Patents

Literature

240results about How to "Reduce shrinkage stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mortar for concrete base surface repair, and preparation method thereof

The present invention belongs to a building mortar, and particularly relates to a mortar for concrete base surface repair, and a preparation method thereof. The mortar comprises the following raw materials by mass: 20-80 parts of silicate cement, 20-100 parts of sulphoaluminate cement, 80-190 parts of aggregate, 40-100 parts of a mineral admixture, 30-80 parts of an aqueous epoxy emulsion, 0.2-0.5 part of cellulose ether, 0.1-0.5 part of anti-cracking fibers, and 20-85 parts of water. The mortar of the present invention has characteristics of strong adhesion, excellent cracking resistance, excellent compression resistance, high bonding strength, and low price.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

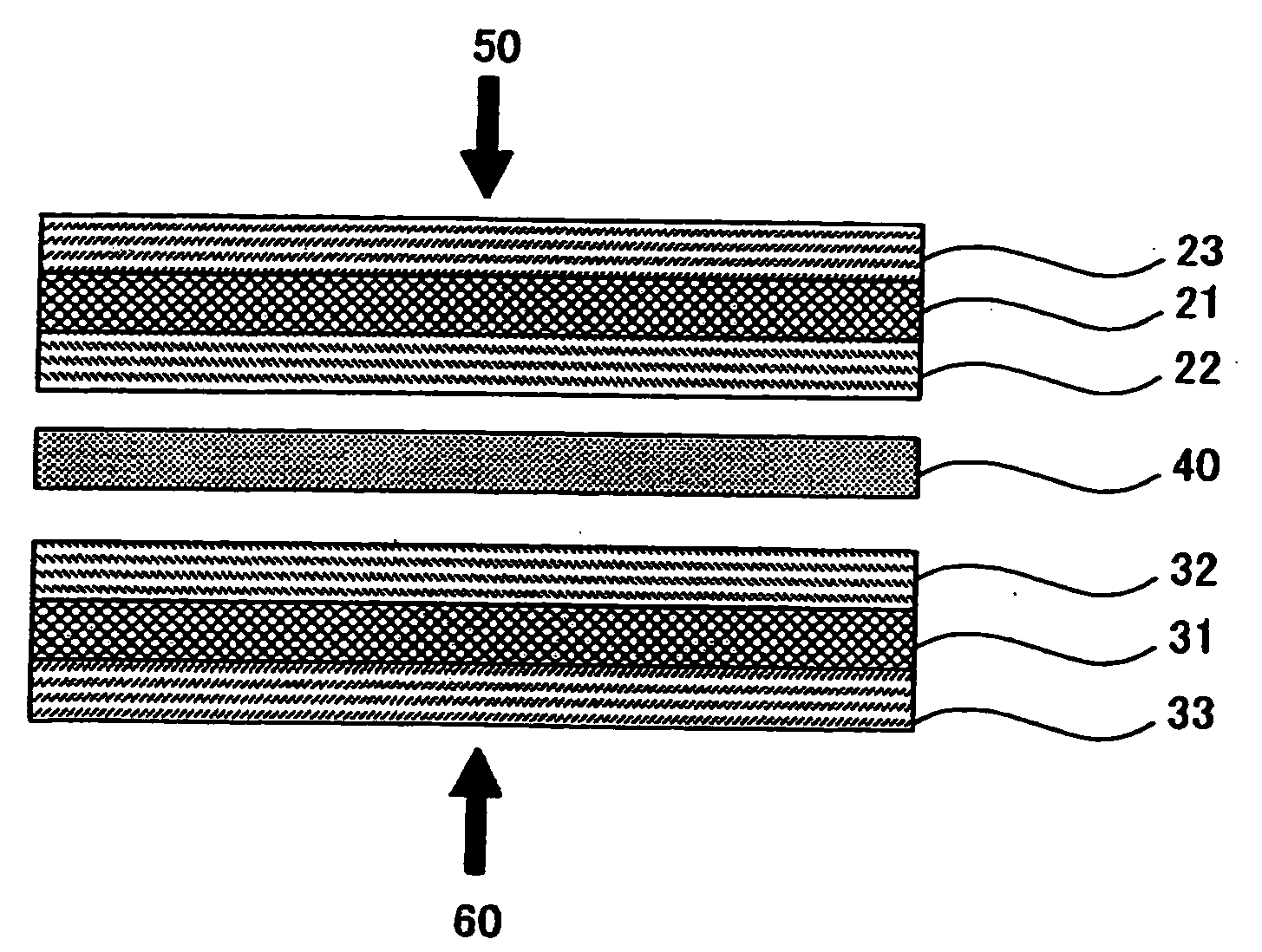

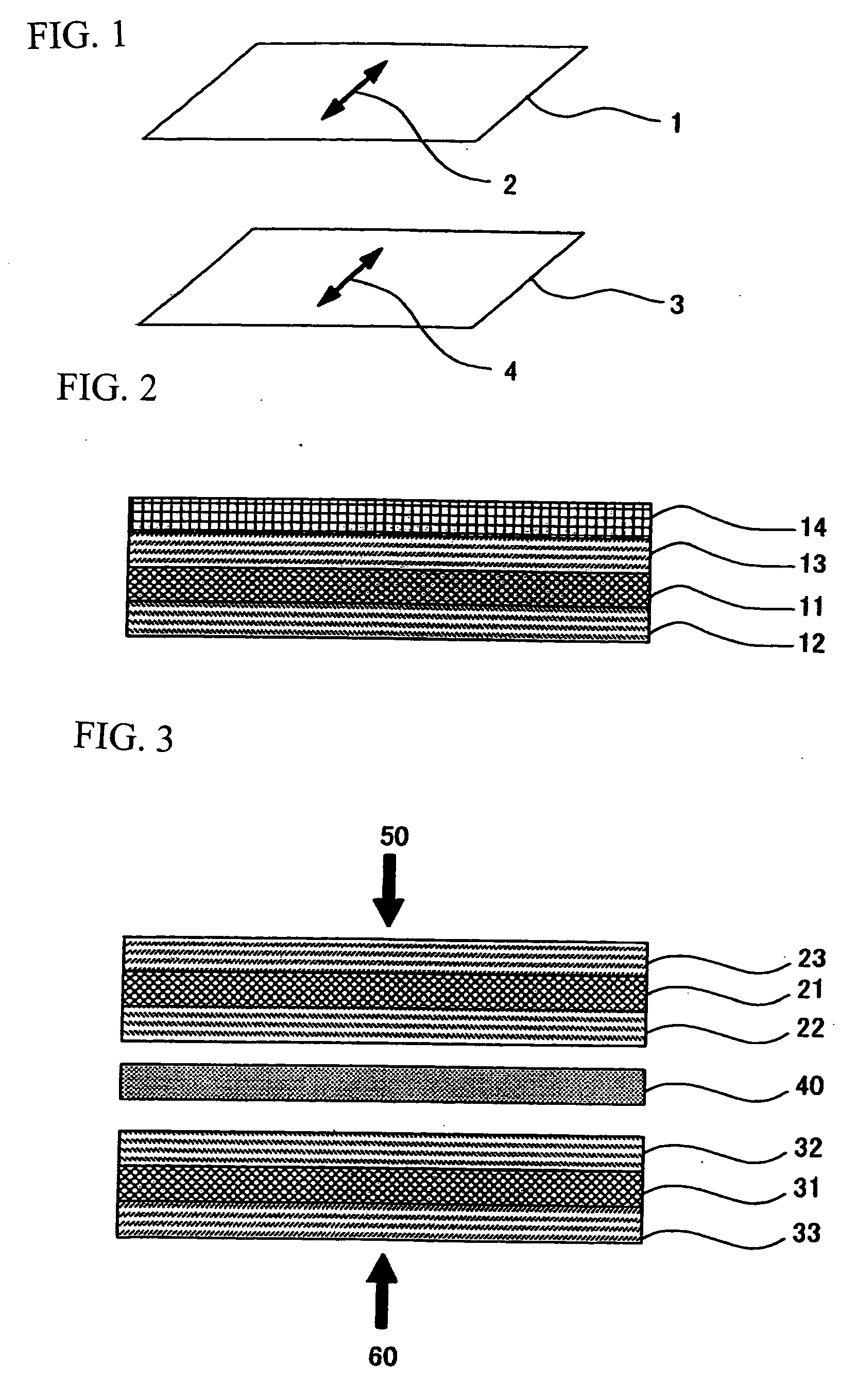

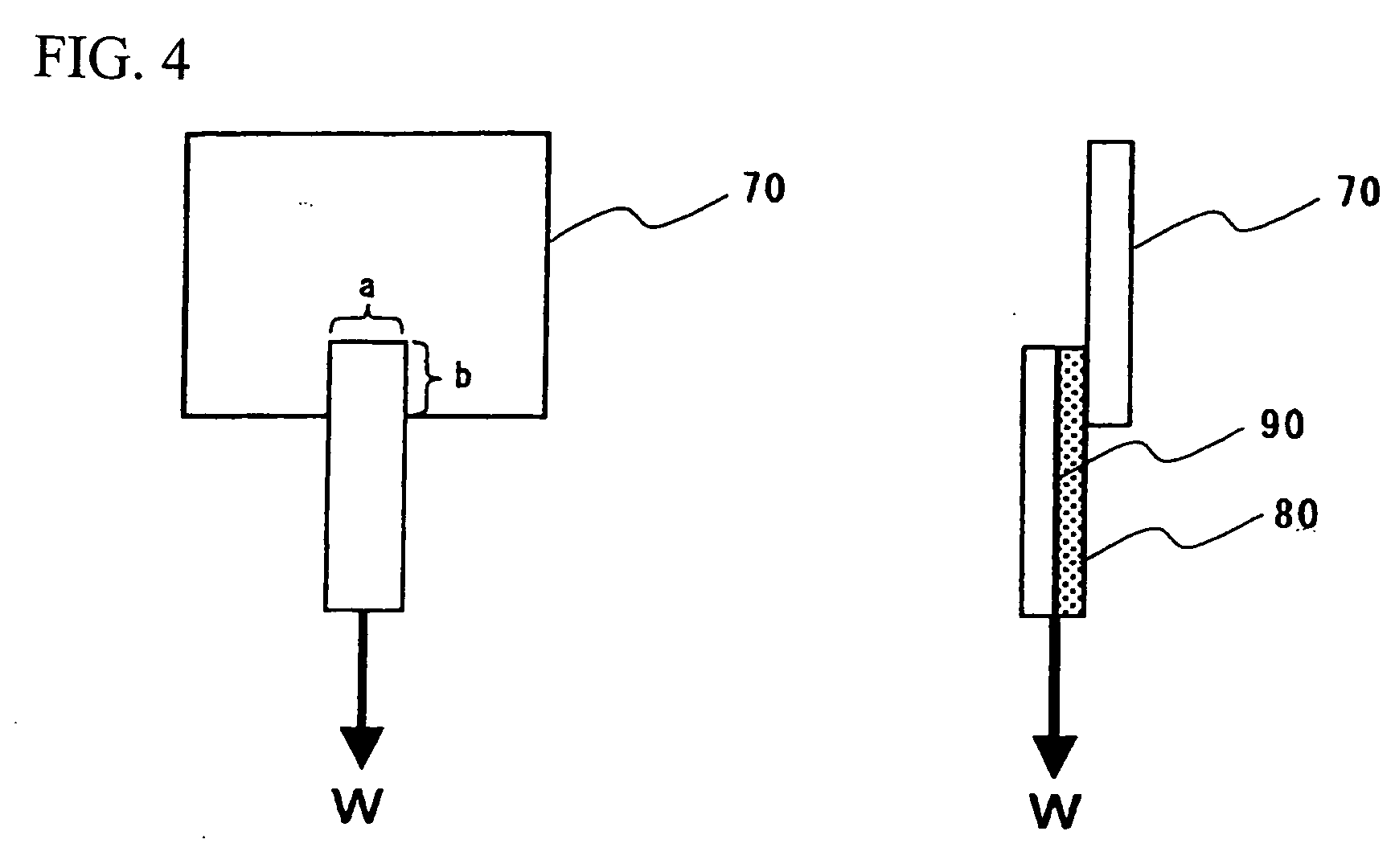

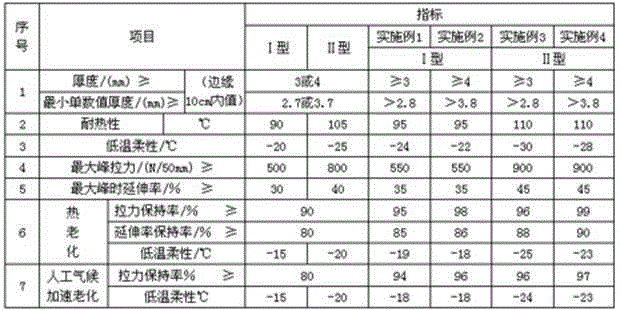

Polarizing plate and liquid crystal display using the same

InactiveUS20060268200A1High optical performanceLess leakage of lightLiquid crystal compositionsThin material handlingPhysicsPolarizer

A polarizing plate is provided and includes: a polarizer; two protective films, the polarizer being between the two protective films; and an adhesive layer on at least one of the two protective films. At least one of the two protective films has an elastic modulus E satisfying formula (1): 5,700 MPa≦E≦10,000 MPa , and the adhesive layer undergoes creep deformation of less than 70 μm when a piece of the adhesive layer having a size of 10 mm in width and 10 mm in length is stuck on an alkali-free glass plate and a load of 200 g is applied to the adhesive layer in an atmosphere of 50° C. for 1 hour.

Owner:FUJIFILM CORP

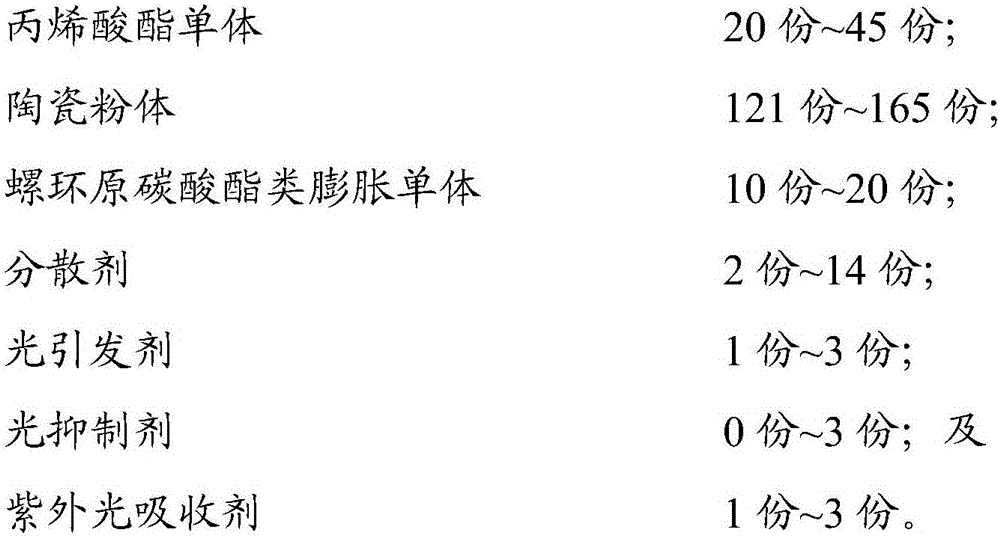

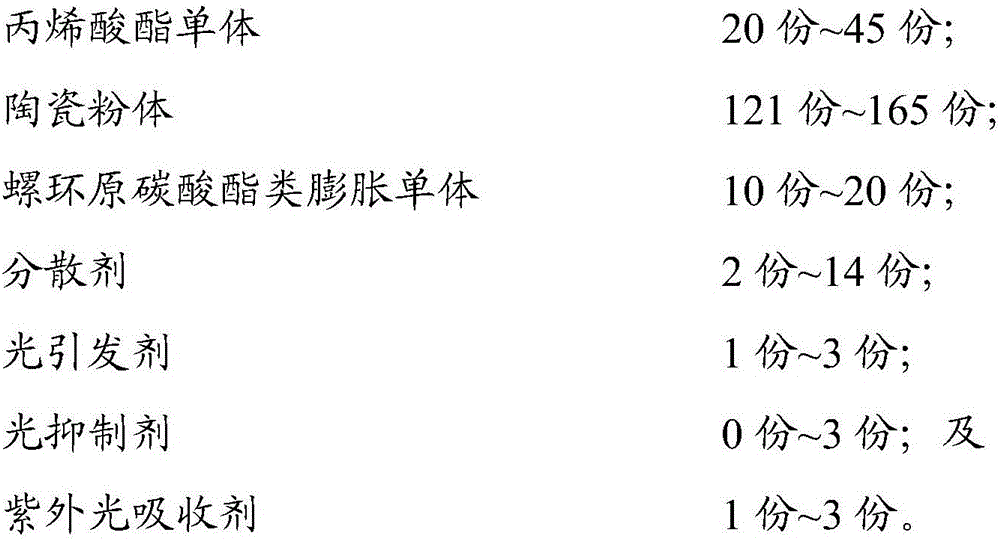

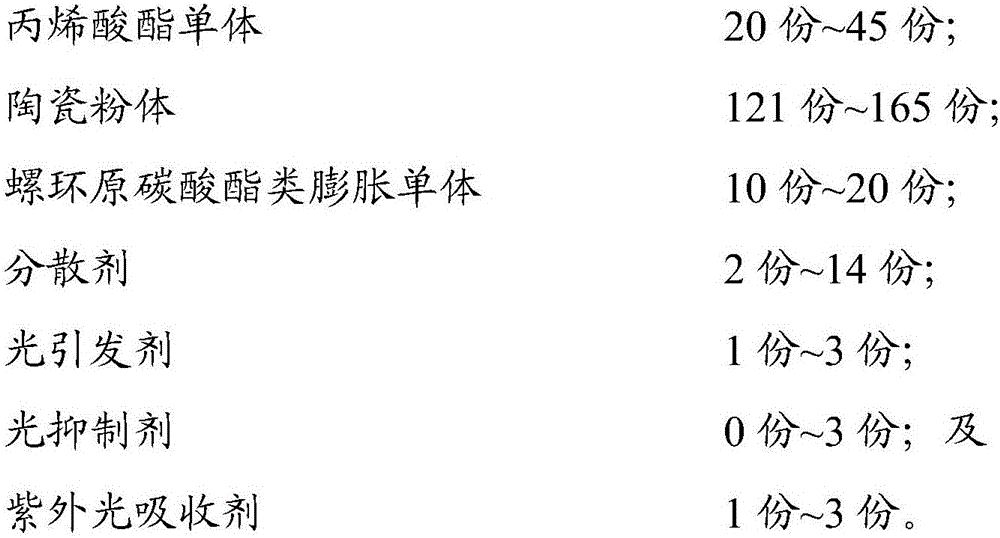

Ceramic composite for 3D printing and preparation method thereof

ActiveCN106007671AReduce shrinkage stressReduce internal stressAdditive manufacturing apparatusCeramic compositeInvestment casting

The invention relates to a ceramic composite for 3D printing and a preparation method thereof. The ceramic composite for 3D printing is characterized by comprising the following components according to parts by weight: 20-45 parts of acrylate monomer, 121-165 parts of ceramic powder, 10-20 parts of spiro-orthocarbonate expansive monomer, 2-14 parts of a dispersant, 1-3 parts of a photo-initiator, 0-3 parts of a photo-inhibitor, and 1-3 parts of an ultraviolet absorber. The ceramic composite for 3D printing is low in curing and contraction degree and short in curing time and therefore is applicable to investment casting.

Owner:深圳长朗智能科技有限公司

Anti-sagging spraying prime coat

InactiveCN102732133AEasy to fillGood flexibilityPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterPolymer science

The present invention discloses an anti-sagging spraying primer coat, which comprises, by weight, 10-25% of a two functionality aliphatic polyurethane acrylate, 20-30% of a modified epoxy acrylate, 10-20% of a polyester acrylate, 10-15% of a monomer, 25-30% of a filler, 3-5% of a photoinitiator, 0.5-2% of an anti-sagging additive, 0.2-0.5% of an anti-foaming agent, and 0.1-0.3% of a leveling agent. With application of the UV paint as the spraying primer coat, the problem of sagging during a coating process can be avoided, the whole coating efficiency can be improved, the environment-friendly characteristic is provided, and the organic solvent emission can be reduced.

Owner:HUIZHOU CHANGRUNFA PAINT

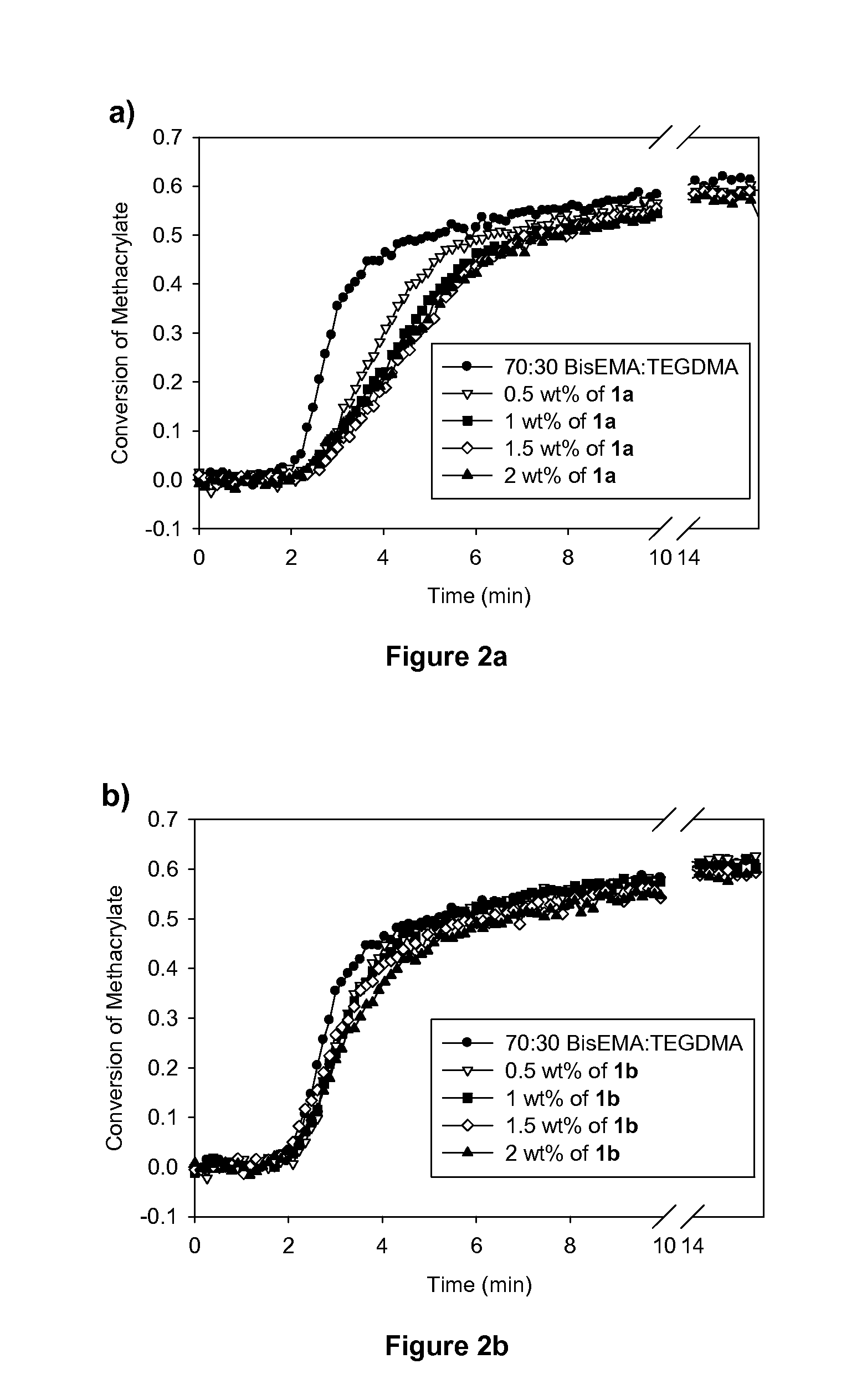

Reducing polymerization-induced shrinkage stress by reversible addition-fragmentation chain transfer

ActiveUS20130096219A1Prevent premature gelationReduce shrinkage stressCross-linkCrosslinked polymers

The invention provides methods of reducing shrinkage stress in cross-linked polymerized materials by combining an addition-fragmentation chain transfer additive with a resin system prior to polymerization. The methods of the invention can improve the performance of conventional resin systems by reducing the shrinkage stress without significantly degrading the mechanical properties of the polymerized material. The shrinkage stress in the crosslinked polymeric materials produced by the methods of the invention may be from 25% to 75% of that of a control material produced by polymerization of the resin system alone to the same conversion.

