Patents

Literature

45results about How to "Suitable for production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

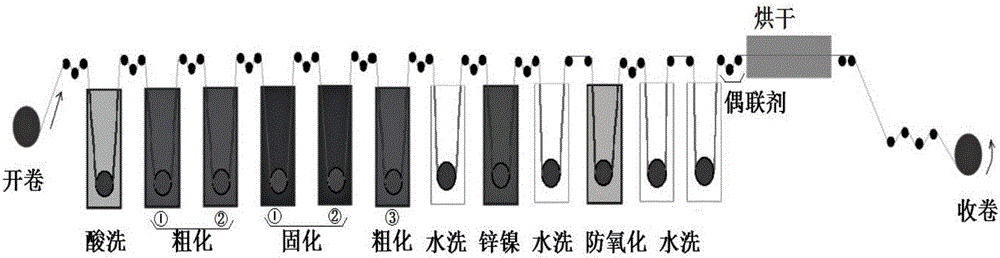

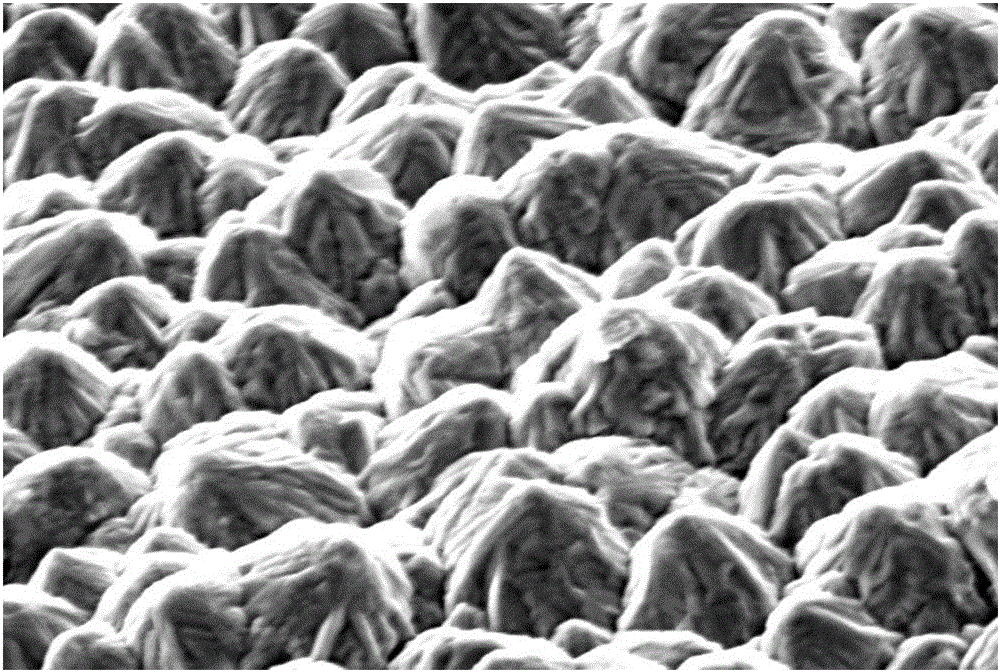

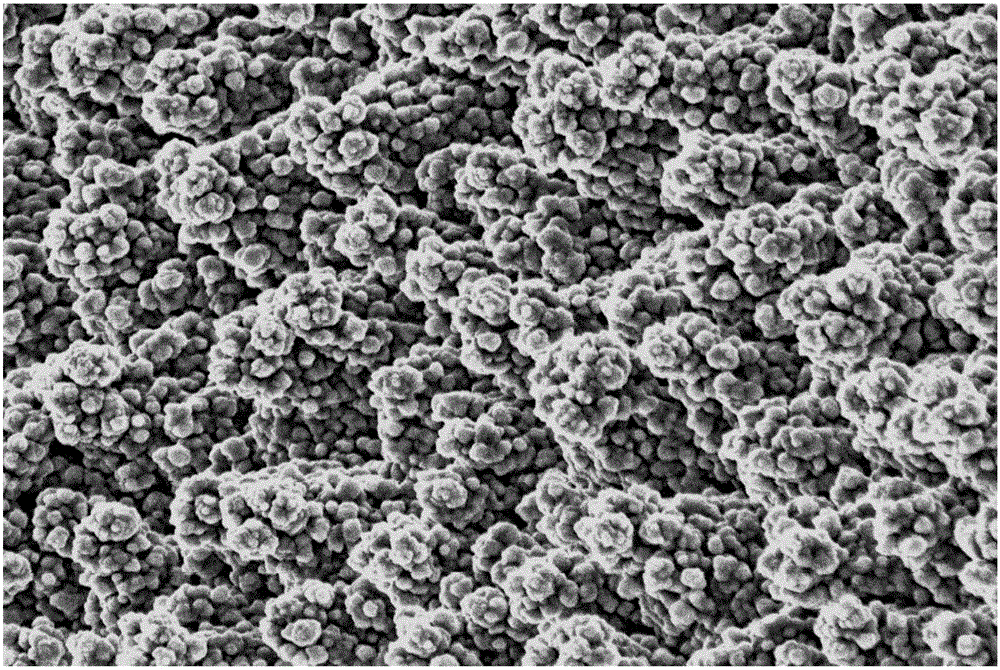

Fine roughing treatment technology for surface of electrolytic copper foil

The invention relates to a fine roughing treatment technology for the surface of electrolytic copper foil. The fine roughing treatment technology includes the following processes of primary roughing, secondary roughing, primary curing, secondary curing, third-level roughing, zinc and nickel alloy plating, oxidization preventing, silane coupling agent treating and drying. The copper foil produced through the technology has relatively low surface roughness, meanwhile has very high stripping resisting strength, especially shows excellent bonding strength on plates of Tg 170 or above and is very suitable for low-loss and ultra-low-loss high-speed circuit boards. Key technology indexes of the copper foil produced through the technology reach the level of the same kind of products of advanced copper foil manufacturers such as Mitsui Mining and Smelting (MHT), Furukawa Electric (MP) and JX Nippon Oil (JTC-LC), replaces imported copper foil of the same kind and is applied to high multi-layer high-end plates, HDI high-end plates, halogen-free high-end plates and other high-end plates in China or Euramerican countries.

Owner:SHANDONG JINBAO ELECTRONICS

Inorganic silver-impregnated zeolite antibiotic papers and method of producing the same

InactiveCN101182689AIncreased durabilityHigh safety to human bodyCoatings with pigmentsPaper/cardboardIon exchangeTemperature resistance

The invention discloses an inorganic silver-loaded zeolite antibacterial paper and a preparation method thereof. In the method, the zeolite is first mixed with a sodium nitrate solution with a mass concentration of 20-30% in a solid-liquid ratio of 1 g / ml, and the reaction is carried out at 70-95 DEG C for 1 ~2 hours, centrifugation and washing to prepare Na-type zeolite; load high content of silver ions by ion exchange method to prepare inorganic silver-carrying antibacterial zeolite for papermaking. The antimicrobial agent is then added to the wet-end sheet or mixed with a coating for surface coating. Calculated by mass percentage content, the silver content of the inorganic silver-carrying zeolite antibacterial paper is 0.05-0.40%. The antibacterial paper prepared by the invention has better antibacterial performance, safety, temperature resistance and durability, simple preparation process and convenient application, and can better meet the antibacterial requirements of household paper and food packaging paper.

Owner:SOUTH CHINA UNIV OF TECH

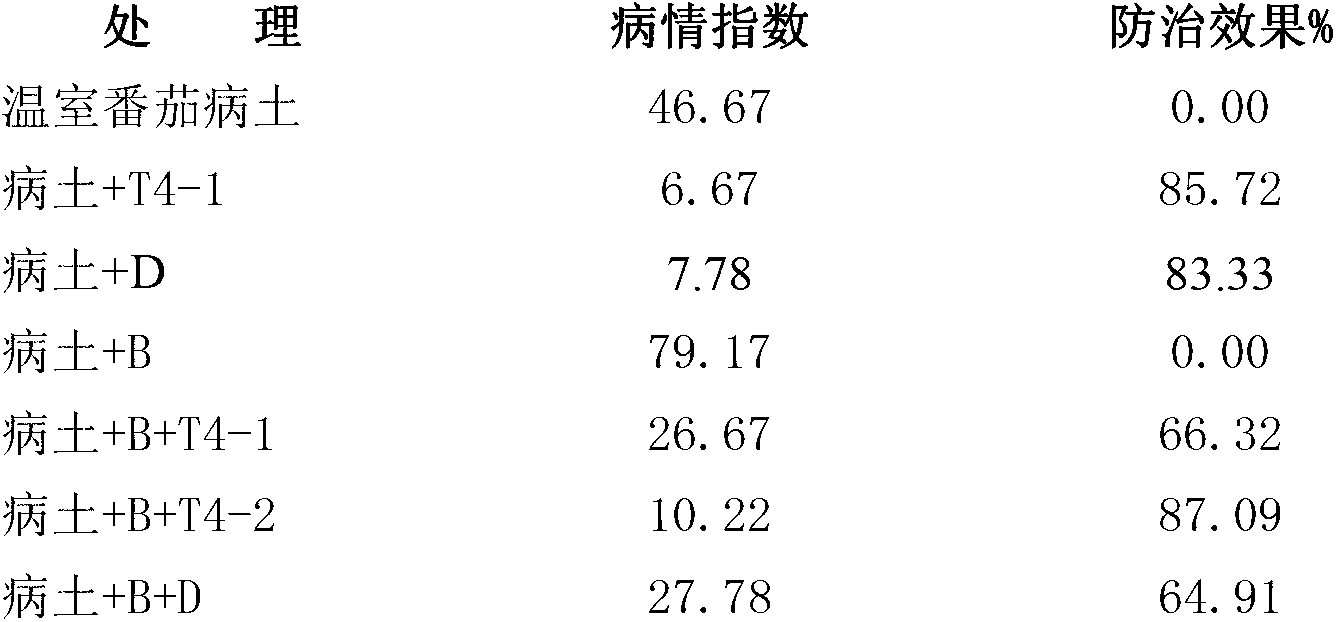

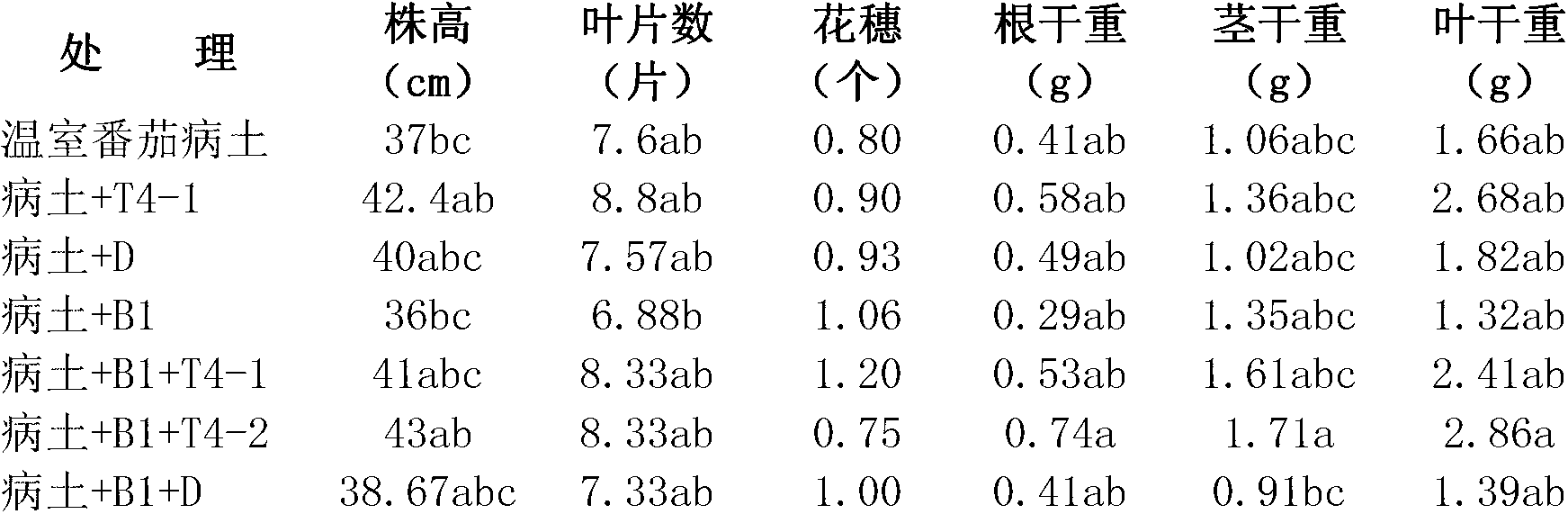

Growth-promoting antibacterial bacillus amyloliquefaciens sp., preparation method of conditioner and application

ActiveCN103074287AHas development and application valueBroad antibacterial spectrumBiocideBacteriaGrowth promotingAntibiotic Y

The invention relates to bacillus amyloliquefaciens sp. Pb-4(T4,4), a preparation method of a conditioner, and an application. The bacillus amyloliquefaciens sp. is preserved in China General Microbiological Culture Collection Center (CGMCC), with the preservation number of CGMCC NO. 7155 and preservation date of January 18, 2013. The bacillus amyloliquefaciens sp. has obvious growth-promoting, antibacterial and disease-prevention effects on crops such as tomatoes, and can be colonized in soil and plants. The preparation method of the conditioner comprises the steps of liquid culture of bean product waste water and the like, and solid fermentation of soybean pod wall powder and the like, wherein a culture has viable bacteria as high as 4*10<9>cfu / ml and 5*10<9>cfu / g, and contains three growth-promoting antibacterial substances, namely antibacterial protein, enzyme and antibiotic. Waste recycling of the bean product waste water is realized, the cost is low, and the conditioner is suitable for industrial production, reduces or substitutes chemical pesticides, is safe and nontoxic, and meets the requirements of ecological agriculture and sustainable agricultural development.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Preparation method of high-activity crystal seed by hydrolysis of titanium sulfate solution

The invention discloses a preparation method of high-activity crystal seed by hydrolysis of a titanium sulfate solution and belongs to the technical field of production of titanium dioxide by a sulfuric acid method. The preparation method comprises the following steps of (A) taking and putting a hydrolytic titanium sulfate solution into a preheating groove to be preheated to 50-65 DEG C, wherein the concentration of TiO2 in the hydrolytic titanium sulfate solution is 195-205g / L, the concentration of Ti<3+> is 1.0-3.0g / L (calculated by TiO2), the concentration ratio F between effective acid andtotal TiO2 is 1.70-1.85, the concentration ratio between Fe and TiO2 is 0.26-0.31, the solid content is less than 30mg / L, and the stability is greater than or equal to 500; (B) preheating alkaline liquid to 50-65 DEG C, and controlling the concentration of the preheated alkaline liquid to 8.0-8.5%; (C) within 1-4 minutes, adding the hydrolytic titanium sulfate solution into the alkaline liquid, and after the reaction is finished, controlling the temperature of the crystal seed titanium sulfate solution to be 40-60 DEG C; (D) diluting and controlling the concentration of TiO2 in the crystal seed titanium sulfate solution to be 30-160g / L. The crystal seed prepared by the method is high in activity, less in added amount in water crystallization and high in hydrolysis rate, and the obtained hydrated titanium dioxide is uniform in particle size distribution.

