Adjustable shell molding line sand box used for casting

A shell molding line and adjustable technology, which is applied in the direction of casting molding equipment, molding boxes, molding machines, etc., can solve the problems of very large differences in external dimensions, etc., and achieve the effects of strong promotion significance, low cost, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

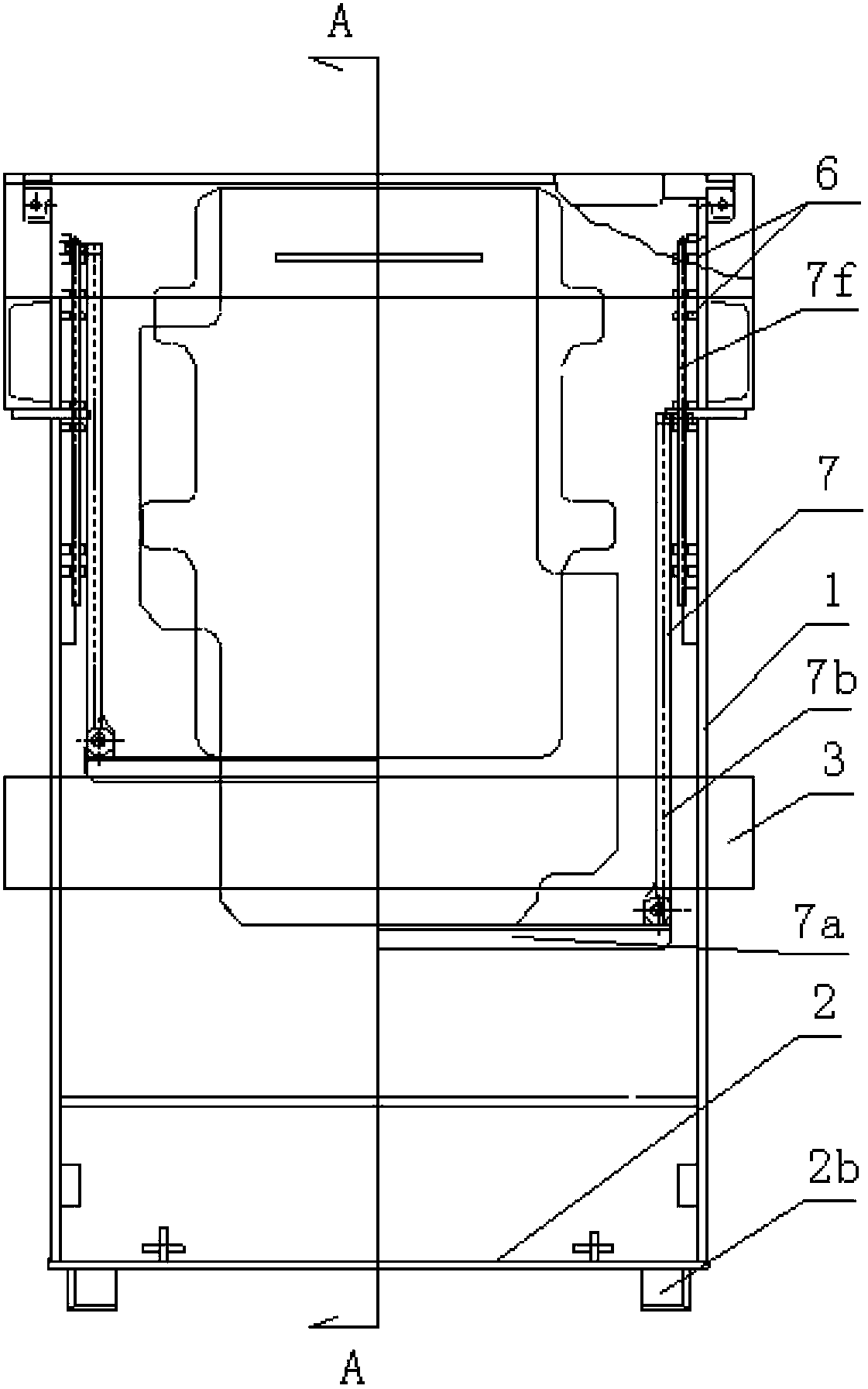

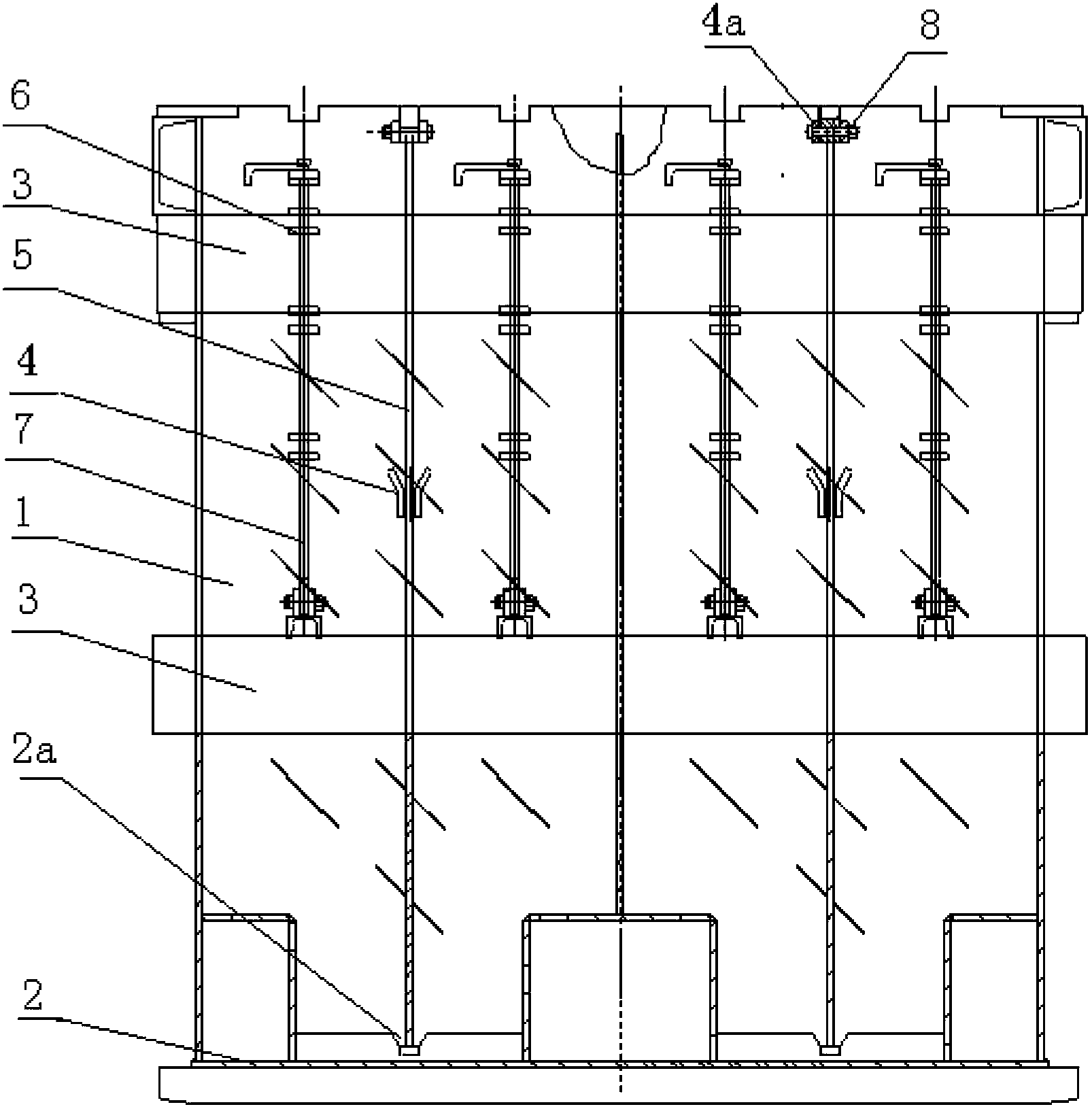

[0018] like figure 1 , figure 2 The adjustable shell molding line sand box for casting of the present invention comprises a box body made up of four side plates 1, box bottom 2 and frame 3, a pair of side plates of the box body are provided with a vertical guide groove 4, and the box bottom 2 corresponds to A card slot 2a is provided, and a vertical partition 5 is inserted into the card slot 2a of the box bottom 2 along the vertical guide slot 4 to divide the box into multiple small boxes. Generally, 2 to 4 vertical partitions 5 and vertical guide grooves 4 are arranged.