Owner:UNIV OF COLORADO THE REGENTS OF

Polyurea adhesive composition and preparation method thereof

InactiveCN106905911ASolve the shortcomings of fast reaction time and short gel timeReduce shrinkage stressNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNano siliconPolyaspartic

The invention discloses a polyurea adhesive composition and a preparation method thereof. The polyurea adhesive composition is mainly prepared from polyaspartic ester, nanofiller and a curing agent. The polyaspartic ester is prepared by enabling an organic diamine compound and maleate to make a Michael addition reaction; the curing agent is prepared from an organic diisocyanate or polyisocyanate component, and can be a monomer, a polymer, a derivative of isocyanate, a prepolymer or a semi-prepolymer; the nanofiller is selected from nano-silicon dioxide, nano-titanium dioxide and nano-silicon carbide. By utilizing the Michael addition reaction of the organic diamine compound and the maleate, primary amine is transformed into secondary amine on the one hand, and a group having higher steric hindrance is introduced on the other hand, so that the defects that a polyurea material is rapid in reaction time and short in gelation time are overcome; the nanofiller is added into the polyurea adhesive composition, so that the stress shrinkage caused during the curing of an adhesive film is effectively reduced, and the polyurea adhesive composition is high in bonding strength.

Owner:北京奥润联创微电子科技开发有限公司

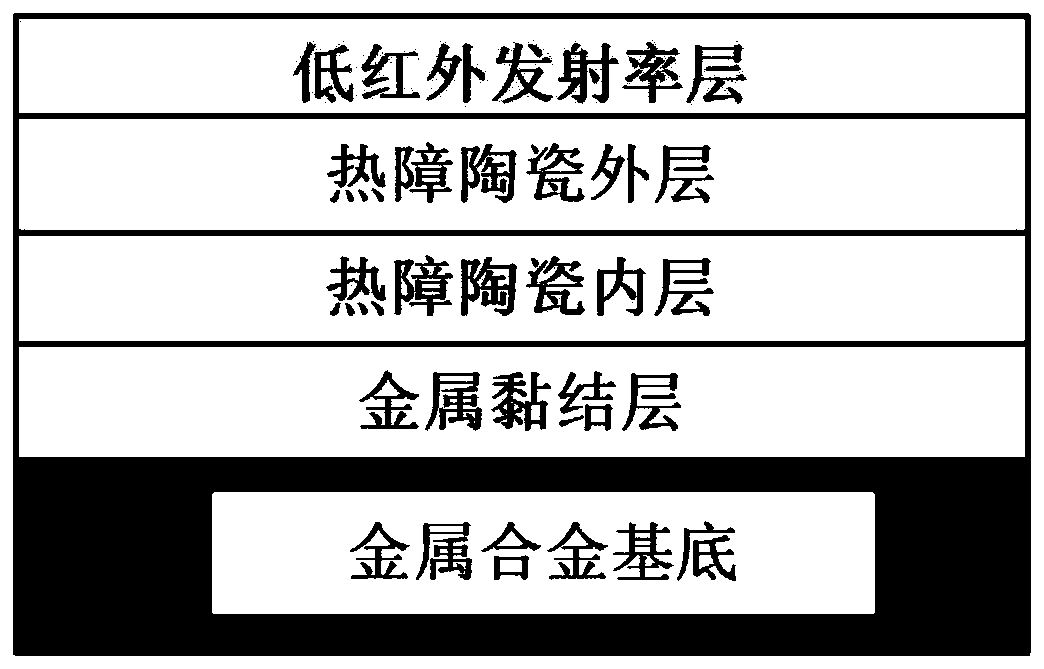

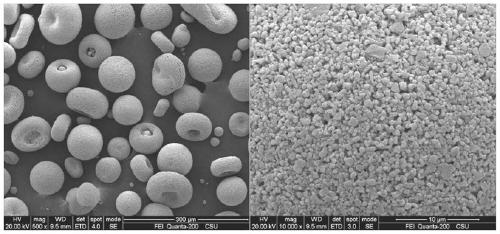

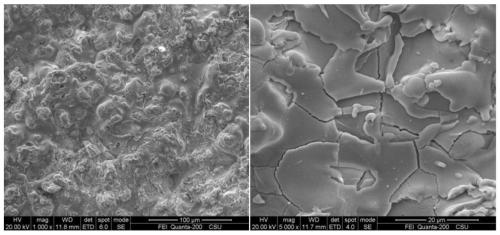

Double-layer thermal barrier/high-temperature low-infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110055486AGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityAlloy

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating which is of a multilayer superposition structure. The multilayer superposition structure sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a thermal barrier ceramic outer layer and a low-infrared emissivity layer from inside to outside, and the thermal barrier ceramic inner layer is La2Zr2O7-8YSZ mixture layer, wherein the mass fraction of La2Zr2O7 powder in the mixture is not more than 45%, the thermal barrier ceramic outer layer is a rare earthzirconate layer, and the low-infrared emissivity layer is a Bi2O3-Al2O3-ZrO2-CaO-SiO2 glass coating comprising conductive phase AuPt alloy powder. The invention also provides a metal composite material with the coating and a preparation method thereof. The integrated coating has the characteristics of heat insulation performance, high-temperature low infrared emissivity, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

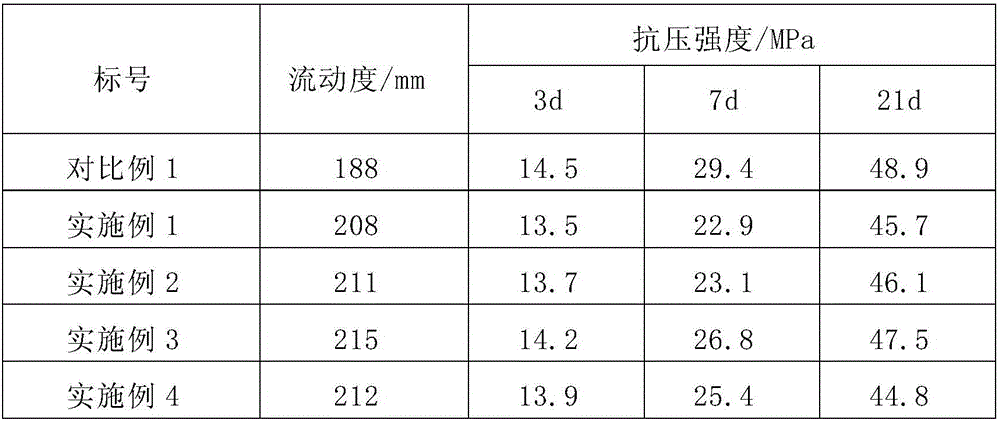

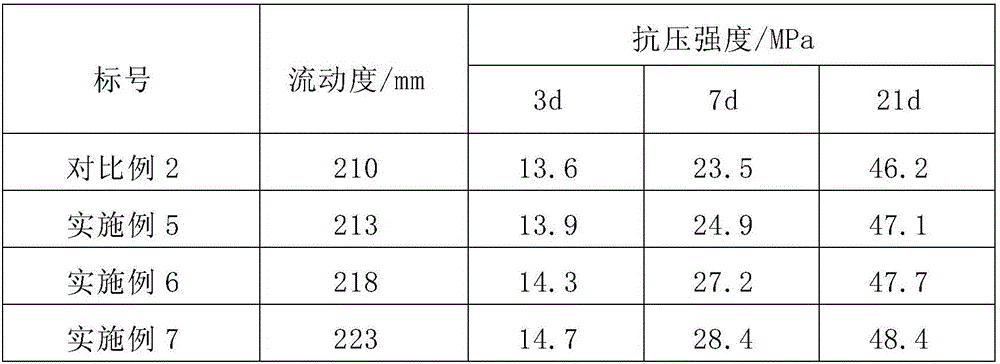

Surface tension adjustment reduction type polycarboxylate superplasticizer and preparation method thereof

The present invention provides a preparation method of a surface tension adjustment reduction type polycarboxylate superplasticizer. The method is simple and high in cost performance, wherein raw materials are easily available and low in cost. The invention also provides a surface tension adjustment reduction type polycarboxylate superplasticizer prepared by the above method. The surface tension adjustment reduction type polycarboxylate superplasticizer can significantly reduce the surface tension of the aqueous solution. The result of the reduction test on the concrete shows that, the surface tension adjustment reduction type polycarboxylate superplasticizer is good in reduction effect. Compared with a conventional ether type polycarboxylate superplasticizer produced by the company of the invention, the shrinkage ratio of the concrete is reduced by 71%. When the polycarboxylate superplasticizer is applied to the concrete, the workability and the strength of the concrete are not affected at all. Therefore, the cost performance is high.

Owner:GUANGDONG REDWALL NEW MATERIALS +1

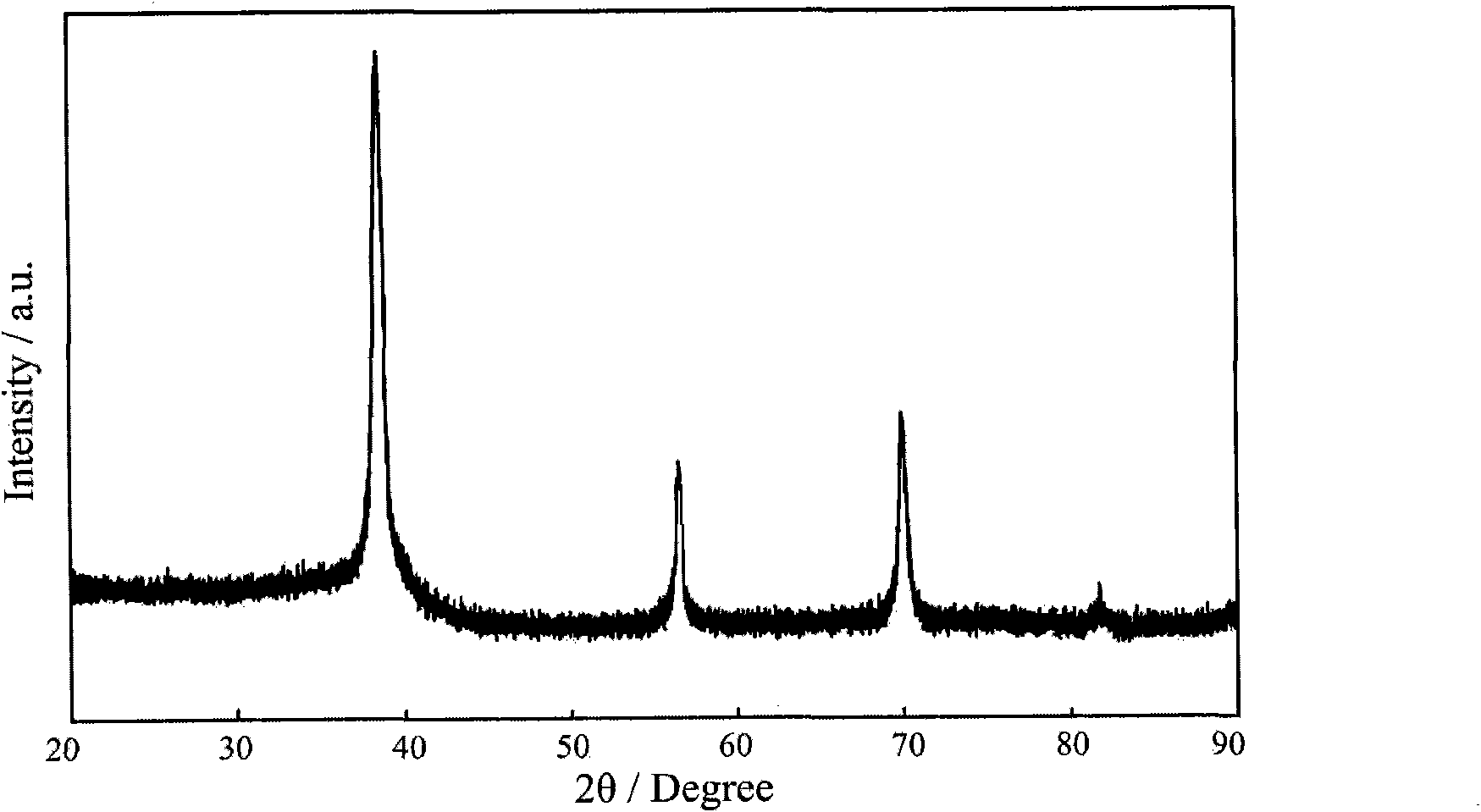

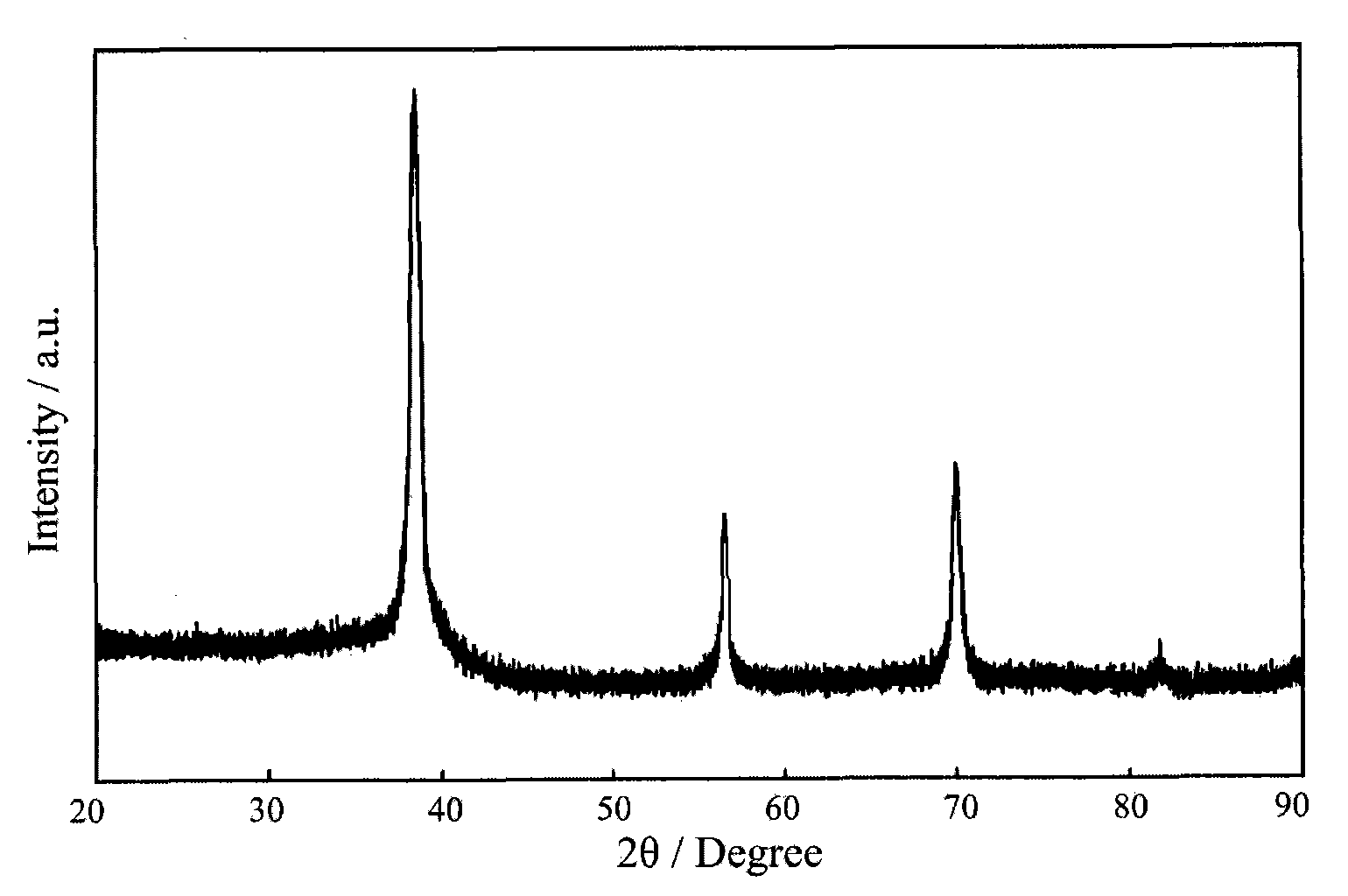

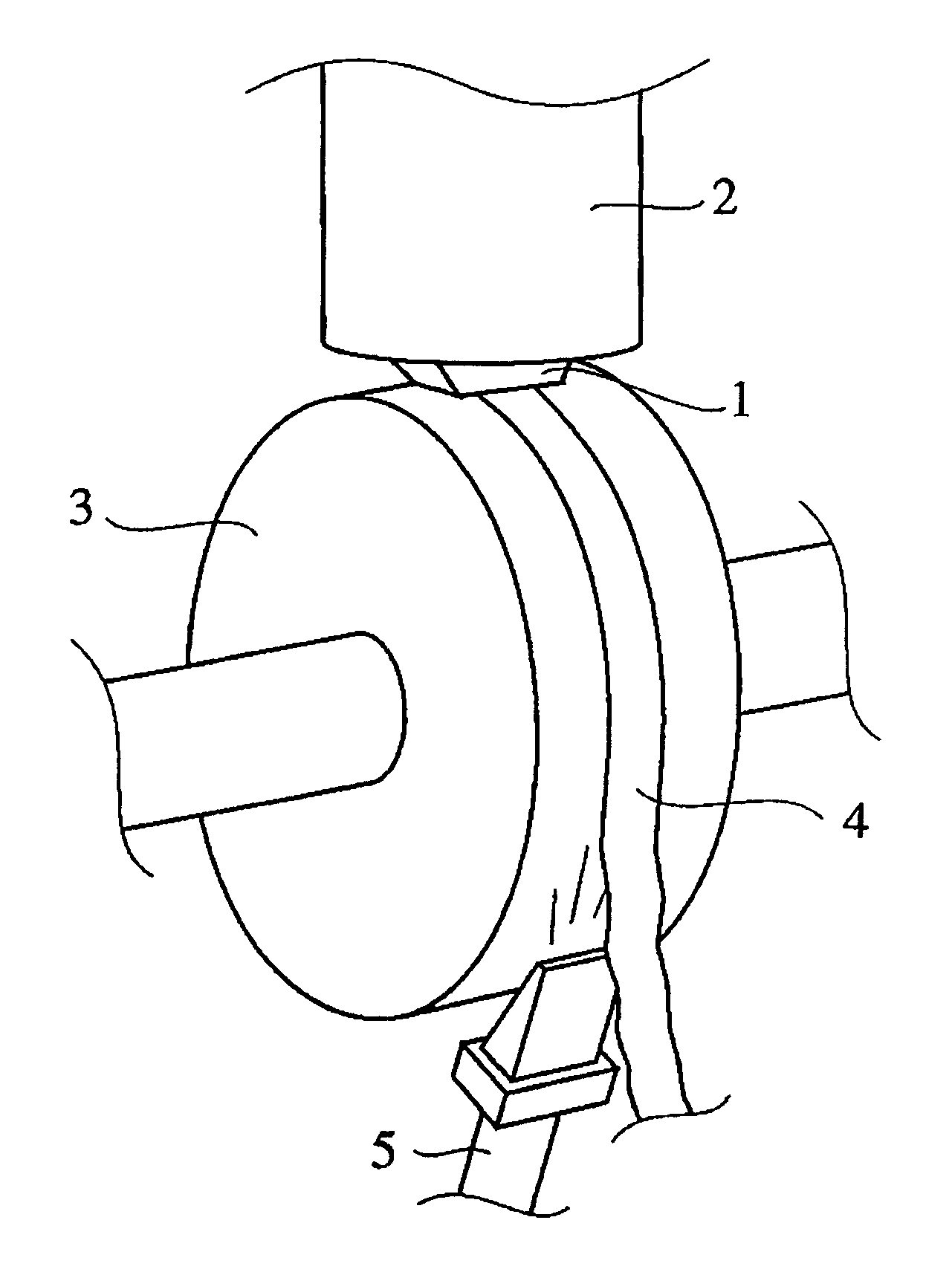

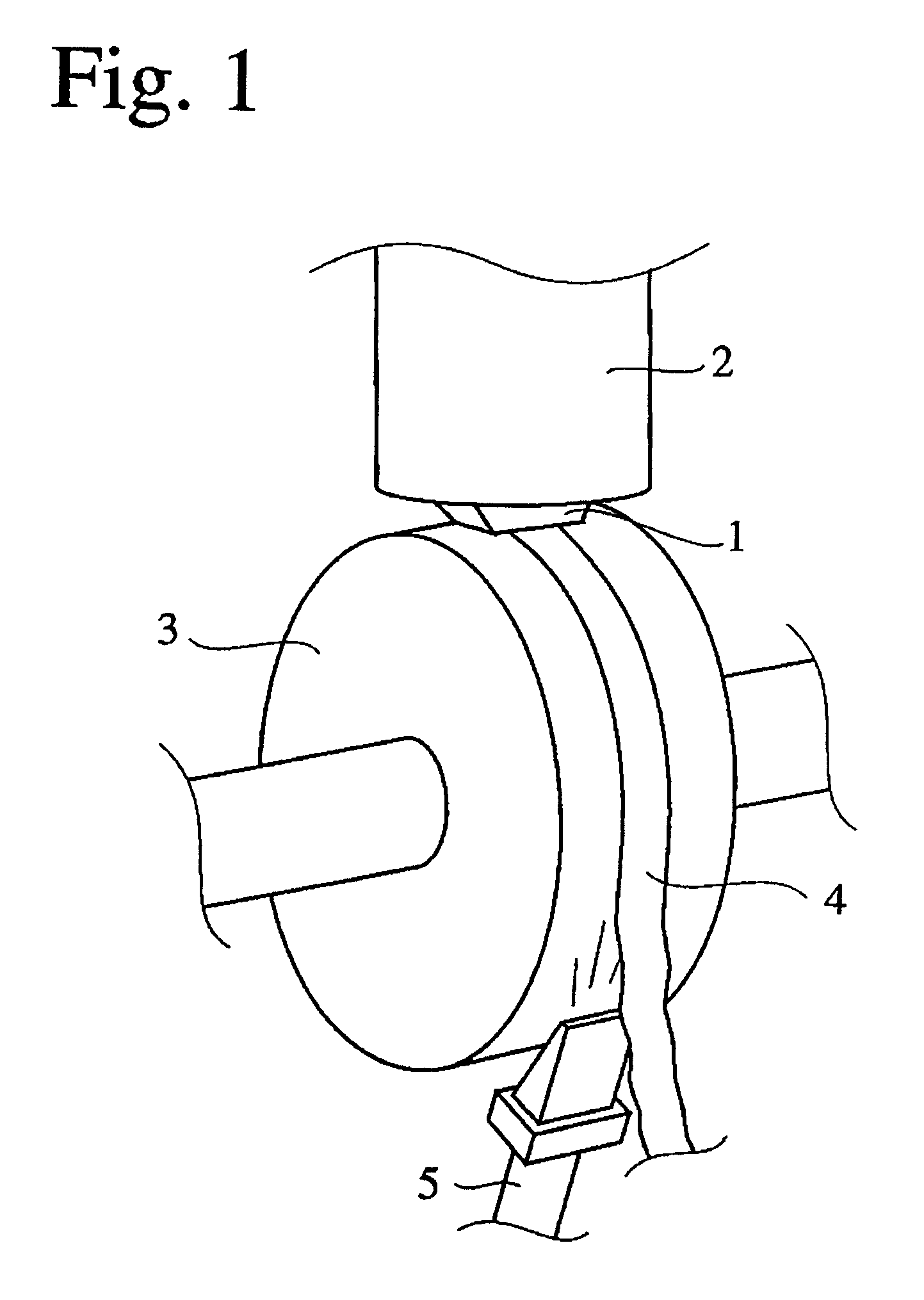

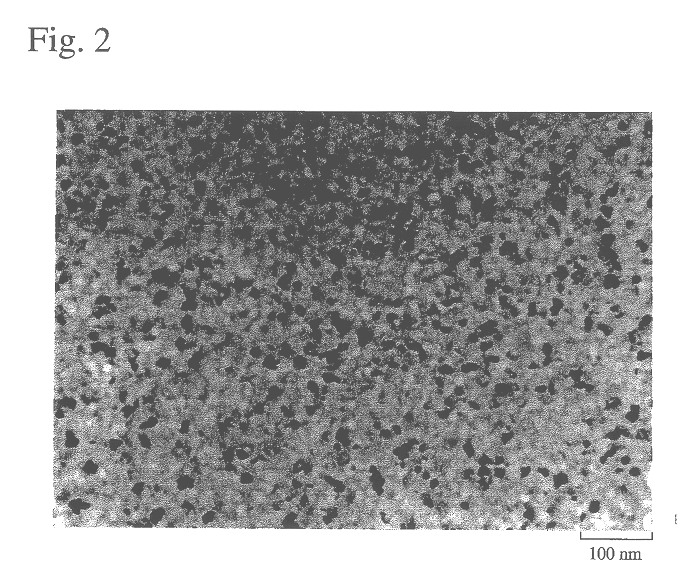

Methods for producing iron-based amorphous alloy ribbon and nanocrystalline material

