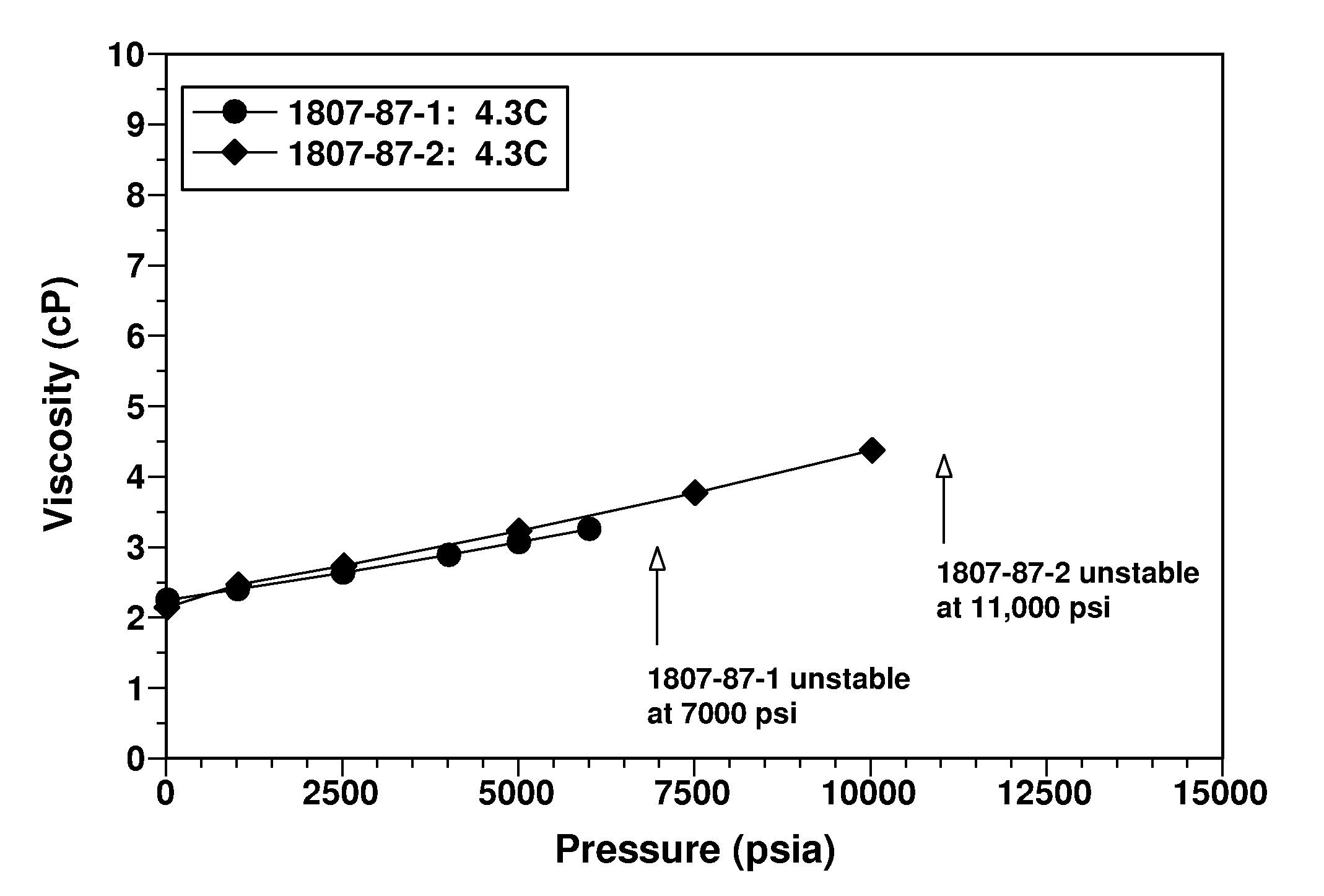

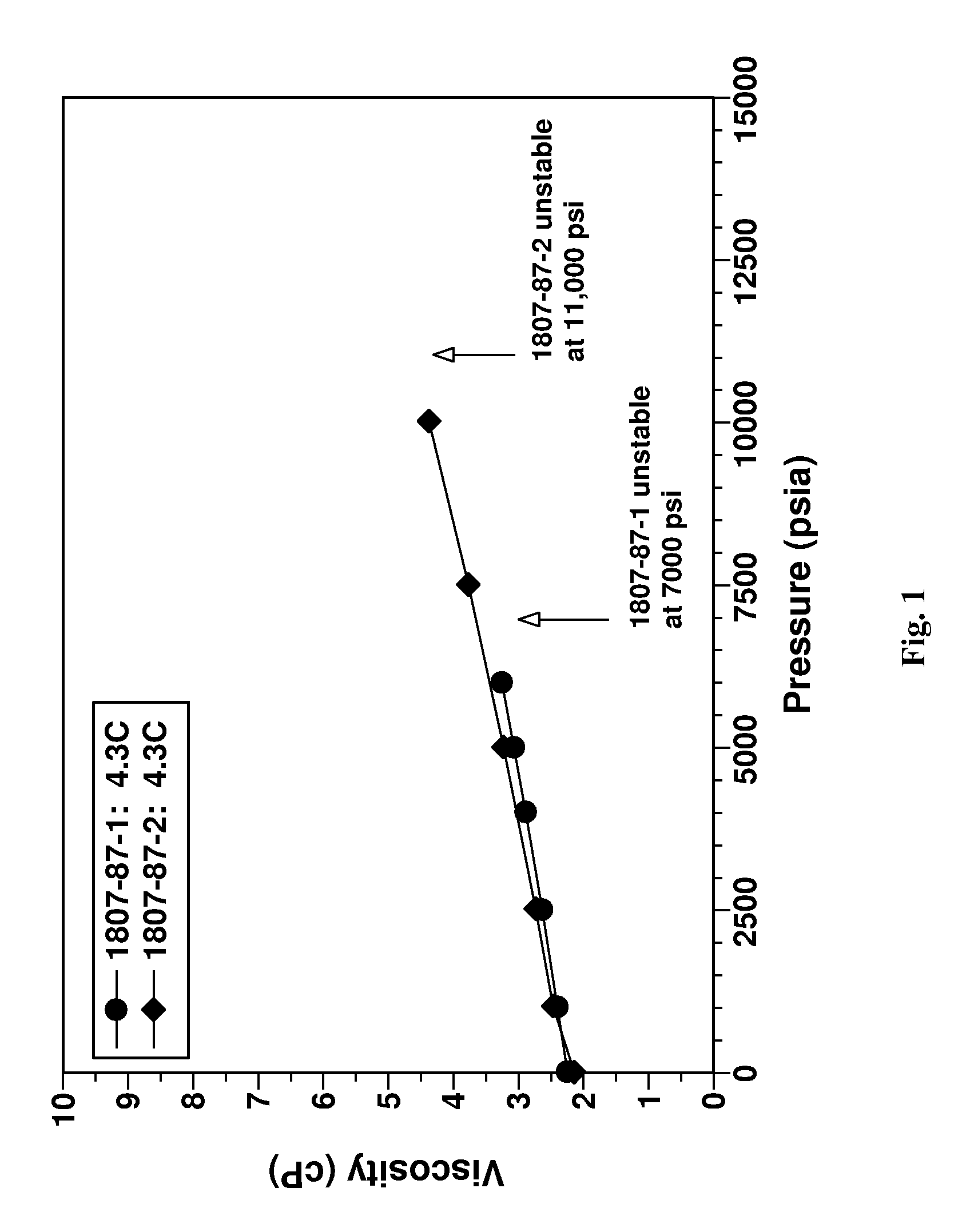

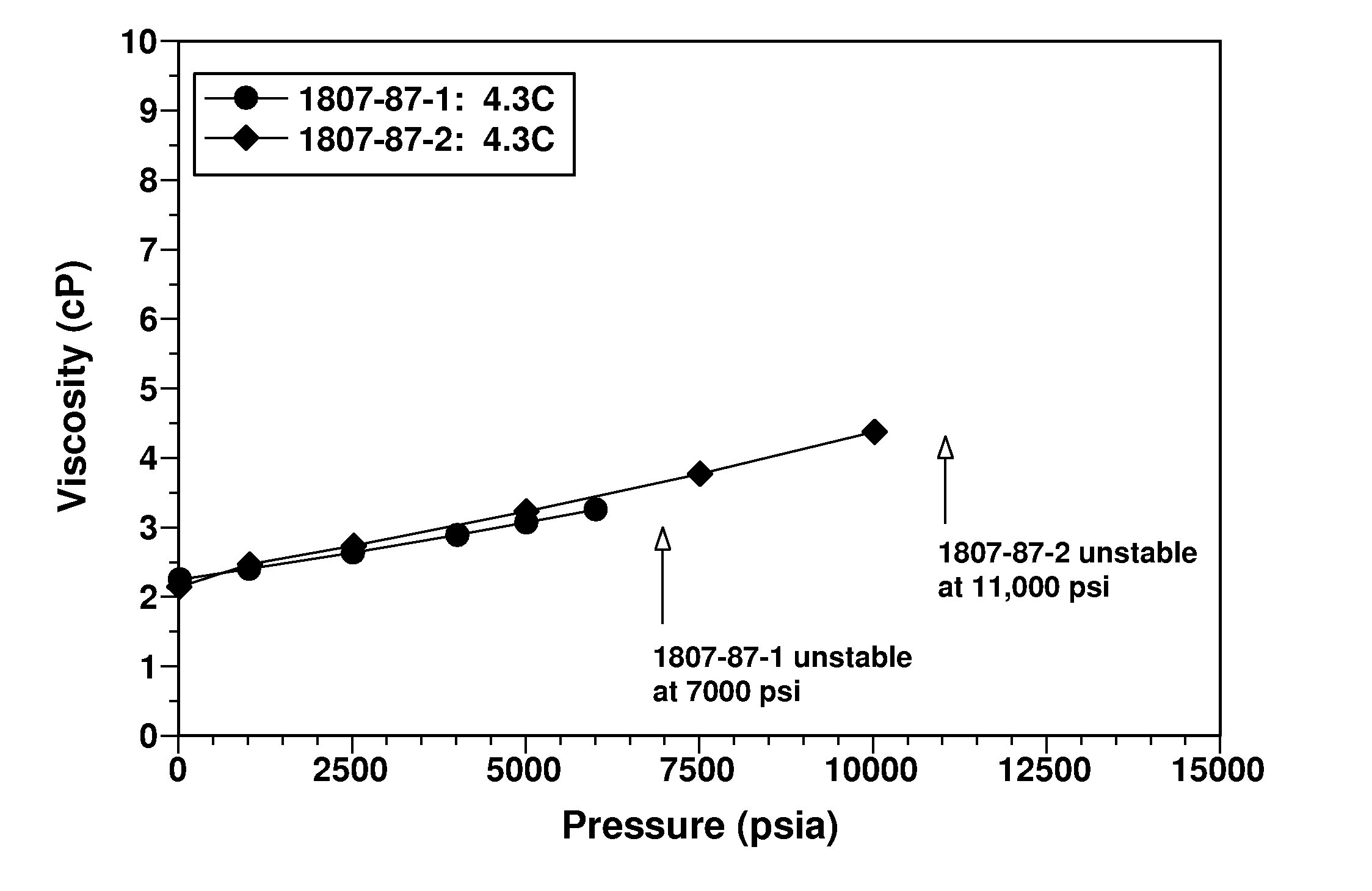

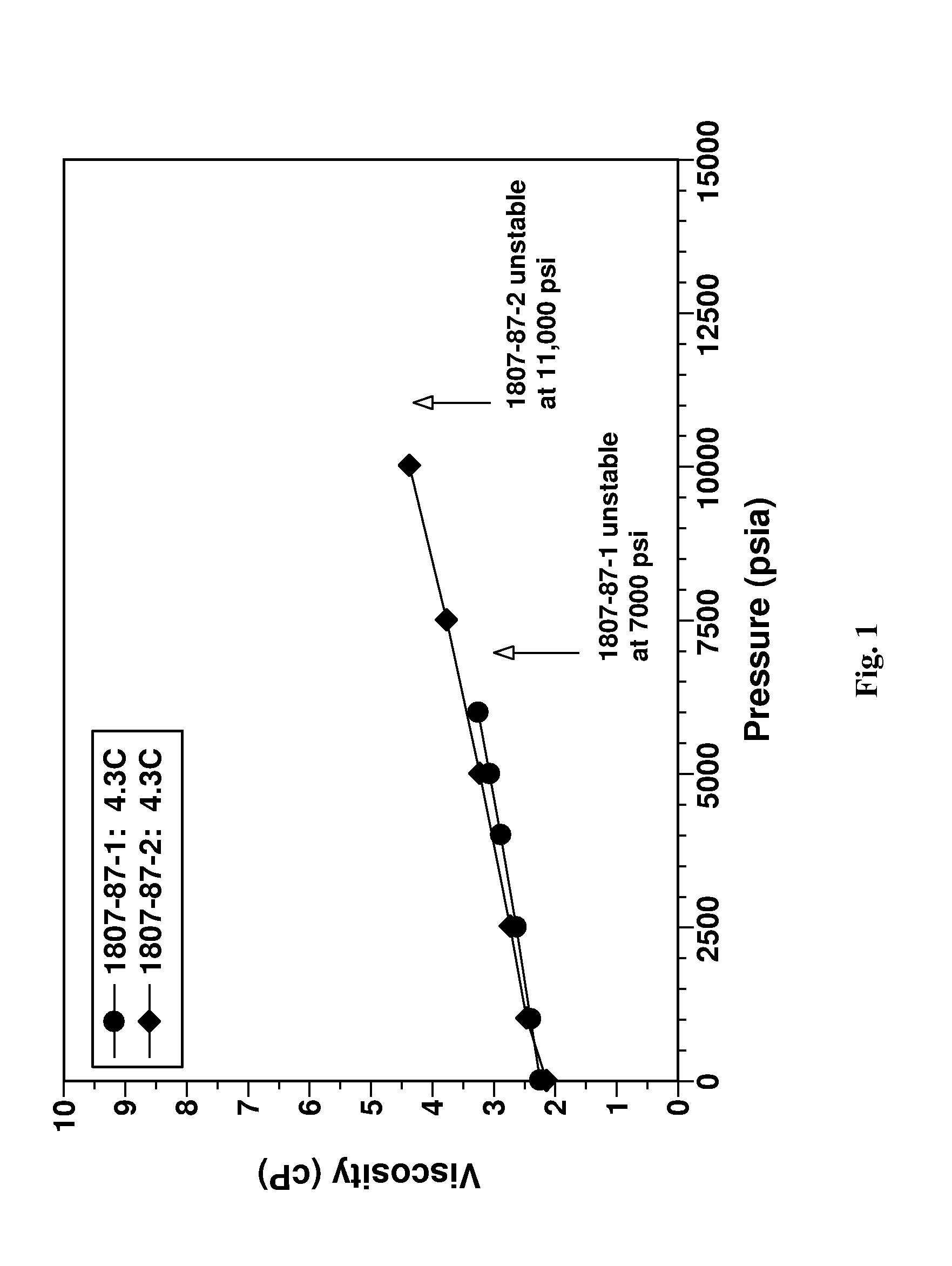

Paraffin inhibitor compositions and their use in oil and gas production

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

Paraffin Inhibitor Compositions and Their Use in Oil and Gas Production

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

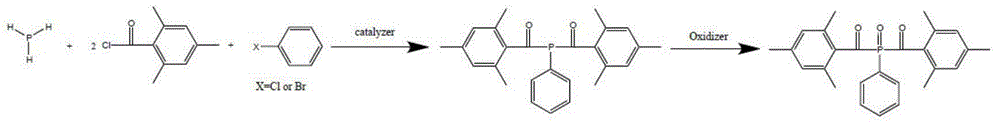

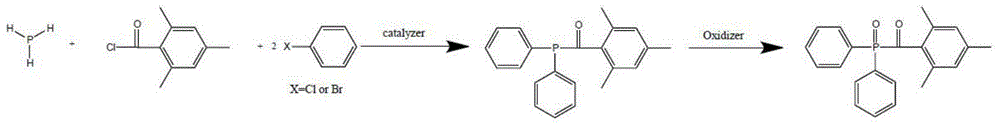

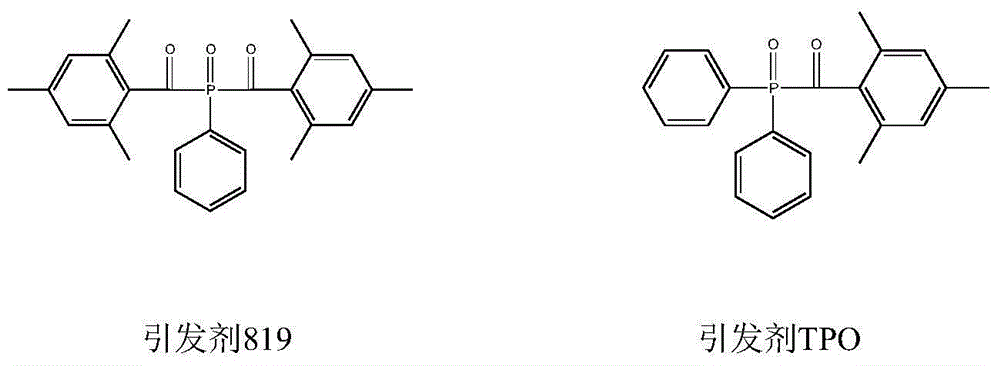

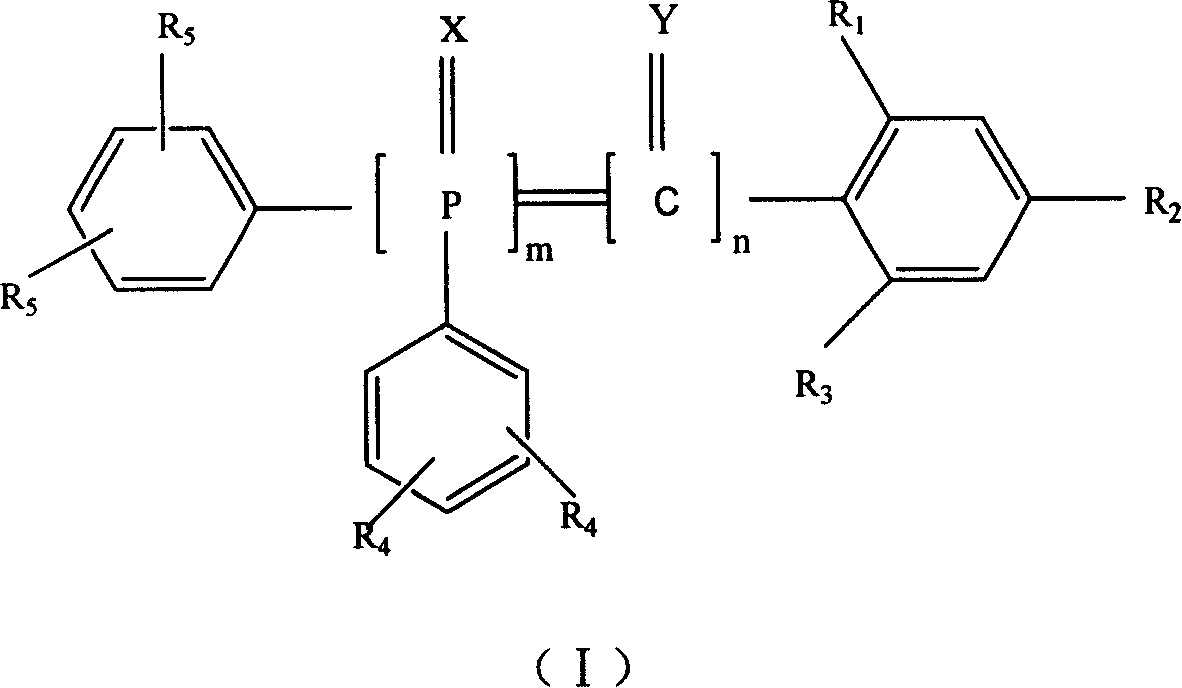

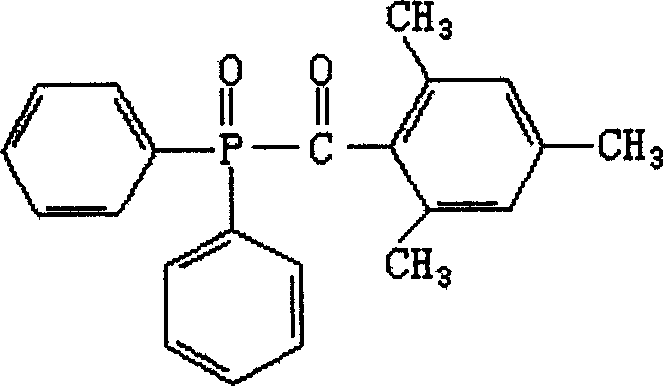

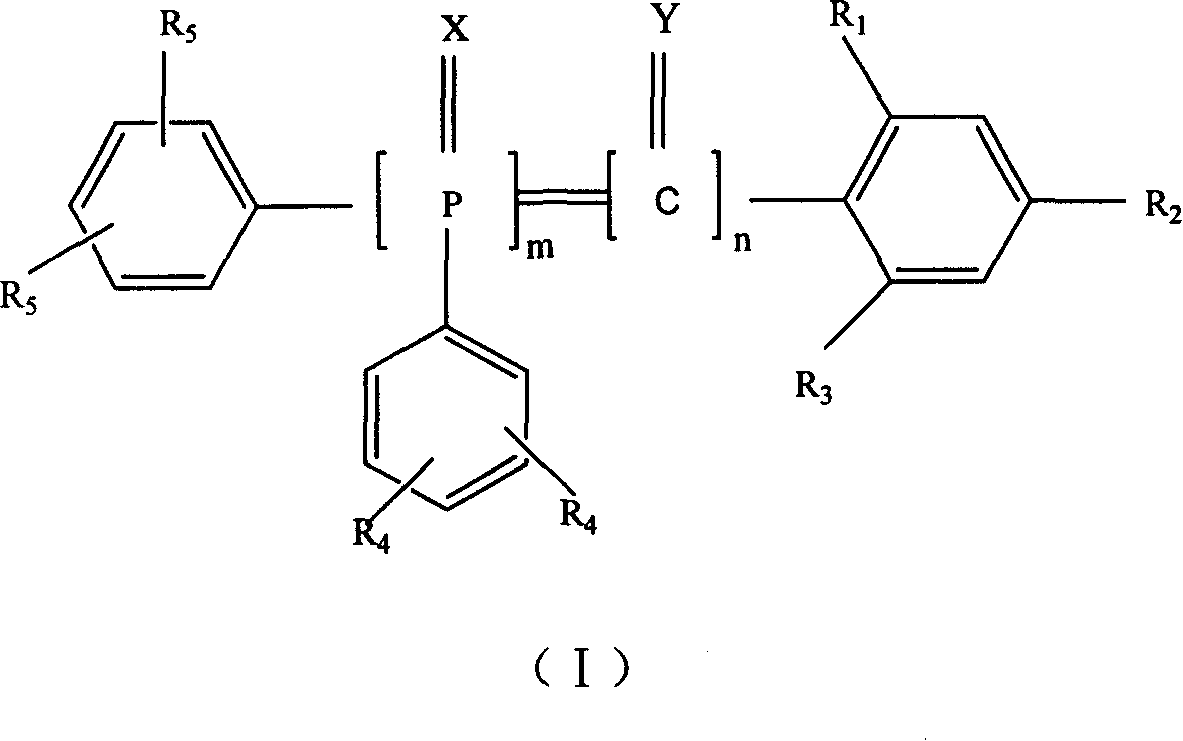

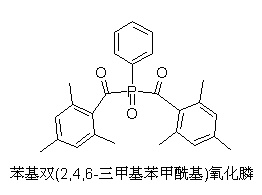

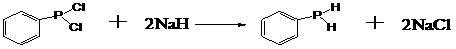

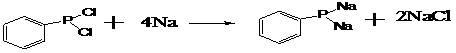

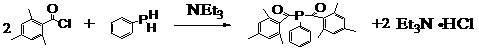

Preparation method of di (2,4,6-trimethylbenzoyl) phenyl phosphine oxide and (2,4,6-trimethylbenzoyl) diphenyl phosphine oxide

The invention relates to a preparation method of di (2,4,6-trimethylbenzoyl) phenyl phosphine oxide and (2,4,6-trimethylbenzoyl) diphenyl phosphine oxide used in the technical field of radiation polymerization curing new materials, hydrogen phosphide as a raw material is reacted with chlorobenzene or bromobenzene and 2,4,6-trimethylbenzoyl chloride, and an acyl oxygen phosphonic compound is obtained by oxidizing with an oxidant. By adjusting the feed ratio, the di (2,4,6-trimethylbenzoyl) phenyl phosphine oxide and the (2,4,6-trimethylbenzoyl) diphenyl phosphine oxide are respectively obtained, and the purpose for simultaneously producing the two target products of di (2,4,6-trimethylbenzoyl) phenyl phosphine oxide and the (2,4,6-trimethylbenzoyl) diphenyl phosphine oxide can be achieved by use of same material and device, and compared with known technology paths reported in literatures, the preparation method has the significant advantages of novelty of the chemical reaction technology, cost economic competitiveness and environmental friendliness.

Owner:TIANJIN MOSEN TECH CO LTD

Method for preparing acyl and bisacyl phosphine oxide or acyl and bisacyl sulfur phosphines