Owner:HEBEI MILSON TITANIUM DIOXIDE

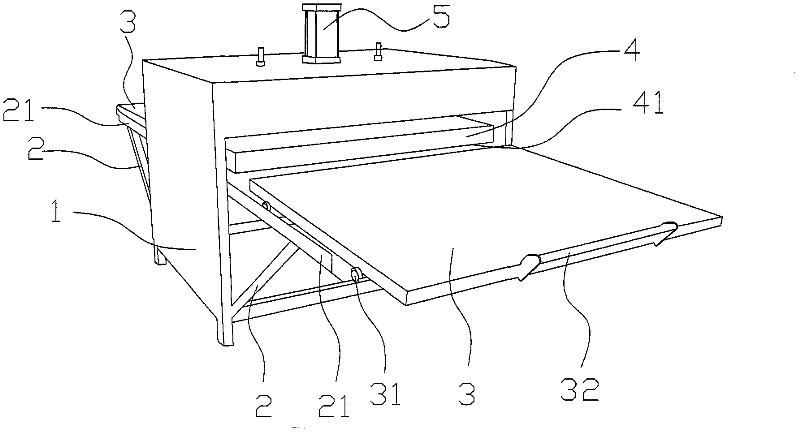

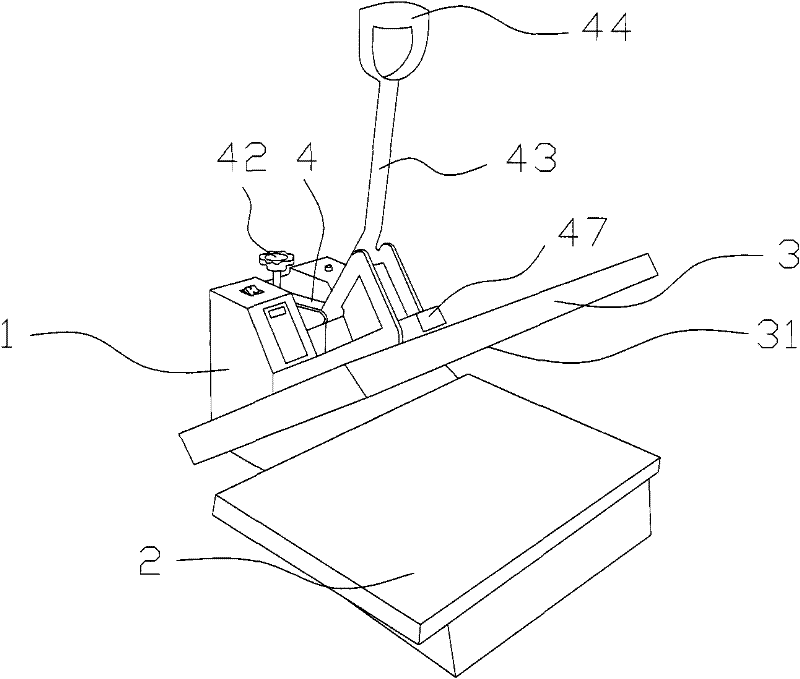

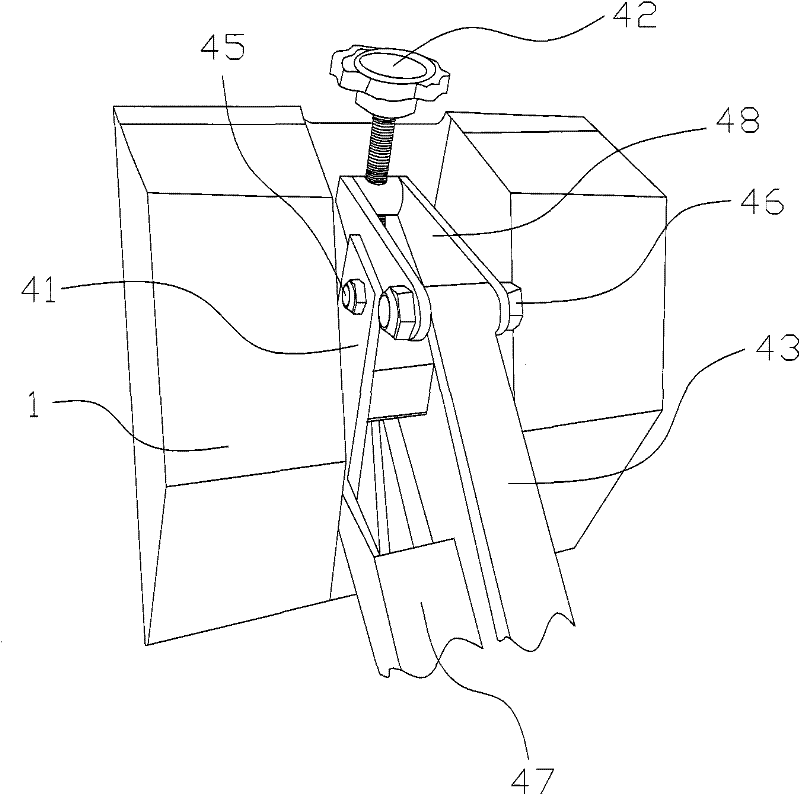

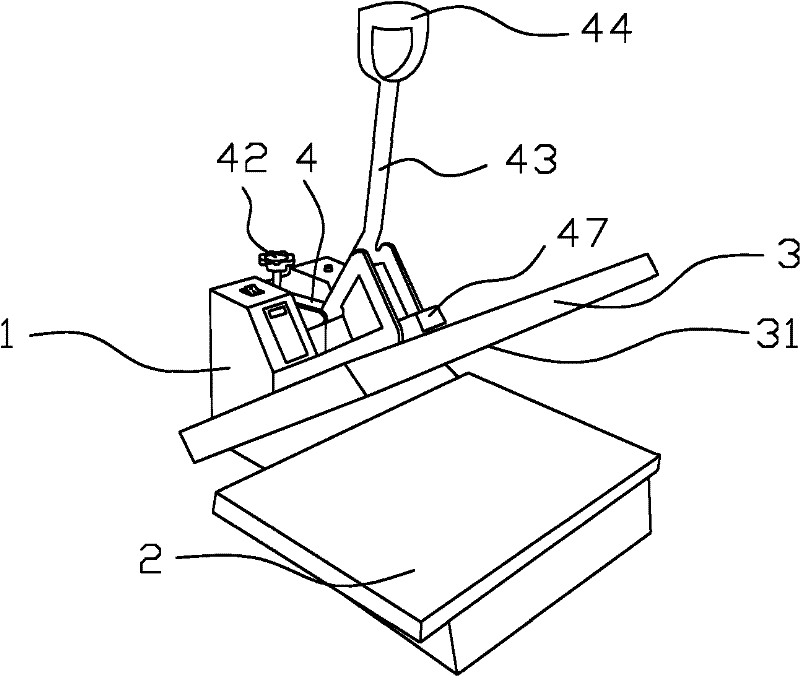

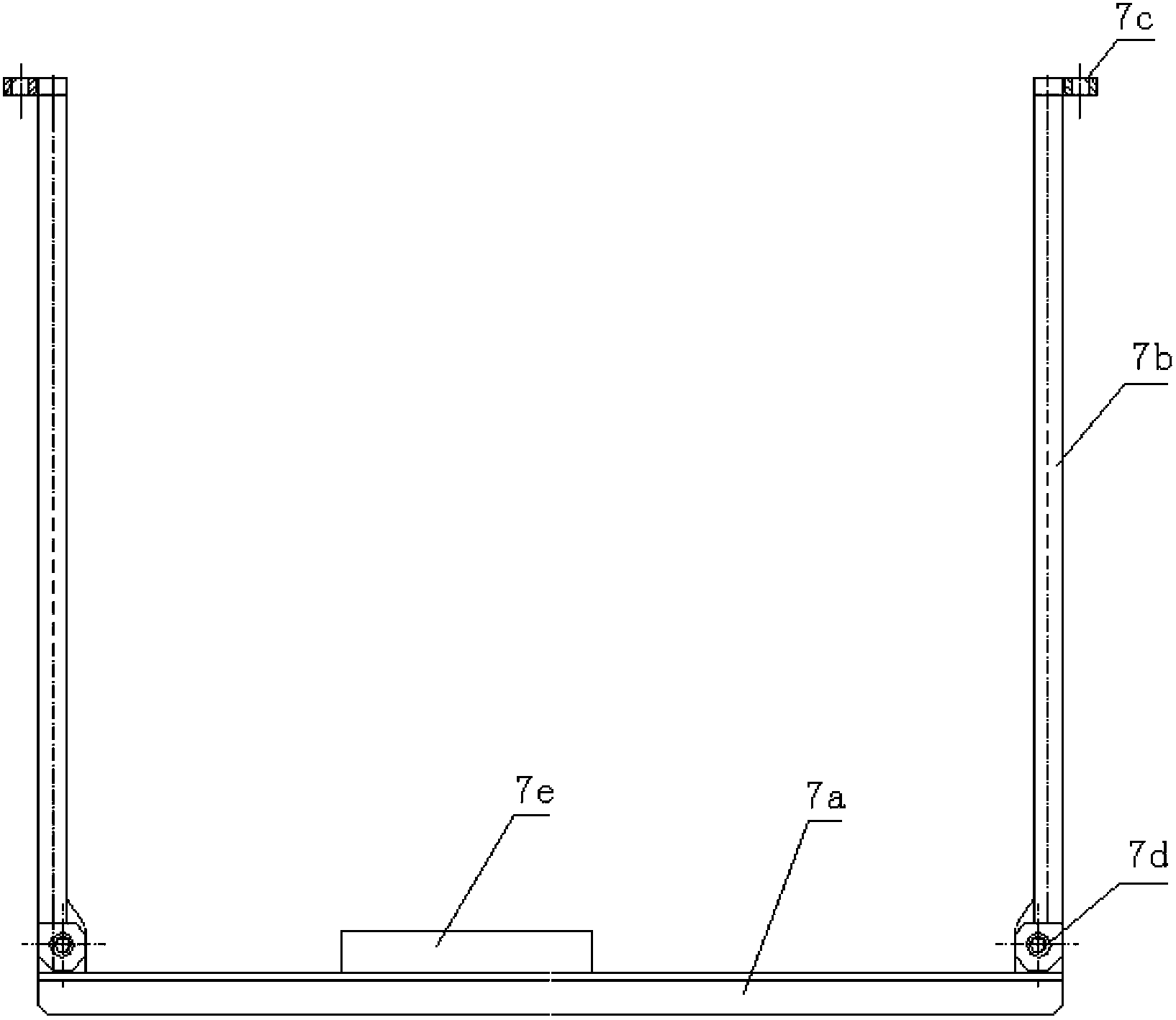

Double-station transfer printing device

InactiveCN102452216AReduce CooldownImprove printing efficiencyTransfer printingEconomic benefitsEngineering

The invention discloses a double-station transfer printing device which is used in the field of textiles. The device comprises a body, drawing plate brackets, drawing plates, a pressing plate and a cylinder, wherein the drawing plate brackets are fixedly arranged on two sides of the body and are provided with guide rails; the drawing plates are slidably arranged on the guide rails and are provided with rollers; the pressing plate is arranged above the interior of the body and is provided with printing paper; the cylinder is fixedly arranged on the upper part of the body; and a telescopic rod of the cylinder is fixedly connected with the pressing plate. According to the double-station transfer printing device, by providing two groups of drawing plates which alternately enter the body for indentation, the indentation efficiency is increased, and the time for waiting a product to be cooled is shortened to increase the production efficiency. Meanwhile, the pressing plate can be used for heating, so that the printing and dyeing effect can be enhanced. The double-station transfer printing device has the advantages of simple structure, easiness and convenience in use, high production efficiency, low cost, good effect, great economic benefit brought to enterprises, high suitability for requirements of textile production and extremely positive significance.

Owner:WUJIANG WAVE TEXTILE

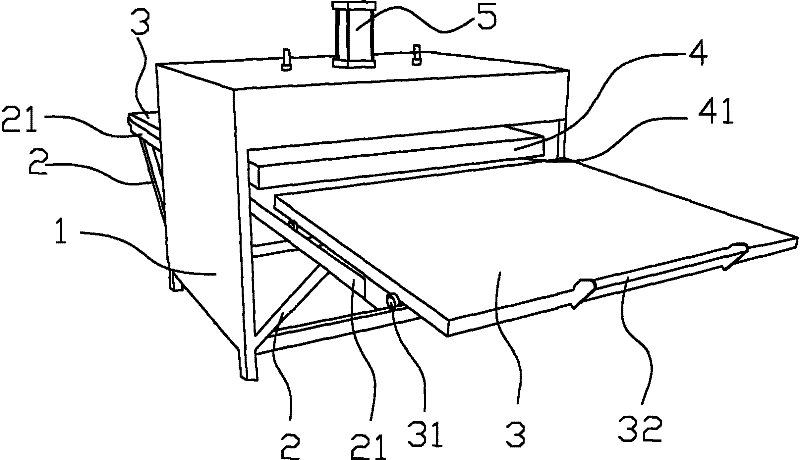

Method for preparing modified maize starch glue

InactiveCN102876255ASimple processGood adhesionNon-macromolecular adhesive additivesStarch derivtive adhesivesChemistryRenewable energy

The invention relates to a method for preparing a modified maize starch glue, comprising the following steps: (1) taking 85kg of maize starch, adding 9kg of oxidant, stirring uniformly, sealing, oxidizing for 10 hours, adding 6kg of quick-drying agent, stirring uniformly, and cooling for 10 hours to obtain the modified maize starch; and (2) adding 70kg of water, stirring uniformly, adding 3kg of sodium hydroxide, gelatinizing, adding 0.25kg of borax, stirring again, adding 15mg of defoaming agent, stirring uniformly, and barreling for use. The adopted maize starch is the environmentally-friendly product and the renewable energy. The modified maize starch glue is produced at the room temperature without heating, and the process for preparing the modified maize starch glue is easy. The materials adopted to produce the modified maize starch glue have good bonding strength, and the modified maize starch glue can be dried and cured quickly and is very suitable for producing honeycomb paperboards.

Owner:ZUNYI HEXIN PACKAGE CO LTD

Method for planting peach tree

InactiveCN107148887AExcellent cultivation methodImprove disease resistanceBio-organic fraction processingExcrement fertilisersSeedlingSurvival rate

The invention provides a method for planting peach trees. The method comprises the following steps: preparing a land, digging holes, planting peach tree seedlings, performing fixed planting of trunks, performing field management, and the like. By adopting a planting method that the trunks are fixedly planted, the growth vitality of the trunks is improved, sunshine is sufficiently utilized, the utilization spaces of lighting are increased for peach trees, the yield of the peach trees is increased, the quality of the peach trees is improved, in addition, as the peach trees are fertilized through special organic farmyard fertilizers, the peach trees are high in seedling survival rate and good in disease resistance, chemical fertilizers and pesticides are not needed, and production requirements of environmental-friendly and safe fruits are met.

Owner:铜仁市绿缘生态农林发展有限公司

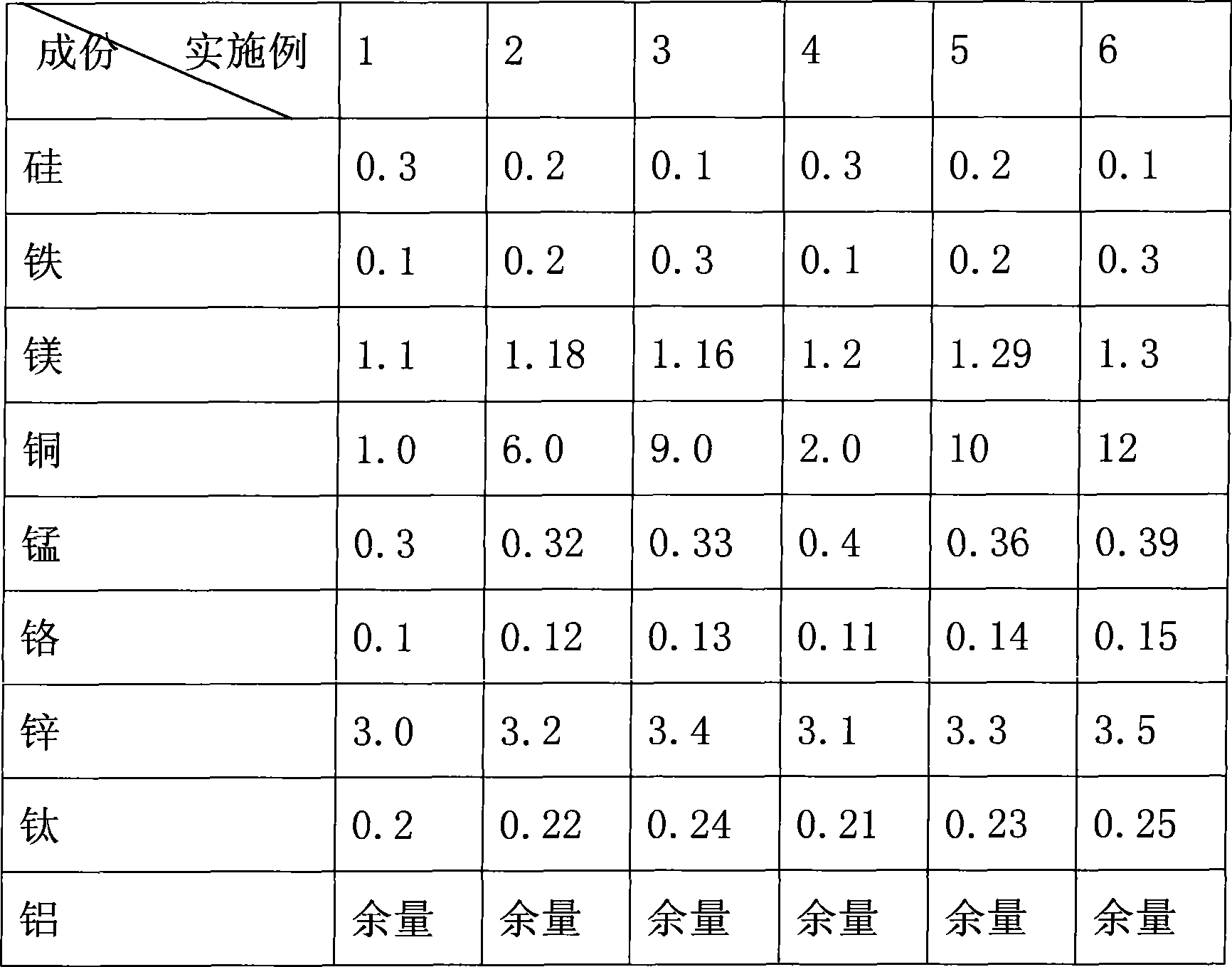

Aluminum alloy lock core

InactiveCN101476412ASuitable for production requirementsImprove ductilityBuilding locksManganeseHardness

The invention discloses an aluminum alloy lock core, which comprises the following components in portion by weight: less than 0.4 portion of silicon, less than 0.4 portion of iron, 1.0 to 1.3 portions of magnesium, 1.0 to 1.2 portions of copper, 0.3 to 0.4 portion of manganese, 0.1 to 0.15 portion of chromium, 3.0 to 3.5 portions of zinc, 0.2 to 0.25 portion of titanium, and the balance being aluminum. The aluminum alloy lock core has the advantages of moderate strength and hardness of formulation materials, and good extensibility, and saves high cost for manufacturing the lock core.

Owner:张家港市华杨金属制品有限公司

Aluminum alloy section of lock cylinder

The invention relates to an aluminum alloy section of a lock cylinder. The aluminum alloy section comprises, by weight, 0.8-1.0 part of silicon, 0.1-0.3 part of iron, 0.7-0.9 part of magnesium, 0.1-0.13 part of copper, 0.2-0.3 part of manganese, 0.01-0.05 part of chromium, 0.2-0.28 part of zinc, 0.1-0.2 part of titanium, 0.06-0.08 part of nickel and 96.96-97.63 parts of aluminum. The aluminum alloy section of the lock cylinder has the advantages that the intensity and the hardness are relatively improved and are appropriate, and the production requirement of the lock cylinder is met; meanwhile, the ductility is good, and the punching requirement can be met; and in addition, the aluminum alloy section of the lock cylinder is very resistant to wearing and corrosion, and therefore the service life of the lock cylinder is accordingly prolonged.

