Patents

Literature

91results about How to "Increase ultimate strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

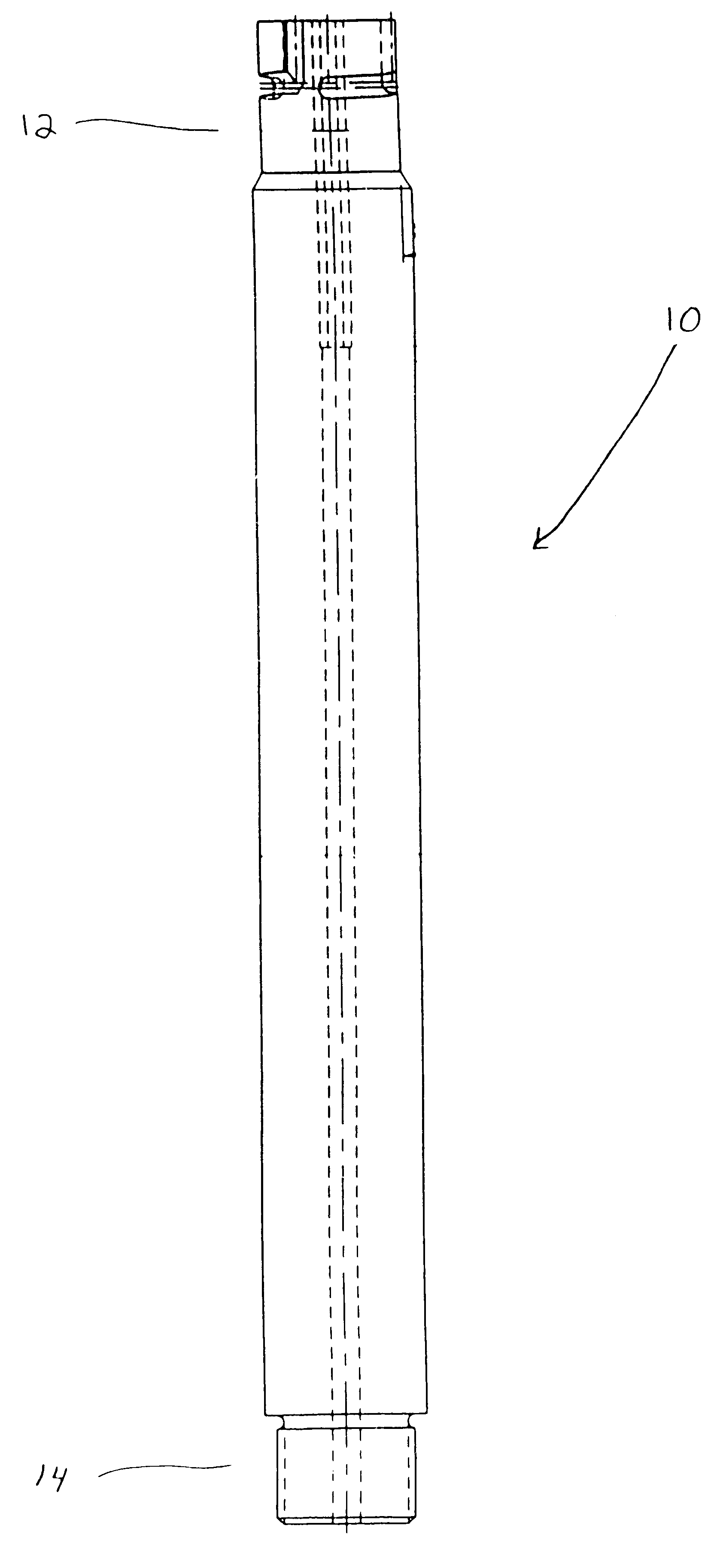

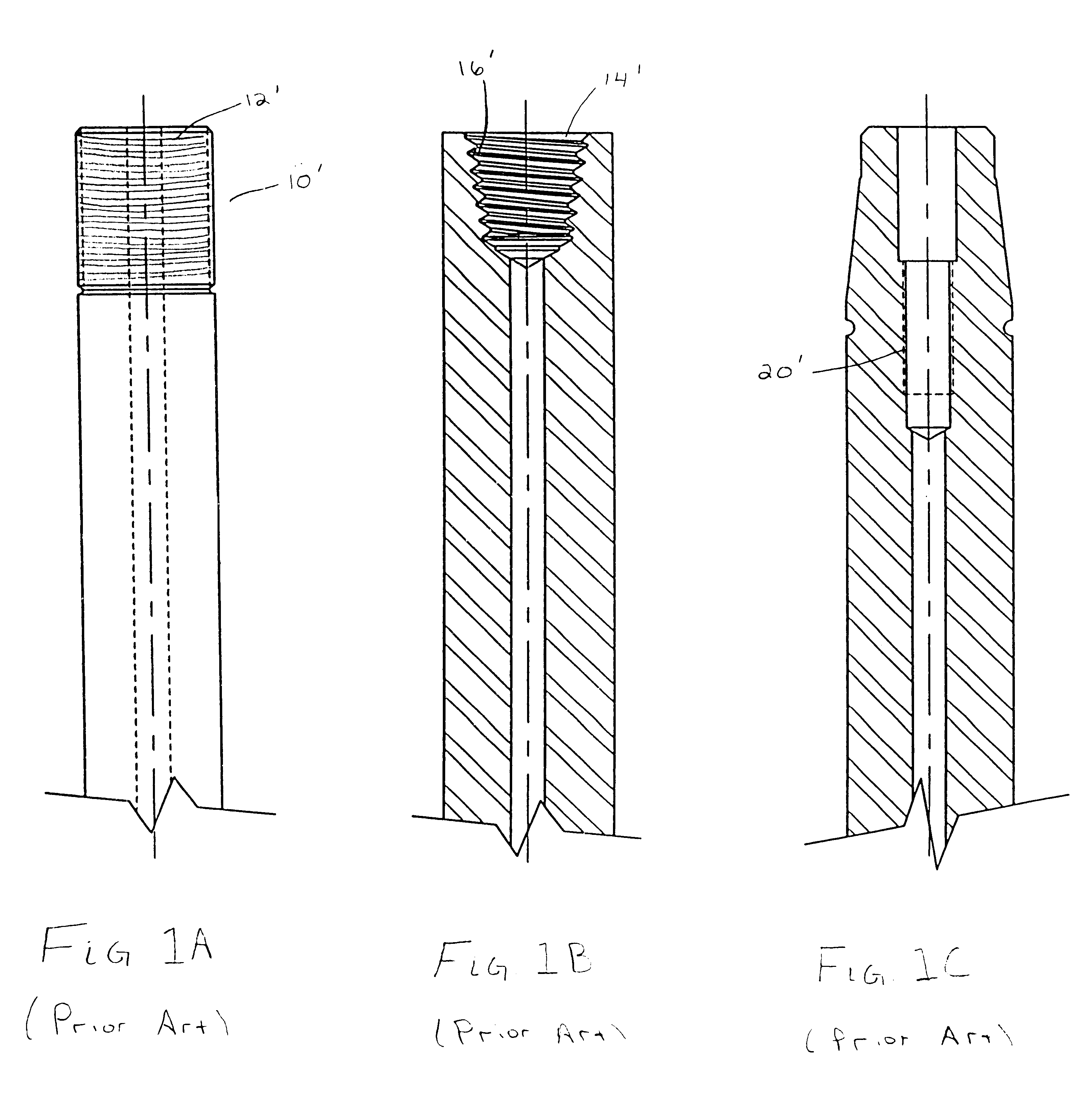

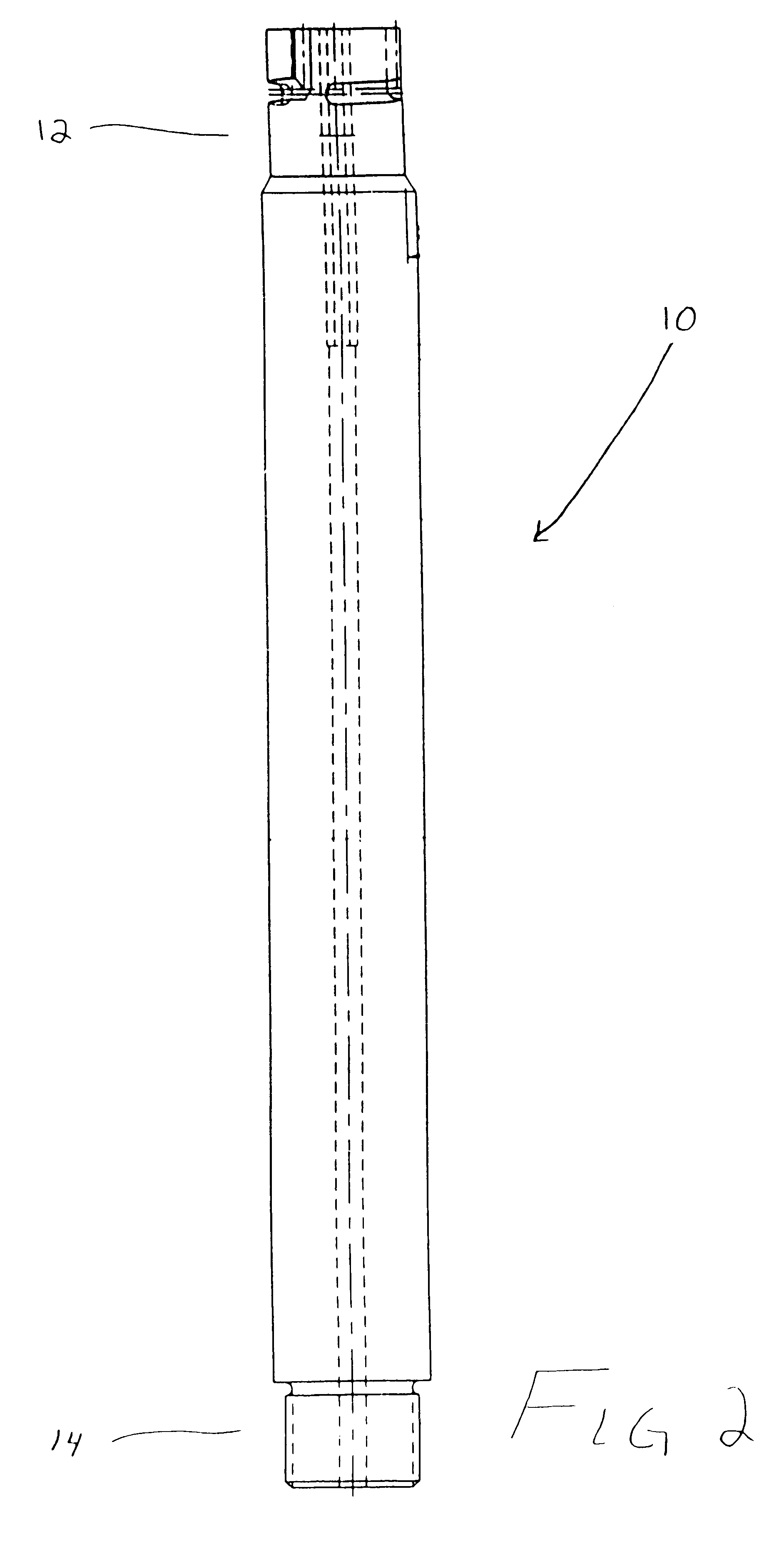

Universal coupling

InactiveUS6358467B1Easily removeQuick and easy mannerMelt-holding vesselsMechanical apparatusEngineeringMolten metal

A coupling mechanism for a molten metal processing system includes an elongated shaft having an upper axial end and a lower axial end. A passage having a torque facilitating shape extends through at least a portion of the shaft. The upper end of the shaft tapers inwardly and forms a tapered seat. At least one channel is machined into an outer surface of the upper end of the shaft. The channel has a first portion extending longitudinally downward from a top surface of the shaft and a second portion extending from the first portion at an angle greater than 90.degree. relative to the first portion. A coupling member, for coupling the shaft to a drive system, includes a body having an annular wall which defines a cavity. At least one locking member is disposed on an inner surface of the annular wall which is adapted to cooperate with the channel in the shaft. The locking member is aligned with the first portion of the channel and the shaft is slid into the cavity. When the locking member reaches a bottom surface of the first portion of the channel, the shaft is turned less than one third of a rotation so that the locking member travels partially across the second portion of the channel thereby pulling the shaft upward. The cavity of the coupling member tapers outwardly forming a mouth which engages the tapered seat of the shaft in a sealing relationship.