InactiveCN101200475AReduce manufacturing stepsReduce decreaseGroup 5/15 element organic compoundsCoatingsBenzaldehydePhosphine oxide

The invention relates to a preparation method of single acyl or two acyl phosphine oxide and single acyl or two acyl sulfur phosphine compound, in particular to a preparation method of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide of the photoinitiator. The addition reaction is carried out between Trimethyl benzaldehyde and diphenyl phosphorus chloride and then the mixture is oxidized by tert-butyl alcohol peroxide. The invention adopts the addition reaction of aldehyde and halogenated phosphorus and replaces the original process of acyl chloride and halogenated phosphorus, and has the advantages of greatly shortening the preparation procedures, low cost, easy operation and quick production. The compound prepared by the invention has more than 98 percent of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide and can be served as the photoinitiator for solid for producing the solidification product with the performance of paint, varnish, porcelain glaze, paint, pigment or ink, and can better satisfy the increasing market demand.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

Paraffin inhibitor compositions and their use in oil and gas production

InactiveUS20040058827A1Desirable utilityReciprocating drilling machinesOther chemical processesSolubilityParaffin wax

Disclosed are paraffin inhibitors prepared by admixing a polymer having the characteristic of inhibiting paraffin crystalline growth in formation fluid from oil and gas wells with a first solvent selected from the weak to moderate wax solvents and a second solvent selected from the strong wax solvents. Exemplary weak to moderate wax solvents include benzene, toluene, xylene, ethyl benzene, propyl benzene, trimethyl benzene and mixtures thereof. Exemplary strong wax solvents include cyclopentane, cyclohexane, carbon disulfide, decalin and mixtures thereof. The solvent system disclosed has desirably better solubility with the polymers, even at reduced temperatures, than either solvent alone.