Owner:RUGAO HUAYANG ALUMINUM PROD

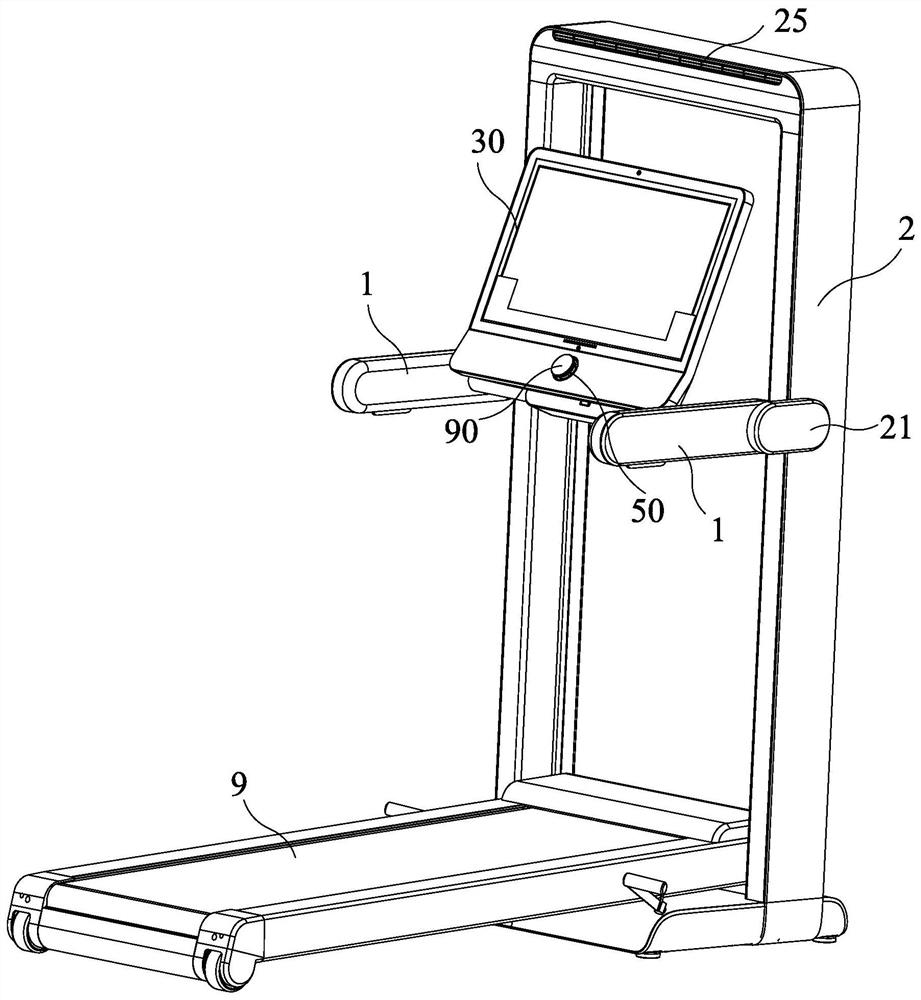

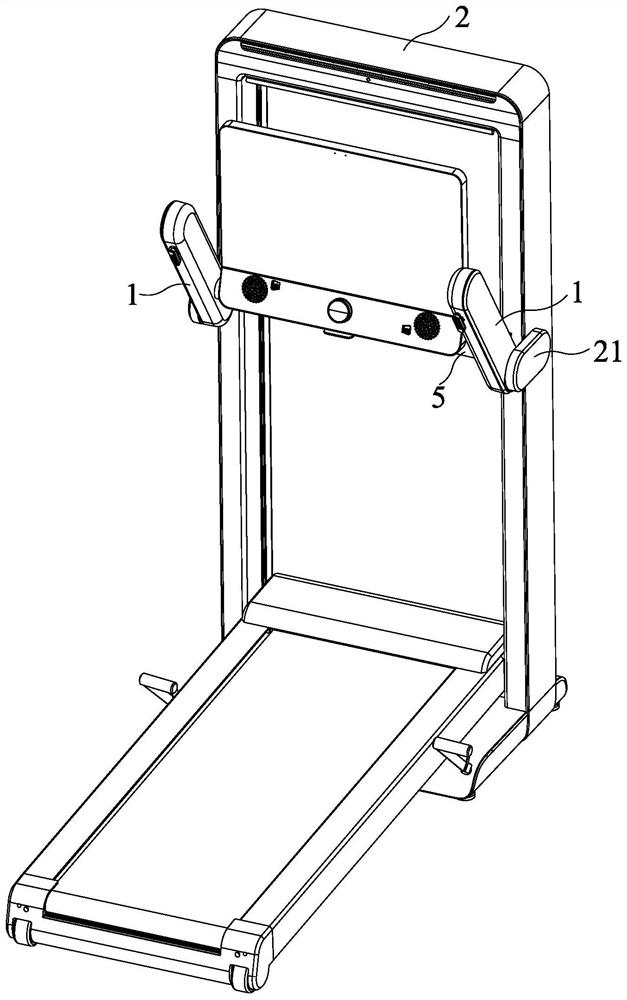

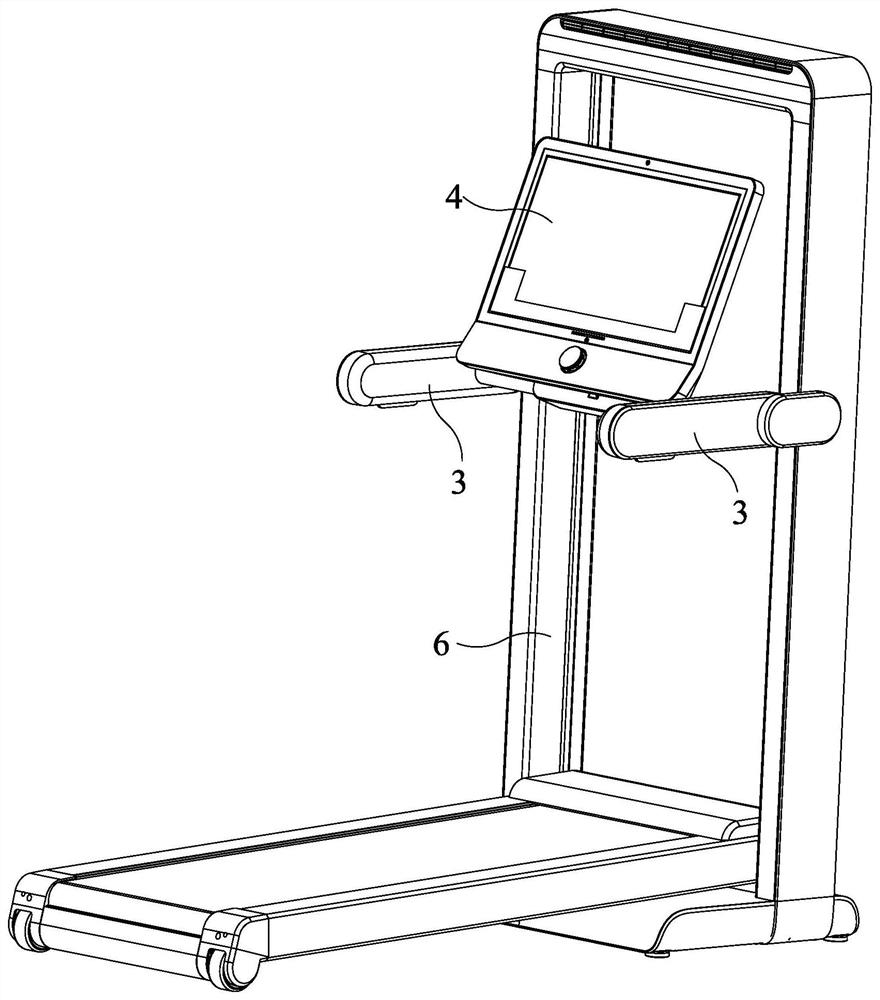

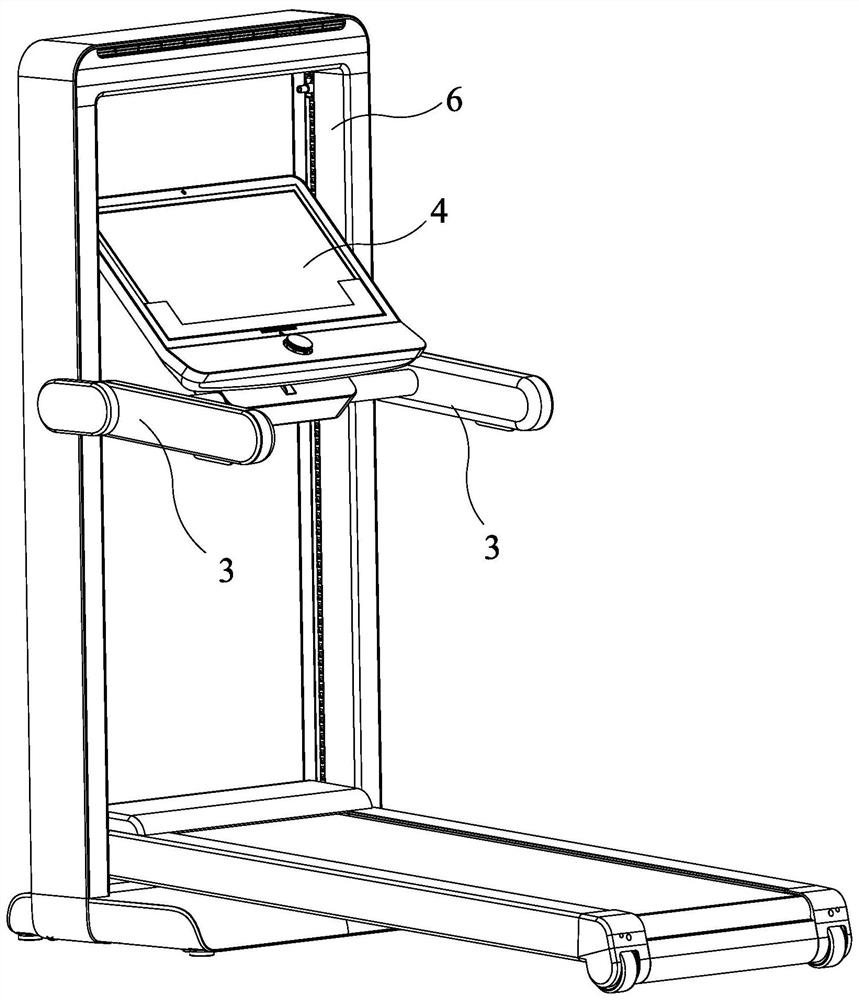

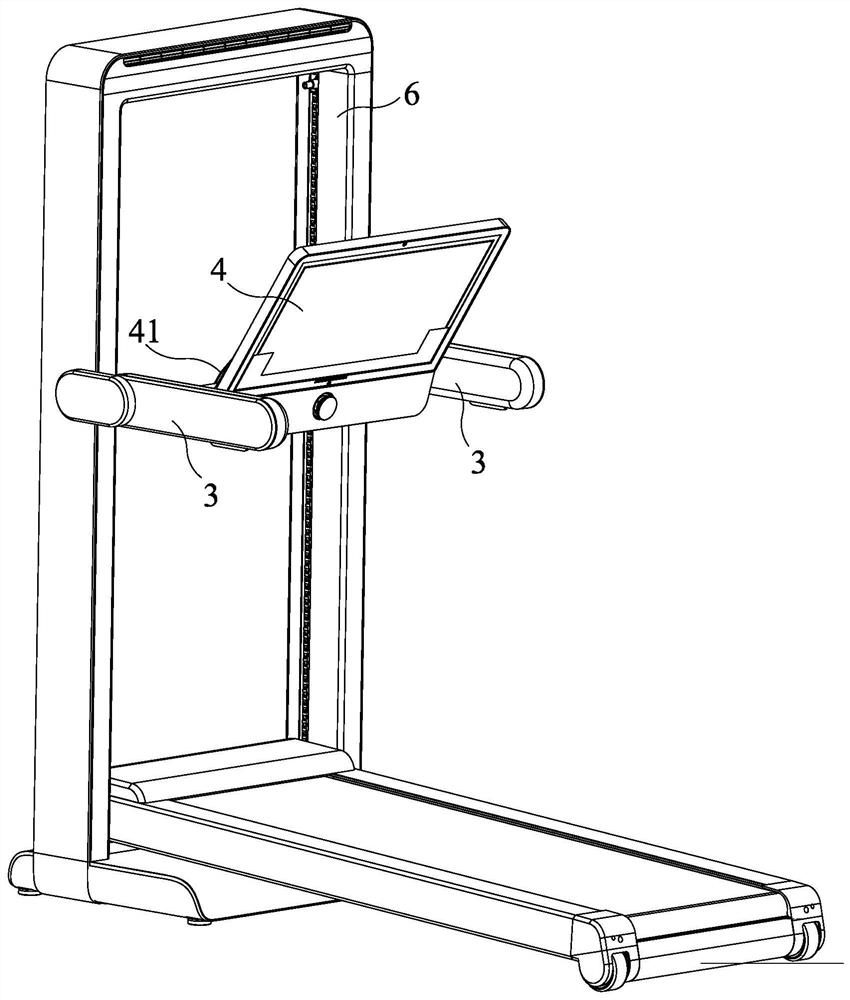

Fitness center

PendingCN112843604AReal-time monitoring of slope dataAvoid Unforeseen DangersPump componentsPump installationsClassical mechanicsElectric machinery

The invention discloses a fitness center which comprises handrails, a frame, a driving device, holding devices, a first lifting mechanism, a running belt, a front roller, a rear roller, a running platform, a motor, a motor control panel, a brake resistor and a gradient sensor. The front roller and the rear roller are connected to the two ends of the running belt, and the gradient sensor is arranged on the running platform. The gradient sensor can automatically record gradient data during gradient lifting of the running platform, and the motor control panel adjusts the resistance value of the brake resistor, so that the running belt can keep constant speed at high and low gradients; the two sides of the frame are each fixedly provided with a holding device, each holding device is rotationally provided with a handrail, and after the driving device drives the handrails to rotate relative to the frame, the handrails are held and fixed through the holding devices; and the front portion of the running platform is connected with the first lifting mechanism, the first lifting mechanism drives the front portion of the running platform to ascend and descend. According to the scheme, a body building user can grasp the rotating and tightly-held handrails to do a similar rock climbing motion mode under the condition of large-gradient running.

Owner:HEFEI PIPISHOU INTELLIGENT TECH CO LTD

Transfer printing device

InactiveCN102452217AConsolidate the printing and dyeing effectSimple structureTransfer printingProduction rateFrame based

The invention discloses a transfer printing device which is used in the field of textiles. The device comprises a body, an indentation table, a driving frame and a pressing plate, wherein the indentation table is fixedly arranged on the body; the driving frame is fixedly arranged on the body; the pressing plate is fixedly connected with the driving frame and is provided with indentation paper; the driving frame comprises a driving frame base, a rotating arm adjusting frame, a rotating arm, a pressing plate connecting block and an adjusting screw, wherein the driving frame base is fixed on the body; the rotating arm adjusting frame is arranged on the driving frame base through a first screw; the rotating arm is rotatably connected with one end of the rotating arm adjusting frame through a second screw; the pressing plate connecting block is fixedly connected to the rotating arm and is rotatably connected to the driving frame at the same time; and the adjusting screw is arranged on the other end of the rotating arm adjusting frame. The transfer printing device has the advantages of simple structure, easiness and convenience in use, high printing and dyeing speed, good printing and dyeing effect, extremely high productivity, high suitability for requirements of textile production and extremely positive significance.