Owner:METAULLICS SYST +1

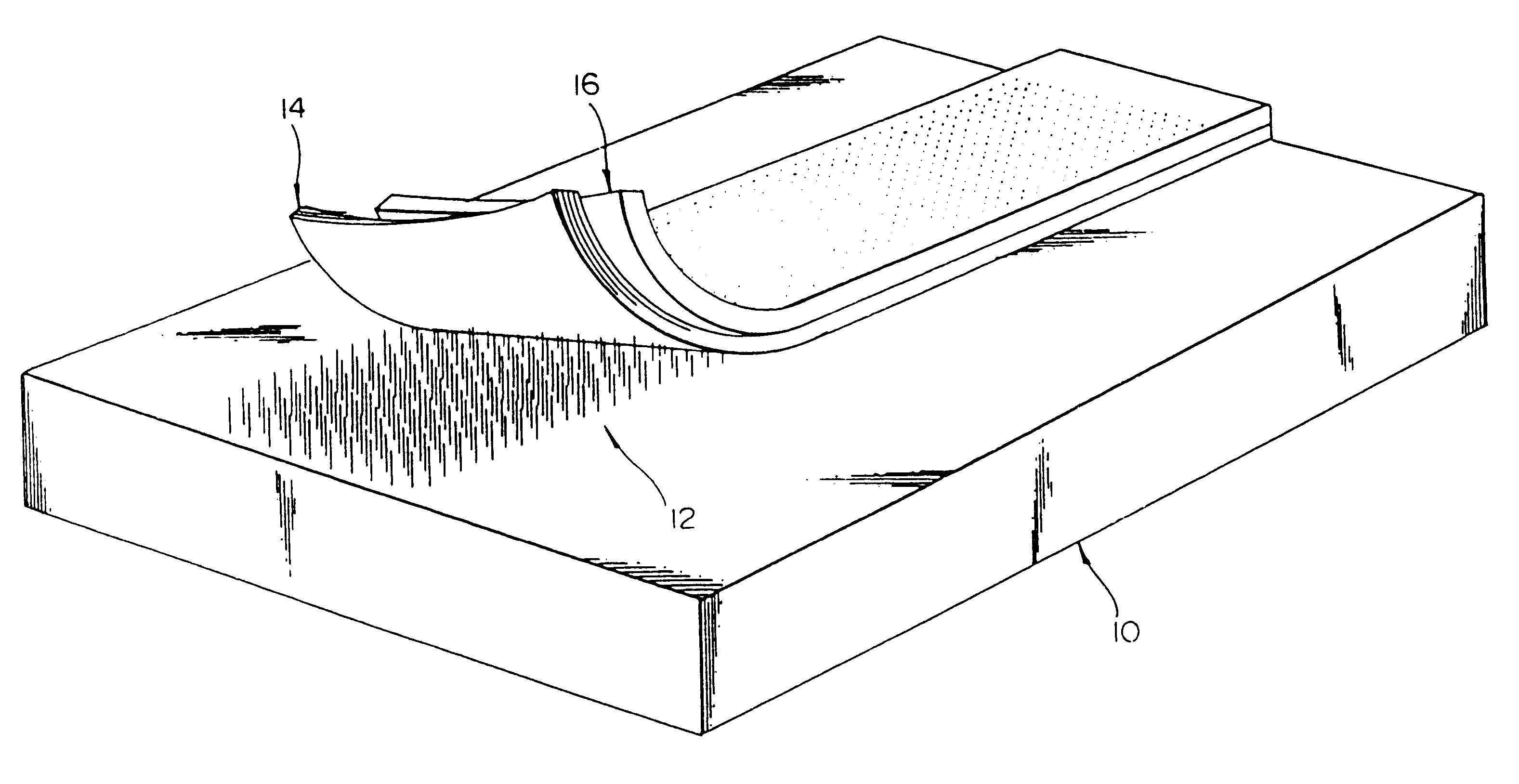

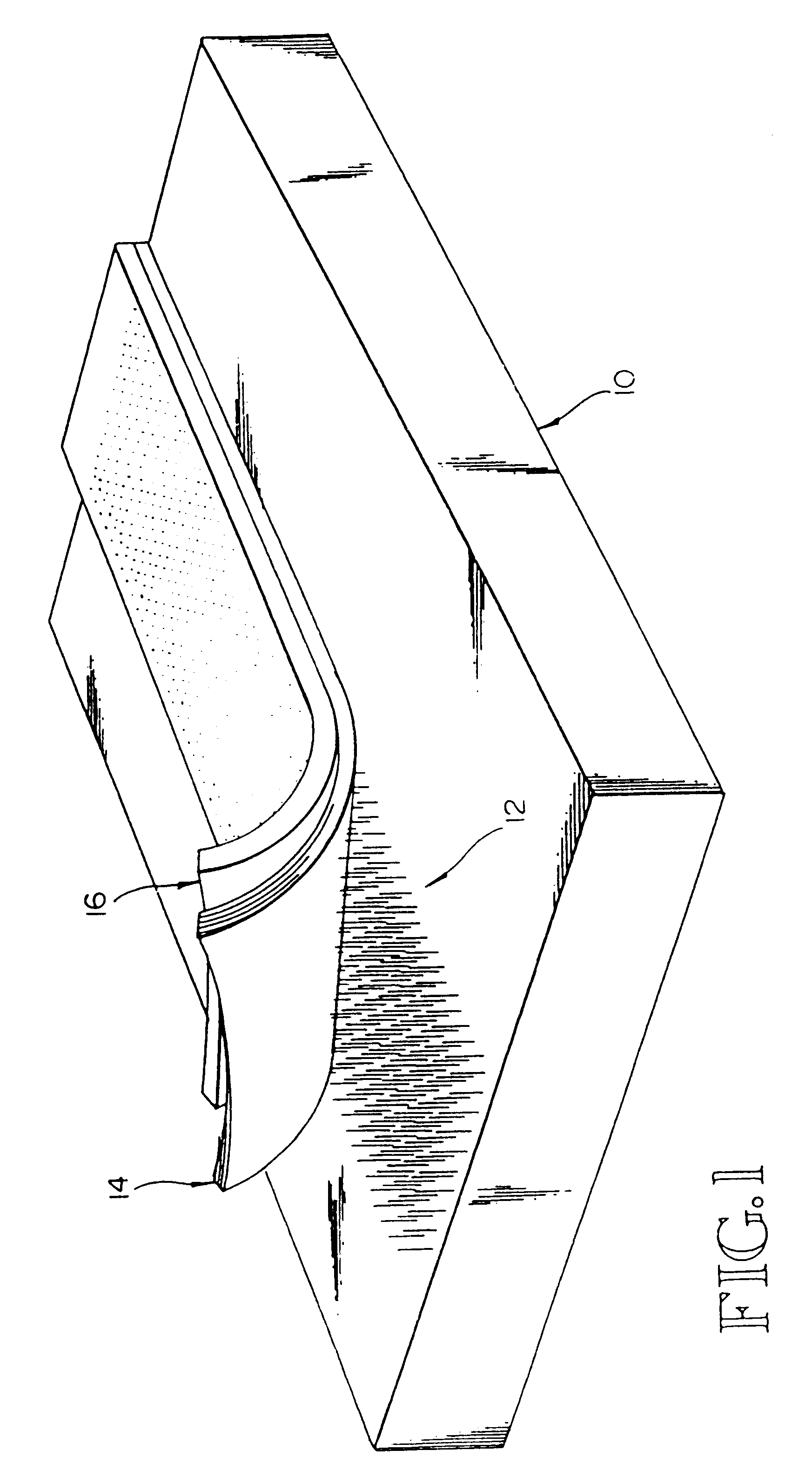

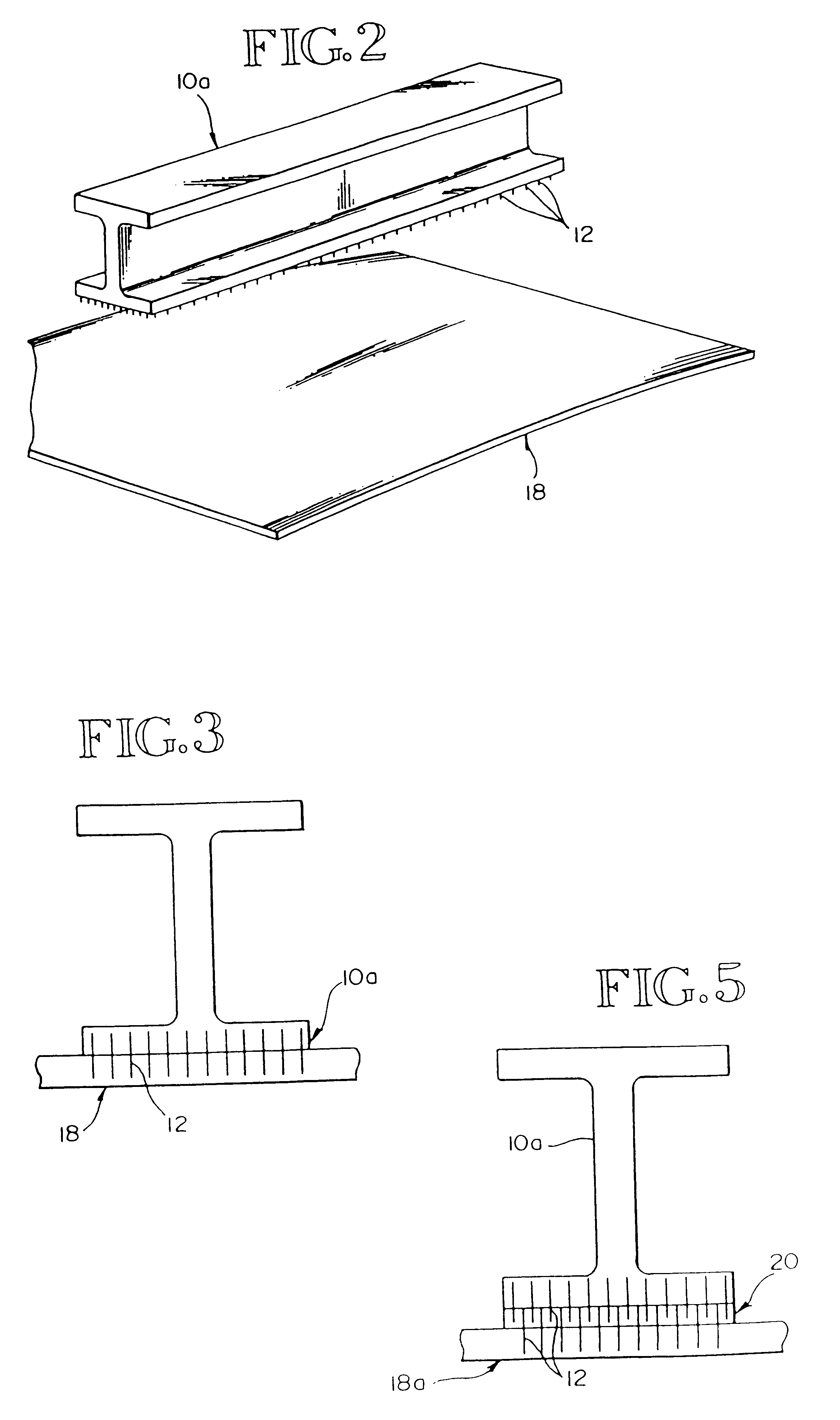

Composites joined with z-pin reinforcement

InactiveUS6436507B1Easy to manufactureLasting shelf-lifeFuselage framesLayered productsEngineeringBond line

Prefabricated composite detail parts use precured strips that include Z-pin reinforcement along the bond line. Each strip has Z-pin stubble protruding from opposed faces so that the pins are embedded into the detail parts when the joint forms.

Owner:THE BOEING CO

Methods and compositions for healing and repair of articular cartilage

InactiveUS7323445B2Improve stabilityIncrease ultimate strengthPeptide/protein ingredientsGenetic material ingredientsDiseaseMedicine

Methods and compositions are provided for the treatment of articular cartilage defects and disease involving the combination of tissue, such as osteochondral grafts, with active growth factor. The active growth factor is preferably a composition containing at least one bone morphogenetic protein and a suitable carrier. The method results in the regeneration and / or functional repair of articular cartilage tissue.

Owner:GENETICS INST INC

EVA hot melt adhesive composition containing linear hydroxyl-terminated polyurethane resin

InactiveCN101787250AImprove initial strengthIncrease ultimate strengthPolyureas/polyurethane adhesivesWaxAntioxidant

The invention discloses an EVA hot melt adhesive composition containing a linear hydroxyl-terminated polyurethane resin, which comprises the linear hydroxyl-terminated polyurethane resin, an ethylene-vinyl acetate polymer, a tackifier, waxes, an antioxidant, an ultraviolet stabilizer, a filling material, a fire retardant and the like. The EVA hot melt adhesive composition containing the linear hydroxyl-terminated polyurethane resin is used for improving the early strength, the final strength and the high- and low-temperature resistance performances of the EVA hot melt adhesive compositions.

Owner:山东久隆高分子材料有限公司 +1

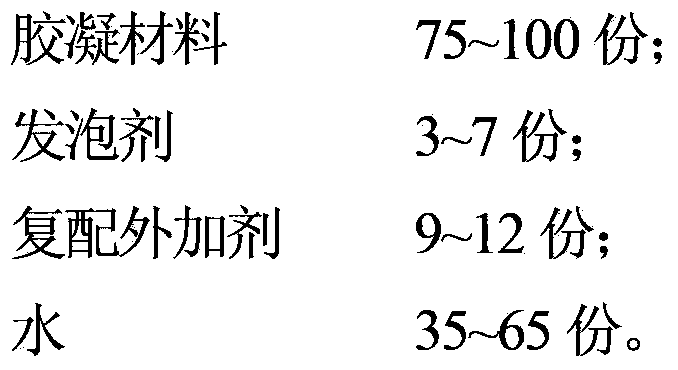

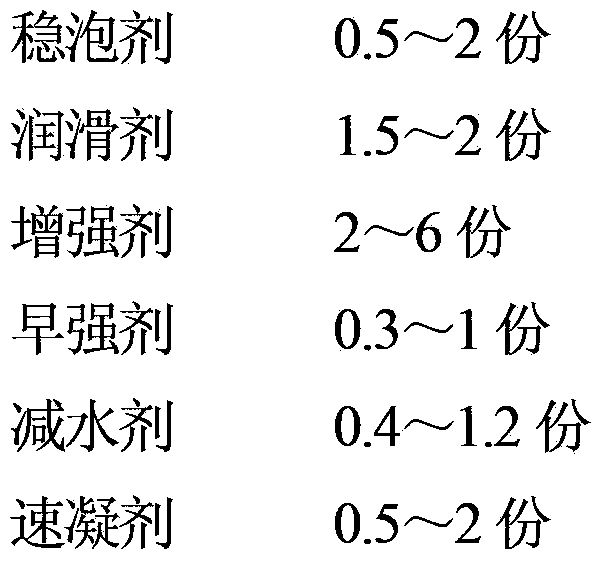

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

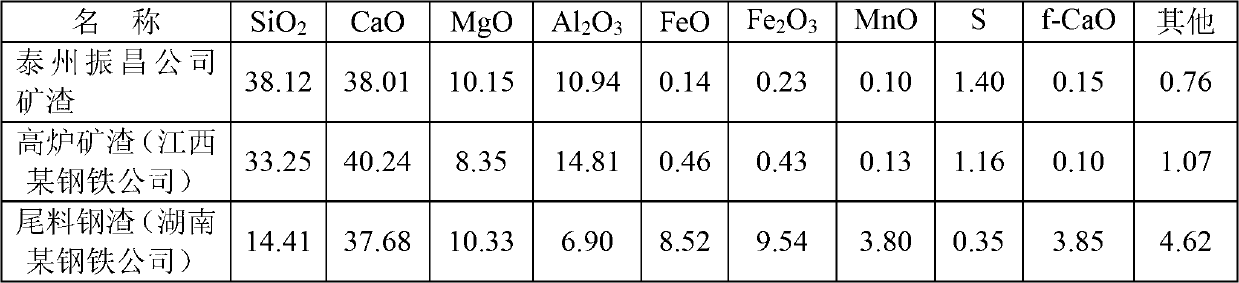

Aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and production method of aerated concrete block

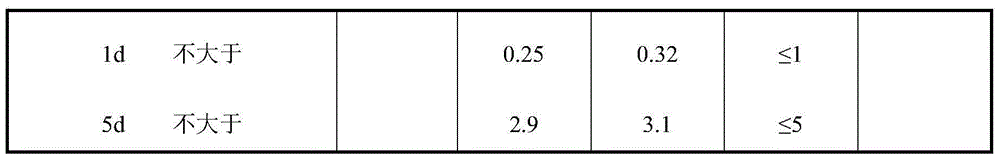

The invention provides an aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and a production method of the aerated concrete block. The aerated concrete block is produced through the following steps: adding an additive A, an additive B and water in components as follows: 40 to 50% of specially-made mineral waste residue obtained in a such way that cinder is obtained through the production process of recycling steel slag discharged from Taizhou Zhenchang Industrial Waste Residue Comprehensive Utilization LTD and metallurgical and chemicalferrous waste residue, and then is water-quenched, 35 to 45% of tailings steel slag, 2 to 4% of cement clinker, 1 to 3% of gypsum, and 8 to 12% of modified wood, wherein the grain size of the specially-made mineral waste residue is less than or equal to 5 mm, the grain size of the tailings steel slag is less than or equal to 20 mm, the additive A accounts for 1% of the total weight of the components, the additive B accounts for 0.05% of the total weight of the components, and water accounts for 0.5 to 0.6 times of the total weight of the components; and conducting mixing, heating, air-entrapping, steaming and pressing, and curing in sequence. The aerated concrete block produced by adopting the production method is high in strength, and small in drying shrinkage value, and can meet the block standards of the A3.5 grade and the B09 grade in the JC1062-2007 foam concrete block standard.