Owner:BAKER HUGHES INC

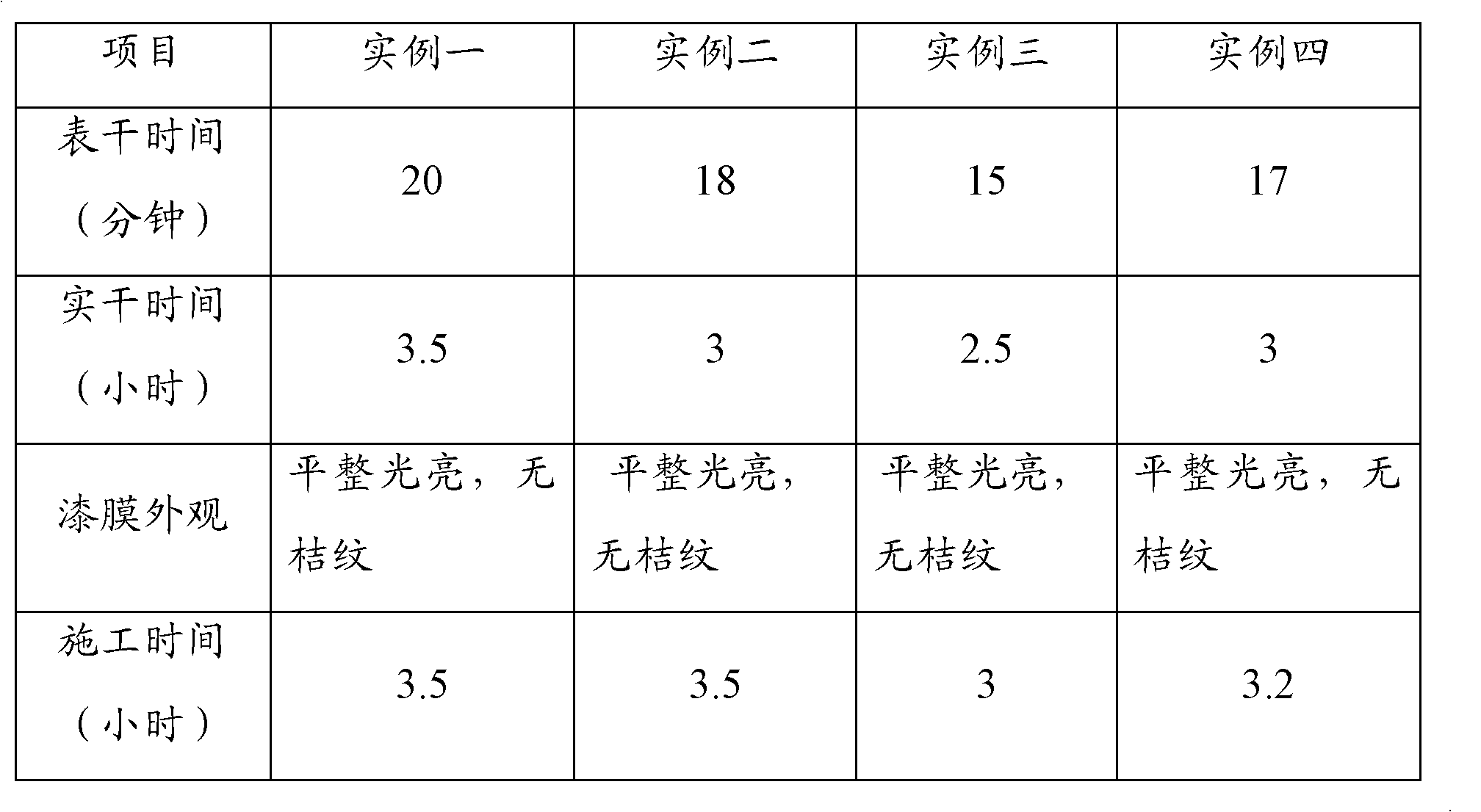

Hydroxy acrylic resin for ultra-fast dry automobile varnish and preparation method thereof

InactiveCN102153691AHas ultra-fast drying and curing propertiesImprove the level ofCoatingsPolymer scienceAcrylic resin

The invention discloses a preparation method of hydroxy acrylic resin for ultra-fast dry automobile varnish. The preparation method comprises the following steps of: 1) putting a material A into a reaction kettle, and heating the material A to the temperature of between 140 and 160 DEG C; 2) dripping a material B for 3 to 4 hours, and controlling the temperature in the reaction kettle at 140 to 160 DEG C; 3) after the dripping is finished, preserving the heat for 3.5 to 4.5 hours at the temperature of between 140 and 160 DEG C; 4) adding a material C, and performing heat preservation reactionfor 3.5 to 4.5 hours; and 5) cooling the reaction product to be less than 80 DEG C, and filtering the reaction product, wherein the material A comprises 10 to 15 weight parts of dimethyl benzene and 28 to 32 weight parts of trimethyl benzene; the material B comprises 20 to 25 weight parts of styrene or alpha-styrene, 12 to 15 weight parts of sec-butyl methacrylate or tert-butyl methacrylate, 10 to 12 weight parts of propyl methacrylate or ethyl methacrylate or ethyl acrylate, 2 to 4 weight parts of methyl acrylic acid, and 0.3 to 1.0 weight part of maleic anhydride or fumaric acid; and the material C is 6 to 9 weight parts of initiator. The hydroxy acrylic resin is applied to the varnish, and has ultra-fast dry curing property, good construction performance and varnish film appearance.

Owner:同宇新材料(广东)股份有限公司

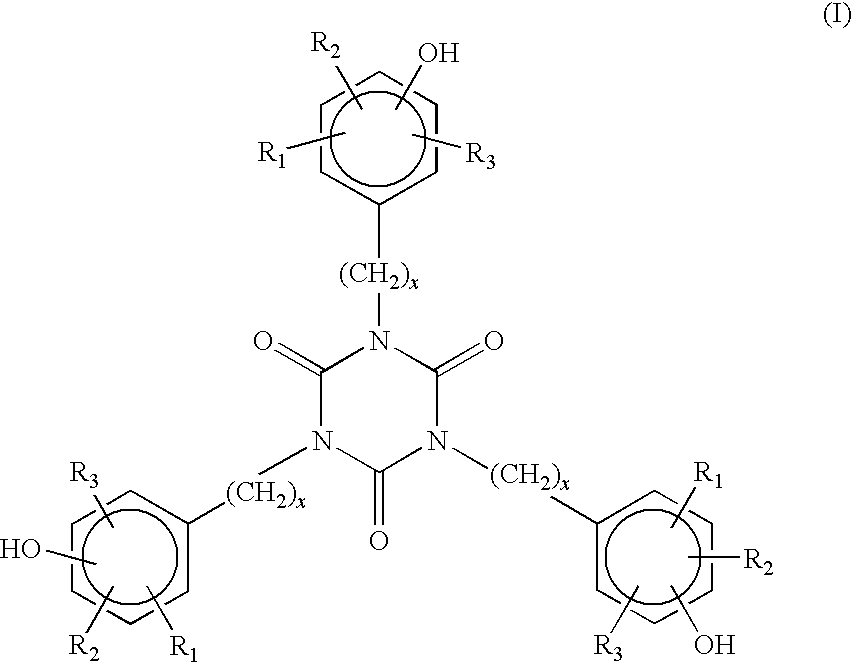

Polymers with low gel content and enhanced gas-fading

ActiveUS20100197837A1Effective amount of stabilizingImpression capsOther chemical processesLinear low-density polyethyleneEthylene Homopolymers

A polymer stabilizing composition comprising a sterically hindered phenol and a phosphite that provides low gel content and enhanced resistance to gas-fading. The stabilizer composition is particular useful for stabilizing polyethylene homopolymers and copolymers, such as linear low density polyethylenes produced from metallocene catalyst. The sterically hindered phenol is selected from the group consisting of 1,3,5-tris-(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)isocyanurate, 1,3,5-tris-(3,5-dicyclohexyl-4-hydroxybenzyl)isocyanurate, 1,3,5-tris-(3,5-di-tert-butyl-4-hydroxybenzyl)isocyanurate, 1,3,5-tris(4-t-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-Triazine-2,4,6-(1H,3H,5H)-trione, and 1,3,5-tris-(3,5-di-tert-butyl-4-hydroxybenzyl)-2,4,6-trimethylbenzene. The phosphite preferably is a liquid phosphite composition comprising two or more alkylated aryl phosphites.

Owner:SI GRP USA USAA LLC

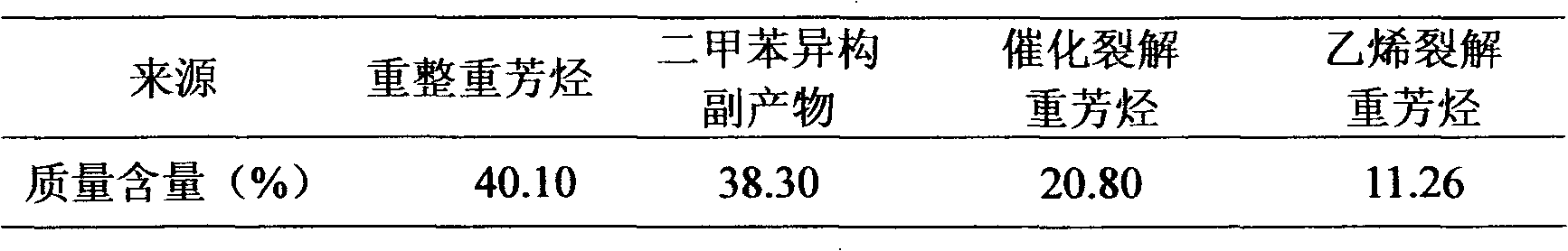

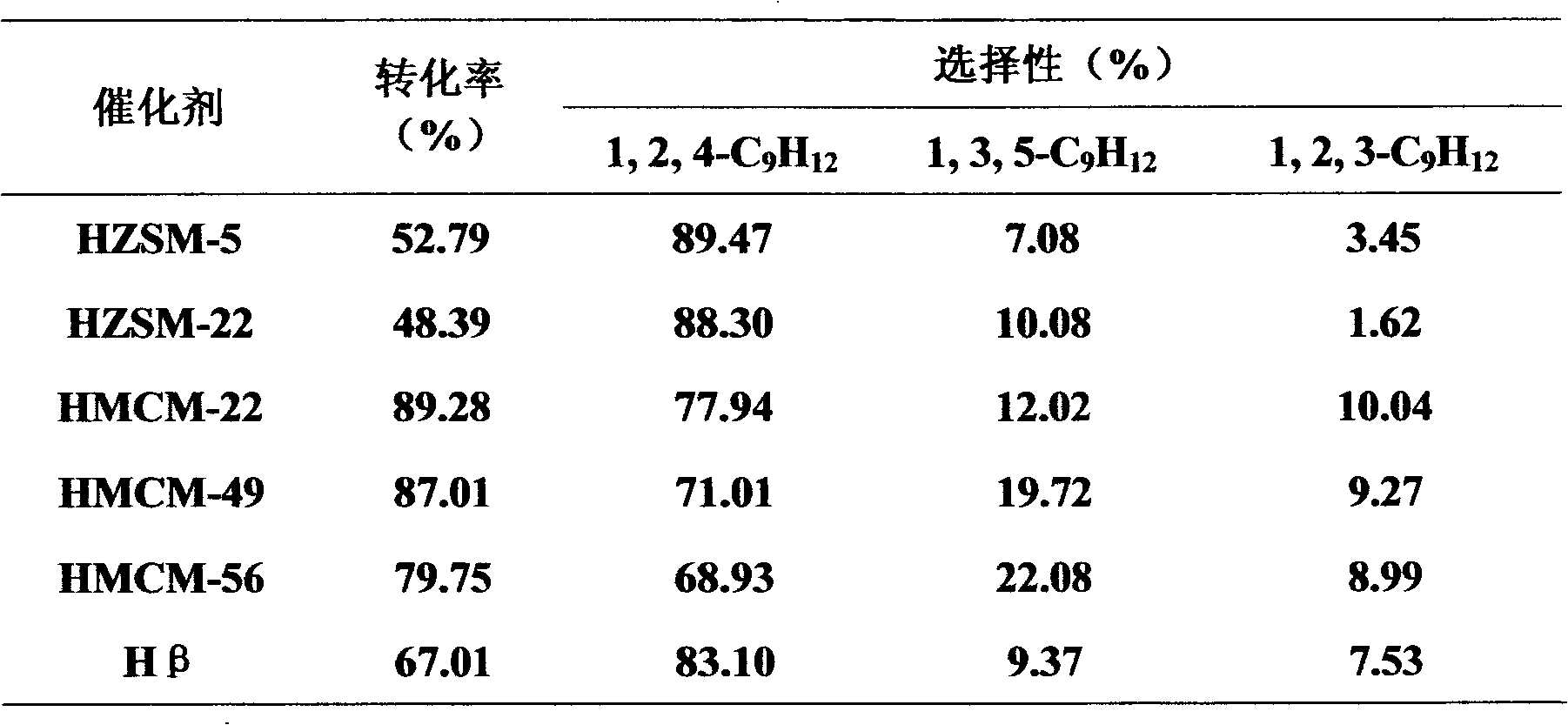

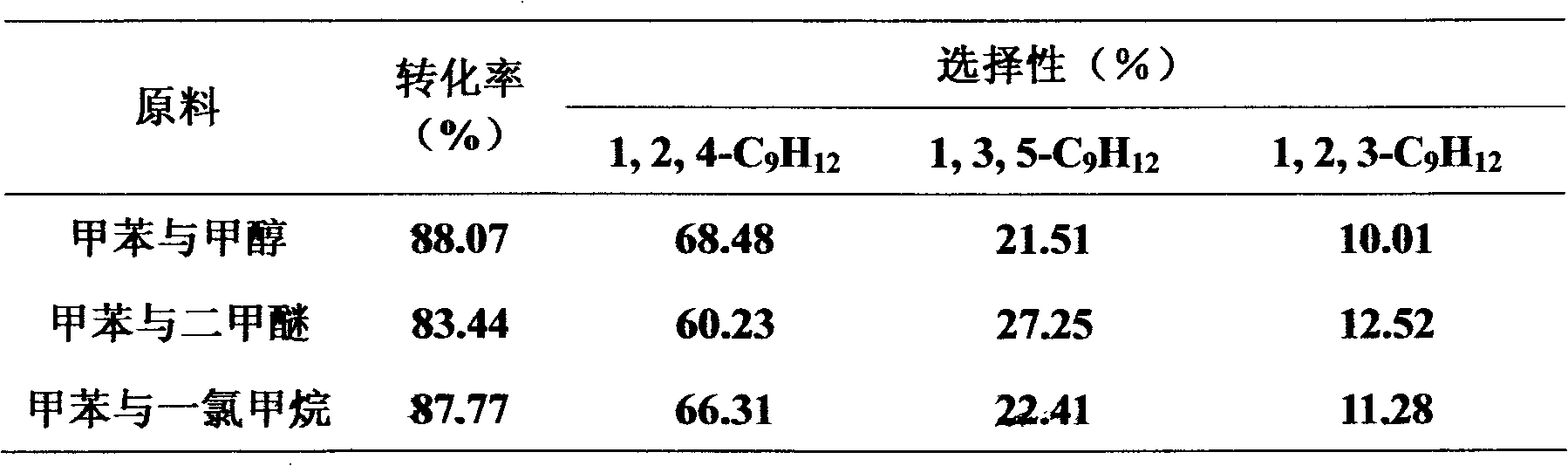

Method for synthesizing BTX aromatic methyl into unsym-trimethyl benzene

ActiveCN101654394ALow costConvenient sourceHydrocarbon by isomerisationHydrocarbon by hydrocarbon and non-hydrocarbon condensationMethylating AgentM-Xylene

The invention relates to a method for synthesizing BTX aromatic methyl into unsym-trimethyl benzene. The method takes BTX aromatic hydrocarbon (comprising any one or more of benzene, toluene, o-xylene, m-xylene, p-xylene and mixed xylenes) and a methylating agent (selected from one or more of methyl alcohol, dimethyl ether and methane chloride) as raw materials to prepare unsym-trimethyl benzene by a methylation reaction under the catalytic action of an acid catalyst. The acid catalyst is selected from any one of halide, liquid acid, complexacid, heteropolyacid, solid super acid, acidic ion exchange resin, acidic oxide, hydrogenous zeolite molecular sieve or supported acid catalyst. The pressure of the methylation reaction is 0.01-10.0Mpa, the temperature is 30-700 DEG C, the mass space velocity of raw material liquid is 0.1-10.0h<-1>, and the mole ratio of the aromatic hydrocarbon and the methylating agent is 1:10 to 10:1. The methylation reaction can adopt a continuous fixed bed reaction or continuous stirred-tank reaction. The method has rich raw material resources, low cost, mild reaction condition as well as higher once-through conversion of the raw materials and yield of the unsym-trimethyl benzene.