Owner:WUJIANG ERLIAN SILK

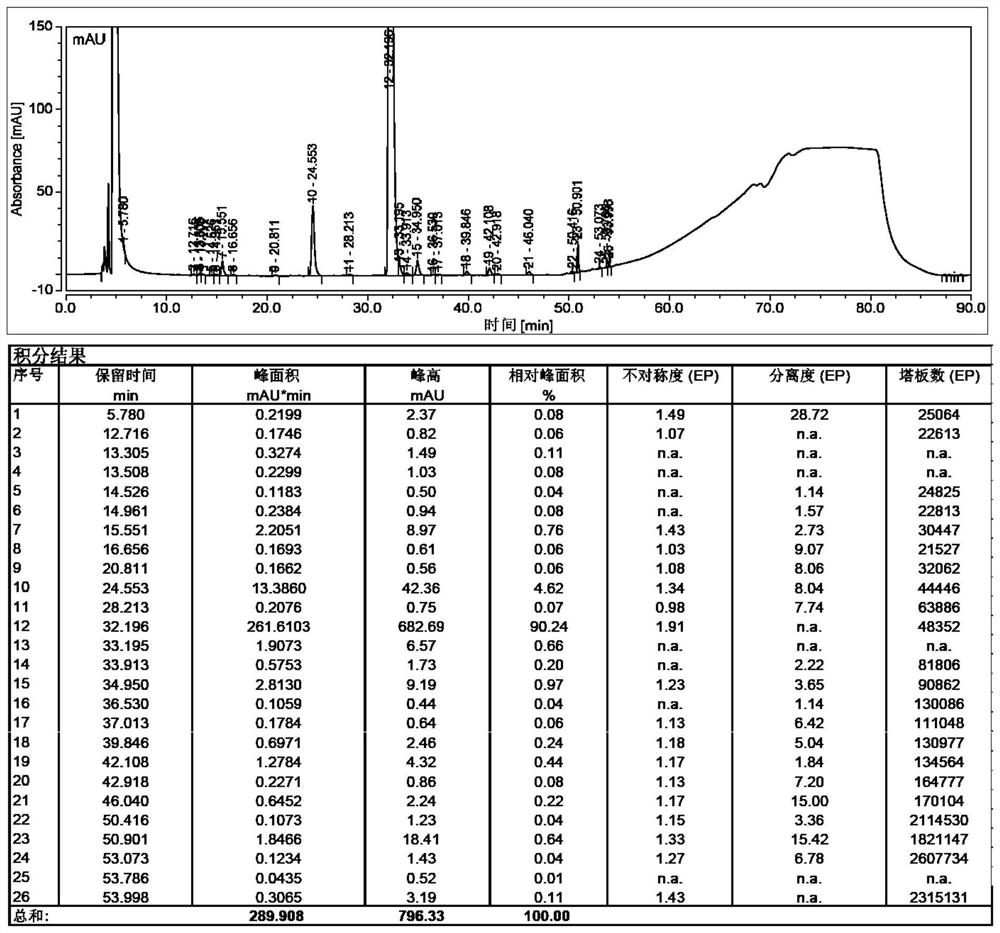

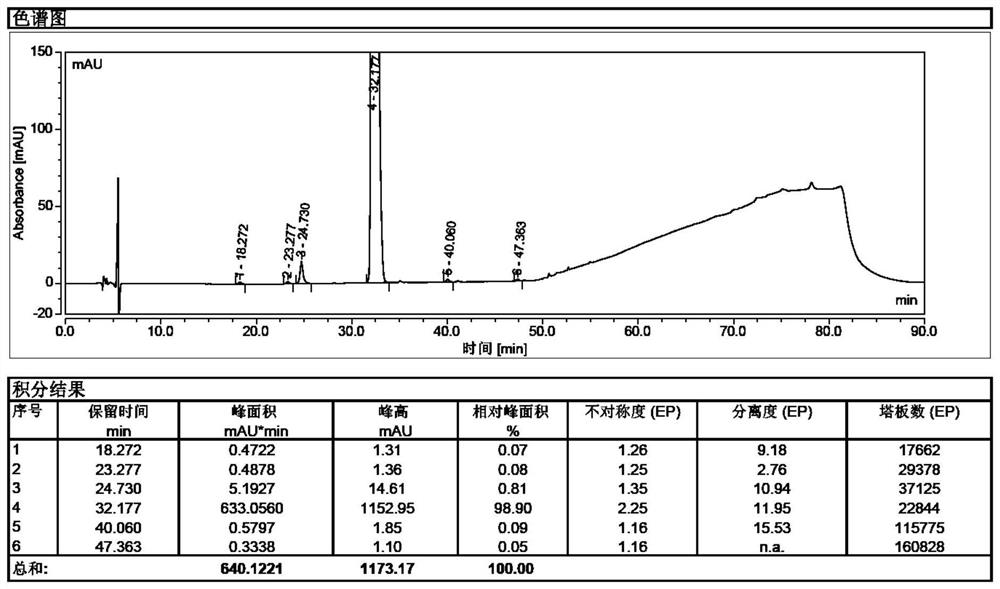

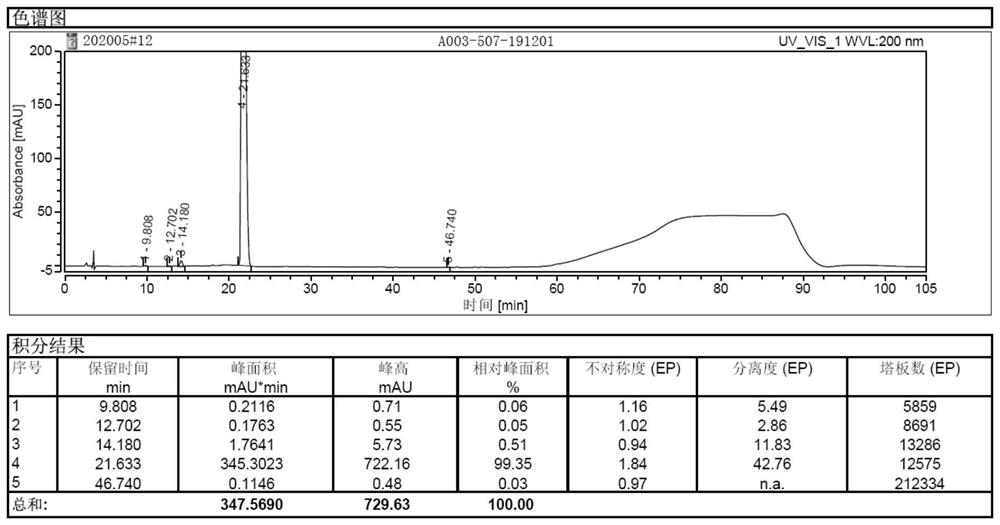

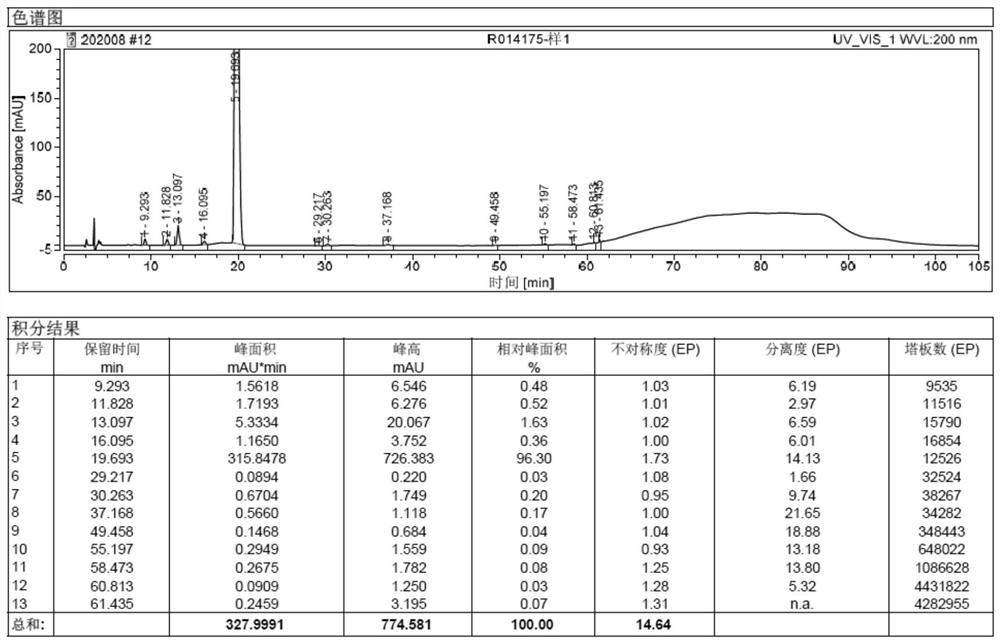

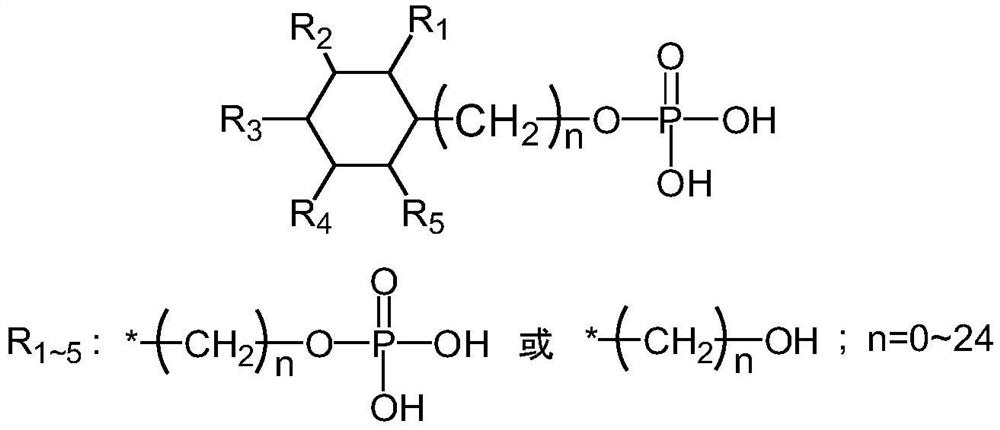

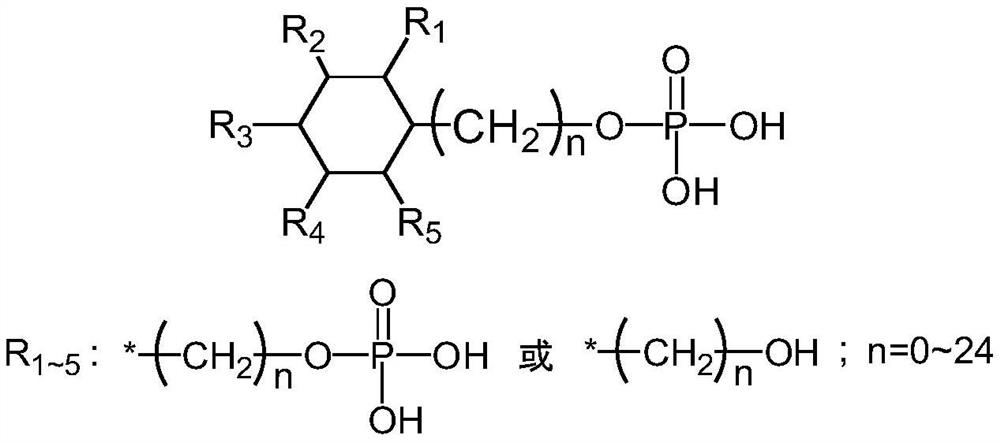

Preparation method of high-purity sugammadex sodium

ActiveCN111978435AReduce the risk of oxidationSuppress generationOrganic active ingredientsMuscular disorderInositol pentaphosphateSugammadex Sodium

The invention discloses a preparation method of high-purity sugammadex sodium. The high-purity sugammadex sodium is prepared from inositol phosphate and derivatives thereof. The specific process comprises the following steps of adding a specific type of protective agent into a crude sugammadex sodium product, and performing recrystallizing under the protection of inert gas to obtain a pure sugammadex sodium product, wherein the protective agent is selected from the inositol phosphate and the derivatives thereof, such as inositol hexaphosphate and salts or esters thereof, partial degradation products of the inositol hexaphosphate, such as inositol pentaphosphate, inositol tetraphosphate, inositol triphosphate, inositol diphosphate and inositol monophosphate, and one or a mixture of two or more of the above-mentioned substances and salts or esters thereof in any proportion. The method is simple and convenient to operate, high in product purity, good in safety, few in anaphylactic reaction, good in economical efficiency and more suitable for industrial production.

