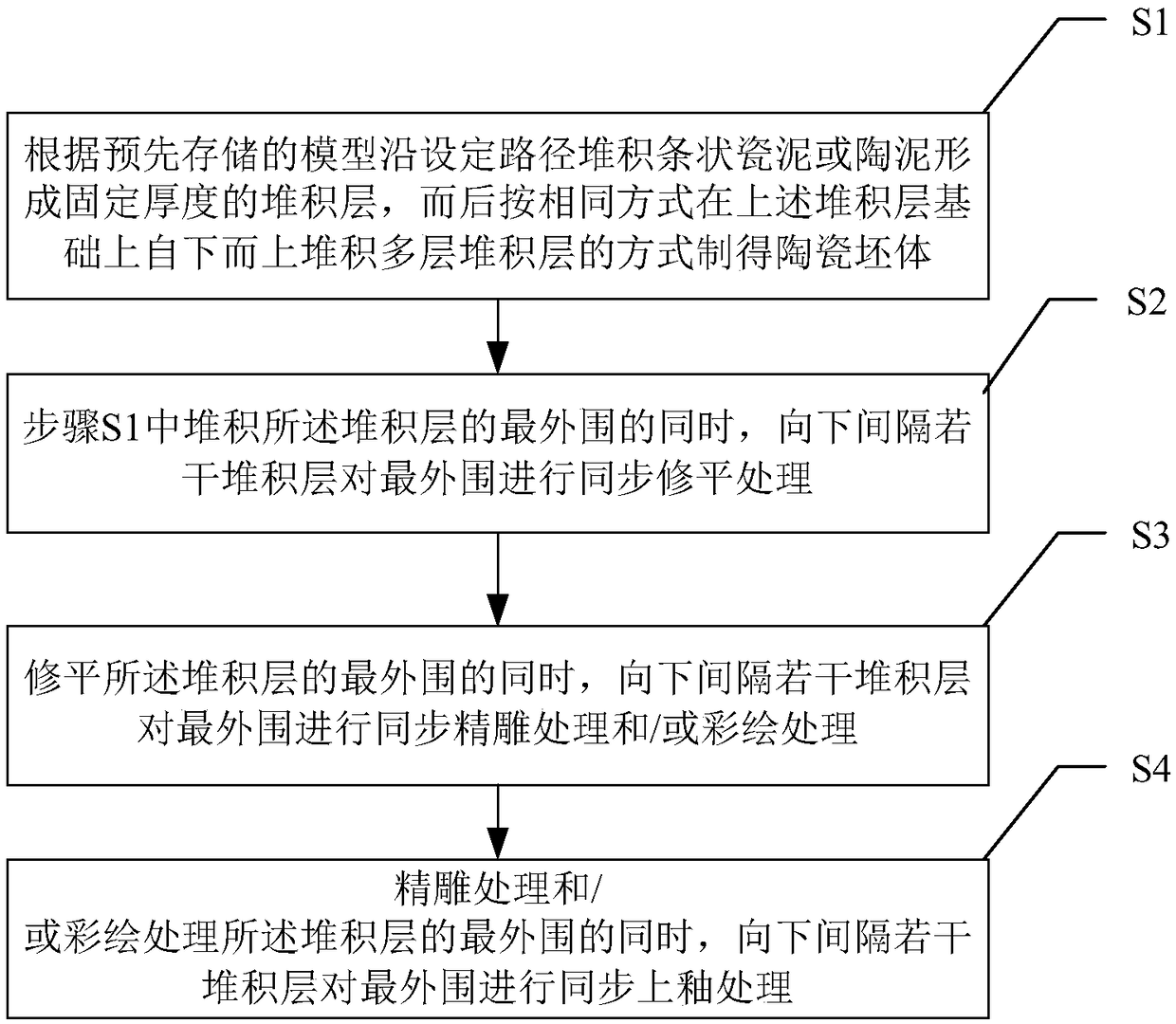

Large and medium chinaware manufacturing method

A manufacturing method, large and medium-sized technology, applied in the direction of manufacturing tools, ceramic molding machines, clay products, etc., can solve the problems of harsh production environment, low efficiency, impact, etc., to achieve the goal of enriching applicable device types, saving man-hours, and reducing manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