Owner:SHANGHAI NOVEL CHEM TECH

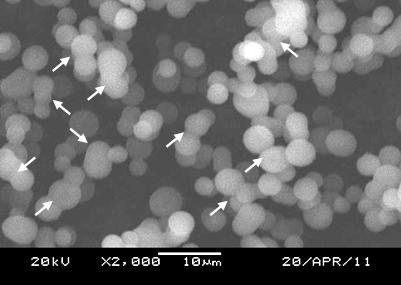

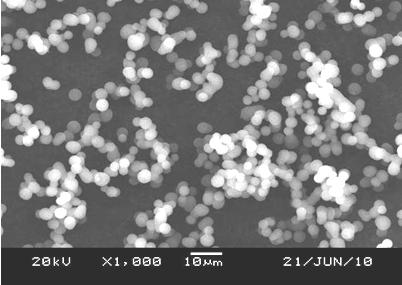

Method for preparing mesoporous SBA-15 unstuck micro spheres

InactiveCN102515173AEffect of specific surface areaEffect of Mesopore SizeSilicaMeth-Polyvinyl alcohol

The invention relates to a method for preparing mesoporous SBA-15 unstuck micro spheres, in particular a method for preparing mesoporous SBA-15 unstuck micro spheres for high-efficiency liquid chromatography. According to the method, a three-block copolymer P123 is used as a template agent, tetraethoxysilane, hydrochloric acid, potassium chloride, mesitylene, ammonium fluoride and polyvinyl alcohol are used as raw materials, and the dispersity of the mesoporous silica spheres can be regulated by adding polyvinyl alcohol. The mesoporous micro spheres prepared by the method are smooth and unstuck basically, and the addition of poly(vinyl acetate) (PVA) prevents the sticking of the micro spheres without influencing the specific surface area and mesoporous aperture obviously.

Owner:LIAOCHENG UNIV

Low-temperature curing color coiled material paint and method for preparing same

ActiveCN101531860ASuitable for continuous roller coatingMeet the hardness and toughnessPolyester coatingsLow temperature curingSolvent

The invention relates to a paint composition, in particular to a low-temperature curing paint used for manufacturing color steel plates and a method for preparing the same. The method comprises the following steps: adding 45 to 60 weight percent of saturated polyester resin, 3 to 5 weight percent of fully-methylated amino resin and 3 to 5 weight percent of partially-methylated amino resin into a reaction kettle; while stirring, adding 3 to 5 weight percent of propylene glycol ether acetate, 2 to 5 weight percent of binary acid dimethyl ester, 2 to 0.5 weight percent of closed cooling catalyst, 0.2 to 0.5 weight percent of open cooling catalyst, 5 to 10 weight percent of trimethyl benzene solvent to the mixture; after stirring the mixture evenly, adding 0.3 to 0.8 weight percent of dispersant to the mixture, and then adding 20 to 40 weight percent of filling pigment and 0.3 to 0.8 weight percent of wax powder while stirring; and after the mixture is dispersed evenly, performing sanding in a sand mill, and then performing paint and color mixing process to obtain the finished product, namely the low-temperature curing color coiled material paint. The method can solve the problems that the prior high-temperature baking curing paint has high curing temperature to cause energy sources waste.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

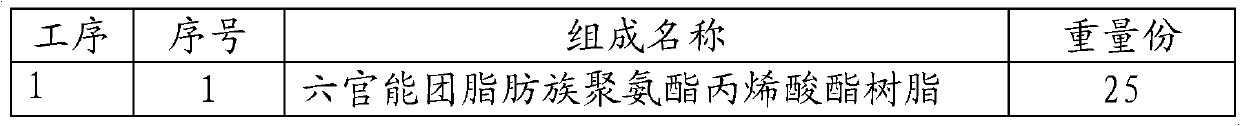

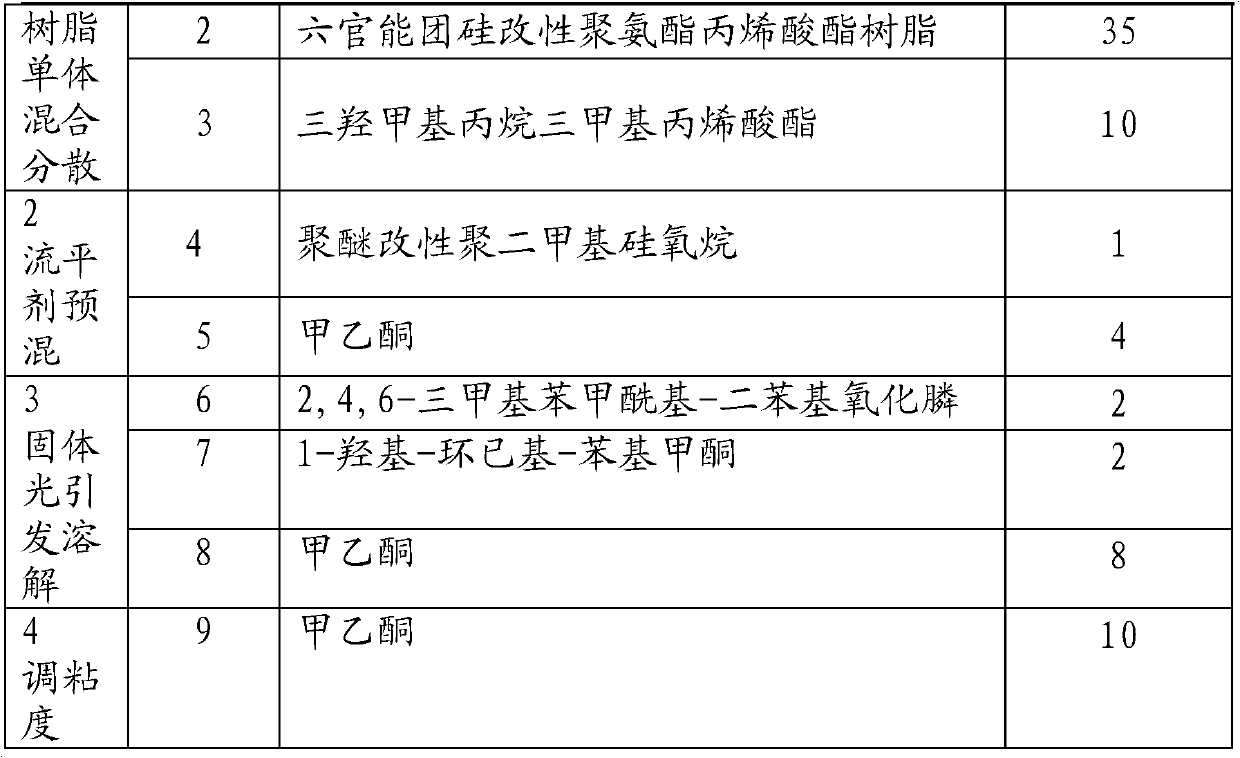

Steel wool-resistant high-hardness ultraviolet (UV) radiation cured coating, and preparation and using methods thereof

InactiveCN102585690AGood adhesionHigh surface hardnessPretreated surfacesPolyurea/polyurethane coatingsAcrylic resinAcrylonitrile

The invention provides a steel wool-resistant high-hardness ultraviolet (UV) radiation cured coating, and preparation and using methods thereof. The coating comprises the following components in part by weight: 25 to 35 parts of six-functional group aliphatic series polyurethane acrylic resin, 25 to 35 parts of six-functional group silicon modified polyurethane acrylic resin, 5 to 10 parts of trimethylolpropane trimethacrylate, 1 to 2 parts of polyether modified polydimethylsiloxane, 1 to 2 parts of diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide, 2 to 6 parts of 1-hydroxycyclohexyl phenyl ketone, and 10 to 22 parts of solvent. The coating is prepared to overcome the defects in the conventional UV cured coating, and is particularly suitable for high-hardness coating which is required by plastic keys such as acrylonitrile-butadiene-styre (ABS) keys, poly carbonate (PC) keys and the like, and can widely applied to coating of various plastic parts of communication, computer and consumer (3C) products, and digital products; and the high requirement of the UV coating is met.

Owner:深圳市嘉卓成科技发展有限公司

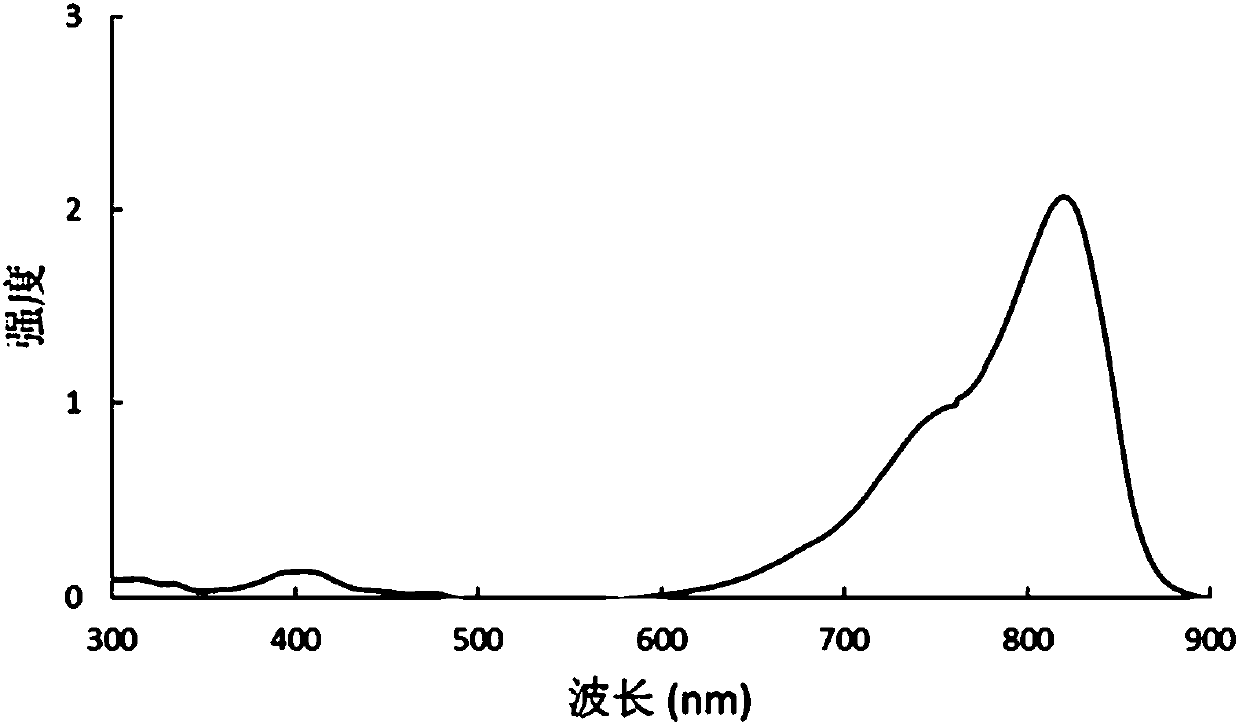

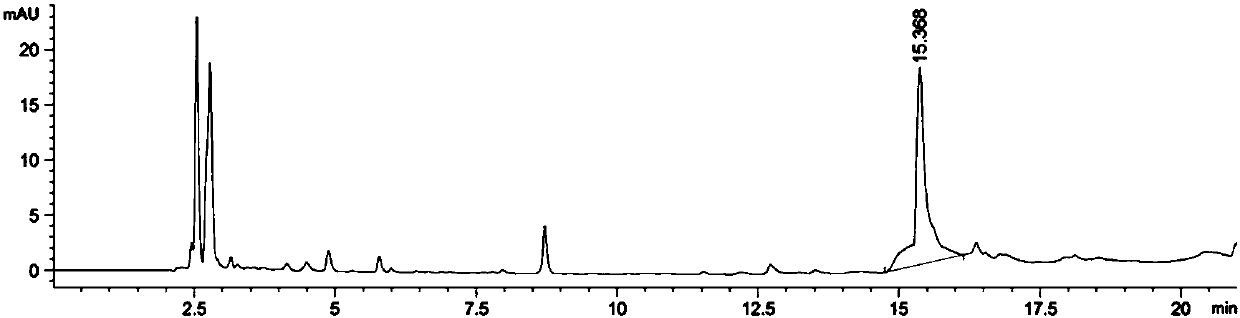

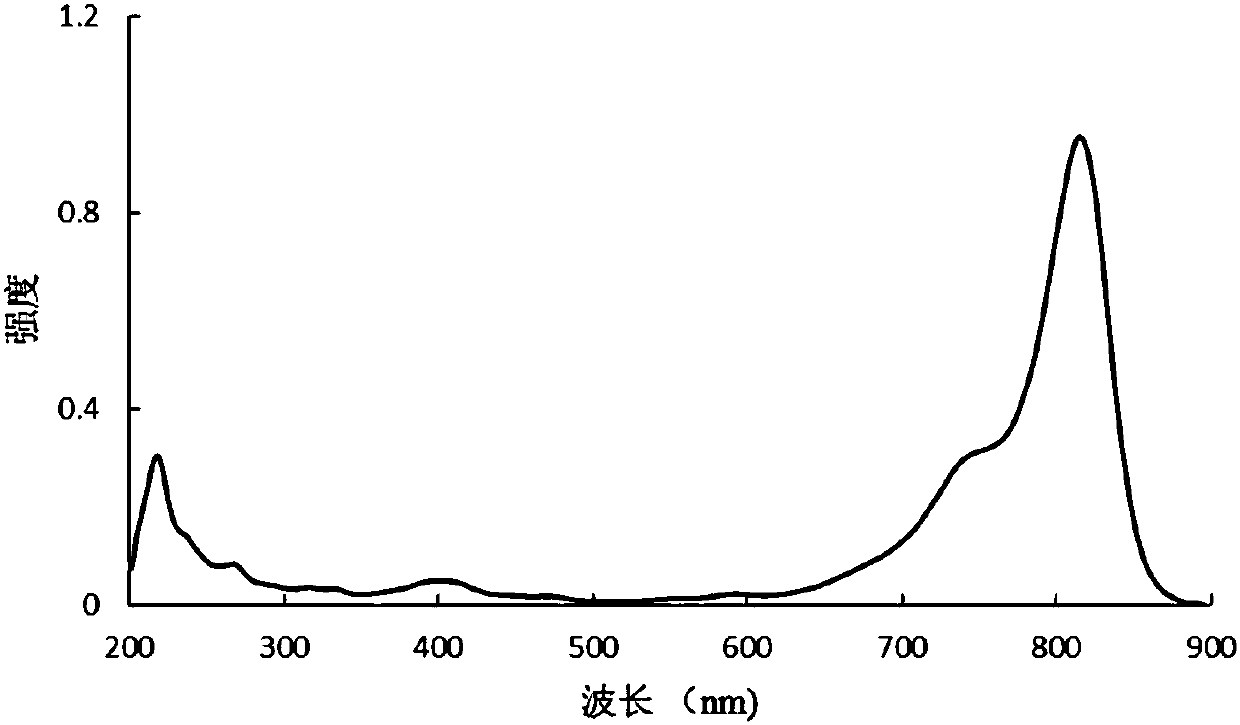

Preparation method of heptamethine benzoindocyanine dye

PendingCN109796779AShort synthetic routeSimple processMethine/polymethine dyesFluorescence/phosphorescenceChromatographic columnSolvent