Owner:TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION +1

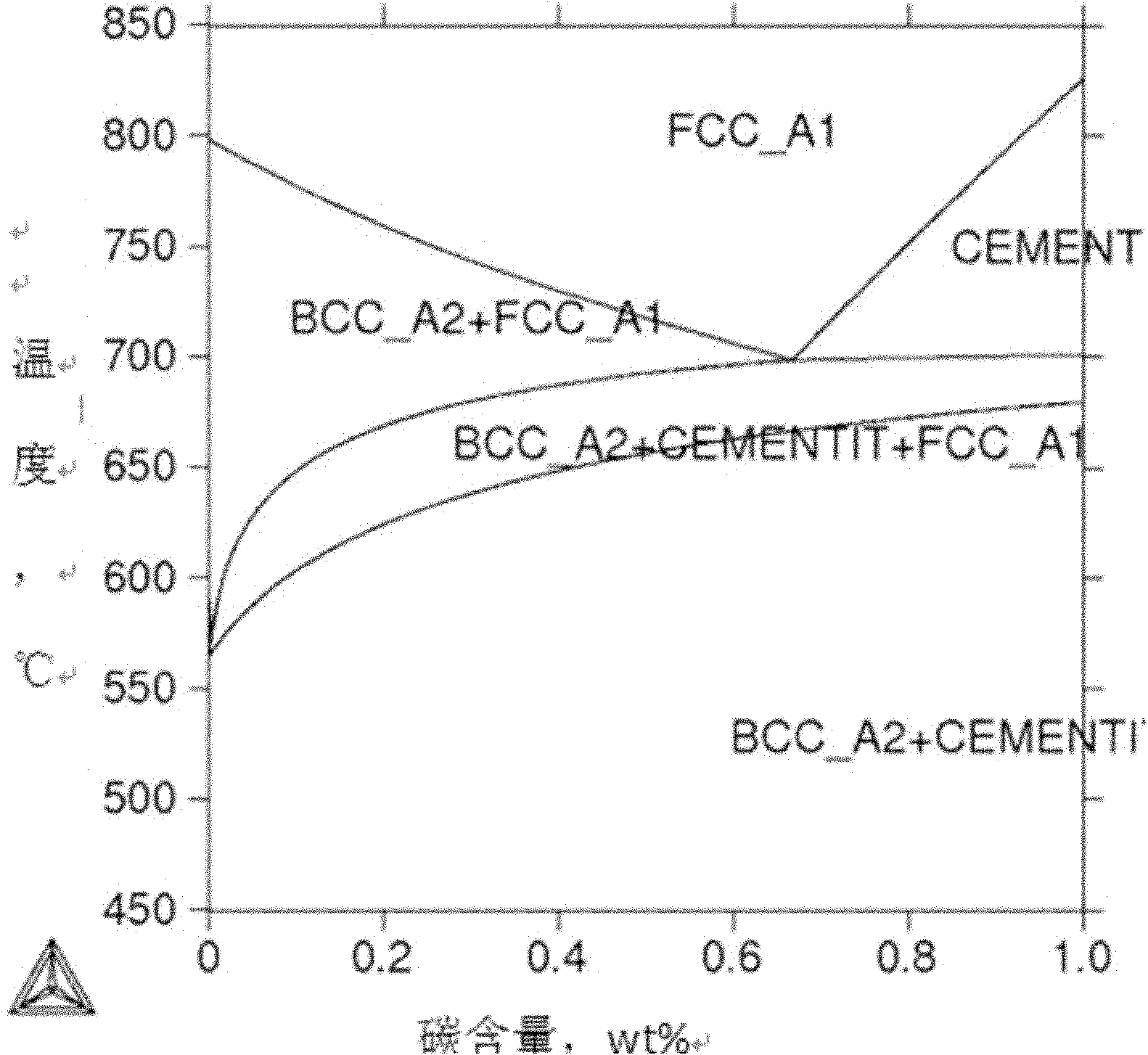

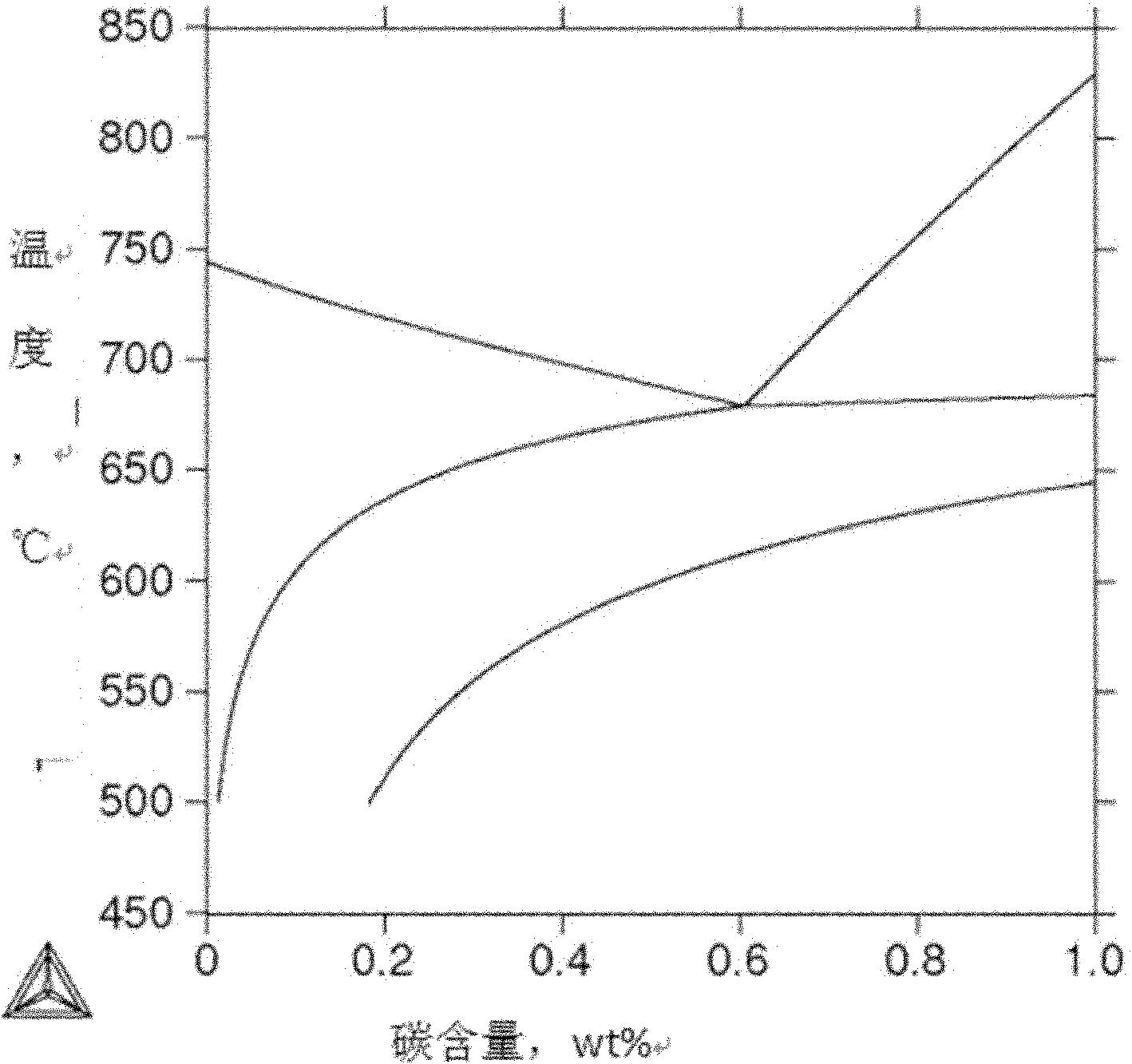

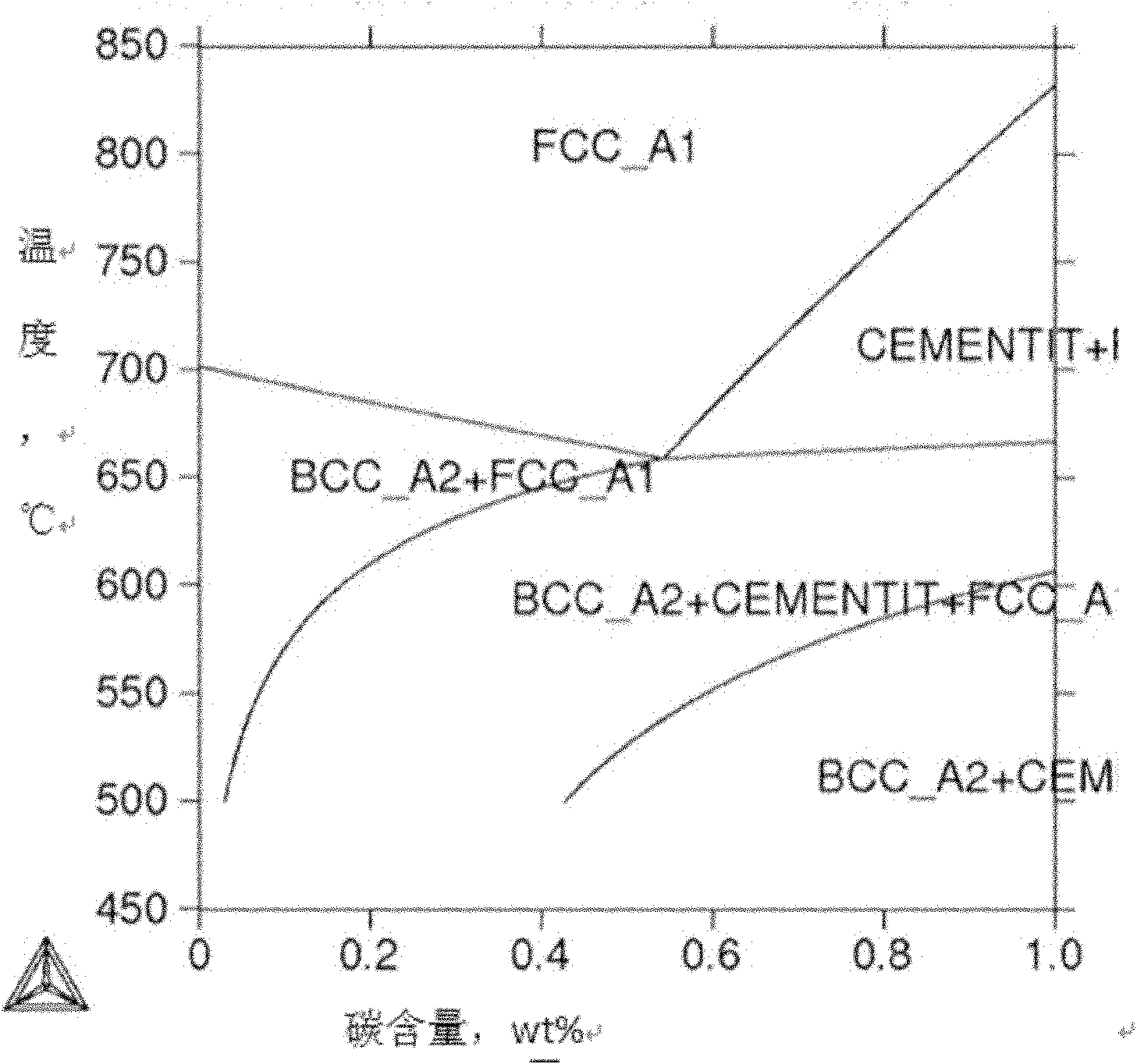

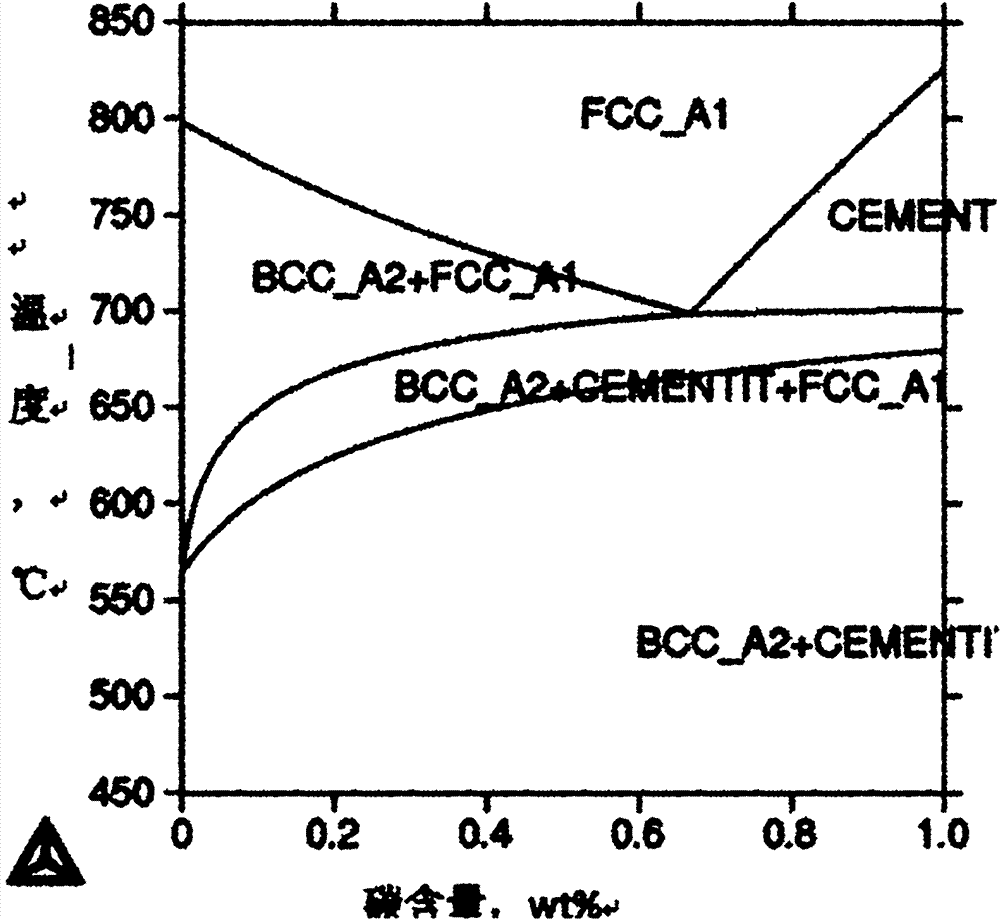

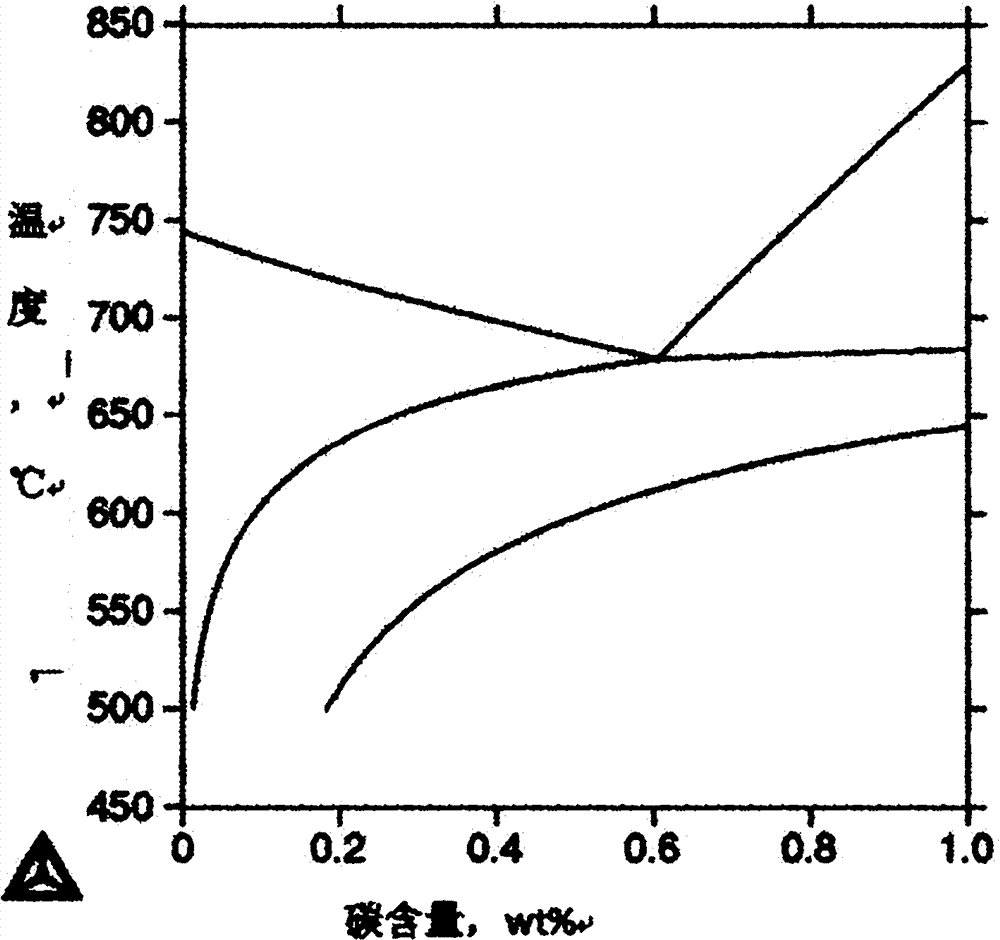

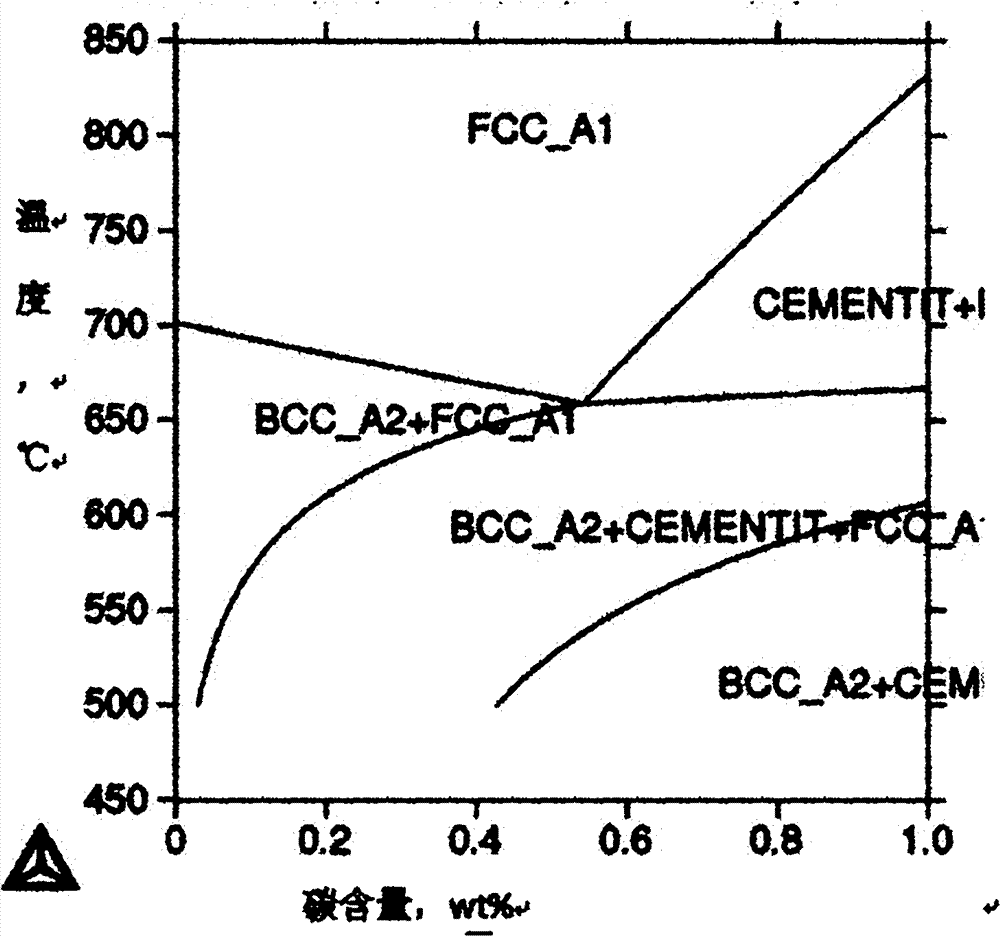

Steel plate warm formed parts with high efficiency, low energy consumption and high quality and production method thereof

The invention relates to steel plate warm formed parts with high efficiency, low energy consumption and high quality and a production method thereof, belonging to the technical field of part forming. The steel plate for producing parts comprises the following components in percent by weight: 0.02-0.45% of C, 3.50-9.0% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. On the basis of these components, one or more of the following components (in percent by weight) are additionally added: 0.1-3.0% of Ni, 0.2-3.0% of Cr, 0.1-0.8% of Mo, 0.3-2.3% of Si, 0.5-2.0% of Cu, 0.0005-0.0050 of B, 0.02-0.30% of Nb, 0.002-0.250% of [N], 0.05-0.25% of Ti, 0.02-0.25% of V, 0.015-3.0% of Al, 0.002-0.005% of RE, and 0.005-0.03% of Ca. The production method comprises the following steps: steel plate heating, steel plate transferring, steel plate precooling, part forming, part cooling, and part temperature control treatment. The production method provided by the invention has the advantages of low cost and high efficiency, and improves the forming rate and final mechanical properties of workpieces.

Owner:CENT IRON & STEEL RES INST

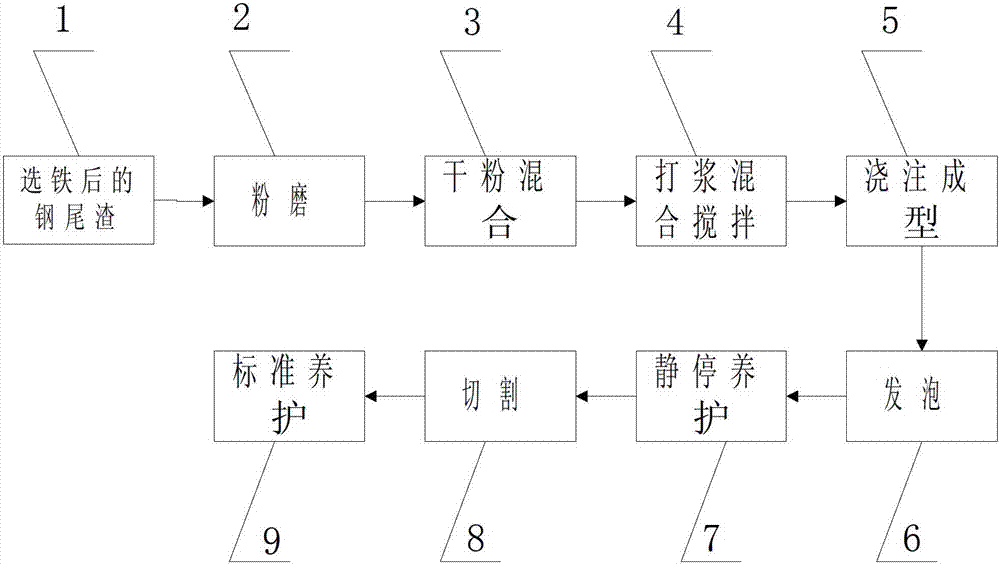

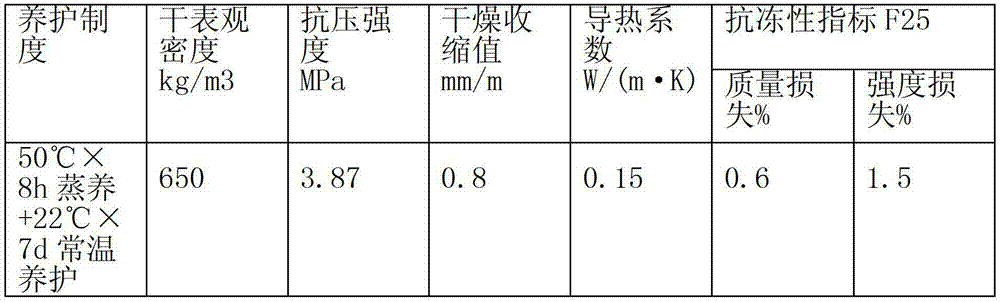

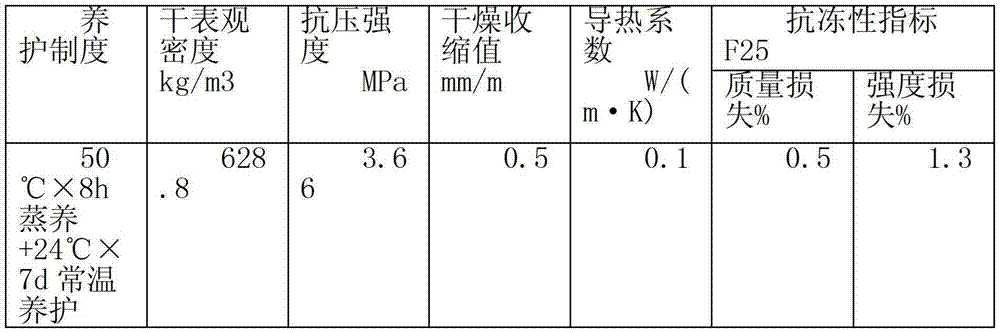

Production method of foamed concrete block manufactured from steel slag

ActiveCN103159450AReduced dry shrinkageIncrease profitSolid waste managementCeramicwareFoam concreteSlag

The invention relates to a production method of a foamed concrete block manufactured from steel slag. The work flow comprises the following steps: 1, taking tailing steel slag after iron dressing; 2, grinding; 3, mixing dry powder; 4, pulping, mixing, and stirring; 5, performing casting molding; 6, foaming; 7, performing static curing; 8, cutting; and 9, performing standard curing. The production method comprises the following specific steps: crushing the steel slag, screening, performing magnetic separation, grading, and drying; performing water quenching on blast furnace slag, and drying; mixing the ground steel slag and ore slag powder with cement clinker, gypsum, lime and the like according to certain weight percents, wherein the ground tailing steel slag powder accounts for 20-60%, the ground ore slag powder accounts for 20-55%, the natural gypsum accounts for 4-10%, the lime accounts for 3-9%, and the cement clinker accounts for 6-12%; mixing and stirring the raw materials, adding water of 40-60 DEG C, and quickly stirring for 1-2 minutes; adding gas-forming aluminum powder, uniformly stirring, and pouring into a mold; and placing in a steam curing box, performing gas forming and steam curing, dismounting the mold, cutting, and curing at normal temperature for 7-12 days. The invention has the following advantages: the produced foamed concrete block meets the requirements of standards; the production cost is low; and comprehensive utilization of resources, energy saving and emission reduction are realized.