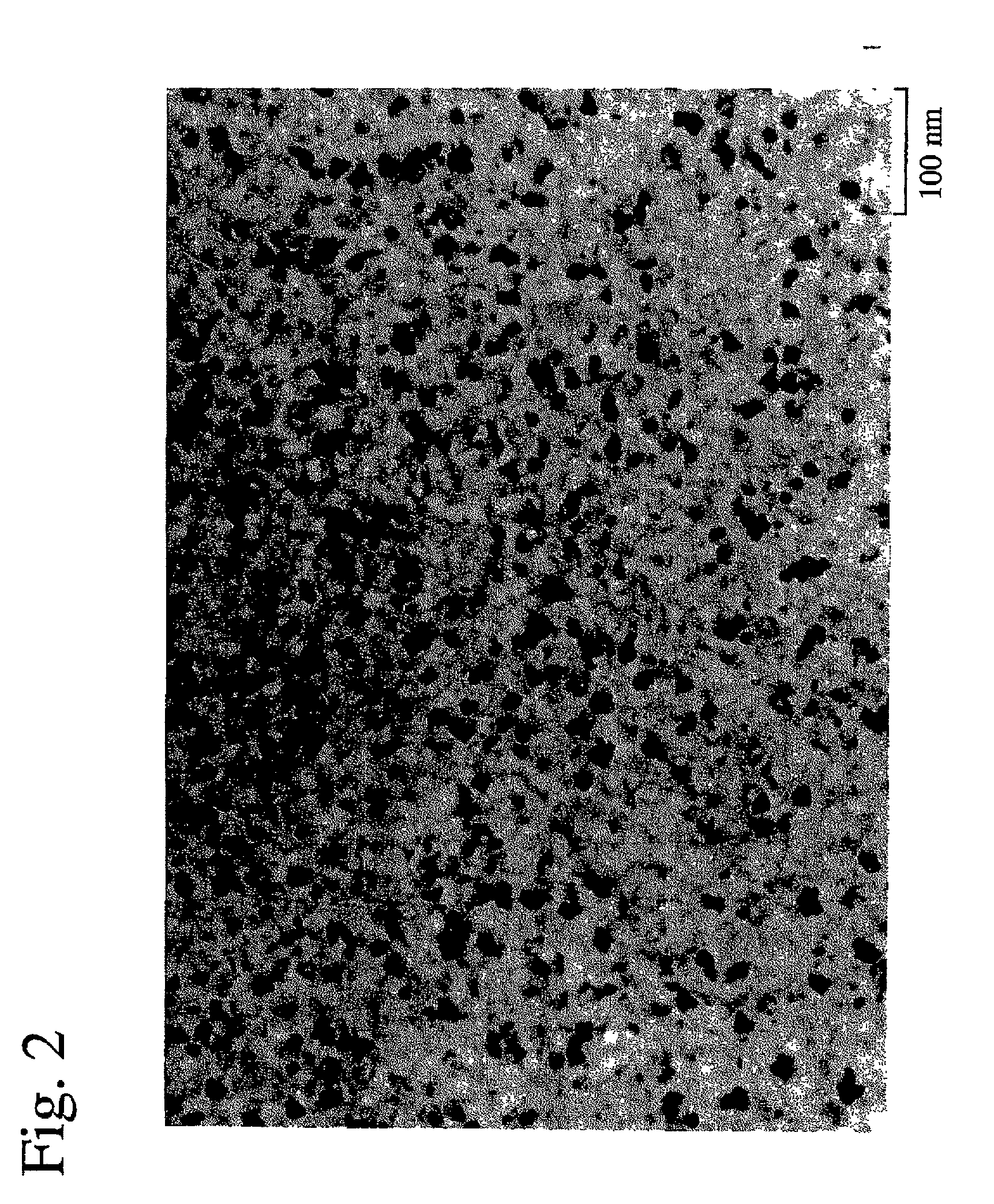

InactiveUS20010007266A1Excellent soft magnetic propertyExcellent soft magnetic propertiesMagnetic materialsIron basedAlloy

The present invention provides a method for producing a Fe-based amorphous alloy ribbon comprising the steps of: ejecting a molten Fe-based alloy containing 10 atomic % or less of B onto a cooling roll to solidify the molten Fe-based alloy; and peeling the solidified Fe-based alloy from the cooling roll when the solidified Fe-based alloy has a temperature of 100 to 300° C. A Fe-based amorphous alloy ribbon having no crystalline phase is stably, continuously produced without breakage by this method.

Owner:HITACHI METALS LTD

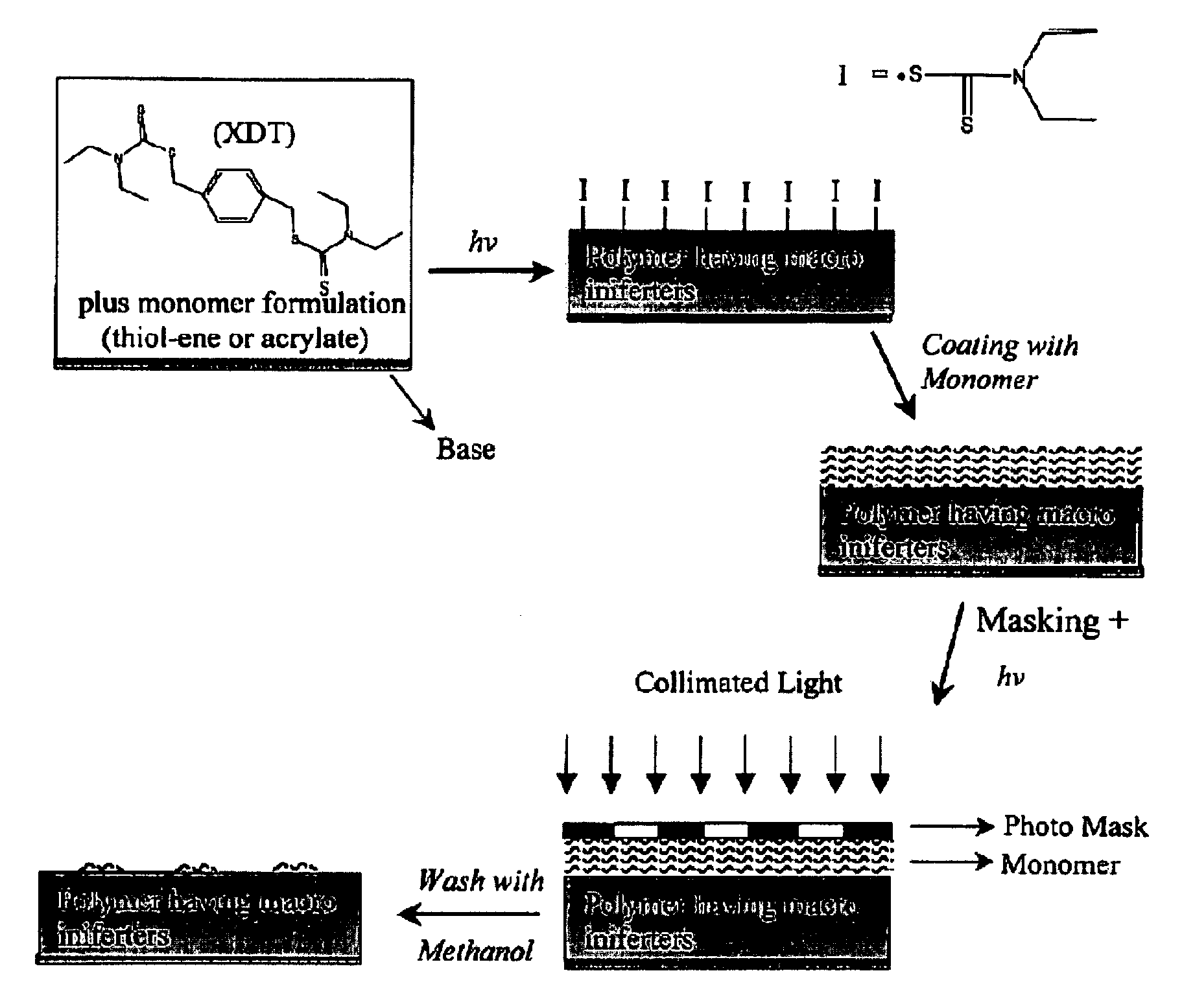

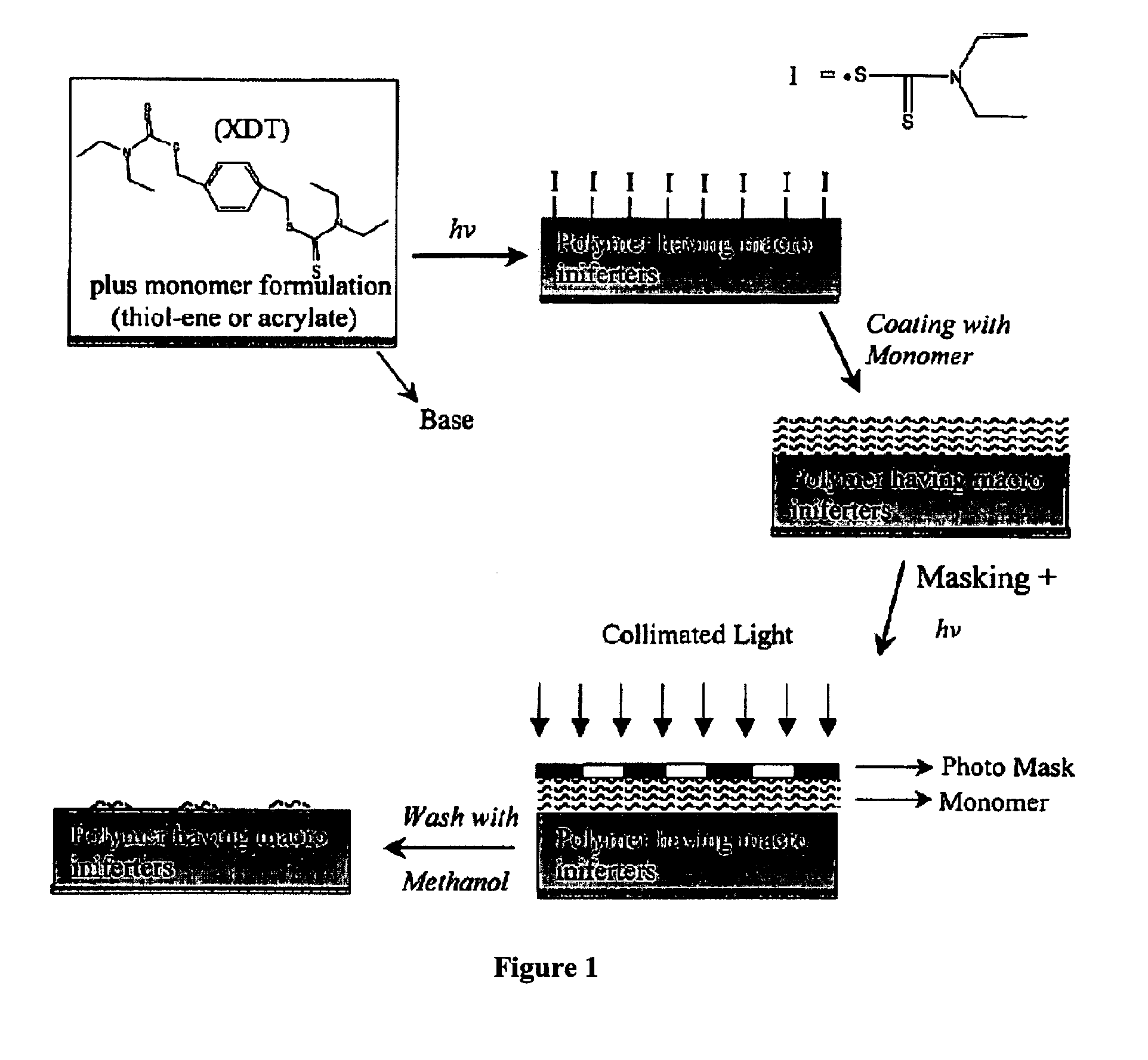

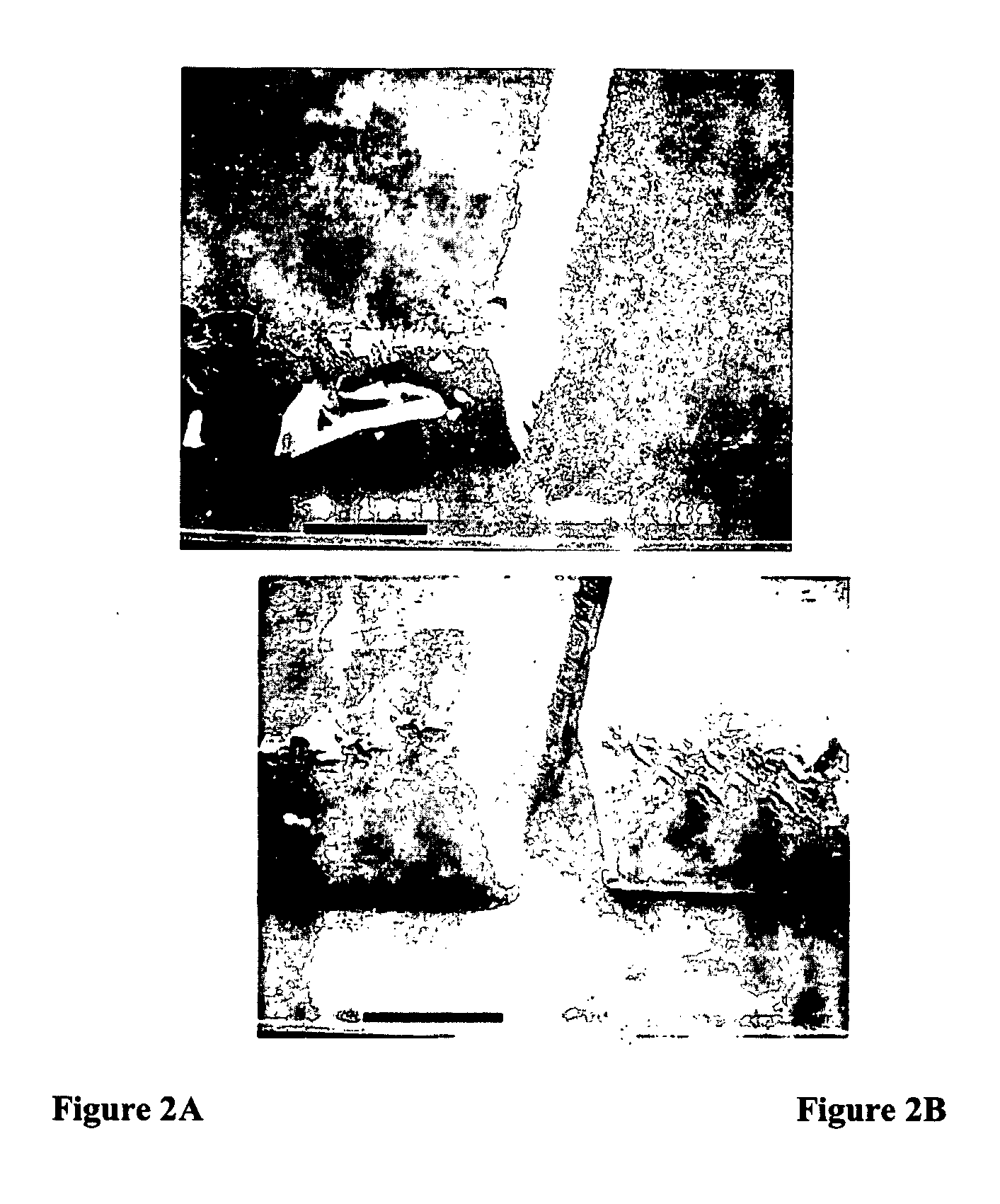

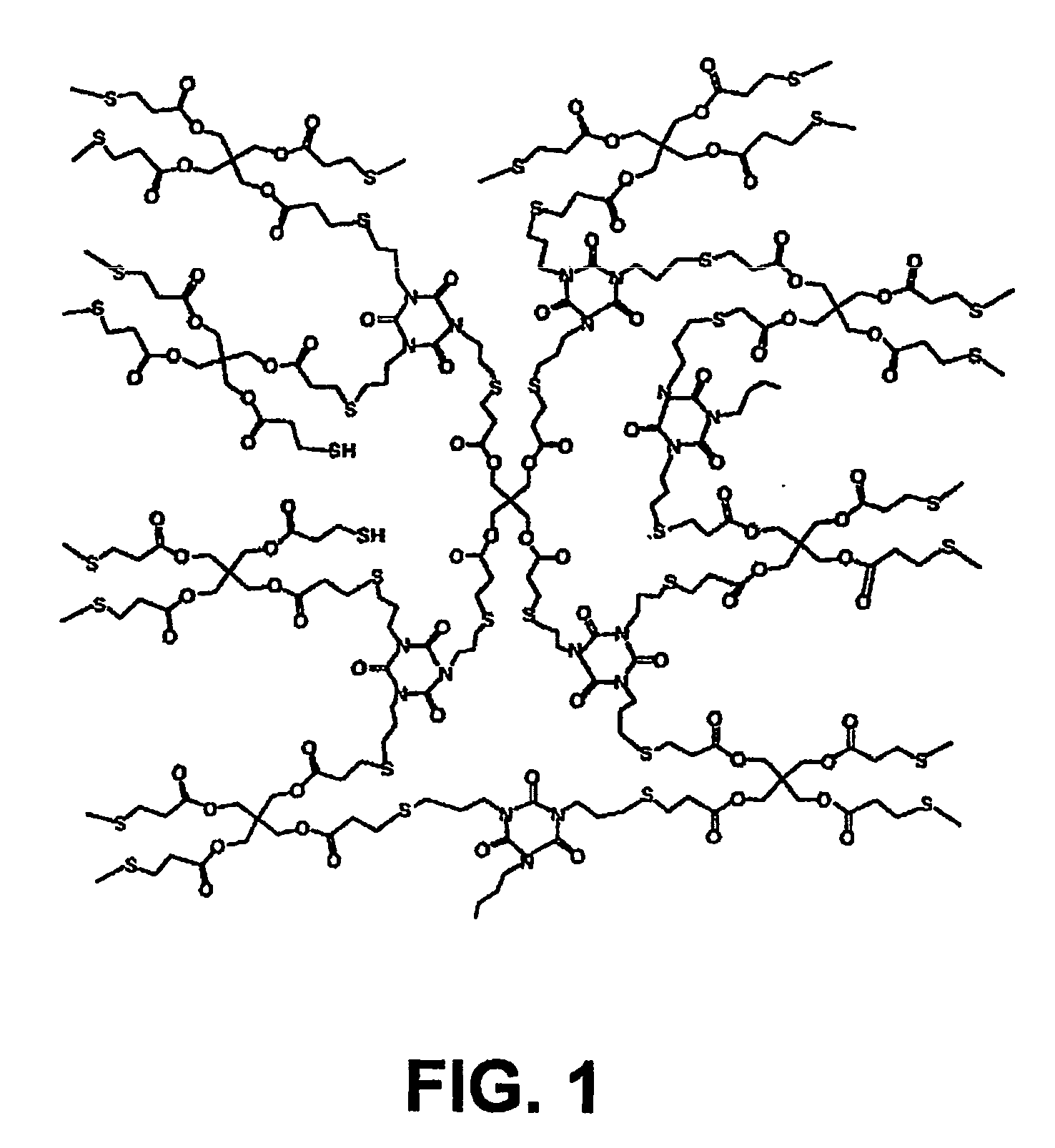

Photolytic Polymer Surface Modification

InactiveUS20080274335A1Reduce shrinkage stressHigh glass transition temperatureLayered productsThin material handlingPolymeric surfacePolymer science

The present invention provides a method for modifying a surface of a polymer derived from a mixture comprising a thiol monomer and an olefinic monomer. The method comprises exposing at least a portion of the polymer surface to electromagnetic radiation of sufficient energy to modify the polymer surface. The present invention also provides a polymer derived from polymerizing a mixture of monomers comprising a thiol monomer, an olefinic monomer, and an iniferter.

Owner:UNIV OF COLORADO THE REGENTS OF

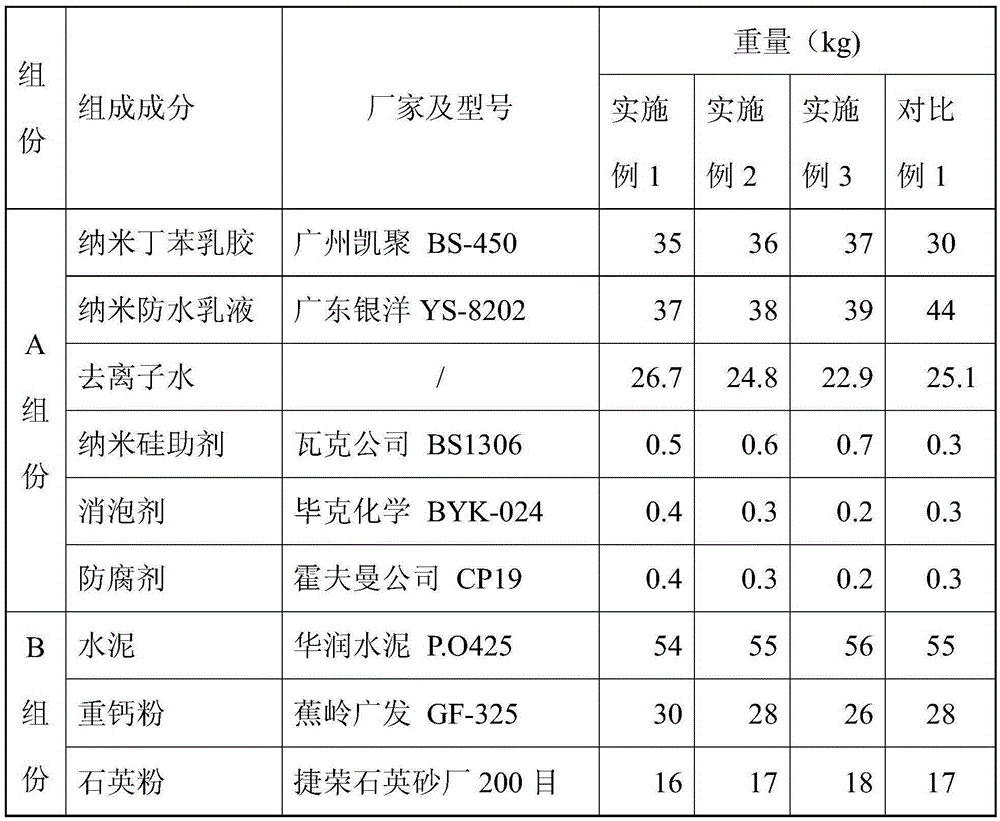

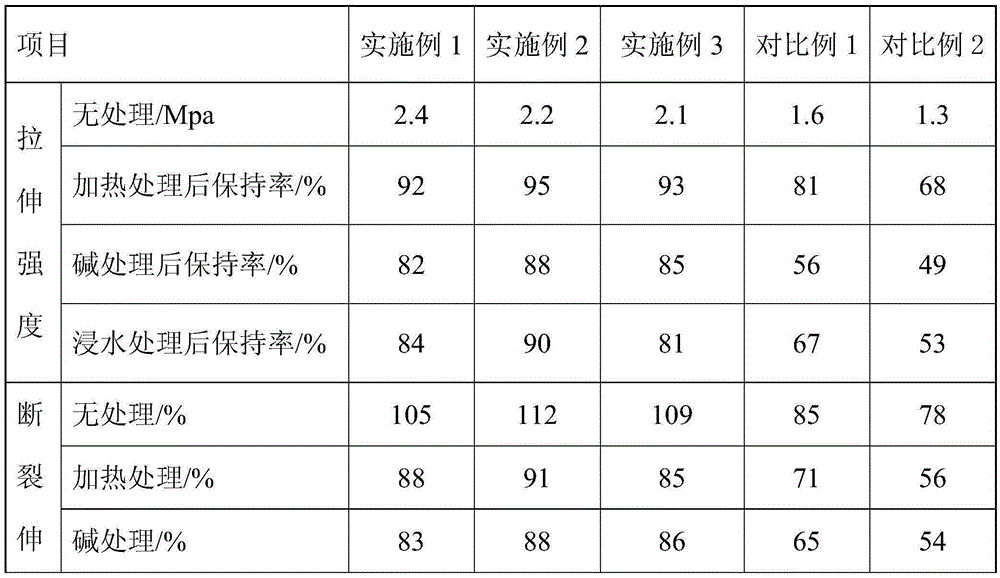

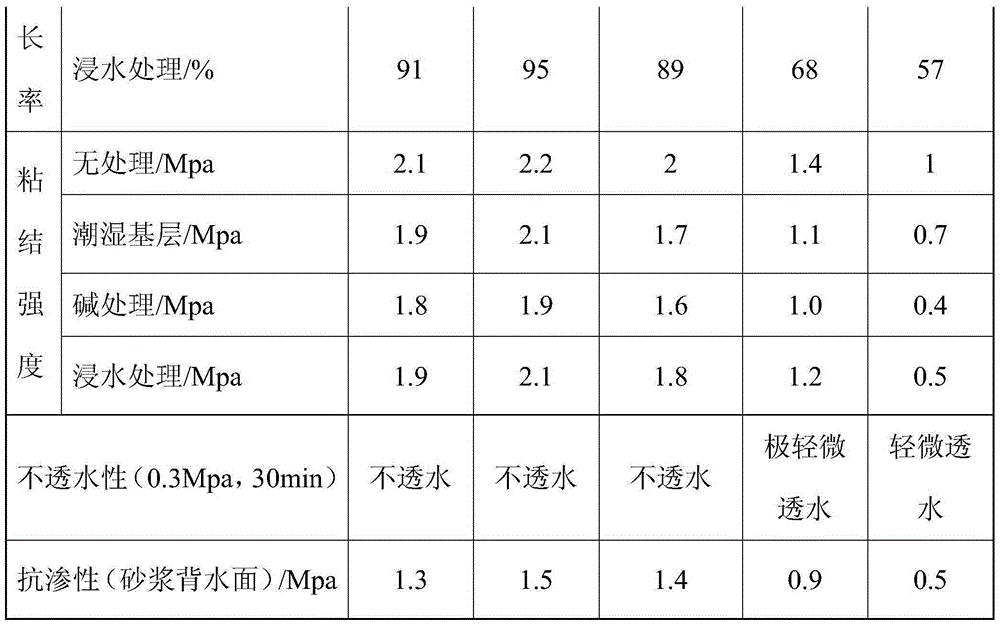

Bicomponent water-based nano waterproof coating and preparation method thereof

The invention discloses a bicomponent water-based nano waterproof coating and a preparation method thereof. The bicomponent water-based nano waterproof coating is prepared by mixing a component A and a component B, wherein the component A comprises the following ingredients in parts by weight: 35-37 parts of nano styrene-butadiene rubber, 37-39 parts of nano waterproof emulsion, 22.9-26.7 parts of deionized water, 0.5-0.7 part of a nano silicon auxiliary agent, 0.2-0.4 part of a defoaming agent and 0.2-0.4 part of a preservative; and the component B comprises the following ingredients in parts by weight: 54-56 parts of cement, 26-30 parts of ground calcium carbonate powder, and 16-18 parts of quartz powder. When the bicomponent water-based nano waterproof coating is used, the component A and the component B are mixed and stirred uniformly with each other according to a ratio of the component A to the component B of 1:(1.0-1.2). By using the bicomponent water-based nano waterproof coating, while the waterproof performance is implemented, the contraction stress of a waterproof coating layer during drying can also be reduced, thereby effectively improving or putting an end to the problem that a brick pasted on the waterproof coating layer generates bellowing and falling off. The construction method of the bicomponent water-based nano waterproof coating is consistent with that of a common polymer cement waterproof coating, and the product is environmentally friendly and nontoxic.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