The invention discloses a preparation method of a heptamethine benzoindocyanine dye. The method at least comprises the following steps that a 2,3,3-trimethyl-4,5-benzindole derivative reacts with a nucleophilic substitution compound and re-crystallized to obtain organic ammonium salt; the organic ammonium salt, a cyclohexene derivative and a sodium acetate solution react with one another, the product is mixed with alcohol and ether, the mixture is extracted many times, and the heptamethine benzoindocyanine dye is obtained. The method is short in synthetic route, simple in process, free of catalysis of precious metal and high in yield, the extraction method is simple, chromatographic column separation is not needed, the solvent consumption is low, the preparation efficiency of the dye is greatly improved, and low-cost batch production can be achieved. The method has great significance in the aspects of production and application research of heptamethine benzoindocyanine. The prepared heptamethine benzoindocyanine dye contains an aliphatic chain substituted N structure, and has or independently has near-infrared light absorption and fluorescent development functions.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

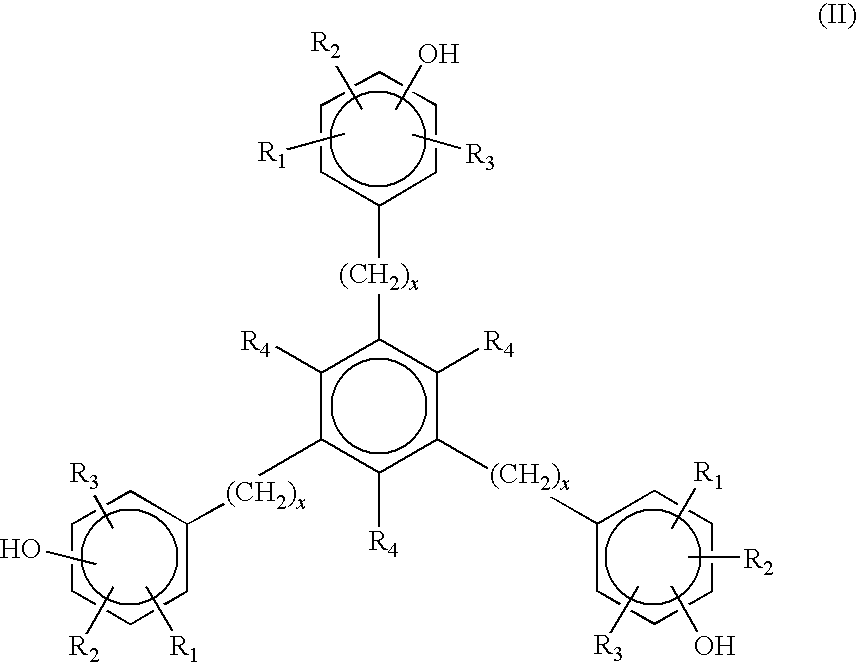

Method for synthesizing antioxidant 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4-hydroxybenzyl)benzene

InactiveCN101717326AEasy to makeEasy to prepareOrganic chemistryOrganic compound preparationAlkyl transferSuperacid

The invention discloses a method for preparing antioxidant 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4-hydroxybenzyl)benzene by using solid superacid as catalyst, wherein 1,3,5-trihalo methyl-2,4,6-trimethyl benzene and 2,6-do-tert-butylphenol, as raw materials, are subject to alkylation in inert solvent under the action of solid superacid-type catalyst SO42- / MXOY, so as to prepare target products. The method simplifies operating process, achieves mild reaction conditions, has the characteristics of easy separation of products, good reusability of the catalyst, small environmental pollutionand the like, and is suitable for industrial production.

Owner:BOHAI UNIV

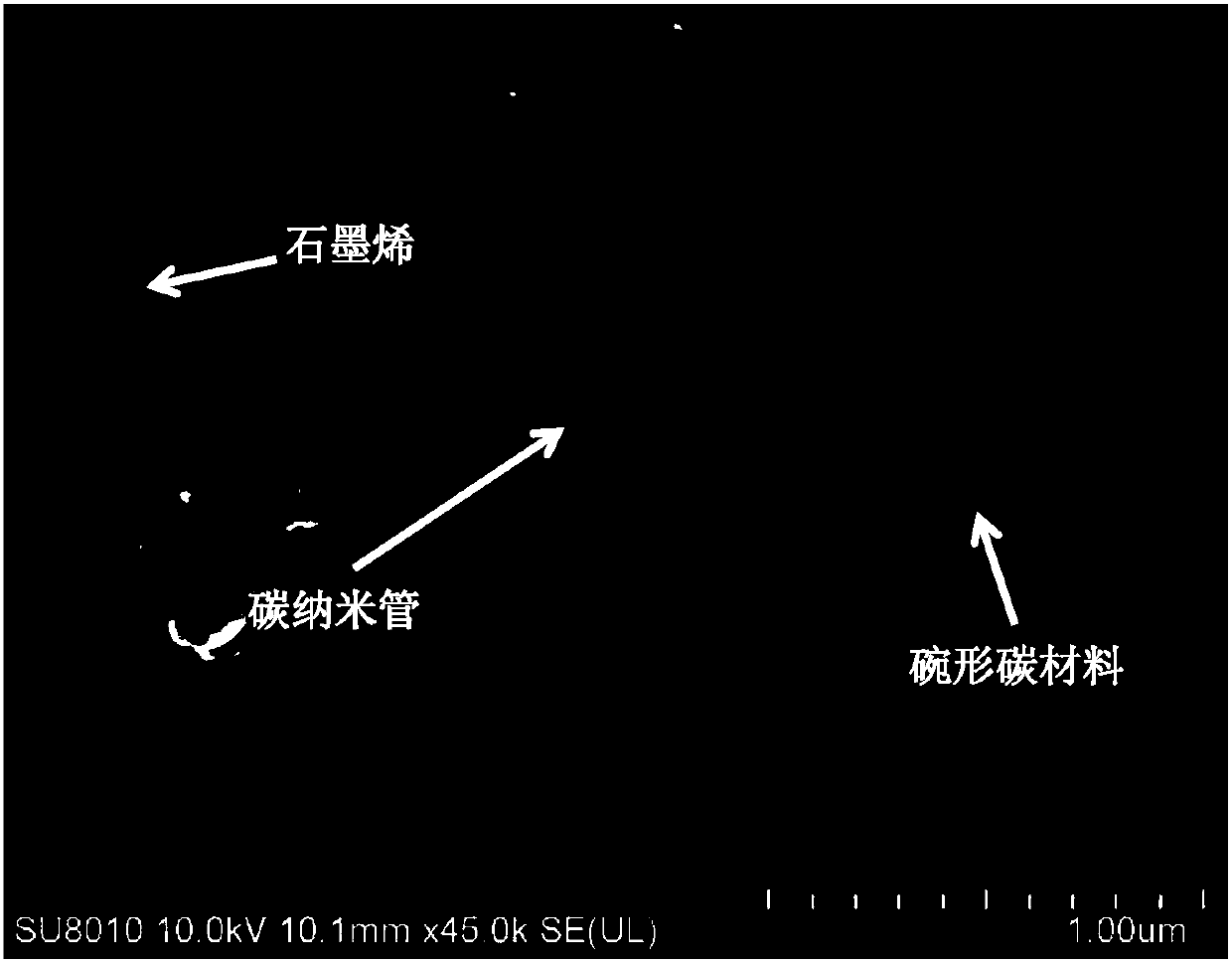

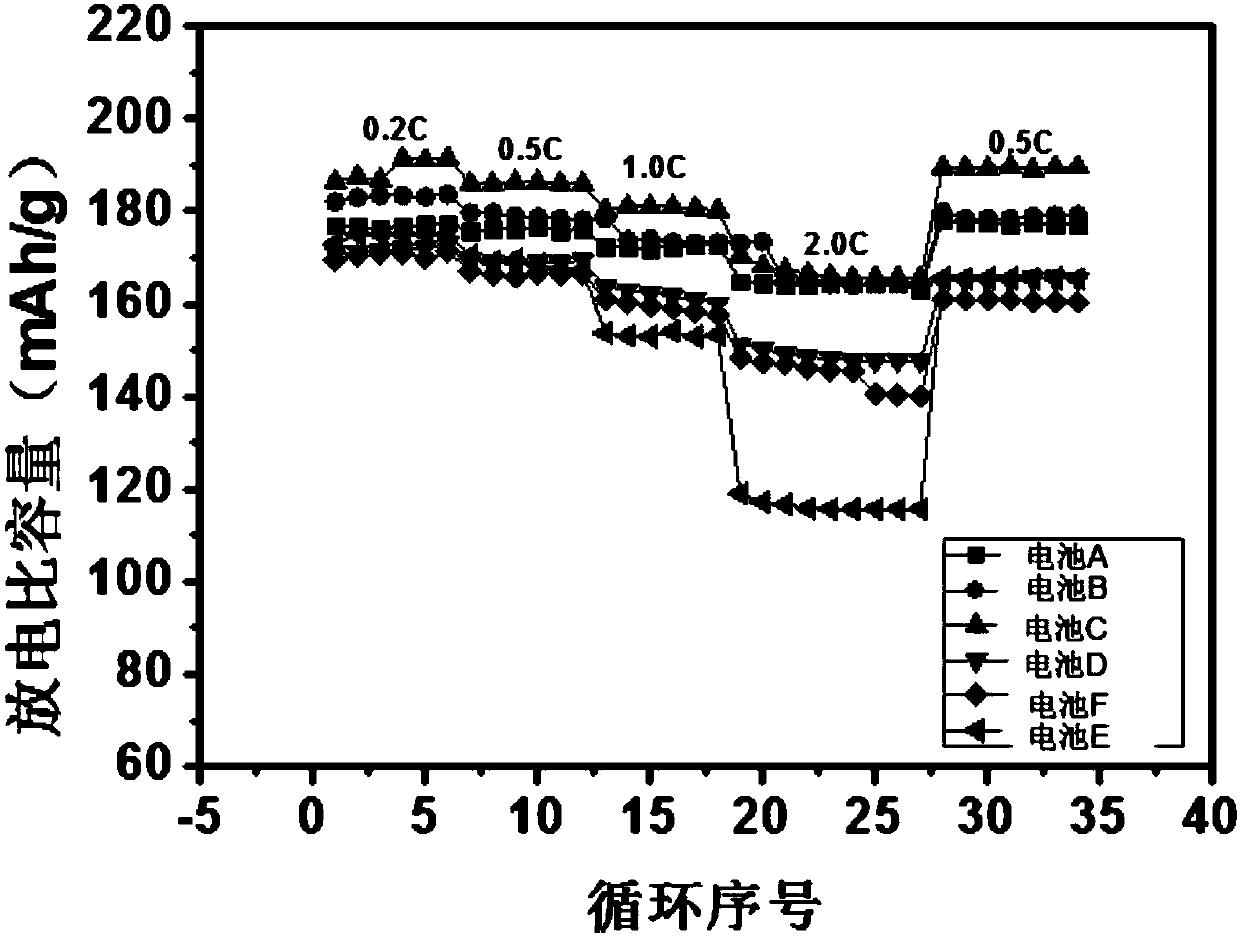

Bowl-shaped carbon material and preparation method thereof, and point-line-plane three-phase composite conductive paste

InactiveCN107611440AImprove performanceDischarge specific capacity value is highCell electrodesConductive pasteAlcohol

The invention provides a bowl-shaped carbon material and a preparation method thereof, and point-line-plane three-phase composite conductive paste. The preparation method of the bowl-shaped carbon material comprises the steps of (1) adding a block copolymer F127 and dopamine hydrochloride into a mixed solution of deionized water and ethyl alcohol in sequence, and next, dropwise adding trimethylbenzene thereto to obtain a mixed solution A; adding ammonium hydroxide to the mixed solution A in a stirring condition, and performing continuous stirring to obtain a mixed solution B; washing the mixedsolution B by the mixed solution of deionized water and ethyl alcohol to remove the block copolymer F127, and performing filtering to obtain polydopamine granules; (2) uniformly dispersing the polydopamine granules into the mixed solution of deionized water and ethyl alcohol, and performing a hydrothermal reaction in a sealing condition; and (3) performing calcining treatment on the product obtained in the hydrothermal reaction in inert atmosphere. The invention also provides the point-line-plane three-phase composite conductive paste comprising the bowl-shaped carbon material; and when the paste is used as the conductive agent of the battery, the battery performance can be improved effectively.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