Owner:北京中冶设备研究设计总院有限公司

Production method of steel plate warm formed parts with high efficiency, low energy consumption and high quality

The invention relates to steel plate warm formed parts with high efficiency, low energy consumption and high quality and a production method thereof, belonging to the technical field of part forming. The steel plate for producing parts comprises the following components in percent by weight: 0.02-0.45% of C, 3.50-9.0% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. On the basis of these components, one or more of the following components (in percent by weight) are additionally added: 0.1-3.0% of Ni, 0.2-3.0% of Cr,0.1-0.8% of Mo, 0.3-2.3% of Si, 0.5-2.0% of Cu, 0.0005-0.0050 of B, 0.02-0.30% of Nb, 0.002-0.250% of [N], 0.05-0.25% of Ti, 0.02-0.25% of V, 0.015-3.0% of Al, 0.002-0.005% of RE, and 0.005-0.03% of Ca. The production method comprises the following steps: steel plate heating, steel plate transferring, steel plate precooling, part forming, part cooling, and part temperature control treatment. The production method provided by the invention has the advantages of low cost and high efficiency, and improves the forming rate and final mechanical properties of workpieces.

Owner:CENT IRON & STEEL RES INST

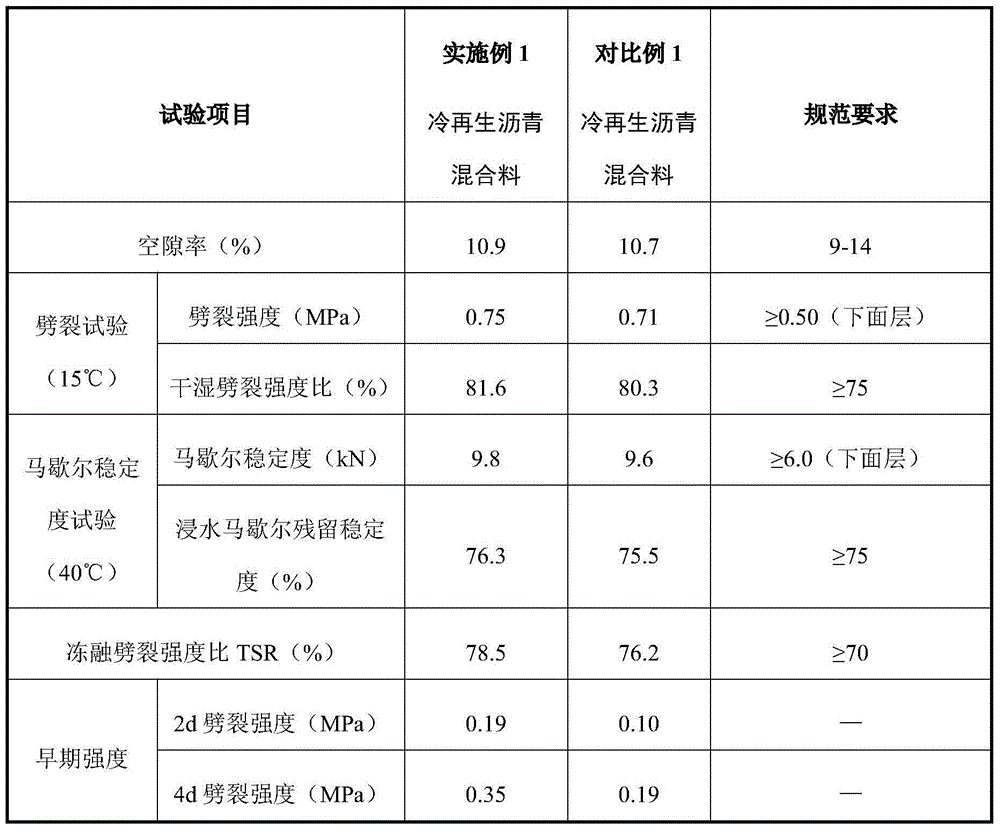

Early-strength emulsion for cold regeneration of waste asphalt pavement and preparation method and application thereof

ActiveCN104559254AReduce mixing water consumptionImprove early strengthSolid waste managementBuilding insulationsEmulsionPetroleum

The invention discloses an early-strength emulsion for the cold regeneration of a waste asphalt pavement and a preparation method and application thereof. The raw material component of the early-strength emulsion for the cold regeneration of the waste asphalt pavement is prepared from the following components in percentage by weight: 50%-65% of road petroleum asphalt, 1.0%-4.5% of an asphalt emulsifying agent, 0%-10% of a modifying agent, 0%-0.4% of an exciting agent, 0.01%-0.4% of a dispersing agent, 0.05%-2.0% of a stabilizer, 0%-0.5% of an auxiliary agent and the balance of water, wherein the auxiliary agent is used for regulating the pH value, and the modifying agent is cationic styrene-butadiene latex. The early-strength emulsion for the cold regeneration can be used for reducing the blended water usage amount of a cold regeneration mixture and accelerating the hydration of cement contained in the cold regeneration mixture, thereby enhancing the early strength of the cold regeneration mixture, shortening the curing time and enlarging the application range of the emulsified asphalt cold regeneration mixture.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

High strength easy-to-cut aluminum alloy

ActiveCN101307403AExcellent machinabilityImprove mechanical properties5005 aluminium alloyMechanical property

The invention relates to a high-strength easy-cutting aluminium alloy. The invention is characterized in that the aluminium alloy is an aluminium-base alloy, containing bismuth, tin, copper, silicon and chromium as alloying elements, and other unavoidable impurity elements. A product produced by the alloy has good easy-cutting capability, excellent mechanical property, excellent corrosion resistance and excellent solderability. The aluminium alloy has low production cost and is equivalent to the prior leady aluminium alloy, so the aluminium has competitive advantages in domestic and foreign markets; The aluminium alloy product can replace partial leady aluminium alloys, thereby not only facilitating the reclamation when the product is consumed completely so as to reduce lead pollution, but also facilitating the expansion of the application field of aluminium alloy products. The aluminium alloy also can replace partial leady easy-cutting aluminium alloys, such as 2011 or 6262 leady aluminium alloy and so on.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

