Emulsifiable concentrate pesticide packaging film

A packaging film and pesticide technology, applied in the field of packaging materials, can solve the problems of emulsifiable oil solvent resistance and hot pressing, and achieve the effects of improving mechanical properties, strong hydrophilic properties, and reducing static contact angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

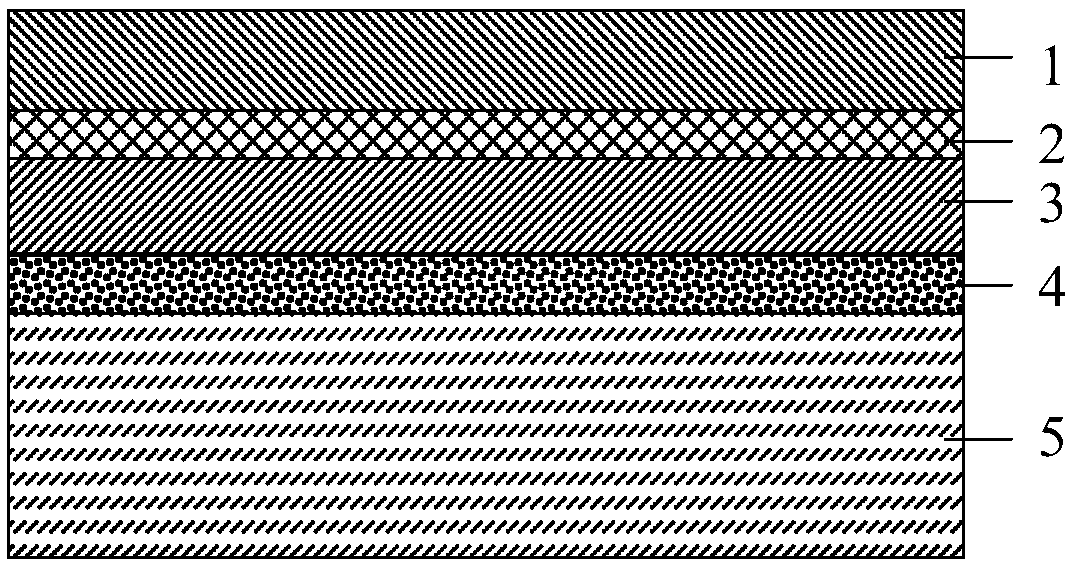

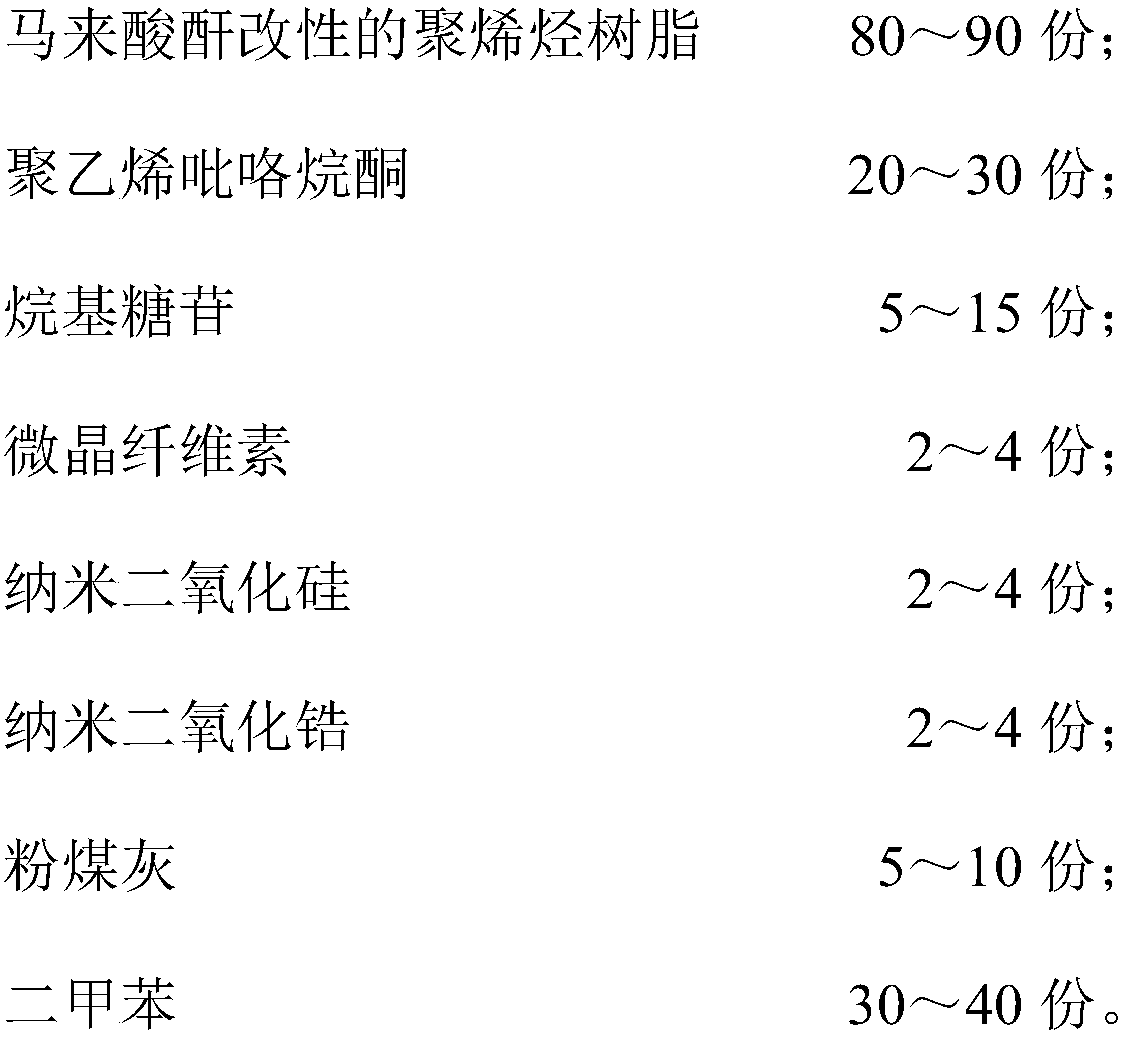

[0037] This embodiment provides a kind of emulsifiable cream pesticide packaging film, such as figure 1 As shown, it includes a support layer 1 , a first adhesive layer 2 , an aluminum foil layer 3 , a second adhesive layer 4 and a heat-sealing layer 5 which are stacked in sequence.

[0038] The support layer 1 is a biaxially stretched polyester film with a thickness of 18 μm. The support layer 1 has high strength, which is beneficial to curing and molding of the packaging film.

[0039] The first adhesive layer 2 is used to bond the support 1 and the aluminum foil layer 3, including 35 parts by weight of polyurethane, 17.5 parts by weight of propenyl phenyl ether, 5 parts by weight of polyvinyl alcohol, poly(3,4-ethylenedioxythiophene ) 2 parts by weight, 1.5 parts by weight of alumina-coated ultrafine barium titanate, 0.4 parts by weight of zeolite powder, 0.4 parts by weight of sodium bentonite, and 3 parts by weight of a curing agent.

[0040] Among them, the aluminum oxi...

Embodiment 2

[0049] This embodiment provides a kind of emulsifiable cream pesticide packaging film, such as figure 1 As shown, it includes a support layer 1 , a first adhesive layer 2 , an aluminum foil layer 3 , a second adhesive layer 4 and a heat-sealing layer 5 which are stacked in sequence.