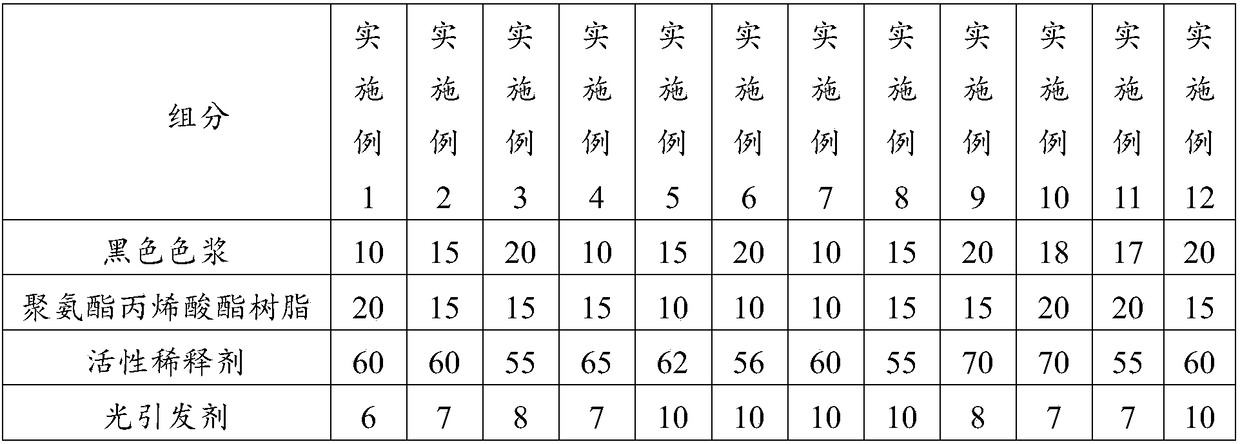

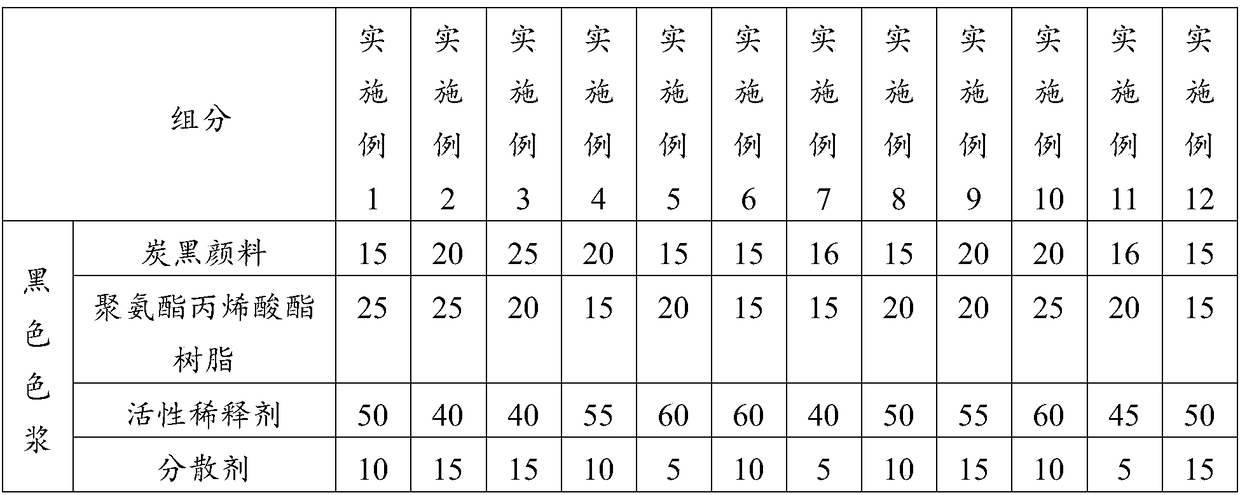

High-adhesion high-gloss black UV inkjet ink and preparation method and application thereof

The invention relates to high-adhesion high-gloss black UV inkjet ink which comprises, by weight, 10-20 parts of black color paste, 10-20 parts of polyurethane acrylate resin, 50-70 parts of reactivediluents, 6-10 parts of photoinitiator and 3-4 parts of auxiliaries. The reactive diluents include, by mass part, a first reactive diluent, a second reactive diluent and a third reactive diluent according to a consumption ratio of 2-3:1-2:2-3; the photoinitiator is at least one of 1-hydroxy-cyclohexylbenzophenone, 2, 4, 6-trimethylbenzoyl-diphenyl phosphine oxide and 2, 4, 6-trimethylbenzoyl ethylphenyl phosphoinate; the auxiliaries include defoamer, leveling agent, adhesion accelerant and polymerization retarder. The invention provides a preparation method and application of the high-adhesion high-gloss black UV inkjet ink. The black UV inkjet ink has the advantages of high gloss value, high adhesion and high hardness.

Owner:SOUTH CHINA AGRI UNIV +2

Preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide

ActiveCN103980310AHigh reaction yieldLow costGroup 5/15 element organic compoundsPtru catalystPhenacyl

The invention discloses a preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide as an efficient free radical photoinitiator. The preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide comprises the concrete steps of with 2,4,6-trimethylbenzaldehyde as a raw material, enabling 2,4,6-trimethylbenzaldehyde and phenylphosphine oxide to be subjected to condensation reaction in the existence of a catalyst, and then, carrying out oxidation reaction. Extraction and solvent replacement are not needed and continuous reaction can be realized in the reaction process. The preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide, disclosed by the invention, is low in price, environment-friendly, easy to operate and suitable for realizing industrialization.

Owner:湖南久日新材料有限公司

Production technique of high-quality trimethyl orthoacetate

InactiveCN102924244AImprove securityEfficient removalOrganic chemistryOrganic compound preparationSolventIon-exchange resin

The invention discloses a production technique of high-quality trimethyl orthoacetate, which comprises the following steps: in the presence of solvent unsym-trimethyl benzene, carrying out salification reaction on acetonitrile, methanol and chlorine hydride to prepare ethyleneimine methyl ether hydrochloride; putting the ethyleneimine methyl ether hydrochloride in a methanol solution, and dropwisely adding an ammonia methanol solution to regulate the pH value; carrying out alcoholysis reaction to obtain a trimethyl orthoacetate crude product; filtering to remove and recycle solid ammonium chloride; adsorbing the filtrate with a strongly alkaline macroporous ion-exchange resin to remove chlorine ions; and finally, carrying out continuous rectification to obtain the trimethyl orthoacetate product of which the content is greater than 99.5% and the yield is greater than 85%. The invention has the advantages of simple technique and high product stability and reliability; and since the used unsym-trimethyl benzene solvent has low toxicity, the trimethyl orthoacetate is safe to use.

Owner:NANTONG TENDENCI CHEM

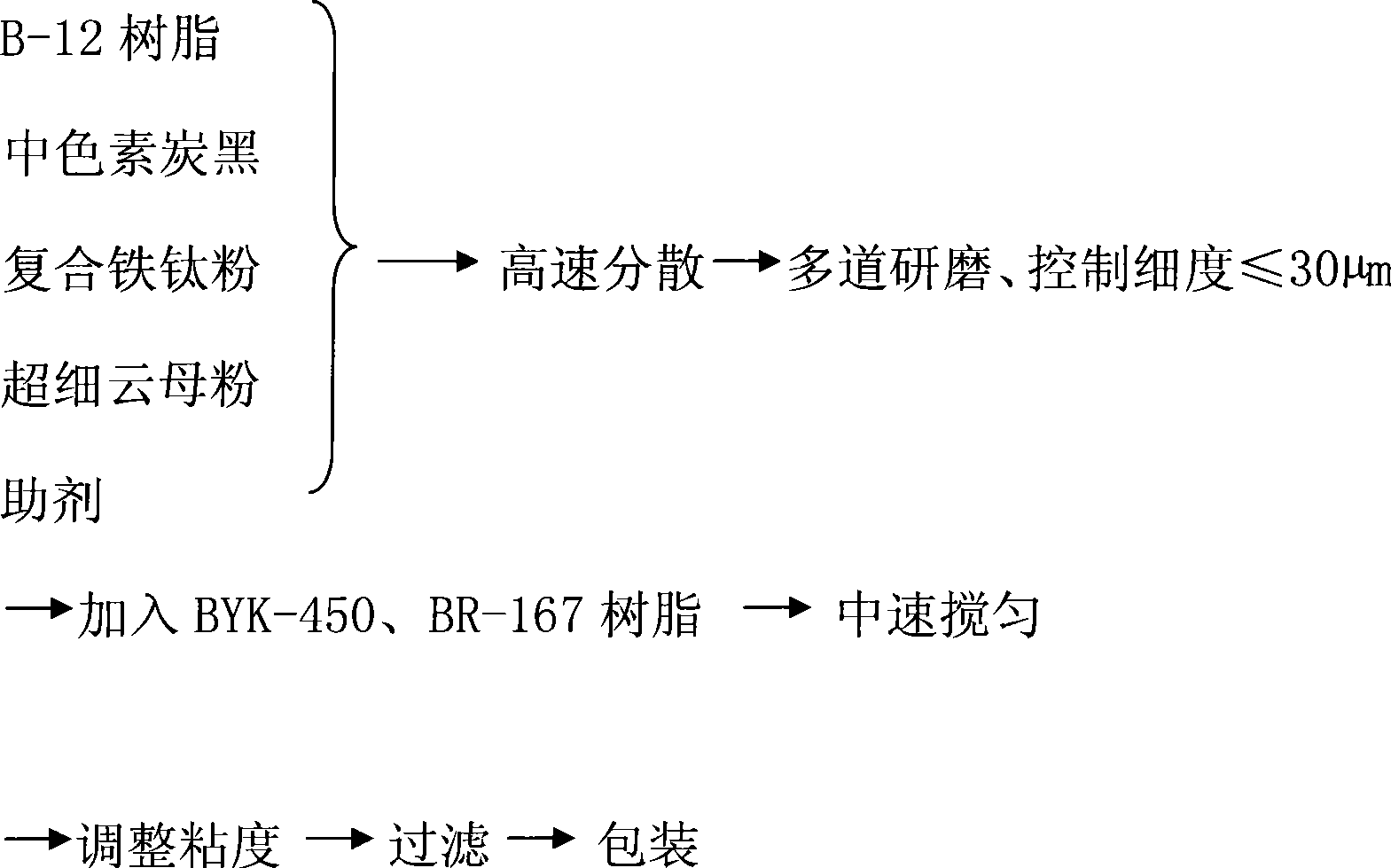

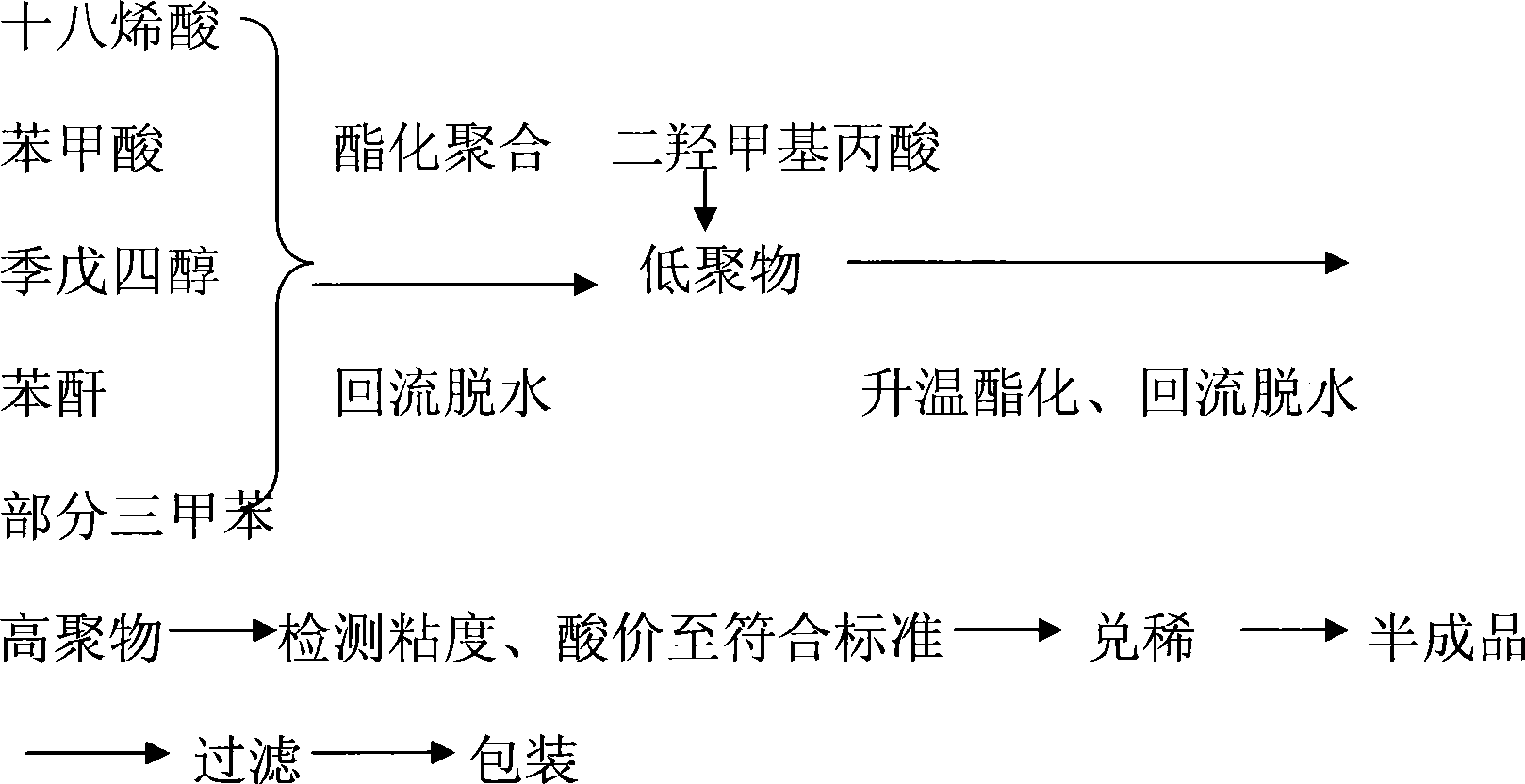

Low temperature quick-drying amino paint for automobile chassis and production method thereof

ActiveCN101434809AImprove efficiencyImprove coating efficiencyPolyester coatingsBenzoic acidPropanoic acid

The invention provides a low-temperature fast-dry amino automobile chassis paint and a production method thereof, wherein, the paint consists of B-12 resin, medium pigment carbon black, compound ferrotitanium powder, ultra-fine mica powder, an auxiliary agent, sealed paratoluenesulfonic acid BYK-450 and BR-167 amino resin; B-12 resin is prepared by octadecenoic acid, benzoic acid, pentaerythritol, phthalic anhydride, dimethylol propionic acid, and trimethyl benzene. The automobile chassis paint adopts special B-12 resin synthetic route to lead the polymer chain to have more active functional groups simultaneously to be matched with the blocked paratoluenesulfonic acid, reduces the baking temperature of the existing amino paint from 130 DEG C to 90 DEG C and reduces the curing film-forming time from 1 hour to half an hour. As the paint film has high crosslinking density, compound ferrotitanium powder and squamous anti-rust pigment are matched for use, and the polyaniline is used for improving the anticorrosive potentials, thus leading the salt spray resistance of the paint to achieve 150 hours and improving the protection performance and the coating efficiency.