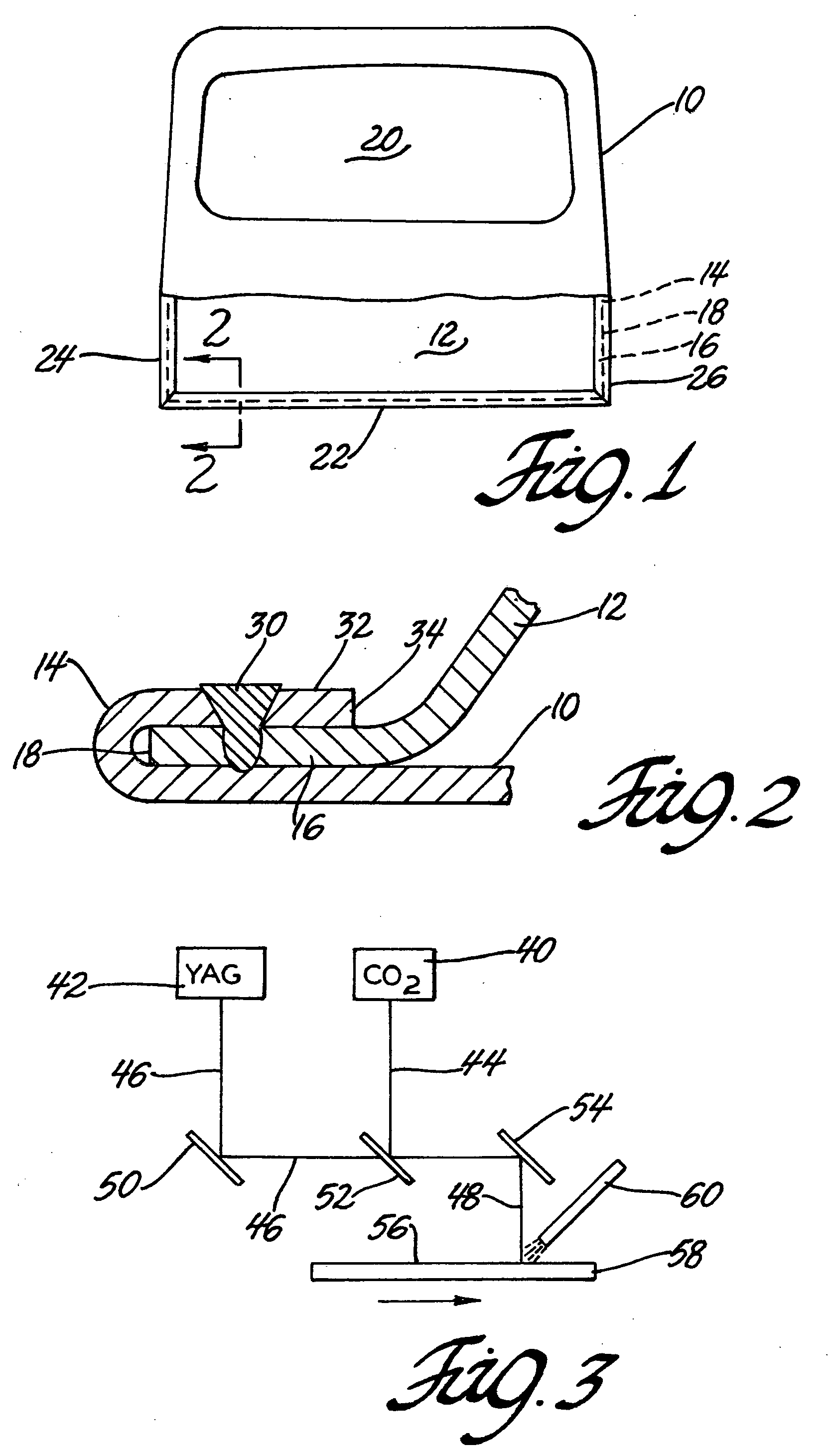

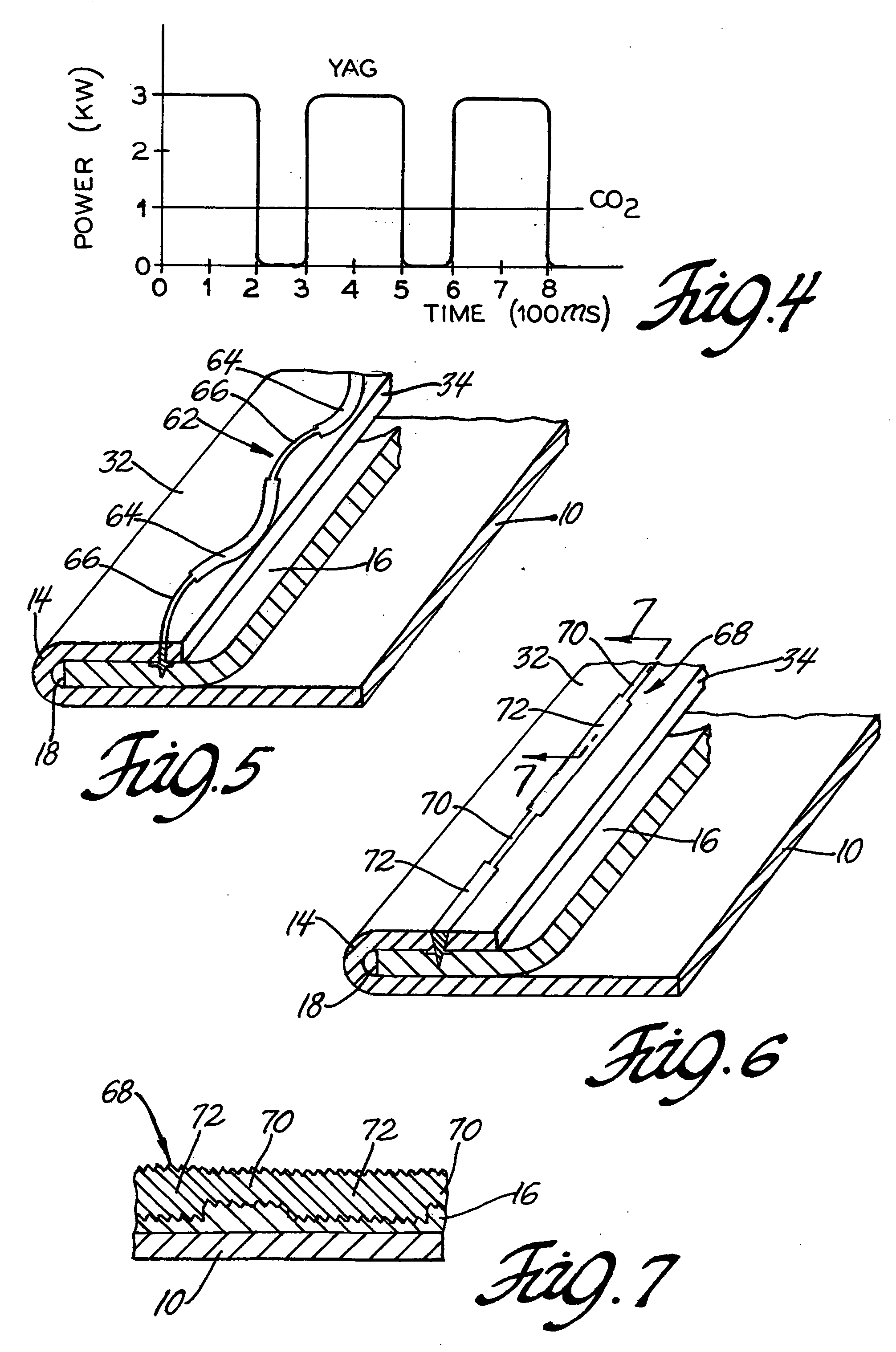

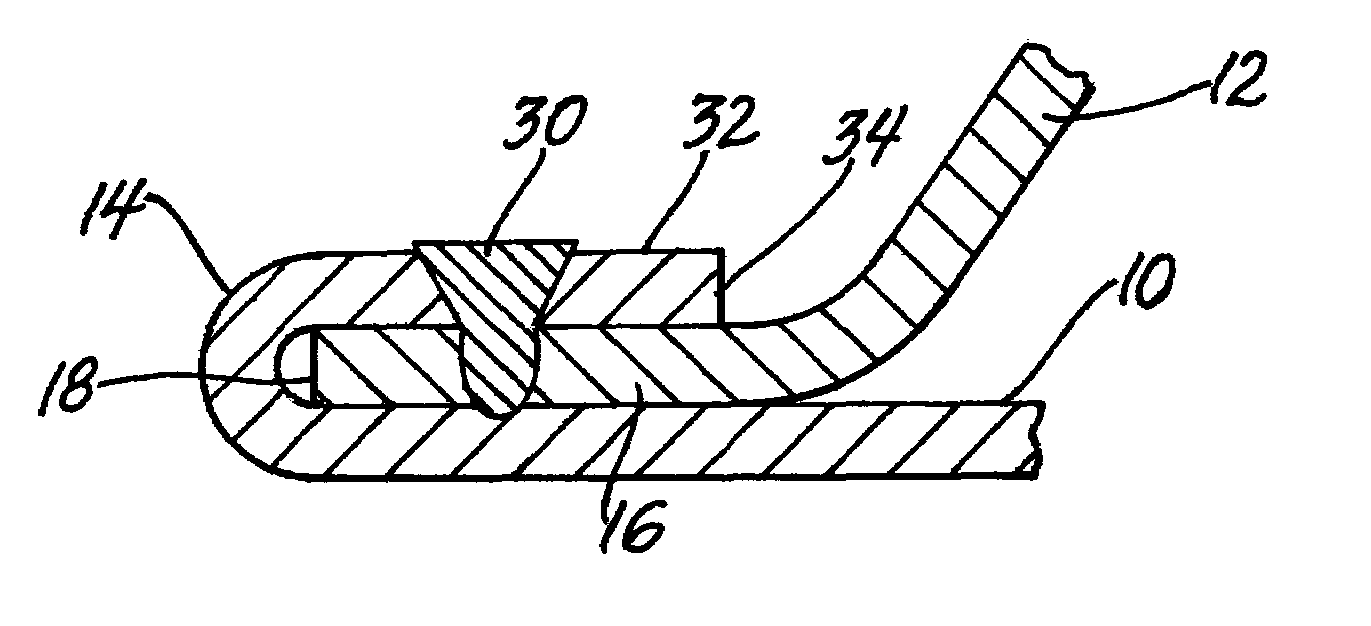

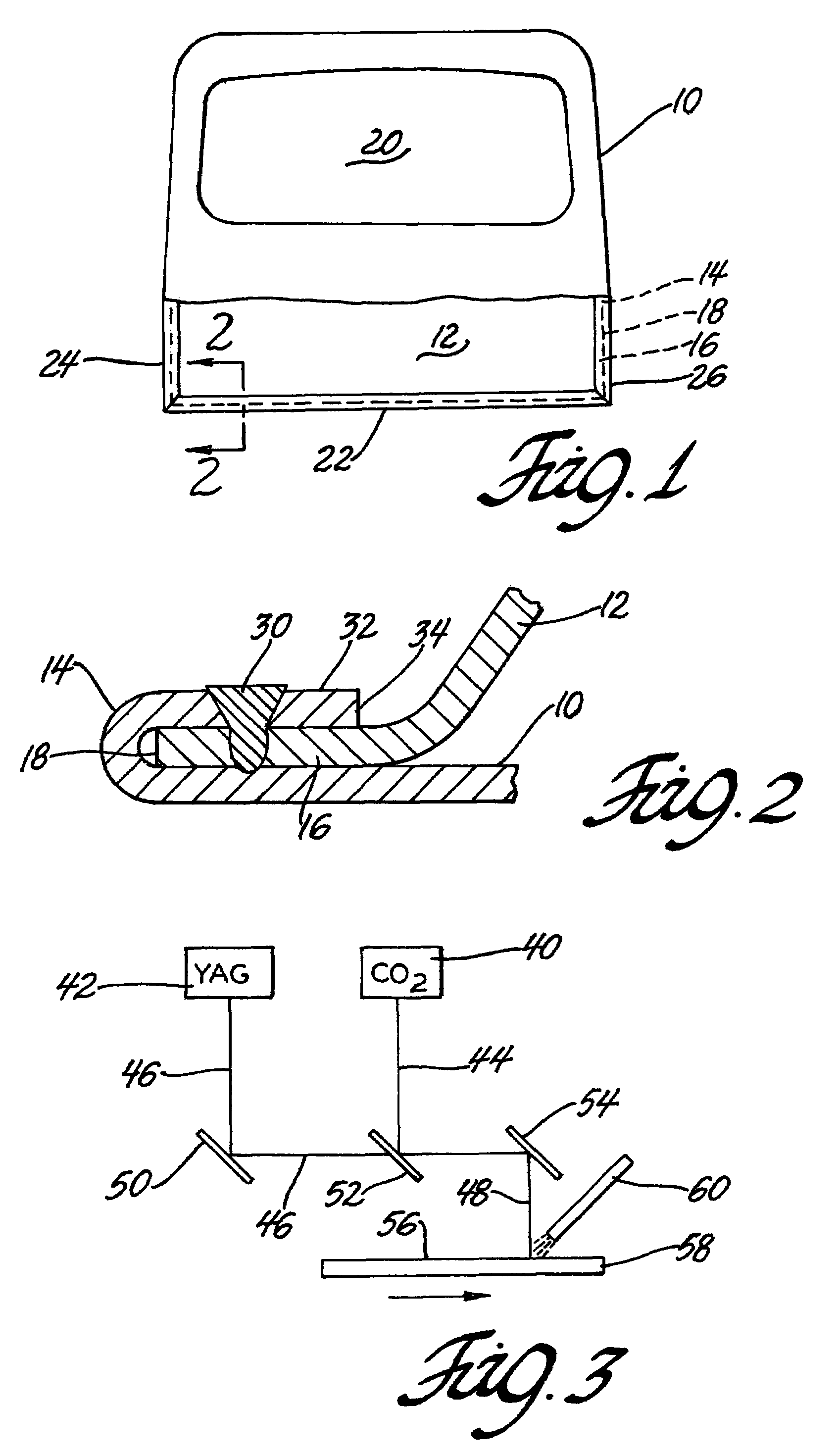

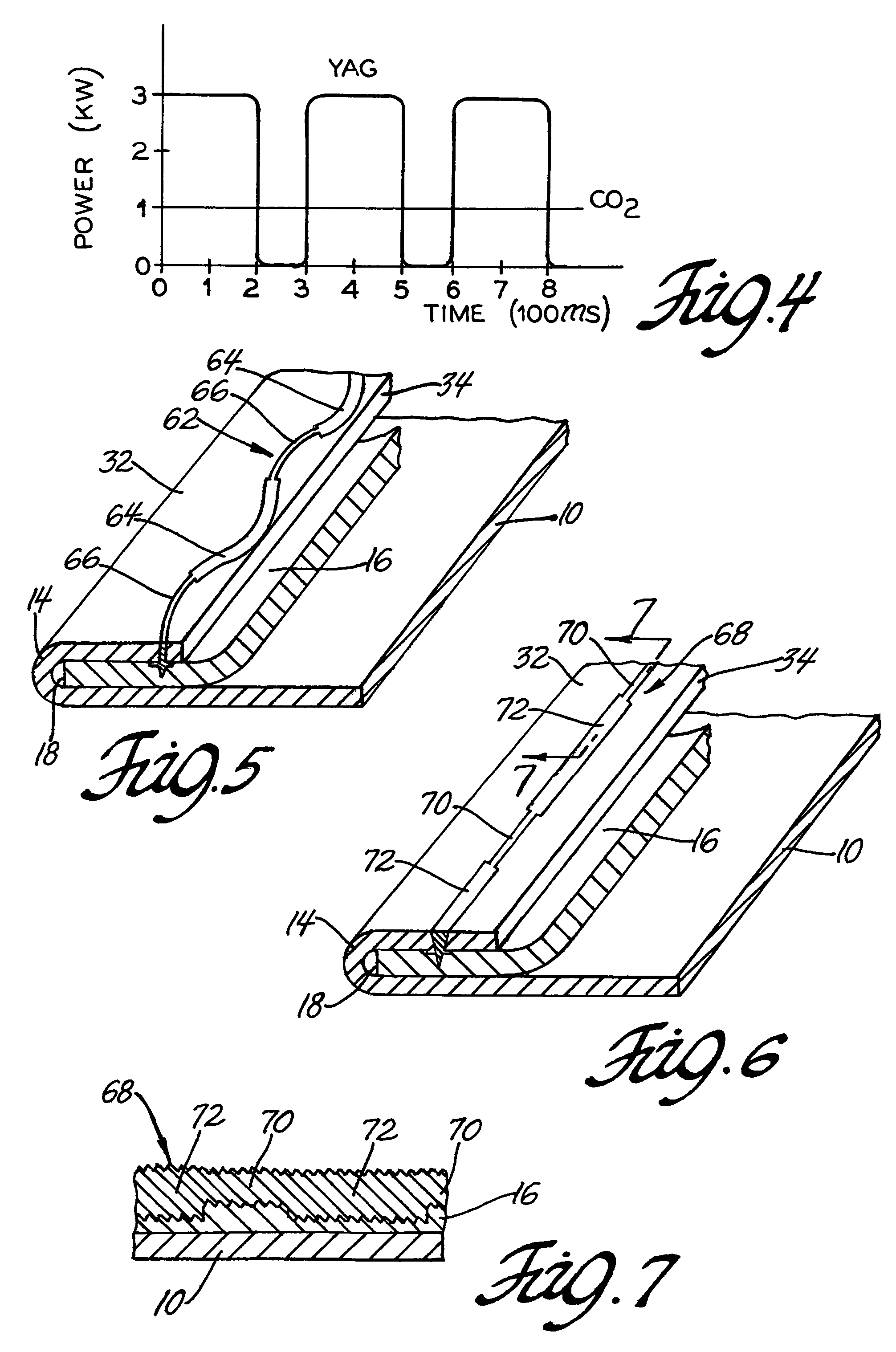

Compound laser beam welding

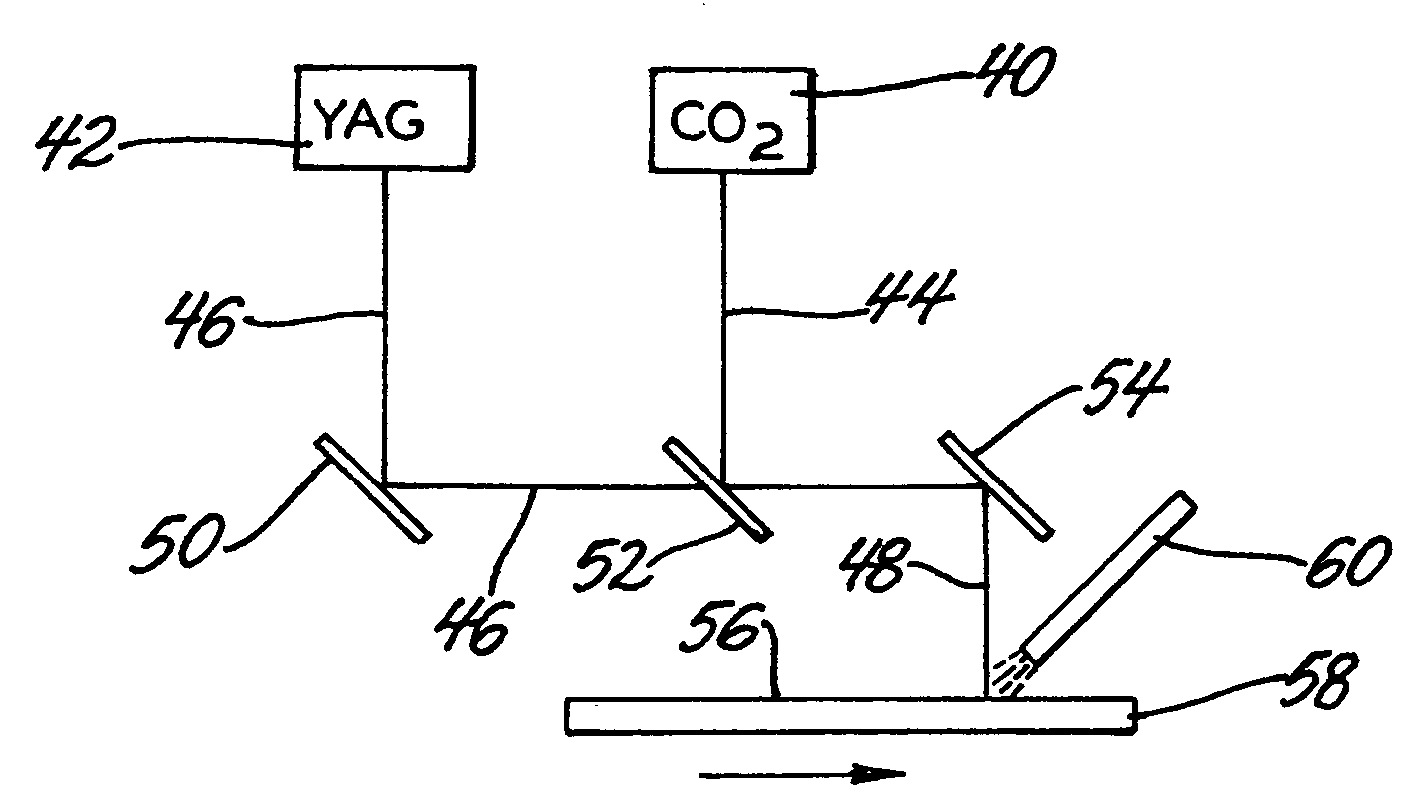

InactiveUS20050230364A1Reduce shrinkage stressWelding/soldering/cutting articlesMetal working apparatusCrack freeLight beam

Hot cracking in laser welds produced in metal workpieces, especially aluminum or magnesium sheet alloys, is avoided by suitably combining the beams of two different lasers, for example a CO2 laser and a YAG laser, into a compound beam that is moved along a weld path in the surface of the workpiece. The power level of at least one of the lasers is cyclically varied so that weld nugget segments of different alternating, hot crack free, configurations are produced in a linear weld.