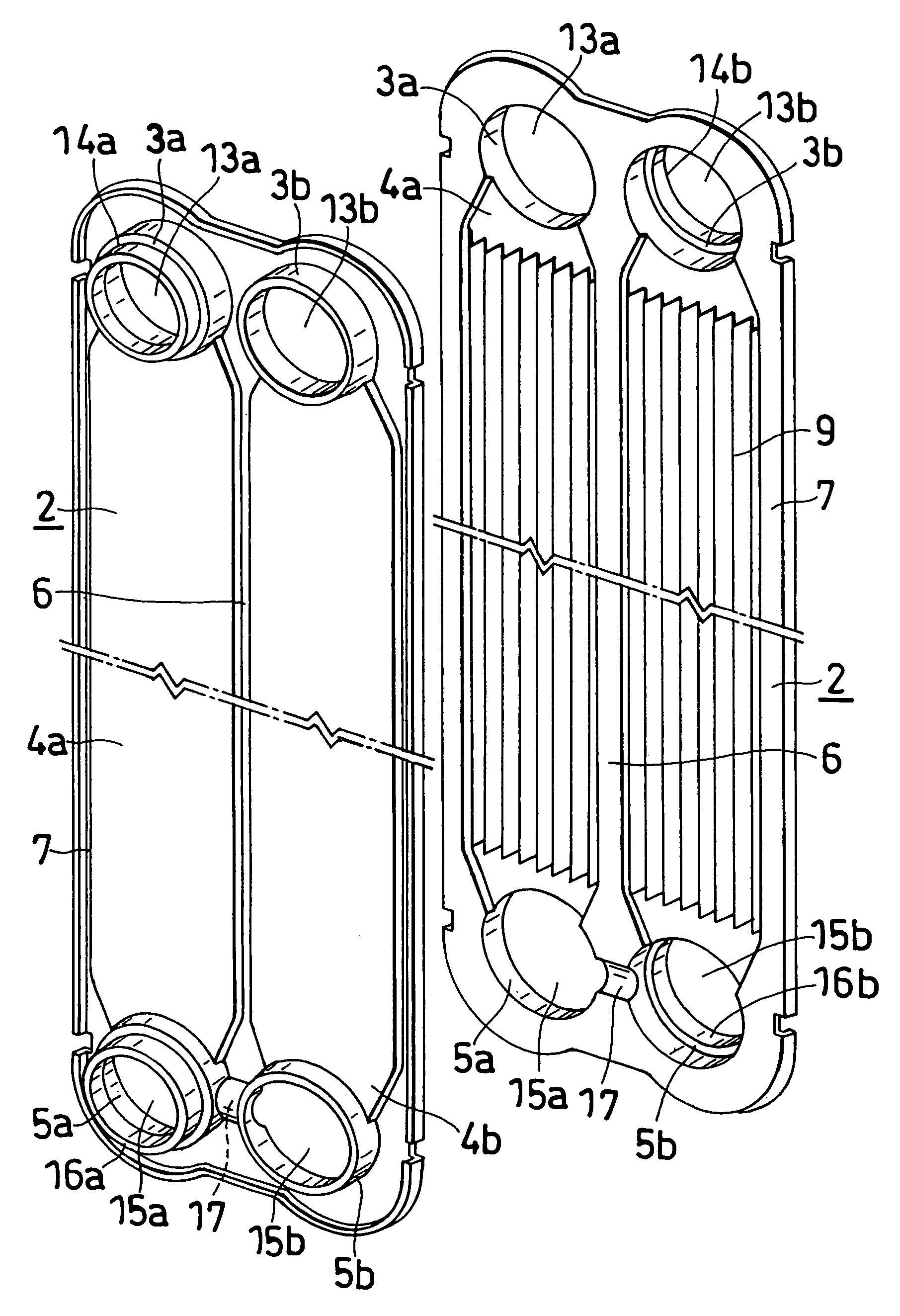

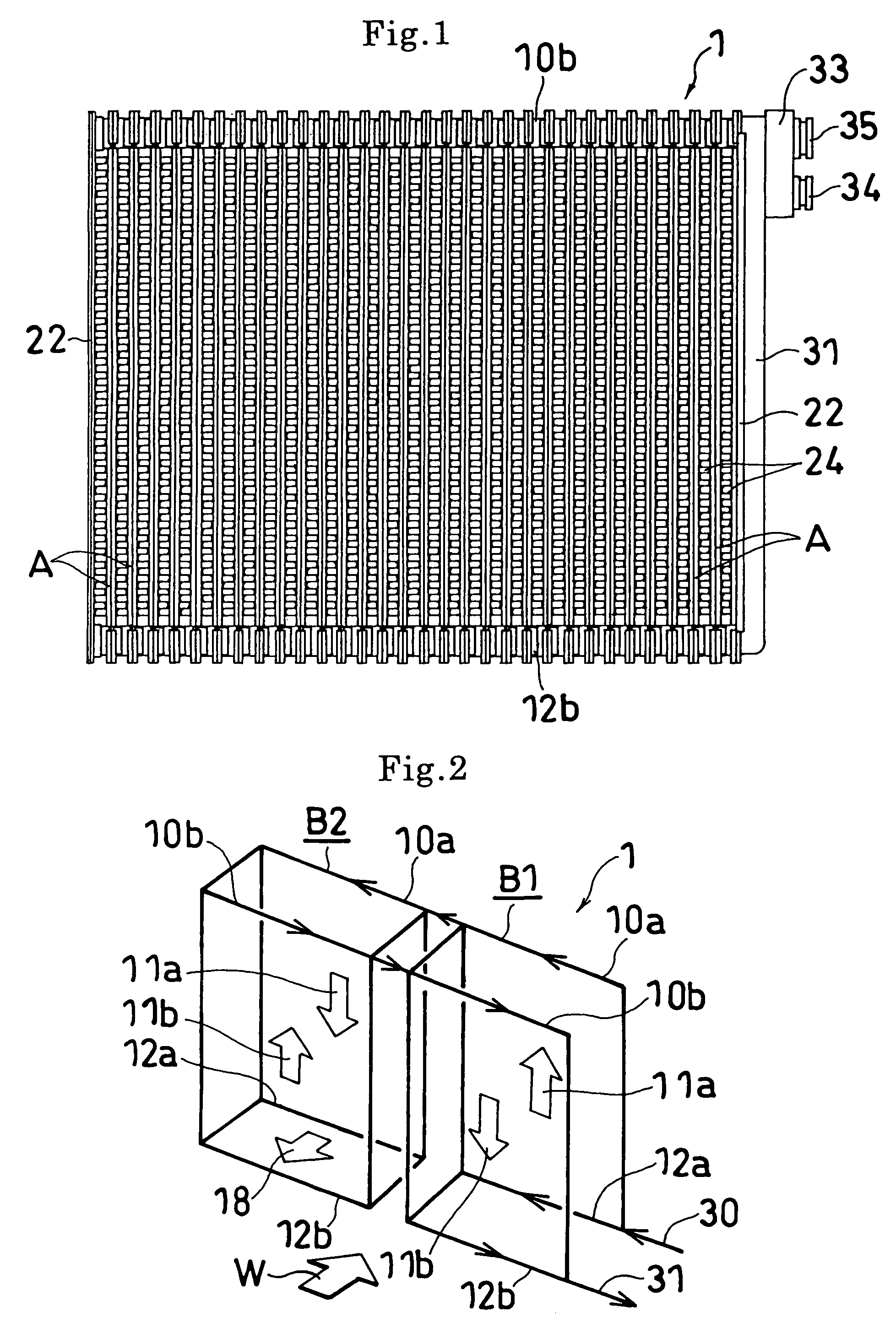

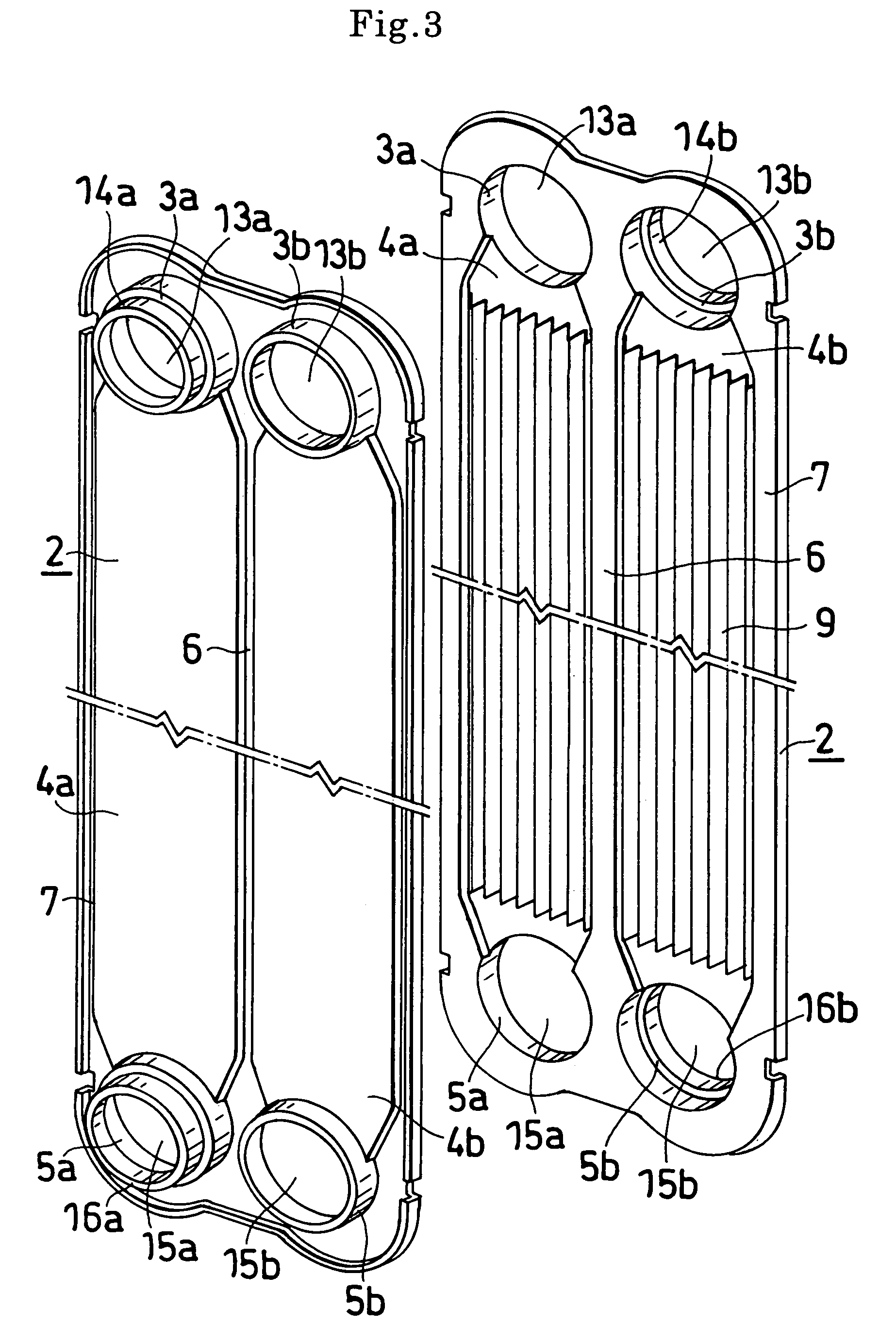

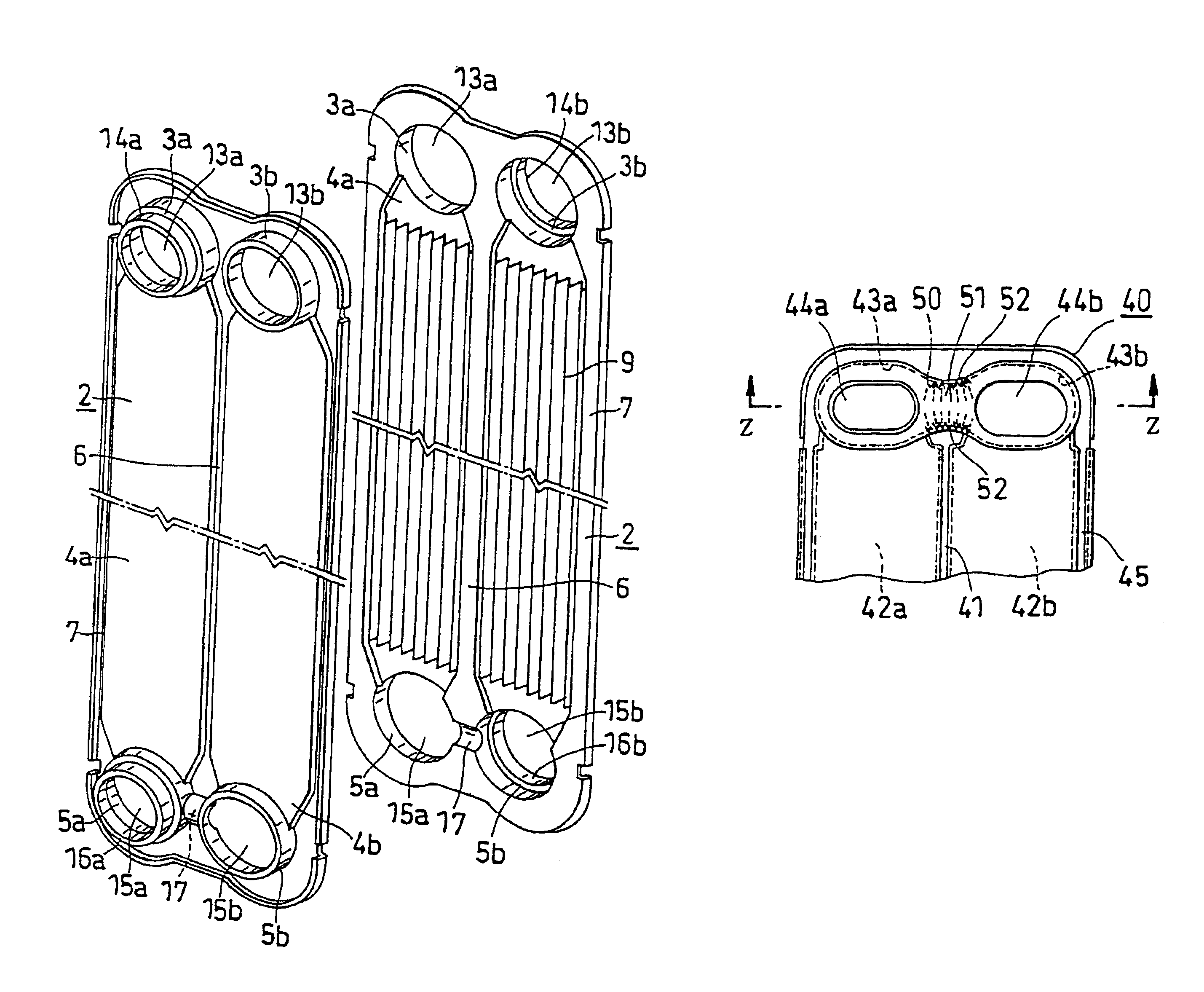

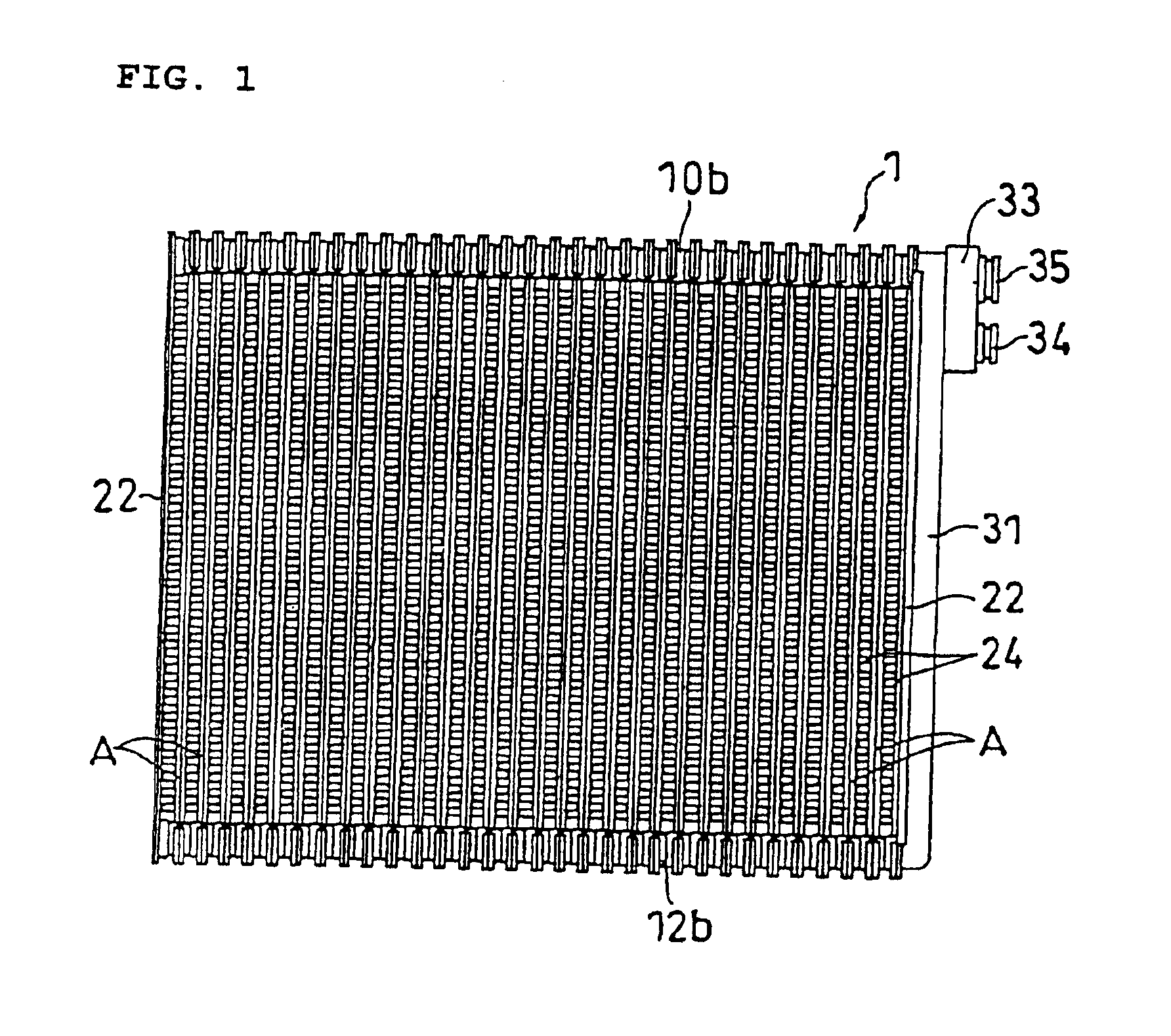

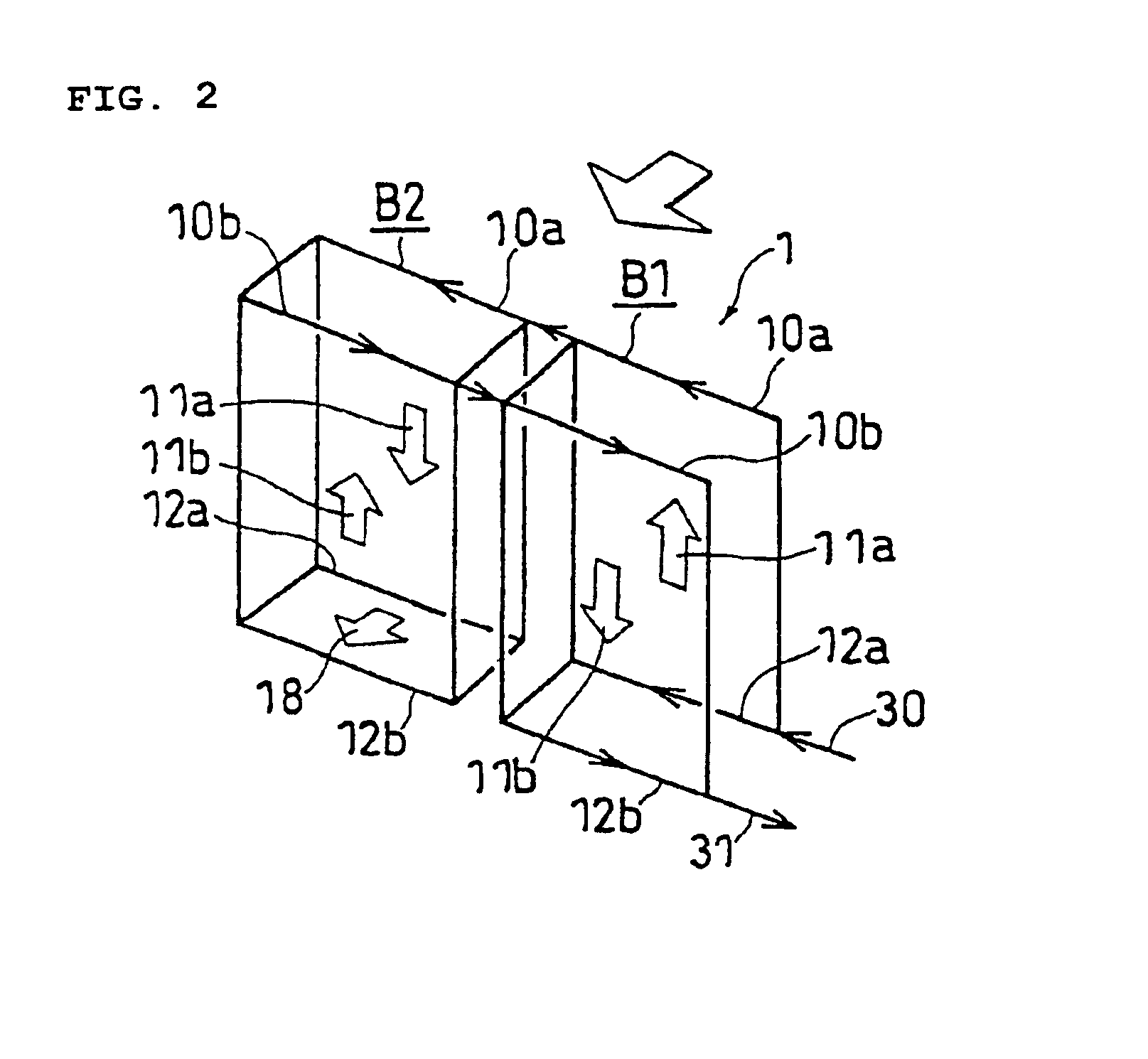

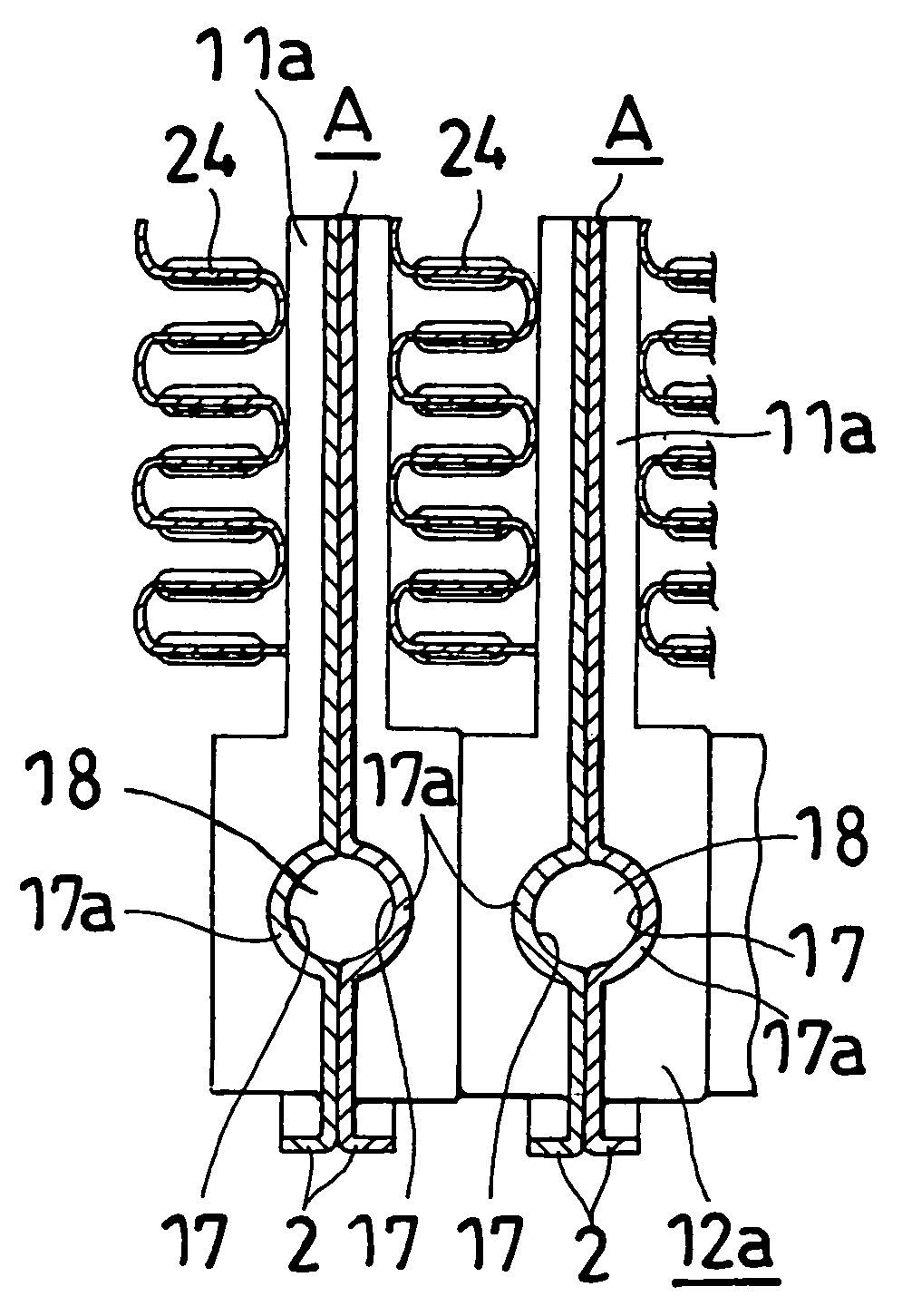

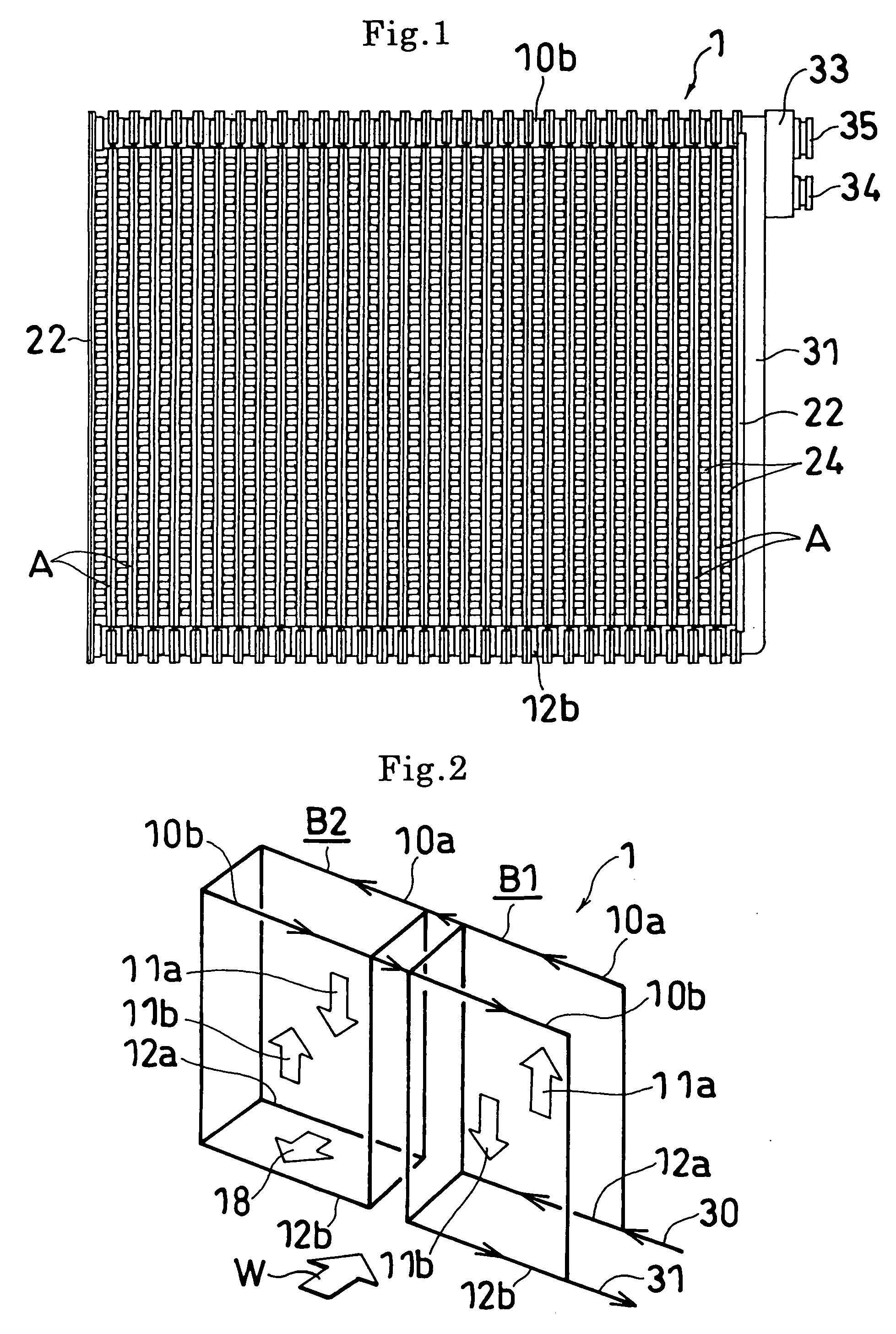

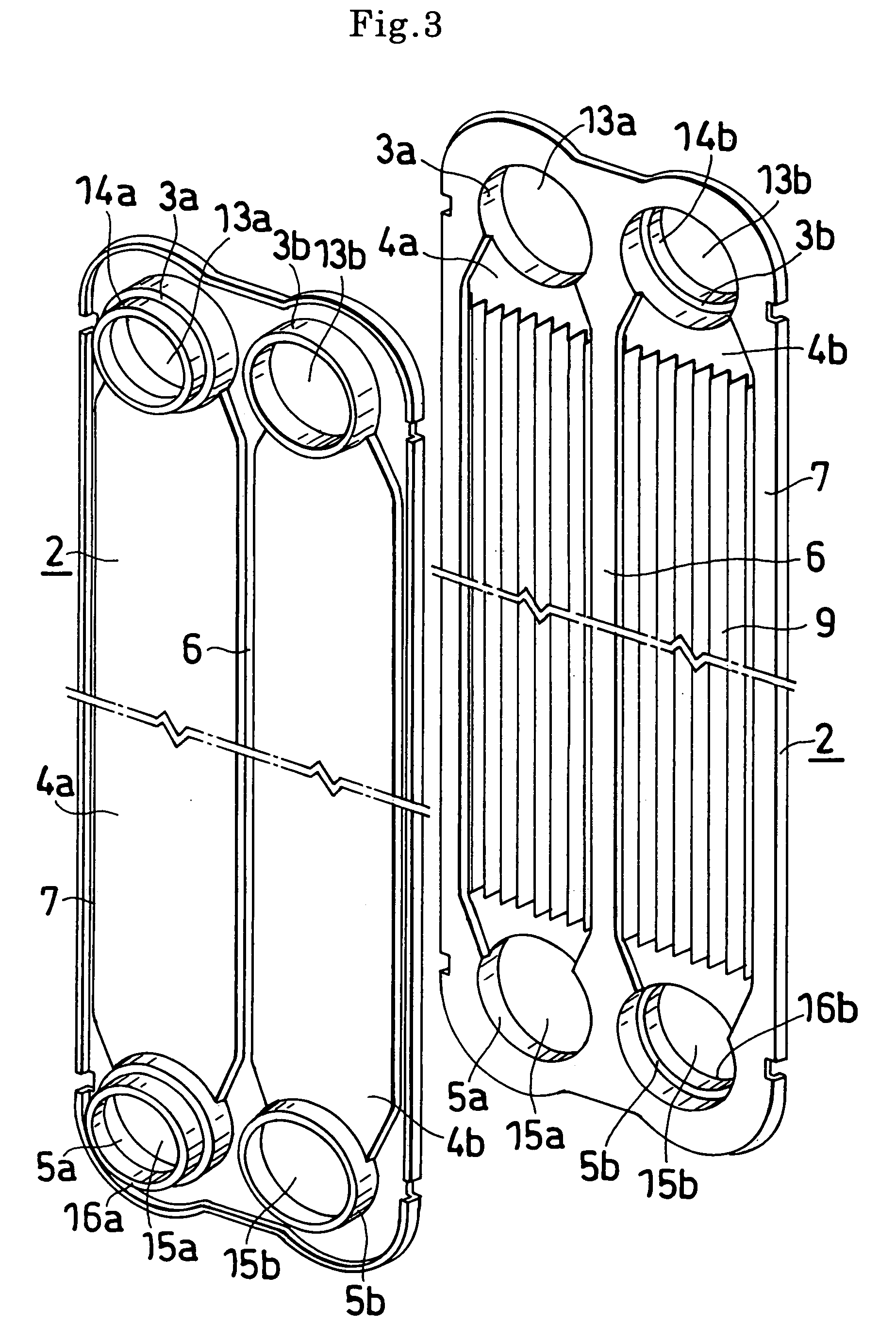

Layered heat exchangers

InactiveUS7044205B2Increase ultimate strengthReduce stress concentrationReinforcing meansEvaporators/condensersInternal pressurePlate heat exchanger