[0050] The support layer 1 is a biaxially stretched nylon film with a thickness of 12 μm. The support layer 1 has high strength, which is beneficial to curing and molding of the packaging film.

[0051] The first adhesive layer 2 is used to bond the support 1 and the aluminum foil layer 3, including 30 parts by weight of polyurethane, 20 parts by weight of propenyl phenyl ether, 4 parts by weight of polyvinyl alcohol, poly(3,4-ethylenedioxythiophene ) 1.5 parts by weight, 2 parts by weight of alumina-coated ultrafine barium titanate, 0.5 parts by weight of zeolite powder, 0.5 parts by weight of sodium bentonite, and 2 parts by weight of curing agent.

[0052] Among them, the aluminum oxide-coate...

Embodiment 3

[0061] This embodiment provides a kind of emulsifiable cream pesticide packaging film, such as figure 1 As shown, it includes a support layer 1 , a first adhesive layer 2 , an aluminum foil layer 3 , a second adhesive layer 4 and a heat-sealing layer 5 which are stacked in sequence.

[0062] The supporting layer 1 is a biaxially stretched polyester film with a thickness of 25 μm. The supporting layer 1 has high strength, which is beneficial to curing and molding of the packaging film.

[0063] The first adhesive layer 2 is used to bond the support 1 and the aluminum foil layer 3, including 40 parts by weight of polyurethane, 15 parts by weight of propenyl phenyl ether, 6 parts by weight of polyvinyl alcohol, poly(3,4-ethylenedioxythiophene ) 2.5 parts by weight, 1 part by weight of alumina-coated ultrafine barium titanate, 0.3 parts by weight of zeolite powder, 0.3 parts by weight of sodium bentonite, and 4 parts by weight of curing agent.

[0064] Among them, the aluminum ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com