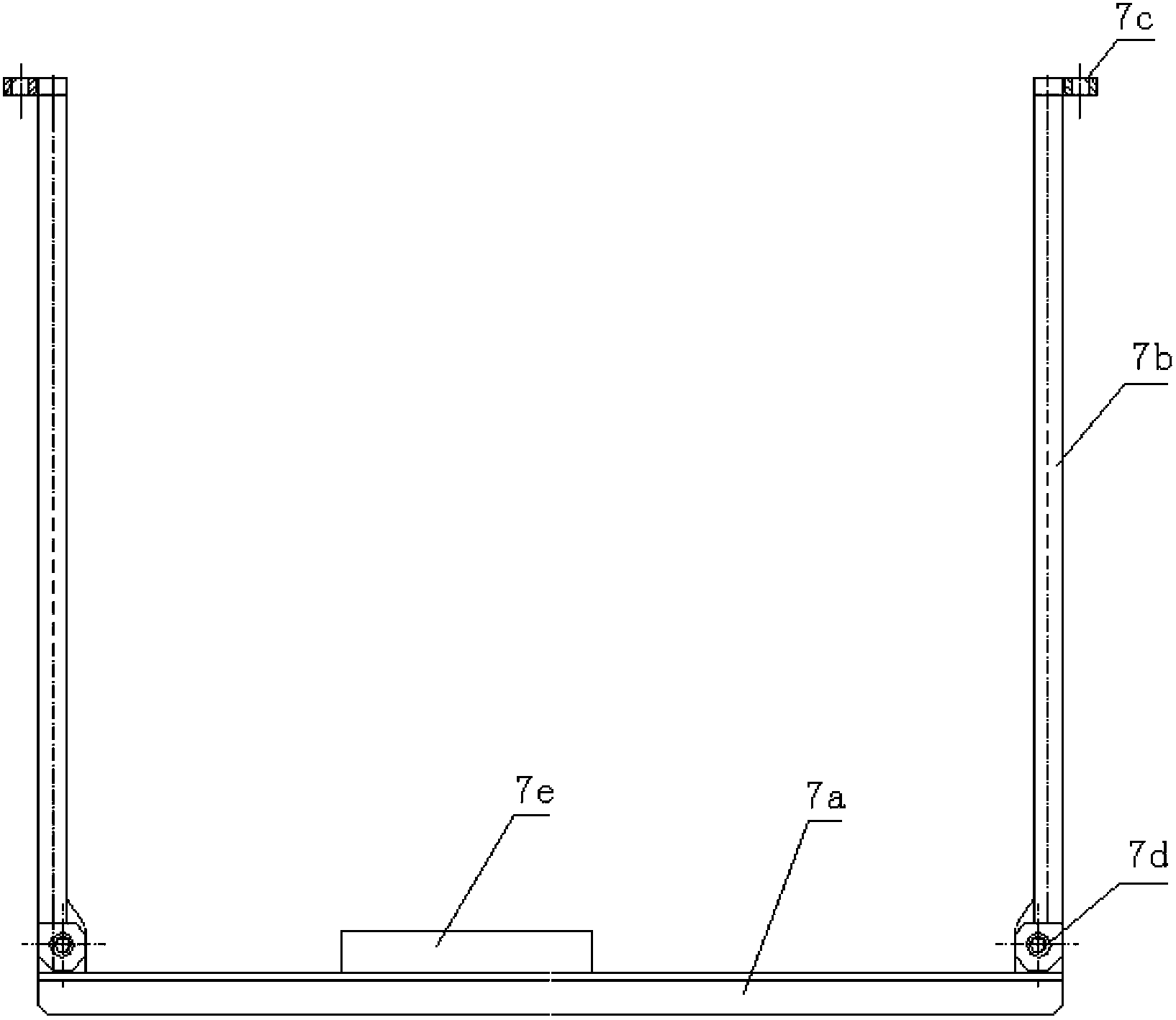

[0019] like figure 1 , figure 2 , image 3 , Figure 4 : 4 rows of multi-level positioning blocks 6 are arranged on the upper part of a pair of side plates of the box body, and vertical jacks are arranged on the positioning blocks 6; 4 height adjustment mechanisms 7 are arranged in the box body, and the height adjustment mechanism 7 includes Transverse channel steel 7a, the two ends of transverse cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com