Synthesis method for ultraviolet photoinitiator XBPO

A synthesis method and initiator technology are applied in the field of environment-friendly high-efficiency ultraviolet photoinitiator XBPO synthesis, which can solve the problems of no phenyl bisulfite, no enterprise production, and difficult synthesis technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

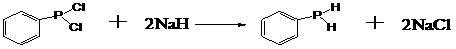

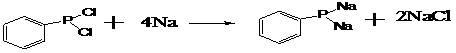

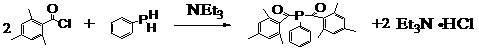

Method used

Image

Examples

Embodiment 1

[0023] Under an inert atmosphere, put 24g (0.5mol) of 50% sodium hydrogen (sodium hydride) and 300ml of benzene into a four-necked reaction flask (1000ml) equipped with a dropping funnel, a stirrer, and a thermometer, and slowly add phenyl dichloride dropwise. Phosphine 90g (0.5mol), the dropping temperature is controlled at 30-50°C, and the dropping time is 2-2.5 hours. After dropping, keep at this temperature for 0.5-1 hour, then cool down to 10°C in ice water. Add 101g (1.0mol) of triethylamine, then slowly add 200g (1.1mol) of 2,4,6-trimethylbenzoyl chloride dropwise, the dropwise temperature is controlled at 10-20°C, and the dropwise time is 3-3.5 hours. After dripping, keep at this temperature for 3 hours, and then slowly add 50ml of pure water dropwise after the heat preservation is over, the dropping temperature is controlled at 20-30°C, and the dropping time is 0.5-1.0 hours. After dripping, keep at this temperature for 0.5 hours, then slowly add 120g of 30% hydrogen...

Embodiment 2

[0025] Under an inert atmosphere, put 24g (0.5mol) of 50% sodium hydrogen (sodium hydride) and 500ml of toluene into a 1000ml four-necked reaction flask equipped with a dropping funnel, a stirrer, and a thermometer, and slowly add phenylphosphine dichloride dropwise. 90g (0.55mol), the dropping temperature is controlled at 30-50°C, and the dropping time is 2-2.5 hours. After dropping, keep at this temperature for 0.5-1 hour, then cool down to 10°C in ice water. Add 110g (1.09mol) of triethylamine, then slowly add 185g (1.0mol) of 2,4,6-trimethylbenzoyl chloride dropwise, the dropwise addition temperature is controlled at 10-20°C, and the dropwise addition time is 3-3.5 hours. After dripping, keep at this temperature for 3 hours, and then slowly add 50ml of pure water dropwise after the heat preservation is over, the dropping temperature is controlled at 20-30°C, and the dropping time is 0.5-1.0 hours. After dripping, keep at this temperature for 0.5 hours, then slowly add 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com