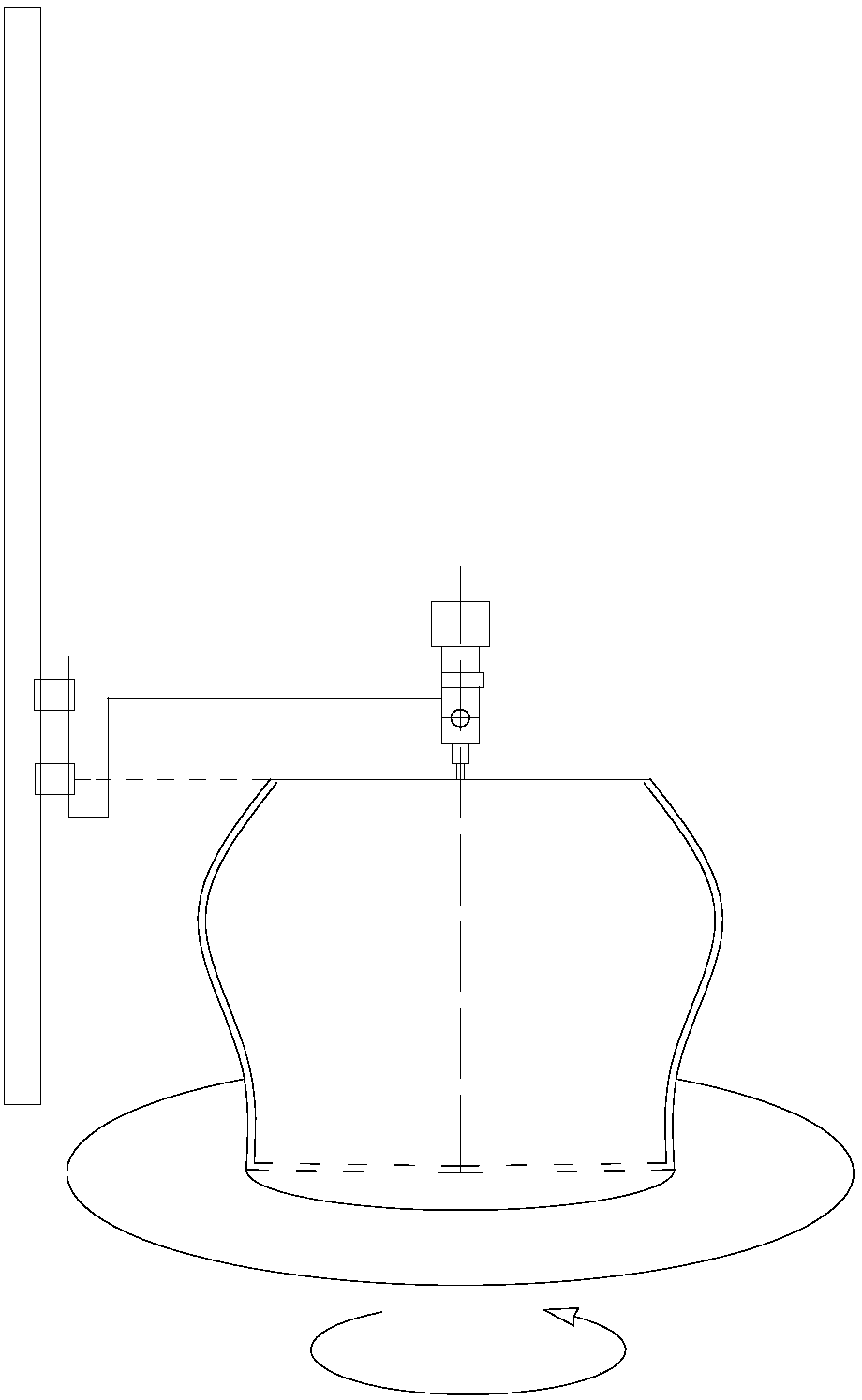

Method used

Image

Examples

Embodiment 1

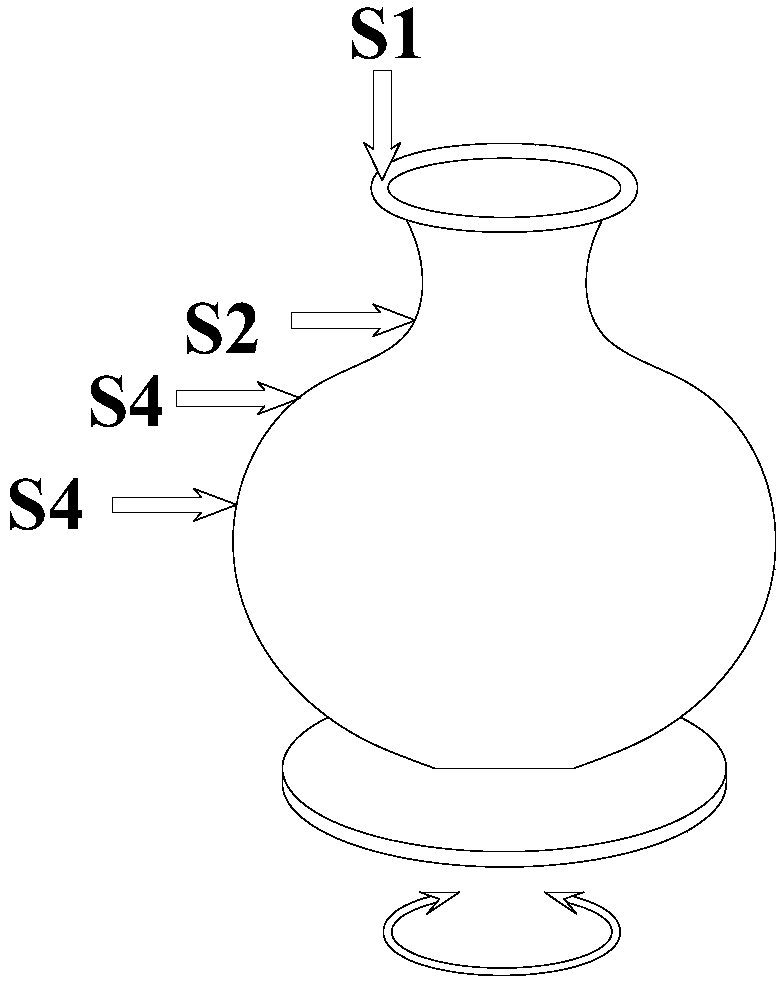

[0098] An art ceramics factory uses the method of the present invention to produce a gourd-shaped wine vat with a custom-made regular octagon in cross section. Each side has a different painting or relief shape, and the body and mouth of the vat are designed with relief decorations such as embossed gourd leaves. For: the tank bottom is produced by the traditional drawing method, and then it is directly molded directly on the tank bottom without maintenance. It takes 12.5 hours to get the finished body of the wine tank, which is trimmed, carved and glazed, and maintained at 40°C and 90% relative humidity for 12 hours. Afterwards, it is dried with hot air for 6 hours and fired, and it takes a total of 40 hours to obtain a customized treasure gourd art-shaped boutique wine tank, which is priced at 1,200 to 1,500 yuan.

Embodiment 2

[0102] Using an 8mm nozzle to imitate the shape of bamboo weaving to "weave" the outer surface of the bamboo basket pattern, the outline of the shape is "sky round place". It takes 9.25h, 40℃90% relative humidity for 12h, hot air drying for 6h, and then firing. It took a total of 37 hours to get the customized "bamboo weaving" wine tank product, priced at 1,800 yuan.

Embodiment 3

[0106]An art ceramics factory originally produced an art sculpture by manual plus semi-mechanical fine carving. Due to market differentiation, the sculpture was reduced to 2 / 3 of the original size and became more popular in the market. The manufacturer adopted the new process of the present invention to simultaneously produce The original size sculpture products and the reduced size new sculpture products consume 2 / 3 and 1 / 6 of the man-hours of the old process respectively, and the total sales and profits increase by 1.5 times and 2.7 times respectively.

[0107] It can be seen that adopting the method of the embodiment of the present invention can save time, reduce labor and manufacturing costs, and can greatly increase product value at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com