Owner:HEFEI BOSIKC PHARMTECH CO LTD

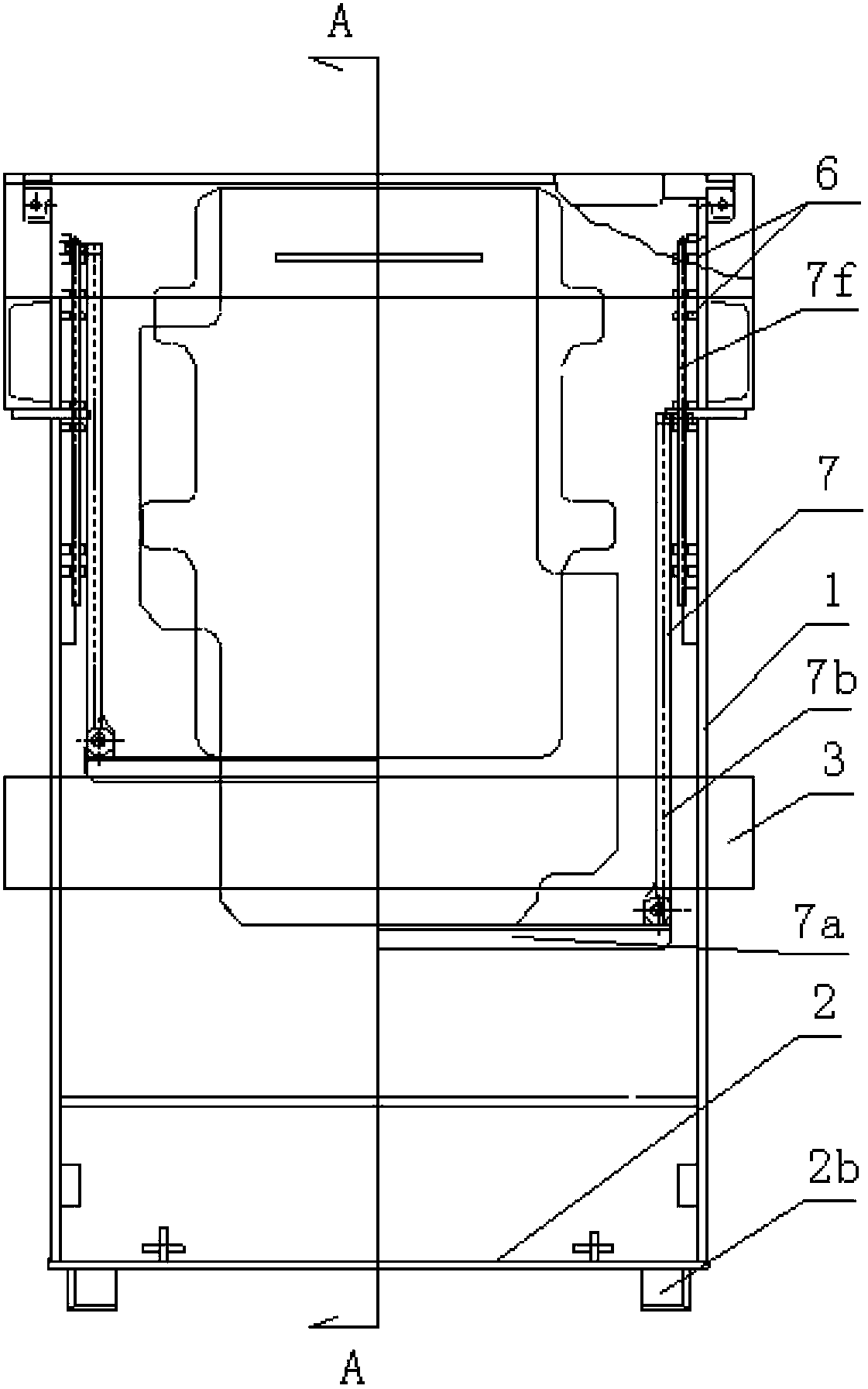

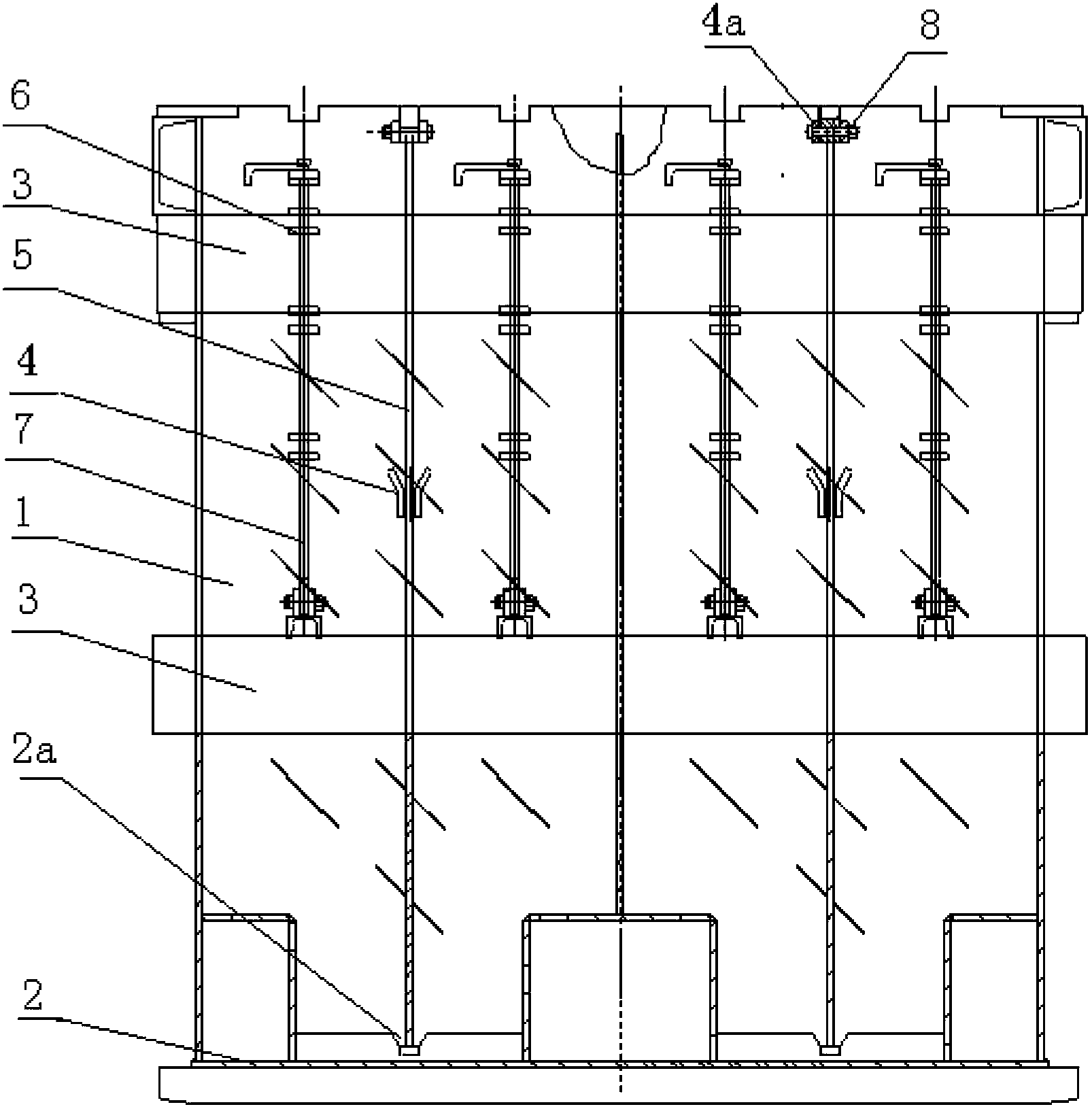

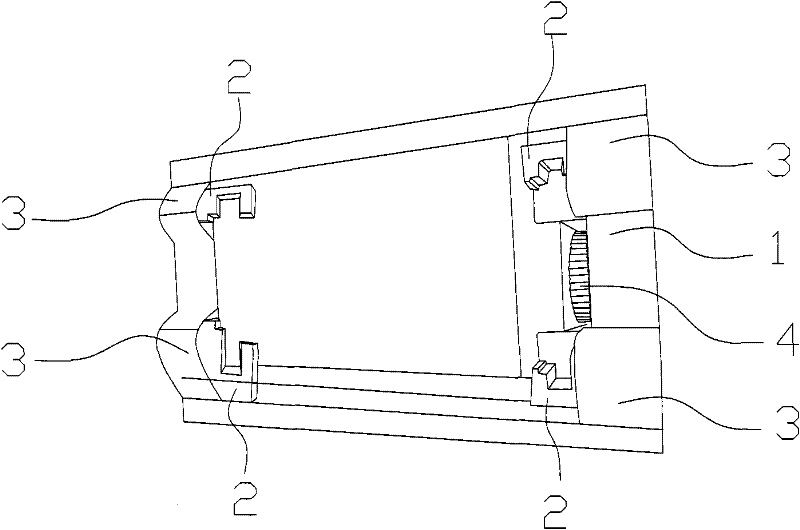

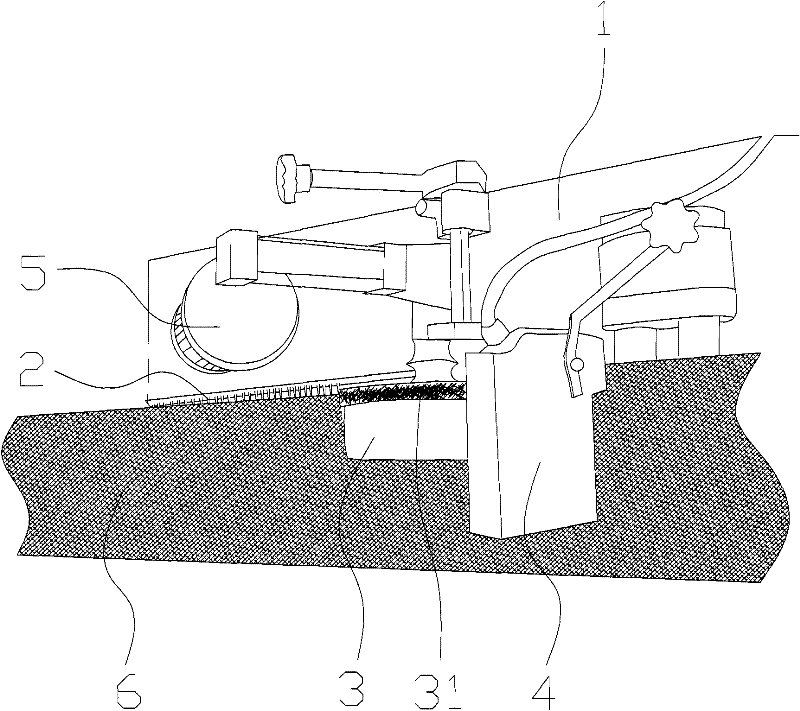

Adjustable shell molding line sand box used for casting

InactiveCN103894556ARealize the production of the same line and boxSuitable for production requirementsMoulding machinesMoulding flasksVertical barShell molding

The invention provides an adjustable shell molding line sand box used for casting. The adjustable shell molding line sand box comprises a box body. The box body comprises four side plates, a box bottom and a frame. The adjustable shell molding line sand box is characterized in that: vertical guide slots are formed in one pair of the side plates of the box body; clamping slots are formed at corresponding positions on the box bottom; and vertical separators are inserted into the clamping slots in the box bottom along the vertical guide slots so as to divide the box body into a plurality of small box bodies. Two to four rows of multi-stage locating clamping blocks are arranged on the upper half part of one pair of the side plates of the box body. Vertical insert holes are formed in the locating clamping blocks. Two to four height adjusting mechanisms are arranged in the box body. The height adjusting mechanisms include transverse U-bars; two ends of each transverse U-bar are respectively hinged with two vertical bars at two sides; locating blocks protruding towards the outside are arranged on the upper ends of each two vertical bars. Pin holes are formed in the locating blocks. The locating blocks and the pin holes in the locating blocks are matched with the locating clamping blocks and the vertical insert holes. Pins penetrate through the vertical insert holes of the locating clamping blocks as well as the pin holes in the locating blocks so as to lock the lifting adjusting mechanisms. Threaded holes are formed in the uppermost guide slots in the pair of the side plates; and two sides of each of the uppermost guide slots are connected and fixed through a bolt and a nut.

Owner:DONGFENG AUTOMOBILE COMPANY

Inorganic silver-impregnated zeolite antibiotic papers and method of producing the same

InactiveCN101182689BTemperature resistantDurableCoatings with pigmentsPaper/cardboardLiquid ratioIon exchange

Owner:SOUTH CHINA UNIV OF TECH

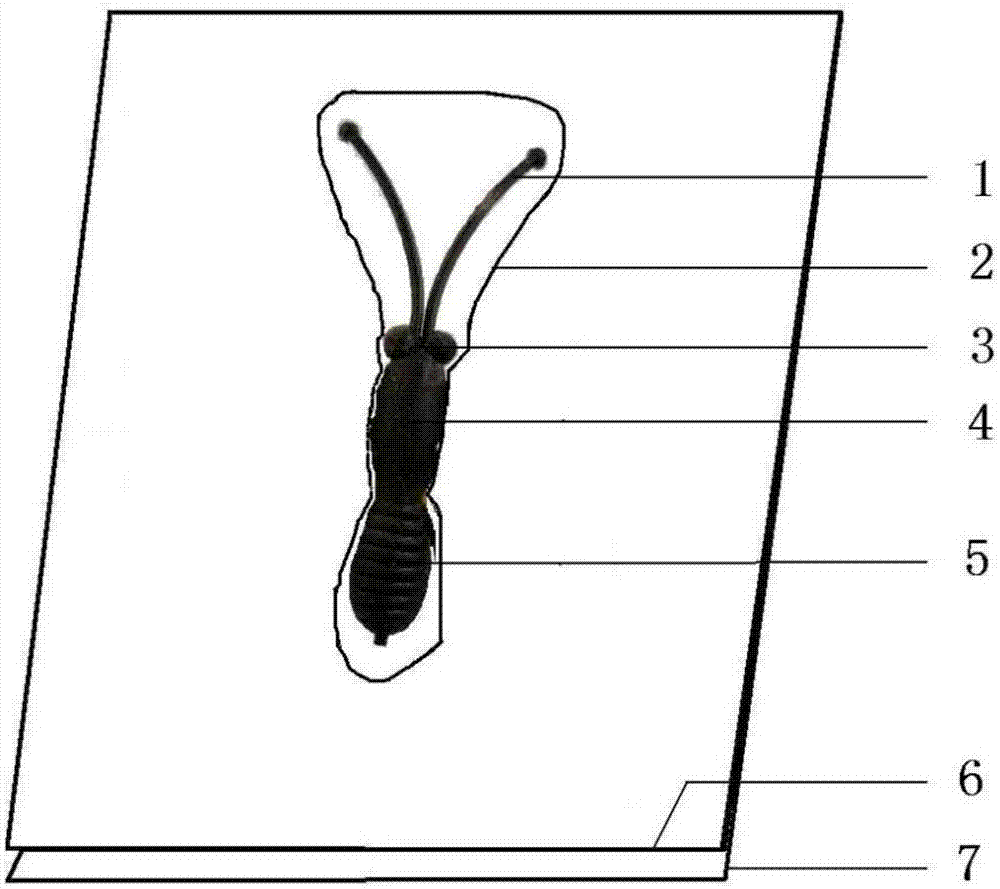

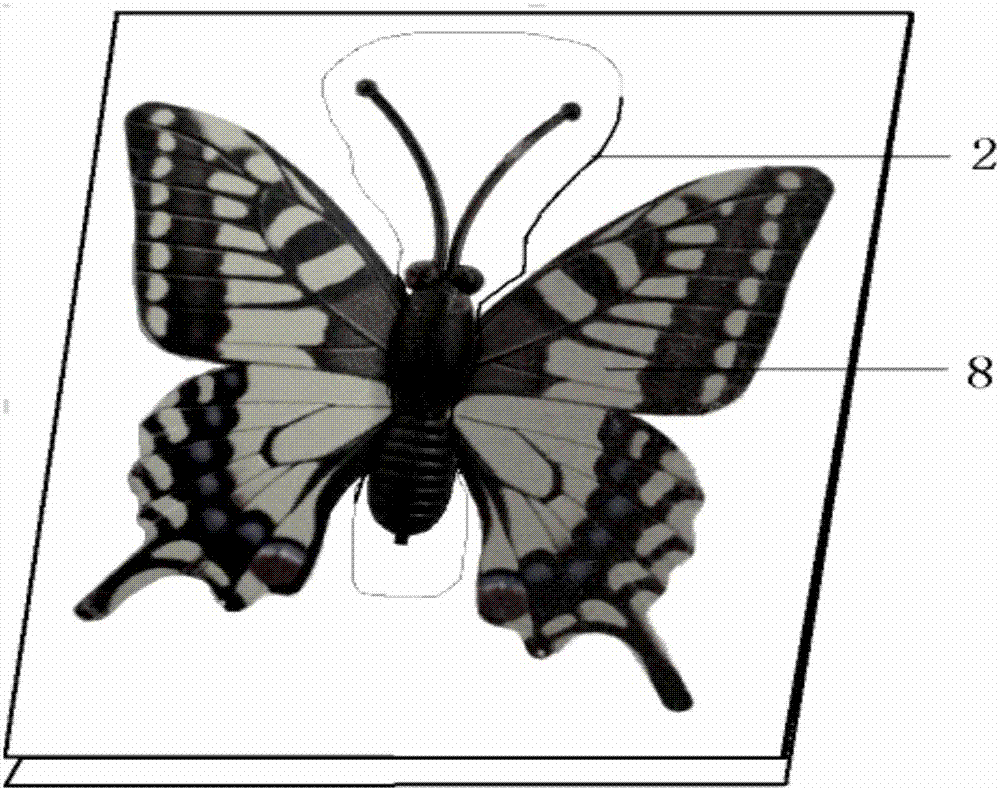

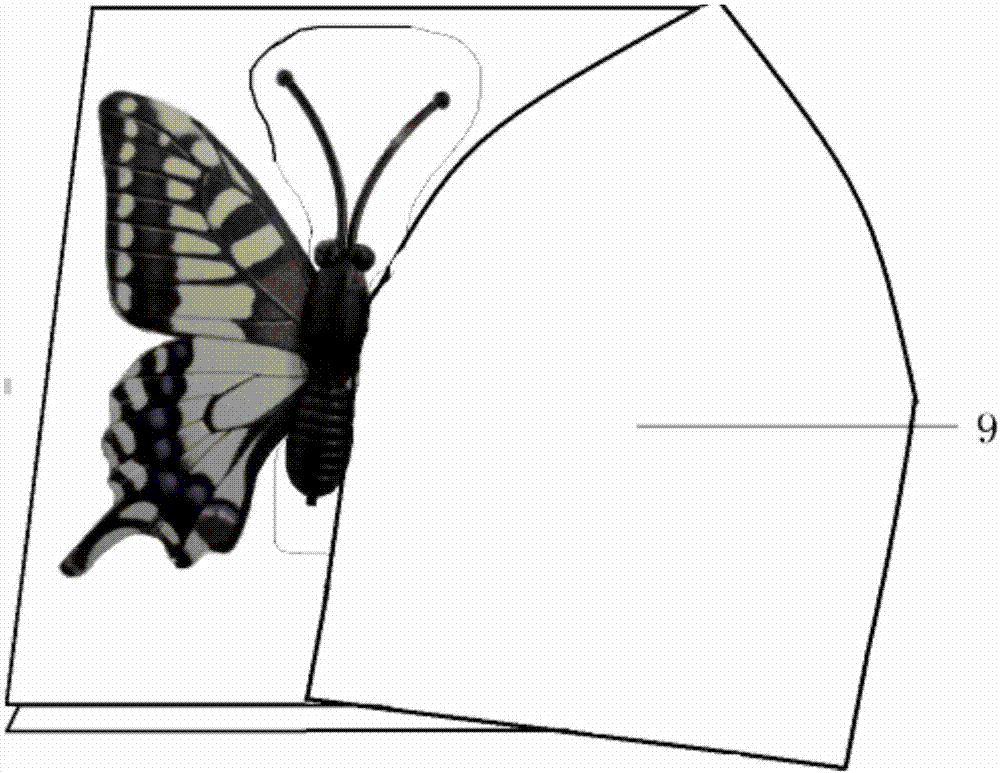

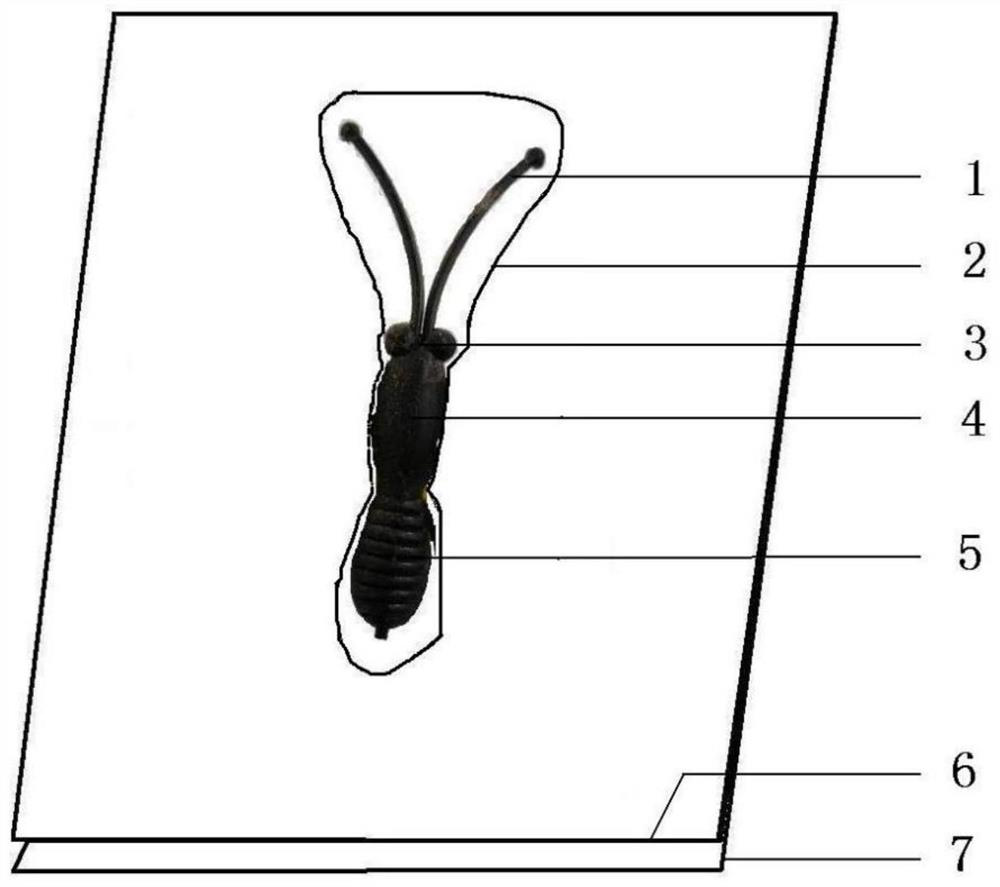

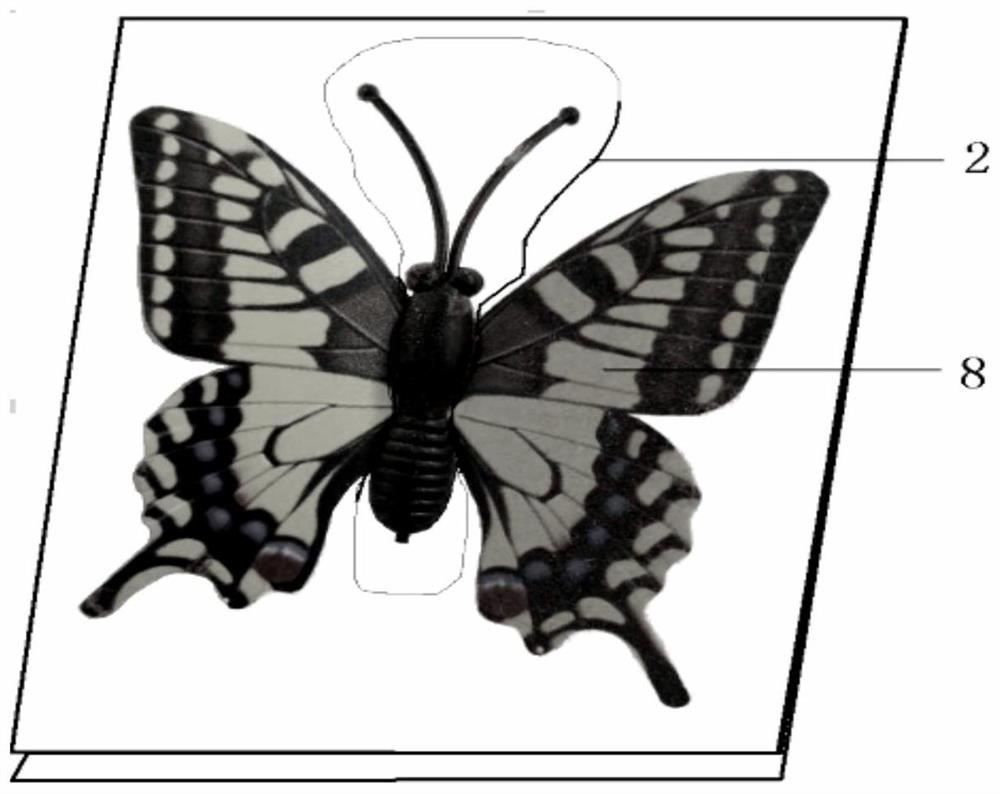

Method for making resin embedded Lepidoptera insect specimen

InactiveCN107950521ASolve discolorationPreserve true colorDead animal preservationResin embeddingOrder Lepidoptera

The invention discloses a method for making a resin embedded Lepidoptera insect specimen. Wings of a Lepidoptera insect are subjected to plastic package firstly with a plastic package film or a scotchtape, then the surplus plastic package film is cut off, the plastic package film for plastic package of the wings is retained, finally, the insect specimen with plastic package of the wings is embedded in resin, and the resin embedded Lepidoptera insect specimen is prepared. The problem of color change of the conventional resin embedded Lepidoptera insect specimen is solved, the original real color of the specimen is retained, and the made resin embedded Lepidoptera insect specimen meets requirements of scientific research and can also meet requirement of artware making.

