A kind of fluorine-containing polymer microemulsion wetting reversal agent and its preparation method and application

A technology of polymer emulsion and wetting reversal, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of limited application, poor solubility of fluorine monomers, limited types of fluorine monomers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

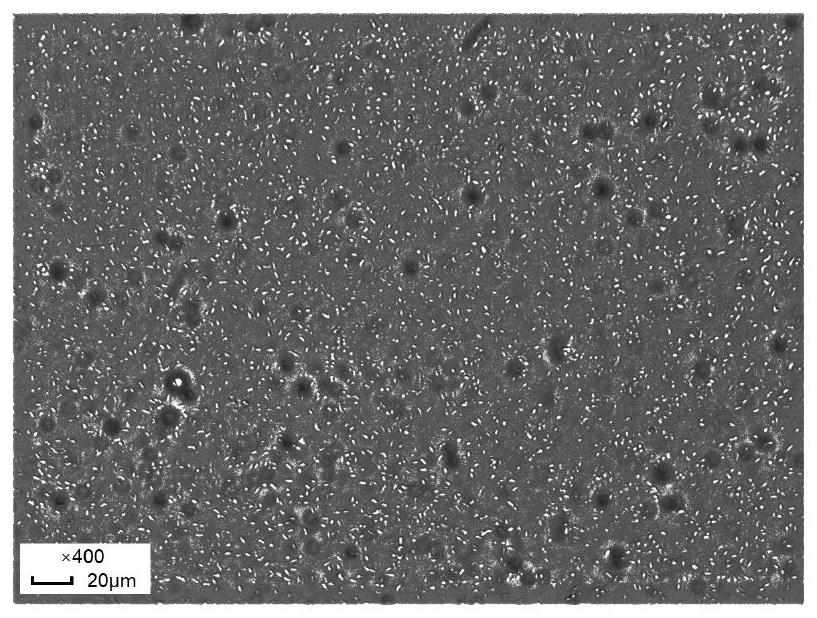

Image

Examples

Embodiment Construction

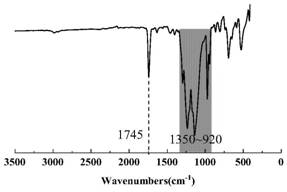

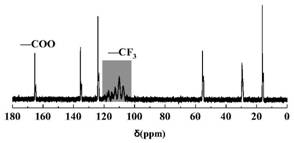

[0009] Technical scheme of the present invention is as follows:

[0010] A preparation method of a fluorine-containing polymer emulsion wetting reversal agent, comprising:

[0011] In the presence of an emulsifier, the fluorine-substituted acrylate monomer is emulsified in water;

[0012] Dissolve the acrylic monomer and initiator in an organic solvent, then drop it into the emulsion of fluorine-substituted acrylate, and carry out polymerization reaction at 75-85°C to obtain a polymer microemulsion wetting reversal agent;

[0013] The fluorine-substituted acrylate monomer is 2,3,4,5,5,5-hexafluoro-2,4-bis(trifluoromethyl)pentyl methacrylate ("12F" for short); the The acrylic monomer is acrylic acid, methacrylic acid, methyl methacrylate, ethyl methacrylate or butyl methacrylate.

[0014] According to the present invention, preferred processing conditions are as one or more of the following:

[0015] The emulsification of the fluorine-substituted acrylate monomer is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com