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

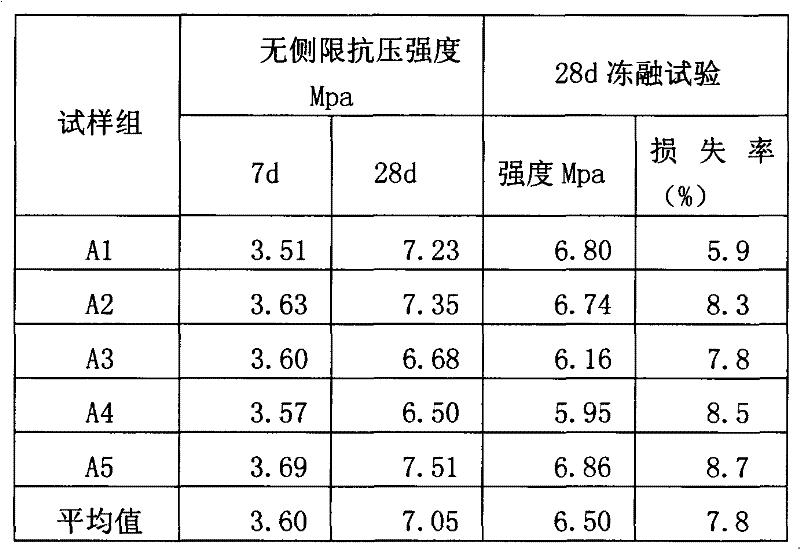

Composite ionic soil curing agent and manufacturing method thereof

ActiveCN102676176AThe formula is scientific and reasonableImprove performanceBuilding constructionsOrganic fertilisersAdditive ingredientReaction temperature

The invention relates a composite ionic soil curing agent and a manufacturing method thereof, aims at providing a high-efficient geotechnological building new material for highways, municipal administration, slope protection, water conservancy dams, building foundations and building anti-seepage works and belongs to the technical field of fine chemistry industry. The manufacturing method comprises the following steps of: enabling four components, namely a strong oxidant, an activating agent, a dispersing agent and a curing catalyst, to react and age in a reaction kettle according to the proportion that the percent by weight of ingredients (1) and (2) of the activating agent is 3% respectively, controlling the temperature at 30-32 DEG C, then adding the dispersing agent, uniformly stirring, reacting for 60 minutes, finally adding concentrated H2SO4, and controlling the reaction temperature below 60 DEG C so as to form the composite ionic soil curing agent. When the composite ionic soil curing agent is applied to construction, the using quantity accounts for 0.01-0.1% of the volume of a cured structure after compaction, after the composite ionic soil curing agent is diluted with water, the composite ionic soil curing agent is uniformly sprayed into soil mixed with other inorganic binders, uniformly mixed, rolled, compacted and maintained for a certain period of time, and then the effect of curing the soil in a stable and lasting manner is further achieved.

Owner:尚路 +1

Reactive Polyurethane Hot-Melt Formulations, Processes for Preparing the Same, and Uses Therefor

InactiveUS20080312361A1High strengthRapid development of strengthPolyureas/polyurethane adhesivesPolymer sciencePolyol

Hot-melt adhesive formulations comprising a polyurethane and a nucleating agent, preferably wherein the polyurethane comprises a reaction product of (a) a diisocyanate component and (b) a polyol component, wherein the diisocyanate component comprises one or more selected from the group consisting of aromatic diisocyanates, aliphatic diisocyanates, araliphatic diisocyanates, cycloaliphatic diisocyanates, and mixtures thereof, and wherein (a) and (b) are present in a ratio such that a molar ratio of NCO to OH is greater than 1; processes for preparing the same; compositions containing such formulations; and uses therefor.

Owner:BAYER MATERIALSCIENCE AG

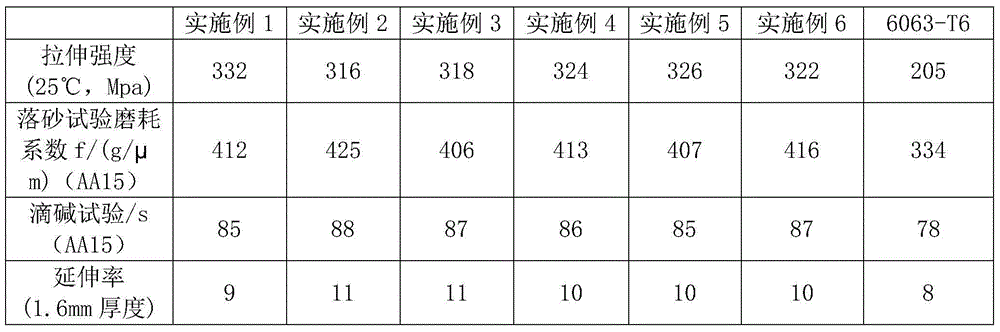

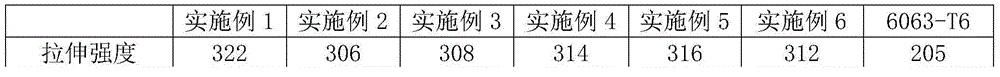

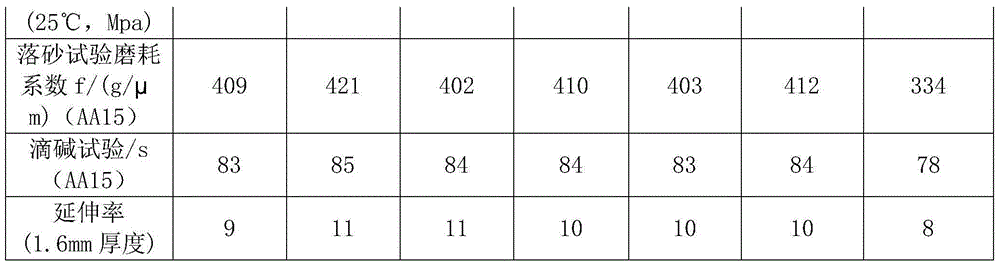

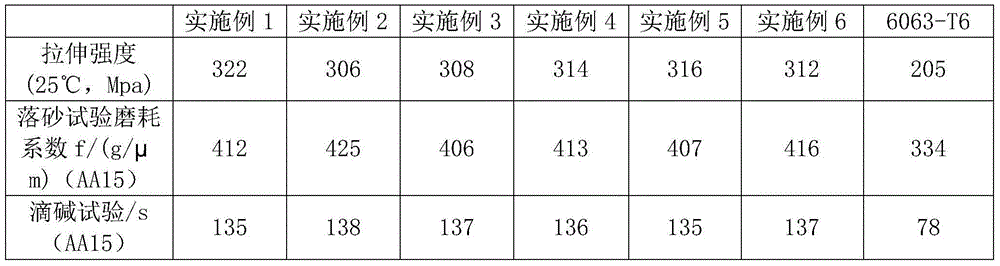

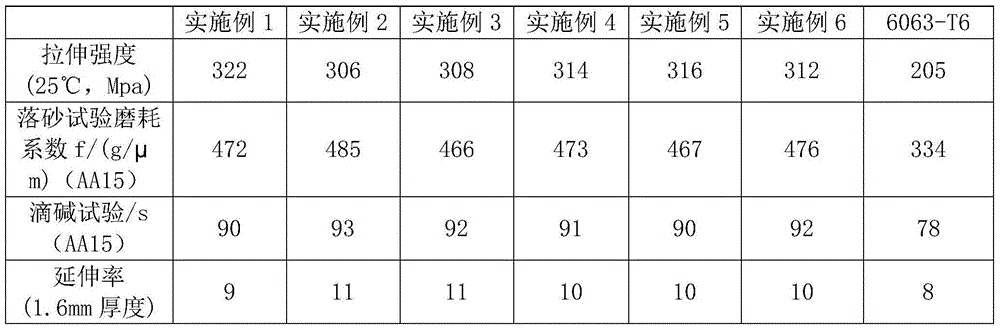

Time-efficient reinforced aluminium alloy extrusion

The invention discloses a time-efficient reinforced aluminium alloy extrusion, which belongs to the field of a metal material. The aluminium alloy extrusion comprises components, by weight percentage: 0.75-0.90 of Mg, 0.5-0.6 of Si, 0.10-0.14 of Cu, 0.20-0.25 of Mn, 0-0.1 of Ti, 0-0.1 of Cr, 0.1-0.3 of Fe, and 0.20-0.28 of Zn, and is balanced with Al. According to the invention, alloy components are optimized; steps of melting and casting, homogenization, extrusion, thermal treatment, and surface treatment in production technology are optimized; and mechanical properties and the surface film quality are effectively improved.

Owner:ANHUI XIN FA ALUMINUM PROD

Comprehensive resource utilization method of electrolytic manganese slag and steel slag tailing mud

PendingCN108585721AReduced activityElicit activitySolid waste managementCeramicwareFoam concreteElectrolysis

The invention provides a production method for producing autoclaved aerated blocks by using raw electrolytic manganese slag and raw steel slag tailing mud. The autoclaved aerated blocks are produced from 30-50% of the electrolytic manganese slag, 10-30% of the steel slag tailing mud, 10-20% of water-quenched blast furnace slag, 5-15% of Portland cement, 5-10% of quicklime, 0.1-0.8% of an aluminumpowder paste (admixture) according to the following sequential steps: S1, performing mixed grinding; S2, proportioning; S3, slurrying; S4, stirring and pouring; S5, heating and standing; S6, cutting;S7, autoclaving; S8, aging. The aerated blocks produced by the production method can meet block standards of A1.5-A5.0, B09 and B10 classes in JC1062-2007 foam concrete block standards.

Owner:中冶武汉冶金建筑研究院有限公司

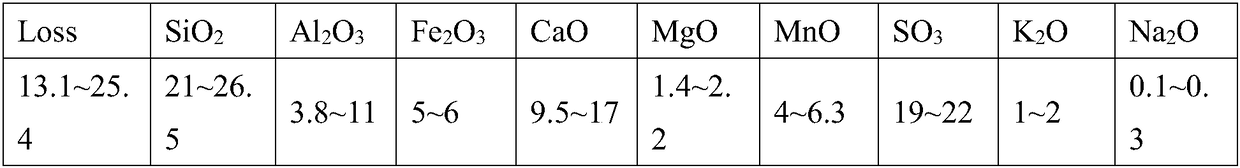

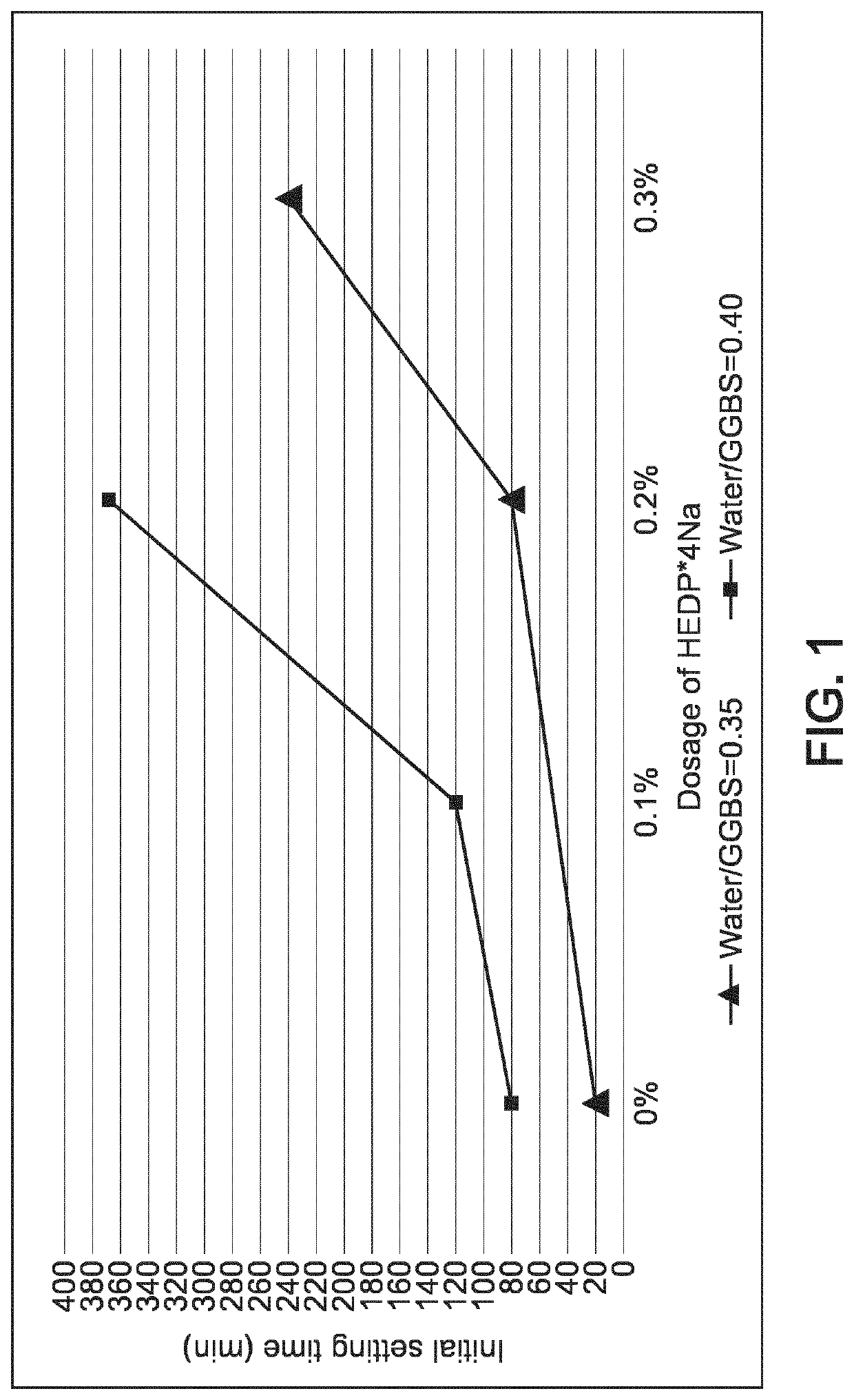

Ground granulated blast furnace slag based binder, dry and wet formulations made therefrom and their preparation methods