Owner:陈宝明

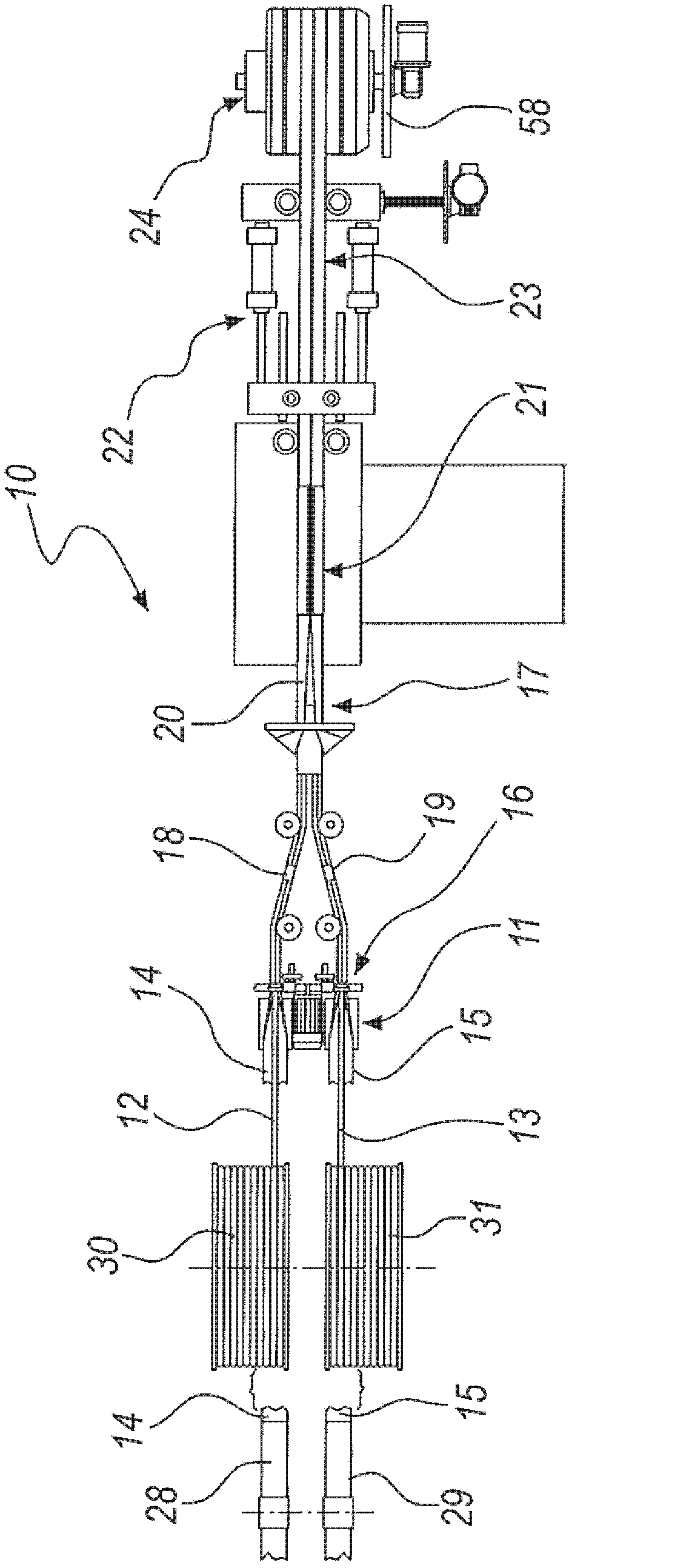

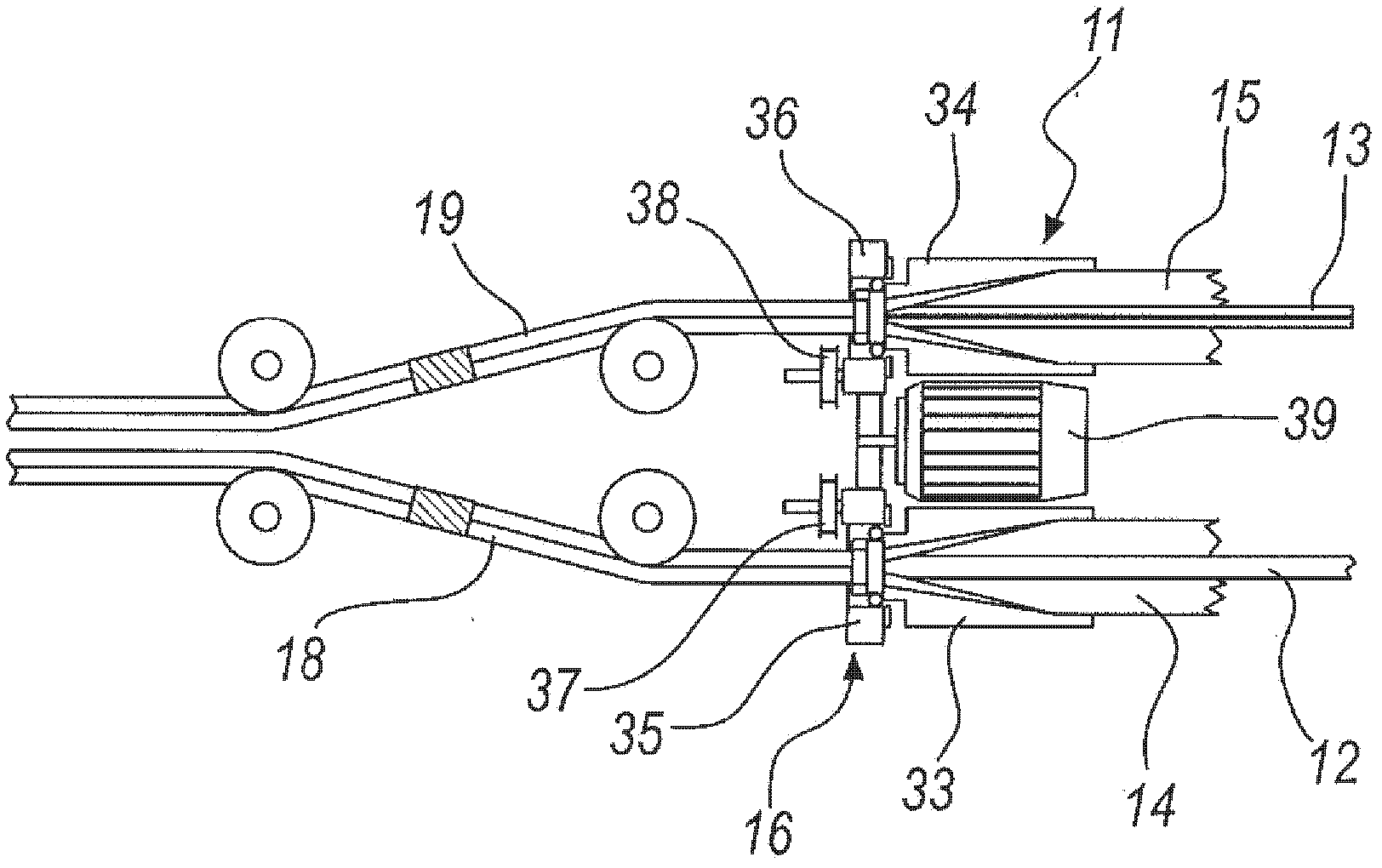

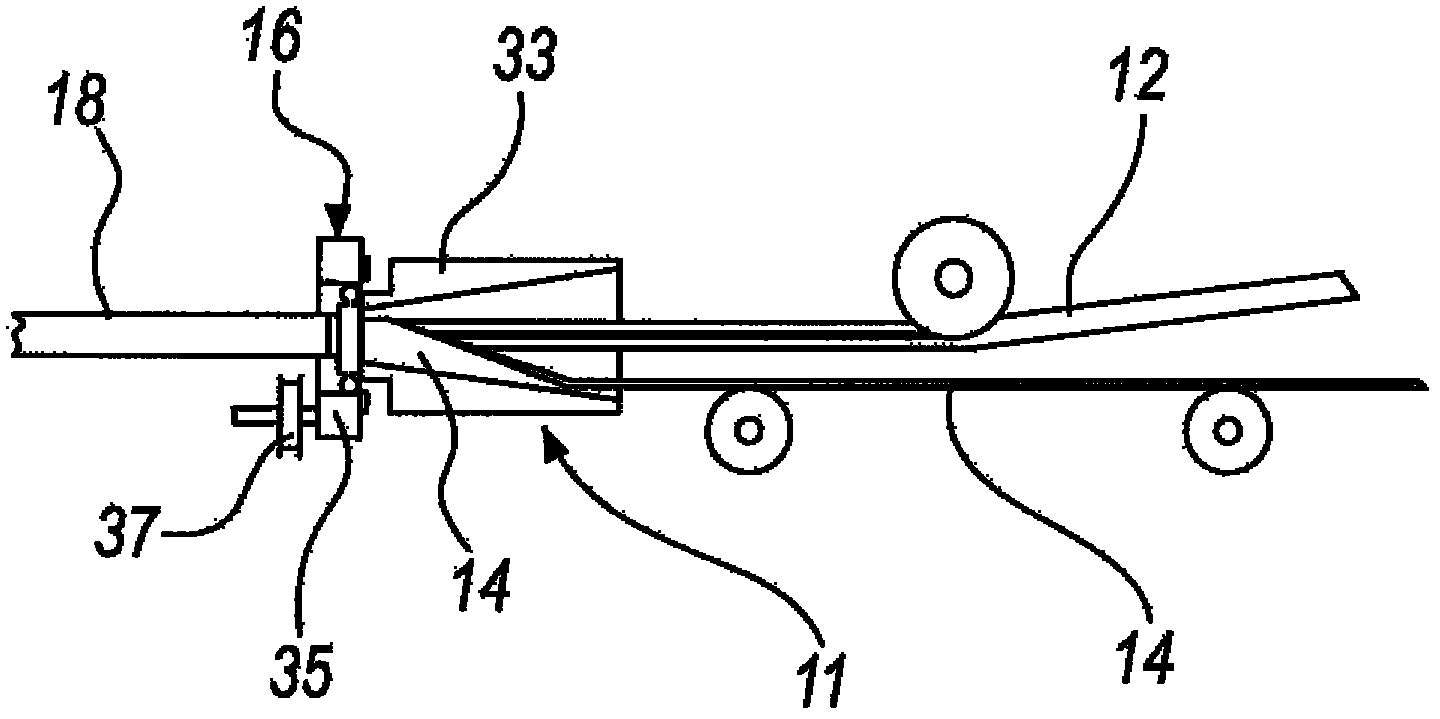

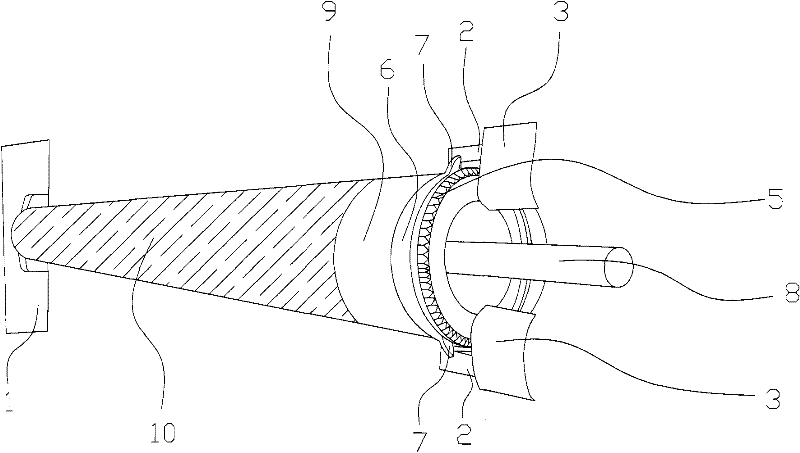

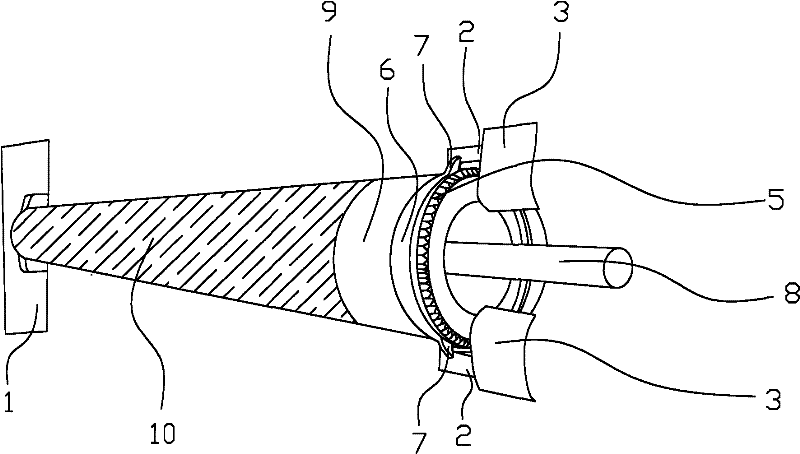

Apparatus for manufacturing a multilayer tube for the hydraulic connection and wiring of solar panels

InactiveCN102655960AEasy to manageSuitable for production requirementsFluid circuit connectionsEngineeringHydraulic connection

An apparatus (10) for manufacturing a multilayer tube for the hydraulic connection and wiring of solar panels, comprising - means (11) for covering at least one flexible tube (12) with at least one tape (14) of thermally insulating material; - means (16) for tying said tape (14) around the corresponding flexible tube (12); - means (17) for covering at least two tubes (18, 19), which are already covered with the insulating tape and are arranged mutually side-by-side and parallel, with a protection and containment sheath (20), - means (21) for the longitudinal closure of the sheath (20).

Owner:艾瓦拉克丝责任有限公司

Roller printing and dyeing device

InactiveCN102454076ASimple structureEasy to useLiquid/gas/vapor textile treatmentContinuous/uninterruptedPulp and paper industry

The invention discloses a roller printing and dyeing device for the textile field. The roller printing and dyeing device comprises a main body, a bracket, a bracket baffle, a driving gear, a supporting bearing, a rotating shaft, a driven gear, a roller and a calico paper, wherein the bracket is fixedly mounted on the main body; the bracket baffle is fixedly mounted on the main body and covers the upper part of the bracket; the driving gear is rotationally mounted on one side of the main body; the supporting bearing is mounted on the bracket and provided with clamping teeth; the rotating shaft is rotationally mounted on the supporting bearing; the driven gear is fixedly mounted on the rotating shaft; the roller is fixedly mounted on the rotating shaft; and the calico paper is fixedly sleeved on the roller. By using the roller printing and dyeing device disclosed by the invention, the cloth can be continuously printed and dyed through fixing the calico paper on the external side of the roller and driving the roller to continuously rotate. The roller printing and dyeing device disclosed by the invention has the advantages of simple structure, simplicity and convenience in use, good printing and dyeing effect, high speed and firm coloring; the printing and dyeing production efficiency is largely enhanced and the production cost is reduced.