Owner:SUZUKI MOTOR CORP +1

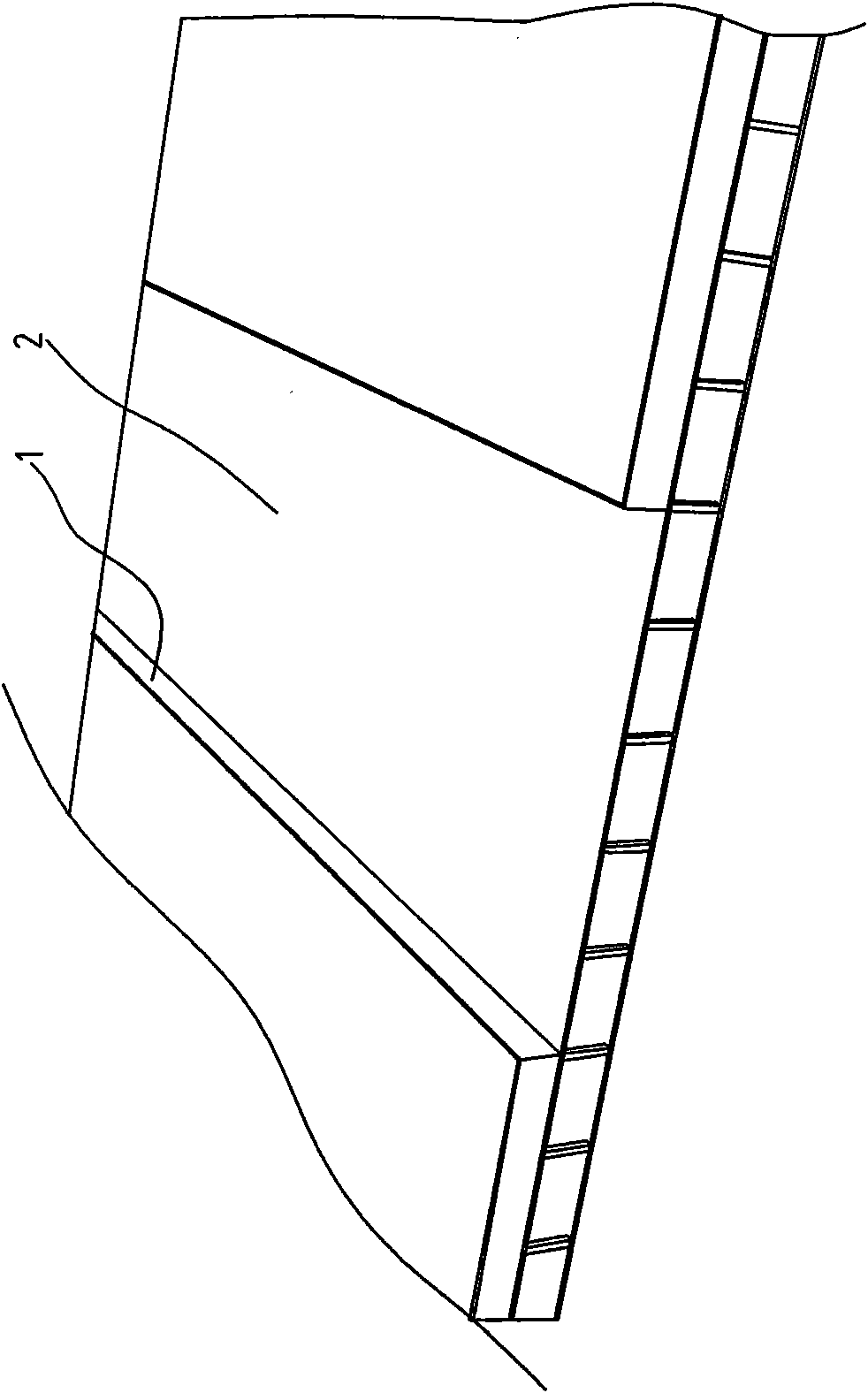

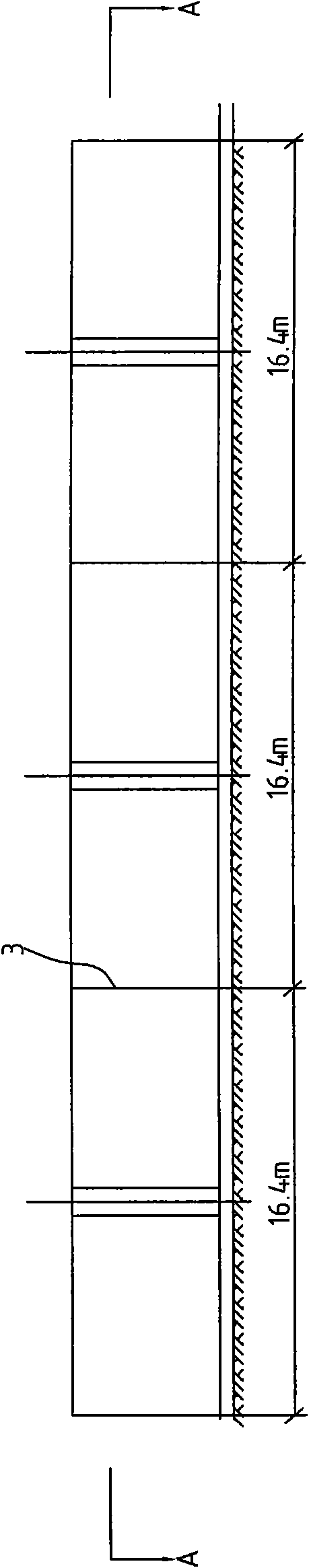

Method for controlling crack of super-long wall body

InactiveCN101608476AThe mechanism of action is clearConcise construction proceduresWallsBuilding material handlingSteel platesWall plate

The invention relates to a method for controlling a crack of a super-long wall body. The method is characterized by comprising the following steps: the super-long wall body is vertically divided by a thin steel plate along the longer inner core concrete of the wall; then a water stop steel plate is arranged on the axial position vertical to a separation steel plate; the separation steel plate divides the water stop steel plate into two parts and leads the two parts to be vertical to each other; and the separation steel plate and the water stop steel plate are positioned between meshes reinforcement at two sides of the wall body, and are bound and fixed with the meshes reinforcement. Compared with the prior art, the method for controlling the crack of the super-long wall body has simple and clear construction procedure, is advantageous to reduction of shrinkage stress of the wall body, can effectively play a role in controlling the crack matched with prestressed reinforcement, can be applied to any wall body structure requiring crack control, in particular to construction of the wall body of an underground garage, the side wall plates of overground and underground artificial channels, a super-long large water pool, side wall of a sewage treating pond and a retaining wall.

Owner:NINGBO CONSTR +2

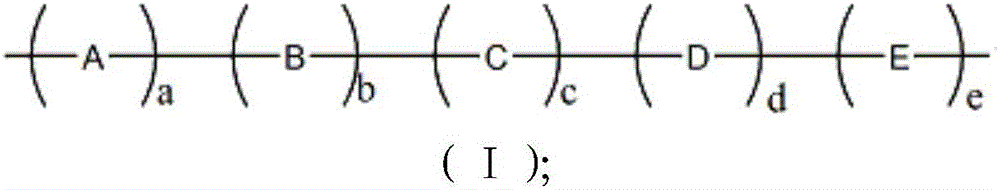

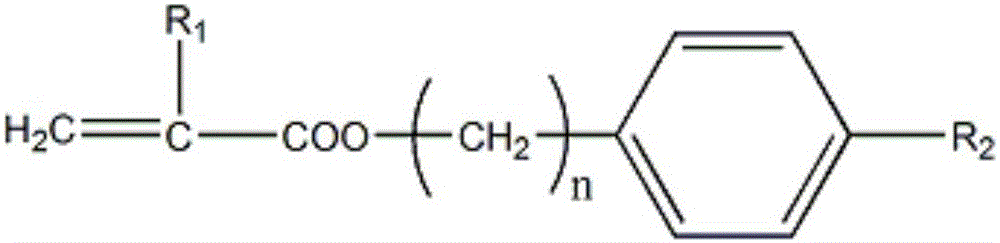

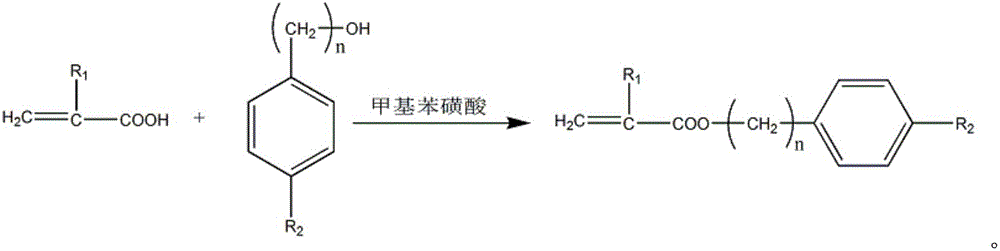

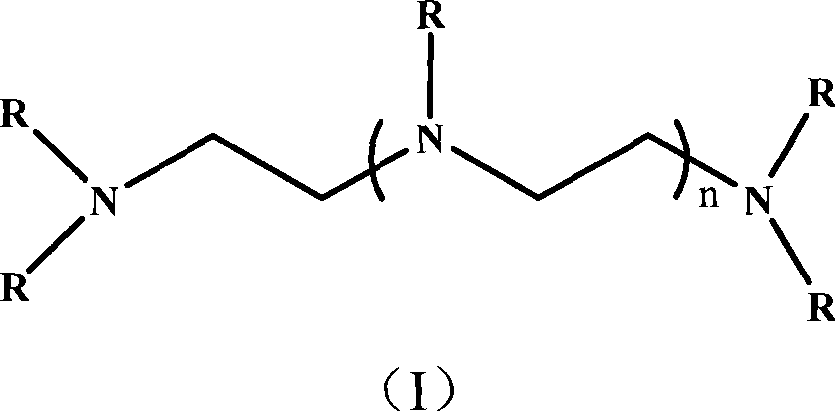

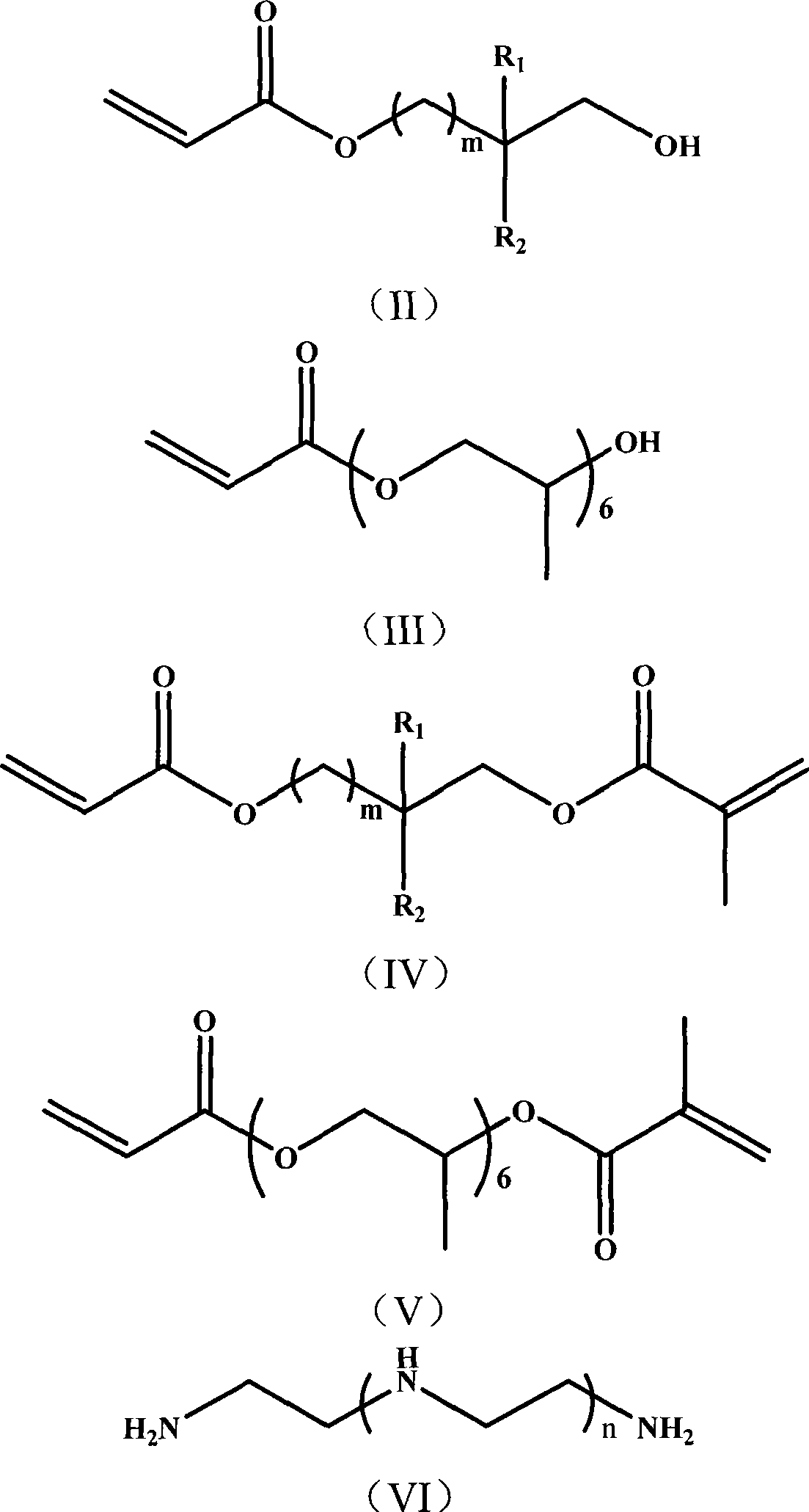

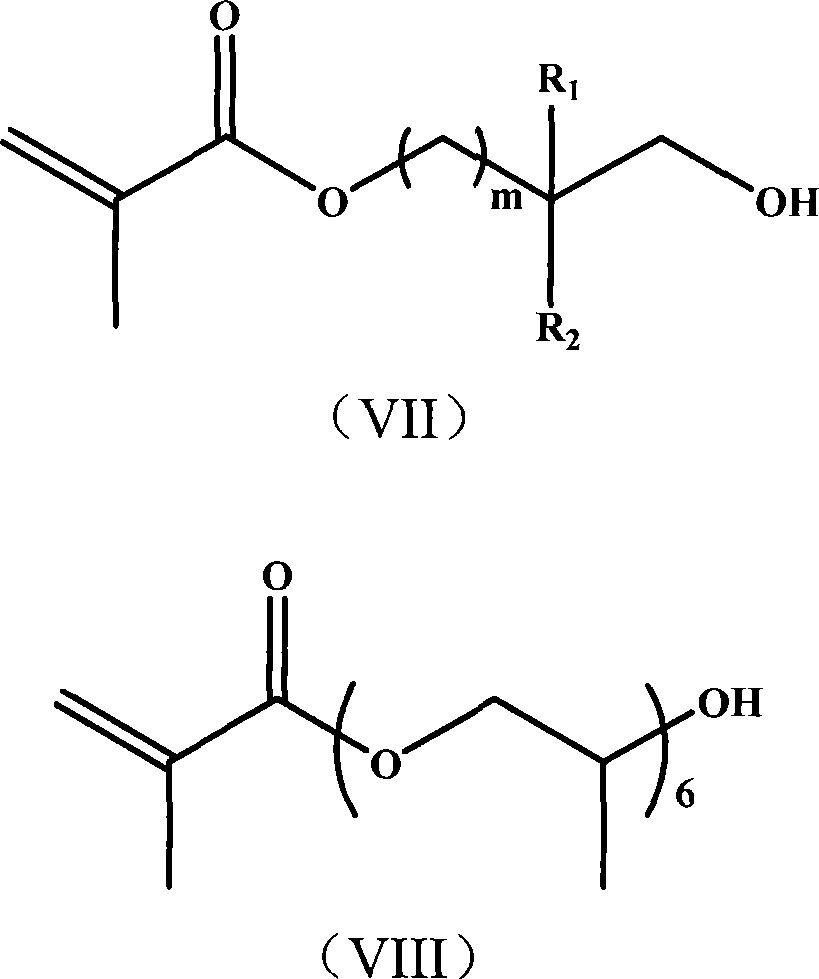

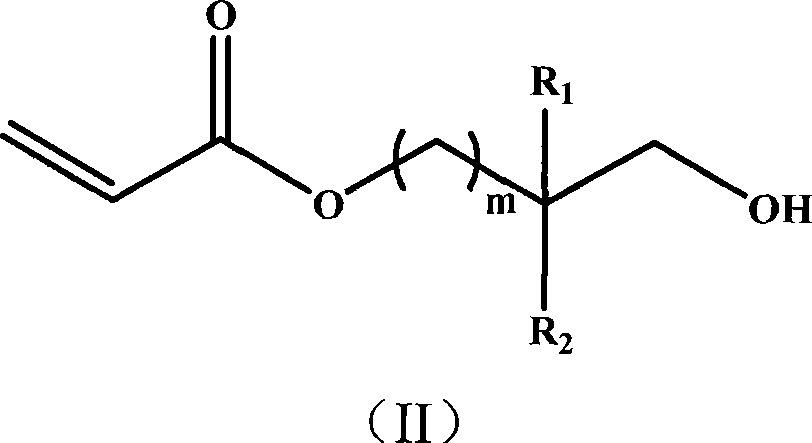

Nitrogen-containing polyfunctionality metacrylic acid ester monomer, preparation and use thereof

InactiveCN101462973AHigh reactivityImprove flexibilityOrganic compound preparationPhotomechanical apparatusDouble bondChemistry

The invention relates to a nitrogenous poly-functionality methyl acrylate monomer and a preparation method and application thereof. The structure of the monomer is shown in general formula (I): R1, R2 are hydrogen or methyl, m is an integer ranging from 0 to 4, and n is an integer ranging from 0 to 5. The preparation method of the monomer includes that (methyl) acrylate compound with hydroxy and (methyl) acryloyl chloride react with each other to obtain an intermediate product with acrylate double-bond and methyl acrylate double-bond; the intermediate product is led to carry out Michael addition reaction with polyamine compound, so as to obtain the product. The method has the advantages of high conversion rate, mild reaction condition and easy separation and purification of the product, and provides a novel photopolymerization active compound system with excellent application prospect.

Owner:BEIJING UNIV OF CHEM TECH

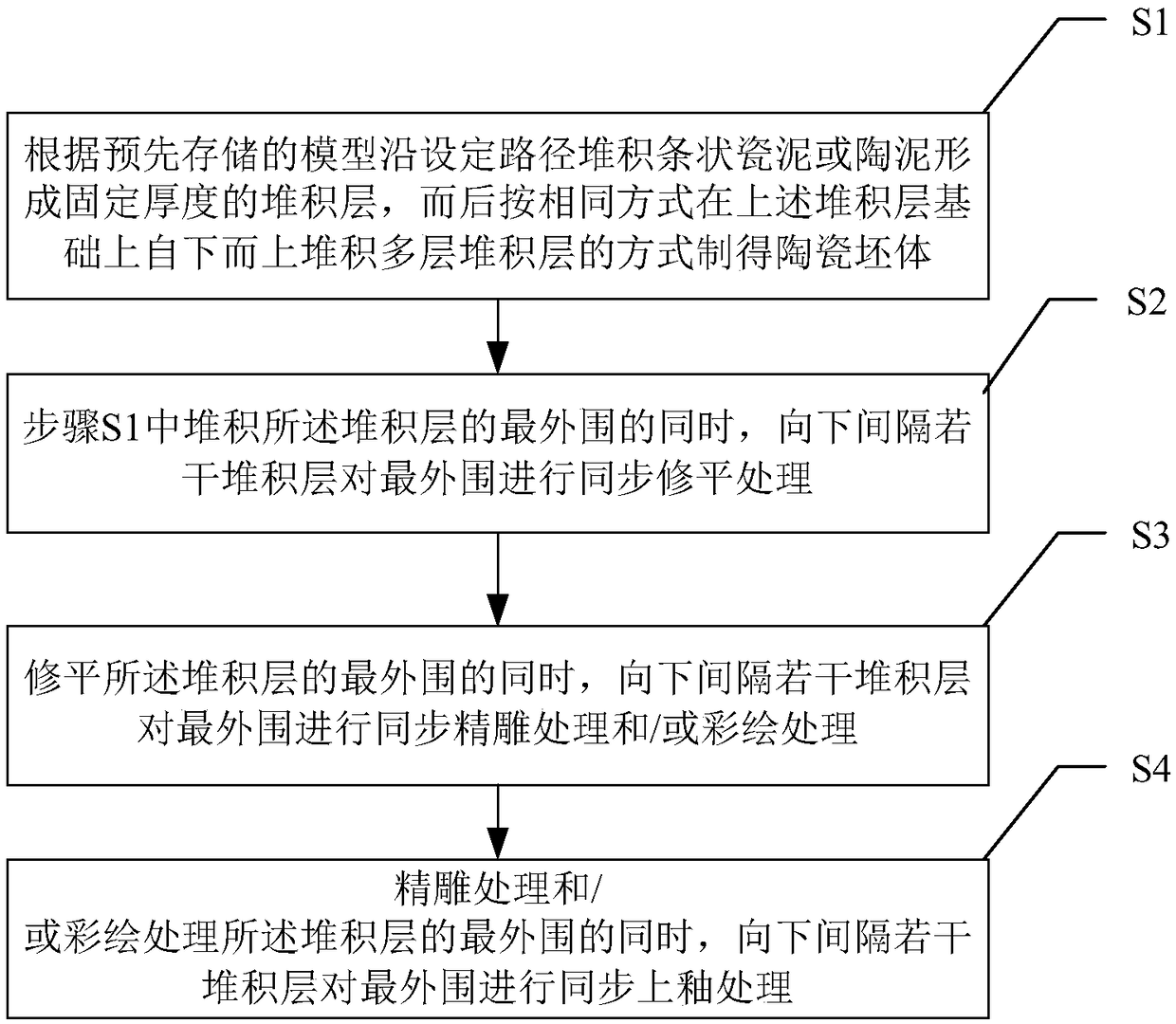

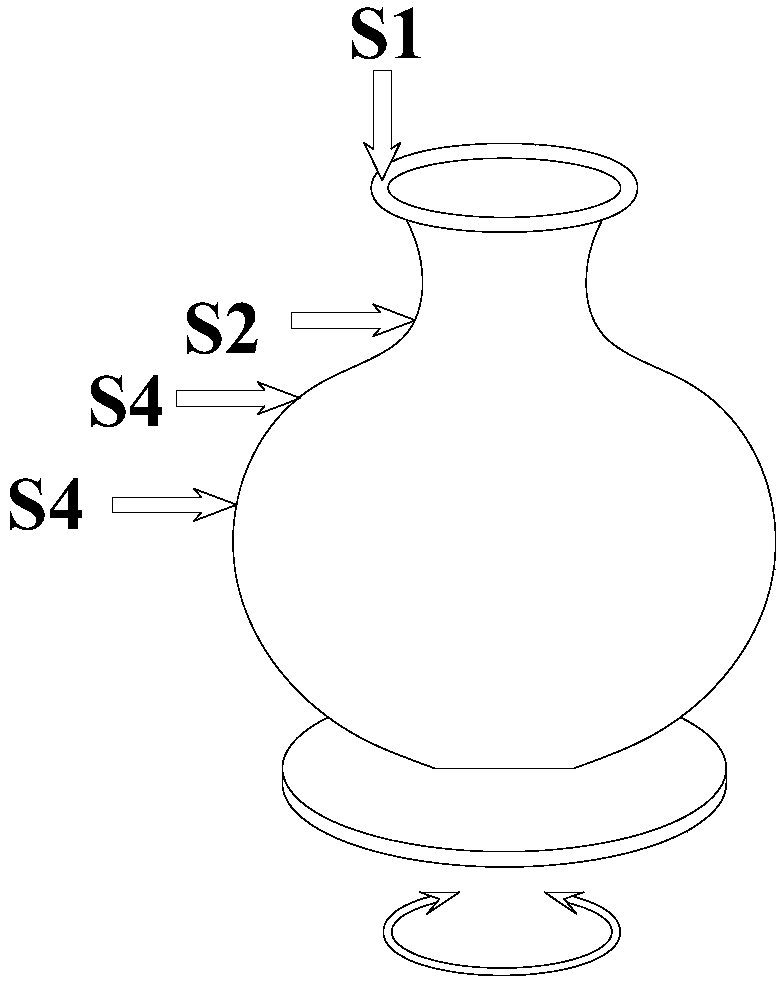

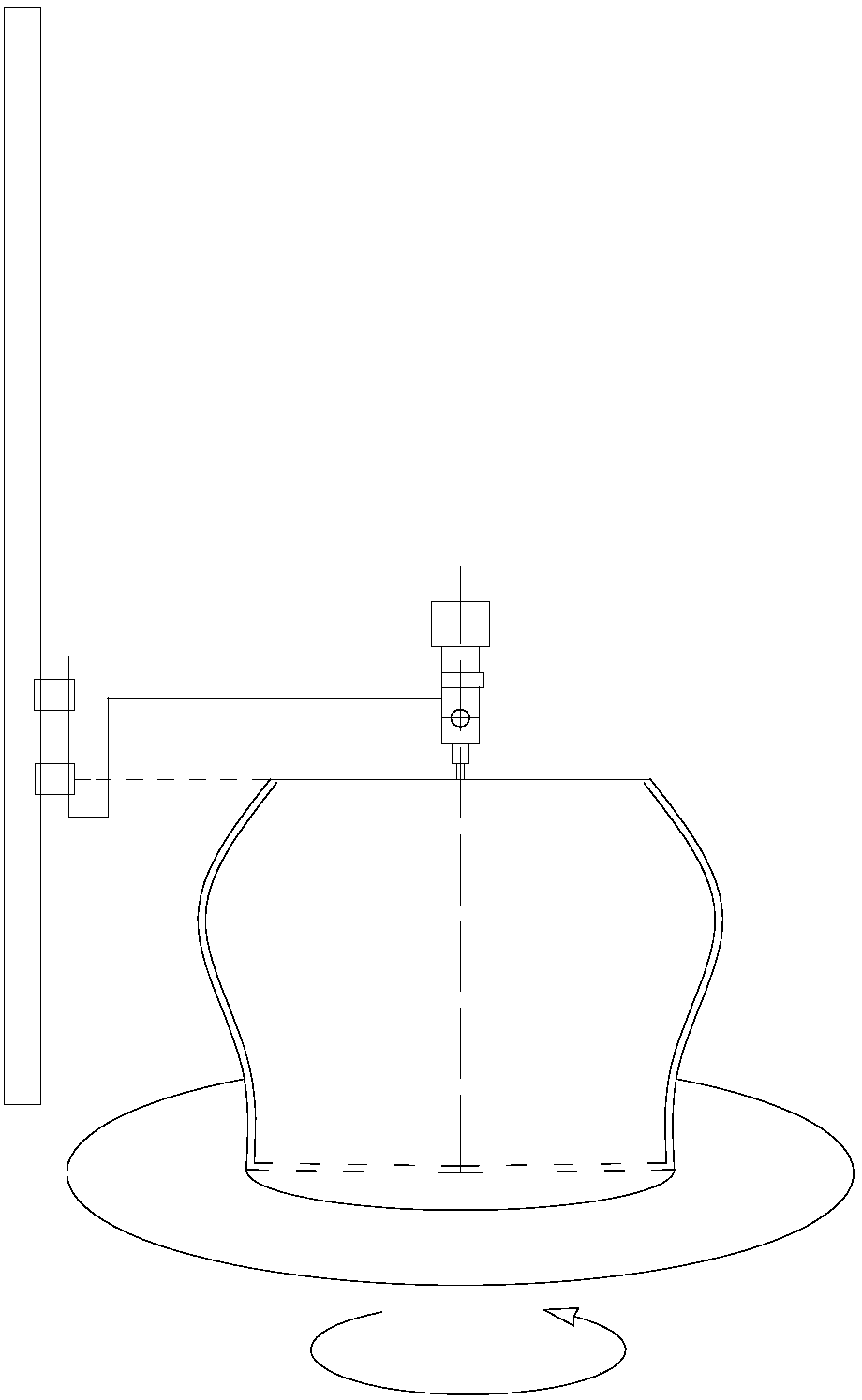

Large and medium chinaware manufacturing method

ActiveCN108582416ARich Applicable TypesReduce manufacturing costCeramic shaping apparatusClaywaresTime spaceCeramic

