Photoinitiator suitable for solidifying LED as well as preparation method and application of photoinitiator

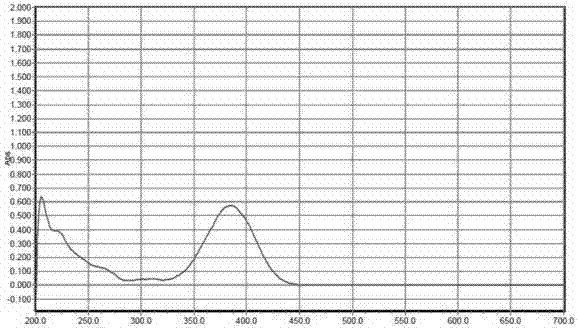

A photoinitiator and compound technology, applied in the field of photoinitiator and its preparation, can solve the problems of single radiation peak and weak absorption, and achieve the effects of good solubility, strong absorption and fast initiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: the preparation of photoinitiator P6601

[0052]

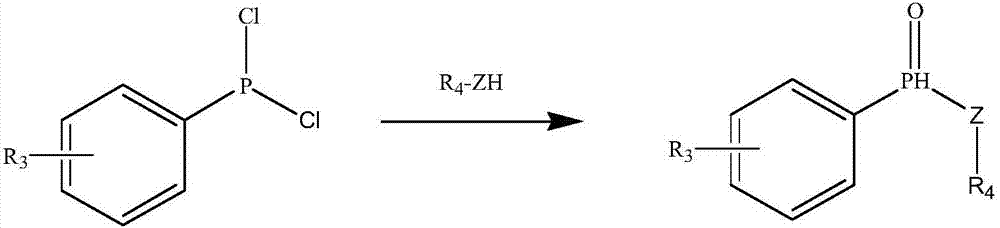

[0053] a. Ethyl phenylphosphonate

[0054]With stirring, 179g (1.0mol) of phenylphosphine dichloride was added dropwise to 138g (3.0mol) of absolute ethanol cooled with ice and kept at 5-10°C. After the dropwise addition, react at room temperature for 3 hours, then evaporate the volatile components under reduced pressure with a water pump, and distill the remaining liquid under reduced pressure to collect 120 g of b.p.120°C / 0.4kpa fraction, with a yield of 70%.

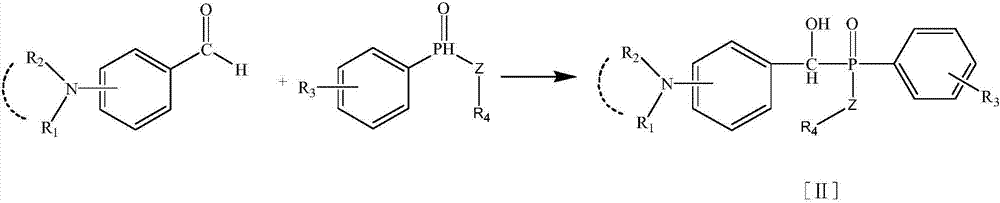

[0055] b. Condensation

[0056] Dissolve 34.0g of ethyl phenylphosphonate and p-dimethylaminobenzaldehyde (29.8g, 0.2mol) in 200ml of tetrahydrofuran, slowly add triethylamine (20.2g, 0.2mol) dropwise under stirring at room temperature, dropwise After completion, the reaction at room temperature was continued for 4 hours. After the reaction was detected by TLC, the solvent was removed and recrystallized to obtain 59.6 g of the intermediate, w...

Embodiment 2

[0059] Embodiment 2: the preparation of photoinitiator P6610

[0060]

[0061] a. S-Ethylphenylphosphinosulfate

[0062] With stirring, 179g (1.0mol) of phenylphosphine dichloride was added dropwise to 186.4g (3.0mol) of anhydrous ethanethiol cooled with ice and kept at 5-10°C. After the dropwise addition, react at room temperature for 3 hours, then evaporate the volatile components under reduced pressure with a water pump, and distill the remaining liquid under reduced pressure to collect 144.6 g of b.p.120°C / 0.4kpa fraction, with a yield of 73.2%.

[0063] b. Condensation

[0064] Dissolve 37.2g of S-ethylphenylphosphinosulfate and p-dimethylaminobenzaldehyde (29.8g, 0.2mol) in 200ml of tetrahydrofuran, slowly add triethylamine (20.2g, 0.2mol) dropwise under normal temperature stirring ), continue to react at room temperature for 4h after the dropwise addition, and after the completion of the TLC detection reaction, remove the solvent and recrystallize to obtain 55.6g o...

Embodiment 3

[0067] Embodiment 3: the application of photoinitiator P6601

[0068] a, the trade mark produced by 25 parts of quality Sartomer company is the four-functional polyester acrylate of CN2203, 20 parts of quality Sartomer company's production mark is the difunctional group bisphenol A epoxy acrylate of CN120, 25 parts of quality The TPGDA produced by the Sartomer company, the TMPTA produced by the Sartomer company of 20 parts of quality are mixed evenly, then the photoinitiator of the present invention that adds 5 parts of quality, the brand that 5 parts of quality BYK companies produce are the leveling agent that is 361, Mix evenly to obtain LED cured coating.

[0069] b. Apply the LED curable coating prepared in this example on a glass sheet, and cure it under the radiation of a UV-LED lamp with a wavelength of 395nm for 1s, 3s, 5s, 10s, 30s, 60s, and 120s, and judge the curing by finger pressure method The tack of the film was used to characterize the curing speed.

[0070] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com