Owner:WUJIANG ERLIAN SILK

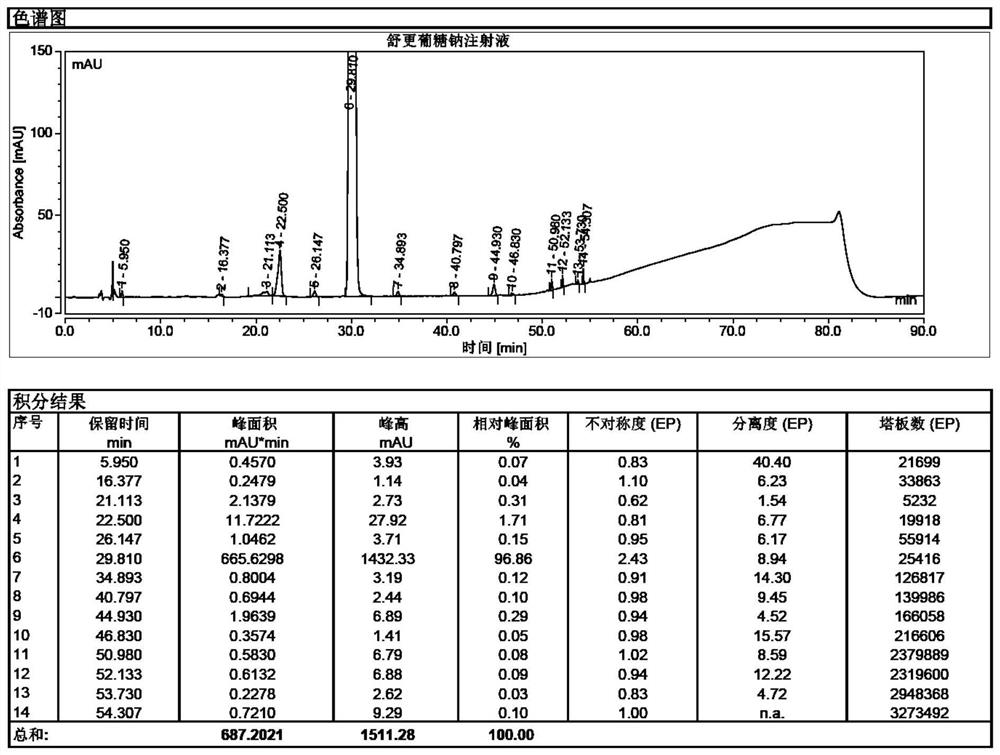

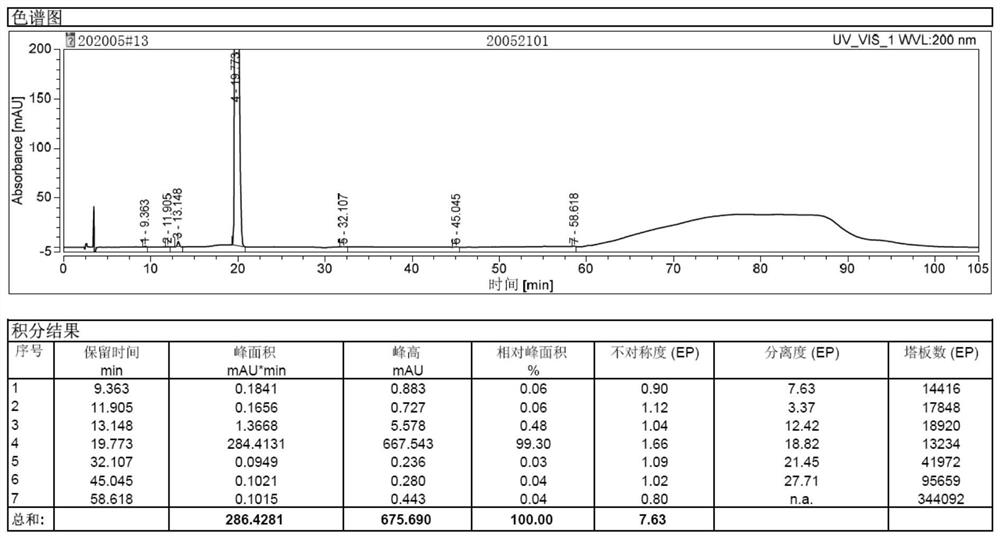

Preparation method of sugammadex sodium injection

PendingCN112933040AReduce oxidationReduce the risk of oxidationOrganic active ingredientsMuscular disorderSugammadex SodiumReverse osmosis

The invention discloses a preparation method of a sugammadex sodium injection, which comprises the following steps: preparing the sugammadex sodium injection under the protection of inert gas, adding a protective agent in the preparation process, coarsely filtering a liquid medicine, and removing the residual protective agent through a reverse osmosis membrane, wherein the protective agent is selected from phosphoinositide and derivatives thereof. The sugammadex sodium injection has good economical efficiency and is more suitable for industrial production, and the prepared sugammadex sodium injection is better in quality, safer and more stable.

Owner:HEFEI BOSIKC PHARMTECH CO LTD

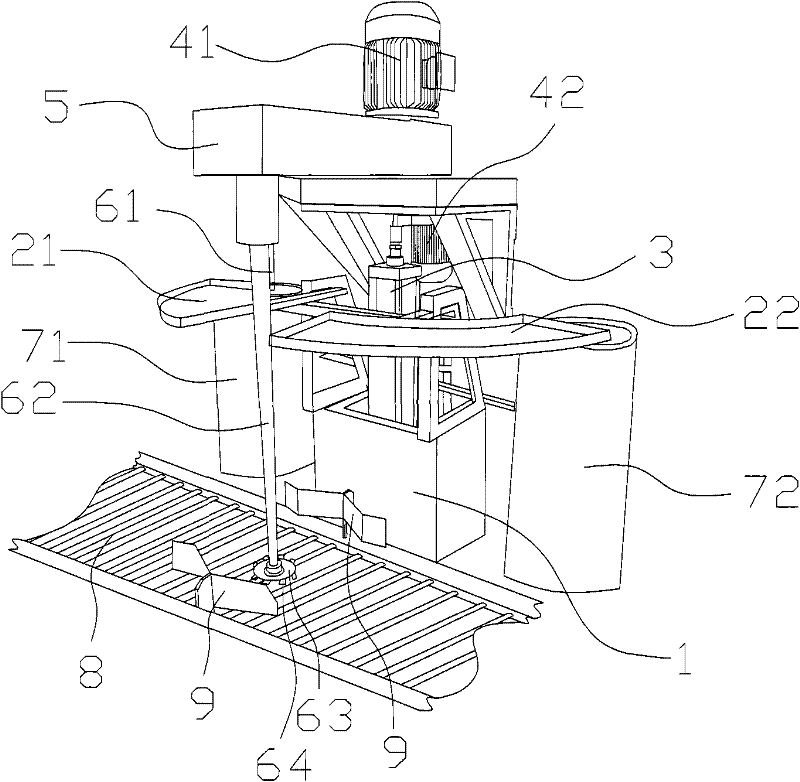

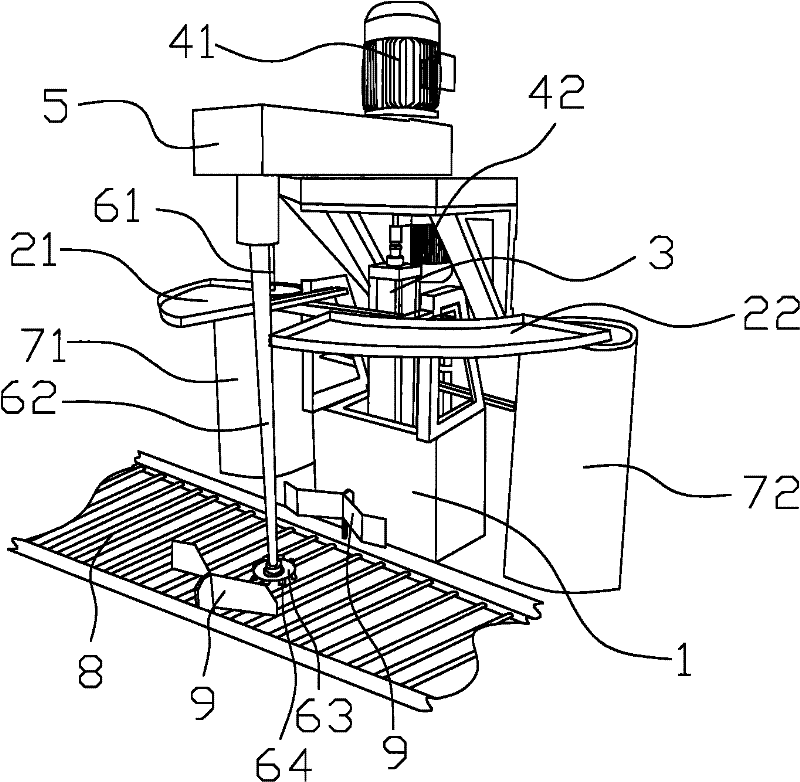

Double-station dye stirring device

InactiveCN102451635AStirring time is the sameSuitable for production requirementsRotary stirring mixersTransportation and packagingEngineeringCleansing Agents

The invention discloses a double-station dye stirring device used in the textile field. The device provided by the invention contains a body, a cylinder fixedly mounted on the body, a first baffle plate fixedly mounted on the body, a second baffle plate fixedly mounted on the body, a transmission case rotationally installed on the top of the body, a first stirring bar which is fixed mounted on the transmission case and is equipped with a stirring wheel disc, a second stirring bar which is fixed mounted on the transmission case and is equipped with the stirring wheel disc, a first cleaning compound barrel fixedly arranged at one side of the body, a second cleaning compound barrel fixedly arranged at the other side of the body, a transmission guide rail fixed disposed at one side of the body, a pair of safety stops fixedly mounted at two sides of the transmission guide rail, a first motor fixedly mounted on the upper portion of the body and a second motor fixedly arranged on the central portion of the body. The invention has advantages of simple structure, simple usage and intelligent control, can be used for alternative motions of dye stirring and stirring bar cleaning, and greatly raises work efficiency.

Owner:WUJIANG ZHONGFU HANDICRAFT PRINTWORKS

Method for removing endotoxin from influenza vaccine formulation

InactiveCN1621088AHigh removal rateStrong specificityAntiviralsPeptide preparation methodsFiltrationEndotoxin removal

The present invention is method of eliminating endotoxin from influenza vaccine. Affinity medium is prepared into affinity column or affinity membrane separator, which is used in processing influenza vaccine to eliminate endotoxin through static adsorption or filtration. The present invention features that the affinity medium has polyethylene imine as affinity ligand and nitrogen content of 0.75-7.0 %. The present invention has high endotoxin eliminating rate, high specificity and high active influenza vaccine recovering rate, and is suitable for production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

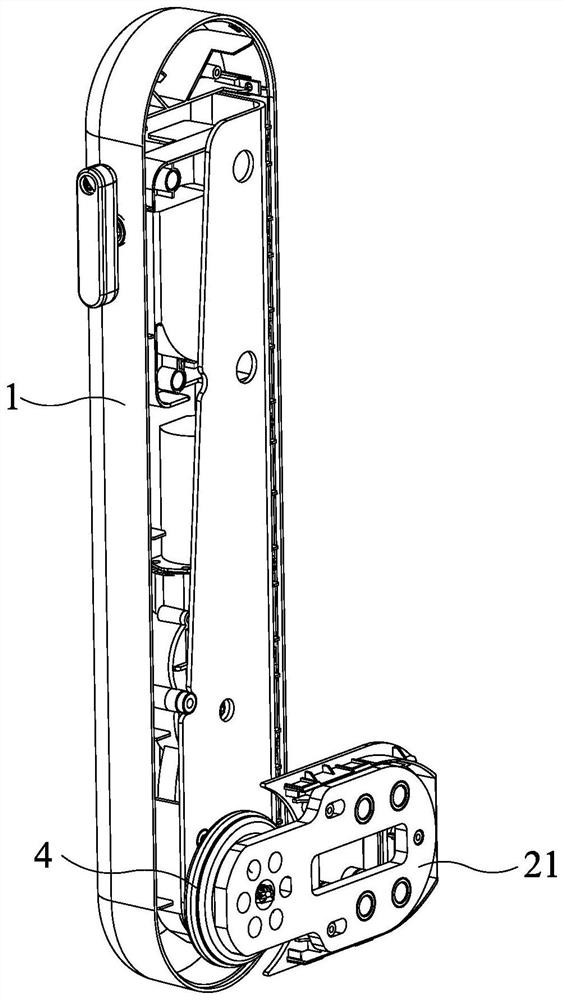

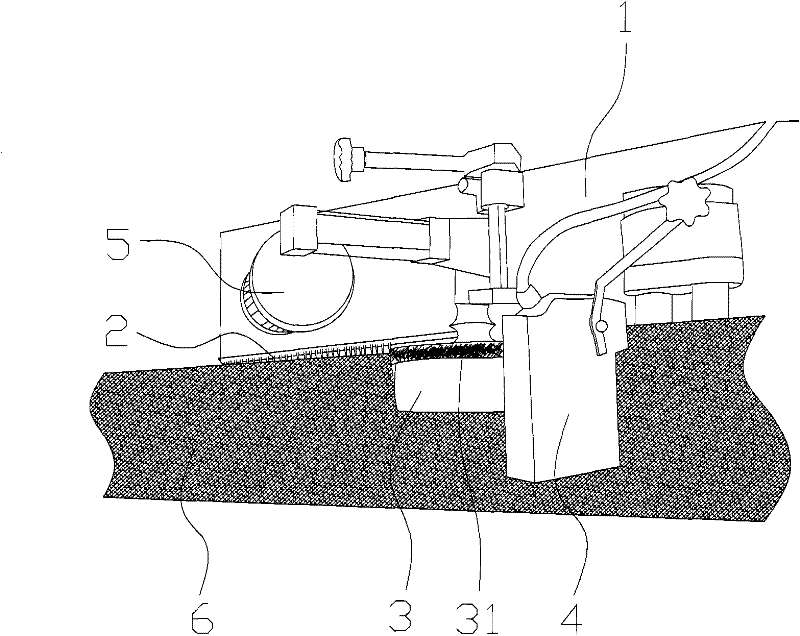

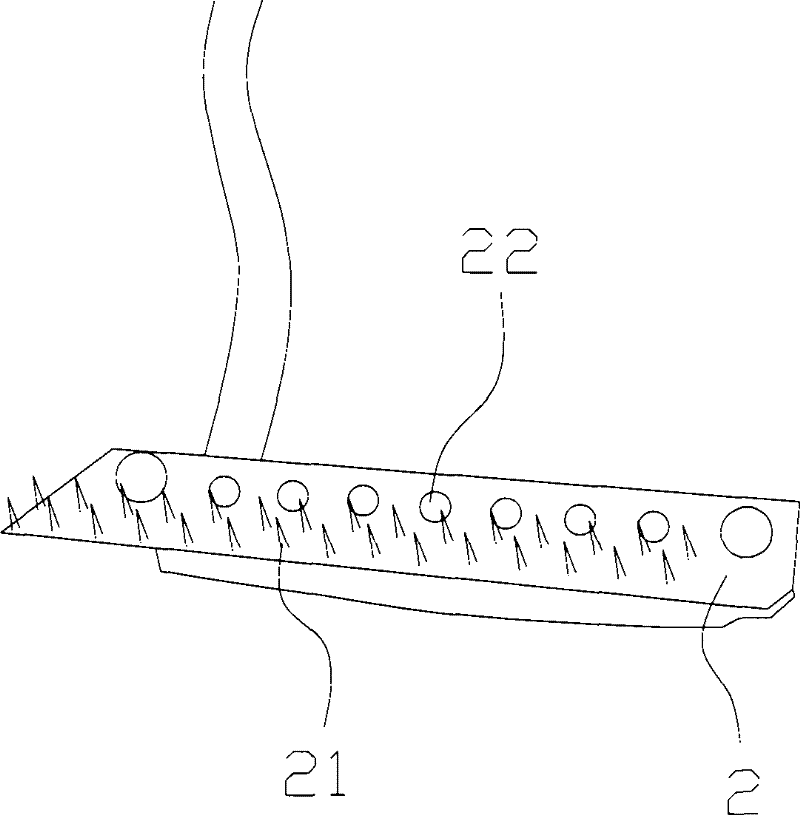

Display screen position adjusting device on armrest of fitness center

PendingCN112780901AMeet the needs of any angleSuitable for production requirementsStands/trestlesSport apparatusGear wheelElectric machinery

The invention discloses a display screen position adjusting device on an armrest of a fitness center. The display screen position adjusting device comprises a pitching mechanism and a rotating mechanism; the pitching mechanism comprises a first rotating motor, a first screw and a first gear; a rotating shaft is fixedly sleeved with the first gear; the first screw is provided with an external thread which is in threaded fit with the first gear; the first rotating motor is connected with and drives the first screw to rotate; the rotating mechanism comprises a second rotating motor, a second screw and a second gear; the second rotating motor, the second screw and the second gear are arranged on a frame; the second rotating motor is connected with and drives the second screw to rotate; external threads are arranged on the second screw and are in threaded fit with the second gear; a convex shaft is arranged on the back of a display screen; and the convex shaft is fixed in a central hole of the second gear in a penetrating manner. According to the display screen position adjusting device on the armrest of the fitness center, the display screen is enabled to move up and down, rotate and pitch conveniently, so that the requirement of people with different heights for any pitch angle of the display screen is met, and the display screen is simple and small in structure, low in cost and suitable for production requirements of most enterprises.

Owner:HEFEI PIPISHOU INTELLIGENT TECH CO LTD

Die casting method for automobile accessory

The invention relates to a die casting method for an automobile accessory. The die casting method adopts an aluminum alloy and comprises the following steps of A, metamorphic treatment, specifically,raw materials are melted and heated up to 800-900 DEG C% for the metamorphism treatment, and still standing is conducted for 2-4 hours; B, smelting, specifically, the raw materials after metamorphic treatment is heated up to 700-800 DEG C and turned into a liquid material; C, die closing, specifically, until there is a 20-30 mm gap in the die molded surface, die closing is stopped; D oxygen injecting into the gap; E, die closing continuing to make the die completely close; F, liquid raw material injecting into a barrel, G, oxygen injecting into the barrel after injecting the liquid material into the barrel, H, die casting, I, cooling, and j, die opening, that is, die-casting of a product is completed. The die casting method has the advantages that the strength and hardness of the automobile accessory made by the aluminum alloy are suitable for production requirements of the automobile accessory, the ductility is good, and the punching demand can be met; and meanwhile, the automobile accessory is super durable and corrosion-resistant, thus the service life of the automobile accessory is improved.

Owner:南通冠达粉末冶金有限公司

Aluminum alloy profile of a lock cylinder

The invention relates to an aluminum alloy section of a lock cylinder. The aluminum alloy section comprises, by weight, 0.8-1.0 part of silicon, 0.1-0.3 part of iron, 0.7-0.9 part of magnesium, 0.1-0.13 part of copper, 0.2-0.3 part of manganese, 0.01-0.05 part of chromium, 0.2-0.28 part of zinc, 0.1-0.2 part of titanium, 0.06-0.08 part of nickel and 96.96-97.63 parts of aluminum. The aluminum alloy section of the lock cylinder has the advantages that the intensity and the hardness are relatively improved and are appropriate, and the production requirement of the lock cylinder is met; meanwhile, the ductility is good, and the punching requirement can be met; and in addition, the aluminum alloy section of the lock cylinder is very resistant to wearing and corrosion, and therefore the service life of the lock cylinder is accordingly prolonged.