The invention discloses a large and medium chinaware manufacturing method. Compared with a traditional method, such subsequent treatment processes as outer surface finishing, finish carving treatmentand / or colored drawing treatment and glazing of large and medium chinaware ceramic blanks and production of chinaware outer profile surfaces belong to simultaneous asynchronous treatment spaced by specific space-time intervals, so that the problem of performing subsequent processes one by one after completion of previous treatment procedures in the traditional method is overcome, and saving of a lot of time and delication of the artistic effect can be both considered. In addition, the method can finish complex shapes, is more suitable for manufacturing of large and medium artistic shape chinaware, meanwhile, greatly enriches the shaping range of large and medium chinaware, and greatly reduces the manufacturing cost of large artistic porcelains.

Owner:湖南筑巢智能科技有限公司

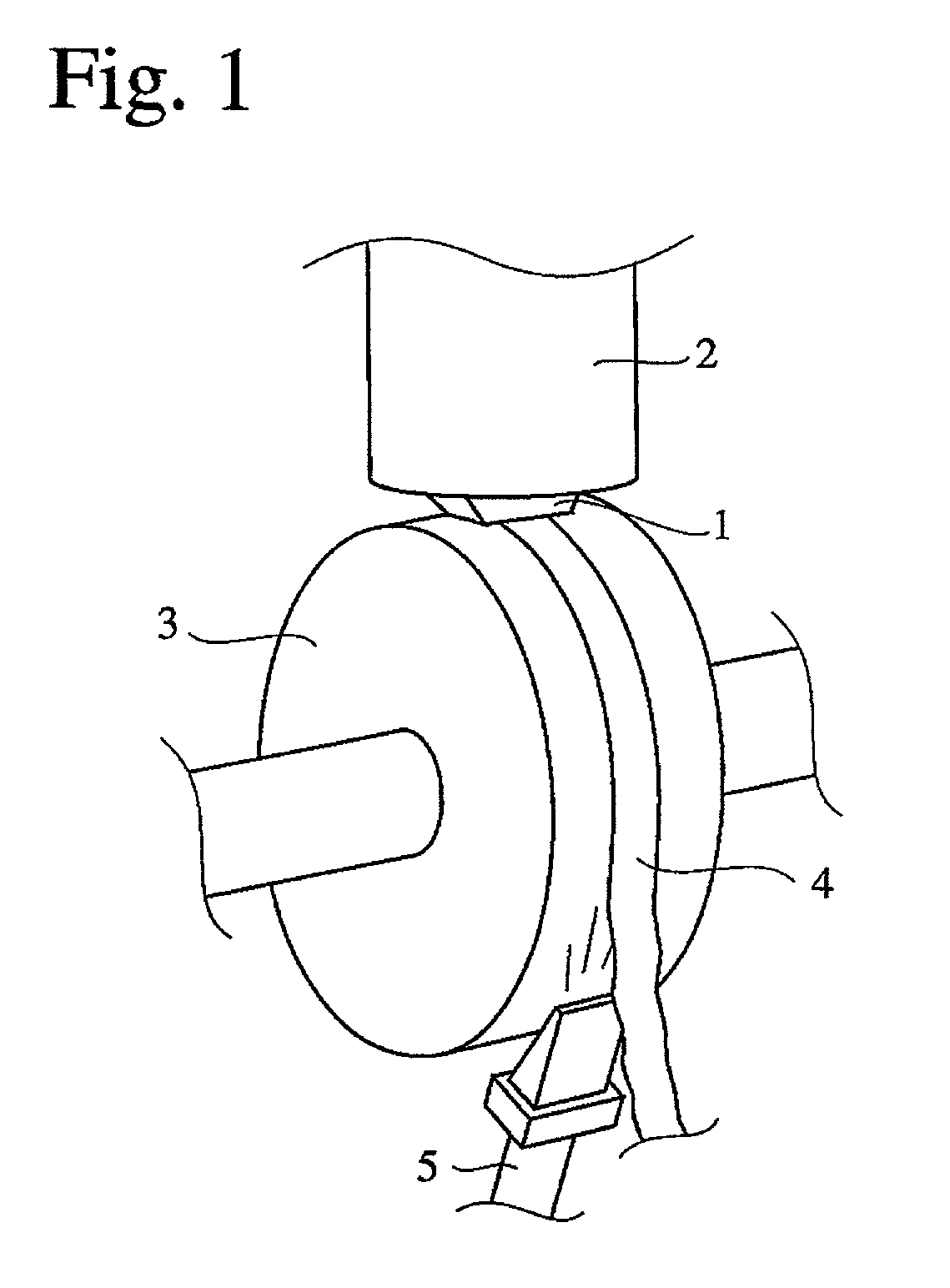

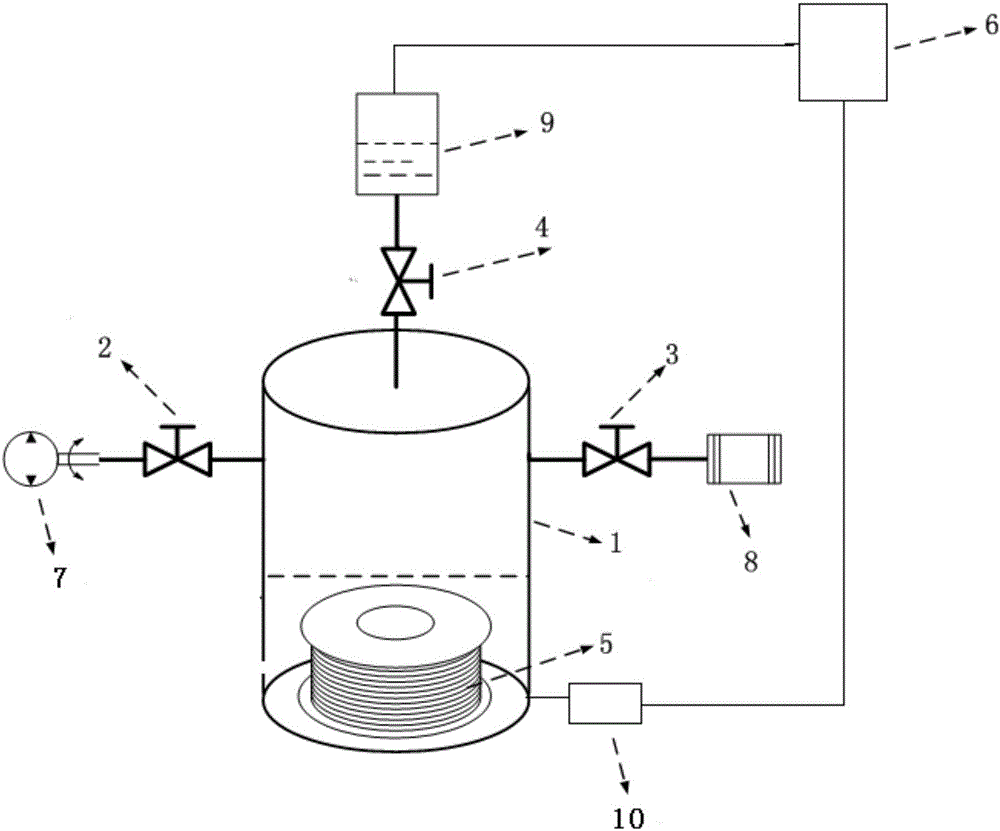

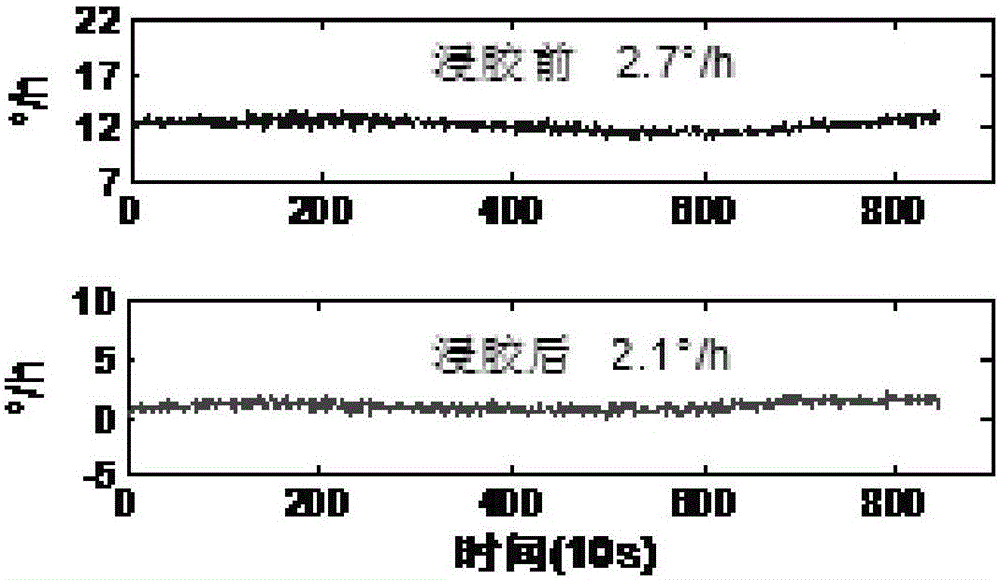

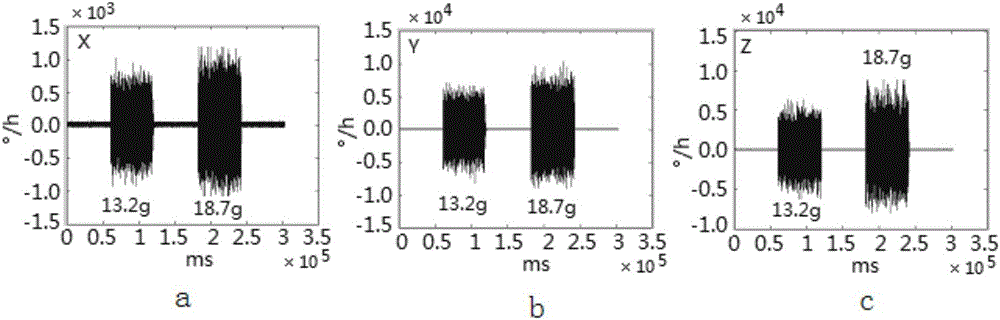

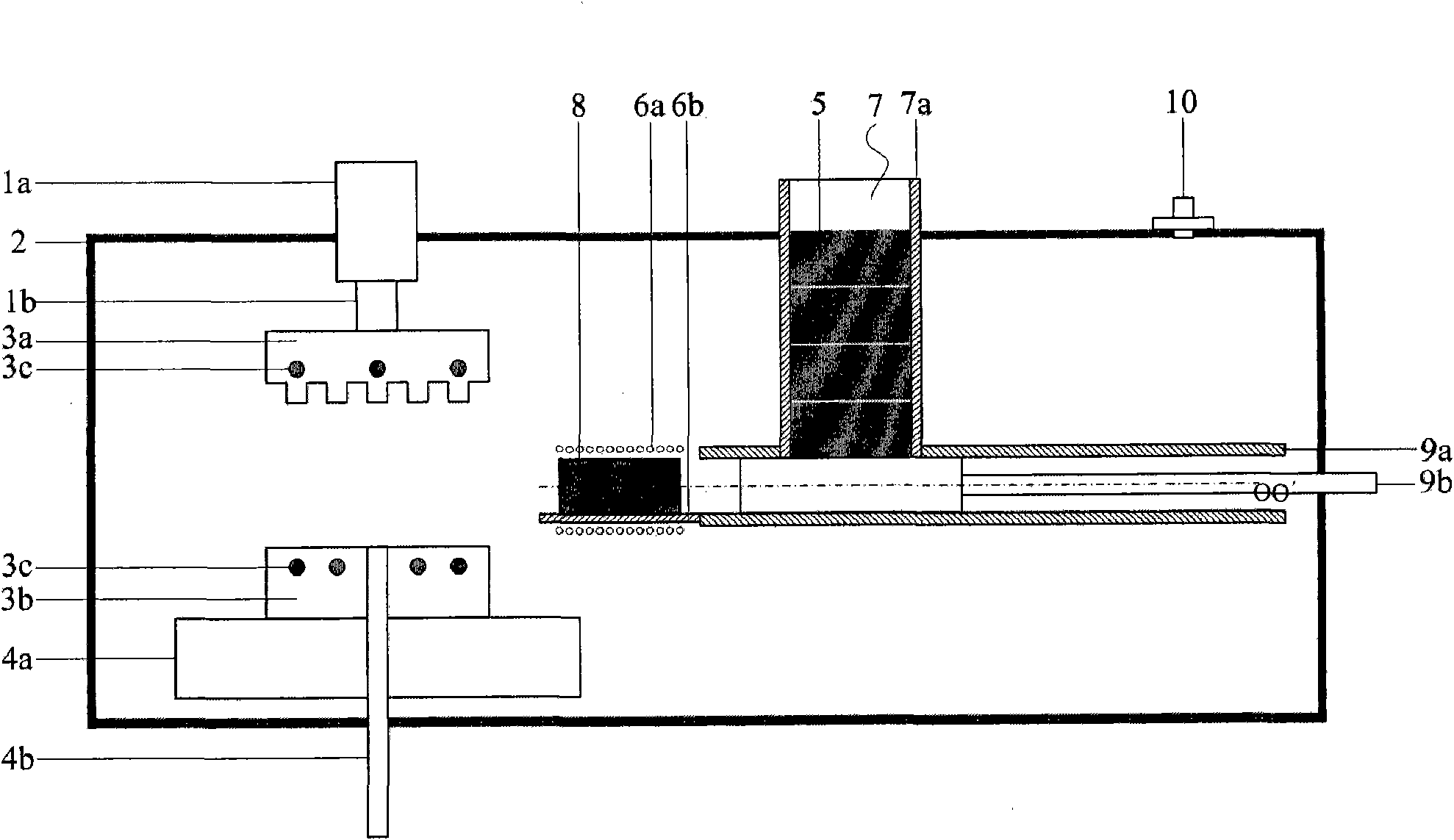

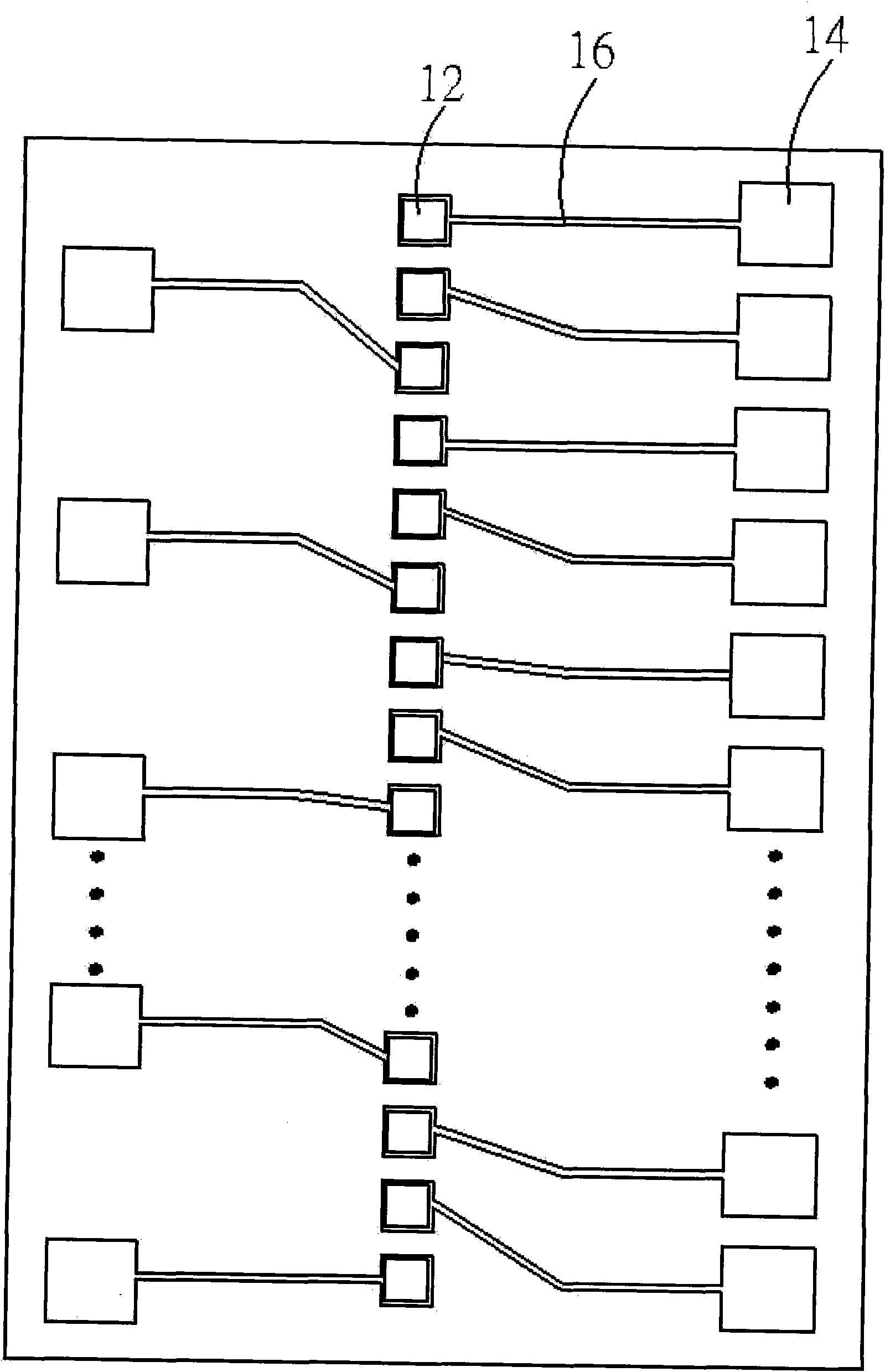

Gum dipping device and method for improving performance of optical fiber coil

ActiveCN104990564AImprove temperature stability and vibration resistanceReduce shrinkage stressMeasurement devicesAdhesiveEngineering

The invention discloses a gum dipping device and a method for improving the performance of an optical fiber coil. According to the method for improving the performance of the optical fiber coil, a wound optical fiber coil is wholly dipped into an adhesive, the gum dipping process that vacuum-pumping is carried out firstly to remove air inside the coil, and then pressurizing is carried out to uniformly press the adhesive in the optical fiber coil is adopted, the optical fiber coil is taken out after dipping, the redundant adhesive on the surface of the optical fiber coil is cleaned up, and stepped curing treatment and stress release treatment are carried to enable the optical fiber coil to be fully cured and the stress of the optical fiber coil to be fully released, so that a cured optic fiber gyroscope with excellent temperature performance and vibration resistance is obtained. After being cured through the curing method provided by the invention, the optical fiber coil is adhered and fixed into a whole through the adhesive uniformly distributed inside the optical fiber coil , so that the local deformation and strain of the optical fiber at the environment that temperature changes and vibration exists can be effectively reduced, the temperature stability and vibration resistance stability are effectively improved, and the application requirement of high precision on the optic fiber gyroscope fields can be met.

Owner:JIANGXI UNIV OF SCI & TECH

Forming method of block-shaped amorphous composite material

The invention relates to a forming method of a block-shaped amorphous composite material, which is characterized by comprising the following steps: (1) selecting a block-shaped amorphous composite material which has the component purity greater than 99.3% and substrate components with strong glass forming capacity, preparing a high-purity block-shaped amorphous composite material, and cutting the block-shaped amorphous composite material into an ingot blank according to a forming part; (2) heating the ingot blank under gas protection at the speed of 0.5-50 DEG C / s to the liquidus temperature and the solidus temperature range of the block-shaped amorphous composite material, and insulating for 3-30 minutes; and (3) under pressure, filling a liquid-solid coexistent metal slurryinto a mold cavity at a deformation rate of 102-106s<-1>, and forcibly cooling for solidifying at the cooling speed of 1-200 DEG C / s while maintaining the pressure. The invention can obtain the metal slurry the second phase of which is uniformly distributed in the liquid phase, has low forming temperature, long service life of the mold and high production efficiency, improves the product performance, can be used for forming parts with complex forming shapes and thin walls, and can be widely applied to amorphous composite materials of Zr-series, Cu-series, Ti-series, La-series, Co-series and the like.