Owner:ANQING LINGHU PAINT

2-ammonia methyl-pyridine nickel composition, preparation method and application thereof

InactiveCN101607934AInhibits chain transfer and chain terminationImprove linearityNickel organic compoundsKetoneChemistry

The invention discloses a 2-ammonia methyl-pyridine nickel composition, a preparation method and the application thereof. The composition has a structure of a formula I, wherein R1 stands for hydrogen or alkyl, R2 stands for hydrogen or alkyl, R3 stands for hydrogen or alkyl, and X stands for halogen. The preparation method of the composition comprises the following steps: (1) generating 2-pyridine imine compound through the ketone-ammonia condensation reaction of an aromatic ketone compound and 2,6-diisopropyl aniline; then, reacting with trimethylbenzene magnesium bromide, trimethylaluminium or lithium aluminum hydride to obtain 2-ammonia methyl-pyridine ligand; and (2) under a waterless and anoxic condition, obtaining a 2-ammonia methyl-pyridine nickel composition I by the complexation reaction of the 2-ammonia methyl-pyridine ligand III and (DME) NiX2. The 2-ammonia methyl-pyridine nickel composition has a specific ligand substitute structure, can catalyze ethylene to actively polymerize so as to obtain polyethylene with high molecular weight, narrow distribution and a certain branching degree.

Owner:SUN YAT SEN UNIV

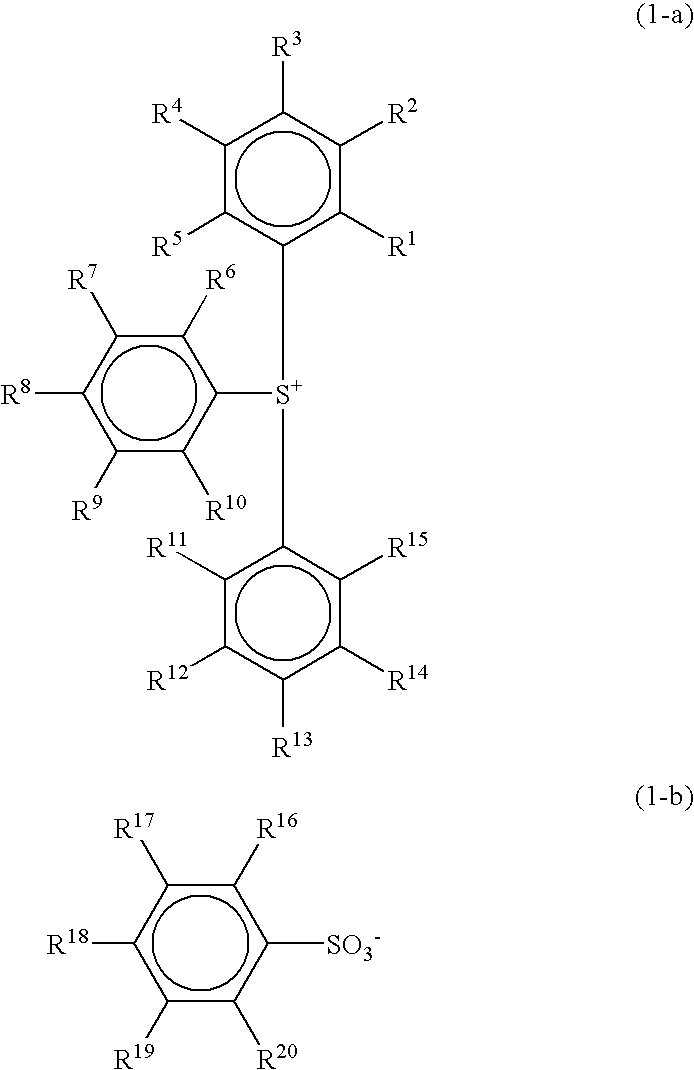

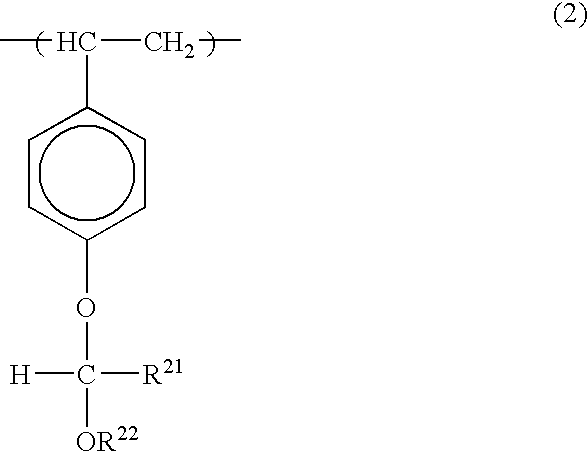

Radiation-sensitive resin composition

A radiation-sensitive resin composition comprising (A) a photoacid generator such as 2,4,6-trimethylphenyldiphenylsulfonium 2,4-difluorobenzenesulfonate or 2,4,6-trimethylphenyldiphenylsulfonium 4-trifluoromethylbenzenesulfonate and (B) a resin having an acetal structure typified by a poly(p-hydroxystyrene) resin in which a part of hydrogen atoms of phenolic hydroxyl groups have been replaced by 1-ethoxyethyl groups, 1-ethoxyethyl groups and t-butoxycarbonyl groups, or 1-ethoxyethyl groups and t-butyl groups. The resin composition is sensitive to deep ultraviolet rays and charged particles such as electron beams, exhibits excellent resolution performance and pattern shape-forming capability, and suppresses a nano-edge roughness phenomenon to a minimal extent.

Owner:JSR CORPORATIOON

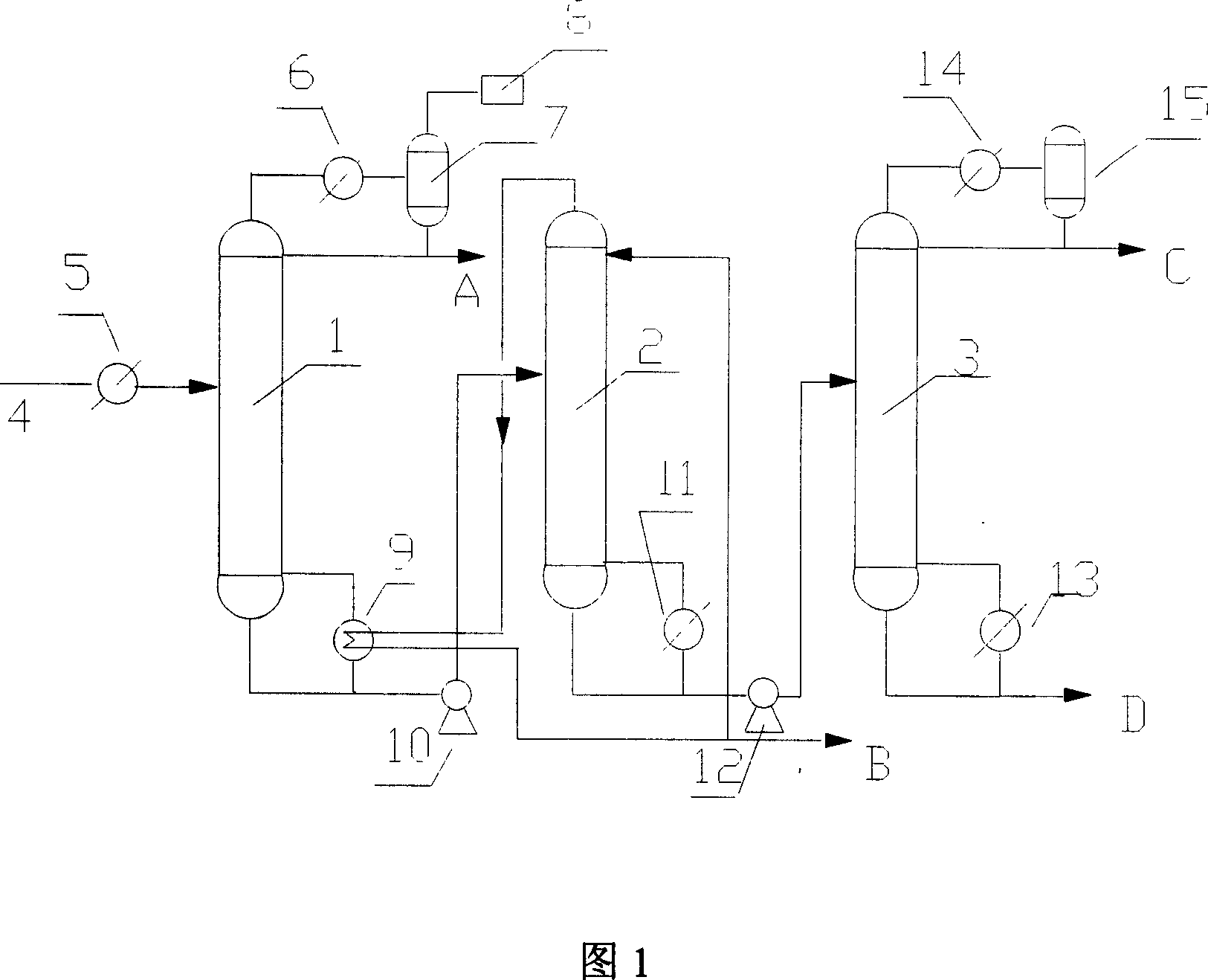

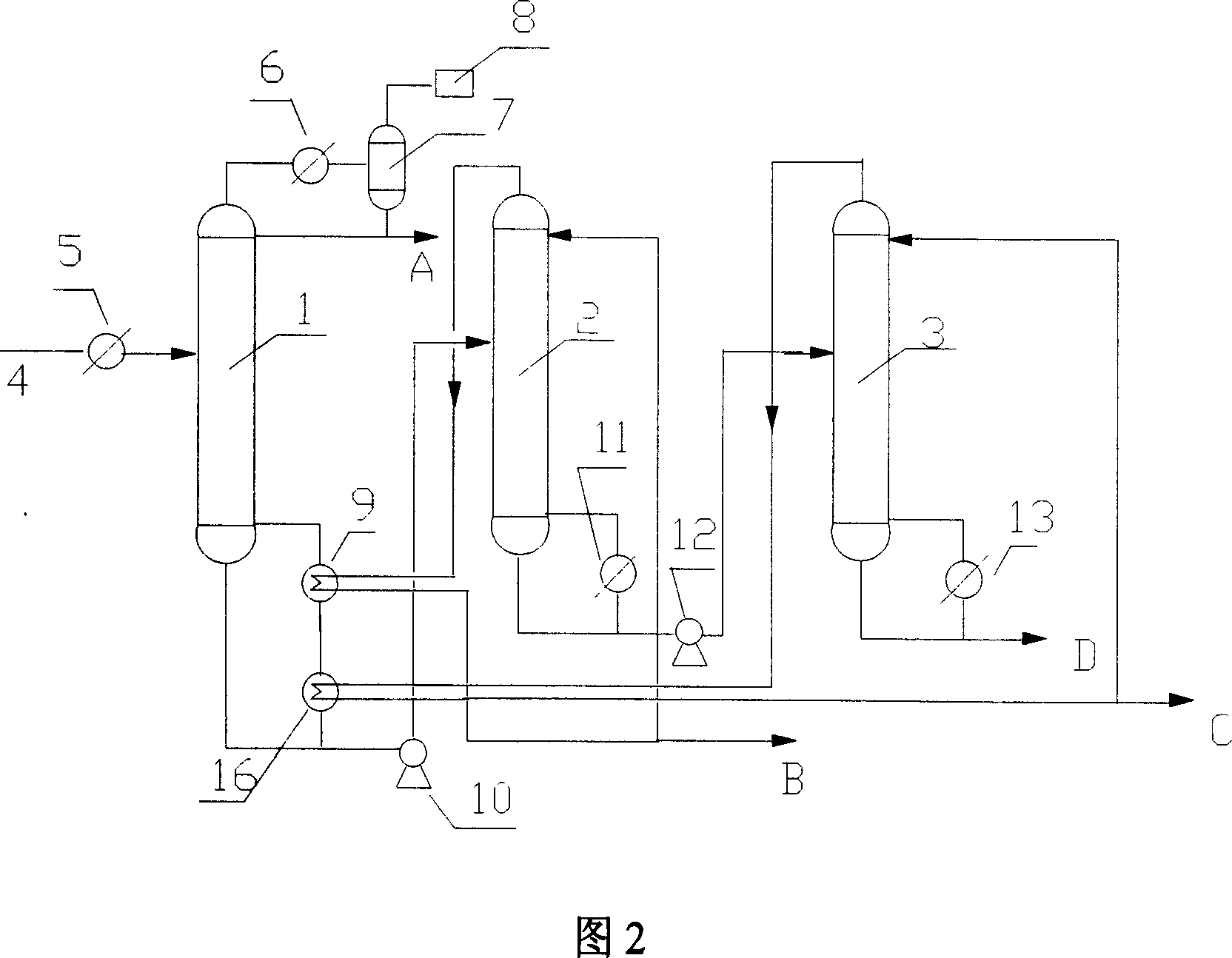

Serial trimethyl benzene separating apparatus and method

InactiveCN1974500AReduce unit energy consumptionRealize Thermal CouplingDistillation purification/separationFractional distillationRefluxReboiler

The present invention relates to serial trimethyl benzene separating apparatus and method. The serial trimethyl benzene separating apparatus includes a pre-separating tower, a sym-trimethyl benzene tower and an unsym-trimethyl benzene tower, and features the condensator on the pre-separating tower connected to the outlet of the pre-separating tower, the reflux accumulator connected to the condensator and one vacuum unit, the reboiler in the bottom of the pre-separating tower connected between the outlet and the inlet of the sym-trimethyl benzene tower. The present invention adopts a serial three-tower process, can produce unsym-trimethyl benzene in purity over 99 % and sym-trimethyl benzene in purity over 35 % simultaneously in the yield over 90 % and power consumption 30 %-40 % lower than one normal pressure process.