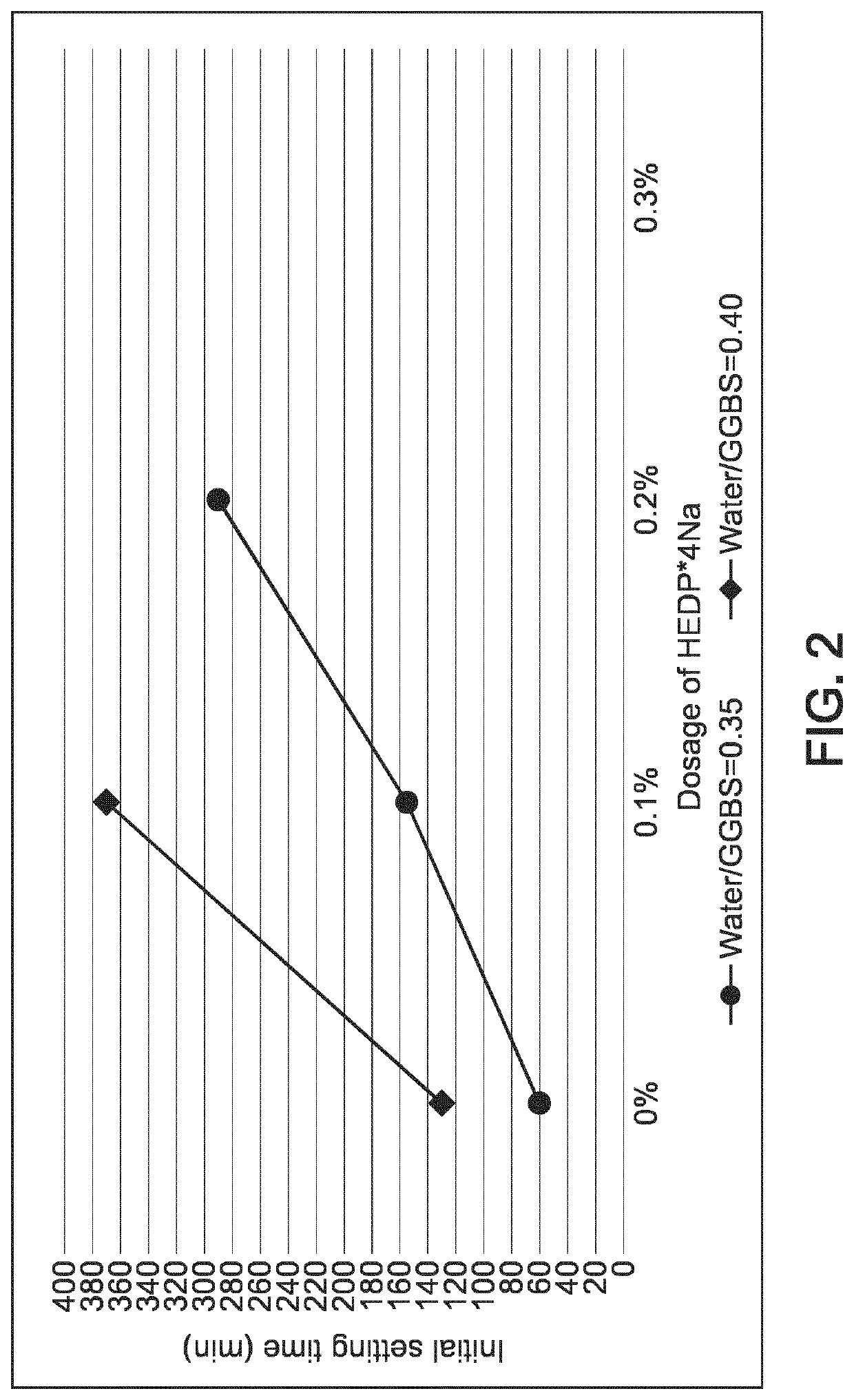

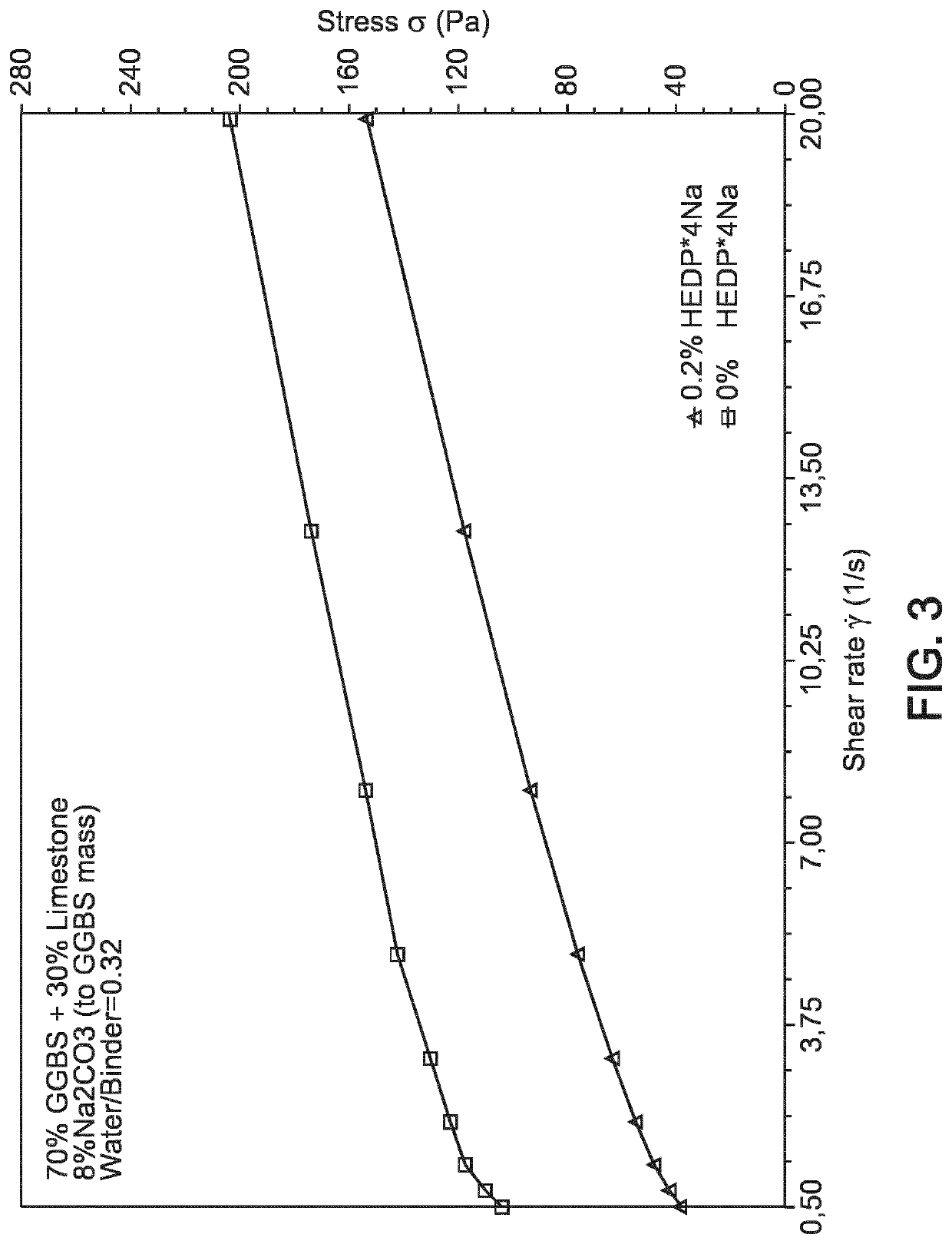

ActiveUS20210238094A1Reduction in initial water demandIncrease ultimate strengthDrilling compositionScreedMining engineering

A slag-based binder has at least one slag, optionally at least one CO3-containing mineral powder, optionally at least one co-binder different from the slag and mineral powder, at least one activator of the water / slag reaction, optionally at least one co-activator different from the one activator, at least one chelatant and / or at least one source of chelatant, said chelatant being preferably a scale inhibitor, and, optionally, at least one superplasticizer different from the chelatant. A kit is provided to make the binder. The binder is combined with an aggregate to make a dry concrete or mortar. A method for the preparation of a wet formulation (binder / water or concrete-mortar / water) is disclosed as is method of manufacturing buildings or civil engineering works or elements thereof, coatings, fillers, screeds, tiles, adhesives and / or internal or external insulation systems from the wet formulation. The binder is a substitute to OPC-based compositions and is environmentally friendly.

Owner:ECOCEM MATERIALS LTD +2

Anodic alumina alloy section bar

The invention discloses an anodic alumina alloy section bar, and relates to the field of metal materials. The anodic alumina alloy section bar comprises0.75-0.90wt% of Mg, 0.5-0.6wt% of Si, 0.10-0.14wt% of Cu, 0.20-0.25wt% of Mn, 0-0.1wt% of Ti, 0-0.1wt% of Cr, 0.1-0.3wt% of Fe, 0.20-0.28wt% of Zn, and the balance of Al. Alloy components in the above aluminum alloy section bar material are optimized, and melting casting, homogenization, extrusion, heat treatment and surface layer treatment in the production process are optimized, so the mechanical performances and the surface layer film quality of the section bar are effectively improved.

Owner:ANHUI XIN FA ALUMINUM PROD

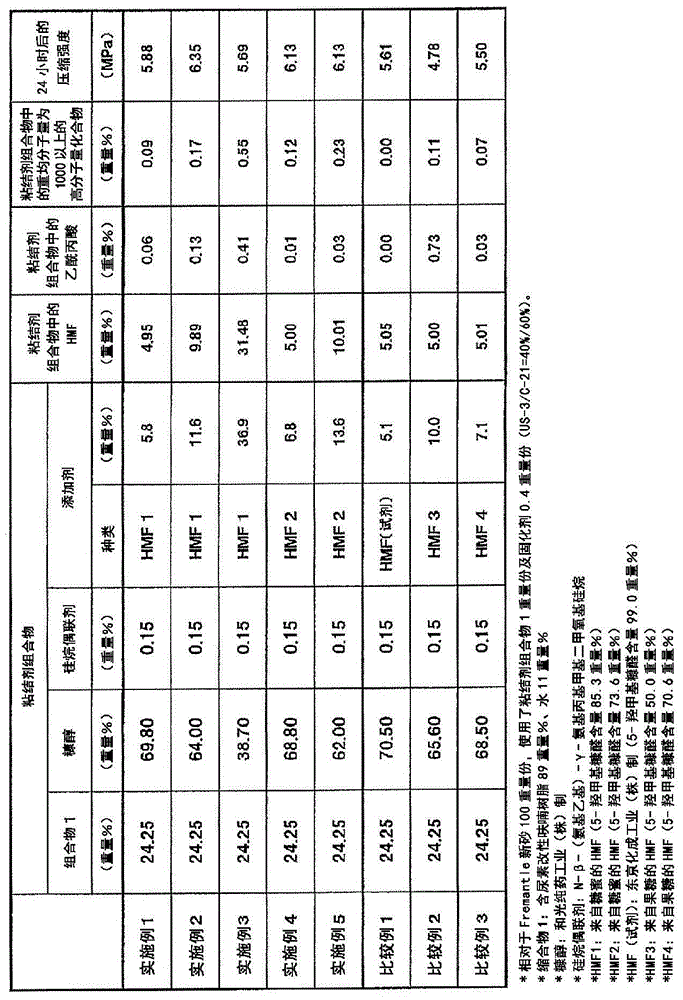

Binder composition for producing template, and method for producing template

A binder composition for producing a template, which comprises a 5-hydroxymethylfurfural composition produced from molasses and an acid-curable resin. It is preferred that the 5-hydroxymethylfurfural composition is produced through a step of subjecting molasses to a dehydration reaction in a solvent in the presence of an acid catalyst to produce a reaction mixture and a step of extracting the reaction mixture with an organic solvent to produce the 5-hydroxymethylfurfural composition, and it is more preferred that the content ratio of the 5-hydroxymethylfurfural composition in the binder composition is 1 to 50 wt% inclusive.

Owner:KAO CORP

Layered heat exchangers

InactiveUS6920916B2Increase ultimate strengthReduce stress concentrationReinforcing meansEvaporators/condensersInternal pressurePlate heat exchanger

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

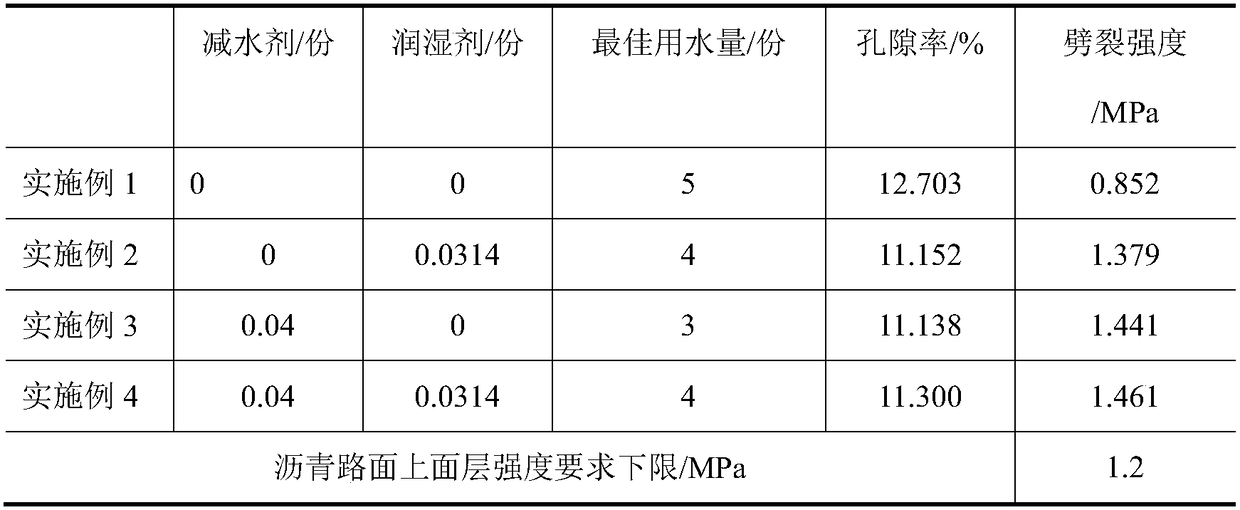

High-strength emulsified asphalt cold recycled mixture

The invention belongs to the field of design for highways and urban roads and provides a high-strength emulsified asphalt cold recycled mixture. The mixture is prepared from following components by mass through weighing: 0-50 parts of new aggregates, 50-100 parts of old aggregates, 0-10 parts of filler, 0-5 parts of cement, 0-10 parts of filler, 2-8 parts of emulsified asphalt, 2-6 parts of waterand a surfactant. Compared with the prior art, a surface active material in a proper proportion is added to increase adhesive property and reduce porosity, and final strength of the high-strength emulsified asphalt cold recycled mixture is improved; a water reducing agent reduces water consumption, a wetting agent wets the emulsified asphalt, so that the wrapping effect of the aggregates becomes better, the utilization rate of the old asphalt mixture is increased while the performance of the emulsified asphalt cold recycled mixture is improved, and green development of roads is realized.

Owner:DALIAN UNIV OF TECH

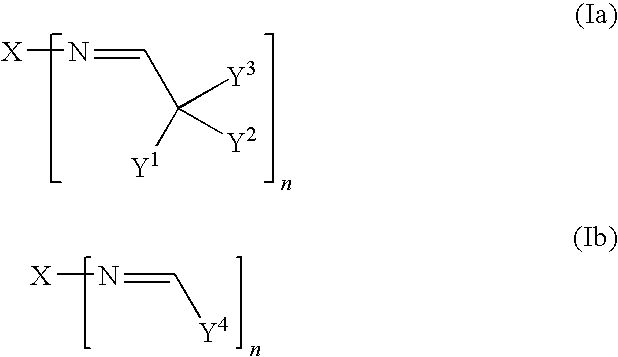

Moisture-curing hot-melt adhesive compound containing polyaldimine

InactiveUS20100291368A1Good ultimate strengthStable storagePolyureas/polyurethane adhesivesSynthetic resin layered productsIsocyanate compoundCarbonic acid

The present invention relates to moisture-reactive hot-melt adhesive compounds, comprising at least one polyurethane polymer P which is solid at room temperature and which has isocyanate groups, at least one polyaldimine ALD of the formula (Ia) or (Ib), and at least one acid K in the form of an organic monocarbon acid, or dicarbon acid, or an organic monosulphonic acid, or disulphonic acid, or a compound which can be hydrolyzed to give one of these acids. These hot-melt adhesive compounds cure without bubbles and exhibit exceptionally quick crosslinking speed and good strength after crosslinking.

Owner:SIKA TECH AG

Nickel-sealing anodized aluminum alloy section bar

The invention discloses a nickel-sealing anodized aluminum alloy section bar and relates to the field of metal materials. The aluminum alloy section bar consists of the following components in percentage by weight: 0.75-0.90% of Mg, 0.5-0.6% of Si, 0.10-0.14% of Cu, 0.20-0.25% of Mn, 0-0.1% of Ti, 0-0.1% of Cr, 0.1-0.3% of Fe, 0.20-0.28% of Zn and the balance of Al. According to the aluminum alloy section bar material disclosed by the invention, alloy components are optimized, and melting-casting, homogenizing, extruding, thermal treatment and surface treatment in a production process are optimized, so that mechanical properties and surface film layer quality of the section bar are effectively improved.

Owner:ANHUI XIN FA ALUMINUM PROD

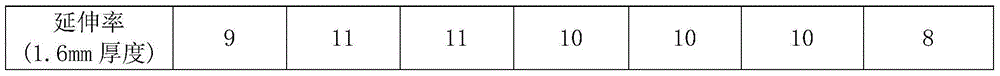

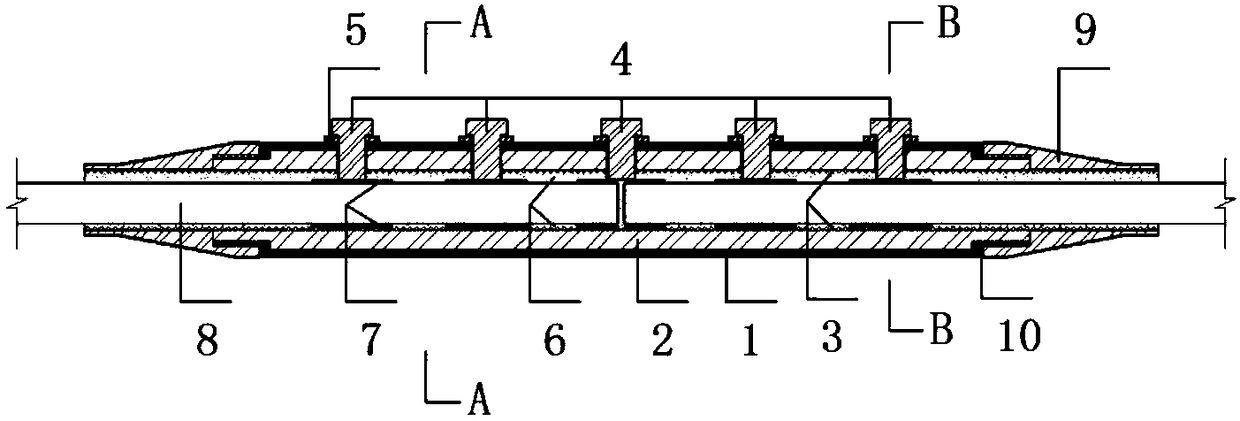

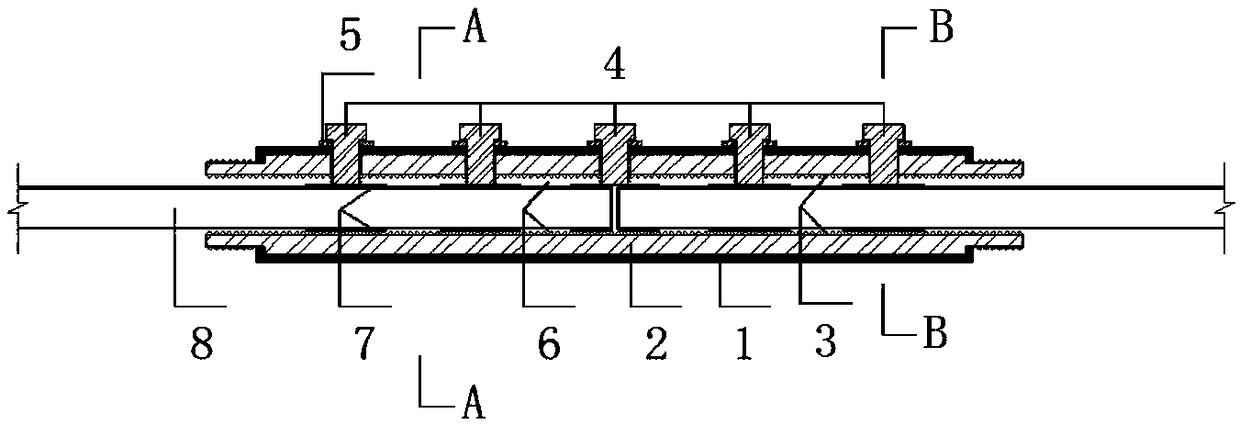

Composite connector for FRP bars and assembly method thereof

PendingCN108797898AThe solution cannot be bent,When solving practical applicationsBuilding reinforcementsFiberScrew thread

The invention discloses a composite connector for FRP bars and an assembly method thereof. The composite connector comprises a steel sleeve. An inner thread is arranged on the inner wall of the steelsleeve. A fiber cloth is winded on the outer wall of the steel sleeve. The steel sleeve is provided with a plurality of bolt holes communicating with the inner wall. Hexagon-head bolts are connected into the bolt holes in a matching mode. Two sections of the FRP bars are arranged in the steel sleeve, and are fixed by fastening the hexagon-head bolts. Arc soft metal gaskets are annually attached atthe positions, located in the bolt holes, of the two sections of the FRP bars. Stainless steel screwed plugs are detachably arranged at two ends of the steel sleeve. Cementation glue is arranged between the inner wall of the steel sleeve and the FRP bars in a filling mode. The connector is simple in structure, reasonable in design, convenient to use, and can be universally applied to engineering.The glue is arranged in the steel sleeve to paste the bars and the sleeve. Bolts are used outside the sleeve for anchoring, and therefore the connector can be more firmly pasted to the bars, and connection of the bars is facilitated.