Owner:NANCHANG UNIV

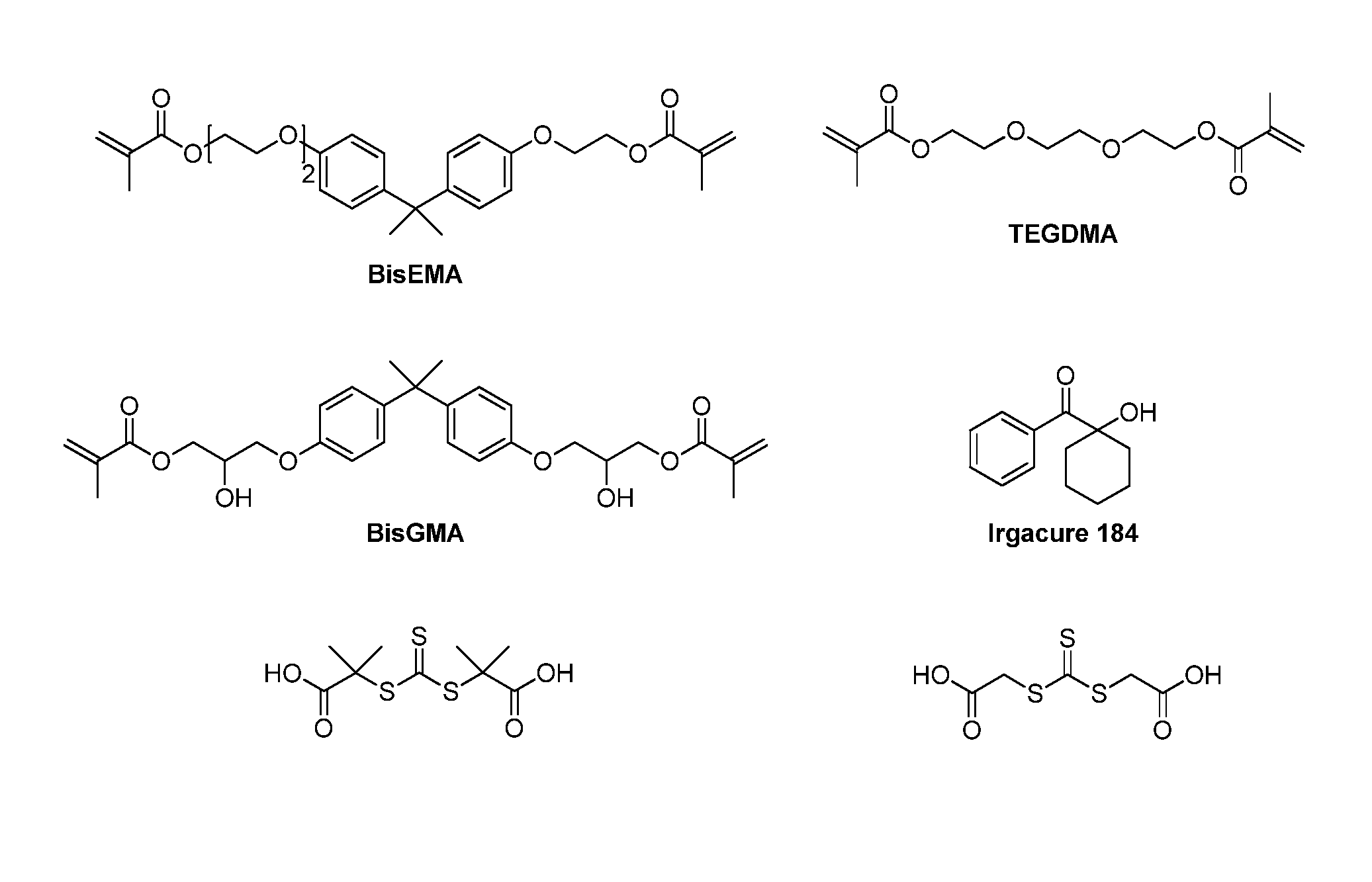

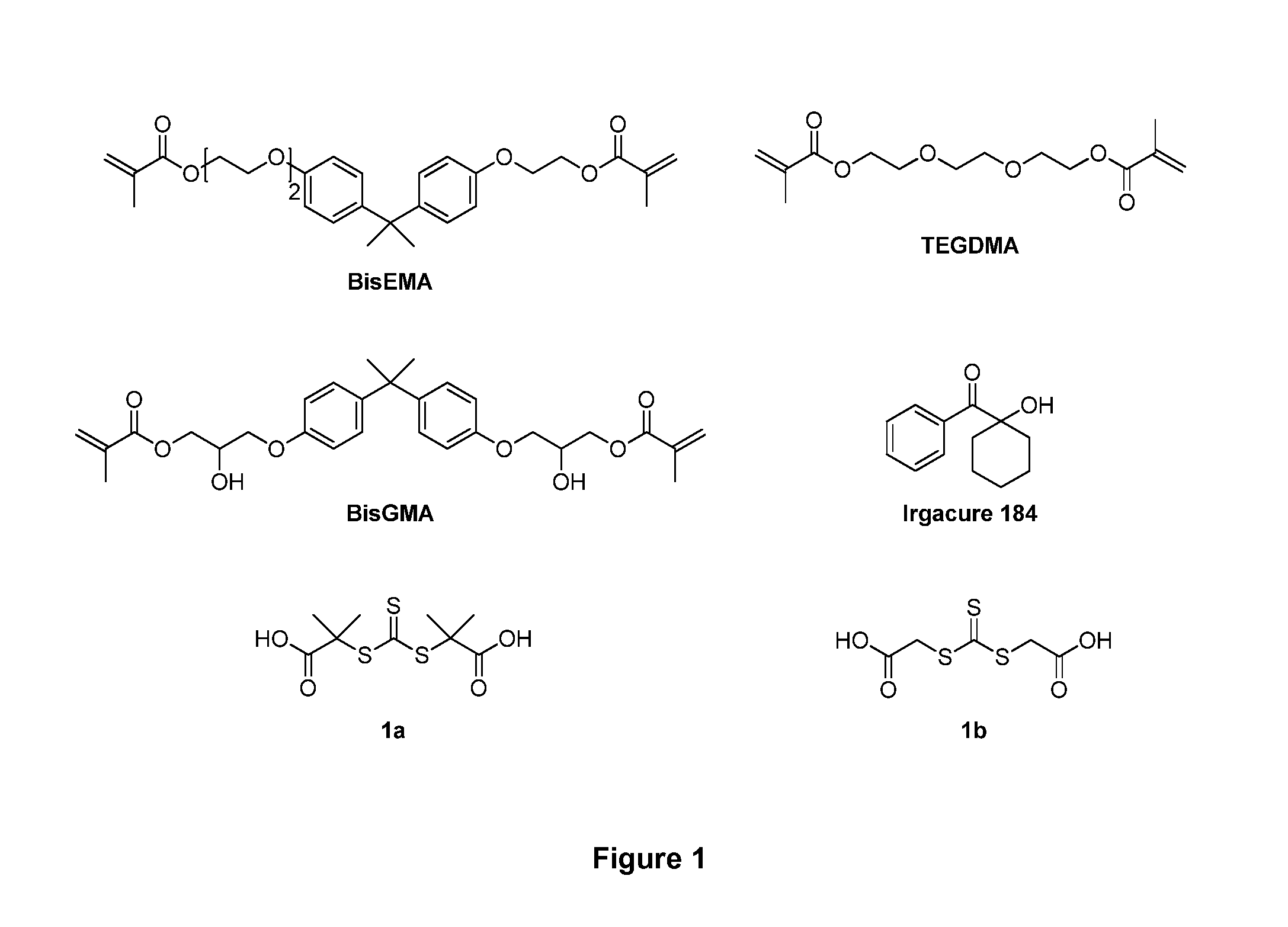

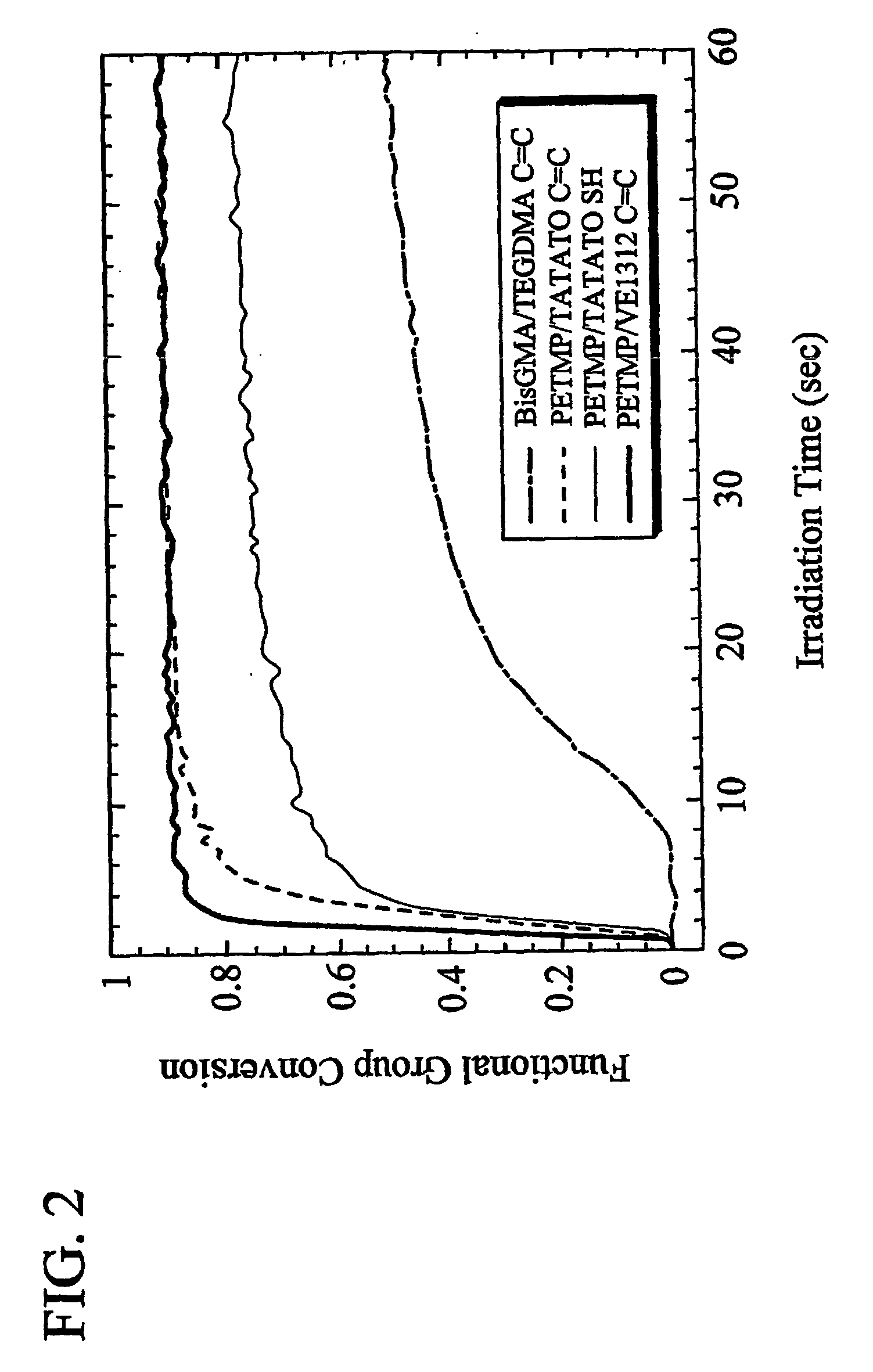

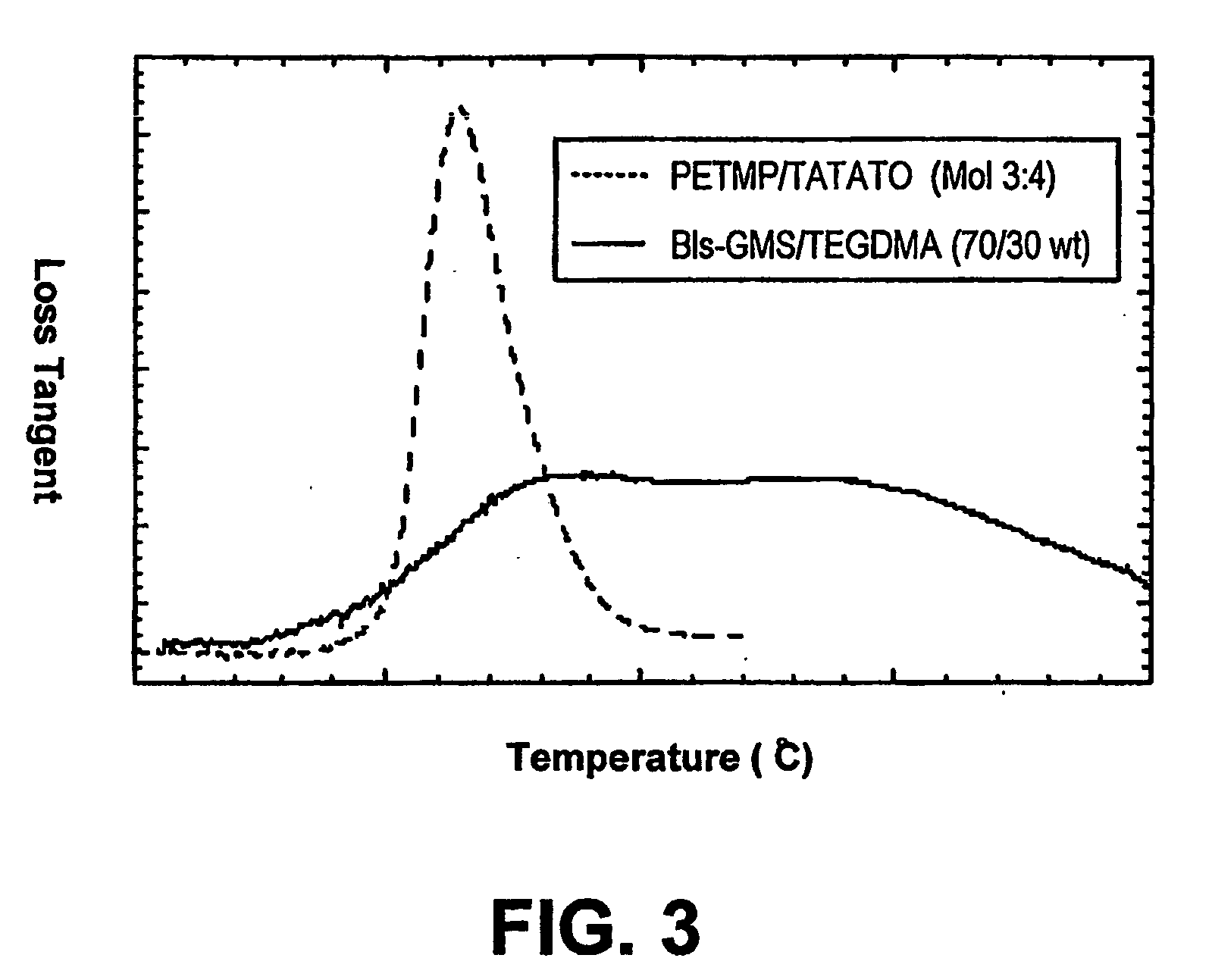

Novel photopolymers and use in dental restorative materials

InactiveUS20070082966A1High conversionLow shrinkage stressImpression capsOrganic chemistryDouble bondPolymer composites

Photopolymerizable polymer composites based on dimethacrylate systems have been increasingly utilized as dental restorative materials. One of the biggest drawbacks of current dental resin systems is the volume shrinkage and shrinkage induced stresses that arise during the polymerization. Other major problems include incomplete double bond conversion and insufficient wear resistance. This invention involves the development of an entirely novel approach to the photopolymerization process that utilizes thiol-ene systems as low shrinkage and ultra-low shrinkage stress dental restorative materials. Compared with the traditional dimethacrylate dental resins, these novel photopolymerizations have demonstrated a dramatically decreased volume shrinkage, extremely rapid polymerization, abilities to photopolymerize ultrathick materials and achieve much higher conversion, lack of oxygen inhibition and ultra-low shrinkage stress due to low volume shrinkage and drastically delayed gel point conversion. These polymers have thus shown outstanding suitability as dental restorative materials.

Owner:UNIV OF COLORADO THE REGENTS OF

Anticorrosion Coating Method for Zinc-Plated Steel Structure

InactiveUS20090148610A1Improve adhesionReduce shrinkage stressPretreated surfacesEpoxy resin coatingsFirming agentMaterials science

The present invention provides an anticorrosion coating method for a galvanized steel structure, the method comprising applying an undercoating composition (I) to a cured thickness of 10 to 200 μm to a surface of a galvanized steel structure, and then applying thereto an overcoating composition (II) to a cured thickness of 100 to 1,500 μm;the undercoating composition (I) comprising an epoxy resin (A) having two or more epoxy groups per molecule, a specific amount of a resin (B) such as a urethane-modified epoxy resin, and an amine-based curing agent (C); the undercoating composition (I) having a shrinkage stress of 20 kg / cm2 or less when it is in the form of a 50 μm-thick cured coating film; and the overcoating composition (II) comprising an epoxy resin (D) having two or more epoxy groups per molecule, a specific amount of a flaky pigment (E), and an amine-based curing agent (F).

Owner:SHIKOKU RES INST +1

Compound laser beam welding

InactiveUS7479616B2Reduce shrinkage stressWelding/soldering/cutting articlesMetal working apparatusCrack freeLight beam

Owner:SUZUKI MOTOR CORP +1

Highly anti-bending and wearing-resistant lightweight concrete

The invention discloses highly anti-bending and wearing-resistant lightweight concrete, which comprises the following raw material constituents in parts by weight: 200-250 parts of cement, 100-150 parts of coal ash, 150-200 parts of river sand, 100-180 parts of manganese residue, 150-200 parts of ceramsite, 20-50 parts of silicon carbide, 15-35 parts of plant fiber, 200-250 parts of water, 0.3-1.5 parts of dipropyl ethylene glycol monobutyl ether, 3-6 parts of silicon resin polyether emulsion, 0.3-1.8 parts of sodium chloride, 2-5 parts of triethanolamine, 0.3-1 part of sodium sulfate, 1-3 parts of epoxy resin, 1-3.5 parts of waste polyurethane, 1-2.3 parts of sodium stearate, 5-16 parts of nano calcium oxide, 0.3-0.9 part of coagulant, 2-5 parts of melamine water reducer and 5-18 parts of foaming agent. The highly anti-bending and wearing-resistant lightweight concrete provided by the invention has high anti-bending strength, good wear resistance, light weight and excellent water resistance.