Owner:RUGAO HUAYANG ALUMINUM PROD

Cloth edge tightening device

InactiveCN102454079AEasy to fixSuitable for production requirementsTextile treatment carriersEngineeringTextile industry

The invention discloses a cloth edge tightening device in the field of textiles. The cloth edge tightening device comprises a body, a plurality of nail ranks arranged on the upper part of the body in a sliding way, a motor fixedly arranged on the upper part of the body, a hairbrush wheel rotationally arranged on the upper part of the body and connected with the motor, cloth fixedly connected with the nail ranks, and an optoelectronic switch fixedly arranged on the upper part of the body, wherein the hairbrush wheel is positioned on one side of the optoelectronic switch. By the cloth edge tightening device, after the optoelectronic switch detects that cloth is required to be fixed, the cloth edge is pressed to the nail rank by the hairbrush wheel, and the nail tank slides to drive the cloth to continuously move. The invention has the advantage that: the cloth edge tightening device is simple in structure and easy and convenient to use, can firmly fix the cloth and simultaneously drive the cloth to rotate, cannot generate false operation, meets the production requirement of the textile industry, and has positive significance.

Owner:WUJIANG ZHONGFU HANDICRAFT PRINTWORKS

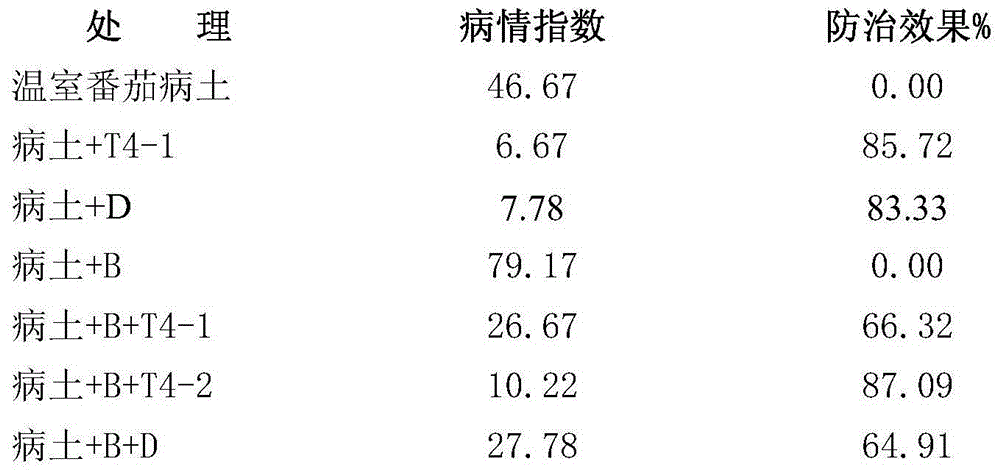

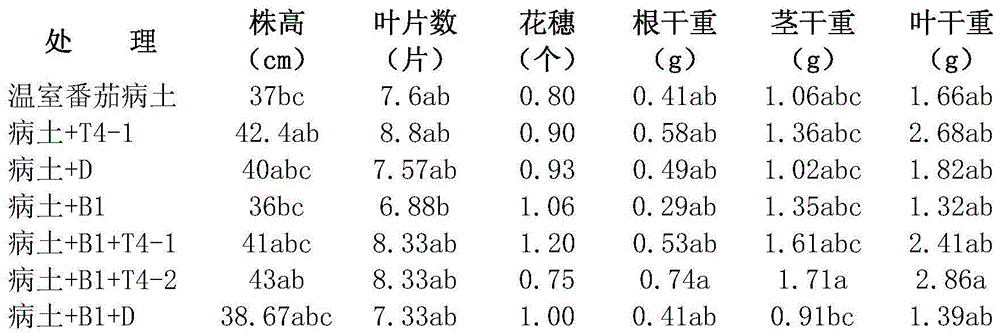

Preparation method and application of a growth-promoting and antibacterial Bacillus amyloliquefaciens, conditioning agent

ActiveCN103074287BSignificantly control the incidence of Fusarium wiltHigh prevention and control rateBiocideBacteriaAntibiotic YGrowth promoting

The invention relates to bacillus amyloliquefaciens sp. Pb-4(T4,4), a preparation method of a conditioner, and an application. The bacillus amyloliquefaciens sp. is preserved in China General Microbiological Culture Collection Center (CGMCC), with the preservation number of CGMCC NO. 7155 and preservation date of January 18, 2013. The bacillus amyloliquefaciens sp. has obvious growth-promoting, antibacterial and disease-prevention effects on crops such as tomatoes, and can be colonized in soil and plants. The preparation method of the conditioner comprises the steps of liquid culture of bean product waste water and the like, and solid fermentation of soybean pod wall powder and the like, wherein a culture has viable bacteria as high as 4*10<9>cfu / ml and 5*10<9>cfu / g, and contains three growth-promoting antibacterial substances, namely antibacterial protein, enzyme and antibiotic. Waste recycling of the bean product waste water is realized, the cost is low, and the conditioner is suitable for industrial production, reduces or substitutes chemical pesticides, is safe and nontoxic, and meets the requirements of ecological agriculture and sustainable agricultural development.

Owner:山西农宜生物科技有限公司

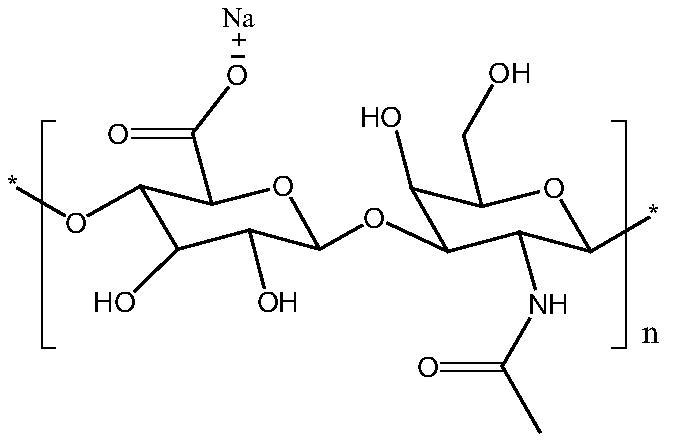

Purification method for reducing protein content in sodium hyaluronate and derivatives thereof

ActiveCN112851833ALow in proteinReduce the risk of allergic reactionsAnaphylactic reactionsBiochemistry

The invention discloses a purification method for reducing the protein content in sodium hyaluronate and derivatives thereof. The specific preparation process comprises the following process steps of adding a specific type of protein complexing agent into a sodium hyaluronate and derivative crude product solution, filtering to remove insoluble substances, and carrying out alcohol precipitation to obtain pure products of sodium hyaluronate and derivatives thereof. Under the action of the protein complexing agent, the method has a very good effect of removing proteins in sodium hyaluronate and derivative products thereof, and the content of the proteins in the sodium hyaluronate and the derivatives thereof can be reduced to 0.015% or below, so that the risk of anaphylactic reaction of sodium hyaluronate and derivative preparations thereof caused by heterologous proteins is remarkably reduced; the clinical application value is extremely high; the method disclosed by the invention is simple in technological process, low in cost, easy to operate, good in economical efficiency and more suitable for industrial production; the sodium hyaluronate and the derivative thereof obtained by the invention are high in purity, good in safety and less in anaphylactic reaction, and bring maximum benefits to patients.

Owner:HEFEI BOSIKC PHARMTECH CO LTD

Aluminum alloy profile of lock cylinder

The invention relates to an aluminum alloy profile of a lock cylinder. The aluminum alloy profile is prepared from, by weight, 0.8-1.0 part of silicon, 0.1-0.3 part of iron, 0.7-0.9 part of magnesium,0.1-0.13 part of copper, 0.2-0.3 part of manganese, 0.01-0.03 part of chrome, 0.2-0.28 part of zinc, 0.1-0.2 part of titanium, 0.06-0.08 part of nickel, 0.01-0.03 part of boron and 96.96-97.63 partsof aluminum. The aluminum alloy profile of the lock cylinder has the advantages that the strength and hardness are relatively improved and moderate and meet production requirements of the lock cylinder, meanwhile, malleability is good, and punching requirements can be met. In addition, the aluminum alloy profile of the lock cylinder is extremely resistant to wear and corrosion, and therefore the service life of the lock cylinder is prolonged.

Owner:江苏昭华精密铸造科技有限公司

A kind of ultraviolet curing gravure printing ink and preparation method thereof

The invention discloses printing ink for ultraviolet light curing intaglio printing, which is characterized in that the printing ink is prepared by the following raw materials in parts by weight: 3-4 parts of organic pigment, 12-14 parts of epoxy acrylate, 4-5 parts of sodium peroxide powder, 10-13 parts of polyester acrylate, 5-8 parts of glycol ether, 1-2 parts of ferrocene, 10-12 parts of 6-hexanediol diacrylate, 3-4 parts of dimethoxy-2-phenylacetophenone, 1.3-1.5 parts of accelerant D, 6-8 parts of carboxymethyl cellulose, 11-14 parts of phenyl glycidyl ether, 1-2 parts of barium metaborate, 1-2 parts of antioxidant DSTP (disteaxyl thiodipropionate), 5-7 parts of 1173 photoinitiator, and 4-5 parts of assistant. According to the printing ink, the assistant improves the toughness of the printing ink, so that the printing ink is dispersed uniformly, and the stability of the printing ink is maintained. The printing ink can achieve good printing effects on a hard substrate and a soft substrate, is suitable for multiple production modes and production requirements, and is excellent in comprehensive performance.

Owner:广东天智印刷科技有限公司

Method for making resin-embedded specimens of Lepidoptera insects

InactiveCN107950521BSolve discolorationPreserve true colorDead animal preservationOrder LepidopteraColor changes

The invention discloses a method for making a resin embedded Lepidoptera insect specimen. Wings of a Lepidoptera insect are subjected to plastic package firstly with a plastic package film or a scotchtape, then the surplus plastic package film is cut off, the plastic package film for plastic package of the wings is retained, finally, the insect specimen with plastic package of the wings is embedded in resin, and the resin embedded Lepidoptera insect specimen is prepared. The problem of color change of the conventional resin embedded Lepidoptera insect specimen is solved, the original real color of the specimen is retained, and the made resin embedded Lepidoptera insect specimen meets requirements of scientific research and can also meet requirement of artware making.

Owner:陈宝明

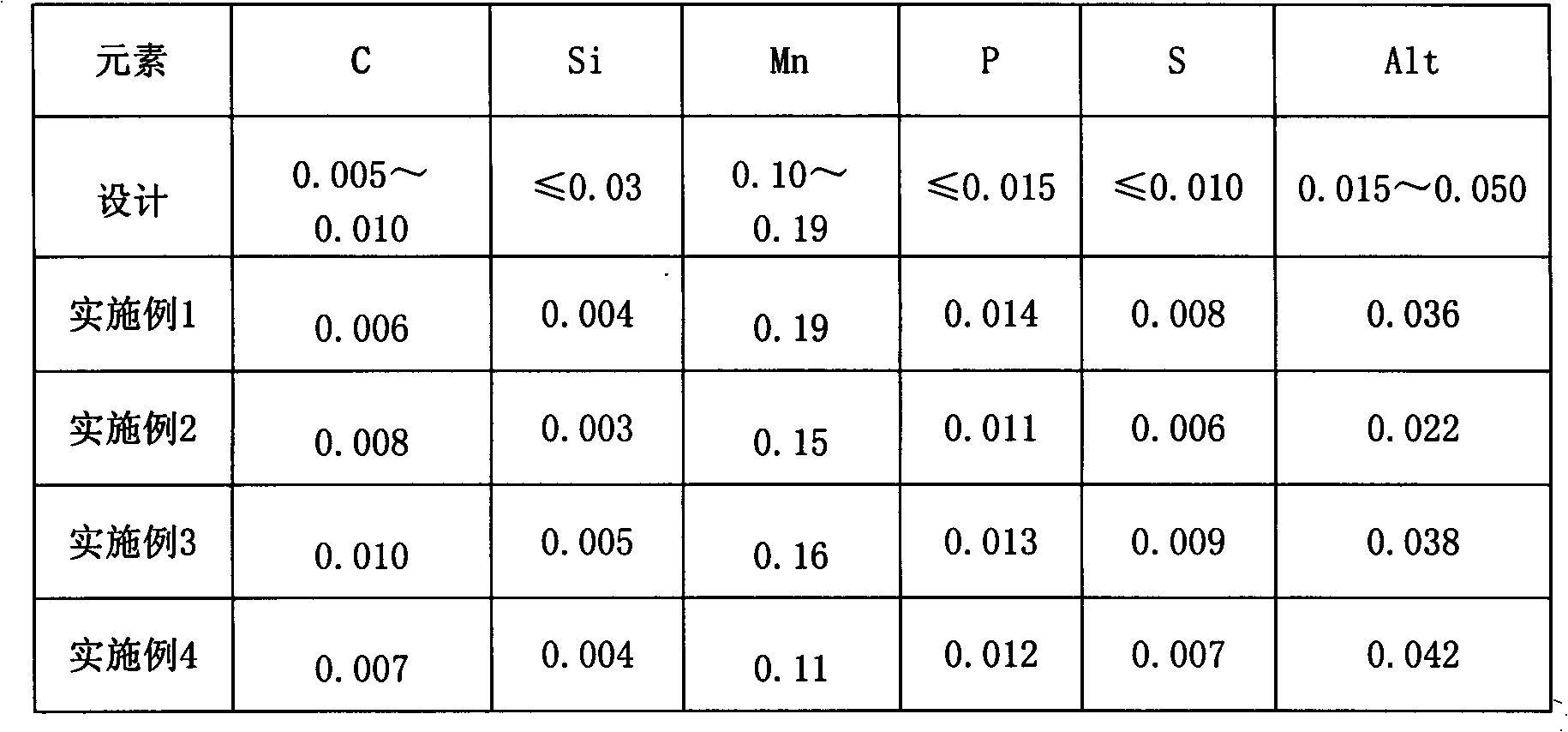

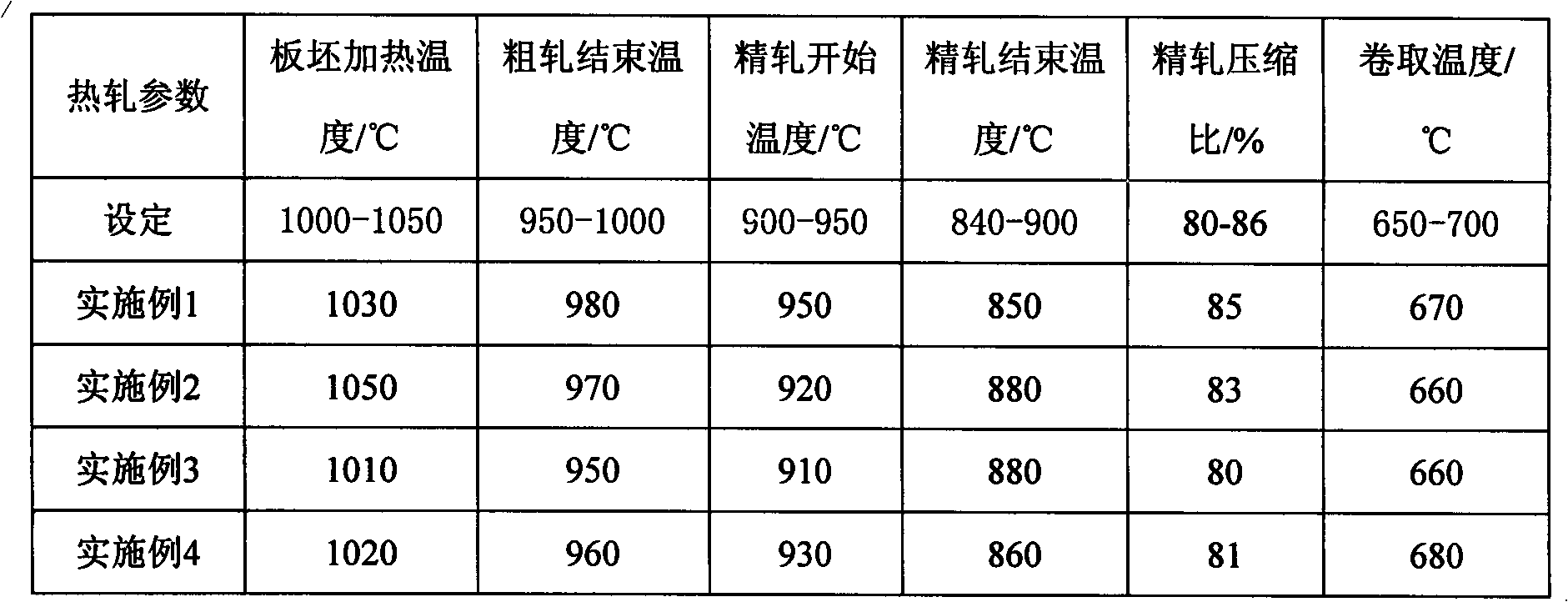

Cold-rolled steel strip for flux-cored wire and production method of cold-rolled steel strip

ActiveCN102676913BHigh elongation after breakGood value for moneyTemperature controlUltimate tensile strength

The invention relates to a cold-rolled steel strip, in particular to a cold-rolled steel strip for a flux-cored wire, and further relates to a production method of the cold-rolled steel strip. The cold-rolled steel strip and the production method mainly solve the technical problems of incapability of achieving good match of strength and plasticity, poor machine-shaping performances and the like of an existing cold-rolled steel strip for a flux-cored wire. The cold-rolled steel strip for the flux-cored wire chemically comprises, by weight, 0.005-0.010% of C, not more than 0.03% of Si, 0.10-0.19% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.015-0.050% of Alt, the balance Fe and inevitable impurity elements. By the aid of the cold-rolled steel strip and the production method, low carbon, low silicon and aluminum deoxidation are used as grain refinement elements, and technologies including inclusion morphology control, hot continuous rolling controlled cooling and continuous annealing temperature control are used for production, so that yield strength and hardness of the steel strip can be guaranteed to be within the specified range beneficially. Besides, the cold-rolled steel strip for the flux-cored wire has the advantages of high percentage elongation after fracture, excellent machine-shaping performance and welding performance, high cost performance and the like.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com