Owner:SOUTHWEAT UNIV OF SCI & TECH

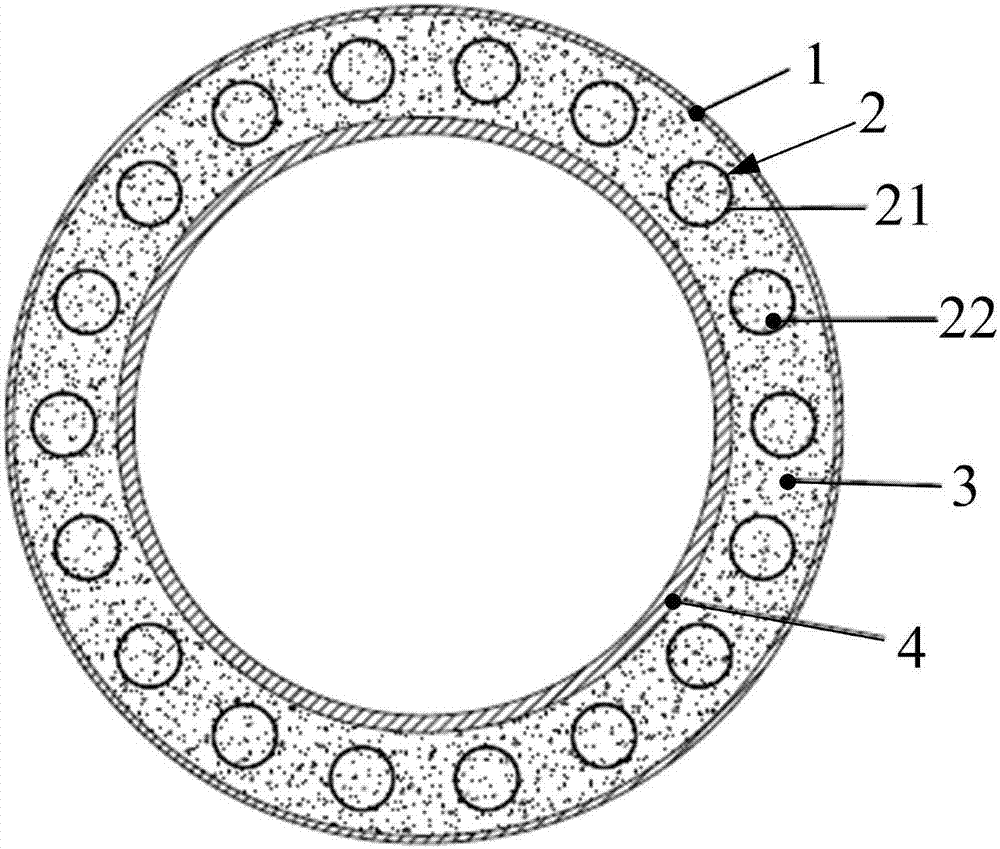

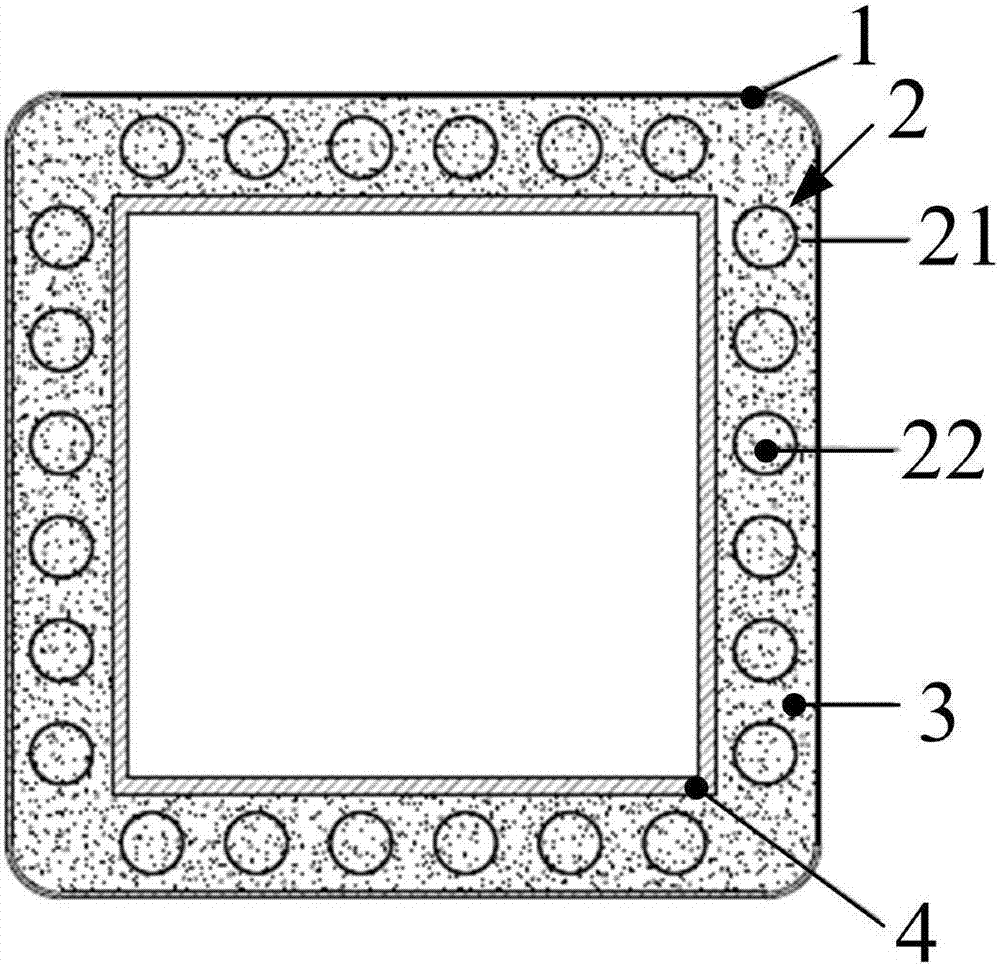

Multi-tube constraint concrete double-wall hollow column and production process

The invention discloses a multi-tube constraint concrete double-wall hollow column which comprises vertical FRP (fiber reinforce plastic) outer pipe, a steel inner pipe is axially arranged at the center of the FRP outer pipe, a self-compacting concrete layer is poured between the inner peripheral surface of the FRP outer pipe and the outer peripheral surface of the steel inner pipe, a plurality of FRP inner pipe bodies are arranged between the inner peripheral surface of the FRP outer pipe and the outer peripheral surface of the steel inner pipe, the insides of FRP inner pipes are filled with concrete to form the FRP inner pipe bodies, and the FRP inner pipe bodies are circumferentially and uniformly distributed about the center of the steel inner pipe. The invention further provides a production process of the multi-tube constraint concrete double-wall hollow column. The multi-tube constraint concrete double-wall hollow column has the advantages of good ductility, high ultimate bearing capacity and the like, the production process of the hollow column is applicable to multi-tube constraint concrete double-wall hollow columns of various section forms such as circles and squares.

Owner:GUANGDONG UNIV OF TECH

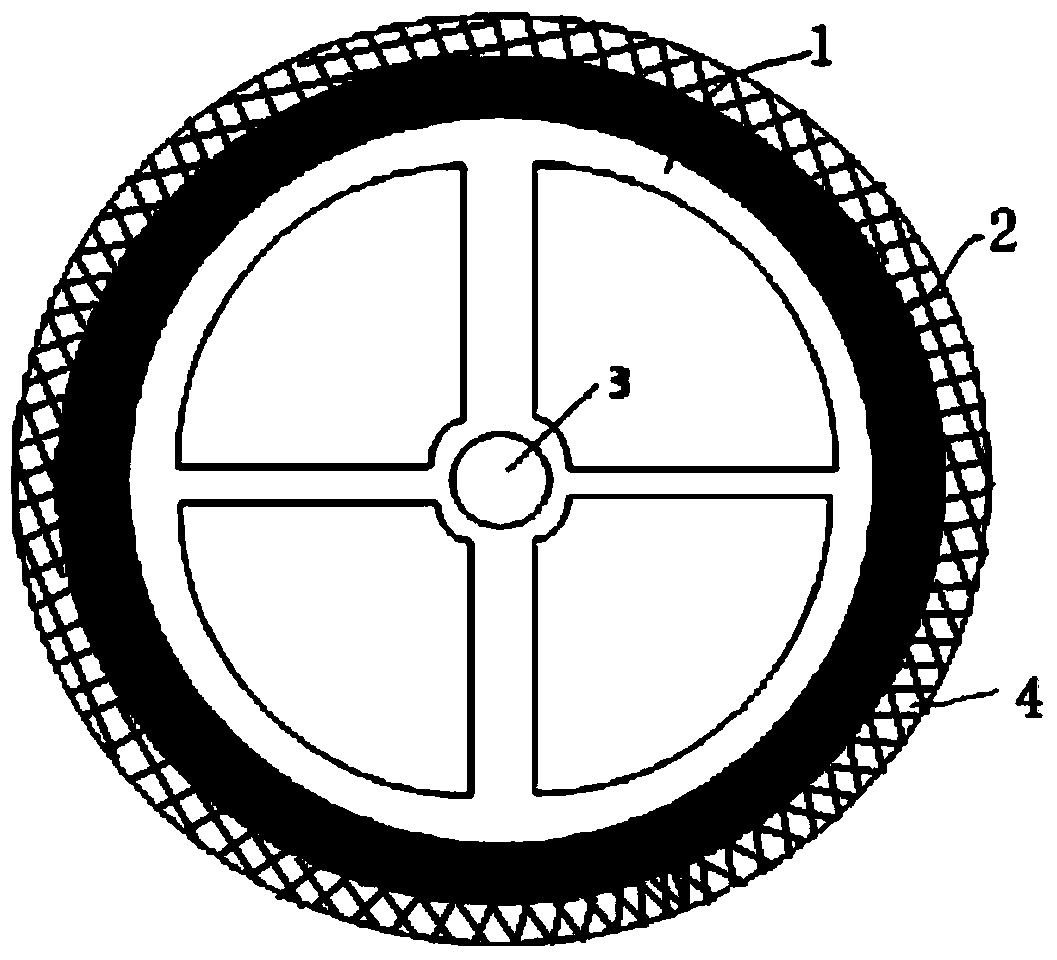

Energy-storing flywheel rotor loop manufactured by winding steel wires

InactiveCN103438152AReduce usageEasy to useFlywheelsMechanical energy handlingInterference fitPre stress

The invention discloses an energy-storing flywheel rotor loop manufactured by winding steel wires, and belongs to a flywheel energy-storing component. By adopting a steel wire winding prestress technology and a composite material fiber filament winding technology, a rotor hub and a composite material loop are in interference fit to assemble a flywheel rotor for solving the problems of insufficient rigidity of a hub material and the compatibility of deformation between the hub and a composite material layer. The rotor hub comprises a metal hub matrix and a steel wire prestress winding layer, the metal hub matrix is disc-shaped or cylindrical, the metal hub matrix and the steel wire pre-stress winding layer are wound and fastened by prestress from inside to outside, the innermost layer is the metal hub matrix, and the outer layer is the steel wire prestress layer. The energy-storing flywheel rotor loop manufactured by winding the steel wires disclosed by the invention has the advantages that the stress state of the flywheel hub is changed, the strength of the metal hub is greatly improved, the use performance of the hub is improved, the inside and outside radius ratio of the flywheel rotor is increased, the compatibility of deformation of the hub and a rim is improved, the energy storage density of the flywheel is improved, and the manufacturing cost of the rotor is obviously reduced.

Owner:UNIV OF SCI & TECH BEIJING

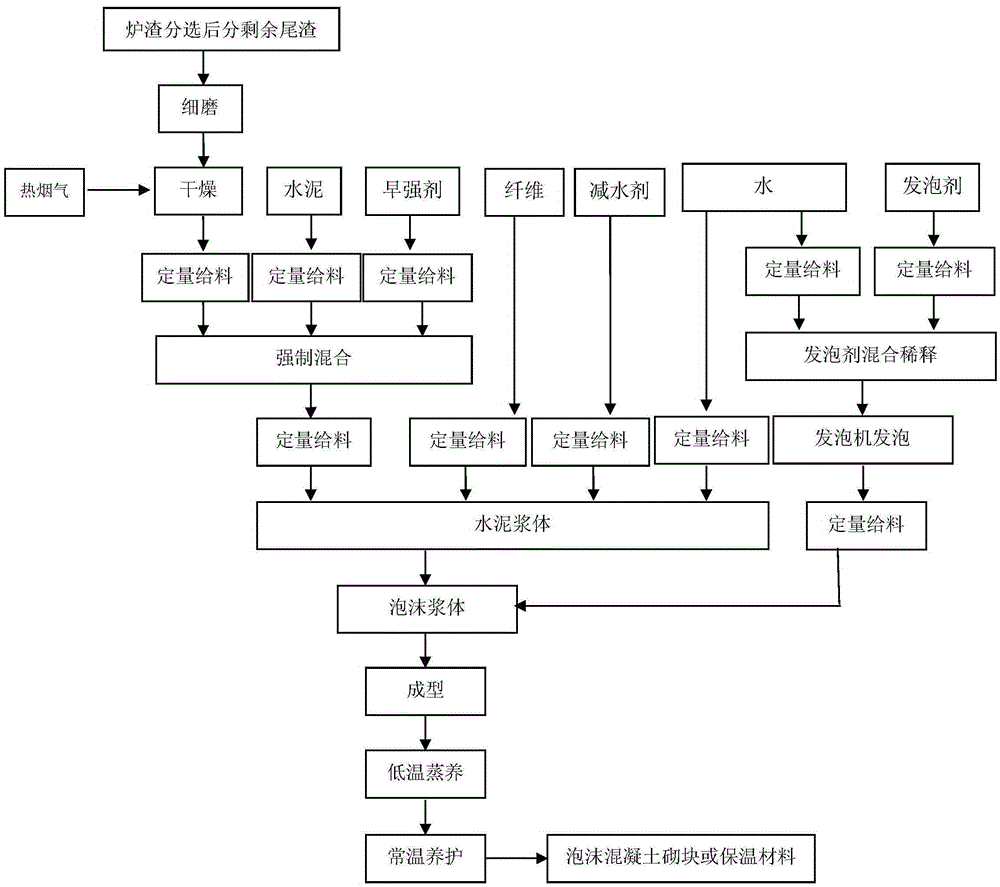

Resource utilization method of household garbage incineration residue sorting tailing

ActiveCN105294156AReduce swelling effectEliminate negative effectsSolid waste managementCeramicwareFoam concreteSlag

The invention relates to a resource utilization method of household garbage incineration residue sorting tailing. The household garbage incineration residue sorting tailing is subjected to fine grinding treatment and is directly dried by utilizing hot smoke, the obtained residue micro powder is forcedly mixed with cement, and processes such as pulping, bubble forming, mixing and soaking, casting moulding, low-temperature oxygen steaming, normal-temperature maintenance and the like are carried out, so that a foam concrete block or a thermal insulation material is prepared. The resource utilization method of the household garbage incineration residue sorting tailing has the advantages that negative effect of free calcium oxide and magnesium oxide on quality of foam concrete is eliminated, and final strength of a foam concrete product is improved; under the combined action of hydration products of cement, and toxic trace heavy metals are solidified, so that a tailing product produces no secondary pollution to the environment; and residue adding proportion is high, resource utilization and large-scale treatment on the garbage incineration residue sorting tailing can be realized, technology is simple, product cost is low, and good economic benefit and environmental benefit are realized.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Aluminum alloy section of lock cylinder

The invention relates to an aluminum alloy section of a lock cylinder. The aluminum alloy section comprises, by weight, 0.8-1.0 part of silicon, 0.1-0.3 part of iron, 0.7-0.9 part of magnesium, 0.1-0.13 part of copper, 0.2-0.3 part of manganese, 0.01-0.05 part of chromium, 0.2-0.28 part of zinc, 0.1-0.2 part of titanium, 0.06-0.08 part of nickel and 96.96-97.63 parts of aluminum. The aluminum alloy section of the lock cylinder has the advantages that the intensity and the hardness are relatively improved and are appropriate, and the production requirement of the lock cylinder is met; meanwhile, the ductility is good, and the punching requirement can be met; and in addition, the aluminum alloy section of the lock cylinder is very resistant to wearing and corrosion, and therefore the service life of the lock cylinder is accordingly prolonged.

Owner:RUGAO HUAYANG ALUMINUM PROD

Acid and alkali corrosion resistant aluminum alloy section bars

The invention discloses acid and alkali corrosion resistant aluminum alloy section bars, and relates to the field of metal material. The aluminum alloy section bars comprise the components by the weight percentage: 0.75-0.90% of Mg, 0.5-0.6% of Si, 0.10-0.14% of Cu, 0.20-0.25% of Mn, 0-0.1% of Ti, 0-0.1% of Cr, 0.1-0.3% of Fe, 0.20-0.28% of Zn, and the balance Al. According to the aluminum alloy section bars, the alloy composition is optimized, smelting casting, homogenization, extrusion, heat treatment and surface treatment in the production technology are optimized, and the mechanical properties of the section bars and the quality of a surface film layer are effectively improved.

Owner:ANHUI XIN FA ALUMINUM PROD

Layered heat exchangers

InactiveUS20050230090A1Increased pressure lossReduce drynessReinforcing meansIce productionInternal pressureEngineering

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com