Owner:无为县严桥双龙建材厂

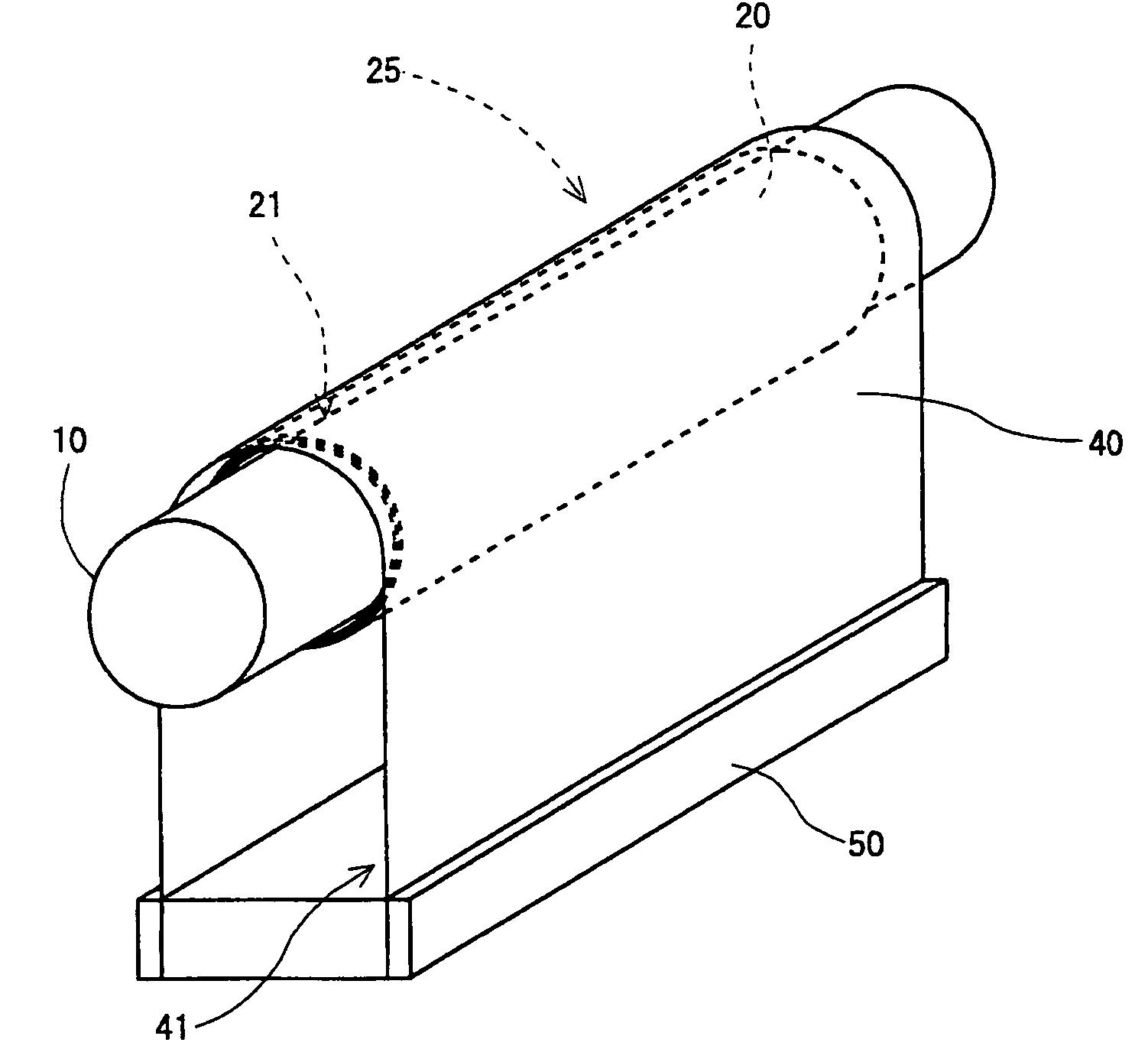

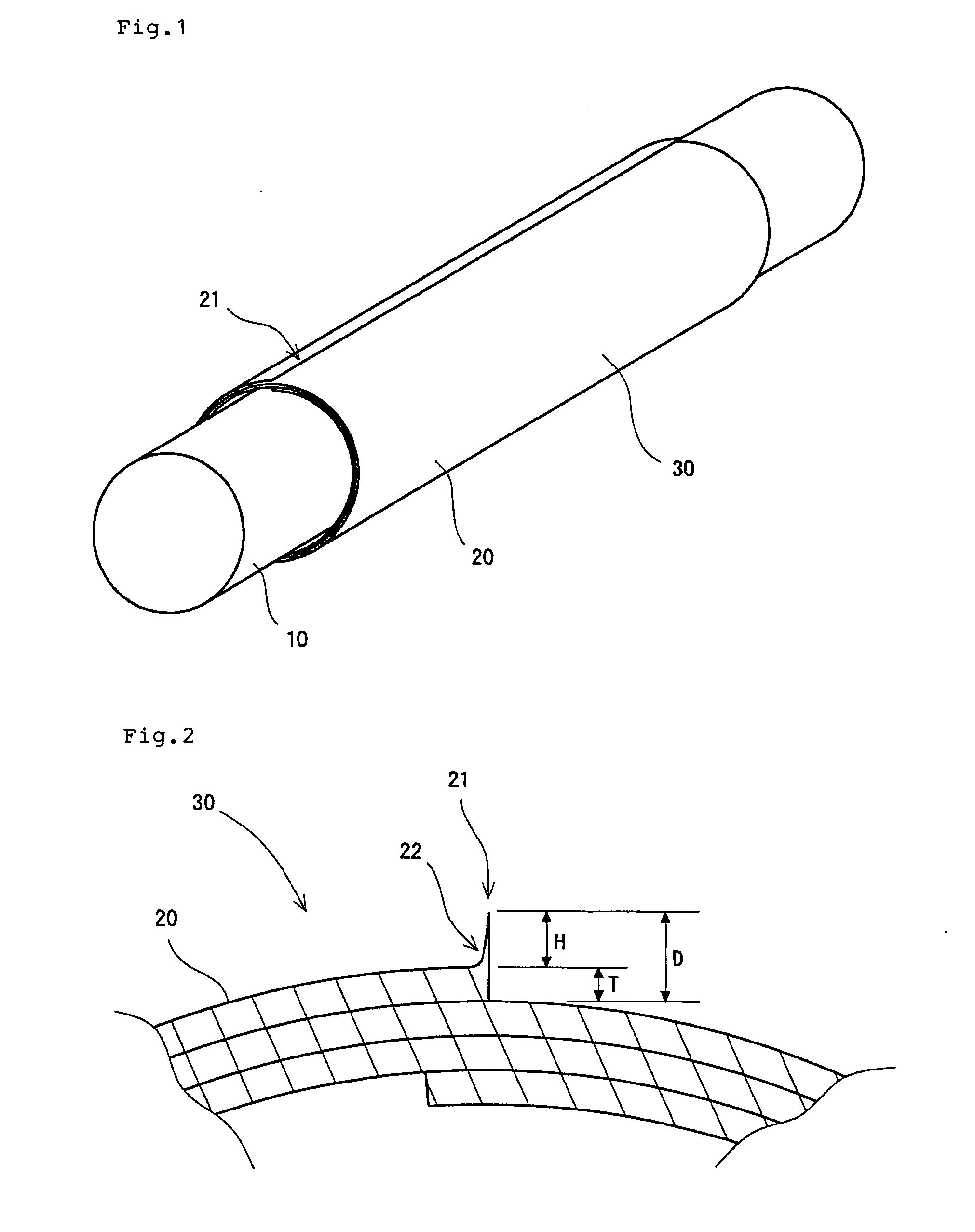

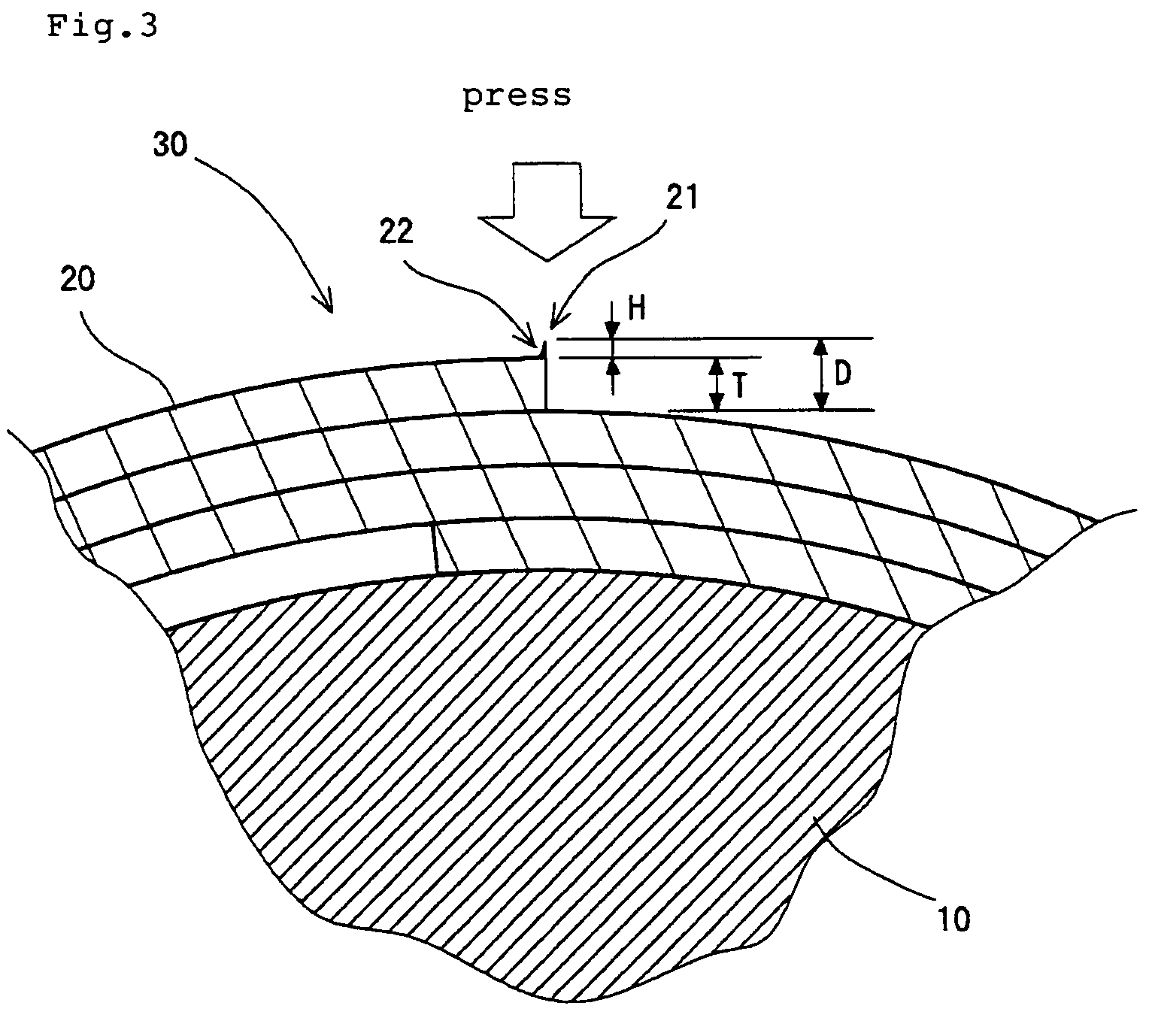

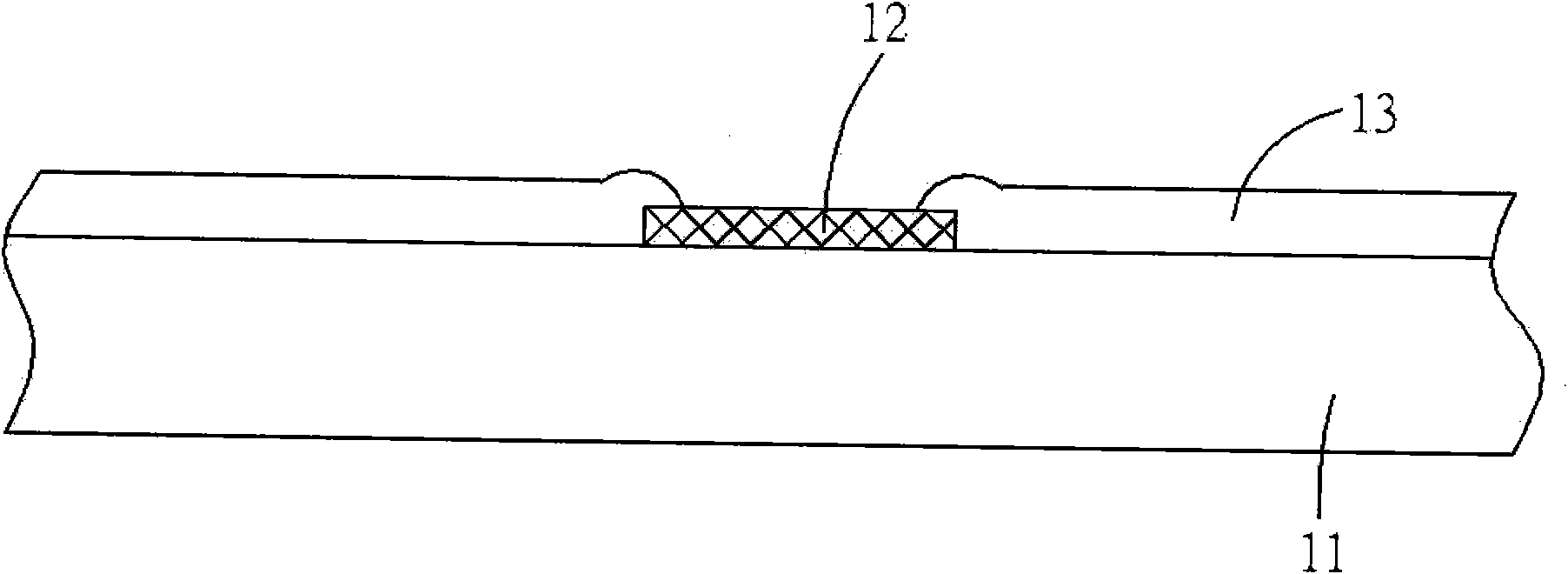

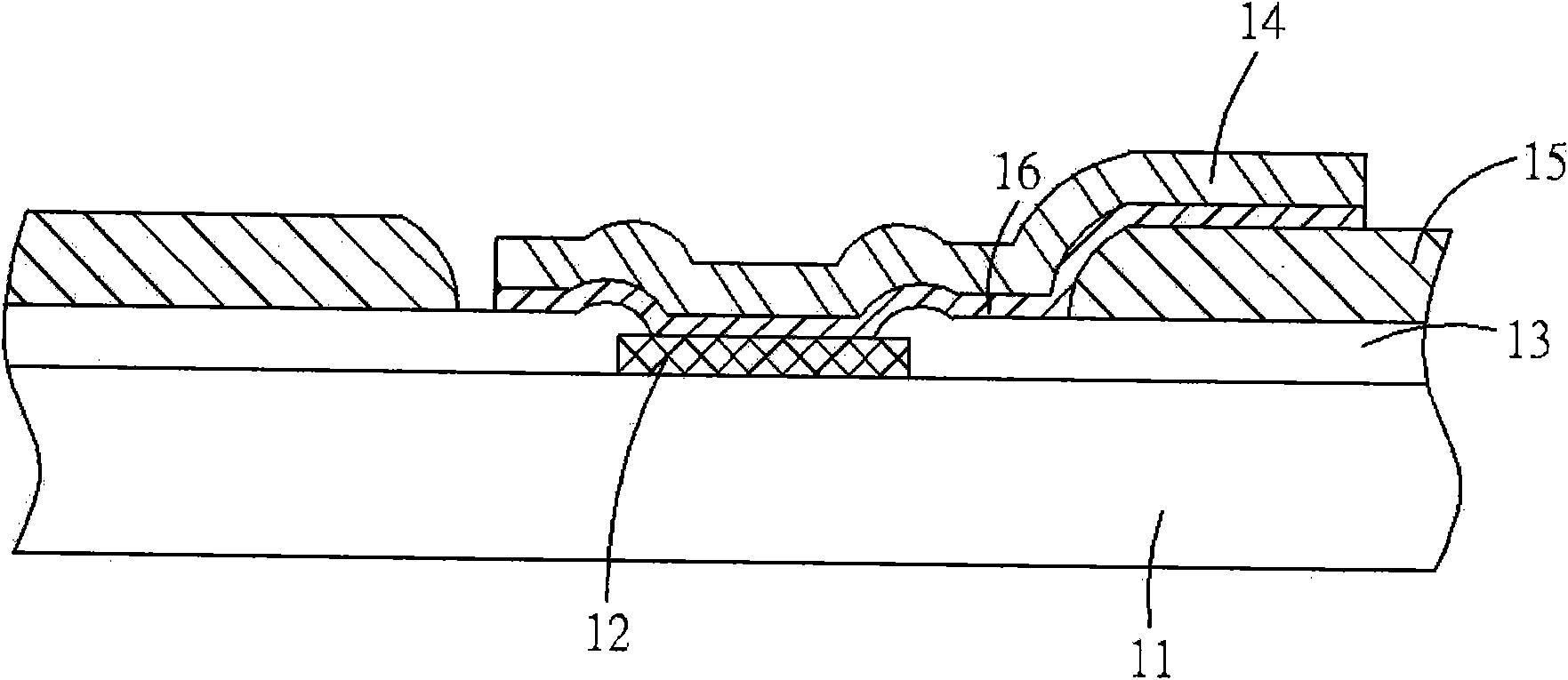

Fluororesin tube and method for producing the same

InactiveUS20090097890A1Excellent abrasion resistanceHigh tensile strengthClosuresPaper/cardboard wound articlesEngineeringUltimate tensile strength

Owner:JAPAN GORE TEX INC

Dielectric layer structure for reducing stress and manufacturing method thereof

InactiveCN101587873AAvoid bendingReduce shrinkage stressSemiconductor/solid-state device detailsSolid-state devicesDielectric layerElectroplating

The invention relates to a dielectric layer structure for reducing stress and a manufacturing method thereof. An integrated circuit component is provided with a weld pad, a protective layer and a first dielectric layer, wherein the protective layer is covered on the surface of the integrated circuit component; the first dielectric layer is covered on the surface of the protective layer; the protective layer and the first dielectric layer enable the weld pad to be exposed; the first dielectric layer is provided with a reconfigured weld pad connected with the weld pad through an under bump metal layer (UBM), a subsequent electroplated metal layer and an original weld pad; a plurality of through grooves are formed on the first dielectric layer, and each through groove passes through the upper surface and the lower surface of the first dielectric layer and divides the first dielectric layer into a plurality of blocks. The shrinkage stress generated after curing of the first dielectric layer is reduced by utilizing the discontinuous blocks, and the heat expansion of the first dielectric layer is buffered through each through groove so as to prevent crystal grains bending after wafer is thinned and cut.

Owner:FUPO ELECTRONICS CORP

Thermal insulation anti-cracking foam concrete

InactiveCN104591776AAdd surface active componentsGood foaming effectCeramicwareFoam concreteThermal insulation

The invention discloses thermal insulation anti-cracking foam concrete. The thermal insulation anti-cracking foam concrete comprises the following raw materials: cement, glass beads, limestone flour, a composite foaming agent, metakaolin, basalt fiber, lignin fiber, alpha-methyl-2,4-pentanediol, vinyl acetate-ethylene copolymer, a water reducer, an early strength agent, a pumping aid and water, wherein the composite foaming agent contains the following raw materials: N-lauroyl-L-sodium glutamate, sodium dodecyl benzene sulfonate, fatty alcohol-polyoxyethylene ether, oleic acid, triethanolamine, lauryl diethanolamine, zeolite powder and water. The thermal insulation anti-cracking foam concrete has high strength, a good anti-cracking effect and excellent thermal insulation performance.

Owner:无为县严桥双龙建材厂

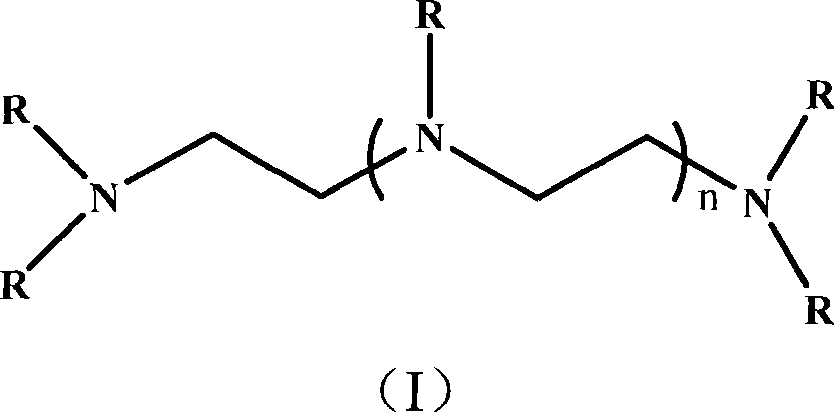

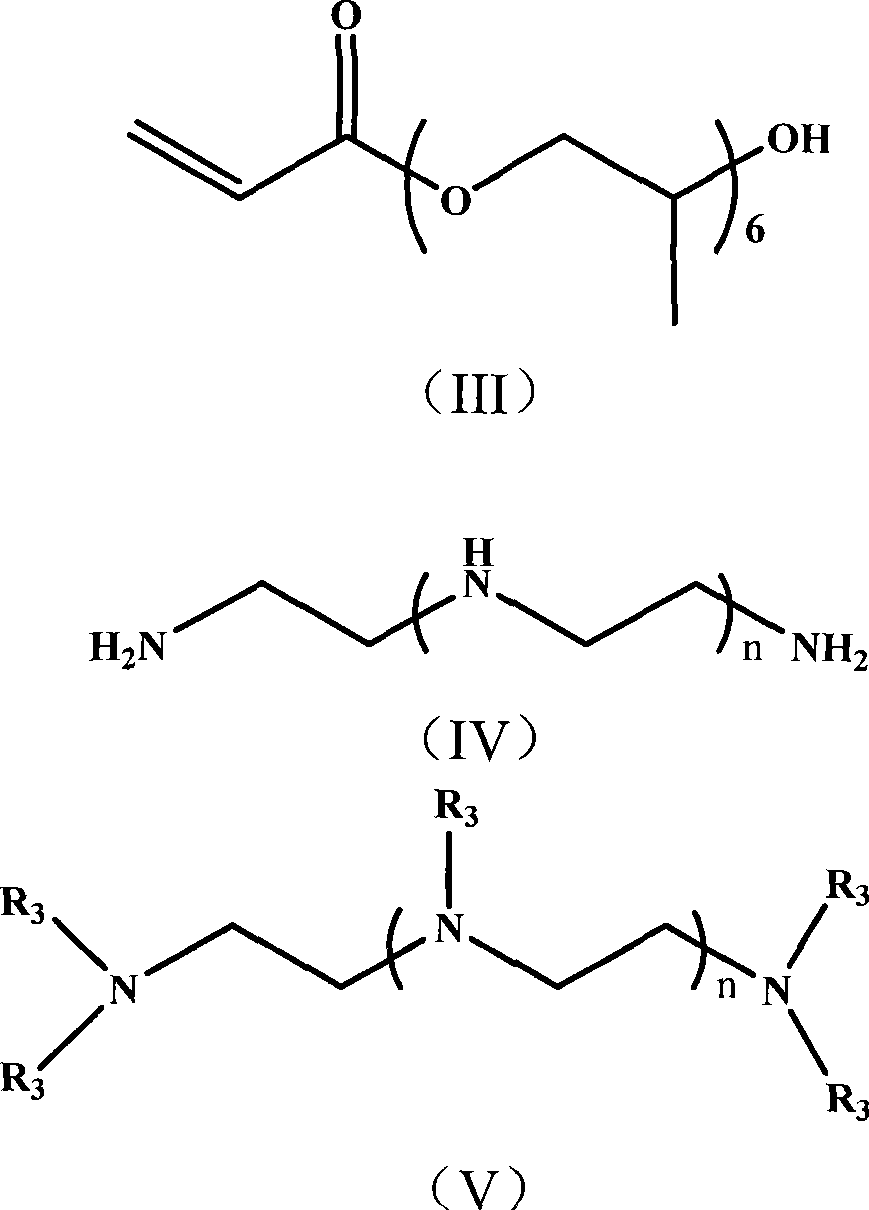

Nitrogenous polyfunctional acrylic ester monomer, preparation and use thereof

InactiveCN101475502ALow viscosityImprove flexibilityOrganic compound preparationAmino-carboxyl compound preparationPolyamine CompoundHydrogen

The invention relates to nitrogen-containing multi-functionality acrylic ester monomers and a preparation method and application thereof. The structure of the monomers is as shown in a general formula (I), wherein R refers to a right formula (1) or a right formula (2); R1 and R2 refer to hydrogen or methyl; m refers to an integer between 0 and 4; and n refers to an integer between 0 and 5. The method for preparing the monomers comprises: firstly, performing Michael addition on polyamine compounds and acrylic ester compounds provided with hydroxyl groups, and obtaining amine compounds provided with the hydroxyl groups; and secondly, making the amine compounds provided with the hydroxyl groups react with acyl chloride to generate products. The method has the advantages of high conversion rate, mild reaction conditions, small number of byproducts, easy separation and purification of products, etc., and the nitrogen-containing multi-functionality acrylic ester monomers are a novel photopolymerisable active compound system with good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

High-performance foam concrete

The invention discloses a high-performance foam concrete which comprises the following raw materials: cement, river sand, lime, a composite foaming agent, fly ash, metakaolin, expanded perlite, lignin fiber, polypropylene glycol, hydroxymethyl propyl cellulose, styrene-acrylic emulsion, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, a water-reducing agent, an early strength agent and water; the composite foaming agent comprises the following raw materials: tea saponin, lauryl sodium sulfate, sodium fatty alcohol polyoxyethylene ether sulfonate, 1,4-butanediol, triethanolamine, soybean oil, sodium hydroxide, zeolite powder, polyacrylate resin and water. The high-performance foam concrete disclosed by the invention is good in pumpability in the construction process, high in compressive strength and good in durability.

Owner:无为县严桥双龙建材厂

Methods for producing iron-based amorphous alloy ribbon and nanocrystalline material

InactiveUS6648994B2Excellent soft magnetic propertiesAvoid breakingMagnetic materialsAlloyMaterials science

The present invention provides a method for producing a Fe-based amorphous alloy ribbon comprising the steps of: ejecting a molten Fe-based alloy containing 10 atomic % or less of B onto a cooling roll to solidify the molten Fe-based alloy; and peeling the solidified Fe-based alloy from the cooling roll when the solidified Fe-based alloy has a temperature of 100 to 300° C. A Fe-based amorphous alloy ribbon having no crystalline phase is stably, continuously produced without breakage by this method.

Owner:HITACHI METALS LTD

Low-ultraviolet energy curing vacuum-spraying UV coating and preparation method thereof

ActiveCN105694678AReduce shrinkage stressGood adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterUrethane acrylate

The invention discloses low-ultraviolet energy curing vacuum-spraying UV coating and a preparation method thereof. The low-ultraviolet energy curing vacuum-sprarying UV coating is made of, by weight, 26-35% of modified low-viscosity high-functionality epoxy acrylate, 10-25% of modified high-functionality polyester acrylate, 8-12% of special modified polyurethane acrylate, 25-40% of TPGDA, 3-7% of HEMA, 0.3-0.8% of wetting dispersant, 5-10% of transparent filler, 4-8% of photoinitiator, 0.3-0.5% of leveling agent, and 0.1-0.3% of other auxiliaries. Compared with common like coatings, the vacuum-spraying UV coating has the advantages that ultraviolet energy required for coating curing is greatly reduced, and energy is saved and effectively used. In addition, possibility to cause quality defect of the backlight side of special-shaped workpieces is decreased. The vacuum-spraying UV coating has the advantages of excellent coating strength and transient leveling property.

Owner:HUNAN JINHAI SCI & TECH

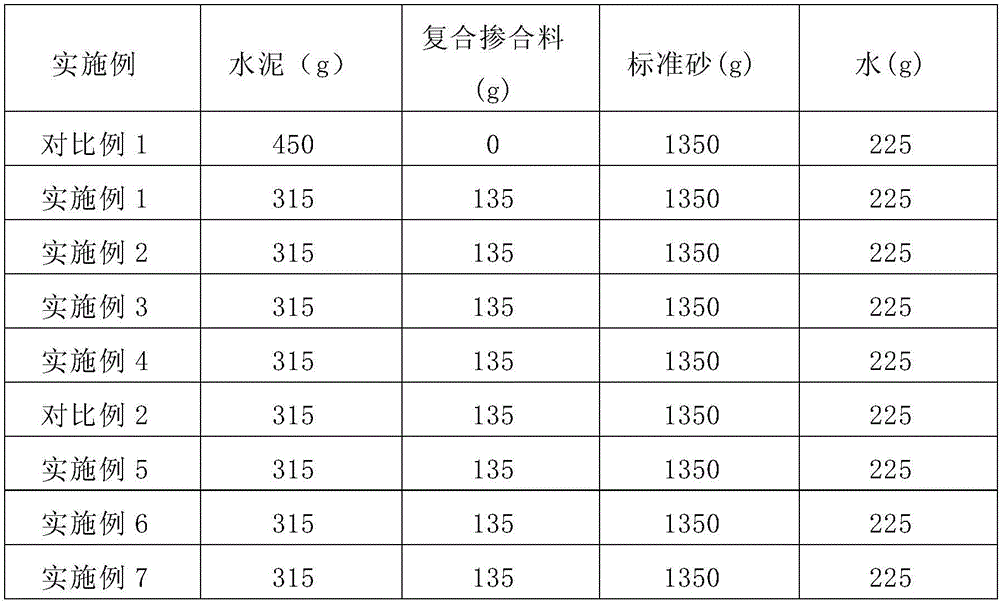

Desulfurization ash-coal ash complex mineral admixture and preparation method thereof

The invention relates to a desulfurization ash-coal ash complex mineral admixture and a preparation method thereof. The admixture is prepared from, by mass, 40-70 parts of desulfurization ash, 22-52 parts of coal ash, 5-10 parts of reinforced activated material, surface modification agent and a grinding aid, the total mass of the desulfurization ash, the coal ash and the reinforced activated material is 100 parts, the mass of the surface modification agent accounts for 0.2-0.5% of the total mass of the desulfurization ash, the coal ash and the reinforced activated material, and the mass of the grinding aid accounts for 0.1-0.2% of the total mass of the desulfurization ash, the coal ash and the reinforced activated material. The two kinds of waste of the coal ash and the desulfurization ash serve as the raw materials, cost is low, environmental pollution is reduced, resource waste is avoided, and great economic benefits and environmental protection significance are achieved. In addition, the two kinds of waste of the coal ash and the desulfurization ash are doped at the same time, negative effects generated when the two kinds of matter are independently used as the concrete admixture are reduced, the comprehensive performance of obtained concrete is good, and use standards are met.

Owner:WUHAN UNIV OF TECH

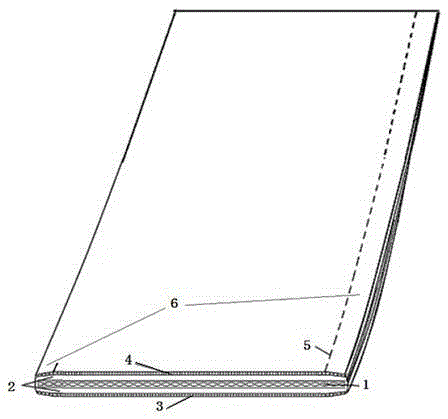

Environment-friendly type elastomer modified asphalt waterproof roll

InactiveCN105386525AReduce generationEmission reductionRoof covering using flexible materialsBuilding insulationsFiberPolyester

The invention relates to an environment-friendly type elastomer modified asphalt waterproof roll which is a multi-layer composite structure. A long fiber polyester base material reinforcing layer is arranged in the middle of an environment-friendly type elastomer modified asphalt layer; and the environment-friendly type elastomer modified asphalt layer consists of the following components in parts by mass: 45-55 parts of low-smoke asphalt, 4-12 parts of SBS (styrene butadiene styrene) thermoplastic rubber, 1-4 parts of powdered butadiene styrene rubber, 5-10 parts of natural asphalt master patch, 0-3 parts of polybutylene elastomer, 5-10 parts of rubber processing oil, 0-2 parts of polyolefin auxiliaries, 0-2 parts of amide wax, and 20-30 parts of 180-mesh talcum powder. The environment-friendly type elastomer modified asphalt waterproof roll has the beneficial effects that: by optimizing and applying environment-friendly raw materials such as the low-smoke asphalt and the like, a low-temperature production process of the modified asphalt is realized, so that generation and discharge of atmospheric contaminant such as non-methane hydrocarbon, particulate matters and the like in a production process of the elastomer modified asphalt waterproof roll are effectively reduced, and therefore, the pollution problem in the production process of the elastomer modified asphalt waterproof roll is completely solved.

Owner:胜利油田大明新型建筑防水材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com