Owner:TIANJIN UNIV

Process for the preparation of 2,3,5-trimethyl-p-benzoquinone

InactiveUS6262311B1Highly active andSolution to short lifePhysical/chemical process catalystsOrganic compound preparationRare earthOxygen

Process for the preparation of 2,3,5-trimethyl-p-benzoquinone by oxidizing 2,3,5-trimethylphenol or 2,3,6-trimethylphenol with oxygen or an oxygen-containing gas mixture in the presence of a catalyst system which can be a copper halide and a transition metal halide; for example iron, chromium, manganese, cobalt, nickel, zinc or a rare earth halide, in a two-phase reaction medium, at elevated temperature.

Owner:DEGUSSA AG

Synthesis method for ultraviolet photoinitiator XBPO

InactiveCN102675365AHigh priming activityHigh activityGroup 5/15 element organic compoundsPhenacylPtru catalyst

The invention provides a synthesis method for ultraviolet photoinitiator XBPO, which comprises the following steps of: putting sodium hydride and solvent benzene into a stirring reaction kettle, dropwise adding dichlorophenyl phosphine, putting catalyst organic base, dropwise adding 2, 4, 6-trimethyl benzoyl chloride, slowly dropwise adding pure water, slowly dropwise adding oxidant, dropwise adding 2% sodium hydroxide, washing with water, concentrating, crystallizing, filtering, and drying to obtain the ultraviolet photoinitiator. The synthesis method has the advantages that the photolytic product of the ultraviolet photoinitiator XBPO has two trimethyl benzoyl chloride and one phenyl phosphine acyl free radical, which are higher in initiation activity, compared with the photo initiation activity of TPO. The wide wave band has light sensitivity, so that the GR-XBPO not only can be independently used, but also can be used in cooperation with the other ultraviolet absorbers.

Owner:HUBEI GURUN TECH CO LTD

Synthetic method of photoinitiator dual (2,4,6-trimethylbenzene formyl group) phenyl phosphine oxide

ActiveCN102942593ALess prone to fireImprove securityGroup 5/15 element organic compoundsDichlorophenylphosphinePhenacyl

The invention discloses a synthetic method of photoinitiator dual (2, 4, 6-trimethylbenzene formyl group) phenyl phosphine oxide. The synthetic method comprises processes of using dichlorophenylphosphine and 2, 4, 6-trimethylbenzene acyl chloride to serve as raw materials, conducting a classification reaction under protection of nitrogen to generate dual(2, 4, 6-trimethylbenzene formyl group) phenyl phosphine, oxidizing hydrogen peroxide to obtain a target object-dual (2, 4, 6-trimethylbenzene formyl group) phenyl phosphine oxide. Compared with the existing industrial production, the process has the advantages of being safe in operation process, free of needs of dangerous metallic sodium or potassium, free of needs of using inflammable midbody phenyl phosphine, simple in reaction process, safe, easy to control, high in obtained product yield, good in quality and prone to achieve mass production and the like.

Owner:SHANDONG UNIV OF SCI & TECH

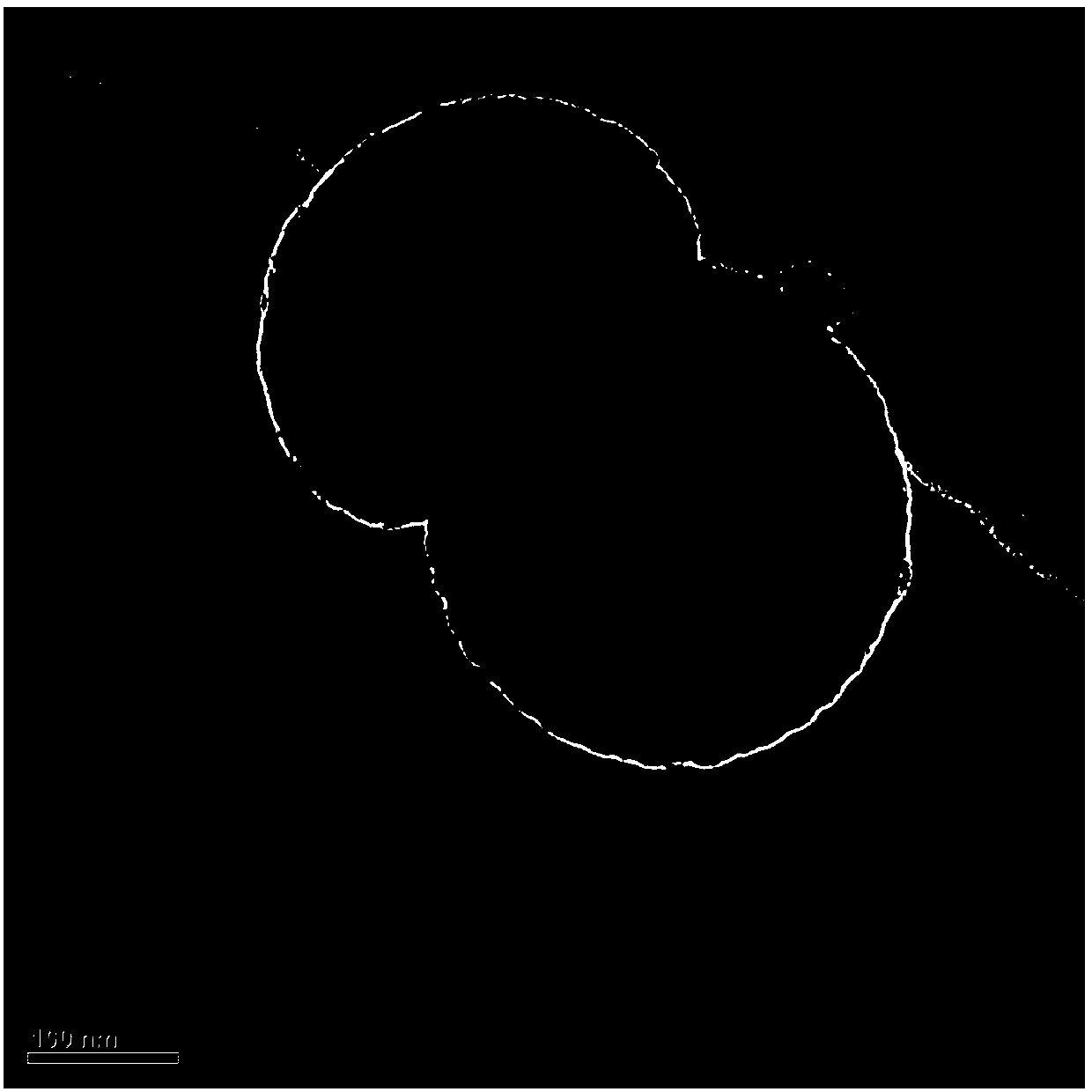

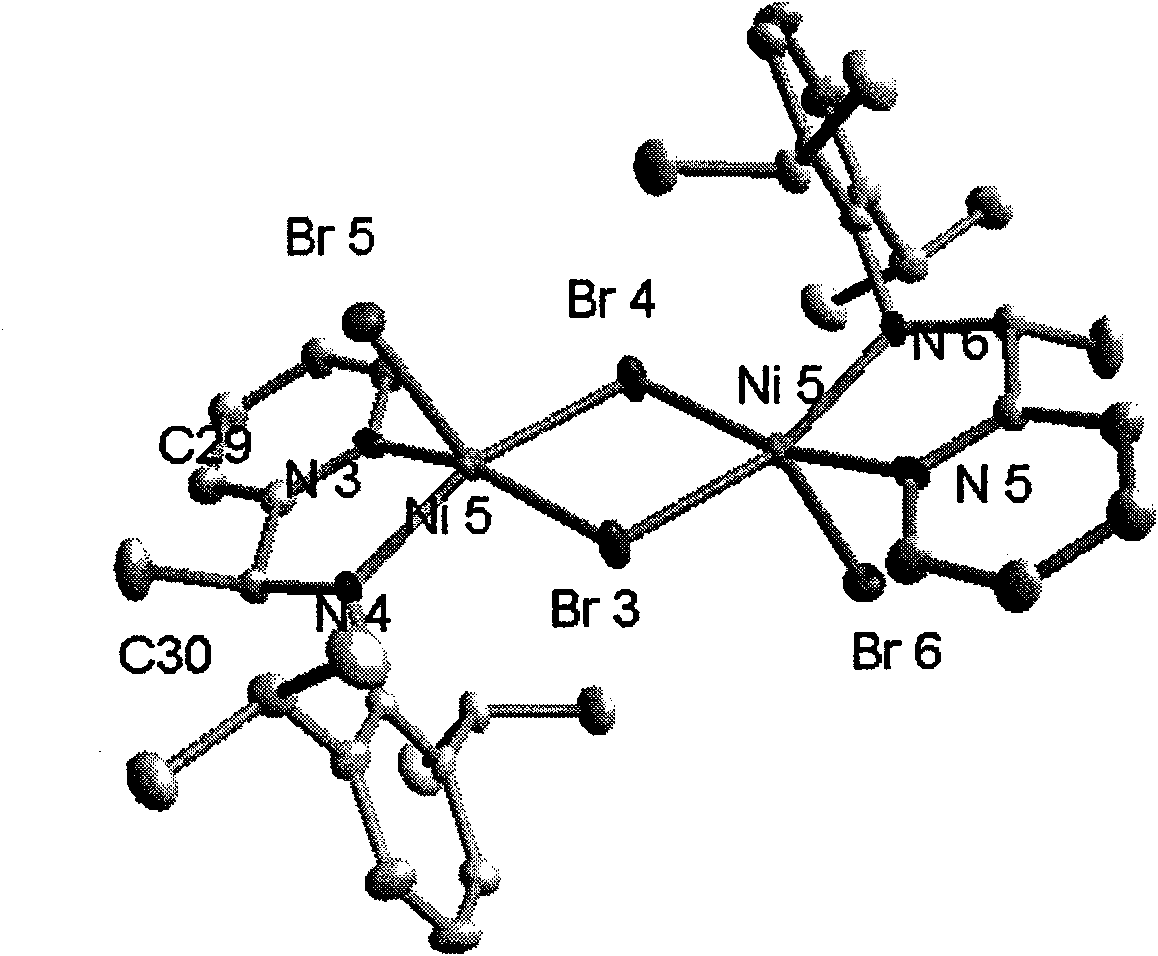

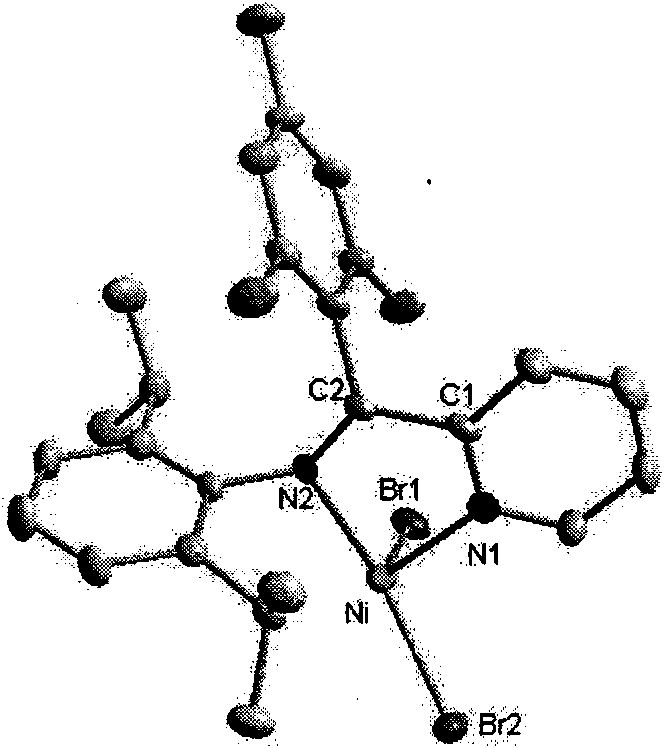

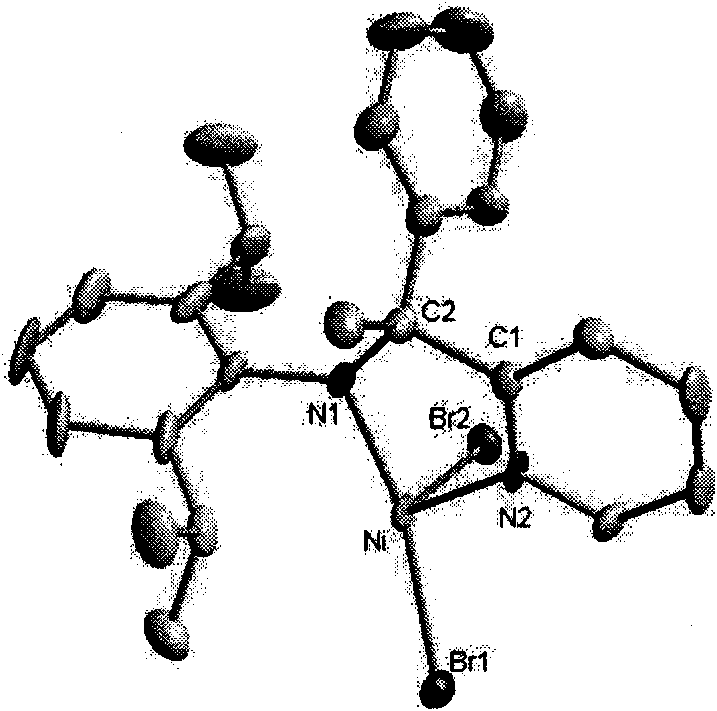

Bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and preparation method and application thereof

ActiveCN106279253AHigh anticancer activityLow costTin organic compoundsAntineoplastic agentsStructural formulaCoordination complex

The invention discloses a bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and a preparation method and application thereof. The structural formula of the complex is shown in the description. The invention further discloses a preparation method for the bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and application of the bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex in preparing antitumor drugs.

Owner:HENGYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and preparation method and application thereof Bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/4d64092a-96ad-4a1d-bffd-3359d71970fc/1608150010361.png)

![Bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and preparation method and application thereof Bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/4d64092a-96ad-4a1d-bffd-3359d71970fc/1608150010362.png)

![Bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and preparation method and application thereof Bis [tris (2-methyl-2-phenyl) propyl-tin] 5-nitro-isophthalate complex and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/4d64092a-96ad-4a1d-bffd-3359d71970fc/1608150010363.png)